instrument cluster CHRYSLER VOYAGER 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 495 of 2399

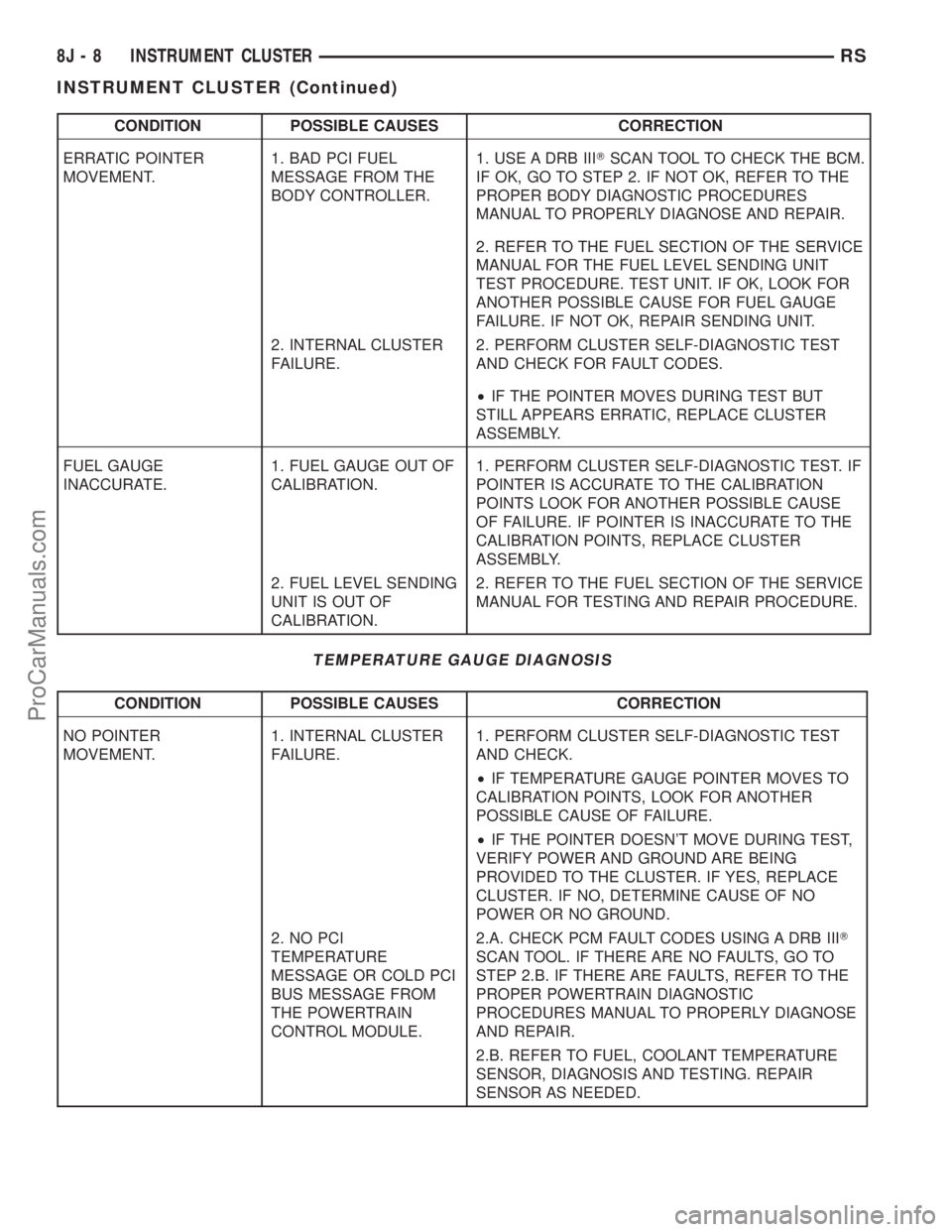

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT.1. BAD PCI FUEL

MESSAGE FROM THE

BODY CONTROLLER.1. USE A DRB IIITSCAN TOOL TO CHECK THE BCM.

IF OK, GO TO STEP 2. IF NOT OK, REFER TO THE

PROPER BODY DIAGNOSTIC PROCEDURES

MANUAL TO PROPERLY DIAGNOSE AND REPAIR.

2. REFER TO THE FUEL SECTION OF THE SERVICE

MANUAL FOR THE FUEL LEVEL SENDING UNIT

TEST PROCEDURE. TEST UNIT. IF OK, LOOK FOR

ANOTHER POSSIBLE CAUSE FOR FUEL GAUGE

FAILURE. IF NOT OK, REPAIR SENDING UNIT.

2. INTERNAL CLUSTER

FAILURE.2. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF THE POINTER MOVES DURING TEST BUT

STILL APPEARS ERRATIC, REPLACE CLUSTER

ASSEMBLY.

FUEL GAUGE

INACCURATE.1. FUEL GAUGE OUT OF

CALIBRATION.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST. IF

POINTER IS ACCURATE TO THE CALIBRATION

POINTS LOOK FOR ANOTHER POSSIBLE CAUSE

OF FAILURE. IF POINTER IS INACCURATE TO THE

CALIBRATION POINTS, REPLACE CLUSTER

ASSEMBLY.

2. FUEL LEVEL SENDING

UNIT IS OUT OF

CALIBRATION.2. REFER TO THE FUEL SECTION OF THE SERVICE

MANUAL FOR TESTING AND REPAIR PROCEDURE.

TEMPERATURE GAUGE DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO POINTER

MOVEMENT.1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK.

²IF TEMPERATURE GAUGE POINTER MOVES TO

CALIBRATION POINTS, LOOK FOR ANOTHER

POSSIBLE CAUSE OF FAILURE.

²IF THE POINTER DOESN'T MOVE DURING TEST,

VERIFY POWER AND GROUND ARE BEING

PROVIDED TO THE CLUSTER. IF YES, REPLACE

CLUSTER. IF NO, DETERMINE CAUSE OF NO

POWER OR NO GROUND.

2. NO PCI

TEMPERATURE

MESSAGE OR COLD PCI

BUS MESSAGE FROM

THE POWERTRAIN

CONTROL MODULE.2.A. CHECK PCM FAULT CODES USING A DRB IIIT

SCAN TOOL. IF THERE ARE NO FAULTS, GO TO

STEP 2.B. IF THERE ARE FAULTS, REFER TO THE

PROPER POWERTRAIN DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE

AND REPAIR.

2.B. REFER TO FUEL, COOLANT TEMPERATURE

SENSOR, DIAGNOSIS AND TESTING. REPAIR

SENSOR AS NEEDED.

8J - 8 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 496 of 2399

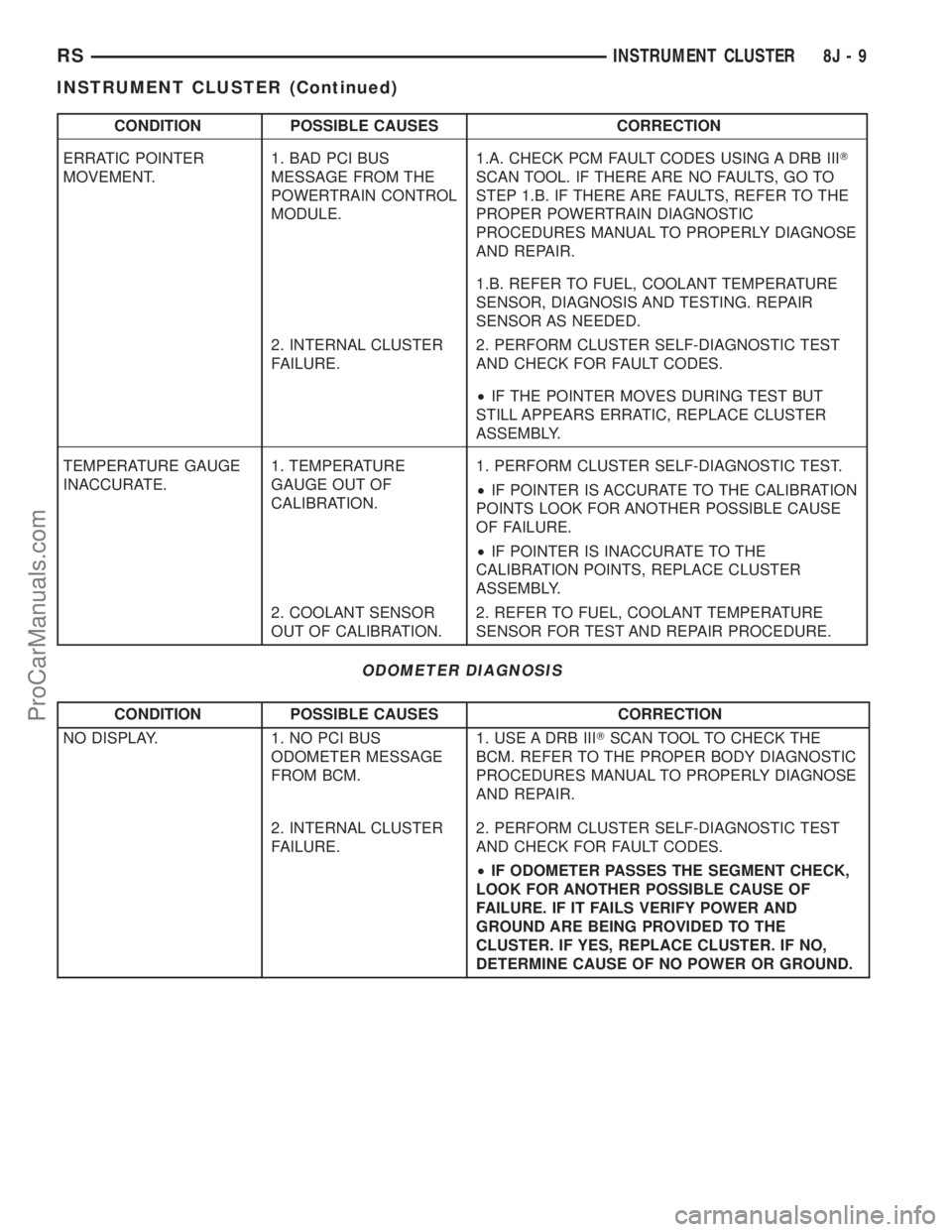

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT.1. BAD PCI BUS

MESSAGE FROM THE

POWERTRAIN CONTROL

MODULE.1.A. CHECK PCM FAULT CODES USING A DRB IIIT

SCAN TOOL. IF THERE ARE NO FAULTS, GO TO

STEP 1.B. IF THERE ARE FAULTS, REFER TO THE

PROPER POWERTRAIN DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE

AND REPAIR.

1.B. REFER TO FUEL, COOLANT TEMPERATURE

SENSOR, DIAGNOSIS AND TESTING. REPAIR

SENSOR AS NEEDED.

2. INTERNAL CLUSTER

FAILURE.2. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF THE POINTER MOVES DURING TEST BUT

STILL APPEARS ERRATIC, REPLACE CLUSTER

ASSEMBLY.

TEMPERATURE GAUGE

INACCURATE.1. TEMPERATURE

GAUGE OUT OF

CALIBRATION.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST.

²IF POINTER IS ACCURATE TO THE CALIBRATION

POINTS LOOK FOR ANOTHER POSSIBLE CAUSE

OF FAILURE.

²IF POINTER IS INACCURATE TO THE

CALIBRATION POINTS, REPLACE CLUSTER

ASSEMBLY.

2. COOLANT SENSOR

OUT OF CALIBRATION.2. REFER TO FUEL, COOLANT TEMPERATURE

SENSOR FOR TEST AND REPAIR PROCEDURE.

ODOMETER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO DISPLAY. 1. NO PCI BUS

ODOMETER MESSAGE

FROM BCM.1. USE A DRB IIITSCAN TOOL TO CHECK THE

BCM. REFER TO THE PROPER BODY DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE

AND REPAIR.

2. INTERNAL CLUSTER

FAILURE.2. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF ODOMETER PASSES THE SEGMENT CHECK,

LOOK FOR ANOTHER POSSIBLE CAUSE OF

FAILURE. IF IT FAILS VERIFY POWER AND

GROUND ARE BEING PROVIDED TO THE

CLUSTER. IF YES, REPLACE CLUSTER. IF NO,

DETERMINE CAUSE OF NO POWER OR GROUND.

RSINSTRUMENT CLUSTER8J-9

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 497 of 2399

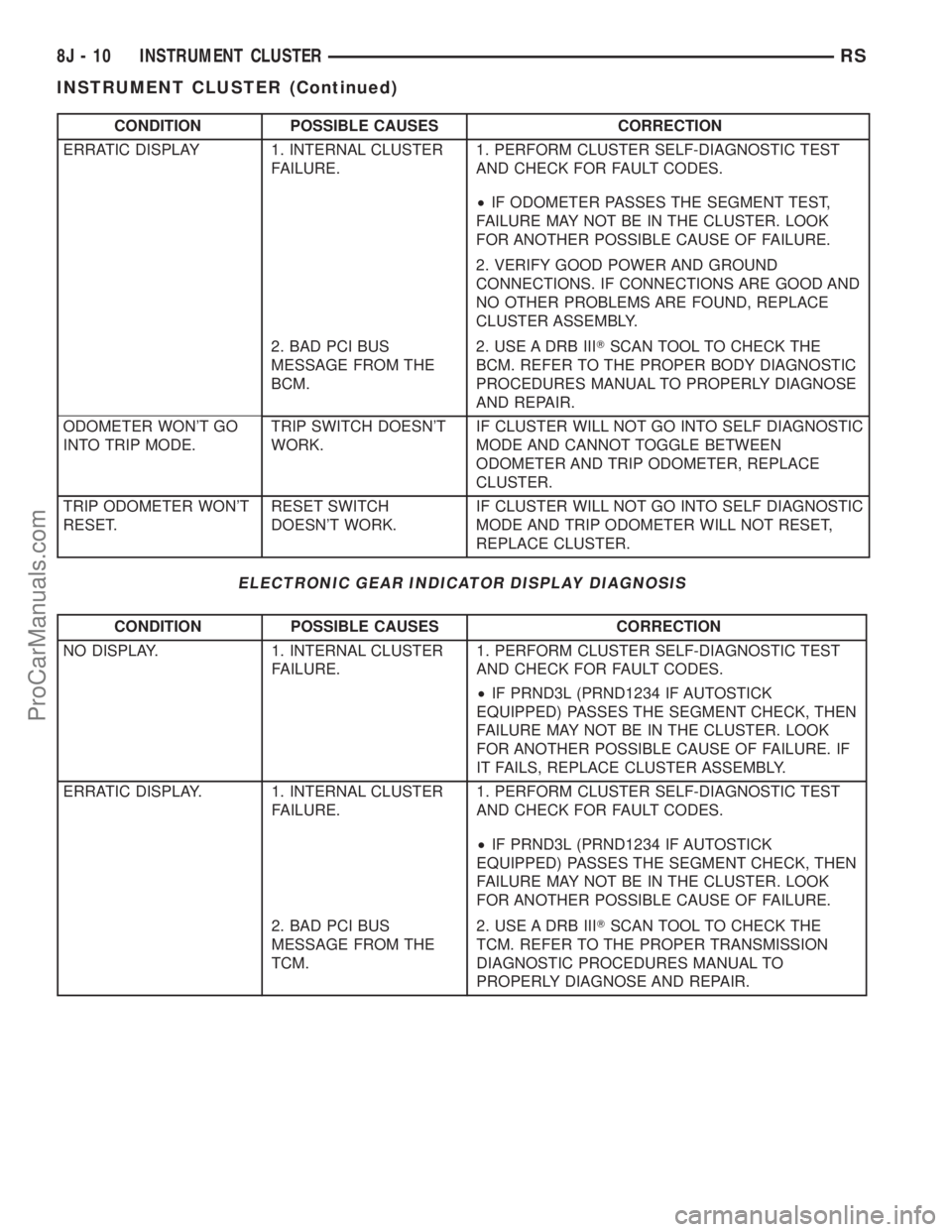

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC DISPLAY 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF ODOMETER PASSES THE SEGMENT TEST,

FAILURE MAY NOT BE IN THE CLUSTER. LOOK

FOR ANOTHER POSSIBLE CAUSE OF FAILURE.

2. VERIFY GOOD POWER AND GROUND

CONNECTIONS. IF CONNECTIONS ARE GOOD AND

NO OTHER PROBLEMS ARE FOUND, REPLACE

CLUSTER ASSEMBLY.

2. BAD PCI BUS

MESSAGE FROM THE

BCM.2. USE A DRB IIITSCAN TOOL TO CHECK THE

BCM. REFER TO THE PROPER BODY DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE

AND REPAIR.

ODOMETER WON'T GO

INTO TRIP MODE.TRIP SWITCH DOESN'T

WORK.IF CLUSTER WILL NOT GO INTO SELF DIAGNOSTIC

MODE AND CANNOT TOGGLE BETWEEN

ODOMETER AND TRIP ODOMETER, REPLACE

CLUSTER.

TRIP ODOMETER WON'T

RESET.RESET SWITCH

DOESN'T WORK.IF CLUSTER WILL NOT GO INTO SELF DIAGNOSTIC

MODE AND TRIP ODOMETER WILL NOT RESET,

REPLACE CLUSTER.

ELECTRONIC GEAR INDICATOR DISPLAY DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO DISPLAY. 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF PRND3L (PRND1234 IF AUTOSTICK

EQUIPPED) PASSES THE SEGMENT CHECK, THEN

FAILURE MAY NOT BE IN THE CLUSTER. LOOK

FOR ANOTHER POSSIBLE CAUSE OF FAILURE. IF

IT FAILS, REPLACE CLUSTER ASSEMBLY.

ERRATIC DISPLAY. 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF PRND3L (PRND1234 IF AUTOSTICK

EQUIPPED) PASSES THE SEGMENT CHECK, THEN

FAILURE MAY NOT BE IN THE CLUSTER. LOOK

FOR ANOTHER POSSIBLE CAUSE OF FAILURE.

2. BAD PCI BUS

MESSAGE FROM THE

TCM.2. USE A DRB IIITSCAN TOOL TO CHECK THE

TCM. REFER TO THE PROPER TRANSMISSION

DIAGNOSTIC PROCEDURES MANUAL TO

PROPERLY DIAGNOSE AND REPAIR.

8J - 10 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 498 of 2399

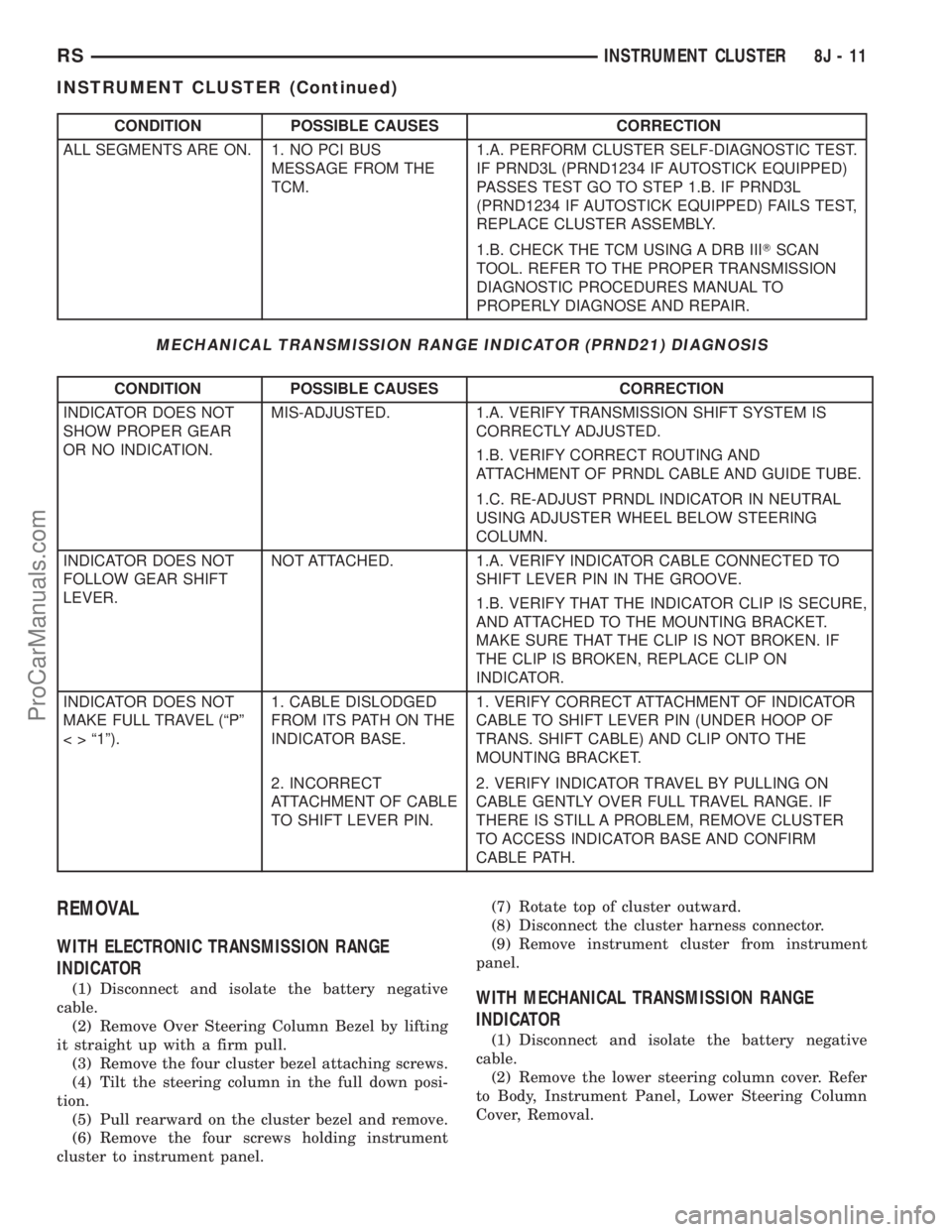

CONDITION POSSIBLE CAUSES CORRECTION

ALL SEGMENTS ARE ON. 1. NO PCI BUS

MESSAGE FROM THE

TCM.1.A. PERFORM CLUSTER SELF-DIAGNOSTIC TEST.

IF PRND3L (PRND1234 IF AUTOSTICK EQUIPPED)

PASSES TEST GO TO STEP 1.B. IF PRND3L

(PRND1234 IF AUTOSTICK EQUIPPED) FAILS TEST,

REPLACE CLUSTER ASSEMBLY.

1.B. CHECK THE TCM USING A DRB IIITSCAN

TOOL. REFER TO THE PROPER TRANSMISSION

DIAGNOSTIC PROCEDURES MANUAL TO

PROPERLY DIAGNOSE AND REPAIR.

MECHANICAL TRANSMISSION RANGE INDICATOR (PRND21) DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

INDICATOR DOES NOT

SHOW PROPER GEAR

OR NO INDICATION.MIS-ADJUSTED. 1.A. VERIFY TRANSMISSION SHIFT SYSTEM IS

CORRECTLY ADJUSTED.

1.B. VERIFY CORRECT ROUTING AND

ATTACHMENT OF PRNDL CABLE AND GUIDE TUBE.

1.C. RE-ADJUST PRNDL INDICATOR IN NEUTRAL

USING ADJUSTER WHEEL BELOW STEERING

COLUMN.

INDICATOR DOES NOT

FOLLOW GEAR SHIFT

LEVER.NOT ATTACHED. 1.A. VERIFY INDICATOR CABLE CONNECTED TO

SHIFT LEVER PIN IN THE GROOVE.

1.B. VERIFY THAT THE INDICATOR CLIP IS SECURE,

AND ATTACHED TO THE MOUNTING BRACKET.

MAKE SURE THAT THE CLIP IS NOT BROKEN. IF

THE CLIP IS BROKEN, REPLACE CLIP ON

INDICATOR.

INDICATOR DOES NOT

MAKE FULL TRAVEL (ªPº

< > ª1º).1. CABLE DISLODGED

FROM ITS PATH ON THE

INDICATOR BASE.1. VERIFY CORRECT ATTACHMENT OF INDICATOR

CABLE TO SHIFT LEVER PIN (UNDER HOOP OF

TRANS. SHIFT CABLE) AND CLIP ONTO THE

MOUNTING BRACKET.

2. INCORRECT

ATTACHMENT OF CABLE

TO SHIFT LEVER PIN.2. VERIFY INDICATOR TRAVEL BY PULLING ON

CABLE GENTLY OVER FULL TRAVEL RANGE. IF

THERE IS STILL A PROBLEM, REMOVE CLUSTER

TO ACCESS INDICATOR BASE AND CONFIRM

CABLE PATH.

REMOVAL

WITH ELECTRONIC TRANSMISSION RANGE

INDICATOR

(1) Disconnect and isolate the battery negative

cable.

(2) Remove Over Steering Column Bezel by lifting

it straight up with a firm pull.

(3) Remove the four cluster bezel attaching screws.

(4) Tilt the steering column in the full down posi-

tion.

(5) Pull rearward on the cluster bezel and remove.

(6) Remove the four screws holding instrument

cluster to instrument panel.(7) Rotate top of cluster outward.

(8) Disconnect the cluster harness connector.

(9) Remove instrument cluster from instrument

panel.WITH MECHANICAL TRANSMISSION RANGE

INDICATOR

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the lower steering column cover. Refer

to Body, Instrument Panel, Lower Steering Column

Cover, Removal.

RSINSTRUMENT CLUSTER8J-11

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 499 of 2399

(3) Remove the plastic knee blocker reinforcement.

Refer to Body, Instrument Panel, Knee Blocker Rein-

forcement, Removal.

(4) Disconnect the transmission range indicator

cable end from shift lever by flexing the HOOP on

the transmission shift cable rearward and slip the

indicator cable loop off the lever pin.

(5) Disconnect the clip holding the indicator cable

to the mounting bracket.

(6) Remove Over Steering Column Bezel by lifting

it straight up with a firm pull.

(7) Remove the four bezel attaching screws.

(8) Tilt the steering column in the full down posi-

tion.

(9) Pull rearward on the cluster bezel and remove.

(10) Remove the four cluster attaching screws.

(11) Rotate top of the cluster rearward.

(12) Disconnect the cluster harness connector.

(13) Remove the instrument cluster carefully while

guiding the range indicator cable and guide tube

through the opening to avoid any damage.

INSTALLATION

WITH ELECTRONIC TRANSMISSION RANGE

INDICATOR

(1) Connect the instrument cluster wire connector.

(2) Rotate top of cluster inward as placing into

instrument panel opening.

(3) Install the four screws holding instrument clus-

ter to instrument panel.

(4) Position cluster bezel into place.

(5) Install the four bezel attaching screws.

(6) Install the Over Steering Column Bezel by

firmly snapping into place.

(7) Connect the battery negative cable.

WITH MECHANICAL TRANSMISSION RANGE

INDICATOR

(1) Guide the range indicator cable and guide tube

through the opening of instrument panel.

(2) Connect the instrument cluster wire connector.

(3) Rotate top of cluster inward as placing into

instrument panel opening.

(4) Install the four screws holding instrument clus-

ter to instrument panel.

(5) Position cluster bezel into place.

(6) Install the four bezel attaching screws.

(7) Install the Over Steering Column Bezel by

firmly snapping into place.

(8) Connect the clip holding the indicator cable to

the mounting bracket.(9) Connect the transmission range indicator cable

end to the shift lever by flexing the HOOP on the

transmission shift cable forward and slip the indica-

tor cable loop on the lever pin.

(10) Install the plastic knee blocker reinforcement.

Refer to Body, Instrument Panel, Knee Blocker Rein-

forcement, Installation.

(11) Install the lower steering column cover. Refer

to Body, Instrument Panel, Lower Steering Column

Cover, Installation.

(12) Connect the battery negative cable.

CLUSTER LENS

REMOVAL

(1) Remove the instrument cluster. Refer to Elec-

trical, Instrument Cluster, Removal.

(2) Remove the screws holding the lens to the

instrument cluster.

(3) Press down on the snap features of the lens

and remove the lens from the cluster.

INSTALLATION

(1) Insert the lens snap features into the cluster.

(2) Install the screws holding the lens to the

instrument cluster.

(3) Install the instrument cluster. Refer to Electri-

cal, Instrument Cluster, Installation.

MECHANICAL TRANSMISSION

RANGE INDICATOR

REMOVAL

(1) Remove the instrument cluster and disconnect

the range indicator cable at both attaching points.

Refer to Electrical, Instrument Cluster, Removal.

(2) From the backside of the cluster, remove two

screws holding the mechanical transmission range

indicator and then remove it fromt instrument clus-

ter.

INSTALLATION

(1) Insert the mechanical transmission range indi-

cator into the backside of the instrument cluster and

install the two screws.

(2) Install the instrument cluster. Refer to Electri-

cal, Instrument Cluster, Installation.

8J - 12 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 500 of 2399

RED BRAKE WARNING

INDICATOR

DESCRIPTION

The red BRAKE warning indicator (lamp) is

located in the instrument panel cluster and is used to

indicate a low brake fluid condition or that the park-

ing brake is applied. In addition, the brake warning

indicator is turned on as a bulb check by the ignition

switch every time the ignition switch is placed in the

crank position.

OPERATION

The red BRAKE warning indicator (lamp) is sup-

plied a 12-volt ignition feed anytime the ignition

switch is on. The bulb is then illuminated by com-

pleting the ground circuit either through the switch

on the parking brake lever, the brake fluid level

switch in the master cylinder reservoir, or the igni-

tion switch when it is placed in the crank position.

RSINSTRUMENT CLUSTER8J-13

ProCarManuals.com

Page 522 of 2399

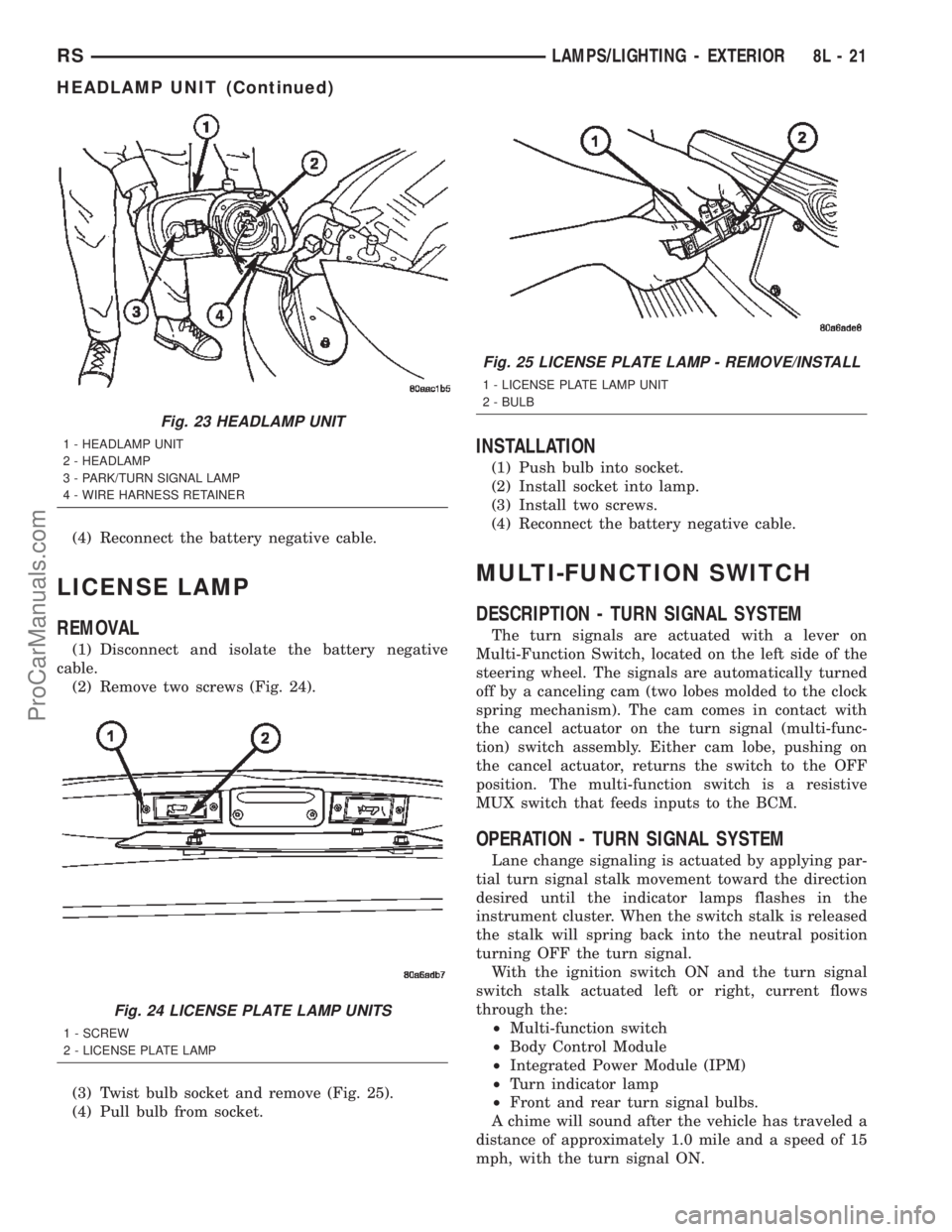

(4) Reconnect the battery negative cable.

LICENSE LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two screws (Fig. 24).

(3) Twist bulb socket and remove (Fig. 25).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into lamp.

(3) Install two screws.

(4) Reconnect the battery negative cable.

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM

The turn signals are actuated with a lever on

Multi-Function Switch, located on the left side of the

steering wheel. The signals are automatically turned

off by a canceling cam (two lobes molded to the clock

spring mechanism). The cam comes in contact with

the cancel actuator on the turn signal (multi-func-

tion) switch assembly. Either cam lobe, pushing on

the cancel actuator, returns the switch to the OFF

position. The multi-function switch is a resistive

MUX switch that feeds inputs to the BCM.

OPERATION - TURN SIGNAL SYSTEM

Lane change signaling is actuated by applying par-

tial turn signal stalk movement toward the direction

desired until the indicator lamps flashes in the

instrument cluster. When the switch stalk is released

the stalk will spring back into the neutral position

turning OFF the turn signal.

With the ignition switch ON and the turn signal

switch stalk actuated left or right, current flows

through the:

²Multi-function switch

²Body Control Module

²Integrated Power Module (IPM)

²Turn indicator lamp

²Front and rear turn signal bulbs.

A chime will sound after the vehicle has traveled a

distance of approximately 1.0 mile and a speed of 15

mph, with the turn signal ON.

Fig. 23 HEADLAMP UNIT

1 - HEADLAMP UNIT

2 - HEADLAMP

3 - PARK/TURN SIGNAL LAMP

4 - WIRE HARNESS RETAINER

Fig. 24 LICENSE PLATE LAMP UNITS

1 - SCREW

2 - LICENSE PLATE LAMP

Fig. 25 LICENSE PLATE LAMP - REMOVE/INSTALL

1 - LICENSE PLATE LAMP UNIT

2 - BULB

RSLAMPS/LIGHTING - EXTERIOR8L-21

HEADLAMP UNIT (Continued)

ProCarManuals.com

Page 527 of 2399

CENTER CONSOLE LAMP

SWITCH

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Open console lid and remove tray.

(3) Using a flat bladed tool, pry up on the switch.

(4) Remove bulb from switch.

INSTALLATION

(1) Install bulb into switch.

(2) Push switch into console opening.

(3) Install tray and close lid.

(4) Connect battery negative cable.

CLUSTER ILLUMINATION

LAMPS

REMOVAL

(1) Remove the Instrument Cluster. Refer to Elec-

trical, Instrument Cluster, Removal.

(2) Turn over cluster and expose the illumination

bulb sockets.

(3) Identify which bulb is defective and twist it out

of the cluster using a counterclockwise motion.

INSTALLATION

(1) Install the new bulb socket into the cluster

using a clockwise motion.

(2) Install the Instrument Cluster. Refer to Electri-

cal, Instrument Cluster, Installation.

COURTESY LAMP

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Using a trim stick, pry lamp from door panel

(Fig. 1).

(3) Disconnect wire harness from the lamp.

(4) Remove lens from the lamp and remove bulb.

INSTALLATION

(1) Install bulb and lens to lamp.

(2) Reconnect wire harness to lamp.

(3) Press lamp into the door panel.

(4) Reconnect battery negative cable.

DOME LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.(2) Using a flat bladed tool, pry off the lamp lens.

(3) Remove bulb from lamp.

INSTALLATION

(1) Install bulb to lamp.

(2) Press lens into place.

(3) Connect battery negative cable.

GLOVE BOX LAMP SWITCH

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Open glove box door.

(3) Push switch through from behind (Fig. 2).

(4) Disconnect wire harness from switch.

(5) Pull bulb from switch.

Fig. 1 COURTESY LAMP

1 - WIRE HARNESS

2 - COURTESY LAMP

Fig. 2 GLOVE BOX LAMP/SWITCH

1 - GLOVE BOX BULB

2 - GLOVE BOX LAMP SWITCH

8L - 26 LAMPS/LIGHTING - INTERIORRS

ProCarManuals.com

Page 536 of 2399

nications and the BCM. If the brightness level is

improper check the J1850 Data Bus circuit.

The DRB IIItis recommended for checking the

J1850 Data Bus circuit and the BCM. Perform the

EVIC self diagnosis before replacing the EVIC mod-

ule.

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING

EVIC PROGRAMMING MODE

Some vehicles are equipped with a Electronic Vehi-

cle Information Center (EVIC) equipped overhead

console. The Electronic Vehicle Information Center

(EVIC) provides the vehicle operator with a user

interface, which allows the selection of several

optional customer programmable electronic features

to suit individual preferences. The EVIC must be

placed into its programming mode in order to view or

change the programmable features. To enter the

EVIC programming mode and to view or change the

selected programmable features options, proceed as

follows:

(1) Turn the ignition switch to the On position.

(2) Depress and release the Menu push button.

The first item in the programmable features menu

list will appear in the EVIC display.

(3) Momentarily depress and release the Menu

push button to step through the programmable fea-

tures list. Each programmable feature and its cur-

rently selected option will appear on the EVIC

display in the sequence shown in the Programmable

Features list that follows.

(4) Momentarily depress and release the Step push

button to step through the available options for the

programmable feature being displayed.

(5) The option that last appears in the display

with a programmable feature before exiting the pro-

gramming mode, becomes the newly selected pro-

grammable feature option.

(6) The EVIC exits the programming mode and

returns to its normal operating mode when the C/T

push button is depressed or when the end of the pro-

grammable features menu list is reached, whichever

occurs first.

PROGRAMMABLE FEATURES

NOTE: TIRE PRESSURE MONITORING (TPM) SYS-

TEM INFORMATION IS NOT COVERED IN THIS SEC-

TION OF THE SERVICE MANUAL. REFER TO THE

TIRES/WHEELS SECTION OF THIS MANUAL FOR

DETAILED TPM SYSTEM INFORMATION.²LANGUAGE?- The options include English,

Francaise, Deutsch, Italiana, or Espanol. The default

is English. All EVIC display nomenclature, including

the trip computer functions, warning messages and

the programmable features appear in the selected

language.

²DISPLAY U.S. OR METRIC?- The options

include U.S. and M. The default is U.S. This feature

toggles the trip computer temperature, fuel economy

and odometer display readings between U.S. and

metric units of measure. It also changes the odome-

ter display in the instrument cluster.

²SERVICE INTV. =- The options include from

1000 to 12000 kilometers in 1000 kilometer incre-

ments (2000 to 7500 miles in 500 mile increments).

The default is 12000 kilometers (7500 miles). The

selected distance becomes the interval at which the

Perform Service warning message will be displayed

by the EVIC. If a new distance is selected, a second

programmable feature appears,RESET SERVICE

DISTANCE?- The options include No and Yes. The

default is Yes. When Yes is selected, the accumulated

distance since the last previous Perform Service

warning message will be reset to zero because the

service interval has been changed. When No is

selected, the distance until the next Perform Service

warning message is reduced by the accumulated dis-

tance since the last previous message.

²USE FACTORY SETTINGS?- The options

include Yes and No. The default is Yes. When yes is

selected all the programmable features will return to

there defaults and the rest of the programmable fea-

tures will not be displayed. If No is selected the rest

of the programmable features will be displayed at

there default values. This feature will automatically

return to the Yes default under two conditions. First,

if no programmable features are changed from there

defaults. Second, if all the programmable features

equal there defaults.

²AUTO DOOR LOCKS?- The options include

Yes and No. The default is Yes. When Yes is selected,

all doors and the liftgate lock automatically when

vehicle speed reaches 25 kilometers-per-hour (15

miles-per-hour). If YES is selected, a second program-

mable feature appears,AUTO UNLOCK ON EXIT?

- The options again include Yes and No. The default

is No. When Yes is selected, following each Auto Door

Lock event all doors and the liftgate will automati-

cally unlock when the driver door is opened, if the

vehicle is stopped and the transmission gear selector

is in Park or Neutral. The Auto Door Unlock event

will only occur once following each Auto Door Lock

event.

²REMOTE UNLOCK- The options include

Driver Door 1st and All Doors. The default is Driver

Door 1st. When Diver Door 1st is selected, only the

RSMESSAGE SYSTEMS8M-7

ELECTRONIC VEHICLE INFO CENTER (Continued)

ProCarManuals.com

Page 658 of 2399

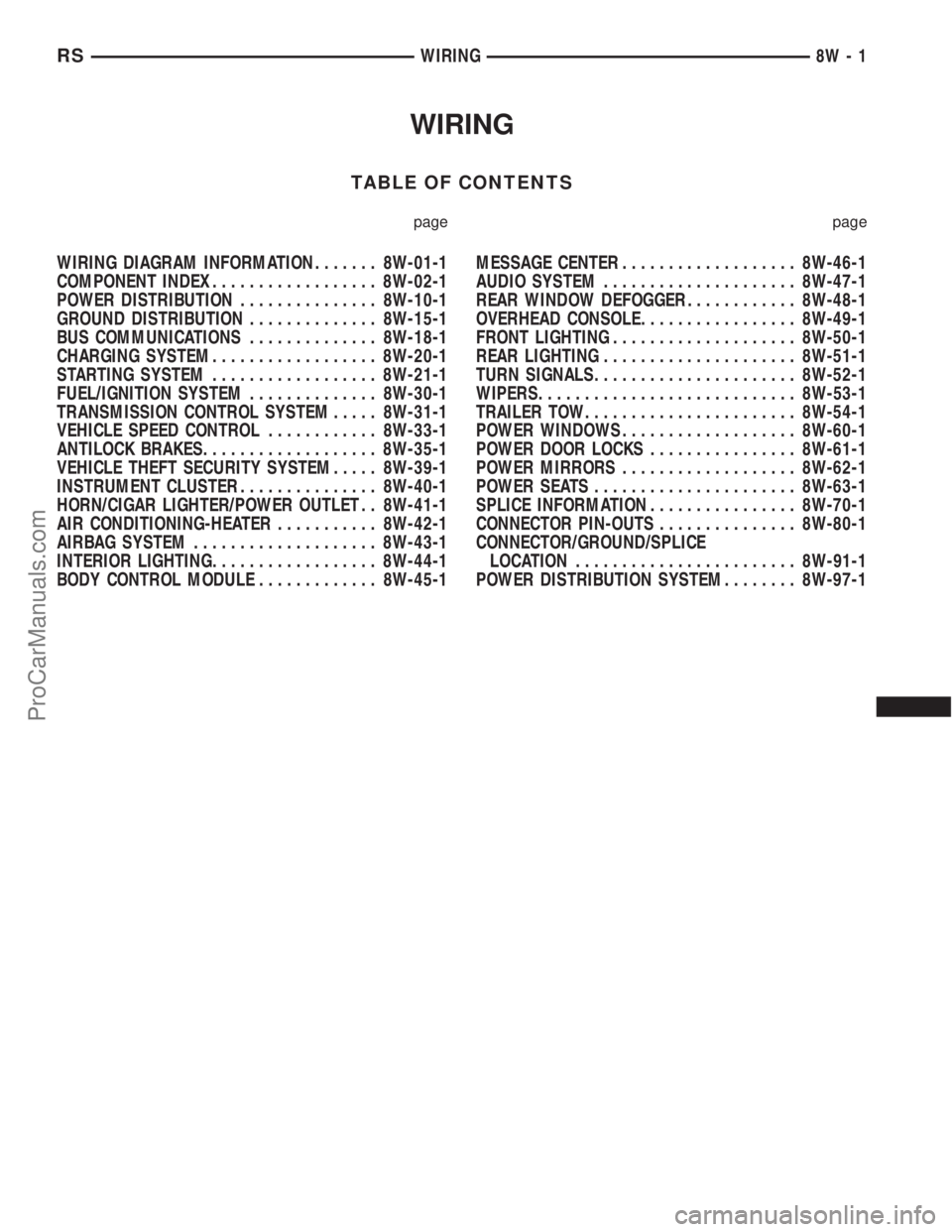

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1

BODY CONTROL MODULE............. 8W-45-1MESSAGE CENTER................... 8W-46-1

AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION SYSTEM........ 8W-97-1 RSWIRING

8W-1

ProCarManuals.com