turn signal CHRYSLER VOYAGER 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 522 of 2399

(4) Reconnect the battery negative cable.

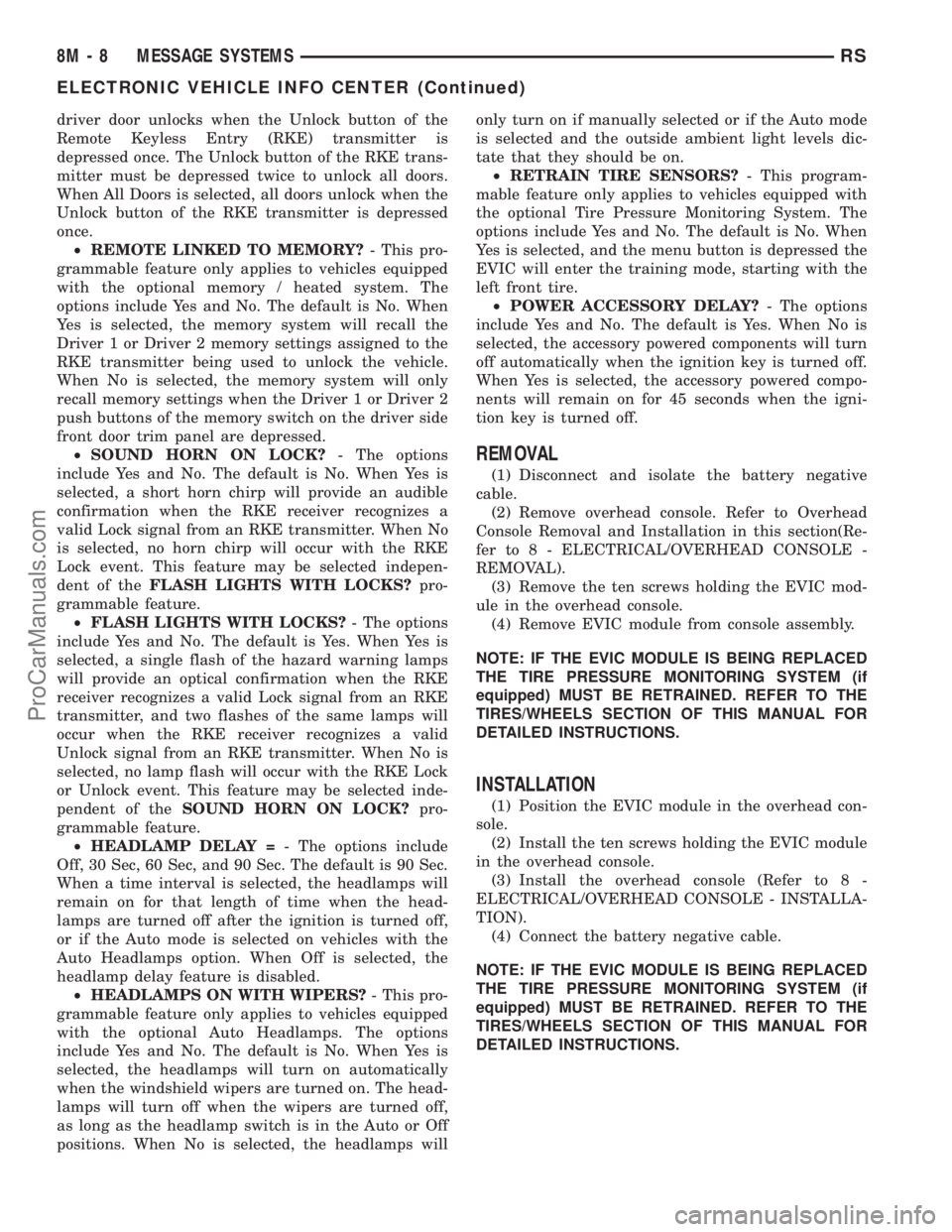

LICENSE LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two screws (Fig. 24).

(3) Twist bulb socket and remove (Fig. 25).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into lamp.

(3) Install two screws.

(4) Reconnect the battery negative cable.

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM

The turn signals are actuated with a lever on

Multi-Function Switch, located on the left side of the

steering wheel. The signals are automatically turned

off by a canceling cam (two lobes molded to the clock

spring mechanism). The cam comes in contact with

the cancel actuator on the turn signal (multi-func-

tion) switch assembly. Either cam lobe, pushing on

the cancel actuator, returns the switch to the OFF

position. The multi-function switch is a resistive

MUX switch that feeds inputs to the BCM.

OPERATION - TURN SIGNAL SYSTEM

Lane change signaling is actuated by applying par-

tial turn signal stalk movement toward the direction

desired until the indicator lamps flashes in the

instrument cluster. When the switch stalk is released

the stalk will spring back into the neutral position

turning OFF the turn signal.

With the ignition switch ON and the turn signal

switch stalk actuated left or right, current flows

through the:

²Multi-function switch

²Body Control Module

²Integrated Power Module (IPM)

²Turn indicator lamp

²Front and rear turn signal bulbs.

A chime will sound after the vehicle has traveled a

distance of approximately 1.0 mile and a speed of 15

mph, with the turn signal ON.

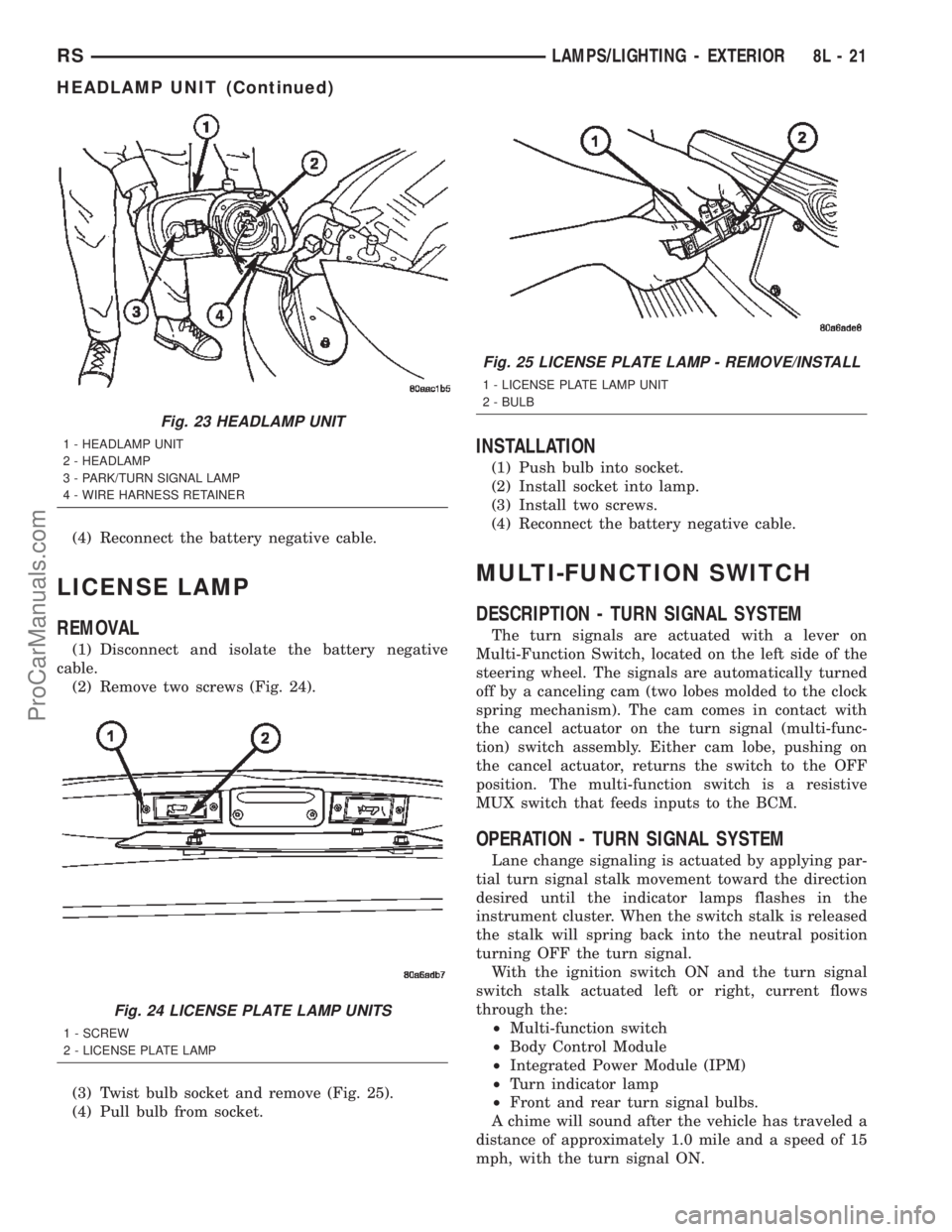

Fig. 23 HEADLAMP UNIT

1 - HEADLAMP UNIT

2 - HEADLAMP

3 - PARK/TURN SIGNAL LAMP

4 - WIRE HARNESS RETAINER

Fig. 24 LICENSE PLATE LAMP UNITS

1 - SCREW

2 - LICENSE PLATE LAMP

Fig. 25 LICENSE PLATE LAMP - REMOVE/INSTALL

1 - LICENSE PLATE LAMP UNIT

2 - BULB

RSLAMPS/LIGHTING - EXTERIOR8L-21

HEADLAMP UNIT (Continued)

ProCarManuals.com

Page 523 of 2399

DIAGNOSIS AND TESTING - MULTI-FUNCTION

SWITCH

To test turn signal, headlamp beam select and opti-

cal horn portion of the multi-function switch:

(1) Remove the multi-function switch, refer to

Electrical, Lamps/Lighting - Exterior, Multi-Function

Switch, Removal, and Installation.

(2) Using an ohmmeter check the resistance read-

ings between multi-function switch pins. Refer to

Wiring Diagrams for proper pin numbers and the

MULTI-FUNCTION SWITCH RESISTANCE table.

MULTI-FUNCTION SWITCH RESISTANCE

SWITCH

POSITIONPIN NUMBER RESISTANCE

LEFT 2 AND 3 1.7V 5%

RIGHT 2 AND 3 1KV 5%

OPTICAL

HORN1 AND 3 4.87KV 5%

HI BEAM 1 AND 3 2.32KV 5%

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove upper and lower steering column

shrouds. Refer to Steering, Column, Shroud,

Removal.

(3) Disconnect wire connector from back of multi-

function switch.

(4) Remove screws holding multi-function switch to

steering column adapter collar.

(5) Remove the multi-function switch.

INSTALLATION

(1) Position the switch on to the steering column.

(2) Install the two retaining screws.

(3) Connect the wire harness connector.

(4) Install the upper and lower steering column

shrouds. Refer to Steering, Column, Shroud, Installa-

tion.

(5) Connect the battery negative cable.

PARK/TURN SIGNAL LAMP

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove headlamp retaining screws.

(3) Twist socket counter - clockwise and remove

(Fig. 26).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Twist socket into headlamp.(3) Install headlamp retaining screws.

(4) Reconnect battery negative cable.

PARK/TURN SIGNAL LAMP -

EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the headlamp unit.

(3) Twist bulb socket and remove from headlamp

unit (Fig. 27).

(4) Twist bulb and remove from bulb socket.

Fig. 26 PARK/TURN SIGNAL LAMP

1 - PARK/TURN SIGNAL LAMP

2 - LAMP SOCKET

Fig. 27 PARK/TURN SIGNAL LAMP

1 - LOW BEAM HEADLAMP

2 - PARK/TURN SIGNAL LAMP

8L - 22 LAMPS/LIGHTING - EXTERIORRS

MULTI-FUNCTION SWITCH (Continued)

ProCarManuals.com

Page 524 of 2399

INSTALLATION

(1) Install bulb to bulb socket.

(2) Install bulb socket to headlamp unit.

(3) Install headlamp unit.

(4) Connect battery negative cable.

REAR FOG LAMP - EXPORT

DESCRIPTION

The rear fog lamps are incorporated into the tail

lamp unit. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/TAIL LAMP - REMOVAL)

for service procedures.

REPEATER LAMP - EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Push the side repeater lamp to one side and

release retaining tab.

(3) Pull side repeater lamp out and disengage bulb

socket from lamp.

(4) Depress, then rotate and pull bulb from socket.

INSTALLATION

(1) Install bulb to socket.

(2) Push lamp socket into the side repeater lamp.

(3) Position side repeater lamp to hole in fender.

(4) Push side repeater lamp to one side and seat

retaining tab into fender.

(5) Connect battery negative cable.

TAIL LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the tail lamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - REMOVAL).

(3) Squeeze the tabs on the bulb socket and

remove from tail lamp unit (Fig. 28).

(4) Pull bulb from lamp socket.

INSTALLATION

(1) Push bulb into the lamp socket.

(2) Install bulb socket into the tail lamp unit.

Ensure that both retaining tabs engage with an audi-

ble click.

(3) Install the tail lamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - INSTALLATION).(4) Reconnect the battery negative cable.

TAIL LAMP - EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the tail lamp unit (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - REMOVAL).

(3) Squeeze the tabs on housing retaining the

bulbs and remove from the tail lamp unit (Fig. 29).

(4) Remove bulbs by depressing, then turning

counter-clockwise.

Fig. 28 TAIL LAMP SOCKET

1 - LAMP SOCKET

2 - TAIL LAMP UNIT

Fig. 29 TAIL LAMP BULBS

1 - TAIL LAMP UNIT

2 - BRAKE/PARK LAMP

3 - TURN SIGNAL LAMP

4 - BACK UP LAMP

5 - REAR FOG LAMP

RSLAMPS/LIGHTING - EXTERIOR8L-23

PARK/TURN SIGNAL LAMP - EXPORT (Continued)

ProCarManuals.com

Page 526 of 2399

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS.....................25

CENTER CONSOLE LAMP SWITCH

REMOVAL.............................26

INSTALLATION.........................26

CLUSTER ILLUMINATION LAMPS

REMOVAL.............................26

INSTALLATION.........................26

COURTESY LAMP

REMOVAL.............................26

INSTALLATION.........................26

DOME LAMP

REMOVAL.............................26INSTALLATION.........................26

GLOVE BOX LAMP SWITCH

REMOVAL.............................26

INSTALLATION.........................27

LIFTGATE LAMP

REMOVAL.............................27

INSTALLATION.........................27

READING LAMP

REMOVAL.............................27

INSTALLATION.........................28

VANITY LAMP

REMOVAL.............................28

INSTALLATION.........................28

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS

BULB APPLICATION TABLE

LAMP BULB

ABS LED

AIRBAG LED

ALARM SET PC74

AUTOSTICK VFD*

BRAKE SYSTEM WARNING LED

CONSOLE 194

CRUISE INDICATOR VFD*

DOME/RAIL LAMPS 578

DOOR AJAR INDICATOR LED

DOOR COURTESY LAMP 578

FRONT DOOR COURTESY 567

GLOVE BOX 194

HIGH BEAM INDICATOR (BASE

CLUSTER)LED

HIGH BEAM INDICATOR PC74

CLUSTER ILLUMINATION PC74

LAMP BULB

LIFTGATE 578

LIFTGATE AJAR LED

LOW FUEL INDICATOR LED

LOW WASHER FLUID

INDICATORLED

MIL (BASE CLUSTER) LED

MIL PC74

OIL INDICATOR (BASE

CLUSTER)LED

OIL INDICATOR PC74

OVERHEAD CONSOLE READING PC579

OVERDRIVE OFF INDICATOR VFD*

READING 578

SEAT BELT INDICATOR LED

TEMPERATURE INDICATOR LED

TRAC OFF INDICATOR VFD*

TURN SIGNAL INDICATOR

(BASE CLUSTER)LED

TURN SIGNAL INDICATOR PC74

VISOR VANITY 6501966

VOLTAGE INDICATOR LED

* VFD = VACUUM FLUORESCENT DISPLAY

RSLAMPS/LIGHTING - INTERIOR8L-25

ProCarManuals.com

Page 537 of 2399

driver door unlocks when the Unlock button of the

Remote Keyless Entry (RKE) transmitter is

depressed once. The Unlock button of the RKE trans-

mitter must be depressed twice to unlock all doors.

When All Doors is selected, all doors unlock when the

Unlock button of the RKE transmitter is depressed

once.

²REMOTE LINKED TO MEMORY?- This pro-

grammable feature only applies to vehicles equipped

with the optional memory / heated system. The

options include Yes and No. The default is No. When

Yes is selected, the memory system will recall the

Driver 1 or Driver 2 memory settings assigned to the

RKE transmitter being used to unlock the vehicle.

When No is selected, the memory system will only

recall memory settings when the Driver 1 or Driver 2

push buttons of the memory switch on the driver side

front door trim panel are depressed.

²SOUND HORN ON LOCK?- The options

include Yes and No. The default is No. When Yes is

selected, a short horn chirp will provide an audible

confirmation when the RKE receiver recognizes a

valid Lock signal from an RKE transmitter. When No

is selected, no horn chirp will occur with the RKE

Lock event. This feature may be selected indepen-

dent of theFLASH LIGHTS WITH LOCKS?pro-

grammable feature.

²FLASH LIGHTS WITH LOCKS?- The options

include Yes and No. The default is Yes. When Yes is

selected, a single flash of the hazard warning lamps

will provide an optical confirmation when the RKE

receiver recognizes a valid Lock signal from an RKE

transmitter, and two flashes of the same lamps will

occur when the RKE receiver recognizes a valid

Unlock signal from an RKE transmitter. When No is

selected, no lamp flash will occur with the RKE Lock

or Unlock event. This feature may be selected inde-

pendent of theSOUND HORN ON LOCK?pro-

grammable feature.

²HEADLAMP DELAY =- The options include

Off, 30 Sec, 60 Sec, and 90 Sec. The default is 90 Sec.

When a time interval is selected, the headlamps will

remain on for that length of time when the head-

lamps are turned off after the ignition is turned off,

or if the Auto mode is selected on vehicles with the

Auto Headlamps option. When Off is selected, the

headlamp delay feature is disabled.

²HEADLAMPS ON WITH WIPERS?- This pro-

grammable feature only applies to vehicles equipped

with the optional Auto Headlamps. The options

include Yes and No. The default is No. When Yes is

selected, the headlamps will turn on automatically

when the windshield wipers are turned on. The head-

lamps will turn off when the wipers are turned off,

as long as the headlamp switch is in the Auto or Off

positions. When No is selected, the headlamps willonly turn on if manually selected or if the Auto mode

is selected and the outside ambient light levels dic-

tate that they should be on.

²RETRAIN TIRE SENSORS?- This program-

mable feature only applies to vehicles equipped with

the optional Tire Pressure Monitoring System. The

options include Yes and No. The default is No. When

Yes is selected, and the menu button is depressed the

EVIC will enter the training mode, starting with the

left front tire.

²POWER ACCESSORY DELAY?- The options

include Yes and No. The default is Yes. When No is

selected, the accessory powered components will turn

off automatically when the ignition key is turned off.

When Yes is selected, the accessory powered compo-

nents will remain on for 45 seconds when the igni-

tion key is turned off.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove overhead console. Refer to Overhead

Console Removal and Installation in this section(Re-

fer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

REMOVAL).

(3) Remove the ten screws holding the EVIC mod-

ule in the overhead console.

(4) Remove EVIC module from console assembly.

NOTE: IF THE EVIC MODULE IS BEING REPLACED

THE TIRE PRESSURE MONITORING SYSTEM (if

equipped) MUST BE RETRAINED. REFER TO THE

TIRES/WHEELS SECTION OF THIS MANUAL FOR

DETAILED INSTRUCTIONS.

INSTALLATION

(1) Position the EVIC module in the overhead con-

sole.

(2) Install the ten screws holding the EVIC module

in the overhead console.

(3) Install the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - INSTALLA-

TION).

(4) Connect the battery negative cable.

NOTE: IF THE EVIC MODULE IS BEING REPLACED

THE TIRE PRESSURE MONITORING SYSTEM (if

equipped) MUST BE RETRAINED. REFER TO THE

TIRES/WHEELS SECTION OF THIS MANUAL FOR

DETAILED INSTRUCTIONS.

8M - 8 MESSAGE SYSTEMSRS

ELECTRONIC VEHICLE INFO CENTER (Continued)

ProCarManuals.com

Page 540 of 2399

firmed to be OK, but the temperature display is

inoperative or incorrect, refer toDiagnosis and

Testing - Overhead Consolein this group. For

complete circuit diagrams, refer to the appropriate

wiring information.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At ±40É C (±40É F), the sensor resis-

tance is 336.6 kilohms. At 60É C (140É F), the sensor

resistance is 2.49 kilohms. The sensor resistance

should read between these two values. If OK, refer to

Diagnosis and Testing - Ambient Temperature

Sensor Circuitin this group. If not OK, replace the

faulty ambient temperature sensor.

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector and the Front Control Module wire

harness connector.

(2) Connect a jumper wire between the two termi-

nals in the body half of the ambient temperature sen-

sor wire harness connector.

(3) Check for continuity between the sensor return

circuit and the ambient temperature sensor signalcircuit cavities of the Front Control Module wire har-

ness connector. There should be continuity. If OK, go

to Step 4. If not OK, repair the open sensor return

circuit or ambient temperature sensor signal circuit

to the ambient temperature sensor as required.

(4) Remove the jumper wire from the body half of

the ambient temperature sensor wire harness con-

nector. Check for continuity between the sensor

return circuit cavity of the Front Control Module

wire harness connector and a good ground. There

should be no continuity. If OK, go to Step 5. If not

OK, repair the shorted sensor return circuit as

required.

(5) Check for continuity between the ambient tem-

perature sensor signal circuit cavity of the Front

Control Module wire harness connector and a good

ground. There should be no continuity. If OK, refer to

Diagnosis and Testing - Overhead Consolein

this group. If not OK, repair the shorted ambient

temperature sensor signal circuit as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Raise and support vehicle on safety stands.

(3) From behind front bumper fascia, remove

screw holding sensor to radiator closure panel.

(4) Remove sensor from vehicle.

INSTALLATION

(1) Position the sensor in the vehicle.

(2) From behind the front bumper fascia, install

the screw holding sensor to radiator closure panel.

(3) Connect the battery negative cable.

RSMESSAGE SYSTEMS8M-11

AMBIENT TEMP SENSOR (Continued)

ProCarManuals.com

Page 581 of 2399

REMOTE KEYLESS ENTRY SYSTEM

The key fob transmitter (Fig. 1) has six buttons.

Three of them, LOCK, UNLOCK, and PANIC, are

used to actuate parts of, and program the Remote

Keyless Entry (RKE) system via the customer pro-

gramming mode. It is not necessary to use the

PANIC button with the DRB IIItscan tool mode of

programming.

OPERATION

POWER DOOR LOCK SYSTEM

The Body Control Module (BCM) locks or unlocks

the doors when an actuation input signal from a door

lock switch or Remote Keyless Entry Module (RKE)

is received. The BCM turns on the output drivers

and provides a voltage level to the door lock motor

for a specified time. The BCM locks the doors auto-

matically when the vehicle is driven beyond the

speed of 25.7 Km/h (16 mph). The rolling door lock

feature can be disabled if desired. All doors and lift-

gate can be locked or unlocked using mechanical but-

ton or key cylinder methods (Liftgate cylinder does

not lock/unlock vehicle. It only unlocks the liftgate).

AUTOMATIC DOOR LOCKS

The BCM is equipped with a disable feature to

stop the speed sensitive automatic door locks from

functioning. The DISABLE feature can be switched

ON or OFF as desired. When the system is DIS-

ABLED the door locks will operate normally, but will

not lock automatically when the vehicle is rolling.

When the door locks are ENABLED the door locks

will automatically lock when the vehicle is moving at

about 25.7 Km/h (16 mph). All doors are closed, the

PCM has set the ªOK TO LOCKº bit, and doors were

not previously locked.

DOOR LOCK INHIBIT

If the key is in the ignition, in any position, and

either front door is ajar, all power door lock function-

ing shall be disabled when activating either door lock

switch. Also, if the Vehicle Theft Alarm (VTA) is

armed, the door lock switch ªUNLOCKº feature will

be disabled until the vehicle is disarmed. Pressing

the RKE lock/unlock button under these conditions

will result in a normal lock/unlock activation.

After the key is removed from the Ignition Switch,

or the doors are closed, the power door locks will

operate normally.

CENTRAL LOCKING

If equipped with Vehicle Theft Security System

(VTSS), all the doors can be locked with the key by

using any of the door lock cylinders. Turning the key

to the LOCK position will lock all the doors.

When either of the front key cylinder switches is

detected active, the BCM will activate the illumi-

nated entry feature and the individual front doors

will become mechanically unlocked. To central unlock

all doors, a second transition from OFF to UNLOCK

has to occur within 2 seconds of the first complete

UNLOCK cycle.

To central unlock the driver door, turn the key to

the rear of the vehicle. This indicates an unlock sig-

nal to the BCM. For the passenger door, turn the key

toward the front of the vehicle. When either key cyl-

inder switch is detected as active, the BCM will acti-

vate the illuminated entry feature. The individual

doors will become mechanically unlocked.

To central lock the vehicle, the driver door lock cyl-

inder is turned toward the front of the vehicle. The

passenger door lock cylinder is turned toward the

rear of the vehicle. When a lock input from either

key cylinder is detected as active, the BCM will can-

cel the illuminated entry feature and perform the

central lock operation.

Fig. 1 KEY FOB

1 - LEFT SLIDING DOOR BUTTON

2 - RIGHT SLIDING DOOR BUTTON

3 - LIFTGATE SWITCH

8N - 40 POWER LOCKSRS

POWER LOCKS (Continued)

ProCarManuals.com

Page 582 of 2399

DOOR LOCK CIRCUIT PROTECTION

The BCM controls the door lock output drivers. If

the door lock switch is actuated continuously for

more than one second the BCM will turn the output

driver OFF (the BCM would consider the switch

stuck). The lock motors are protected with Positive

Temperature Coefficient (PTC) device that prevents

motor burn out.

REMOTE KEYLESS ENTRY SYSTEM

²LOCK: Pressing the LOCK button locks all

doors and sounds horn (chirp) and arm the Vehicle

Theft Security System, if equipped. The chirp verifies

that the RKE receiver has sent a message to the

BCM for door lock operation. If a door has not been

closed before pressing the LOCK button, the vehicle

may not be secured and the VTSS will not arm until

the door is closed.

²UNLOCK: Pressing the UNLOCK button once

will unlock the driver's side doors and activate the

illuminated entry system and disarm Vehicle Theft

Security System, if equipped. Pressing the UNLOCK

button twice within five seconds will unlock all doors

and activate the illuminated entry system.

²LEFT SLIDING DOOR: Pressing the LEFT

SLIDING DOOR BUTTON opens/closes the left

power sliding door remotely.

²RIGHT SLIDING DOOR: Pressing the RIGHT

SLIDING DOOR BUTTON opens/closes the right

power sliding door remotely.

²LIFTGATE:

Pressing the LIFTGATE BUTTON

opens/closes the liftgate remotely, if equipped.If not

equipped with power liftgate, pressing the liftgate but-

ton will allow a one time 30 second access to liftgate.

²PANIC: Pressing the PANIC button sounds the

horns at half second intervals, flashes the exterior

lamps, and turns ON the interior lamps. The panic

alarm will remain on for three minutes, or until the

PANIC button is actuated again or the ignition

switch is turned to the RUN position.

The Remote Keyless Entry Module is capable of

retaining the transmitter Vehicle Access Code(s)

(VAC) in its memory even after vehicle power has

been interrupted.

NOTE: Additional features available to the customer

are described in the Vehicle Owners Manual.

The RKE system activates the optional memory

seat, mirror system and adjustable pedals, if

equipped. Two primary key fob transmitters can be

programmed to actuate memory seat and mirror set-

ting 1 or 2. Two additional key fob transmitters can be

added, but they will not be able to operate the mem-

ory seat and mirror system (Refer to 8 - ELECTRI-

CAL/POWER SEATS - OPERATION) and (Refer to 8 -

ELECTRICAL/POWER MIRRORS - OPERATION).

DOOR CYLINDER LOCK

SWITCH

DESCRIPTION

The Door Cylinder Lock Switch is used to:

²Unlock/Lock all the doors via the Central Lock-

ing feature.

²Arm/Disarm the Vehicle Theft Security System.

²Trigger the Illuminated Entry feature.

The door cylinder lock switch is mounted to the

rear of the driver and passenger door lock cylinders.

When installed on the rear of the cylinder, there is a

tab on the lock cylinder that aligns with the switch

to prevent it from turning. An anti-rotating device.

The door cylinder lock switch is a one time use

switch. Once it is removed from the rear of the door

lock cylinder, it may not be reinstalled and a new

switch must be used.

OPERATION

When the Door Cylinder Lock Switch is turned

either way using the door key cylinder, the BCM

reads a direct message signal from the switch, via

the Programmable Communication Interface (PCI)

bus.

If turning the key cylinder once, toward the front

of the vehicle (for either driver or passenger doors),

this will:

(1) Mechanically unlock the door lock.

(2) Disarm the Vehicle Theft Security System (if

equipped).

(3) Turn on the Illuminated Entry (if equipped) for

approximately 30 seconds.

If the key cylinder is turned to the unlock position

(toward the front of vehicle) twice within two sec-

onds, all the doors and liftgate will unlock (if

equipped with the central locking feature).

To lock the vehicle using the door cylinder lock

switch, turn the key cylinder toward the rear of the

vehicle (either passenger or driver doors) once. This

will lock the door that you are using the key on. If

equipped with the central locking feature, this will

lock all the other doors and liftgate. Furthermore,

this will arm the vehicle theft security system and

turn off the illuminated entry.

DIAGNOSIS AND TESTING - DOOR CYLINDER

LOCK SWITCH

(1) Visually inspect the switch for proper installa-

tion. Make sure it is seated on the rear of the key

cylinder, with the tab of the door key cylinder prop-

erly aligned with the slot on the door cylinder lock

switch.

(2) Disconnect the switch at the harness connector

and check the resistance in each switch position.

RSPOWER LOCKS8N-41

POWER LOCKS (Continued)

ProCarManuals.com

Page 589 of 2399

The mirror switch allows the driver a manual con-

trol of whether the automatic dimming feature is

operational. When AUTO is selected a small Light-

Emitting Diode (LED), to the right of the mirror

switch, is illuminated. The automatic dimming fea-

ture will only operate when the ignition switch is in

the On position. The mirror also senses the backup

lamp circuit, and will automatically disable its self-

dimming feature whenever the transmission gear

selector is in the Reverse position.

NOTE: The mirror always defaults to an ON state

upon ignition.

The driver side automatic dimming mirror is stan-

dard with the automatic dimming inside mirror. The

signal to control the dimming of that mirror is gen-

erated by the automatic day/night inside rear view

mirror circuitry. That signal is then delivered to the

driver side outside rear view mirror on a hard wired

circuit.

The automatic day/night mirror cannot be

repaired. If faulty or damaged, the entire inside rear

view mirror assembly must be replaced.

DIAGNOSIS AND TESTING - AUTOMATIC DAY /

NIGHT MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuse in the intelligent power module.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the intelli-

gent power module. If OK, go to Step 3. If not OK,

repair the open circuit to the ignition switch as

required.

(3) Unplug the wire harness connector from the

automatic day/night mirror. Check for battery voltage

at the fused ignition switch output circuit cavity of

the automatic day/night mirror wire harness connec-

tor. If OK, go to Step 4. If not OK, repair the open

circuit to the junction block as required.

(4) Turn the ignition switch to the Off position.

Check for continuity between the ground circuit cav-

ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.(5) Turn the ignition switch to the On position. Set

the parking brake. Place the transmission gear selec-

tor lever in the Reverse position. Check for battery

voltage at the backup lamp switch output circuit cav-

ity of the automatic day/night mirror wire harness

connector. If voltage is present, reinstall the auto-

matic day/night mirror wire harness connector and

go to Step 6. If not OK, repair the open circuit as

required.

(6) Place the transmission gear selector lever in

the Neutral position. Place the automatic day/night

mirror switch in the On (LED in the switch is

lighted) position. Cover the forward facing ambient

photocell sensor to keep out any ambient light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The automatic day/night mir-

ror should darken. The automatic day/night mirror

should darken within 2 minutes if testing for the

first time. For immediate response, turn the vehicle

OFF and back ON with the forward-facing light sen-

sor still covered. This defeats the day-detect logic. If

OK, go to Step 8. If not OK, replace the faulty mirror

unit.

(8) With the mirror darkened, place the transmis-

sion gear selector lever in the Reverse position. The

automatic day/night mirror should return to its nor-

mal reflectance. If not OK, replace the faulty mirror

unit.

Bench testing both mirrors can be done, of care is

exercised. For an inside mirror, the pin closest to he

mount is 12V (+), the next is 12V (-). The third is

reverse override. The fourth is outside mirror (+),

and the fifth is outside mirror (-).Do not apply 12

volts to the fourth and fifth pins.With 12 volts

on pins 1 and 2, the mirror can be tested by blocking

the rear sensor and shining a light into the forward

sensor. For an outside mirror, there is a 2±pin con-

nector. Applying 1.2 volts will cause the mirror to

dim. If the mirror does not dim, the entire glass

assembly can be replaced just as it is when the glass

is broken.

WARNING: Do not apply 12 volts to the outside mir-

ror. Damage to the mirror will result.

8N - 48 POWER MIRRORSRS

AUTOMATIC DAY / NIGHT MIRROR (Continued)

ProCarManuals.com

Page 616 of 2399

(2) Install airbag attaching bolts to the instrument

panel.

(3) Connect yellow wire connector from passenger

airbag.

(4) Install Instrument panel. Refer to Body, Instru-

ment Panel, Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

UNDEPLOYED AIRBAG

(1) Install Passenger Airbag into instrument panel.

(2) Install airbag attaching bolts to the instrument

panel.

(3) Connect yellow wire connector from passenger

airbag.

(4) Install Instrument panel. Refer to Body, Instru-

ment Panel, Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

SEAT AIRBAG

DESCRIPTION

The side impact airbag system Seat Airbags are

located in the outboard side of the front seat backs.One in each front seat. The seat airbag inflator

assembly is within the airbag housing (Fig. 1). Each

airbag is mounted to the seat back frame. If deployed

or defective, the entire seat back assembly must be

replaced.

OPERATION

Only the Side Impact Airbag Control Module

(SIACM) can deploy the side airbags. When supplied

with the proper electrical signal, the seat airbag

inflator will produce a gas and discharge the bag

directly between the occupant and the side of the

vehicle, protecting the occupant. Upon deployment,

the seat back trim cover will tear open and allow the

side airbag to fully inflate and quickly deflate.

SEAT BELT OUTBOARD

FRONT

REMOVAL

Inspect the condition of the shoulder belt and lap

belt. Replace any belt that is cut, frayed, torn, or

damaged in any way. Also, replace the shoulder belt

if the retractor is either damaged or inoperative.

(1) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(2) Remove cover from seat belt turning loop.

(3) Remove bolt attaching turning loop to shoulder

belt height adjuster (Fig. 2).

(4) Remove turning loop from B-pillar.

(5) Remove lower B-pillar trim cover or quarter

trim panel.

(6) Remove bolt attaching seat belt retractor to

B-pillar (Fig. 2).

(7) Lift retractor upward and disengage arrow

head retainer attaching retractor to B-pillar.

(8) Remove seat belt from vehicle.

INSTALLATION

Inspect the condition of the shoulder belt and lap

belt. Replace any belt that is cut, frayed, torn, or

damaged in any way. Also, replace the shoulder belt

if the retractor is either damaged or inoperative.

(1) Place seat belt into position.

(2) Lower retractor into position B-pillar.

(3) Install bolt attaching seat belt retractor to

B-pillar. Tighten all seat belt anchor bolts to 39 N´m

(29 ft. lbs.) torque.

(4) Install turning loop onto B-pillar.

(5) Install lower B-pillar trim cover or quarter

trim panel.

(6) Install bolt attaching turning loop to shoulder

belt height adjuster. Tighten all seat belt anchor

bolts to 39 N´m (29 ft. lbs.) torque.

(7) Press cover onto the seat belt turning loop.

Fig. 1 SEAT AIRBAG - TYPICAL

RSRESTRAINTS8O-7

PASSENGER AIRBAG (Continued)

ProCarManuals.com