windshield wipers CHRYSLER VOYAGER 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 2092 of 2399

(15) Clean access urethane from exterior with

MopartSuper Kleen or equivalent.

(16) Apply 150 mm (6 in.) lengths of 50 mm (2 in.)

masking tape spaced 250 mm (10 in.) apart to hold

molding in place until urethane cures.

(17) Engage wire connectors to windshield

defroster grid.

(18) Install A-pillar trim panels.

(19) Install cowl cover and wipers.

(20) Install inside rear view mirror.

(21) After urethane has cured, remove tape strips

and water test windshield to verify repair.SLIDING DOOR GLASS

REMOVAL

The temperature of the vehicle should be at least

21É C (70É F) before removing the stationary quarter/

sliding door glass. Butyl sealer becomes more pliable

at high temperatures.

(1) Remove interior trim as necessary to gain

access attaching locations on back of glass.

(2) Remove nuts holding stationary glass to fence.

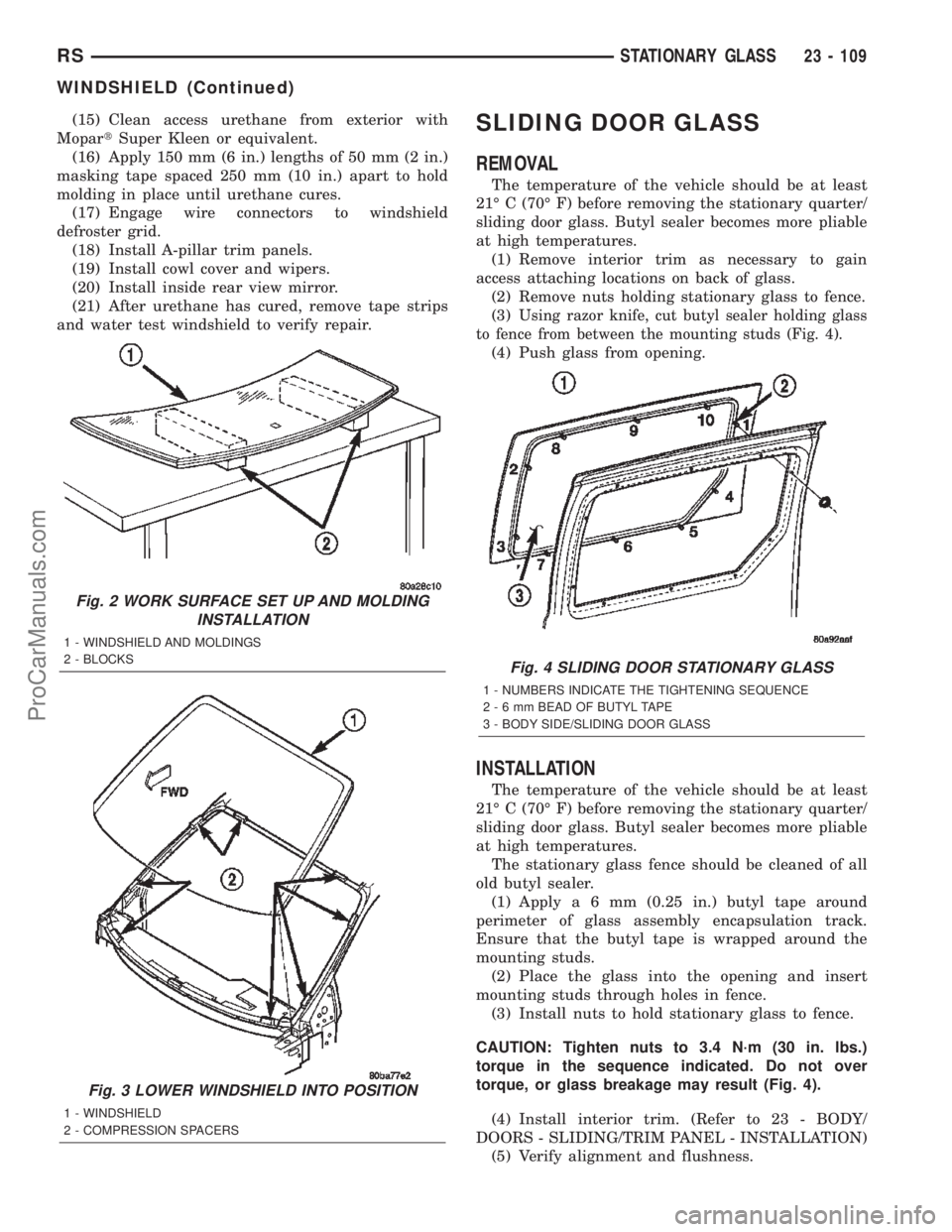

(3)

Using razor knife, cut butyl sealer holding glass

to fence from between the mounting studs (Fig. 4).

(4) Push glass from opening.

INSTALLATION

The temperature of the vehicle should be at least

21É C (70É F) before removing the stationary quarter/

sliding door glass. Butyl sealer becomes more pliable

at high temperatures.

The stationary glass fence should be cleaned of all

old butyl sealer.

(1) Applya6mm(0.25 in.) butyl tape around

perimeter of glass assembly encapsulation track.

Ensure that the butyl tape is wrapped around the

mounting studs.

(2) Place the glass into the opening and insert

mounting studs through holes in fence.

(3) Install nuts to hold stationary glass to fence.

CAUTION: Tighten nuts to 3.4 N´m (30 in. lbs.)

torque in the sequence indicated. Do not over

torque, or glass breakage may result (Fig. 4).

(4) Install interior trim. (Refer to 23 - BODY/

DOORS - SLIDING/TRIM PANEL - INSTALLATION)

(5) Verify alignment and flushness.

Fig. 2 WORK SURFACE SET UP AND MOLDING

INSTALLATION

1 - WINDSHIELD AND MOLDINGS

2 - BLOCKS

Fig. 3 LOWER WINDSHIELD INTO POSITION

1 - WINDSHIELD

2 - COMPRESSION SPACERS

Fig. 4 SLIDING DOOR STATIONARY GLASS

1 - NUMBERS INDICATE THE TIGHTENING SEQUENCE

2-6mmBEAD OF BUTYL TAPE

3 - BODY SIDE/SLIDING DOOR GLASS

RSSTATIONARY GLASS23 - 109

WINDSHIELD (Continued)

ProCarManuals.com

Page 2266 of 2399

The evaporator temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

OPERATION

The evaporator temperature sensor monitors the

temperature of the evaporator through its connection

to the top of the expansion valve. The sensor will

change its internal resistance in response to the tem-

peratures it monitors. The heater-A/C control module

is connected to the sensor through a sensor ground

circuit and a sensor signal circuit. As the evaporator

temperature increases, the resistance of the sensor

decreases and the voltage monitored by the module

decreases. The module uses this monitored voltage

reading to an indication of the evaporator tempera-

ture. The heater-A/C control module is programmed

to respond to this input by sending electronic mes-

sages to the Powertrain Control Module (PCM) over

the Programmable Communications Interface (PCI)

data bus, and the PCM then cycles the air condition-

ing compressor clutch as necessary to optimize air

conditioning system performance and to protect the

system from evaporator freezing. The external loca-

tion of the sensor and the use of a screw allows the

sensor to be removed or installed from the expansion

valve without disturbing the refrigerant in the sys-

tem. The evaporator temperature sensor is diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the air cleaner housing from the right

side of the engine compartment.

(3) Remove the windshield wiper assembly from

the vehicle(Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MODULE - REMOVAL).

(4) Remove the temperature sensor attaching

screw from the expansion valve.

(5) Pull the evaporator temperature sensor away

from the expansion valve far enough to access the

red release ring on the wiring connector. Push the

red ring toward the connector to release lock and

remove the HVAC wire harness connector from the

temperature sensor.

(6) Remove the evaporator temperature sensor

from the engine compartment. Please note that any

grease removed with the old temperature sensor

must be replaced, failure to do so could result in poor

a/c performance.

INSTALLATION

(1) Position the evaporator temperature sensor

into the right rear corner of the engine compartment.

Please make sure any grease removed with the old

sensor has been replaced before the new sensor is

installed, failure to do so could lead to poor a/c per-

formance.

(2) Reconnect the HVAC wire harness connector

for the evaporator temperature sensor to the sensor

connector receptacle.

(3) Position the evaporator temperature sensor

onto the top of the expansion valve with the sensor

probe inserted into the well in the expansion valve.

(4) Install the temperature sensor retaining screw

and tighten.

(5) Install the window wiper assembly to the vehi-

cle(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - INSTALLATION).

(6) Reinstall the air cleaner housing into the right

side of the engine compartment.

(7) Reconnect the battery negative cable.

(8) Run the HVAC Cool Down test to verify system

is operating properly(Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND TESTING).

Fig. 18 Evaporator Temperature Sensor

1 - RIGHT FRONT STRUT TOWER

2 - EVAPORATOR TEMPERATURE SENSOR

3 - EXPANSION VALVE

4 - DASH PANEL

5 - RETAINER

RSCONTROLS - FRONT24-23

EVAPORATOR TEMPERATURE SENSOR (Continued)

ProCarManuals.com