CHRYSLER VOYAGER 2002 Service Manual

Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 361 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P1683 SPD CTRL PWR Relay; or S/C 12v

Driver CKTAn open or shorted condition detected in the speed control

servo power control circuit. (SBECII: ext relay).

P1684 Battery Loss In The Last 50 Starts The battery has been disconnected within the last 50 starts.

P1685 Skim Invalid Key The engine controller has received an invalid key from the

SKIM.

P1686 No SKIM BUS Messages Received No CCD/J1850 messages received from the Smart Key

Immobilizer Module (SKIM).

P1687 No MIC BUS Message No CCD/J1850 messages received from the Mechanical

Instrument Cluster (MIC) module.

P1693 DTC Detected in Companion Module A fault has been generated in the companion engine control

module.

P1694 Fault In Companion Module No CCD/J1850 messages received from the powertrain

control module-Aisin transmission.

P1695 No CCD/J1850 Message From Body

Control ModuleNo CCD/J1850 messages received from the body control

module.

P1696 (M) PCM Failure EEPROM Write Denied Unsuccessful attempt to write to an EEPROM location by the

control module.

P1697 (M) PCM Failure SRI Mile Not Stored Unsuccessful attempt to update Service Reminder Indicator

(SRI or EMR) mileage in the control module EEPROM.

P1698 (M) No CCD/J1850 Message From TCM No CCD/J1850 messages received from the electronic

transmission control module (EATX) or the Aisin transmission

controller.

P1719 Skip Shift Solenoid Circuit An open or shorted condition detected in the transmission

2-3 gear lock-out solenoid control circuit.

P1740 TCC or O/D Solenoid Performance Rationality error detected in either the torque convertor

clutch or solenoid or overdrive solenoid system.

P1756 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear. (Mid Pressure Malfunction)

P1757 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear (Zero Pressure Malfunction)

P1762 Gov Press Sen Offset Volts Too Low

or HighThe Governor Pressure Sensor input is greater than a

calibration limit or is less than a calibration limit for 3

consecutive park/neutral calibrations.

P1763 Governor Pressure Sensor Volts Too

HiThe Governor Pressure Sensor input is above an acceptable

voltage level.

P1764 Governor Pressure Sensor Volts Too

LowThe Governor Pressure Sensor input is below an acceptable

voltage level.

P1765 Trans 12 Volt Supply Relay CTRL

CircuitAn open or shorted condition is detected in the Transmission

Relay control circuit. This relay supplies power to the TCC

P1899 (M) P/N Switch Stuck in Park or in Gear Incorrect input state detected for the Park/Neutral switch.

8E - 24 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 362 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P2008 Short Runner Valve Solenoid Circuit An open or shorted condition detected in the short runner

tuning valve control circuit.

P2302 Ignition Coil Secondary #1 Circuit

P2305 Ignition Coil Secondary #2 Circuit

P2308 Ignition Coil Secondary #3 Circuit

P2311 Ignition Coil Secondary #4 Circuit

P2314 Ignition Coil Secondary #5 Circuit

P2317 Ignition Coil Secondary #6 Circuit

P2320 Ignition Coil Secondary #7 Circuit

P2323 Ignition Coil Secondary #8 Circuit

P2503 Charging System Voltage Low Charging system voltage below minimum acceptable voltage.

OPERATION - SENSOR RETURN - PCM INPUT

The sensor return circuit provides a low electrical

noise ground reference for all of the systems sensors.

The sensor return circuit connects to internal ground

circuits within the Powertrain Control Module (PCM).

OPERATION - SCI RECEIVE - PCM INPUT

SCI Receive is the serial data communication

receive circuit for the DRB scan tool. The Powertrain

Control Module (PCM) receives data from the DRB

through the SCI Receive circuit.

OPERATION - IGNITION SENSE - PCM INPUT

The ignition sense input informs the Powertrain

Control Module (PCM) that the ignition switch is in

the crank or run position.

OPERATION - PCM GROUND

Ground is provided through multiple pins of the

PCM connector. Depending on the vehicle there may

be as many as three different ground pins. There are

power grounds and sensor grounds.

The power grounds are used to control the ground

side of any relay, solenoid, ignition coil or injector.

The signal ground is used for any input that uses

sensor return for ground, and the ground side of any

internal processing component.

The SBEC III case is shielded to prevent RFI and

EMI. The PCM case is grounded and must be firmly

attached to a good, clean body ground.

Internally all grounds are connected together, how-

ever there is noise suppression on the sensor ground.

For EMI and RFI protection the case is also

grounded separately from the ground pins.

OPERATION

OPERATION - 8-VOLT SUPPLY - PCM OUTPUT

The PCM supplies 8 volts to the crankshaft posi-

tion sensor, camshaft position sensor.

OPERATION - 5 VOLT SUPPLY - PCM OUTPUT

The PCM supplies 5 volts to the following sensors:

²A/C pressure transducer

²Engine coolant temperature sensor

²Manifold absolute pressure sensor

²Throttle position sensor

²Linear EGR solenoid

²Battery temperature

²Knock sensor

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES

BULB CHECK

Key on: Bulb illuminated until vehicle starts, as

long as all once per trip (readiness) monitors com-

pleted. If monitors havenotbeen completed, then:

Key on: bulb check for about 8 seconds, lamp then

flashes if once per trip (readiness) monitors havenot

been completed until vehicle is started, then MIL is

extinguished.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

RSELECTRONIC CONTROL MODULES8E-25

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 363 of 2399

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

OBTAINING DTC'S USING IGNITION KEY

(1) Cycle the ignition key On - Off - On - Off - On

within 5 seconds.

(2) The Odometer will show the P-code for the

DTC code number. Refer to the Emission section for

the DTC chart for a detailed explanation of the DTC

codes.

(3) If no DTC's are present, the cluster will display

one of two texts: ªP1684º and ªdoneº or only ªdoneº.

²P1684 is only a status and indicates that the

PCM memory has been cleared within the last 50

ignition cycles and does not indicate a problem.

²done indicates that NO DTCs are present and

the procedure is complete.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the battery shield, refer to the Battery

section for more information.

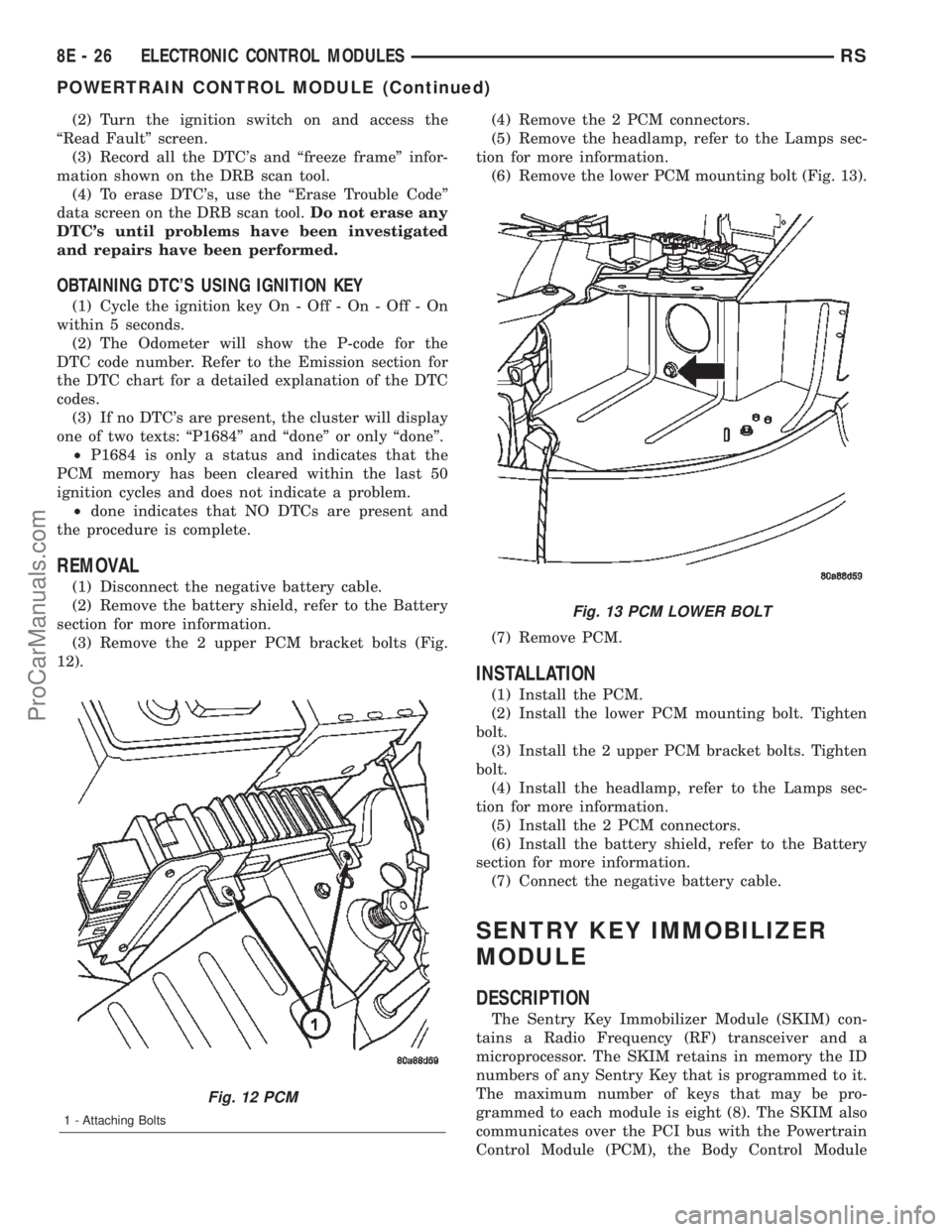

(3) Remove the 2 upper PCM bracket bolts (Fig.

12).(4) Remove the 2 PCM connectors.

(5) Remove the headlamp, refer to the Lamps sec-

tion for more information.

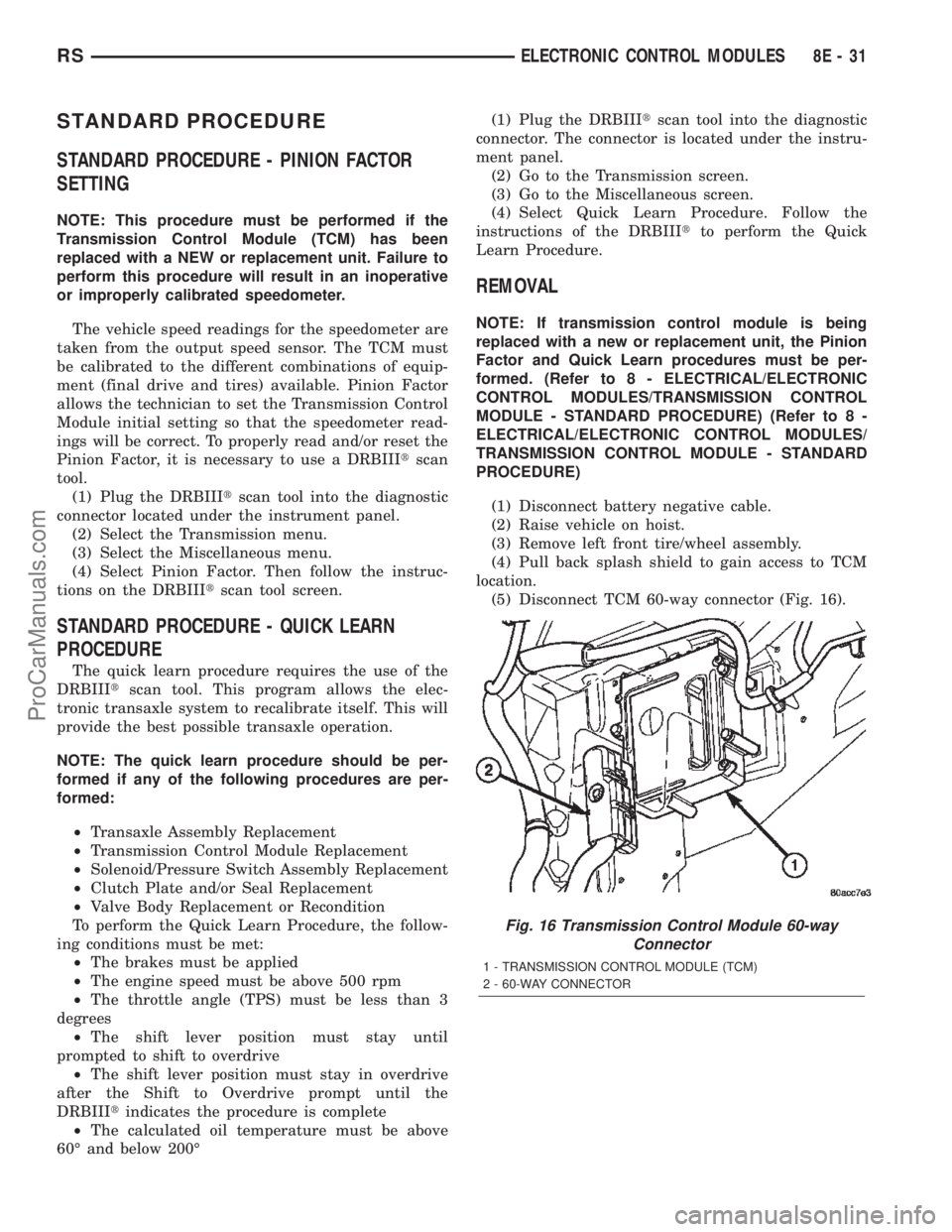

(6) Remove the lower PCM mounting bolt (Fig. 13).

(7) Remove PCM.

INSTALLATION

(1) Install the PCM.

(2) Install the lower PCM mounting bolt. Tighten

bolt.

(3) Install the 2 upper PCM bracket bolts. Tighten

bolt.

(4) Install the headlamp, refer to the Lamps sec-

tion for more information.

(5) Install the 2 PCM connectors.

(6) Install the battery shield, refer to the Battery

section for more information.

(7) Connect the negative battery cable.

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a

microprocessor. The SKIM retains in memory the ID

numbers of any Sentry Key that is programmed to it.

The maximum number of keys that may be pro-

grammed to each module is eight (8). The SKIM also

communicates over the PCI bus with the Powertrain

Control Module (PCM), the Body Control Module

Fig. 12 PCM

1 - Attaching Bolts

Fig. 13 PCM LOWER BOLT

8E - 26 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 364 of 2399

(BCM), and the DRB IIItscan tool. The SKIM trans-

mits and receives RF signals through a tuned

antenna enclosed within a molded plastic ring forma-

tion that is integral to the SKIM housing. When the

SKIM is properly installed on the steering column,

the antenna ring fits snugly around the circumfer-

ence of the ignition lock cylinder housing. If this ring

is not mounted properly, communication problems

may arise in the form of transponder-related faults.

For added system security, each SKIM is pro-

grammed with a unique9Secret Key9code. This code

is stored in memory and is sent over the PCI bus to

the PCM and to each key that is programmed to

work with the vehicle. The9Secret Key9code is there-

fore a common element found in all components of

the Sentry Key Immobilizer System (SKIS). In the

event that a SKIM replacement is required, the

9Secret Key9code can be restored from the PCM by

following the SKIM replacement procedure found in

the DRB IIItscan tool. Proper completion of this

task will allow the existing ignition keys to be repro-

grammed. Therefore, new keys will NOT be needed.

In the event that the original9Secret Key9code can

not be recovered, new ignition keys will be required.

The DRB IIItscan tool will alert the technician if

key replacement is necessary. Another security code,

called a PIN, is used to gain secured access to the

SKIM for service. The SKIM also stores in its mem-

ory the Vehicle Identification Number (VIN), which it

learns through a bus message from the assembly

plant tester. The SKIS scrambles the information

that is communicated between its components in

order to reduce the possibility of unauthorized SKIM

access and/or disabling.

OPERATION

When the ignition switch is moved to the RUN

position, the SKIM transmits an RF signal to the

transponder in the ignition key. The SKIM then

waits for a response RF signal from the transponder

in the key. If the response received identifies the key

as valid, the SKIM sends a9valid key9message to

the PCM over the PCI bus. If the response received

identifies the key as invalid or no response is

received from the transponder in the ignition key, the

SKIM sends an9invalid key9message to the PCM.

The PCM will enable or disable engine operation

based upon the status of the SKIM messages. It is

important to note that the default condition in the

PCM is9invalid key.9Therefore, if no response is

received by the PCM, the engine will be immobilized

after two (2) seconds of running.The SKIM also sends indicator light status mes-

sages to the BCM to operate the light. This is the

method used to turn the light ON solid or to flash it

after the indicator light test is complete to signify a

fault in the SKIS. If the light comes ON and stays

ON solid after the indicator light test, this signifies

that the SKIM has detected a system malfunction

and/or that the SKIS has become inoperative. If the

SKIM detects an invalid keyORa key-related fault

exists, the indicator light will flash following the

indicator light test. The SKIM may also request an

audible chime if the customer key programming fea-

ture is available and the procedure is being utilized

(Refer to 8 - ELECTRICAL/VEHICLE THEFT SECU-

RITY/TRANSPONDER KEY - STANDARD PROCE-

DURE).

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Remove Lower Instrument Panel Cover. Refer

to Body, Instrument Panel, Lower Instrument Panel

Cover, Removal.

(3) Remove the steering column upper and lower

shrouds. Refer to Steering, Column, Column Shroud,

Removal.

(4) Disengage the steering column wire harness

from the Sentry Key Immobilizer Module (SKIM).

(5) Remove the one screws securing the SKIM to

the steering column.

(6) Rotate the SKIM upwards and then to the side

away from the steering column to slide the SKIM

antenna ring from around the ignition switch lock

cylinder housing.

(7) Remove the SKIM from the vehicle.

INSTALLATION

(1) Slip the SKIM antenna ring around the igni-

tion switch lock cylinder housing. Rotate the SKIM

downwards and then towards the steering column.

(2) Install the one screws securing the SKIM to

the steering column.

(3) Engage the steering column wire harness from

the Sentry Key Immobilizer Module (SKIM).

(4) Install the steering column upper and lower

shrouds. Refer to Steering, Column, Column Shroud,

Installation.

(5) Install the Lower Instrument Panel Cover.

Refer to Body, Instrument Panel, Lower Instrument

Panel Cover, Installation.

(6) Connect the battery negative cable.

RSELECTRONIC CONTROL MODULES8E-27

SENTRY KEY IMMOBILIZER MODULE (Continued)

ProCarManuals.com

Page 365 of 2399

TRANSMISSION CONTROL

MODULE

DESCRIPTION

The Transmission Control Module (TCM) is located

behind the left fender and is fastened with three

screws to three clips in the left frame rail forward of

the suspension (Fig. 14).

OPERATION

The TCM is the controlling unit for all electronic

operations of the transaxle. The TCM receives infor-

mation regarding vehicle operation from both direct

and indirect inputs, and selects the operational mode

of the transaxle. Direct inputs are hardwired to, and

used specifically by the TCM. Indirect inputs origi-

nate from other components/modules, and are shared

with the TCM via the J1850 communication bus.Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor (CKP)

²Transmission Range Sensor (TRS)

²Pressure Switches (L/R, 2/4, OD)

²Transmission Temperature Sensor (Integral to

TRS)

²Input Shaft Speed Sensor

²Output Shaft Speed Sensor

Some examples ofindirect inputsto the TCM are:

²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Speed Control ON/OFF Switch

²Engine Coolant Temperature

²Ambient/Battery Temperature

²Brake Switch Status

²DRB Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids (LR/CC, 2/4, OD and UD)

²Vehicle Speed (to PCM)

²Torque Reduction Request (to PCM)

An example of a TCMindirect outputis:

²Transmission Temperature (to PCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indices

(CVI)

²

Storing and selecting appropriate Shift Schedules

²System self-diagnostics

²Diagnostic capabilities (with DRB scan tool)

Fig. 14 Transmission Control Module (TCM)

Location

1 - TRANSMISSION CONTROL MODULE (TCM)

8E - 28 ELECTRONIC CONTROL MODULESRS

ProCarManuals.com

Page 366 of 2399

CLUTCH VOLUME INDEX (CVI)

An important function of the TCM is to monitor

Clutch Volume Index (CVI). CVIs represent the vol-

ume of fluid needed to compress a clutch pack.

The TCM monitors gear ratio changes by monitor-

ing the Input and Output Speed Sensors. The Input,

or Turbine Speed Sensor sends an electrical signal to

the TCM that represents input shaft rpm. The Out-

put Speed Sensor provides the TCM with output

shaft speed information.

By comparing the two inputs, the TCM can deter-

mine transaxle gear ratio. This is important to the

CVI calculation because the TCM determines CVIs

by monitoring how long it takes for a gear change to

occur (Fig. 15).

Gear ratios can be determined by using the DRB

Scan Tool and reading the Input/Output Speed Sen-

sor values in the ªMonitorsº display. Gear ratio can

be obtained by dividing the Input Speed Sensor value

by the Output Speed Sensor value.

For example, if the input shaft is rotating at 1000

rpm and the output shaft is rotating at 500 rpm,

then the TCM can determine that the gear ratio is

2:1. In direct drive (3rd gear), the gear ratio changes

to 1:1. The gear ratio changes as clutches are applied

and released. By monitoring the length of time it

takes for the gear ratio to change following a shift

request, the TCM can determine the volume of fluid

used to apply or release a friction element.

The volume of transmission fluid needed to apply

the friction elements are continuously updated for

adaptive controls. As friction material wears, the vol-

ume of fluid need to apply the element increases.

Certain mechanical problems within the clutch

assemblies (broken return springs, out of position

snap rings, excessive clutch pack clearance, improper

assembly, etc.) can cause inadequate or out-of-rangeclutch volumes. Also, defective Input/Output Speed

Sensors and wiring can cause these conditions. The

following chart identifies the appropriate clutch vol-

umes and when they are monitored/updated:

CLUTCH VOLUMES

ClutchWhen Updated

Proper Clutch

Volume

Shift Sequence Oil Temperature Throttle Angle

L/R2-1 or 3-1 coast

downshift>70É <5É 35to83

2/4 1-2 shift

> 110É5 - 54É20 to 77

OD 2-3 shift 48 to 150

UD 4-3 or 4-2 shift > 5É 24 to 70

Fig. 15 Example of CVI Calculation

1 - OUTPUT SPEED SENSOR

2 - OUTPUT SHAFT

3 - CLUTCH PACK

4 - SEPARATOR PLATE

5 - FRICTION DISCS

6 - INPUT SHAFT

7 - INPUT SPEED SENSOR

8 - PISTON AND SEAL

RSELECTRONIC CONTROL MODULES8E-29

TRANSMISSION CONTROL MODULE (Continued)

ProCarManuals.com

Page 367 of 2399

SHIFT SCHEDULES

As mentioned earlier, the TCM has programming that

allows it to select a variety of shift schedules. Shift

schedule selection is dependent on the following:

²Shift lever position

²Throttle position

²Engine load²Fluid temperature

²Software level

As driving conditions change, the TCM appropri-

ately adjusts the shift schedule. Refer to the follow-

ing chart to determine the appropriate operation

expected, depending on driving conditions.

Schedule Condition Expected Operation

Extreme ColdOil temperature at start-up below

-16É FPark, Reverse, Neutral and 2nd

gear only (prevents shifting which

may fail a clutch with frequent

shifts)

ColdOil temperature at start-up above

-12É F and below 36É F± Delayed 2-3 upshift

(approximately 22-31 mph)

± Delayed 3-4 upshift (45-53 mph)

± Early 4-3 costdown shift

(approximately 30 mph)

± Early 3-2 coastdown shift

(approximately 17 mph)

± High speed 4-2, 3-2, 2-1 kickdown

shifts are prevented

± No EMCC

WarmOil temperature at start-up above

36É F and below 80 degree F± Normal operation (upshift,

kickdowns, and coastdowns)

± No EMCC

HotOil temperature at start-up above

80É F± Normal operation (upshift,

kickdowns, and coastdowns)

± Full EMCC, no PEMCC except to

engage FEMCC (except at closed

throttle at speeds above 70-83 mph)

OverheatOil temperature above 240É F or

engine coolant temperature above

244É F± Delayed 2-3 upshift (25-32 mph)

± Delayed 3-4 upshift (41-48 mph)

± 3rd gear FEMCC from 30-48 mph

± 3rd gear PEMCC from 27-31 mph

Super OverheatOil temperature above 260É F ± All9Overheat9shift schedule

features apply

± 2nd gear PEMCC above 22 mph

± Above 22 mph the torque

converter will not unlock unless the

throttle is closed or if a wide open

throttle 2nd PEMCC to 1 kickdown

is made

8E - 30 ELECTRONIC CONTROL MODULESRS

TRANSMISSION CONTROL MODULE (Continued)

ProCarManuals.com

Page 368 of 2399

STANDARD PROCEDURE

STANDARD PROCEDURE - PINION FACTOR

SETTING

NOTE: This procedure must be performed if the

Transmission Control Module (TCM) has been

replaced with a NEW or replacement unit. Failure to

perform this procedure will result in an inoperative

or improperly calibrated speedometer.

The vehicle speed readings for the speedometer are

taken from the output speed sensor. The TCM must

be calibrated to the different combinations of equip-

ment (final drive and tires) available. Pinion Factor

allows the technician to set the Transmission Control

Module initial setting so that the speedometer read-

ings will be correct. To properly read and/or reset the

Pinion Factor, it is necessary to use a DRBIIItscan

tool.

(1) Plug the DRBIIItscan tool into the diagnostic

connector located under the instrument panel.

(2) Select the Transmission menu.

(3) Select the Miscellaneous menu.

(4) Select Pinion Factor. Then follow the instruc-

tions on the DRBIIItscan tool screen.

STANDARD PROCEDURE - QUICK LEARN

PROCEDURE

The quick learn procedure requires the use of the

DRBIIItscan tool. This program allows the elec-

tronic transaxle system to recalibrate itself. This will

provide the best possible transaxle operation.

NOTE: The quick learn procedure should be per-

formed if any of the following procedures are per-

formed:

²Transaxle Assembly Replacement

²Transmission Control Module Replacement

²Solenoid/Pressure Switch Assembly Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

²The shift lever position must stay until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the

DRBIIItindicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É(1) Plug the DRBIIItscan tool into the diagnostic

connector. The connector is located under the instru-

ment panel.

(2) Go to the Transmission screen.

(3) Go to the Miscellaneous screen.

(4) Select Quick Learn Procedure. Follow the

instructions of the DRBIIItto perform the Quick

Learn Procedure.

REMOVAL

NOTE: If transmission control module is being

replaced with a new or replacement unit, the Pinion

Factor and Quick Learn procedures must be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE) (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/

TRANSMISSION CONTROL MODULE - STANDARD

PROCEDURE)

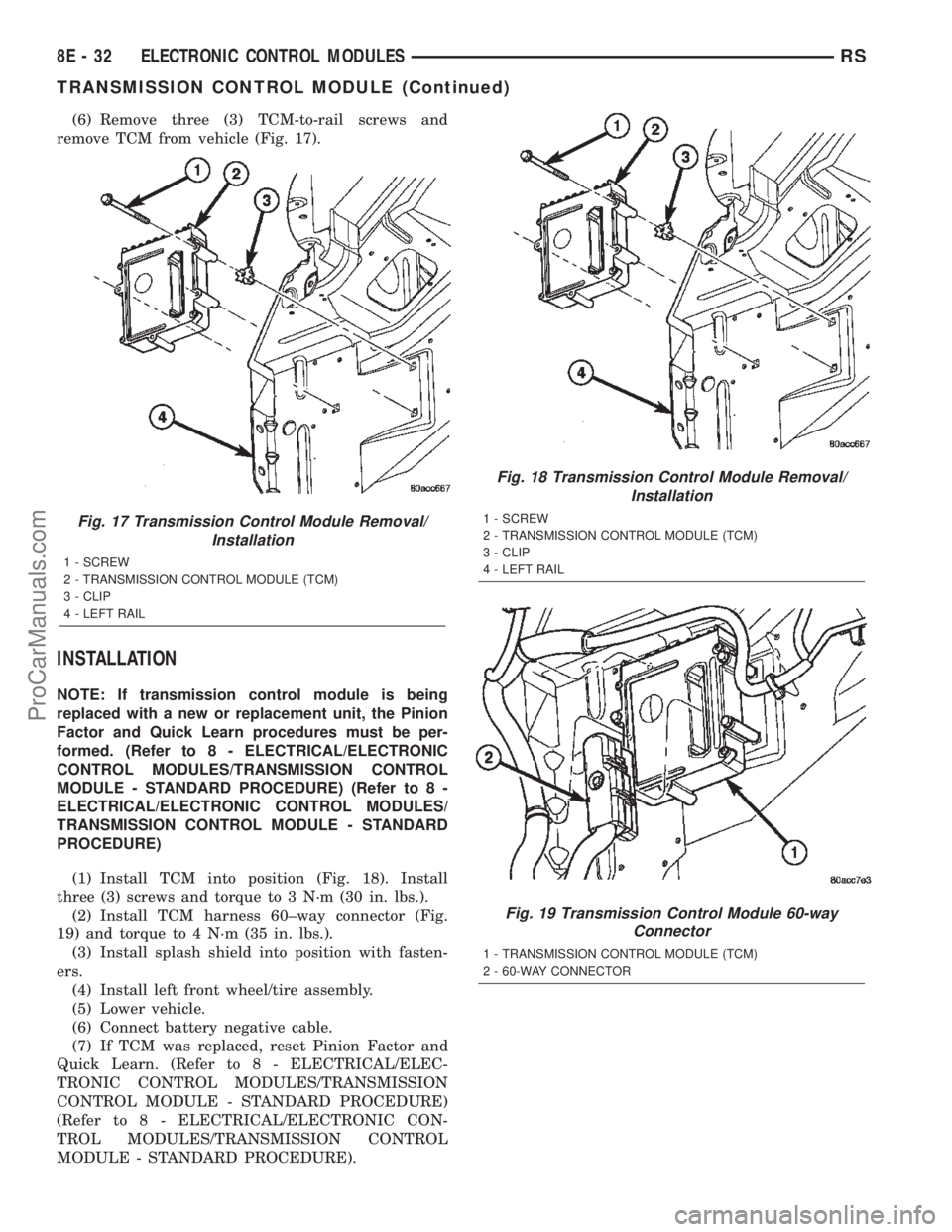

(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3) Remove left front tire/wheel assembly.

(4) Pull back splash shield to gain access to TCM

location.

(5) Disconnect TCM 60-way connector (Fig. 16).

Fig. 16 Transmission Control Module 60-way

Connector

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - 60-WAY CONNECTOR

RSELECTRONIC CONTROL MODULES8E-31

ProCarManuals.com

Page 369 of 2399

(6) Remove three (3) TCM-to-rail screws and

remove TCM from vehicle (Fig. 17).

INSTALLATION

NOTE: If transmission control module is being

replaced with a new or replacement unit, the Pinion

Factor and Quick Learn procedures must be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE) (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/

TRANSMISSION CONTROL MODULE - STANDARD

PROCEDURE)

(1) Install TCM into position (Fig. 18). Install

three (3) screws and torque to 3 N´m (30 in. lbs.).

(2) Install TCM harness 60±way connector (Fig.

19) and torque to 4 N´m (35 in. lbs.).

(3) Install splash shield into position with fasten-

ers.

(4) Install left front wheel/tire assembly.

(5) Lower vehicle.

(6) Connect battery negative cable.

(7) If TCM was replaced, reset Pinion Factor and

Quick Learn. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE).

Fig. 17 Transmission Control Module Removal/

Installation

1 - SCREW

2 - TRANSMISSION CONTROL MODULE (TCM)

3 - CLIP

4 - LEFT RAIL

Fig. 18 Transmission Control Module Removal/

Installation

1 - SCREW

2 - TRANSMISSION CONTROL MODULE (TCM)

3 - CLIP

4 - LEFT RAIL

Fig. 19 Transmission Control Module 60-way

Connector

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - 60-WAY CONNECTOR

8E - 32 ELECTRONIC CONTROL MODULESRS

TRANSMISSION CONTROL MODULE (Continued)

ProCarManuals.com

Page 370 of 2399

MEMORY SEAT/MIRROR

MODULE

DESCRIPTION

Vehicles equipped with the memory seat/mirror

option, utilize a memory module located under the

drivers front seat. This module is basically wired in-

line between the power seat switch and the power

seat track/adjuster motors, or in-line between the

power mirror switch and the power side view mir-

ror(s) motor(s). The MSMM contains a central pro-

cessing unit that communicates with other modules

on the Programmable Communications Interface

(PCI) data bus network.

The Memory Seat/Mirror Module (MSMM) receives

hard wired inputs from the driver power seat switch

and the potentiometers on each of the driver side

power seat track motors, or from the power mirror

switch and the potentiometers on the side view mir-

ror. The MSMM receives messages over the PCI data

bus from the Body Control Module (BCM) (memory

switch status), the Powertrain Control Module (PCM)

(vehicle speed status). The MSMM will prevent the

seat memory recall function from being initiated if

the driver side seat belt is buckled, if the transmis-

sion gear selector lever is not in the Park or Neutral

positions, or if the vehicle is moving.

For diagnosis of the MSMM or the PCI data bus, a

DRB IIItscan tool and the proper Diagnostic Proce-

dures manual are recommended. The MSMM cannot

be repaired and, if faulty or damaged, it must be

replaced. Refer toMemory Systemin the Power

Seat or Power Mirror section of this manual for more

information on the memory system option.

OPERATION

When memory system operation is requested

(depressing of the memory switch), a resistor multi-

plexed signal is sent from the memory switch to the

body control module (BCM). The body control module

will then send the appropriate signals out to the

memory/mirror seat module, the memory/mirror seat

module then applies the voltage supply to the power

seat track or side-view mirror if the proper require-

ments are met. The vehicle speed must equal zero

and the transmission must be in park or neutral in

order for the memory system to function.

DIAGNOSIS AND TESTING - MEMORY

SEAT/MIRROR MODULE

Visually inspect the related wiring harness connec-

tors. Look for broken, bent, pushed out, or corroded

terminals. If any of the above conditions are present,

repair as necessary. If not, use a DRB IIItscan tool

and the proper Diagnostic Procedures Manual to testthe memory/mirror seat module. For complete circuit

diagrams, refer toWiring Diagrams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side front bucket seat

retaining nuts from under the vehicle (Refer to 23 -

BODY/SEATS/SEAT - REMOVAL).

(3) Lift the drivers seat up and out of the mount-

ing holes in the floor pan and lay the seat rearward

to access the module located under the seat. It is not

necessary to disconnect the seat electrical, just use

care not to damage the wiring by over-extending.

(4) Disconnect the memory/mirror seat module

electrical connectors. Depress the retaining tab and

pull straight apart.

(5) Remove the module retaining bolts and remove

the module from the bracket.

INSTALLATION

(1) Position and install the module retaining bolts.

(2) Connect the memory/mirror seat module elec-

trical connectors.

(3) Position the drivers seat in the mounting holes

in the floor pan.

(4) Install the driver side front bucket seat retain-

ing nuts from under the vehicle (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION).

(5) Connect the battery negative cable.

SLIDING DOOR CONTROL

MODULE

DESCRIPTION

Vehicles equipped with a power sliding door utilize

a sliding door control module. The sliding door con-

trol module is located behind the sliding door trim

panel in the center of the door, just above the sliding

door motor (Fig. 20). This module controls the opera-

tion of the door through the Programmable Commu-

nication Interface (PCI) J1850 data bus circuit and

the Body Control Module. The sliding door control

module contains software technology which enables it

to detect resistance to door travel and to reverse door

travel in order to avoid damage to the door or to

avoid possible personal injury if the obstruction is a

person. This feature functions in both the opening

and closing cycles. If the power sliding door system

develops any problems the control module will store

and recall Diagnostic Trouble Codes (DTC). The use

of a diagnostic scan tool, such as the DRB IIItis

required to read and troubleshoot these trouble

codes. The sliding door control module can be

RSELECTRONIC CONTROL MODULES8E-33

ProCarManuals.com