fuel CHRYSLER VOYAGER 2002 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 372 of 2399

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ENGINE CONTROL MODULE

DESCRIPTION..........................1

OPERATION............................1

STANDARD PROCEDURE - PCM/ECM/SKIM

PROGRAMMING - DIESEL...............2REMOVAL.............................4

INSTALLATION..........................4

ENGINE CONTROL MODULE

DESCRIPTION

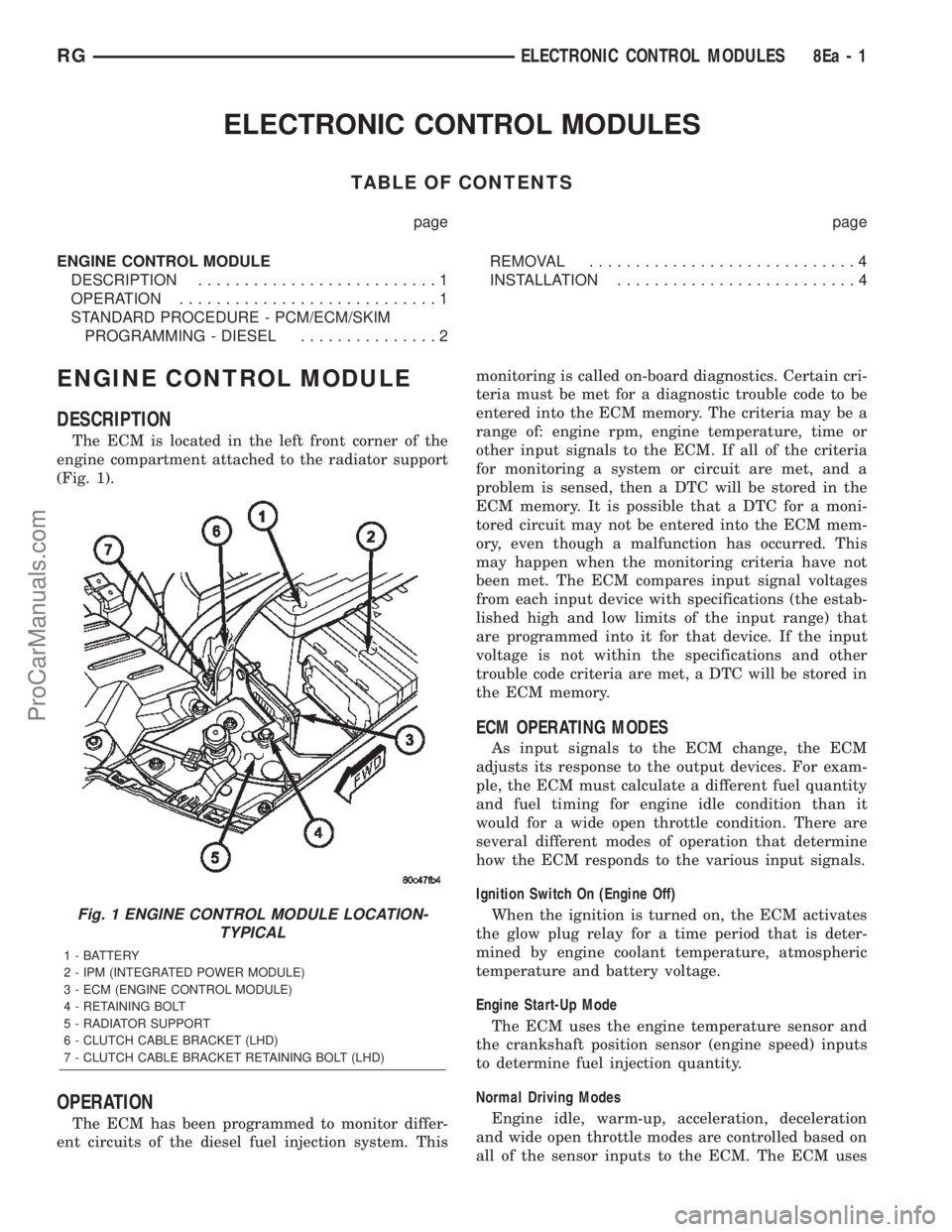

The ECM is located in the left front corner of the

engine compartment attached to the radiator support

(Fig. 1).

OPERATION

The ECM has been programmed to monitor differ-

ent circuits of the diesel fuel injection system. Thismonitoring is called on-board diagnostics. Certain cri-

teria must be met for a diagnostic trouble code to be

entered into the ECM memory. The criteria may be a

range of: engine rpm, engine temperature, time or

other input signals to the ECM. If all of the criteria

for monitoring a system or circuit are met, and a

problem is sensed, then a DTC will be stored in the

ECM memory. It is possible that a DTC for a moni-

tored circuit may not be entered into the ECM mem-

ory, even though a malfunction has occurred. This

may happen when the monitoring criteria have not

been met. The ECM compares input signal voltages

from each input device with specifications (the estab-

lished high and low limits of the input range) that

are programmed into it for that device. If the input

voltage is not within the specifications and other

trouble code criteria are met, a DTC will be stored in

the ECM memory.

ECM OPERATING MODES

As input signals to the ECM change, the ECM

adjusts its response to the output devices. For exam-

ple, the ECM must calculate a different fuel quantity

and fuel timing for engine idle condition than it

would for a wide open throttle condition. There are

several different modes of operation that determine

how the ECM responds to the various input signals.

Ignition Switch On (Engine Off)

When the ignition is turned on, the ECM activates

the glow plug relay for a time period that is deter-

mined by engine coolant temperature, atmospheric

temperature and battery voltage.

Engine Start-Up Mode

The ECM uses the engine temperature sensor and

the crankshaft position sensor (engine speed) inputs

to determine fuel injection quantity.

Normal Driving Modes

Engine idle, warm-up, acceleration, deceleration

and wide open throttle modes are controlled based on

all of the sensor inputs to the ECM. The ECM uses

Fig. 1 ENGINE CONTROL MODULE LOCATION-

TYPICAL

1 - BATTERY

2 - IPM (INTEGRATED POWER MODULE)

3 - ECM (ENGINE CONTROL MODULE)

4 - RETAINING BOLT

5 - RADIATOR SUPPORT

6 - CLUTCH CABLE BRACKET (LHD)

7 - CLUTCH CABLE BRACKET RETAINING BOLT (LHD)

RGELECTRONIC CONTROL MODULES8Ea-1

ProCarManuals.com

Page 373 of 2399

these sensor inputs to adjust fuel quantity and fuel

injector timing.

Limp-In Mode

If there is a fault detected with the accelerator

pedal position sensor, the ECM will set the engine

speed at 1100 RPM.

Overspeed Detection Mode

If the ECM detects engine RPM that exceeds 5200

RPM, the ECM will set a DTC in memory and illu-

minate the MIL until the DTC is cleared.

After-Run Mode

The ECM transfers RAM information to ROM and

performs an Input/Output state check.

MONITORED CIRCUITS

The ECM is able to monitor and identify most

driveability related trouble conditions. Some circuits

are directly monitored through ECM feedback cir-

cuitry. In addition, the ECM monitors the voltage

state of some circuits and compares those states with

expected values. Other systems are monitored indi-

rectly when the ECM conducts a rationality test to

identify problems. Although most subsytems of the

engine control module are either directly or indirectly

monitored, there may be occasions when diagnostic

trouble codes are not immediately identified. For a

trouble code to set, a specific set of conditions must

occur and unless these conditions occur, a DTC will

not set.

DIAGNOSTIC TROUBLE CODES

Each diagnostic trouble code (DTC) is diagnosed by

following a specific procedure. The diagnostic test

procedure contains step-by-step instruction for deter-

mining the cause of the DTC as well as no trouble

code problems. Refer to the appropriate Diesel Pow-

ertrain Diagnostic Manual for more information.

HARD CODE

A DTC that comes back within one cycle of the

ignition key is a hard code. This means that the

problem is current every time the ECM/SKIM checks

that circuit or function. Procedures in this manual

verify if the DTC is a hard code at the beginning of

each test. When the fault is not a hard code, an

intermittent test must be performed. NOTE: If the

DRBIIItdisplays faults for multiple components (i.e.

ECT, VSS, IAT sensors) identify and check the

shared circuits for possible problems before continu-

ing (i.e. sensor grounds or 5-volt supply circuits).

Refer to the appropriate schematic to identify shared

circuits. Refer to the appropriate Diesel Powertrain

Diagnostic Manual for more information.INTERMITTENT CODE

A DTC that is not current every time the ECM/

SKIM checks the circuit or function is an intermit-

tent code. Most intermittent DTCs are caused by

wiring or connector problems. Problems that come

and go like this are the most difficult to diagnose;

they must be looked for under specific conditions that

cause them.NOTE: Electromagnetic (radio)

interference can cause an intermittent system

malfunction.This interference can interrupt com-

munication between the ignition key transponder and

the SKIM. The following checks may assist you in

identifying a possible intermittent problem:

²Visually inspect the related wire harness connec-

tors. Look for broken, bent, pushed out or corroded

terminals.

²Visually inspect the related wire harness. Look

for chafed, pierced or partially broken wire.

²Refer to hotlines or technical service bulletins

that may apply. Refer to the appropriate Diesel Pow-

ertrain Diagnostic Manual for more information.

ECM DIAGNOSTIC TROUBLE CODES

IMPORTANT NOTE: Before replacing the ECM for

a failed driver, control circuit or ground circuit, be

sure to check the related component/circuit integrity

for failures not detected due to a double fault in the

circuit. Most ECM driver/control circuit failures are

caused by internal failures to components (i.e. relays

and solenoids) and shorted circuits (i.e. sensor pull-

ups, drivers and ground circuits). These faults are

difficult to detect when a double fault has occurred

and only one DTC has set. If the DRBIIItdisplays

faults for multiple components (i.e.VSS, ECT, Batt

Temp, etc.) identify and check the shared circuits for

possible problems before continuing (i.e. sensor

grounds or 5-volt supply circuits). Refer to the appro-

priate wiring diagrams to identify shared circuits.

Refer to the appropriate Diesel Powertrain Diagnos-

tic Manual for more information.

STANDARD PROCEDURE - PCM/ECM/SKIM

PROGRAMMING - DIESEL

NOTE: Before replacing the PCM/ECM for a failed

driver, control circuit or ground circuit, be sure to

check the related component/circuit integrity for

failures not detected due to a double fault in the cir-

cuit. Most PCM/ECM driver/control circuit failures

are caused by internal component failures (i.e. relay

and solenoids) and shorted circuits (i.e. pull-ups,

drivers and switched circuits). These failures are

difficult to detect when a double fault has occurred

and only one DTC has set.

8Ea - 2 ELECTRONIC CONTROL MODULESRG

ENGINE CONTROL MODULE (Continued)

ProCarManuals.com

Page 406 of 2399

CONDITION POSSIBLE CAUSE CORRECTION

STARTER

ENGAGES,

SPINS OUT

BEFORE

ENGINE

STARTS.1. BROKEN TEETH ON

STARTER RING GEAR.1. REMOVE STARTER. INSPECT RING GEAR AND REPLACE

IF NECESSARY.

2. STARTER ASSEMBLY

FAULTY.2. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

STARTER DOES

NOT

DISENGAGE.1. STARTER

IMPROPERLY

INSTALLED.1. INSTALL STARTER. TIGHTEN STARTER MOUNTING

HARDWARE TO CORRECT TORQUE SPECIFICATIONS.

2. STARTER RELAY

FAULTY.2. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

3. IGNITION SWITCH

FAULTY.3. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION. REPLACE SWITCH, IF NECESSARY.

4. STARTER ASSEMBLY

FAULTY.4. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

5. FAULTY TEETH ON

RING GEAR.5. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST

The starter control circuit has:

²Starter motor with integral solenoid

²Starter relay

²Transmission range sensor, or Park/Neutral

Position switch with automatic transmissions

²Ignition switch

²Battery

²All related wiring and connections

²Powertrain Control Module (PCM)

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

²To disable ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the Power Distribution Center (PDC).

Refer to the PDC cover for the proper relay location.

STARTER SOLENOID

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED.

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests.

(2) Perform Starter Solenoid test BEFORE per-

forming the starter relay test.(3) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring.

(4) Locate and remove the starter relay from the

Power Distribution Center (PDC). Refer to the PDC

label for relay identification and location.

(5) Connect a remote starter switch or a jumper

wire between the remote battery positive post and

terminal 87 of the starter relay connector.

(a) If engine cranks, starter/starter solenoid is

good. Go to the Starter Relay Test.

(b) If engine does not crank or solenoid chatters,

check wiring and connectors from starter relay to

starter solenoid for loose or corroded connections.

Particularly at starter terminals.

(c) Repeat test. If engine still fails to crank prop-

erly, trouble is within starter or starter mounted

solenoid, and replace starter. Inspect the ring gear

teeth.

STARTER RELAY

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK/NEUTRAL POSITION

WITH THE PARKING BRAKE APPLIED.

RELAY TEST

The starter relay is located in the Power Distribu-

tion Center (PDC) in the engine compartment. Refer

to the PDC label for relay identification and location.

RSSTARTING8F-31

STARTING (Continued)

ProCarManuals.com

Page 408 of 2399

tion. If that checks OK check for continuity between

PCM and the terminal 85. Repair open circuit as

required. If OK, the PCM may be defective.

SAFETY SWITCHES

For diagnostics of the Transmission Range Sensor,

refer to the Transaxle section for more information.

If equipped with Clutch Interlock/Upstop Switch,

refer to Diagnosis and Testing in the Clutch section.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Refer to the Ignition Section

or Wiring Diagrams for more information. Check all

wiring for opens or shorts, and all connectors for

being loose or corroded.

BATTERY

For battery diagnosis and testing, refer to the Bat-

tery section for procedures.

ALL RELATED WIRING AND CONNECTORS

Refer to Wiring Diagrams for more information.

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition and Fuel systems must be dis-

abled to prevent engine start while performing the

following tests.

(1) To disable the Ignition and Fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) Gain access to battery terminals.

(3) With all wiring harnesses and components

properly connected, perform the following:

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp. Rotate and hold the

ignition switch in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post.(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point.

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at ground cable attaching point. If

voltage reading is still above 0.2 volt after correct-

ing poor contacts, replace ground cable.

(4) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal. Hold the ignition switch key in

the START position. If voltage reads above 0.2 volt,

correct poor starter to engine ground.

(a) Connect the positive voltmeter lead to the

battery positive terminal, and negative lead to bat-

tery cable terminal on starter solenoid. Rotate and

hold the ignition switch in the START position. If

voltage reads above 0.2 volt, correct poor contact at

battery cable to solenoid connection. If reading is

still above 0.2 volt after correcting poor contacts,

replace battery positive cable.

(b) If resistance tests do not detect feed circuit

failures, replace the starter motor.

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST

NOTE: The following results are based upon the

vehicle being at room temperature.

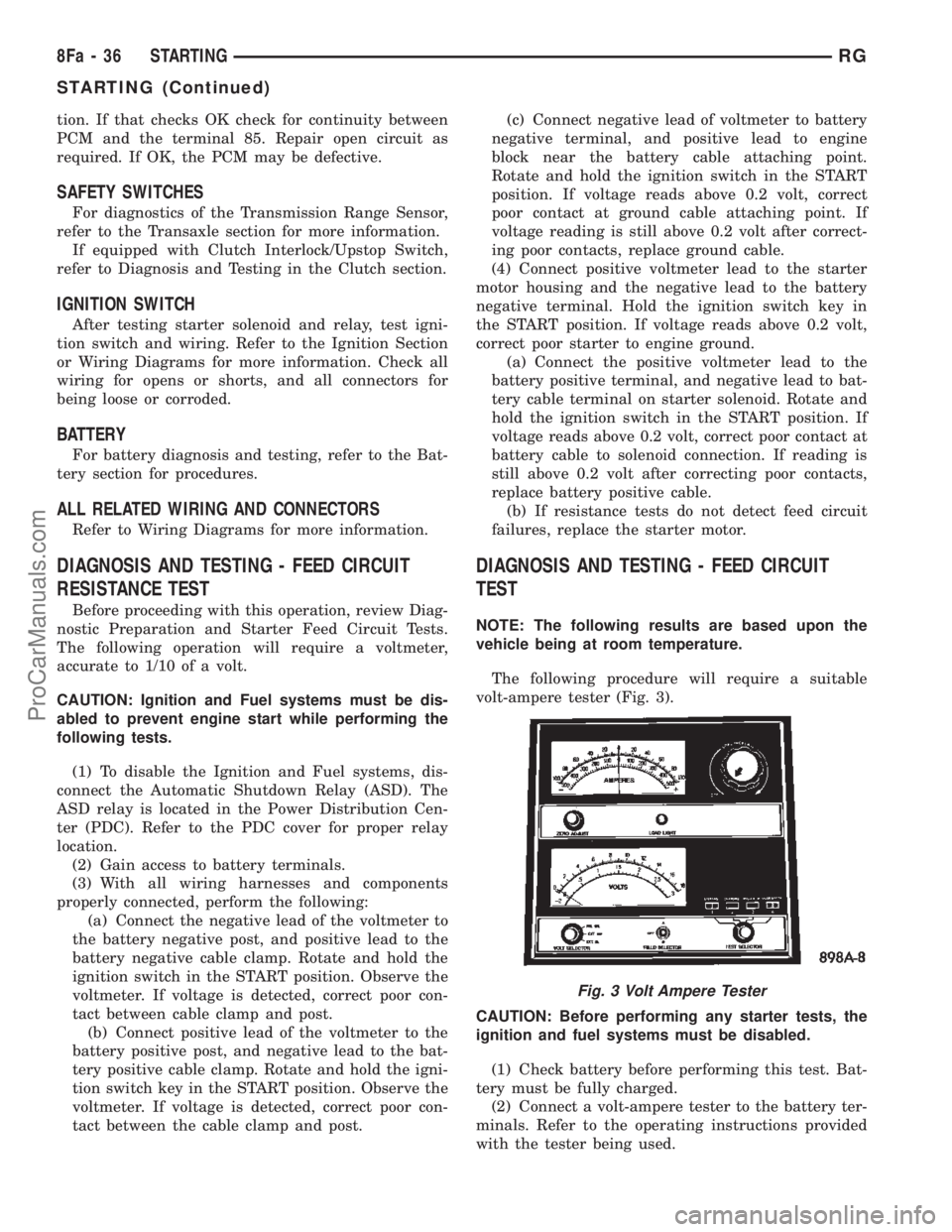

The following procedure will require a suitable

volt-ampere tester (Fig. 3).

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

(1) Check battery before performing this test. Bat-

tery must be fully charged.

(2) Connect a volt-ampere tester to the battery ter-

minals. Refer to the operating instructions provided

with the tester being used.

Fig. 3 Volt Ampere Tester

RSSTARTING8F-33

STARTING (Continued)

ProCarManuals.com

Page 409 of 2399

(3) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(4) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARK

and SET parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(5) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

3).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps, check for engine seizing

or faulty starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²Voltage below 9.6 volts and amperage draw

above 300 amps, the problem is the starter. Replace

the starter refer to starter removal.

(6) After the starting system problems have been

corrected, verify the battery state-of-charge and

charge battery if necessary. Disconnect all testing

equipment and connect ASD relay. Start the vehicle

several times to assure the problem has been cor-

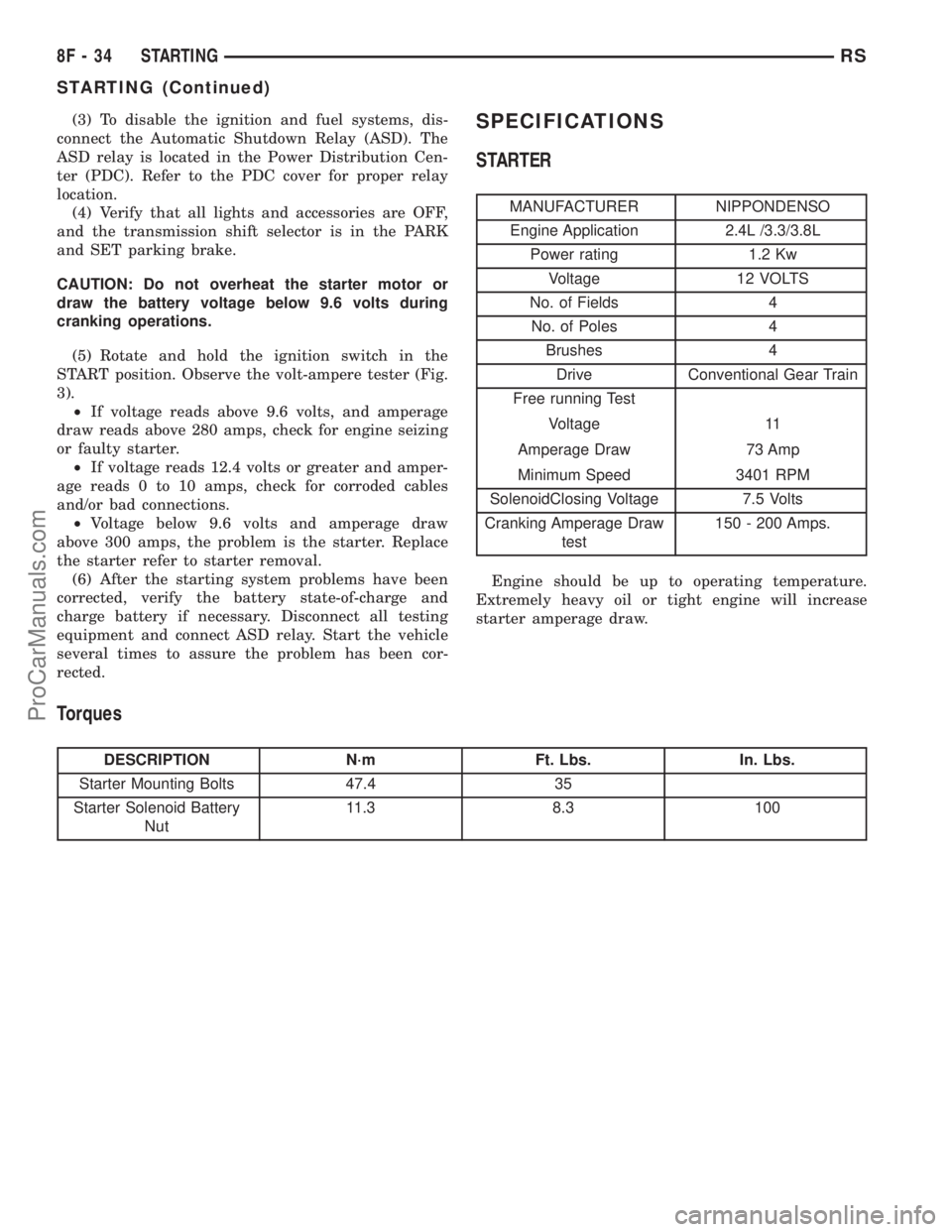

rected.SPECIFICATIONS

STARTER

MANUFACTURER NIPPONDENSO

Engine Application 2.4L /3.3/3.8L

Power rating 1.2 Kw

Voltage 12 VOLTS

No. of Fields 4

No. of Poles 4

Brushes 4

Drive Conventional Gear Train

Free running Test

Voltage 11

Amperage Draw 73 Amp

Minimum Speed 3401 RPM

SolenoidClosing Voltage 7.5 Volts

Cranking Amperage Draw

test150 - 200 Amps.

Engine should be up to operating temperature.

Extremely heavy oil or tight engine will increase

starter amperage draw.

Torques

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Starter Mounting Bolts 47.4 35

Starter Solenoid Battery

Nut11.3 8.3 100

8F - 34 STARTINGRS

STARTING (Continued)

ProCarManuals.com

Page 445 of 2399

CONDITION POSSIBLE CAUSE CORRECTION

STARTER

ENGAGES,

SPINS OUT

BEFORE

ENGINE

STARTS.1. BROKEN TEETH ON

STARTER RING GEAR.1. REMOVE STARTER. INSPECT RING GEAR AND REPLACE

IF NECESSARY.

2. STARTER ASSEMBLY

FAULTY.2. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

STARTER DOES

NOT

DISENGAGE.1. STARTER

IMPROPERLY

INSTALLED.1. INSTALL STARTER. TIGHTEN STARTER MOUNTING

HARDWARE TO CORRECT TORQUE SPECIFICATIONS.

2. STARTER RELAY

FAULTY.2. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

3. IGNITION SWITCH

FAULTY.3. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION. REPLACE SWITCH, IF NECESSARY.

4. STARTER ASSEMBLY

FAULTY.4. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

5. FAULTY TEETH ON

RING GEAR.5. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST

The starter control circuit has:

²Starter motor with integral solenoid

²Starter relay

²Transmission range sensor, or Park/Neutral

Position switch with automatic transmissions

²Ignition switch

²Battery

²All related wiring and connections

²Powertrain Control Module (PCM)

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

²To disable ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the Power Distribution Center (PDC).

Refer to the PDC cover for the proper relay location.

STARTER SOLENOID

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED.

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests.

(2) Perform Starter Solenoid test BEFORE per-

forming the starter relay test.(3) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring.

(4) Locate and remove the starter relay from the

Power Distribution Center (PDC). Refer to the PDC

label for relay identification and location.

(5) Connect a remote starter switch or a jumper

wire between the remote battery positive post and

terminal 87 of the starter relay connector.

(a) If engine cranks, starter/starter solenoid is

good. Go to the Starter Relay Test.

(b) If engine does not crank or solenoid chatters,

check wiring and connectors from starter relay to

starter solenoid for loose or corroded connections.

Particularly at starter terminals.

(c) Repeat test. If engine still fails to crank prop-

erly, trouble is within starter or starter mounted

solenoid, and replace starter. Inspect the ring gear

teeth.

STARTER RELAY

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK/NEUTRAL POSITION

WITH THE PARKING BRAKE APPLIED.

RELAY TEST

The starter relay is located in the Power Distribu-

tion Center (PDC) in the engine compartment. Refer

to the PDC label for relay identification and location.

8Fa - 34 STARTINGRG

STARTING (Continued)

ProCarManuals.com

Page 447 of 2399

tion. If that checks OK check for continuity between

PCM and the terminal 85. Repair open circuit as

required. If OK, the PCM may be defective.

SAFETY SWITCHES

For diagnostics of the Transmission Range Sensor,

refer to the Transaxle section for more information.

If equipped with Clutch Interlock/Upstop Switch,

refer to Diagnosis and Testing in the Clutch section.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Refer to the Ignition Section

or Wiring Diagrams for more information. Check all

wiring for opens or shorts, and all connectors for

being loose or corroded.

BATTERY

For battery diagnosis and testing, refer to the Bat-

tery section for procedures.

ALL RELATED WIRING AND CONNECTORS

Refer to Wiring Diagrams for more information.

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition and Fuel systems must be dis-

abled to prevent engine start while performing the

following tests.

(1) To disable the Ignition and Fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) Gain access to battery terminals.

(3) With all wiring harnesses and components

properly connected, perform the following:

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp. Rotate and hold the

ignition switch in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post.(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point.

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at ground cable attaching point. If

voltage reading is still above 0.2 volt after correct-

ing poor contacts, replace ground cable.

(4) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal. Hold the ignition switch key in

the START position. If voltage reads above 0.2 volt,

correct poor starter to engine ground.

(a) Connect the positive voltmeter lead to the

battery positive terminal, and negative lead to bat-

tery cable terminal on starter solenoid. Rotate and

hold the ignition switch in the START position. If

voltage reads above 0.2 volt, correct poor contact at

battery cable to solenoid connection. If reading is

still above 0.2 volt after correcting poor contacts,

replace battery positive cable.

(b) If resistance tests do not detect feed circuit

failures, replace the starter motor.

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST

NOTE: The following results are based upon the

vehicle being at room temperature.

The following procedure will require a suitable

volt-ampere tester (Fig. 3).

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

(1) Check battery before performing this test. Bat-

tery must be fully charged.

(2) Connect a volt-ampere tester to the battery ter-

minals. Refer to the operating instructions provided

with the tester being used.

Fig. 3 Volt Ampere Tester

8Fa - 36 STARTINGRG

STARTING (Continued)

ProCarManuals.com

Page 448 of 2399

(3) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(4) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARK

and SET parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(5) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

3).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps, check for engine seizing

or faulty starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²Voltage below 9.6 volts and amperage draw

above 300 amps, the problem is the starter. Replace

the starter refer to starter removal.

(6) After the starting system problems have been

corrected, verify the battery state-of-charge and

charge battery if necessary. Disconnect all testing

equipment and connect ASD relay. Start the vehicle

several times to assure the problem has been cor-

rected.SPECIFICATIONS

STARTER

MANUFACTURER NIPPONDENSO

Engine Application 2.4L /3.3/3.8L

Power rating 1.2 Kw

Voltage 12 VOLTS

No. of Fields 4

No. of Poles 4

Brushes 4

Drive Conventional Gear Train

Free running Test

Voltage 11

Amperage Draw 73 Amp

Minimum Speed 3401 RPM

SolenoidClosing Voltage 7.5 Volts

Cranking Amperage Draw

test150 - 200 Amps.

Engine should be up to operating temperature.

Extremely heavy oil or tight engine will increase

starter amperage draw.

Torques

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Starter Mounting Bolts 47.4 35

Starter Solenoid Battery Nut 11.3 8.3 100

RGSTARTING8Fa-37

STARTING (Continued)

ProCarManuals.com

Page 478 of 2399

FIRING ORDERAUTO SHUT DOWN RELAY

DESCRIPTION

The relay is located in the Power Distribution Cen-

ter (PDC). For the location of the relay within the

PDC, refer to the PDC cover for location. Check elec-

trical terminals for corrosion and repair as necessary

OPERATION

The ASD sense circuit informs the PCM when the

ASD relay energizes. A 12 volt signal at this input

indicates to the PCM that the ASD has been acti-

vated. This input is used only to sense that the ASD

relay is energized.

When energized, the ASD relay supplies battery

voltage to the fuel injectors, ignition coils and the

heating element in each oxygen sensor.

When energized, the ASD relay provides power to

operate the injectors, ignition coil, generator field, O2

sensor heaters (both upstream and downstream),

(EGR solenoid and PCV heater if equipped) and also

provides a sense circuit to the PCM for diagnostic

purposes. If the PCM does not receive 12 volts from

this input after grounding the ASD relay, it sets a

Diagnostic Trouble Code (DTC). The PCM energizes

the ASD any time there is a Crankshaft Position sen-

sor signal that exceeds a predetermined value. The

ASD relay can also be energized after the engine has

been turned off to perform an O2 sensor heater test,

if vehicle is equipped with OBD II diagnostics.

As mentioned earlier, the PCM energizes the ASD

relay during an O2 sensor heater test. This test is

performed only after the engine has been shut off.

The PCM still operates internally to perform several

checks, including monitoring the O2 sensor heaters.

CAMSHAFT POSITION

SENSOR

DESCRIPTION

The camshaft position sensorfor the 3.3/3.8L is

mounted in the front of the timing case cover (Fig. 6)

and the camshaft position sensor for the 2.4L is

mounted on the end of the cylinder head (Fig. 3).

FIRING ORDER 2.4L

Firing Order 1-2-3-4-5-6 3.3/3.8L

1 - Electrical Connector

RSIGNITION CONTROL8I-3

IGNITION CONTROL (Continued)

ProCarManuals.com

Page 487 of 2399

The Glow Plug lamp is tied to this circuit. Lamp

operation is also controlled by the ECM.

With a cold engine, the glow plug relays and glow

plugs may be activated for a maximum time of 200

seconds. Refer to the following Glow Plug Control

chart for a temperature/time comparison of the glow

plug relay operation.

In this chart, Pre-Heat and Post-Heat times are

mentioned. Pre-Heat is the amount of time the glow

plug relay control circuit is activated when the igni-

tion (key) is switched ON, without the engine run-

ning. Post-Heat is the amount of time the glow plug

relay control circuit is activated after the engine is

operated. The Glow Plug lamp will not be activated

during the post-heat cycle.

Engine

Coolant

Temperature

9Key ON9Wait-To

Start Lamp

9ON9

(Seconds)Pre-Heat

Cycle

(Glow

Plugs On

Seconds)Post-Heat

Cycle

(Seconds)

-30C 20 SEC. 35 SEC. 200 SEC.

-10C 8 SEC. 23 SEC. 180 SEC.

+10C 6 SEC. 21 SEC. 160 SEC.

+30C 5 SEC. 20 SEC. 140 SEC.

+40C 4 SEC. 19 SEC. 70 SEC.

+70C 1 SEC. 16 SEC. 20 SEC.

CAMSHAFT POSITION

SENSOR

DESCRIPTION

The camshaft position (CMP) sensor is mounted in

the top of cylinder head cover/intake manifold at the

rear of the engine. The CMP sensor is a hall effect

device (Fig. 3).

OPERATION

The CMP sensor is a hall effect switch. A tooth

made of a ferromagnetic material is attached to the

camshaft. When this tooth passes the CMP sensor an

lectronic signal is created. This signal is then sent to

the engine control module (ECM). This signal is used

by the ECM to determine which cylinder has just

entered its compression phase.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE

COVER - REMOVAL).

(3) Disconnect camshaft position sensor electrical

connector (Fig. 4).

(4) Remove sensor retaining bolt and remove sen-

sor from cylinder head cover.

INSTALLATION

(1) Lubricate O-ring and install sensor in cylinder

head cover. Torque retaining bolt to 5.4 N´m.

(2) Connect camshaft position sensor electrical

connector.

(3) Install engine cover (Refer to 9 - ENGINE

COVER - INSTALLATION).

(4) Connect negative battery cable.

Fig. 3 CAMSHAFT POSITION SENSOR

Fig. 4 CAMSHAFT POSITION SENSOR LOCATION

1 - CAMSHAFT POSITION SENSOR

2 - CAMSHAFT POSITION SENSOR ELCTRICAL SENSOR

3 - FUEL INJECTOR

4 - CYLINDER HEAD COVER

5 - OIL SEPARATOR

8Ia - 2 IGNITION CONTROLRG

GLOW PLUG RELAY (Continued)

ProCarManuals.com