service CHRYSLER VOYAGER 2002 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 98 of 2399

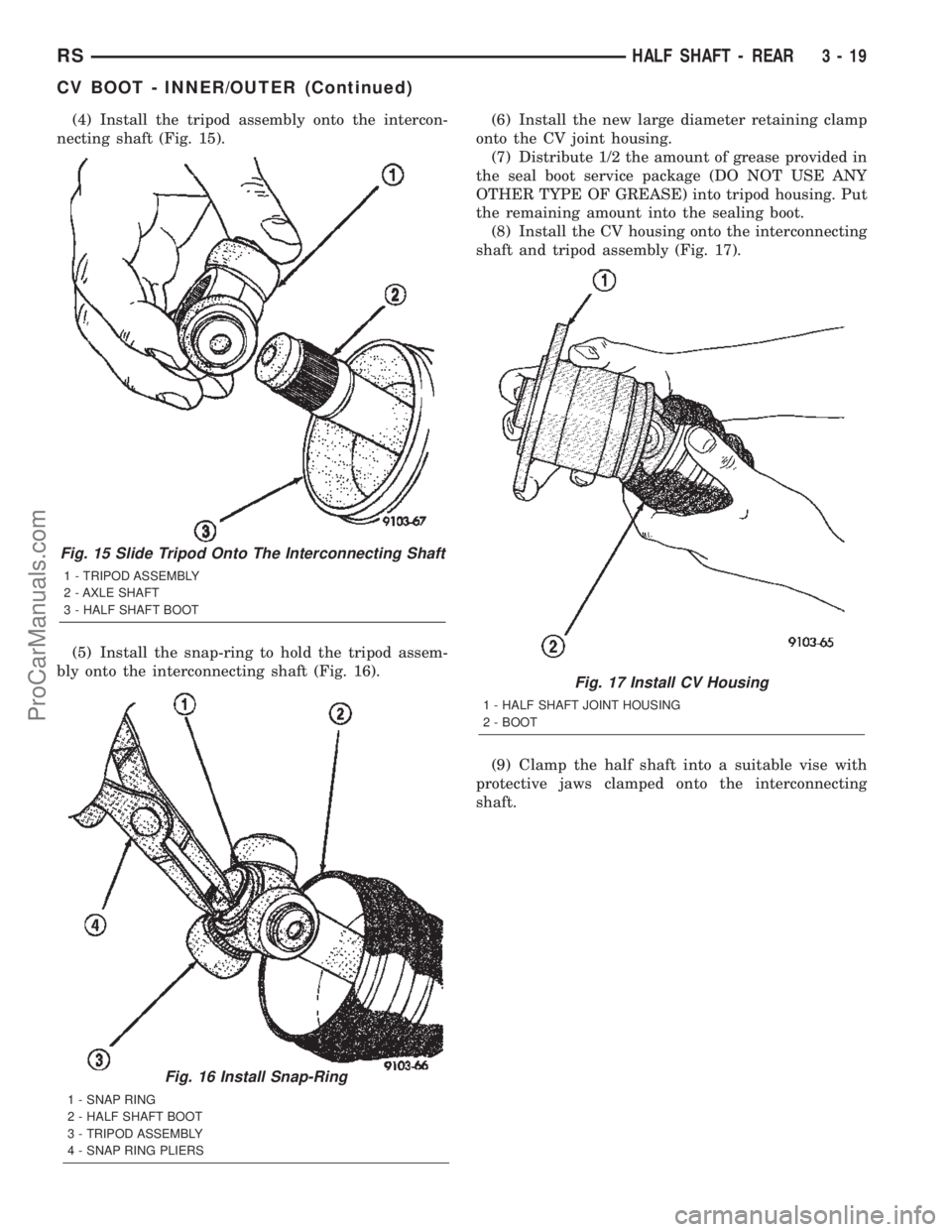

(4) Install the tripod assembly onto the intercon-

necting shaft (Fig. 15).

(5) Install the snap-ring to hold the tripod assem-

bly onto the interconnecting shaft (Fig. 16).(6) Install the new large diameter retaining clamp

onto the CV joint housing.

(7) Distribute 1/2 the amount of grease provided in

the seal boot service package (DO NOT USE ANY

OTHER TYPE OF GREASE) into tripod housing. Put

the remaining amount into the sealing boot.

(8) Install the CV housing onto the interconnecting

shaft and tripod assembly (Fig. 17).

(9) Clamp the half shaft into a suitable vise with

protective jaws clamped onto the interconnecting

shaft.

Fig. 16 Install Snap-Ring

1 - SNAP RING

2 - HALF SHAFT BOOT

3 - TRIPOD ASSEMBLY

4 - SNAP RING PLIERS

Fig. 15 Slide Tripod Onto The Interconnecting Shaft

1 - TRIPOD ASSEMBLY

2 - AXLE SHAFT

3 - HALF SHAFT BOOT

Fig. 17 Install CV Housing

1 - HALF SHAFT JOINT HOUSING

2 - BOOT

RSHALF SHAFT - REAR3-19

CV BOOT - INNER/OUTER (Continued)

ProCarManuals.com

Page 101 of 2399

PROPELLER SHAFT

TABLE OF CONTENTS

page page

PROPELLER SHAFT

DESCRIPTION.........................22

OPERATION...........................22REMOVAL.............................23

INSTALLATION.........................23

SPECIFICATIONS - PROPELLER SHAFT.....23

PROPELLER SHAFT

DESCRIPTION

WARNING: Due to propeller shaft imbalance con-

cerns, the propeller shaft can only be serviced as

an assembly.

AWD models utilize a ªtwo-pieceº propeller shaft

(Fig. 1) to transmit power to the rear driveline mod-

ule assembly. This two-piece design consists of:

²Front and rear shaft segments.

²Plunging center CV joint²Center support bearing

²Rubber coupler at driveline module flange

The front shaft segment utilizes a CV joint at the

power transfer unit connection, and a plunging CV

joint at the center bearing location.

The rear shaft segment utilizes a center support

bearing at the forward position, and a rubber coupler

at the driveline module flange.

OPERATION

The propeller shaft (Fig. 1) is used to transmit

torque from the transaxle power transfer unit (PTU)

Fig. 1 Propeller Shaft Removal/Installation

1 - PTU FLANGE 3 - REAR DRIVELINE MODULE 5 - BOLT-CENTER SUPPORT BEARING-TO-

CROSSMEMBER

2 - CROSSMEMBER 4 - BOLT-PROPELLER SHAFT COUPLER-

T0-DRIVELINE MODULE6 - PROPELLER SHAFT ASSEMBLY

3 - 22 PROPELLER SHAFTRS

ProCarManuals.com

Page 103 of 2399

REAR DRIVELINE MODULE

TABLE OF CONTENTS

page page

REAR DRIVELINE MODULE

DESCRIPTION.........................24

OPERATION...........................24

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REAR

DRIVELINE MODULE NOISE.............25

DIAGNOSIS AND TESTING - REAR

DRIVELINE MODULE OPERATION........27

REMOVAL.............................27

DISASSEMBLY.........................28

ASSEMBLY............................30

INSTALLATION.........................34

SPECIFICATIONS - REAR DRIVELINE

MODULE............................35

SPECIAL TOOLS.......................35

BI-DIRECTIONAL OVERRUNNING CLUTCH

DESCRIPTION.........................36

OPERATION...........................38

DIFFERENTIAL ASSEMBLY

DESCRIPTION.........................41OPERATION...........................41

FLUID - DIFFERENTIAL ASSEMBLY

STANDARD PROCEDURE - DIFFERENTIAL

ASSEMBLY FLUID DRAIN AND FILL.......42

FLUID

STANDARD PROCEDURE - OVERRUNNING

CLUTCH HOUSING FLUID CHANGE.......43

VISCOUS COUPLER

DESCRIPTION.........................44

OPERATION...........................44

TORQUE ARM

REMOVAL.............................46

INSTALLATION.........................46

INPUT FLANGE SEAL

REMOVAL.............................46

INSTALLATION.........................47

OUTPUT FLANGE SEAL

REMOVAL.............................48

INSTALLATION.........................49

REAR DRIVELINE MODULE

DESCRIPTION

The rear driveline module assembly (Fig. 1) con-

sists of four main components:

²Bi-Directional Overrunning Clutch (BOC)

²Viscous Coupling

²Differential Assembly

²Torque Arm

The viscous coupling and bi-directional overrun-

ning clutch are contained within an overrunning

clutch housing, which fastens to the differential

assembly. The overrunning clutch housing and differ-

ential assembly have unique fluid sumps, each

requiring their own type and capacity of fluid. The

overrunning clutch housing requires MopartATF+4

(Automatic Transmission FluidÐType 9602) or equiv-

alent. The differential assembly requires

Driveline module service is limited to the following

components:

²Differential Assembly (serviced only as assem-

bly)

²Viscous Coupling

²Bi-Directional Overrunning Clutch (BOC)

²Overrunning Clutch Housing

²Seals (Input Flange, Output Flange, Overrun-

ning Clutch Housing O-rings)²Input Flange/Shield

²Torque Arm

²Vents

²Fasteners

OPERATION

The primary benefits of All Wheel Drive are:

²Superior straight line acceleration, and corner-

ing on all surfaces

²Better traction and handling under adverse con-

ditions, resulting in improved hill climbing ability

and safer driving.

The heart of the system is an inter-axle viscous

coupling. The vehicle retains predominantly front-

wheel drive characteristics, but the All Wheel Drive

capability takes effect when the front wheels start to

slip. Under normal level road, straight line driving,

100% of the torque is allocated to the front wheels.

The viscous coupling controls and distributes torque/

power to the rear wheels. The viscous coupling trans-

mits torque to the rear wheels in proportion of the

amount of the slippage at the front wheels. Thais

variable torque distribution is automatic with no

driver inputs required. The coupling is similar to a

multi-plate clutch. It consists of a series of closely

spaced discs, which are alternately connected to the

front and rear drive units. The unit is totally sealed

and partially filled with silicone fluid. There is no

3 - 24 REAR DRIVELINE MODULERS

ProCarManuals.com

Page 107 of 2399

DISASSEMBLY

WARNING: Differential is only to be serviced as an

assembly, and no disassembly is required.

(1) Remove six torque arm-to-differential case

bolts and remove torque arm assembly (Fig. 4).

(2) Remove input flange nut and washer using

Tool 6958 and a breaker bar (Fig. 5).(3) Remove input flange (Fig. 6).

(4) Remove input flange seal from overrunning

clutch housing using suitable screwdriver (Fig. 7).

Fig. 4 Torque Arm Fasteners

1 - TORQUE ARM ASSEMBLY

2 - BOLT (SIX)

Fig. 5 Input Flange Nut

1 - INPUT FLANGE

2 - TOOL 6958

Fig. 6 Input Flange

1 - INPUT FLANGE/SHIELD

Fig. 7 Input Flange Seal Removal

1 - INPUT FLANGE SEAL

2 - SCREWDRIVER

3 - 28 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 133 of 2399

come in contact with a hub mounted drum (drum for

disc/drum brakes or drum-in-hat for disc/disc brakes)

and hold it in place.

WARNING

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.

DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

CAUTION

CAUTION: During service procedures, grease or

any other foreign material must be kept off brake

shoe assemblies, and braking surfaces of brake

rotor or drum, and external surfaces of hub and

bearing assembly.

CAUTION: Handling of brake rotors and calipers

must be done in such a way as to avoid damage to

the rotor and scratching or nicking of brake lining

on the brake shoes.

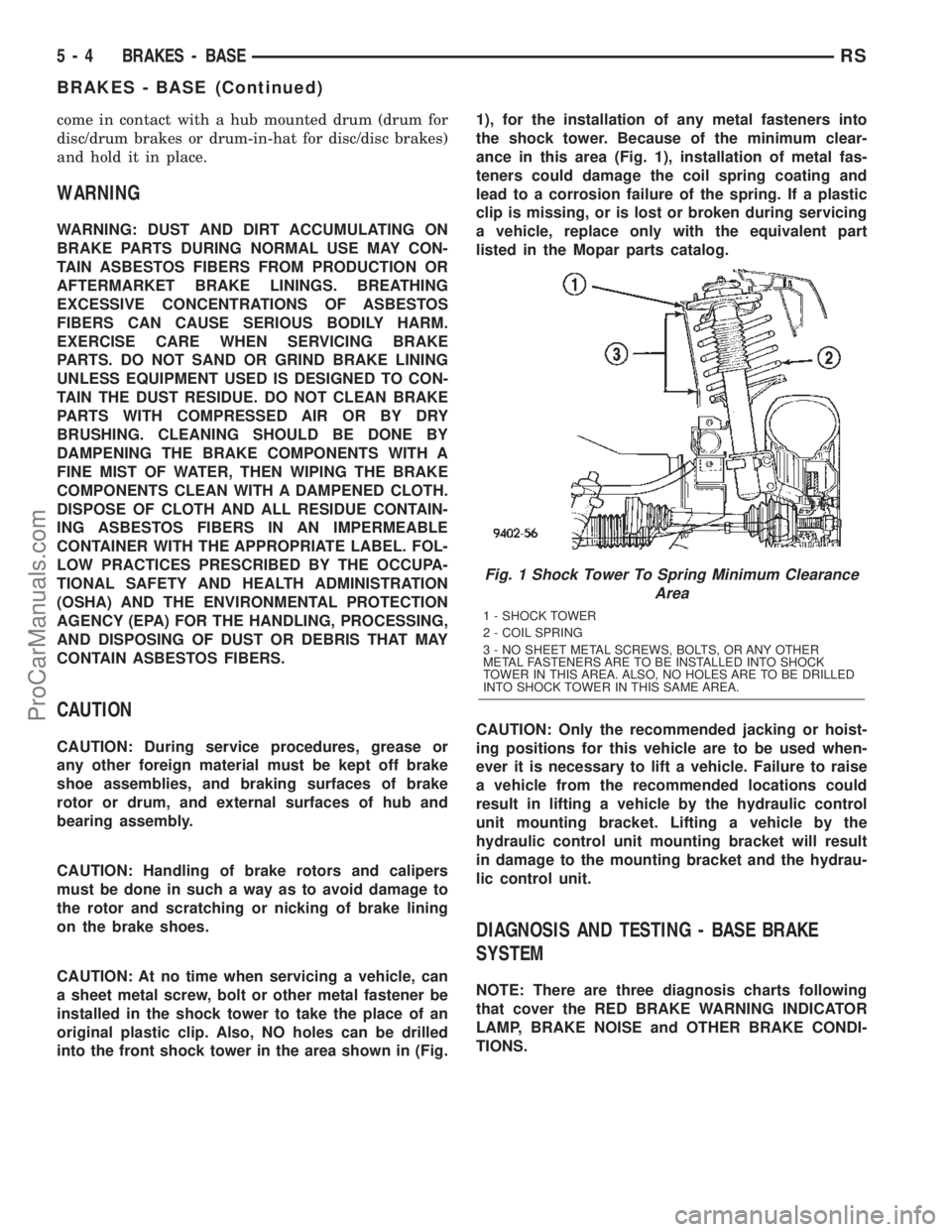

CAUTION: At no time when servicing a vehicle, can

a sheet metal screw, bolt or other metal fastener be

installed in the shock tower to take the place of an

original plastic clip. Also, NO holes can be drilled

into the front shock tower in the area shown in (Fig.1), for the installation of any metal fasteners into

the shock tower. Because of the minimum clear-

ance in this area (Fig. 1), installation of metal fas-

teners could damage the coil spring coating and

lead to a corrosion failure of the spring. If a plastic

clip is missing, or is lost or broken during servicing

a vehicle, replace only with the equivalent part

listed in the Mopar parts catalog.

CAUTION: Only the recommended jacking or hoist-

ing positions for this vehicle are to be used when-

ever it is necessary to lift a vehicle. Failure to raise

a vehicle from the recommended locations could

result in lifting a vehicle by the hydraulic control

unit mounting bracket. Lifting a vehicle by the

hydraulic control unit mounting bracket will result

in damage to the mounting bracket and the hydrau-

lic control unit.

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

NOTE: There are three diagnosis charts following

that cover the RED BRAKE WARNING INDICATOR

LAMP, BRAKE NOISE and OTHER BRAKE CONDI-

TIONS.

Fig. 1 Shock Tower To Spring Minimum Clearance

Area

1 - SHOCK TOWER

2 - COIL SPRING

3 - NO SHEET METAL SCREWS, BOLTS, OR ANY OTHER

METAL FASTENERS ARE TO BE INSTALLED INTO SHOCK

TOWER IN THIS AREA. ALSO, NO HOLES ARE TO BE DRILLED

INTO SHOCK TOWER IN THIS SAME AREA.

5 - 4 BRAKES - BASERS

BRAKES - BASE (Continued)

ProCarManuals.com

Page 135 of 2399

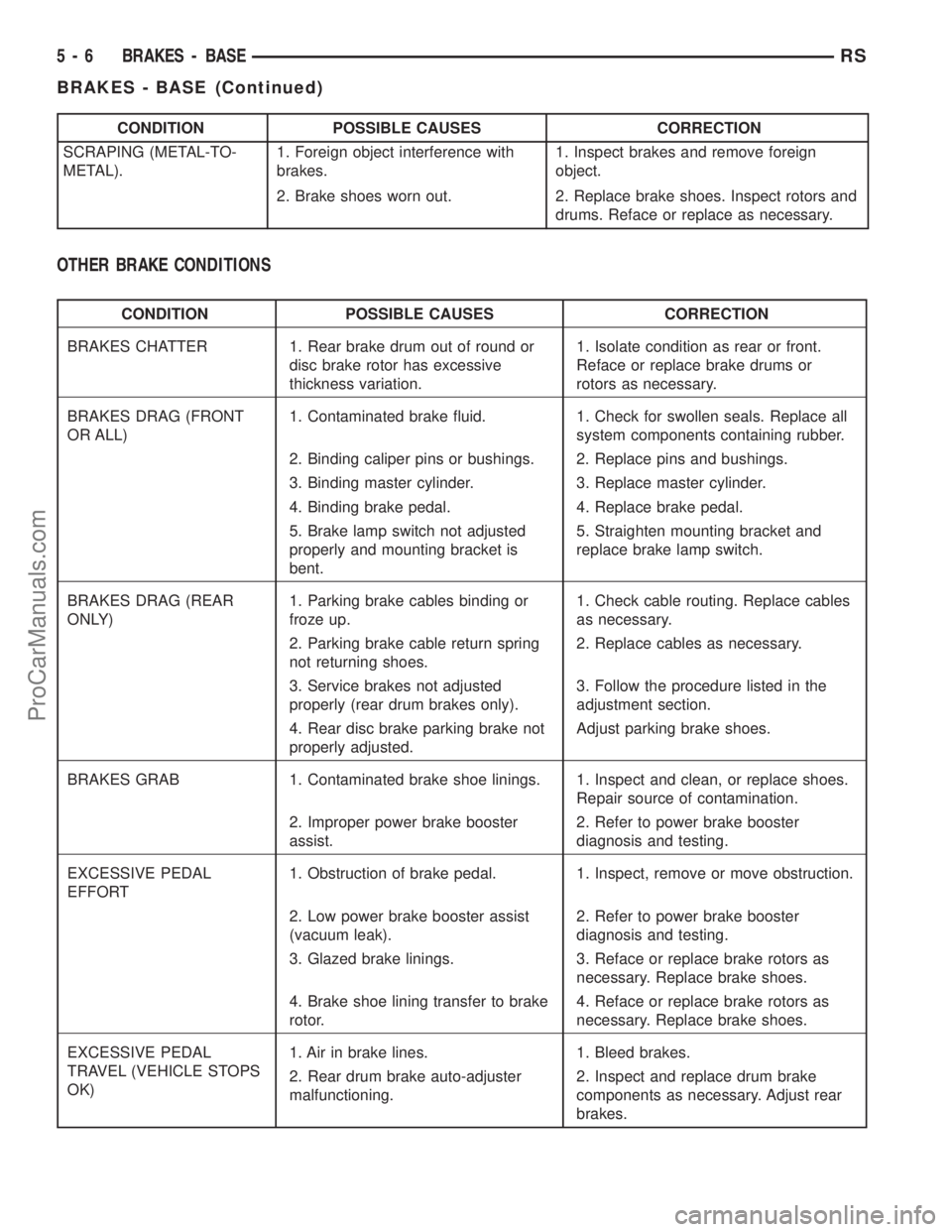

CONDITION POSSIBLE CAUSES CORRECTION

SCRAPING (METAL-TO-

METAL).1. Foreign object interference with

brakes.1. Inspect brakes and remove foreign

object.

2. Brake shoes worn out. 2. Replace brake shoes. Inspect rotors and

drums. Reface or replace as necessary.

OTHER BRAKE CONDITIONS

CONDITION POSSIBLE CAUSES CORRECTION

BRAKES CHATTER 1. Rear brake drum out of round or

disc brake rotor has excessive

thickness variation.1. Isolate condition as rear or front.

Reface or replace brake drums or

rotors as necessary.

BRAKES DRAG (FRONT

OR ALL)1. Contaminated brake fluid. 1. Check for swollen seals. Replace all

system components containing rubber.

2. Binding caliper pins or bushings. 2. Replace pins and bushings.

3. Binding master cylinder. 3. Replace master cylinder.

4. Binding brake pedal. 4. Replace brake pedal.

5. Brake lamp switch not adjusted

properly and mounting bracket is

bent.5. Straighten mounting bracket and

replace brake lamp switch.

BRAKES DRAG (REAR

ONLY)1. Parking brake cables binding or

froze up.1. Check cable routing. Replace cables

as necessary.

2. Parking brake cable return spring

not returning shoes.2. Replace cables as necessary.

3. Service brakes not adjusted

properly (rear drum brakes only).3. Follow the procedure listed in the

adjustment section.

4. Rear disc brake parking brake not

properly adjusted.Adjust parking brake shoes.

BRAKES GRAB 1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes.

Repair source of contamination.

2. Improper power brake booster

assist.2. Refer to power brake booster

diagnosis and testing.

EXCESSIVE PEDAL

EFFORT1. Obstruction of brake pedal. 1. Inspect, remove or move obstruction.

2. Low power brake booster assist

(vacuum leak).2. Refer to power brake booster

diagnosis and testing.

3. Glazed brake linings. 3. Reface or replace brake rotors as

necessary. Replace brake shoes.

4. Brake shoe lining transfer to brake

rotor.4. Reface or replace brake rotors as

necessary. Replace brake shoes.

EXCESSIVE PEDAL

TRAVEL (VEHICLE STOPS

OK)1. Air in brake lines. 1. Bleed brakes.

2. Rear drum brake auto-adjuster

malfunctioning.2. Inspect and replace drum brake

components as necessary. Adjust rear

brakes.

5 - 6 BRAKES - BASERS

BRAKES - BASE (Continued)

ProCarManuals.com

Page 144 of 2399

front brakes utilize the familiar internally-vented hat

style rotor. Internally-vented refers to the fact that

the inner most diameter of the braking disc vents to

the inboard side of the rotor (Fig. 16).

CAUTION: TRW and Continental Teves brake rotors

are not interchangeable. If brake rotors are inter-

changed, noise and wear problems can result.

DESCRIPTION - DISC BRAKES (REAR)

There are several distinctive features to the rear

disc brakes on this vehicle (Fig. 17). The single pis-

ton, floating caliper rear disc brake system includes a

hub and bearing assembly, adapter, rotor, caliper, and

brake shoes.

This vehicle is equipped with a caliper having a 42

mm (1.65 in.) piston and uses a 15 inch solid non-

vented brake rotor. The brake rotor is described as a

drum-in-hat style because of its dual role as a brak-

ing disc and parking brake drum.

The parking brake system on vehicles equipped

with rear disc brakes consists of a small duo-servo

drum brake mounted to the caliper adapter and uses

the interior of the rear disc brake rotor as a drum

(hat section of drum-in-hat style brake rotor).

The outboard rear disc brake shoes (pads) are side-

oriented. The shoes are marked indicating which side

they belong on.

DESCRIPTION - DISC BRAKES (EXPORT)

All vehicles are equipped with Four-Wheel-Disc

brakes. Both 15º (BRE) and 16º (BR3) disc/disc brake

systems are available. The disc brakes are manufac-

tured by Continental Teves. The BR3 system is stan-

dard equipment on all-wheel drive and all right-hand

drive models. It is optional on other models.

The BR3 system features larger, externally vented

front brake rotors.

Although there are different disc/disc systems, they

are serviced using the same service procedures. Some

specifications differ.

Fig. 15 ANTI-RATTLE DEVICES ON CALIPERS

1 - CONTINENTAL TEVES CALIPER

2 - TRW CALIPER

3 - ANTI-RATTLE CLIP

4 - ANTI-RATTLE CLIP

Fig. 16 Externally and Internally Vented Rotors

(Cross-Sectional View)

1 - EXTERNAL VENTS (TRW)

2 - INTERNAL VENTS (Continetal Teves)

Fig. 17 Rear Disc Brakes

1 - CALIPER

2 - COTTER PIN

3 - ROTOR

4 - NUT RETAINER

5 - OUTER C/V JOINT

RSBRAKES - BASE5-15

HYDRAULIC/MECHANICAL (Continued)

ProCarManuals.com

Page 145 of 2399

DESCRIPTION - DRUM BRAKES (REAR)

This vehicle's rear wheel drum brakes are a two-

shoe, internal-expanding type with an automatic

adjuster screw. The automatic adjuster screw is

located directly below the wheel cylinder that is

mounted near the top of the brake assembly (Fig.

18). These and two brake shoes (and attaching parts)

are mounted to a support plate at each rear wheel. A

brake drum covers each brake assembly.

OPERATION

OPERATION - DISC BRAKES (FRONT)

When the brakes are applied, fluid pressure is sent

to each brake caliper. The pressure at the caliper is

exerted equally against the caliper piston. The pres-

sure applied to the piston is transmitted directly to

the inboard brake shoe. This forces the shoe lining

against the inner surface of the brake rotor. At the

same time, fluid pressure within the caliper piston

bore forces the caliper to slide inward on its guide

pins. This action brings the outboard shoe lining into

contact with the outer surface of the brake rotor.

This pressure on both sides of the brake rotor causes

friction, bringing the vehicle to a stop.

When the brake pedal is released, so is the fluid

pressure. The piston seal inside the caliper is

designed to pull the piston back into the bore of the

caliper when the brake pedal is released (Fig. 19).

This action helps maintain the proper brake shoe-to-

rotor clearance.

As disc brake shoe linings wear, master cylinder

reservoir brake fluid level will drop. Adjust as neces-sary. Fluid level should always be checked after

replacing shoes.

OPERATION - DISC BRAKES (REAR)

The rear disc brakes operate similarly to front disc

brakes, however, there are some features that require

different service procedures.

DIAGNOSIS AND TESTING - DRUM BRAKE

AUTOMATIC ADJUSTER

The rear drum brakes on this vehicle automatically

adjust when required during the normal operation of

the vehicle every time the brakes are applied. Use

the following procedure to test the operation of the

automatic adjuster.

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the adjustment hole in each brake support

plate to provide visual access of the brake adjuster

star wheel.

To eliminate the condition where maximum adjust-

ment of the rear brake shoes does not allow the auto-

matic adjuster to operate when tested, back the star

wheel off approximately 30 notches. It will be neces-

sary to hold the adjuster lever away from the star

wheel to permit this adjustment.

Have the helper apply the brakes. Upon applica-

tion of the brake pedal, the adjuster lever should

move down, turning the adjuster star wheel. Thus, a

definite rotation of the adjuster star wheel can be

observed if the automatic adjuster is working prop-

erly. If one or more adjusters do not function prop-

erly, the respective drum must be removed for

adjuster servicing.

Fig. 18 Drum Brake Assembly (Right Shown)

1 - WHEEL CYLINDER

2 - BRAKE SHOE UPPER RETURN SPRING

3 - AUTOMATIC ADJUSTER LEVER

4 - TENSION CLIP

5 - AUTOMATIC ADJUSTER ASSEMBLY

Fig. 19 Caliper Piston Seal Function For Automatic

Adjustment

1 - PISTON

2 - CYLINDER BORE

3 - PISTON SEAL BRAKE PRESSURE OFF

4 - CALIPER HOUSING

5 - DUST BOOT

6 - PISTON SEAL BRAKE PRESSURE ON

5 - 16 BRAKES - BASERS

HYDRAULIC/MECHANICAL (Continued)

ProCarManuals.com

Page 146 of 2399

BRAKE LINES

DESCRIPTION - BRAKE TUBES AND HOSES

The brake tubes are steel with a corrosion-resis-

tant nylon coating applied to the external surfaces.

The flex hoses are made of reinforced rubber with fit-

tings at each end.

The primary and secondary brake tubes leading

from the master cylinder to the ABS ICU Hydraulic

Control Unit (HCU) or the non-ABS junction block

have a special flexible section. This flexible section is

required due to cradle movement while the vehicle is

in motion (The ICU and non-ABS junction block are

mounted to the cradle).If replacement of these

lines is necessary, only the original factory

brake line containing the flexible section must

be used.

OPERATION - BRAKE TUBES AND HOSES

The purpose of the chassis brake tubes and flex

hoses is to transfer the pressurized brake fluid devel-

oped by the master cylinder to the wheel brakes of

the vehicle. The flex hoses are made of rubber to

allow for the movement of the vehicle's suspension.

INSPECTION - BRAKE TUBES AND HOSES

Flexible rubber hose is used at both front brakes

and at the rear axle. Inspection of brake hoses

should be performed whenever the brake system is

serviced and every 7,500 miles or 12 months, which-

ever comes first (every engine oil change). Inspect

hydraulic brake hoses for surface cracking, scuffing,

or worn spots. If the fabric casing of the rubber hose

becomes exposed due to cracks or abrasions in the

rubber hose cover, the hose should be replaced imme-

diately. Eventual deterioration of the hose can take

place with possible burst failure. Faulty installation

can cause twisting, resulting in wheel, tire, or chassis

interference.

The brake tubing should be inspected periodically

for evidence of physical damage or contact with mov-

ing or hot components.

The flexible brake tube sections used on this vehi-

cle in the primary and secondary tubes from the

master cylinder to the ABS hydraulic control unit

connections must also be inspected. This flexible tub-

ing must be inspected for kinks, fraying and contact

with other components or with the body of the vehi-

cle.

BRAKE PADS/SHOES - FRONT

REMOVAL

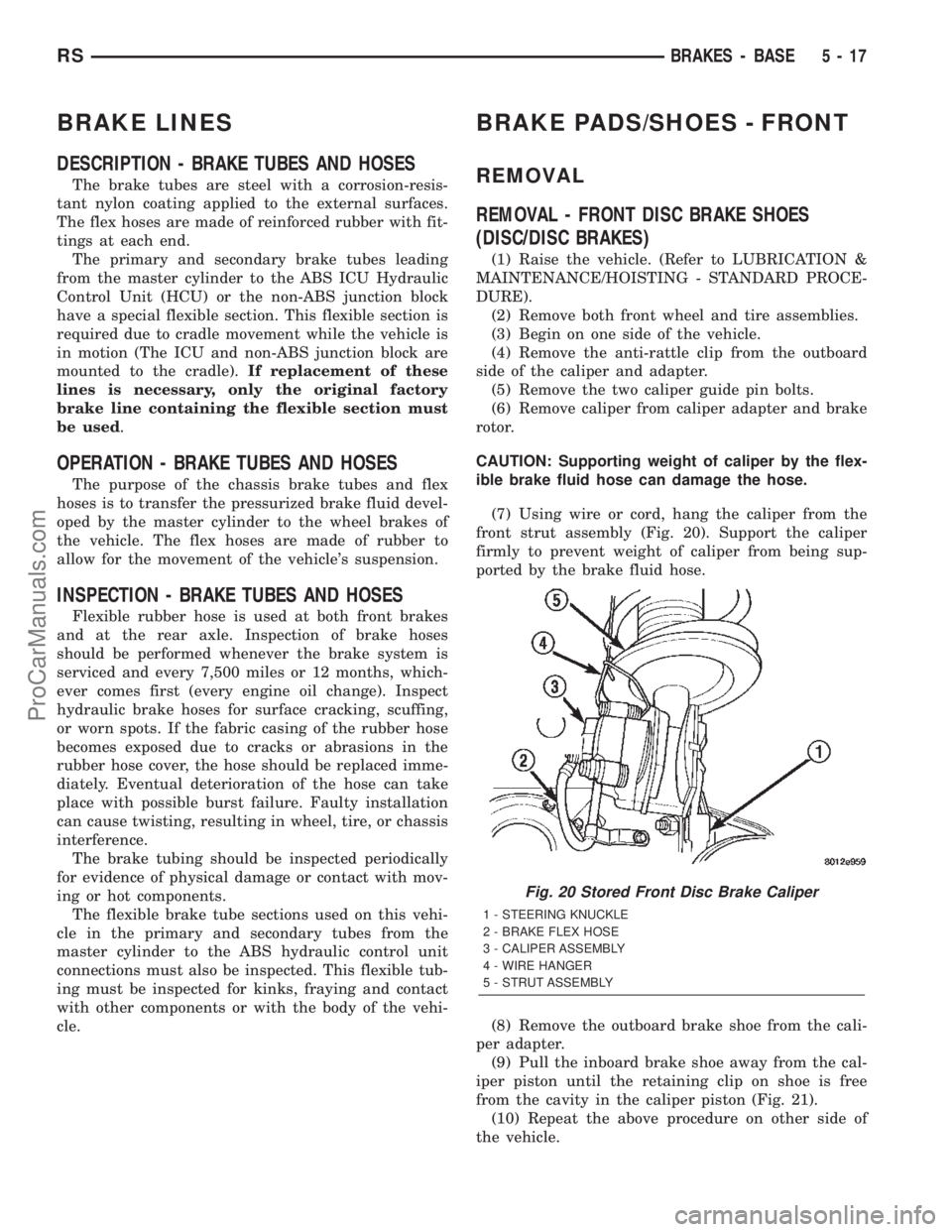

REMOVAL - FRONT DISC BRAKE SHOES

(DISC/DISC BRAKES)

(1) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(2) Remove both front wheel and tire assemblies.

(3) Begin on one side of the vehicle.

(4) Remove the anti-rattle clip from the outboard

side of the caliper and adapter.

(5) Remove the two caliper guide pin bolts.

(6) Remove caliper from caliper adapter and brake

rotor.

CAUTION: Supporting weight of caliper by the flex-

ible brake fluid hose can damage the hose.

(7) Using wire or cord, hang the caliper from the

front strut assembly (Fig. 20). Support the caliper

firmly to prevent weight of caliper from being sup-

ported by the brake fluid hose.

(8) Remove the outboard brake shoe from the cali-

per adapter.

(9) Pull the inboard brake shoe away from the cal-

iper piston until the retaining clip on shoe is free

from the cavity in the caliper piston (Fig. 21).

(10) Repeat the above procedure on other side of

the vehicle.

Fig. 20 Stored Front Disc Brake Caliper

1 - STEERING KNUCKLE

2 - BRAKE FLEX HOSE

3 - CALIPER ASSEMBLY

4 - WIRE HANGER

5 - STRUT ASSEMBLY

RSBRAKES - BASE5-17

ProCarManuals.com

Page 163 of 2399

DISC BRAKE CALIPER

ADAPTER

REMOVAL - FRONT DISC BRAKE CALIPER

ADAPTER

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove front wheel and tire assembly, disc

brake caliper and brake shoes. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/BRAKE PADS/SHOES

- REMOVAL)

(3) Remove two bolts fastening adapter to steering

knuckle, then remove disc brake caliper adapter.

INSTALLATION - FRONT DISC BRAKE CALIPER

ADAPTER

(1) Place adapter over brake rotor and align

adapter mounting holes to knuckle.

CAUTION: Adapter mounting bolts have a special

DacrometTcoating applied to resist corrosion. If

mounting bolts need to be replaced, use only

MoparTreplacement parts.

(2) Install adapter mounting bolts and tighten to

169 N´m (125 ft. lbs.) torque.

(3) Install brake shoes, disc brake caliper and

wheel and tire assembly. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/BRAKE PADS/SHOES -

INSTALLATION)

(4) Lower vehicle.

(5) Pump the brake pedal several times to set the

pads to the brake rotor.

(6) Check and adjust brake fluid level as neces-

sary.

DISC BRAKE CALIPER GUIDE

PINS

REMOVAL - DISC BRAKE CALIPER GUIDE PINS

(DISC/DRUM BRAKES)

(1) Raise the vehicle. Refer to HOISTING in

LUBRICATION AND MAINTENANCE.

(2) Remove the front tire and wheel assembly.

(3) Remove the two brake caliper guide pin bolts

(Fig. 51).

(4) Remove the disc brake caliper from the disc

brake caliper adapter and hang it out of the way

using wire or a bungee cord. Use care not to overex-

tend the brake hose when doing this.

(5) Remove the guide pins and boots from the

adapter as shown (Fig. 52).

INSTALLATION - DISC BRAKE CALIPER GUIDE

PINS (DISC/DRUM BRAKES)

(1) Lubricate the guide pins and inside the boots

with the packet supplied with the service kit, Syth-

eso GLK-1 lubricant or equivalent.

(2) Install the guide pins and boots in the adapter

as shown (Fig. 52). The boots have grooves built into

their inner lips to fit onto the pins and adapter.

CAUTION: Use care when installing the caliper onto

the disc brake adapter to avoid damaging the boots

on the caliper guide pins.

Fig. 51 Brake Caliper Mounting

1 - BRAKE HOSE

2 - ADAPTER MOUNTING BOLTS

3 - BANJO BOLT

4 - CALIPER GUIDE PIN BOLTS

Fig. 52 Guide Pins And Boots

1 - PINS

2 - BOOTS

5 - 34 BRAKES - BASERS

ProCarManuals.com