service CHRYSLER VOYAGER 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 195 of 2399

The vehicle has four flexible steel parking brake

cables. They are:

²Front

²Intermediate

²Left rear

²Right rear

The front parking brake cable extends from the

parking brake lever. A steel equalizer bracket con-

nects the front parking brake cable to the left rear

and intermediate cable. The intermediate cable is

connected to the right rear cable using a parking

brake cable connector.

On vehicles equipped with rear drum brakes, the

rear service brakes also act as the vehicle's parking

brakes.

Vehicles equipped with rear disc brakes use a

small duo-servo brake assembly mounted to the each

rear disc brake caliper adapter as the parking brake.

The inside of the brake rotor (hat section of drum-in-

hat style brake rotor) is used as the parking brake

drum.

DESCRIPTION - EXPORT

The parking brake system on this vehicle features

a hand-operated parking brake lever. The lever is

located between the two front seats and requires a

special front cable.

OPERATION

The automatic-adjusting feature in the foot oper-

ated parking brake lever continuously applies mini-

mal tension to the parking brake cables when the

parking brake lever is in the released position to

keep them in adjustment at all times. Due to this

feature, the parking brake cables require no periodic

adjustment.

When the parking brake lever is applied, the

cables are pulled, thus applying the brake shoes

(rear drum brakes) or parking brake shoes (rear disc

brakes) at each rear wheel.

The brake shoes are mechanically operated by an

internal lever and strut connected to the rear park-

ing brake cables.

An equalizer bracket is used at the rear end of the

front parking brake cable to distribute tension

equally to each parking brake cable.

STANDARD PROCEDURE

STANDARD PROCEDURE - PARKING BRAKE

AUTOMATIC ADJUSTER TENSION RELEASE

The parking brake lever (pedal) mechanism used

in this vehicle is designed so that the automatic

adjuster is not required to be locked out when servic-ing the parking brake lever (pedal) or the parking

brake cables.

This parking brake lever (pedal) mechanism is

designed so that the adjuster mechanism will rotate

only half a turn when the tension is released from

the parking brake cable. This eliminates the require-

ment to lock out the automatic adjuster when servic-

ing the parking brake lever (pedal) mechanism and

cables.

Use the following procedure to release the tension

from the parking brake cables and the automatic

adjuster in the parking brake lever (pedal) mecha-

nism.

(1) Grasp the exposed section of the front parking

brake cable and pull rearward on it. While holding

the park brake in this position, install a pair of lock-

ing pliers on the front parking brake cable just rear-

ward of the second body outrigger bracket (Fig. 106).

(2) Remove the left rear and intermediate parking

brake cables from the parking brake cable equalizer

(Fig. 107).

(3) Remove the equalizer from the front parking

brake cable.

(4) Remove the locking pliers from the front park-

ing brake cable. This will allow the adjuster in the

parking brake lever (pedal) mechanism to rotate

around to its stop. This will remove the tension from

the adjuster and front park brake cable (Refer to 5 -

BRAKES/PARKING BRAKE - STANDARD PROCE-

DURE).

Fig. 106 Locking Out Automatic Adjuster

1 - PARK BRAKE CABLE

2 - REAR BODY OUTRIGGER BRACKET

3 - LOCKING PLIERS

5 - 66 BRAKES - BASERS

PARKING BRAKE (Continued)

ProCarManuals.com

Page 198 of 2399

REMOVAL - PARKING BRAKE CABLE (RIGHT

REAR)

(1) Raise vehicle on jackstands or centered on a

hoist. (Refer to LUBRICATION & MAINTENANCE/

HOISTING - STANDARD PROCEDURE).

(2) Remove rear tire and wheel assembly.

(3) Remove rear brake drum from the rear wheel

of the vehicle requiring service to the rear park

brake cable.

(4) Create slack in the rear parking brake cables

by locking out the automatic adjuster as described

here. Grasp an exposed section of front parking

brake cable near the equalizer and pull down on it.

At this time install a pair of locking pliers on the

cable just rearward of the second body outrigger

bracket (Fig. 113).

(5) Disconnect the right rear parking brake cable

from the connector on the intermediate cable (Fig.

114).

(6) To remove the right parking brake cable hous-

ing from the body bracket, slide a 14 mm box end

wrench over the end of cable retainer to compress the

retaining fingers (Fig. 115). The alternate method

using an aircraft type hose clamp will not work on

the right side of the vehicle.

(7) Remove the brake shoes from the brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES - REMOVAL).(8) Disconnect parking brake cable from parking

brake actuator lever.

(9) Remove the parking brake cable housing

retainer from the brake support plate using a 14mm

wrench to compress the retaining fingers (Fig. 116).

Remove the cable.

Fig. 112 Intermediate Cable Attachment To Right

1 - RIGHT REAR PARKING BRAKE CABLE

2 - LOCKING NUT

3 - INTERMEDIATE PARKING BRAKE CABLEFig. 113 Locking Out Automatic Adjuster

1 - PARK BRAKE CABLE

2 - REAR BODY OUTRIGGER BRACKET

3 - LOCKING PLIERS

Fig. 114 Right Rear Cable Connection To

Intermediate Cable

1 - RIGHT REAR PARKING BRAKE CABLE

2 - LOCKING NUT

3 - INTERMEDIATE PARKING BRAKE CABLE

RSBRAKES - BASE5-69

CABLES - PARKING BRAKE (Continued)

ProCarManuals.com

Page 199 of 2399

REMOVAL - PARKING BRAKE CABLE (LEFT

REAR)

(1) Raise vehicle on jackstands or centered on a

hoist. (Refer to LUBRICATION & MAINTENANCE/

HOISTING - STANDARD PROCEDURE).

(2) Remove rear tire and wheel assembly.

(3) Remove rear brake drum from the rear wheel

of the vehicle requiring service to the rear park

brake cable.(4) Create slack in rear park brake cables by lock-

ing out the automatic adjuster as described here.

Grasp an exposed section of front park brake cable

near the equalizer and pull down on it. Then install

a pair of locking pliers on the cable just rearward of

the second body outrigger bracket (Fig. 117).

(5) Disconnect the left rear parking brake cable

from the parking brake cable equalizer (Fig. 118).

(6) To remove parking brake cable housing from

the body bracket, slide a 14 mm box end wrench over

retainer end compressing the three fingers (Fig. 119).

Alternate method is to use an aircraft type hose

clamp.

Fig. 115 Right Park Brake Cable Removal From

Body Bracket

1 - RIGHT REAR BODY BRACKET

2 - PARK BRAKE CABLE

3 - 14MM WRENCH

4 - LEAF SPRING AND BRACKET

Fig. 116 Removing Park Brake Cable From Brake

Support Plate

1 - PARK BRAKE CABLE RETAINER

2 - PARK BRAKE CABLE

3 - 14MM BOX WRENCH

4 - BRAKE SUPPORT PLATE

Fig. 117 Locked Out Park Brake Automatic Adjuster

1 - PARK BRAKE CABLE

2 - REAR BODY OUTRIGGER BRACKET

3 - LOCKING PLIERS

Fig. 118 Parking Brake Cables At Equalizer

1 - EQUALIZER

2 - LEFT REAR PARKING BRAKE CABLE

3 - LOCKING NUT

4 - INTERMEDIATE PARKING BRAKE CABLE

5 - FRONT PARKING BRAKE CABLE

5 - 70 BRAKES - BASERS

CABLES - PARKING BRAKE (Continued)

ProCarManuals.com

Page 201 of 2399

(7) Install and position the foam collar on the

parking brake cable to prevent it from rattling

against the vehicle's floor.

(8) Lower the vehicle and apply the park brake

pedal 1 time, this will seat the park brake cables.

INSTALLATION - PARKING BRAKE CABLE

(RIGHT REAR)

(1) Install the rear parking brake cable in the

brake support plate. Insert cable housing retainer

into brake support plate making certain that cable

housing retainer fingers lock the housing and

retainer firmly into place.

(2) Attach the parking brake cable onto the park-

ing brake actuator lever.

(3) Install the brake shoes on the rear brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES -

INSTALLATION).

(4) Insert cable housing retainer into body outrig-

ger bracket making certain that cable housing

retainer fingers lock the housing firmly into place.

(5) Connect the right rear parking brake cable to

the connector on the intermediate parking brake

cable (Fig. 114).

(6) Install the brake drum, then the wheel and tire

assembly.

(7) Remove the locking pliers from the front park

brake cable. This will automatically adjust the park

brake cables.

(8) Lower the vehicle.

(9) Apply and release park brake pedal 1 time.

This will seat the park brake cables.

INSTALLATION - PARKING BRAKE CABLE

(LEFT REAR)

(1) Install the rear parking brake cable in the

brake support plate. Insert cable housing retainer

into brake support plate making certain that cable

housing retainer fingers lock the housing and

retainer firmly into place.

(2) Attach the parking brake cable onto the park

brake actuator lever.

(3) Install the brake shoes on the rear brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES -

INSTALLATION).

(4) Insert cable housing retainer into body outrig-

ger bracket making certain that cable housing

retainer fingers lock the housing firmly into place.

(5) Connect rear parking brake cable to the equal-

izer bracket (Fig. 118).

(6) Install brake drum, and wheel and tire assem-

bly.(7) Remove the locking pliers from the front park

brake cable. This will automatically adjust the park

brake cables.

(8) Apply and release park brake pedal 1 time.

This will seat the park brake cables.

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE CABLES

The park brake cables on this vehicle have an

automatic self adjuster built into the park brake

pedal mechanism. When the foot operated park brake

pedal is in its released (upward most) position, a

clock spring automatically adjusts the park brake

cables. The park brake cables are adjusted (ten-

sioned) just enough to remove all the slack from the

cables. The automatic adjuster system will not over

adjust the cables causing rear brake drag.

Due to the automatic adjust feature of the park

brake pedal, adjustment of the parking brake cables

on these vehicles relies on proper drum brake and

park brake shoe adjustment. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/DRUM - ADJUST-

MENTS) and (Refer to 5 - BRAKES/PARKING

BRAKE/SHOES - ADJUSTMENTS).

When the park brake pedal is applied the self

adjuster is by-passed and the pedal operates nor-

mally to engage the park brakes.

When a service procedure needs to be performed on

the park brake pedal or the park brake cables, the

automatic self adjuster can be manually locked out

by the service technician.

CABLES - PARKING BRAKE

(EXPORT)

REMOVAL - FRONT CABLE

(Refer to 5 - BRAKES - BASE/PARKING BRAKE/

LEVER - REMOVAL)

INSTALLATION - FRONT CABLE

(Refer to 5 - BRAKES - BASE/PARKING BRAKE/

LEVER - INSTALLATION)

LEVER - PARKING BRAKE

REMOVAL

(1) Manually release the automatic self-adjusting

mechanism tension of the parking brake lever (pedal)

assembly. (Refer to 5 - BRAKES/PARKING BRAKE -

STANDARD PROCEDURE).

(2) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

5 - 72 BRAKES - BASERS

CABLES - PARKING BRAKE (Continued)

ProCarManuals.com

Page 214 of 2399

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION

DESCRIPTION - ANTILOCK BRAKE

SYSTEM............................85

DESCRIPTION - ANTILOCK BRAKE

SYSTEM (EXPORT)....................85

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............86

DESCRIPTION - TRACTION CONTROL

SYSTEM............................86

OPERATION

OPERATION - ANTILOCK BRAKE SYSTEM . . 86

OPERATION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............87

OPERATION - TRACTION CONTROL

SYSTEM............................87

CAUTION

CAUTIONS..........................88

STANDARD PROCEDURE - ANTILOCK BRAKE

SYSTEM BLEEDING...................88

SPECIFICATIONS

ABS FASTENER TORQUE...............89

TONE WHEEL RUNOUT................89

WHEEL SPEED SENSOR AIR GAP........89

FRONT WHEEL SPEED SENSOR

REMOVAL.............................89

INSTALLATION.........................89

REAR WHEEL SPEED SENSOR - AWD

REMOVAL.............................90INSTALLATION.........................90

REAR WHEEL SPEED SENSOR - FWD

REMOVAL.............................91

INSTALLATION.........................91

TONE WHEEL

INSPECTION - TONE WHEEL..............92

TRACTION CONTROL SWITCH

DIAGNOSIS AND TESTING - TRACTION

CONTROL SWITCH....................92

HYDRAULIC/MECHANICAL

OPERATION - HYDRAULIC CIRCUITS AND

VALVES .............................93

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................99

OPERATION...........................99

ICU (INTEGRATED CONTROL UNIT)

DESCRIPTION........................100

OPERATION..........................100

REMOVAL

REMOVAL - LHD.....................100

REMOVAL - RHD.....................101

DISASSEMBLY - ICU...................103

ASSEMBLY - ICU......................103

INSTALLATION

INSTALLATION - LHD.................104

INSTALLATION - RHD.................105

BRAKES - ABS

DESCRIPTION

DESCRIPTION - ANTILOCK BRAKE SYSTEM

This section covers the physical and operational

descriptions and the on-car service procedures for the

Mark 20e Antilock Brake System and the Mark 20e

Antilock Brake System with traction control.

The purpose of the antilock brake system (ABS) is

to prevent wheel lockup under braking conditions on

virtually any type of road surface. Antilock braking is

desirable because a vehicle that is stopped without

locking the wheels retains directional stability and

some steering capability. This allows the driver to

retain greater control of the vehicle during braking.

DESCRIPTION - ANTILOCK BRAKE SYSTEM

(EXPORT)

Four-wheel disc antilock brakes are standard on all

models. The Mark 20e antilock brake system is used

on all models. Depending on whether the vehicle is a

left-hand drive (LHD) or right-hand drive (RHD)

model, the integrated control unit (ICU) is located in

one of two locations. On LHD models, the ICU is

mounted above the front suspension cradle/cross-

member below the master cylinder. On RHD models,

the ICU is located behind the front suspension cra-

dle/crossmember on the left side of the vehicle.

RSBRAKES - ABS5-85

ProCarManuals.com

Page 217 of 2399

ªthermo-protection mode,º the traction control func-

tion lamp illuminates TRAC OFF; note that no trou-

ble code is registered.

CAUTION

CAUTIONS

The ABS uses an electronic control module, the

CAB. This module is designed to withstand normal

current draws associated with vehicle operation.

Care must be taken to avoid overloading the CAB

circuits.

CAUTION: In testing for open or short circuits, do

not ground or apply voltage to any of the circuits

unless instructed to do so for a diagnostic proce-

dure.

CAUTION: These circuits should only be tested

using a high impedance multi-meter or the DRBIIIT

scan tool as described in this section. Power

should never be removed or applied to any control

module with the ignition in the ON position. Before

removing or connecting battery cables, fuses, or

connectors, always turn the ignition to the OFF

position.

CAUTION: The CAB 24-way connector should never

be connected or disconnected with the ignition

switch in the ON position.

CAUTION: This vehicle utilizes active wheel speed

sensors. Do not apply voltage to wheel speed sen-

sors at any time.

CAUTION: Use only factory wiring harnesses. Do

not cut or splice wiring to the brake circuits. The

addition of aftermarket electrical equipment (car

phone, radar detector, citizen band radio, trailer

lighting, trailer brakes, etc.) on a vehicle equipped

with antilock brakes may affect the function of the

antilock brake system.

CAUTION: When performing any service procedure

on a vehicle equipped with ABS, do not apply a

12-volt power source to the ground circuit of the

pump motor in the HCU. Doing this will damage the

pump motor and will require replacement of the

entire HCU.CAUTION: An attempt to remove or disconnect cer-

tain system components may result in improper

system operation. Only those components with

approved removal and installation procedures in

this manual should be serviced.

CAUTION: If welding work is to be performed on the

vehicle, using an electric arc welder, the CAB con-

nector should be disconnected during the welding

operation.

CAUTION: Many components of the ABS System

are not serviceable and must be replaced as an

assembly. Do not disassemble any component

which is not designed to be serviced.

CAUTION: Only the recommended jacking or hoist-

ing positions for this vehicle are to be used when-

ever it is necessary to lift a vehicle. Failure to raise

a vehicle from the recommended locations could

result in lifting a vehicle by the hydraulic control

unit mounting bracket. Lifting a vehicle by the

hydraulic control unit mounting bracket will result

in damage to the mounting bracket and the hydrau-

lic control unit.

CAUTION: Brake fluid will damage painted surfaces.

If brake fluid is spilled on any painted surface,

wash off with water immediately.

STANDARD PROCEDURE - ANTILOCK BRAKE

SYSTEM BLEEDING

The base brake's hydraulic system must be bled

anytime air enters the hydraulic system. The ABS

though, particularly the ICU (HCU), should only be

bled when the HCU is replaced or removed from the

vehicle. The ABS must always be bled anytime it is

suspected that the HCU has ingested air. Under

most circumstances that require the bleeding of the

brakes hydraulic system, only the base brake

hydraulic system needs to be bled.

It is important to note that excessive air in the

brake system will cause a soft or spongy feeling

brake pedal.

During the brake bleeding procedure, be sure the

brake fluid level remains close to the FULL level in

the master cylinder fluid reservoir. Check the fluid

level periodically during the bleeding procedure and

add DOT 3 brake fluid as required.

The ABS must be bled as two independent braking

systems. The non-ABS portion of the brake system

with ABS is to be bled the same as any non-ABS sys-

tem.

5 - 88 BRAKES - ABSRS

BRAKES - ABS (Continued)

ProCarManuals.com

Page 221 of 2399

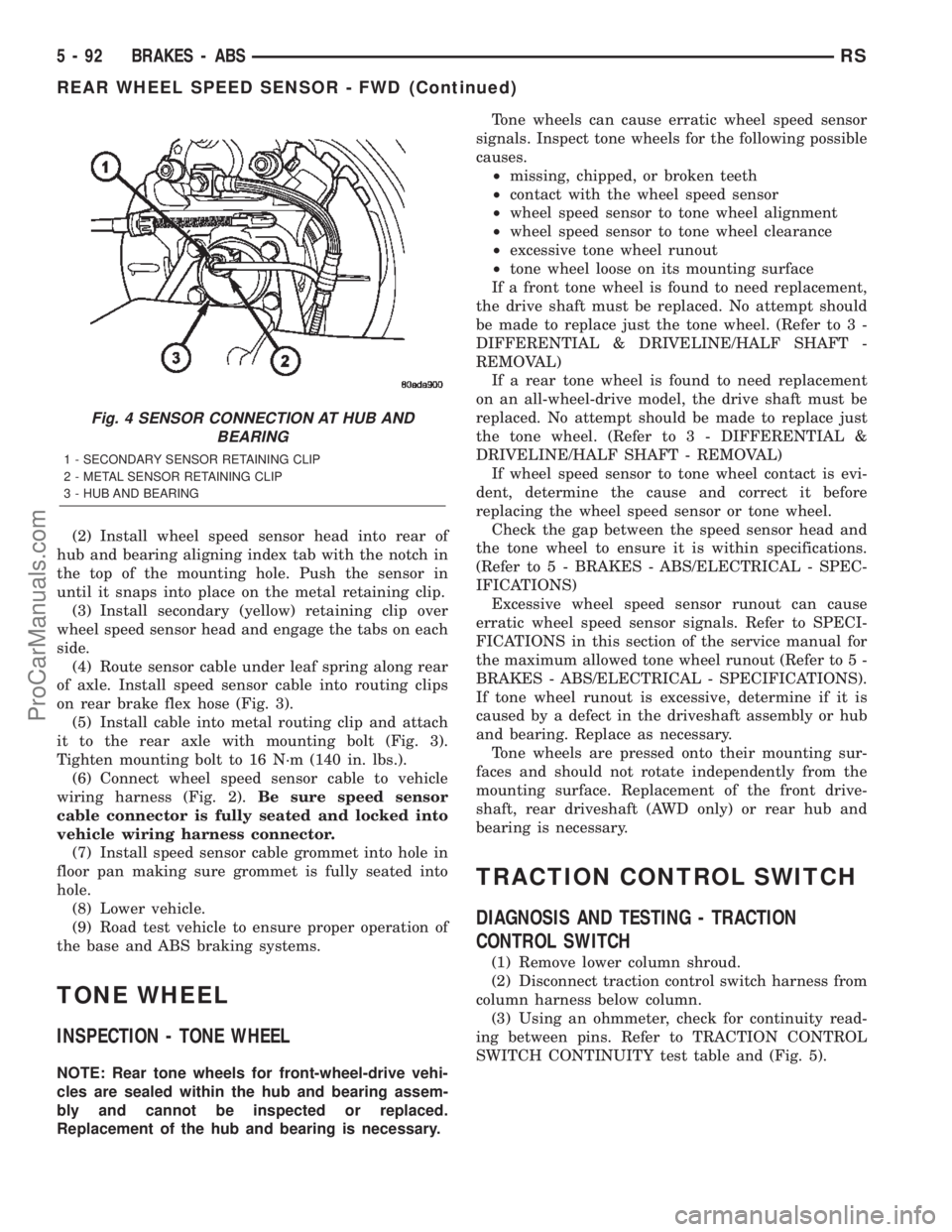

(2) Install wheel speed sensor head into rear of

hub and bearing aligning index tab with the notch in

the top of the mounting hole. Push the sensor in

until it snaps into place on the metal retaining clip.

(3) Install secondary (yellow) retaining clip over

wheel speed sensor head and engage the tabs on each

side.

(4) Route sensor cable under leaf spring along rear

of axle. Install speed sensor cable into routing clips

on rear brake flex hose (Fig. 3).

(5) Install cable into metal routing clip and attach

it to the rear axle with mounting bolt (Fig. 3).

Tighten mounting bolt to 16 N´m (140 in. lbs.).

(6) Connect wheel speed sensor cable to vehicle

wiring harness (Fig. 2).Be sure speed sensor

cable connector is fully seated and locked into

vehicle wiring harness connector.

(7) Install speed sensor cable grommet into hole in

floor pan making sure grommet is fully seated into

hole.

(8) Lower vehicle.

(9) Road test vehicle to ensure proper operation of

the base and ABS braking systems.

TONE WHEEL

INSPECTION - TONE WHEEL

NOTE: Rear tone wheels for front-wheel-drive vehi-

cles are sealed within the hub and bearing assem-

bly and cannot be inspected or replaced.

Replacement of the hub and bearing is necessary.Tone wheels can cause erratic wheel speed sensor

signals. Inspect tone wheels for the following possible

causes.

²missing, chipped, or broken teeth

²contact with the wheel speed sensor

²wheel speed sensor to tone wheel alignment

²wheel speed sensor to tone wheel clearance

²excessive tone wheel runout

²tone wheel loose on its mounting surface

If a front tone wheel is found to need replacement,

the drive shaft must be replaced. No attempt should

be made to replace just the tone wheel. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/HALF SHAFT -

REMOVAL)

If a rear tone wheel is found to need replacement

on an all-wheel-drive model, the drive shaft must be

replaced. No attempt should be made to replace just

the tone wheel. (Refer to 3 - DIFFERENTIAL &

DRIVELINE/HALF SHAFT - REMOVAL)

If wheel speed sensor to tone wheel contact is evi-

dent, determine the cause and correct it before

replacing the wheel speed sensor or tone wheel.

Check the gap between the speed sensor head and

the tone wheel to ensure it is within specifications.

(Refer to 5 - BRAKES - ABS/ELECTRICAL - SPEC-

IFICATIONS)

Excessive wheel speed sensor runout can cause

erratic wheel speed sensor signals. Refer to SPECI-

FICATIONS in this section of the service manual for

the maximum allowed tone wheel runout (Refer to 5 -

BRAKES - ABS/ELECTRICAL - SPECIFICATIONS).

If tone wheel runout is excessive, determine if it is

caused by a defect in the driveshaft assembly or hub

and bearing. Replace as necessary.

Tone wheels are pressed onto their mounting sur-

faces and should not rotate independently from the

mounting surface. Replacement of the front drive-

shaft, rear driveshaft (AWD only) or rear hub and

bearing is necessary.

TRACTION CONTROL SWITCH

DIAGNOSIS AND TESTING - TRACTION

CONTROL SWITCH

(1) Remove lower column shroud.

(2) Disconnect traction control switch harness from

column harness below column.

(3) Using an ohmmeter, check for continuity read-

ing between pins. Refer to TRACTION CONTROL

SWITCH CONTINUITY test table and (Fig. 5).

Fig. 4 SENSOR CONNECTION AT HUB AND

BEARING

1 - SECONDARY SENSOR RETAINING CLIP

2 - METAL SENSOR RETAINING CLIP

3 - HUB AND BEARING

5 - 92 BRAKES - ABSRS

REAR WHEEL SPEED SENSOR - FWD (Continued)

ProCarManuals.com

Page 228 of 2399

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The hydraulic control unit (HCU) is mounted to

the CAB as part of the ICU (Fig. 22). The HCU con-

trols the flow of brake fluid to the brakes using a

series of valves and accumulators. A pump/motor is

mounted on the HCU to supply build pressure to the

brakes during an ABS stop.

The HCU on a vehicle equipped with ABS and

traction control has a valve block housing that is

approximately 1 inch longer on the low pressure fluid

accumulators side than a HCU on a vehicle that is

equipped with only ABS.

For more information, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ICU (INTEGRATED CON-

TROL UNIT) - DESCRIPTION)

OPERATION

For information on the operation of the HCU as a

whole, refer to Hydraulic Circuits And Valve Opera-

tion which can be found elsewhere in this section.

For information on the operation of the components

within the HCU, refer to the following three topics.

VALVES AND SOLENOIDS

The valve block contains four inlet valves and four

outlet valves. The inlet valves are spring-loaded in

the open position and the outlet valves are spring-

loaded in the closed position during normal braking.

The fluid is allowed to flow from the master cylinder

to the wheel brakes.

During an ABS stop, these valves cycle to maintain

the proper slip ratio for each wheel. The inlet valve

closes preventing further pressure increase and the

outlet valve opens to provide a path from the wheel

brake to the HCU accumulators and pump/motor.

This releases (decays) pressure from the wheel brake,

thus releasing the wheel from excessive slippage.

Once the wheel is no longer slipping, the outlet valve

is closed and the inlet valve is opened to reapply

(build) pressure.

On vehicles with traction control, there is an extra

set of valves and solenoids. The ASR valves, mounted

in the HCU valve block, are normally in the open

position and close only when the traction control is

applied.

These isolator valves are used to isolate the rear

(non-driving) wheels of the vehicle from the hydraulicpressure that the HCU pump/motor is sending to the

front (driving) wheels when traction control is being

applied. The rear brakes need to be isolated from the

master cylinder when traction control is being

applied so the rear wheels do not drag. For more

information, refer to Traction Control System in this

section.

BRAKE FLUID ACCUMULATORS

There are two fluid accumulators in the HCU±one

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Each hydraulic circuit uses

a 5 cc accumulator.

The fluid accumulators temporarily store brake

fluid that is removed from the wheel brakes during

an ABS cycle. This stored fluid is used by the pump/

motor to provide build pressure for the brake hydrau-

lic system. When the antilock stop is complete, the

accumulators are drained by the pump/motor.

On ABS-only vehicles, there is a mini-accumulator

on the secondary hydraulic circuit that protects the

master cylinder seals during an ABS stop, and there

is a noise dampening chamber on the primary circuit.

On ABS with traction control vehicles, there are

two noise dampening chambers in the HCU.

PUMP/MOTOR

There are two pump assemblies in the HCUÐone

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Both pumps are driven by a

common electric motor. This DC-type motor is inte-

gral to the HCU and is controlled by the CAB.

The pump/motor provides the extra amount of

brake fluid needed during antilock braking. Brake

fluid is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

mechanism consists of two opposing pistons operated

by an eccentric camshaft. In operation, one piston

draws fluid from the accumulators, and the opposing

piston pumps fluid to the master cylinder circuits.

When the antilock stop is complete, the pump/motor

drains the accumulators.

The CAB may turn on the pump/motor when an

antilock stop is detected. The pump/motor continues

to run during the antilock stop and is turned off after

the stop is complete. Under some conditions, the

pump/motor runs to drain the accumulators during

the next drive-off.

The pump/motor is not a serviceable item; if it

requires replacement, the HCU must be replaced.

RSBRAKES - ABS5-99

ProCarManuals.com

Page 229 of 2399

ICU (INTEGRATED CONTROL

UNIT)

DESCRIPTION

The hydraulic control unit (HCU) and the control-

ler antilock brake (CAB) used with this antilock

brake system are combined (integrated) into one

unit, which is called the integrated control unit (ICU)

(Fig. 12). The ICU is located below the master cylin-

der in the engine compartment (Fig. 13).Two different ICU's (HCU and CAB) are used on

this vehicle depending on whether or not the vehicle

is equipped with traction control. The HCU on a

vehicle equipped with traction control has a valve

block that is approximately one inch longer than a

HCU on a vehicle that is equipped with ABS only.

The ABS-only ICU consists of the following compo-

nents: the CAB, eight (build/decay) solenoid valves

(four inlet valves and four outlet valves), valve block,

fluid accumulators, a pump, and an electric motor.

The ABS-with traction control ICU consists of the

following components: the CAB, eight (build/decay)

solenoid valves (four inlet valves and four outlet

valves), two traction control (ASR) valves, two

hydraulic shuttle valves, valve block, fluid accumula-

tors, a pump, and an electric motor.

The replaceable components of the ICU are the

HCU and the CAB. No attempt should be made to

service any individual components of the HCU or

CAB. For information on the CAB, (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/CONTROLLER ANTILOCK BRAKE -

DESCRIPTION).

OPERATION

For information of the ICU, refer to these individ-

ual components of the ICU:

²CONTROLLER ANTILOCK BRAKE (CAB)

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/CONTROLLER ANTILOCK

BRAKE - OPERATION)

²HYDRAULIC CONTROL UNIT (HCU) (Refer to

5 - BRAKES - ABS/HYDRAULIC/MECHANICAL/

HCU (HYDRAULIC CONTROL UNIT) - OPERA-

TION)

For information on the ICU's hydraulic circuits,

refer to HYDRAULIC CIRCUITS AND VALVE

OPERATION. (Refer to 5 - BRAKES - ABS/HY-

DRAULIC/MECHANICAL - OPERATION)

REMOVAL

REMOVAL - LHD

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Remove the battery shield.

(3) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(4) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(5) Remove the screw securing the engine coolant

filler neck to the battery tray.

(6) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

Fig. 12 INTEGRATED CONTROL UNIT (ICU)

1 - PUMP/MOTOR

2 - HCU

3 - PUMP/MOTOR CONNECTOR

4 - CAB

Fig. 13 ICU LOCATION IN VEHICLE

1 - POWER BRAKE BOOSTER

2 - MASTER CYLINDER

3 - ICU

5 - 100 BRAKES - ABSRS

ProCarManuals.com

Page 236 of 2399

CLUTCH

TABLE OF CONTENTS

page page

CLUTCH

DESCRIPTION..........................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CLUTCH

SYSTEM.............................3

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT.......................5

DIAGNOSIS AND TESTING - CLUTCH

COVER AND DISC RUNOUT..............6

DIAGNOSIS AND TESTING - CLUTCH

CHATTER COMPLAINTS.................6

SPECIAL TOOLS - T850 TRANSAXLE........6

CLUTCH RELEASE LEVER AND BEARING

REMOVAL.............................6

INSTALLATION..........................7

MASTER CYLINDER - RHD

REMOVAL.............................8INSTALLATION..........................8

MASTER CYLINDER - LHD

REMOVAL.............................9

INSTALLATION.........................10

MODULAR CLUTCH ASSY - 2.4L GAS

REMOVAL.............................11

INSTALLATION.........................11

SLAVE CYLINDER

REMOVAL.............................11

INSTALLATION.........................11

CLUTCH DISC AND PRESSURE PLATE - 2.5L

TD

REMOVAL.............................12

INSTALLATION.........................12

FLYWHEEL

REMOVAL.............................13

INSTALLATION.........................13

CLUTCH

DESCRIPTION

CLUTCH COMPONENTS

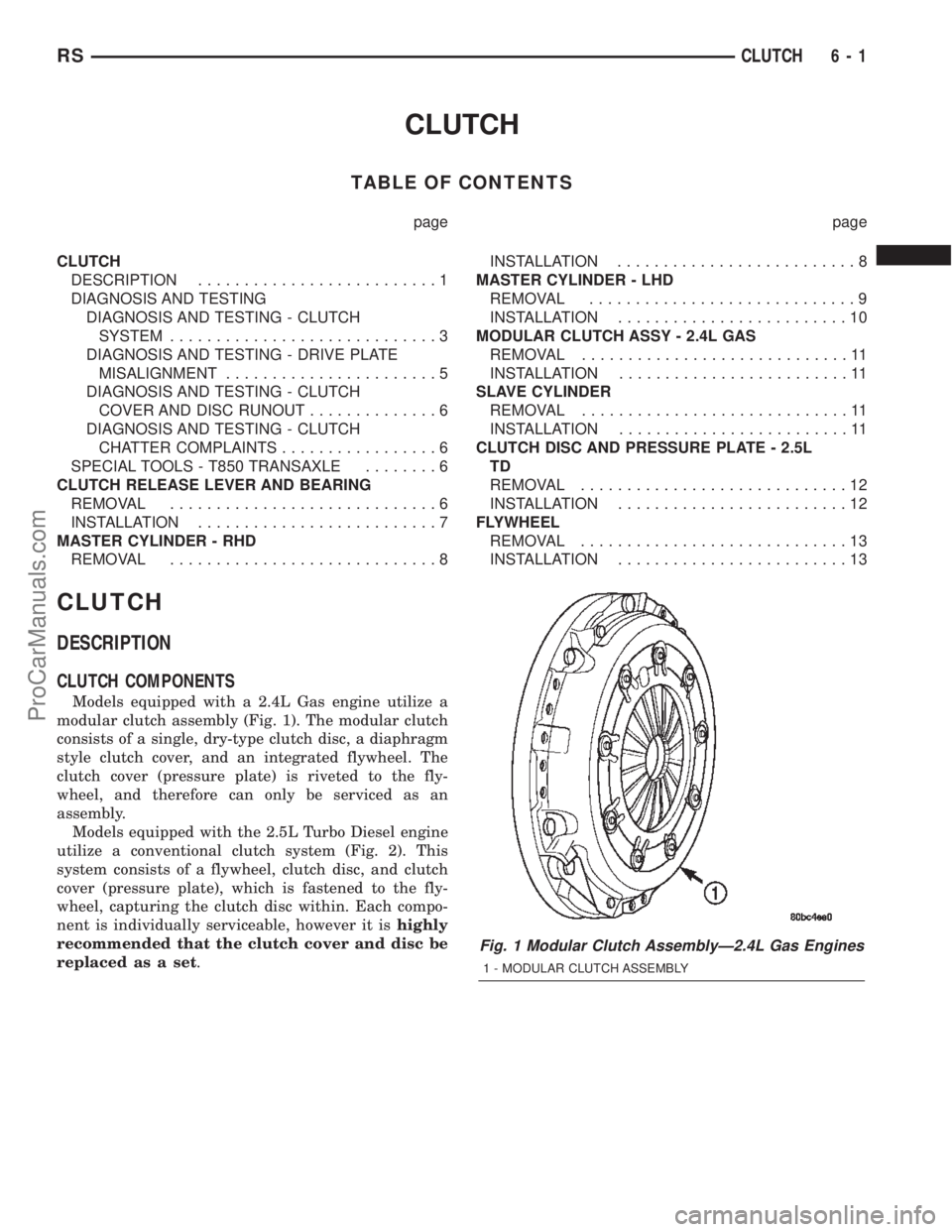

Models equipped with a 2.4L Gas engine utilize a

modular clutch assembly (Fig. 1). The modular clutch

consists of a single, dry-type clutch disc, a diaphragm

style clutch cover, and an integrated flywheel. The

clutch cover (pressure plate) is riveted to the fly-

wheel, and therefore can only be serviced as an

assembly.

Models equipped with the 2.5L Turbo Diesel engine

utilize a conventional clutch system (Fig. 2). This

system consists of a flywheel, clutch disc, and clutch

cover (pressure plate), which is fastened to the fly-

wheel, capturing the clutch disc within. Each compo-

nent is individually serviceable, however it ishighly

recommended that the clutch cover and disc be

replaced as a set.

Fig. 1 Modular Clutch AssemblyÐ2.4L Gas Engines

1 - MODULAR CLUTCH ASSEMBLY

RSCLUTCH6-1

ProCarManuals.com