oil CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1885 of 2399

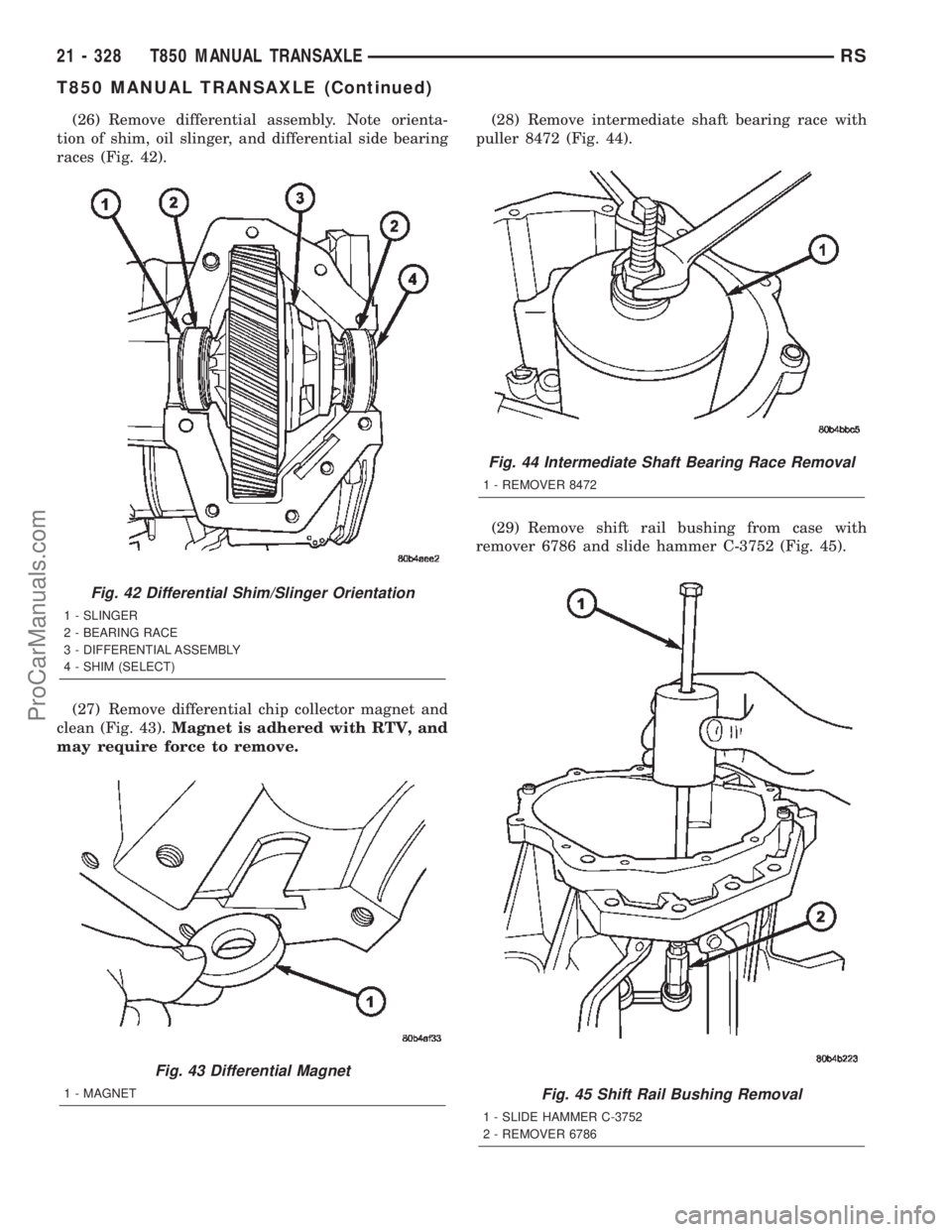

(26) Remove differential assembly. Note orienta-

tion of shim, oil slinger, and differential side bearing

races (Fig. 42).

(27) Remove differential chip collector magnet and

clean (Fig. 43).Magnet is adhered with RTV, and

may require force to remove.(28) Remove intermediate shaft bearing race with

puller 8472 (Fig. 44).

(29) Remove shift rail bushing from case with

remover 6786 and slide hammer C-3752 (Fig. 45).

Fig. 42 Differential Shim/Slinger Orientation

1 - SLINGER

2 - BEARING RACE

3 - DIFFERENTIAL ASSEMBLY

4 - SHIM (SELECT)

Fig. 43 Differential Magnet

1 - MAGNET

Fig. 44 Intermediate Shaft Bearing Race Removal

1 - REMOVER 8472

Fig. 45 Shift Rail Bushing Removal

1 - SLIDE HAMMER C-3752

2 - REMOVER 6786

21 - 328 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1890 of 2399

(14) Install input shaft sealed roller bearing using

installer 8482 (Fig. 58).

(15) Installnewinput shaft bearing snap ring

(Fig. 59).(16) Install shift rail bushing to end cover using

installer 8475 (Fig. 60).

(17) Applya1mm(0.04 in.) bead of MopartGas-

ket Maker to transaxle end cover and install to

transaxle case (Fig. 61).While installing end

cover, be sure to guide oil trough into pocket

(Fig. 62).Torque end cover-to-case bolts to 28 N´m

(250 in. lbs.) (Fig. 63).

Fig. 58 Install Input Shaft Sealed Roller Bearing

1 - INSTALLER 8482

2 - SEALED ROLLER BEARING

Fig. 59 Input Shaft Bearing Snap Ring

1 - SNAP RING

Fig. 60 Shift Rail Bushing Installation

1 - INSTALLER 8475

Fig. 61 End Cover Removal/Installation

1 - END COVER

2 - OIL TROUGH

RST850 MANUAL TRANSAXLE21 - 333

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1891 of 2399

(18) Install lifting bar 8489 to geartrain.

(19) Lift up on bar (input shaft side) and install

input shaft bearing snap ring (Fig. 64).

(20) Lift up on bar (intermediate shaft side) and

install intermediate shaft bearing snap ring.

(21) Remove lifting bar 8489.

(22) Install a bead of MopartGear Lube RTV to

end plate and immediately install to case. Install and

torque bolts to 28 N´m (250 in. lbs.) (Fig. 65).

Fig. 62 Oil Trough Pocket

1 - OIL TROUGH

2 - POCKET

Fig. 63 End Cover Bolts

1 - BOLT (12)

Fig. 64 Input Bearing Snap Ring

1 - SNAP RING PLIERS

2 - LIFTING BAR 8489

3 - SNAP RING

Fig. 65 End Cover Bolts

1 - BOLT (11)

21 - 334 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1900 of 2399

(19) Install battery thermal shield and clutch cable

eyelet (Fig. 91).(20) Connect battery cables.

(21) Check transaxle fluid and engine coolant lev-

els. Adjust if necessary. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/FLUID - STANDARD

PROCEDURE)

SPECIFICATIONS - T850 MANUAL TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle TypeConstant-mesh, fully synchronized 5-speed with integral

differential

Lubrication MethodSplash oil collected in case passage and oil trough and

distributed to mainshafts via gravity

Fluid Type ATF+4 (Automatic Transmission FluidÐType 9602)

GEAR RATIOS

GEAR RATIO (2.4L Gas) RATIO (2.5L TD)

1st 3.65 3.46

2nd 2.07 2.05

3rd 1.39 1.37

4th 1.03 0.97

5th 0.83 0.76

Reverse 3.47 3.47

Final Drive Ratio 3.77 3.53

Overall Top Gear 3.12 2.66

Fig. 91 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

RST850 MANUAL TRANSAXLE21 - 343

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1940 of 2399

(12) Remove 3rd gear (Fig. 214). (13) Inspect third gear thrust washer for signs of

excessive wear. To replace, drive off of input shaft

with suitable drift and hammer.

ASSEMBLY

NOTE: When servicing the input shaft assembly, all

snap rings MUST be replaced with new ones upon

assembly. 5th gear nut must also be replaced.

NOTE: When installing 3/4 synchronizer hub to

shaft, make sure to align oil slots on synchronizer

hub face with oil hole in the shaft splined hub jour-

nal.

NOTE: Refer to (Fig. 215) for input shaft assembly

reference.

Fig. 215 Input Shaft Assembly

1 - INPUT SHAFT 6 - 5TH GEAR NUT

2 - THRUST WASHER 7 - SNAP RING

3 - 3RD GEAR 8 - INPUT BEARING (SEALED)

4 - 4TH GEAR 9 - SNAP RING

5 - 5TH GEAR 10 - 3/4 SYNCHRONIZER

Fig. 214 3rd Gear Removal/Installation

1 - 3RD GEAR

RST850 MANUAL TRANSAXLE21 - 383

INPUT SHAFT (Continued)

ProCarManuals.com

Page 1941 of 2399

(1) Install input shaft into fixture 8487.

(2) Install thrust washer if removed upon disas-

sembly.

(3) Install 3rd gear (Fig. 216).

(4) Install 3rd gear blocker ring (Fig. 217).(5) Install 3/4 synchronizer (Fig. 218).When

installing 3/4 synchronizer hub to shaft, make

sure to align oil slots on synchronizer hub face

with oil hole in the shaft splined hub journal.

(6) InstallNEW3/4 synchronizer snap ring (Fig.

219).

Fig. 216 3rd Gear Removal/Installation

1 - 3RD GEAR

Fig. 217 3rd Gear Blocker Ring

1 - 3RD GEAR BLOCKER RING

Fig. 218 3/4 Synchro Assembly

1 - 3/4 SYNCHRONIZER

Fig. 219 3/4 Synchro Snap Ring

1 - SNAP RING

2 - 3/4 SYNCHRONIZER

21 - 384 T850 MANUAL TRANSAXLERS

INPUT SHAFT (Continued)

ProCarManuals.com

Page 1952 of 2399

ASSEMBLY

NOTE: Do not re-use snap rings when servicing the

intermediate shaft assembly. Discard snap rings

and install new ones provided with available snap

ring service kit.

NOTE: When installing 1/2 & 5/R synchronizers,

make sure to align oil slots on synchronizer hub

face with oil hold in the shaft splined hub journal.

NOTE: Refer to (Fig. 252) for intermediate shaft

assembly reference.

(1) Press intermediate shaft into NEW roller bear-

ing with arbor press (Fig. 253).

Fig. 252 Intermediate Shaft Assembly

1 - INTERMEDIATE SHAFT 10 - SNAP RING

2 - ROLLER BEARING 11 - SEALED ROLLER BEARING

3 - SNAP RING 12 - THRUST WASHER

4 - NEEDLE BEARING 13 - NEEDLE BEARING

5 - 1ST SPEED GEAR 14 - REVERSE GEAR

6 - SNAP RING 15 - SNAP RING

7 - 2ND SPEED GEAR 16 - 5/R SYNCHRO

8 - 3/4 CLUSTER GEAR 17 - 5TH SPEED GEAR

9 - SNAP RING 18 - 1/2 SYNCHRO

Fig. 253 Intermediate Shaft Bearing Installation

1 - ARBOR PRESS

2 - INTERMEDIATE SHAFT

3 - CAGED ROLLER BEARING

4 - BEARING SPLITTER

RST850 MANUAL TRANSAXLE21 - 395

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1954 of 2399

(6) Install intermediate shaft to synchro assembly

on fixture (Fig. 258).When installing 1/2 synchro-

nizer, make sure to align oil slots on synchro-

nizer hub face with oil hole in the shaft splined

hub journal.Line up friction cone and reactor ring

tabs to gear slots. Remove shaft assembly from fix-

ture.

(7) InstallNEW1/2 synchro snap ring (Fig. 259).

(8) Install 2nd gear blocker ring (Fig. 260).

Fig. 258 Install 1/2 Synchro to Intermediate Shaft

1 - INTERMEDIATE SHAFT

2 - 1ST GEAR

3 - 1/2 SYNCHRO ASSEMBLY

4 - FIXTURE 8483

Fig. 259 1/2 Synchro Snap Ring

1 - SNAP RING

2 - 1/2 SYNCHRO HUB

Fig. 260 2nd Gear Blocker Ring

1 - 2ND GEAR BLOCKER RING

RST850 MANUAL TRANSAXLE21 - 397

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1956 of 2399

(13) InstallNEW3/4 cluster gear snap ring (Fig.

265).

(14) Install 5th gear to intermediate shaft (Fig.

266).(15) Install 5th gear blocker ring to synchronizer

(Fig. 267).

(16) Install 5th gear synchronizer assembly to

intermediate shaft (Fig. 268).When installing 5/R

synchronizer, make sure to align oil slots on

synchronizer hub face with oil hole in the shaft

splined hub journal.

Fig. 265 3/4 Cluster Gear Snap Ring

1 - SNAP RING

Fig. 266 5th Gear Installation

1 - 5th GEAR

Fig. 267 5th Gear Blocker Ring to Synchro

1 - 5th GEAR BLOCKER RING

2 - 5/R SYNCHRONIZER

Fig. 268 Install 5/R Synchro and 5th Blocker Ring to

5th Gear

1 - 5/R SYNCHRONIZER

2 - 5TH GEAR BLOCKER RING

3 - 5TH GEAR

RST850 MANUAL TRANSAXLE21 - 399

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1969 of 2399

(3) Grasp the wheel cover at the edges in line with

the remaining installed wheel mounting nuts and

pull straight outward from the wheel. This will pop

the wheel cover retaining tabs over the two remain-

ing wheel nuts, removing the wheel cover from the

vehicle.

(4) Remove the two remaining wheel mounting

nuts from the hub's studs.

(5) Remove the wheel and tire from the hub.

INSTALLATION

INSTALLATION - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)

NOTE: Never use oil or grease on studs or wheel

mounting nuts.

(1) Position the tire and wheel assembly on the

wheel mounting studs using the hub pilot as a guide.

Place and hold the wheel flush up against the mount-

ing surface.

(2) Loosely install all 5 wheel mounting nuts.

Lightly snug the wheel nuts, then progressively

tighten them in the proper sequence (Fig. 13).

Tighten wheel mounting nuts to 135 N´m (100 ft.

lbs.).

(3) Lower the vehicle.

INSTALLATION - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL)

NOTE: Never use oil or grease on studs or wheel

mounting nuts.(1) Position the tire and wheel assembly on the

wheel mounting studs using the hub pilot as a guide.

Place and hold the wheel flush up against the mount-

ing surface.

NOTE: Wheel mounting nuts must be installed on

the studs as shown (Fig. 14) to allow proper instal-

lation of the wheel cover.

(2) Using the valve stem as an index placed at the

12 O'clock position, install andlightly tightentwo

wheel mounting nuts on the studs located at the 4

O'clock and 8 O'clock positions as shown (Fig. 14).

(3) Place the wheel cover on the wheel in the fol-

lowing fashion:

Fig. 12 NUTS SECURING WHEEL COVER

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 13 Tightening Sequence

Fig. 14 TWO WHEEL MOUNTING NUTS INSTALLED

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

22 - 8 TIRES/WHEELSRS

TIRES/WHEELS (Continued)

ProCarManuals.com