oil CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 2263 of 2399

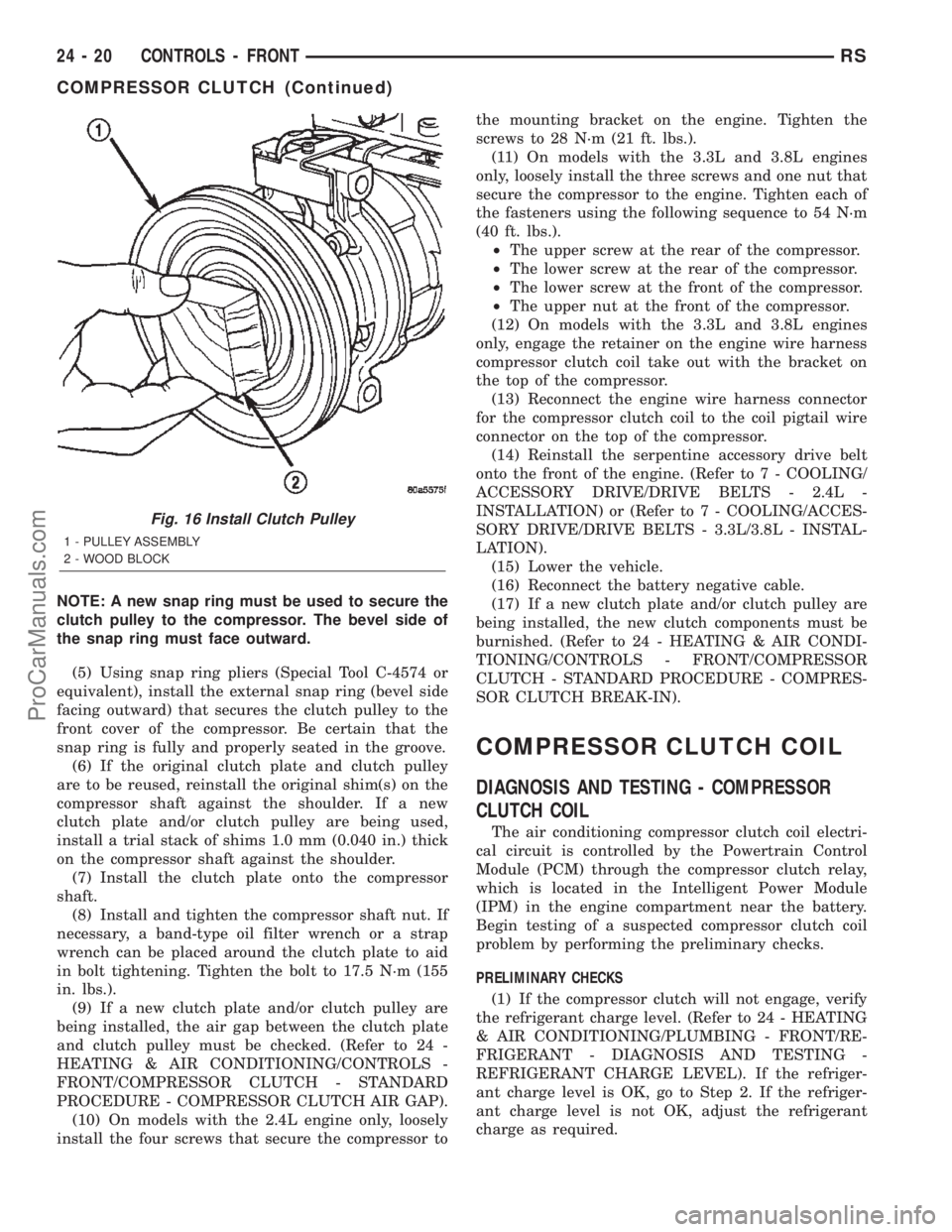

NOTE: A new snap ring must be used to secure the

clutch pulley to the compressor. The bevel side of

the snap ring must face outward.

(5) Using snap ring pliers (Special Tool C-4574 or

equivalent), install the external snap ring (bevel side

facing outward) that secures the clutch pulley to the

front cover of the compressor. Be certain that the

snap ring is fully and properly seated in the groove.

(6) If the original clutch plate and clutch pulley

are to be reused, reinstall the original shim(s) on the

compressor shaft against the shoulder. If a new

clutch plate and/or clutch pulley are being used,

install a trial stack of shims 1.0 mm (0.040 in.) thick

on the compressor shaft against the shoulder.

(7) Install the clutch plate onto the compressor

shaft.

(8) Install and tighten the compressor shaft nut. If

necessary, a band-type oil filter wrench or a strap

wrench can be placed around the clutch plate to aid

in bolt tightening. Tighten the bolt to 17.5 N´m (155

in. lbs.).

(9) If a new clutch plate and/or clutch pulley are

being installed, the air gap between the clutch plate

and clutch pulley must be checked. (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS -

FRONT/COMPRESSOR CLUTCH - STANDARD

PROCEDURE - COMPRESSOR CLUTCH AIR GAP).

(10) On models with the 2.4L engine only, loosely

install the four screws that secure the compressor tothe mounting bracket on the engine. Tighten the

screws to 28 N´m (21 ft. lbs.).

(11) On models with the 3.3L and 3.8L engines

only, loosely install the three screws and one nut that

secure the compressor to the engine. Tighten each of

the fasteners using the following sequence to 54 N´m

(40 ft. lbs.).

²The upper screw at the rear of the compressor.

²The lower screw at the rear of the compressor.

²The lower screw at the front of the compressor.

²The upper nut at the front of the compressor.

(12) On models with the 3.3L and 3.8L engines

only, engage the retainer on the engine wire harness

compressor clutch coil take out with the bracket on

the top of the compressor.

(13) Reconnect the engine wire harness connector

for the compressor clutch coil to the coil pigtail wire

connector on the top of the compressor.

(14) Reinstall the serpentine accessory drive belt

onto the front of the engine. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - 2.4L -

INSTALLATION) or (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - 3.3L/3.8L - INSTAL-

LATION).

(15) Lower the vehicle.

(16) Reconnect the battery negative cable.

(17) If a new clutch plate and/or clutch pulley are

being installed, the new clutch components must be

burnished. (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - FRONT/COMPRESSOR

CLUTCH - STANDARD PROCEDURE - COMPRES-

SOR CLUTCH BREAK-IN).

COMPRESSOR CLUTCH COIL

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL

The air conditioning compressor clutch coil electri-

cal circuit is controlled by the Powertrain Control

Module (PCM) through the compressor clutch relay,

which is located in the Intelligent Power Module

(IPM) in the engine compartment near the battery.

Begin testing of a suspected compressor clutch coil

problem by performing the preliminary checks.

PRELIMINARY CHECKS

(1) If the compressor clutch will not engage, verify

the refrigerant charge level. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - FRONT/RE-

FRIGERANT - DIAGNOSIS AND TESTING -

REFRIGERANT CHARGE LEVEL). If the refriger-

ant charge level is OK, go to Step 2. If the refriger-

ant charge level is not OK, adjust the refrigerant

charge as required.

Fig. 16 Install Clutch Pulley

1 - PULLEY ASSEMBLY

2 - WOOD BLOCK

24 - 20 CONTROLS - FRONTRS

COMPRESSOR CLUTCH (Continued)

ProCarManuals.com

Page 2264 of 2399

(2) If the a/c compressor clutch still will not

engage, disconnect the headlamp and dash wire har-

ness connector for the A/C pressure transducer and

check for battery current at the connector with the

engine running and the heater-A/C control set to the

A/C mode. If OK, go to TESTS . If not OK, use a

DRBIIItscan tool to perform further diagnosis. Refer

to the appropriate diagnostic information.

TESTS

(1) Verify the battery state of charge. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY -

DIAGNOSIS AND TESTING).

(2) Connect an ammeter (0 to 10 ampere scale

selected) in series with the clutch coil feed terminal.

Connect a voltmeter (0 to 20 volt scale selected) to

measure voltage across the battery and the clutch

coil.

(3) With the heater-A/C control in the A/C mode

and the blower at low speed, start the engine and

allow it to run at a normal idle speed.

(4) The compressor clutch should engage immedi-

ately, and the clutch coil voltage should be within

two volts of the battery voltage. If the coil voltage is

not within two volts of battery voltage, test the

clutch coil feed circuit for excessive voltage drop. If

the compressor clutch does not engage, use a

DRBIIItscan tool to perform further diagnosis. Refer

to the appropriate diagnostic information.

(5) With the ambient temperature at 21É C (70É F),

the compressor clutch coil is acceptable if the current

draw is 2.0 to 3.7 amperes at 11.5 to 12.5 volts at the

clutch coil. If the voltage is more than 12.5 volts, add

electrical loads by turning on electrical accessories

until the voltage reads below 12.5 volts.

(a) If the compressor clutch coil current reading

is zero, the coil is open and must be replaced.

(b) If the compressor clutch coil current reading

is four amperes or more, the coil is shorted and

must be replaced.

COMPRESSOR CLUTCH RELAY

DESCRIPTION

The compressor clutch relay (Fig. 17) is a Interna-

tional Standards Organization (ISO) micro-relay.

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The ISO

micro-relay terminal functions are the same as a con-

ventional ISO relay. However, the ISO micro-relay

terminal pattern (or footprint) is different, the cur-

rent capacity is lower, and the physical dimensions

are smaller than those of the conventional ISO relay.

The compressor clutch relay is located in the Intelli-gent Power Module (IPM), which is in the engine

compartment near the battery. See the fuse and relay

layout map molded into the inner surface of the IPM

cover for compressor clutch relay identification and

location.

The black, molded plastic case is the most visible

component of the compressor clutch relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal.

OPERATION

The compressor clutch relay is an electromechani-

cal switch that uses a low current input from the

Powertrain Control Module (PCM) to control the high

current output to the compressor clutch electromag-

netic coil. The movable common feed contact point is

held against the fixed normally closed contact point

by spring pressure. When the relay coil is energized,

an electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. The resistor or diode is connected in

parallel with the relay coil in the relay, and helps to

dissipate voltage spikes and electromagnetic interfer-

ence that can be generated as the electromagnetic

field of the relay coil collapses.

The compressor clutch relay terminals are con-

nected to the vehicle electrical system through a

receptacle in the Intelligent Power Module (IPM).

The inputs and outputs of the compressor clutch

relay include:

²The common feed terminal (30) receives a bat-

tery current input from a fuse in the IPM through a

fused B(+) circuit at all times.

²The coil ground terminal (85) receives a ground

input from the PCM through the compressor clutch

relay control circuit only when the PCM electroni-

cally pulls the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the PCM through a fused ignition

switch output (run-start) circuit only when the igni-

tion switch is in the On or Start positions.

²The normally open terminal (87) provides a bat-

tery current output to the compressor clutch coil

through the compressor clutch relay output circuit

only when the compressor clutch relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

RSCONTROLS - FRONT24-21

COMPRESSOR CLUTCH COIL (Continued)

ProCarManuals.com

Page 2265 of 2399

a battery current output only when the compressor

clutch relay coil is de-energized.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH RELAY

The compressor clutch relay (Fig. 17) is located in

the Intelligent Power Module (IPM), which is in the

engine compartment near the battery. See the fuse

and relay layout map molded into the inner surface

of the IPM cover for compressor clutch relay identifi-

cation and location. Remove the relay from the IPM

to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, use a DRBIIItscan tool to perform

further diagnosis of the relay circuits. Refer to the

appropriate diagnostic information. If not OK,

replace the faulty relay.

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Intelli-

gent Power Module (IPM).

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for compressor

clutch relay identification and location.

(4) Remove the compressor clutch relay from the

IPM by pulling it straight up.

INSTALLATION

(1) See the fuse and relay layout map molded into

the inner surface of the Intelligent Power Module

(IPM) cover for compressor clutch relay identification

and location.

(2) Position the compressor clutch relay to the

proper receptacle in the IPM.

(3) Align the compressor clutch relay terminals

with the terminal cavities in the IPM relay recepta-

cle.

(4) Push down firmly on the compressor clutch

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install and latch the cover onto the IPM.

(6) Reconnect the battery negative cable.

EVAPORATOR TEMPERATURE

SENSOR

DESCRIPTION

The evaporator temperature sensor is a switch that

is installed on the top of the expansion valve in the

right rear corner of the engine compartment (Fig.

18). The sensor has a small probe that is inserted in

a small well in the body of the expansion valve that

is filled with a special silicone-based thermal grease.

A small molded plastic push-in retainer secures the

sensor to a threaded hole in the top surface of the

expansion valve. Two terminals within a molded

plastic connector receptacle on the sensor connect it

to the vehicle electrical system through a take out

and connector of the HVAC wire harness.

Fig. 17 Compressor Clutch Relay

24 - 22 CONTROLS - FRONTRS

COMPRESSOR CLUTCH RELAY (Continued)

ProCarManuals.com

Page 2275 of 2399

quarter inner panel. Tighten the screw to 11 N´m (97

in. lbs.).

(7) Install and tighten the screw that secures the

back of the rear heater-A/C unit housing to the right

D-pillar. Tighten the screw to 11 N´m (97 in. lbs.).

(8) Install and tighten the two screws that secure

the top of the quarter trim panel attaching bracket to

the quarter inner panel. Tighten the screws to 1.7

N´m (15 in. lbs.).

(9) Reinstall the right quarter trim panel and

right D-pillar trim panel onto the quarter inner

panel. (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - INSTALLATION).

(10) Reconnect the battery negative cable.

(11) Perform the heater-A/C control calibration

procedure. (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - FRONT/A/C-HEATER CON-

TROL - STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION).

BLOWER MOTOR RELAY

DESCRIPTION

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

The blower motor relay (Fig. 5) is a International

Standards Organization (ISO) mini-relay. Relays con-

forming to the ISO specifications have common phys-

ical dimensions, current capacities, terminalpatterns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The blower

motor relay is located in the Intelligent Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout map

molded into the inner surface of the IPM cover for

compressor clutch relay identification and location.

The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The factory-installed blower motor relay cannot be

adjusted or repaired. If the relay is damaged or

faulty, it must be replaced.

OPERATION

The blower motor relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control the high current

output to the blower motor resistor (manual heater-

A/C control) or blower power module (automatic heat-

er-A/C control). The movable common feed contact

point is held against the fixed normally closed con-

tact point by spring pressure. When the relay coil is

energized, an electromagnetic field is produced by the

coil windings. This electromagnetic field draws the

movable relay contact point away from the fixed nor-

mally closed contact point, and holds it against the

fixed normally open contact point. When the relay

coil is de-energized, spring pressure returns the mov-

able contact point back against the fixed normally

closed contact point. The resistor or diode is con-

nected in parallel with the relay coil in the relay, and

helps to dissipate voltage spikes and electromagnetic

interference that can be generated as the electromag-

netic field of the relay coil collapses.

Fig. 5 Blower Motor Relay

24 - 32 CONTROLS - REARRS

BLEND DOOR ACTUATOR (Continued)

ProCarManuals.com

Page 2276 of 2399

The blower motor relay terminals are connected to

the vehicle electrical system through a receptacle in

the Intelligent Power Module (IPM). The inputs and

outputs of the compressor clutch relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(automatic heater-A/C control) through a fuse in the

IPM on the fused rear blower motor relay output cir-

cuit only when the blower motor relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the blower motor

relay coil is de-energized.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RELAY

The rear blower motor relay (Fig. 6) is located in

the Intelligent Power Module (IPM), which is in the

engine compartment near the battery. See the fuse

and relay layout map molded into the inner surface

of the IPM cover for rear blower motor relay identi-

fication and location. Remove the relay from the IPM

to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, use a DRBIIItscan tool to perform

further diagnosis of the relay circuits. Refer to the

appropriate diagnostic information. If not OK,

replace the faulty relay.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Intelli-

gent Power Module (IPM) (Fig. 7).

Fig. 6 Blower Motor Relay

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL GROUND

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 7 Intelligent Power Module

1 - BATTERY THERMAL GUARD

2 - INTELLIGENT POWER MODULE

3 - FRONT CONTROL MODULE

RSCONTROLS - REAR24-33

BLOWER MOTOR RELAY (Continued)

ProCarManuals.com

Page 2277 of 2399

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for rear blower

motor relay identification and location.

(4) Remove the rear blower motor relay from the

IPM.

INSTALLATION

(1) See the fuse and relay layout map molded into

the inner surface of the Intelligent Power Module

(IPM) cover for rear blower motor relay identification

and location.

(2) Position the rear blower motor relay to the

proper receptacle in the IPM.

(3) Align the rear blower motor relay terminals

with the terminal cavities in the IPM relay recepta-

cle.

(4) Push down firmly on the rear blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install and latch the cover onto the IPM.

(6) Reconnect the battery negative cable.

BLOWER MOTOR RESISTOR

DESCRIPTION

A blower motor resistor is used on this model when

it is equipped with the manual heater-A/C control

(Fig. 8). Models equipped with the optional Auto-

matic Temperature Control (ATC) use a blower power

module, instead of the blower motor resistor. The

blower motor resistor is installed in a mounting hole

on the back of the rear heater-A/C unit housing,

directly above the expansion valve. The resistor con-

sists of a molded plastic mounting plate with an inte-

gral connector receptacle. Concealed behind the

mounting plate within the rear heater-A/C unit hous-

ing are two coiled resistor wires contained within a

protective stamped steel cage. The resistor mounting

plate is secured with two screws to the rear heater-

A/C unit housing and is accessed for service by

removing the right quarter and D-pillar trim panels.

The blower motor resistor wires will get hot when

in use. Do not touch the resistor wires or the protec-

tive cage if the blower motor has been running. The

blower motor resistor cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The blower motor resistor is connected to the vehi-

cle electrical system through a dedicated take out

and connector of the rear HVAC wire harness. The

blower motor resistor has two resistor wires, each of

which will reduce the current flow through the

blower motor to change the blower motor speed. The

blower motor switch in the manual heater-A/C con-trol directs the ground path for the blower motor

through the correct resistor wire to obtain the

selected speed. With the blower motor switch in the

lowest speed position, the ground path for the motor

is applied through both resistor wires. Each higher

speed selected with the blower motor switch applies

the blower motor ground path through fewer of the

resistor wires, increasing the blower motor speed.

When the blower motor switch is in the highest

speed position, the blower motor resistor wires are

bypassed and the blower motor receives a direct path

to ground through the blower motor switch. The

blower motor resistor may be diagnosed using con-

ventional diagnostic tools and methods.

Fig. 8 Blower Motor Resistor

1 - REAR HEATER-A/C UNIT HOUSING

2 - D-PILLAR

3 - BLOWER PIGTAIL WIRE

4 - CONNECTOR

5 - EXPANSION VALVE

6 - SCREW (2)

7 - BLOWER MOTOR RESISTOR

24 - 34 CONTROLS - REARRS

BLOWER MOTOR RELAY (Continued)

ProCarManuals.com

Page 2300 of 2399

(8) Install and tighten the two screws that secure

the bottom of the quarter trim panel attaching

bracket to the rear heater-A/C unit housing. Tighten

the screws to 1.7 N´m (15 in. lbs.).

(9) Install and tighten the two screws that secure

the top of the quarter trim panel attaching bracket to

the quarter inner panel.

(10) Reconnect the body wire harness connector for

the rear heater-A/C unit housing to the rear HVAC

wire harness connector located near the expansion

valve at the back of the unit.

(11) Reinstall the auxiliary A/C distribution duct

onto the rear heater-A/C unit and the rear roof duct.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION - REAR/AUXILIARY A/C DISTRI-

BUTION DUCT - INSTALLATION).

(12) Reinstall the right quarter trim panel and

right D-pillar trim panel onto the quarter inner

panel. (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - INSTALLATION).

(13) Raise and support the vehicle.(14) Install and tighten the three nuts that secure

the rear heater-A/C unit mounting studs to the rear

floor panel behind the right rear wheel housing.

Tighten the nuts to 9 N´m (80 in. lbs.).

(15) Remove the tape or plugs from the underbody

liquid line and suction line fittings and both ports in

the rear heater-A/C unit evaporator extension line

sealing plate that extends through the rear floor

panel behind the right rear wheel housing.

(16) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the liquid line and

suction line fittings.

(17) Reconnect the underbody refrigerant line seal-

ing plate to the evaporator extension line sealing

plate.

(18) Install and tighten the screw that secures the

underbody refrigerant line sealing plate to the evap-

orator extension line sealing plate. Tighten the screw

to 23 N´m (17 ft. lbs.).

(19) Lower the vehicle.

(20) Reconnect the battery negative cable.

Fig. 8 Rear Heater-A/C Housing

1 - U-NUT (3)

2 - REAR HEATER-A/C HOUSING

3 - SCREW (3)

4 - EXPANSION VALVE5 - STUD (3)

6 - HEATER LINES

7 - NUT (5)

8 - STUD (2)

RSDISTRIBUTION - REAR24-57

REAR HEATER-A/C HOUSING (Continued)

ProCarManuals.com

Page 2302 of 2399

PLUMBING - FRONT

TABLE OF CONTENTS

page page

PLUMBING - FRONT

WARNING

WARNING...........................60

WARNING...........................60

WARNING - A/C PLUMBING.............60

CAUTION - A/C PLUMBING...............61

COMPRESSOR

DESCRIPTION.........................62

OPERATION...........................62

DIAGNOSIS AND TESTING - COMPRESSOR

NOISE DIAGNOSIS....................62

REMOVAL

REMOVAL - COMPRESSOR.............63

REMOVAL - COMPRESSOR MOUNTING

BRACKET - 2.4L ENGINE...............64

INSTALLATION

INSTALLATION - COMPRESSOR..........64

INSTALLATION - COMPRESSOR

MOUNTING BRACKET - 2.4L ENGINE......65

CONDENSER

DESCRIPTION.........................65

OPERATION...........................65

REMOVAL.............................65

INSTALLATION.........................66

DISCHARGE LINE

REMOVAL.............................67

INSTALLATION.........................68

EVAPORATOR

DESCRIPTION.........................68

OPERATION...........................68

REMOVAL.............................69

INSTALLATION.........................70

EXPANSION VALVE

DESCRIPTION.........................71

OPERATION...........................71

DIAGNOSIS AND TESTING - EXPANSION

VALVE ..............................71

REMOVAL.............................72

INSTALLATION.........................73

HEATER CORE

DESCRIPTION.........................73

OPERATION...........................73

REMOVAL

REMOVAL- HEATER CORE EXTENSION

TUBES.............................74

REMOVAL - HEATER CORE.............75

INSTALLATION

INSTALLATION- HEATER CORE

EXTENSION TUBES...................76

INSTALLATION - HEATER CORE..........77HEATER HOSE

REMOVAL.............................78

INSTALLATION.........................79

HEATER HOSES - DIESEL SUPPLEMENTAL

HEATER - BUX

REMOVAL.............................80

INSTALLATION.........................80

HEATER PIPES - DIESEL SUPPLEMENTAL

HEATER - BUX

REMOVAL.............................80

INSTALLATION.........................82

LIQUID LINE

REMOVAL.............................82

INSTALLATION.........................84

RECEIVER/DRIER

DESCRIPTION.........................85

OPERATION...........................85

REMOVAL.............................85

INSTALLATION.........................86

REFRIGERANT

DESCRIPTION.........................87

OPERATION...........................87

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM CHARGE LEVEL...............87

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM LEAKS......................88

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM CHARGE LEVEL 2.5L DIESEL.....89

STANDARD PROCEDURE

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT..........90

STANDARD PROCEDURE - REFRIGERANT

SYSTEM CHARGE.....................91

STANDARD PROCEDURE - REFRIGERANT

SYSTEM EVACUATE...................92

STANDARD PROCEDURE - REFRIGERANT

RECOVERY..........................93

REFRIGERANT OIL

DESCRIPTION.........................93

OPERATION...........................93

STANDARD PROCEDURE - REFRIGERANT

OIL LEVEL...........................93

SUCTION LINE

REMOVAL.............................94

INSTALLATION.........................95

SERVICE PORTS

REMOVAL.............................95

INSTALLATION.........................96

RSPLUMBING - FRONT24-59

ProCarManuals.com

Page 2303 of 2399

PLUMBING - FRONT

WARNING

WARNING

WARNING: DO NOT OPERATE DCHA IN AN

ENCLOSED AREA SUCH AS A GARAGE THAT

DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA'S EXHAUST WHEN

OPERATING THE DCHA. FAILURE TO FOLLOW

THESE INSTRUCTION MAY RESULT IN PERSONAL

INJURY OR DEATH.

ALLOW THE DCHA ASSEMBLY TO COOL BEFORE

PERFORMING A COMPONENT INSPECTION/RE-

PAIR/REPLACEMENT. FAILURE TO FOLLOW THESE

INSTRUCTIONS MY RESULT IN PERSONAL INJURY.

VERIFY THAT ALL DCHA FUEL LINES ARE

SECURELY FASTENED TO THEIR RESPECTIVE

COMPONENTS BEFORE THIS PROCEDURE.

WARNING

WARNING:: THE ENGINE COOLING SYSTEM IS

DESIGNED TO DEVELOP INTERNAL PRESSURES

OF 97 TO 123 KILOPASCALS (14 TO 18 POUNDS

PER SQUARE INCH). DO NOT REMOVE OR

LOOSEN THE COOLANT PRESSURE CAP, CYLIN-

DER BLOCK DRAIN PLUGS, RADIATOR DRAIN,

RADIATOR HOSES, HEATER HOSES, OR HOSE

CLAMPS WHILE THE SYSTEM IS HOT AND UNDER

PRESSURE. FAILURE TO OBSERVE THIS WARNING

CAN RESULT IN SERIOUS BURNS FROM THE

HEATED ENGINE COOLANT. ALLOW THE VEHICLE

TO COOL FOR A MINIMUM OF 15 MINUTES

BEFORE OPENING THE COOLING SYSTEM FOR

SERVICE.

WARNING: THE ENGINE COOLING SYSTEM CON-

TAINS ANTIFREEZE. ANTIFREEZE IS AN ETHYLENE

GLYCOL BASED COOLANT AND IS HARMFUL IF

SWALLOWED OR IF THE VAPORS ARE INHALED. IF

SWALLOWED, DRINK TWO GLASSES OF WATER

AND INDUCE VOMITING. IF VAPORS ARE INHALED,

MOVE TO AN AREA FOR FRESH AIR. SEEK MEDI-

CAL ATTENTION IMMEDIATELY. DO NOT STORE IN

OPEN OR UNMARKED CONTAINERS. WASH SKIN

AND CLOTHING THOROUGHLY AFTER COMING IN

CONTACT WITH ETHYLENE GLYCOL. KEEP OUT

OF REACH OF CHILDREN.

WARNING: DISPOSE OF ETHYLENE GLYCOL

BASED COOLANT PROPERLY. CONTACT YOURDEALER OR A LOCAL GOVERNMENT AGENCY FOR

THE LOCATION OF AN APPROVED ETHYLENE GLY-

COL COLLECTION AND/OR RECYCLING CENTER IN

YOUR AREA.

WARNING - A/C PLUMBING

WARNING:: THE AIR CONDITIONING SYSTEM CON-

TAINS REFRIGERANT UNDER HIGH PRESSURE.

SEVERE PERSONAL INJURY MAY RESULT FROM

IMPROPER SERVICE PROCEDURES. REPAIRS

SHOULD ONLY BE PERFORMED BY QUALIFIED

SERVICE PERSONNEL.

WARNING: AVOID BREATHING THE REFRIGERANT

AND REFRIGERANT OIL VAPOR OR MIST. EXPO-

SURE MAY IRRITATE THE EYES, NOSE, AND/OR

THROAT. WEAR EYE PROTECTION WHEN SERVIC-

ING THE AIR CONDITIONING REFRIGERANT SYS-

TEM. SERIOUS EYE INJURY CAN RESULT FROM

DIRECT CONTACT WITH THE REFRIGERANT. IF

EYE CONTACT OCCURS, SEEK MEDICAL ATTEN-

TION IMMEDIATELY.

WARNING: DO NOT EXPOSE THE REFRIGERANT

TO OPEN FLAME. POISONOUS GAS IS CREATED

WHEN REFRIGERANT IS BURNED. AN ELEC-

TRONIC LEAK DETECTOR IS RECOMMENDED.

WARNING: IF ACCIDENTAL SYSTEM DISCHARGE

OCCURS, VENTILATE THE WORK AREA BEFORE

RESUMING SERVICE. LARGE AMOUNTS OF

REFRIGERANT RELEASED IN A CLOSED WORK

AREA WILL DISPLACE THE OXYGEN AND CAUSE

SUFFOCATION.

WARNING: THE EVAPORATION RATE OF R-134a

REFRIGERANT AT AVERAGE TEMPERATURE AND

ALTITUDE IS EXTREMELY HIGH. AS A RESULT,

ANYTHING THAT COMES IN CONTACT WITH THE

REFRIGERANT WILL FREEZE. ALWAYS PROTECT

THE SKIN OR DELICATE OBJECTS FROM DIRECT

CONTACT WITH THE REFRIGERANT.

WARNING: THE R-134a SERVICE EQUIPMENT OR

THE VEHICLE REFRIGERANT SYSTEM SHOULD

NOT BE PRESSURE TESTED OR LEAK TESTED

WITH COMPRESSED AIR. SOME MIXTURES OF AIR

AND R-134a HAVE BEEN SHOWN TO BE COMBUS-

TIBLE AT ELEVATED PRESSURES. THESE MIX-

TURES ARE POTENTIALLY DANGEROUS, AND MAY

RESULT IN FIRE OR EXPLOSION CAUSING INJURY

OR PROPERTY DAMAGE.

24 - 60 PLUMBING - FRONTRS

ProCarManuals.com

Page 2304 of 2399

CAUTION - A/C PLUMBING

CAUTION:: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with the service equipment being used.

CAUTION: Never add R-12 to a refrigerant system

designed to use R-134a. Damage to the system will

result.

CAUTION: R-12 refrigerant oil must not be mixed

with R-134a refrigerant oil. They are not compatible.

CAUTION: Do not use R-12 equipment or parts on

the R-134a system. Damage to the system will

result. All parts, tools, and equipment must be

designed for R-134a refrigerant.

CAUTION: Do not discharge refrigerant into the

atmosphere. Use an R-134a refrigerant recovery/re-

cycling device that meets SAE Standard J2210.

CAUTION: The refrigerant must be recovered com-

pletely from the system before opening any fitting

or connection. Open the fittings with caution, even

after the system has been discharged. If any pres-

sure is noticed as a fitting is loosened, tighten the

fitting and recover the refrigerant from the system

again.

CAUTION: The refrigerant system must always be

evacuated before charging.

CAUTION: Do not overcharge the refrigerant sys-

tem. This will cause excessive compressor head

pressure and can cause noise and system failure.

CAUTION: Do not open the refrigerant system or

remove the sealing caps from a replacement com-

ponent until it is to be installed. This will prevent

contamination in the system.

CAUTION: Before disconnecting a component,

clean the outside of the fittings thoroughly to pre-

vent contamination from entering the refrigerant

system.

CAUTION: When it is necessary to open the refrig-

erant system, have everything needed to service

the system ready. Immediately after disconnecting acomponent from the refrigerant system, seal the

open fittings with a cap or plug to prevent the

entrance of dirt and moisture. The refrigerant sys-

tem should not be left open to the atmosphere any

longer than necessary.

CAUTION: Before connecting an open refrigerant

fitting, always install a new seal or gasket. All fit-

tings with O-rings need to be coated with refriger-

ant oil before installation. Use only O-rings that are

the correct size and approved for use with R-134a

refrigerant. Failure to do so may result in a leak.

Coat the fitting and seal with clean refrigerant oil

before connecting. Unified plumbing connections

with gaskets cannot be serviced with O-rings. The

gaskets are not reusable and new gaskets do not

require lubrication before installing.

CAUTION: When installing a refrigerant line, avoid

sharp bends that may restrict refrigerant flow. A

good rule for the flexible hose refrigerant lines is to

keep the radius of all bends at least ten times the

diameter of the hose. Sharp bends will reduce the

flow of refrigerant.

CAUTION: Position the refrigerant lines away from

exhaust system components or any sharp edges,

which may damage the line. The flexible hose lines

should be routed so they are at least 80 millimeters

(3 inches) from the exhaust manifold. Inspect all

flexible refrigerant system hose lines at least once

a year to make sure they are in good condition and

properly routed.

CAUTION: High pressures are produced in the

refrigerant system when it is operating. Extreme

care must be exercised to make sure that all refrig-

erant system connections are pressure tight.

CAUTION: Tighten refrigerant fittings only to the

specified torque. The aluminum fittings used in the

refrigerant system will not tolerate overtightening.

CAUTION: When disconnecting a refrigerant fitting,

use a wrench on both halves of the fitting. This will

prevent twisting of the refrigerant lines or tubes.

CAUTION: Refrigerant oil will absorb moisture from

the atmosphere if left uncapped. Do not open a

container of refrigerant oil until you are ready to

use it. Replace the cap on the oil container immedi-

ately after using. Store refrigerant oil only in a

clean, airtight, and moisture-free container.

RSPLUMBING - FRONT24-61

PLUMBING - FRONT (Continued)

ProCarManuals.com