engine CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1375 of 2399

VM.1056 BALANCE SHAFT LOCKING PIN

VM.1059 OIL PRESSURE RELIEF VALVE INSTALLER

VM.1060 OIL JET REMOVER /INSTALLER

VM.1061 FRONT OIL SEAL INSTALLER

VM.1062 POWER STEERING PUMP INSTALLER

VM.1063 FUEL INJECTOR REMOVER

9a - 14 ENGINERG

ENGINE 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 1376 of 2399

VM.1064 POWER STEERING PUMP GEAR

REMOVER

VM.1065 PISTON RING COMPRESSOR

VM.1066 CYLINDER HEAD COVER ALIGNMENT

PINS

VM.1068 90 DEGREES AFTER TDC ALIGNMENT PIN

VM.1069 CRANKSHAFT REM/INSTALL SLEEVE

VM.1070 FLYWHEEL LOCKING TOOL

RGENGINE9a-15

ENGINE 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 1377 of 2399

VM.1072 COMPRESSION TESTER ADAPTER

VM.1073 CRANKSHAFT FRONT BEARING

REMOVER/INSTALLER

VM.1074 TIMING BELT RETAINER

VM.1075 FLYWHEEL ALIGNMENT PINS

VM.1077 POWER STEERING BELT REMOVER

VM.1078 POWER STEERING BELT INSTALLER

9a - 16 ENGINERG

ENGINE 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 1378 of 2399

CYLINDER HEAD

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVE SERVICE

This procedure is done with the engine cylinder

head removed from the block.

DISASSEMBLY

(1) Remove the engine cylinder head from the cyl-

inder block. Refer to cylinder head removal and

installation in this section.

(2) Use Valve Spring Compressor Tool and com-

press each valve spring.

(3) Remove the valve locks, retainers, and springs.

(4) Use an Arkansas smooth stone or a jewelers

file to remove any burrs on the top of the valve stem,

especially around the groove for the locks.

(5) Remove the valves, and place them in a rack in

the same order as removed.

VALVE CLEANING

(1) Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

(2) Clean all grime and gasket material from the

engine cylinder head machined gasket surface.

INSPECTION

(1) Inspect for cracks in the combustion chambers

and valve ports.

(2) Inspect for cracks on the exhaust seat.

(3) Inspect for cracks in the gasket surface at each

coolant passage.

(4) Inspect valves for burned, cracked or warped

heads.

(5) Inspect for scuffed or bent valve stems.

(6) Replace valves displaying any damage.

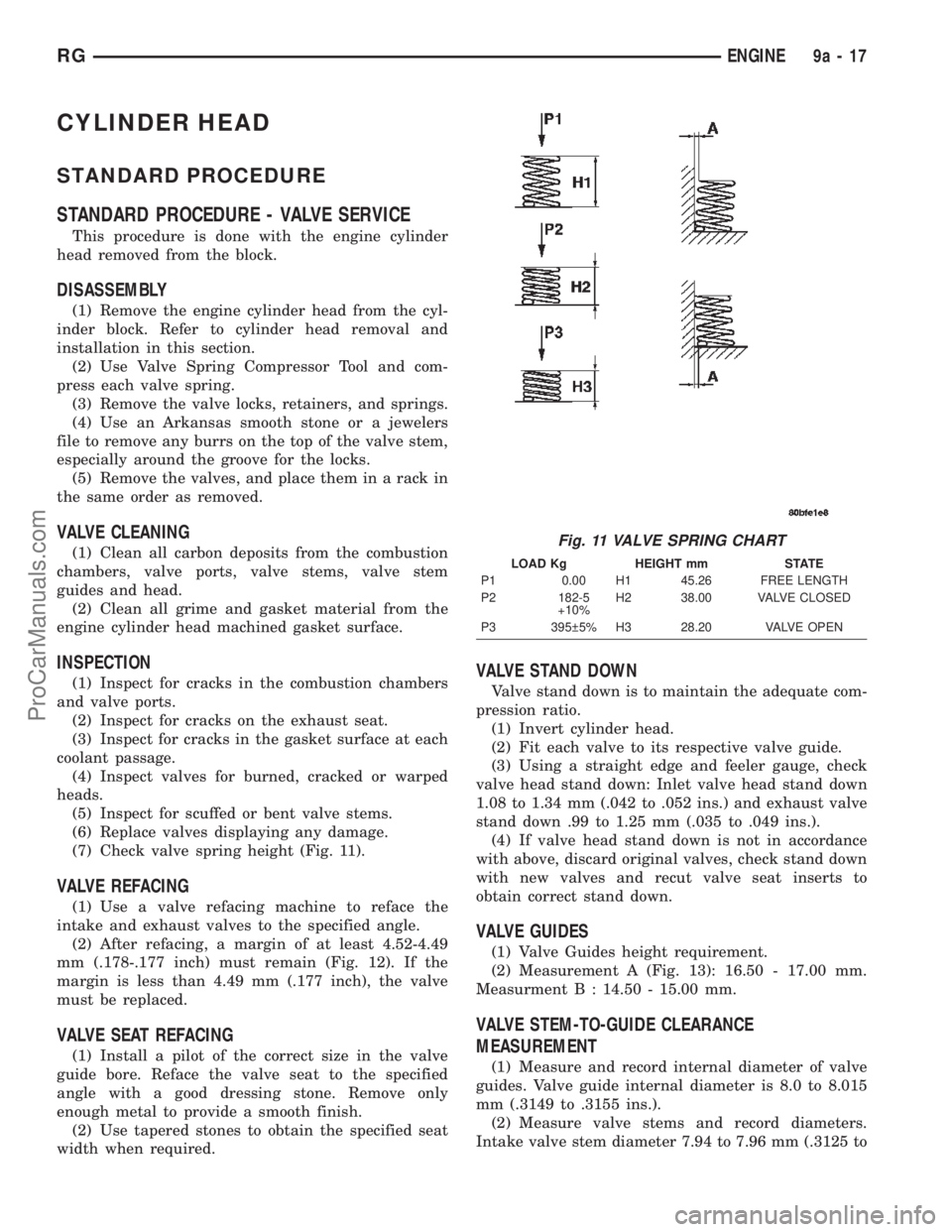

(7) Check valve spring height (Fig. 11).

VALVE REFACING

(1) Use a valve refacing machine to reface the

intake and exhaust valves to the specified angle.

(2) After refacing, a margin of at least 4.52-4.49

mm (.178-.177 inch) must remain (Fig. 12). If the

margin is less than 4.49 mm (.177 inch), the valve

must be replaced.

VALVE SEAT REFACING

(1) Install a pilot of the correct size in the valve

guide bore. Reface the valve seat to the specified

angle with a good dressing stone. Remove only

enough metal to provide a smooth finish.

(2) Use tapered stones to obtain the specified seat

width when required.

VALVE STAND DOWN

Valve stand down is to maintain the adequate com-

pression ratio.

(1) Invert cylinder head.

(2) Fit each valve to its respective valve guide.

(3) Using a straight edge and feeler gauge, check

valve head stand down: Inlet valve head stand down

1.08 to 1.34 mm (.042 to .052 ins.) and exhaust valve

stand down .99 to 1.25 mm (.035 to .049 ins.).

(4) If valve head stand down is not in accordance

with above, discard original valves, check stand down

with new valves and recut valve seat inserts to

obtain correct stand down.

VALVE GUIDES

(1) Valve Guides height requirement.

(2) Measurement A (Fig. 13): 16.50 - 17.00 mm.

Measurment B : 14.50 - 15.00 mm.

VALVE STEM-TO-GUIDE CLEARANCE

MEASUREMENT

(1) Measure and record internal diameter of valve

guides. Valve guide internal diameter is 8.0 to 8.015

mm (.3149 to .3155 ins.).

(2) Measure valve stems and record diameters.

Intake valve stem diameter 7.94 to 7.96 mm (.3125 to

Fig. 11 VALVE SPRING CHART

LOAD Kg HEIGHT mm STATE

P1 0.00 H1 45.26 FREE LENGTH

P2 182-5

+10%H2 38.00 VALVE CLOSED

P3 395 5% H3 28.20 VALVE OPEN

RGENGINE9a-17

ProCarManuals.com

Page 1379 of 2399

.3133 in). Exhaust valve stem diameter 7.92 to 7.94

mm (.3118 to .31215 in).

(3) Subtract diameter of valve stem from internal

diameter of its respective valve guide to obtain valve

stem clearance in valve guide. Clearance of inlet

valve stem in valve guide is .040 to .075 mm (.0015

to .0029 in). Clearance of exhaust valve stem in valve

guide is .060 to .093 mm (.0023 to .0036 in).

(4) If valve stem clearance in valve guide exceeds

tolerances, new valve guides must be installed.

STANDARD PROCEDURE - MEASURING

PISTON PROTRUSION

(1) Use special tool VM.1010 with dial indicator

special tool VM.1013 (Fig. 14).

(2) Bring the piston of cylinder no. 1 exactly to top

dead center.

(3) Zero the dial indicator on the cylinder block

mating surface.

(4) Setup the dial indicator on the piston crown

(above the center of the piston pin) 5mm (1/8 in.)

from the edge of the piston and note the measure-

ment.

(5) Repeat the procedure with the rest of the cyl-

inders.

(6) Establish the thickness of the steel gasket by

averaging the four piston potrusion readings.Fig. 12 VALVE SPECS.

MEASUREMENT INTAKE EXHAUST

A 7.940-7.960 7.922-7.940

B 8.00-8.015 8.000-8.015

C 1.08-1.34 0.990-1.250

+0.07

D 2.2 0.08 2.09

20.09

E 1.80-2.20 1.65-2.05

F 2.73-3.44 2.45-3.02

G 41.962-41.985 35.964-35.987

H 42.070-42.086 36.050-36.066

I 7.14-7.19 7.00-7.05

L 3.11-3.26 3.10-3.25

Fig. 13 VALVE GUIDE HEIGHT

9a - 18 ENGINERG

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1380 of 2399

Measure Dimension

(mm)0.49-0.60

Cylinder Head Gasket

Thickness (mm)1.32

No Holes or Notches

Piston Clearance (mm) 0.72-0.83

Measure Dimension

(mm)0.61-0.70

Cylinder Head Gasket

Thickness (mm)1.42

1 Hole or Notch

Piston Clearance (mm) 0.72-0.84

Measure Dimension

(mm)0.71-0.83

Cylinder Head Gasket

Thickness (mm)1.52

2 Holes or Notches

Piston Clearance (mm) 0.68-0.81

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(3) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(4) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).(8) Support engine and remove right engine mount

(Refer to 9 - ENGINE/ENGINE MOUNTING/RIGHT

MOUNT - REMOVAL).

CAUTION: Before removing the cylinder head cover/

intake manifold or timing belt the engine must put

at 90É after TDC. Failure to do so could result in

valve and/or piston damage during reassembly.

(Refer to 9 - ENGINE/VALVE TIMING - STANDARD

PROCEDURE)

(9) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(10) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(11) Remove timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(12) Remove cylinder head cover/intake manifold

(Fig. 15)(Refer to 9 - ENGINE/CYLINDER HEAD/

CYLINDER HEAD COVER(S) - REMOVAL).

Fig. 14 MEASURING PISTON PROTRUSION

Fig. 15 CYLINDER HEAD COVER/INTAKE

MANIFOLD ASSEMBLY

1 - CYLINDER HEAD COVER/INTAKE MANIFOLD BOLTS(LONG)

2 - CYLINDER HEAD COVER/INTAKE MANIFOLD

3 - CYLINDER HEAD

4 - CYLINDER HEAD COVER/INTAKE MANIFOLD GASKET

5 - CYLINDER HEAD COVER/INTAKE MANIFOLD

BOLTS(SHORT)

RGENGINE9a-19

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1381 of 2399

(13) Remove rocker arm and lifter assemblies from

cylinder head.

(14) Remove cylinder head cover/intake manifold

gasket from cylinder head.

(15) Disconnect glow plug and engine coolant tem-

perture electrical connectors.

(16) Remove coolant recovery pressure container

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESS CONTAINER - REMOVAL).

(17) Remove thermostat housing to upper radiator

hose pipe (Fig. 16).

(18) Remove turbocharger outlet to charge air

cooler pipe (Fig. 16).(19) Remove exhaust manifold heat shield (Fig.

17).

(20) Remove exhaust manifold retaining nuts (Fig.

17).

(21) Slide exhaust manifold and turbocharger off of

exhaust manifold studs (Fig. 17).

(22) Remove cylinder head bolts.

Fig. 16 TURBOCHARGER AND COOLANT PIPES

1 - TURBOCHARGER OUTLET PIPE RETAINING BOLT

2 - TURBOCHARGER OUTLET PIPE

3 - ADAPTER HOSE

4 - HEAT SHIELD

5 - HOSE CLAMPS

6 - TURBOCHARGER INLET PIPE RETAINING BOLT

7 - TURBOCHARGER INLET PIPE

8 - ADAPTER HOSE

9 - HOSE CLAMPS

10 - CLAMP

11 - EGR VALVE TO INTAKE AIR INLET PIPE

12 - CLAMP

13 - THERMOSTAT HOUSING TO UPPER RADIATOR HOSE

PIPE

Fig. 17 EXHAUST MANIFOLD AND

TURBOCHARGER

1 - TURBOCHARGER OIL SUPPLY BANJO BOLT

2 - COPPER WASHER

3 - EXHAUST MANIFOLD GASKET

4 - COPPER WASHER

5 - EXHAUST MANIFOLD HEAT SHIELD RETAINING BOLT

6 - TURBOCHARGER

7 - ENGINE LIFT HOOK

8 - ENGINE LIFT HOOK RETAINING BOLT

9 - SPACER

10 - EXHAUST MANIFOLD RETAINING NUT

11 - TURBOCHARGER OIL RETURN HOSE

12 - HOSE CLAMPS

13 - EXHAUST MANIFOLD STUDS

9a - 20 ENGINERG

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1382 of 2399

(23) Remove cylinder head assembly from engine

block (Fig. 18).

CLEANING

Thoroughly clean the engine cylinder head and cyl-

inder block mating surfaces. Clean the intake and

exhaust manifold and engine cylinder head mating

surfaces. Remove all gasket material and carbon.

Check to ensure that no coolant or foreign material

has fallen into the tappet bore area.

Remove the carbon deposits from the combustion

chambers and top of the pistons.

INSPECTION

Use a straightedge and feeler gauge to check the

flatness of the engine cylinder head and block mating

surfaces.

The minimum cylinder head thickness is 89.95mm

(3.541 in.).

INSTALLATION

CAUTION: Piston protrusion must be measured to

determine cylinder head gasket thickness if one or

more cylinder liners have been replaced (Refer to 9

- ENGINE/CYLINDER HEAD - STANDARD PROCE-

DURE).

NOTE: If cylinder liner(s) have not been removed,

the same thickness head gasket that was removed

can be used.

(1) Clean and inspect gasket mating surfaces.

(2) Position correct head gasket on engine block.

(3) Place cylinder head on engine block (Fig. 18).

CAUTION: New cylinder head bolts must be used.

(4) Tighten cylinder head bolts following procedure

below.

Cylinder Head Bolt Torquing Procedure

(1) Lubricate cylinder head bolts with engine oil.

(2) Torque bolts to 30N´m in numerical starting

with bolt #1 (Fig. 19).

(3) Tighten all bolts an additional 75É, starting

with bolt #4 then 5-6-7-8-9-10-1-2-3 (Fig. 19).

(4) Tighten all bolts an additional 50É in numerical

order starting with bolt #11 then 12-13-14-15-16-

17-18 (Fig. 19).

(5) Without loosening any bolts tighten all bolts an

additional 75É in the following seguence: 4-5-6-7-8-9-

10-1-2-3-11-12-13-14-15-16-17-18.

Fig. 18 CYLINDER HEAD ASSEMBLY

1 - VALVE SPRING

2 - CYLINDER HEAD BOLT

3 - GLOW PLUG

4 - COOLANT TEMPERATURE SENSOR

5 - CYLINDER HEAD ALIGNMENT DOWEL

6 - CYLINDER BLOCK

7 - CYLINDER LINER

8 - ENGINE BLOCK DECK

9 - CYLINDER HEAD GASKET

10 - CYLINDER HEAD

11 - ROCKER ARM AND LIFTER ASSEMBLY

Fig. 19 CYLINDER HEAD TORQUE SEQUENCE

RGENGINE9a-21

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1383 of 2399

(5) Slide exhaust manifold and turbocharger on

exhaust manifold studs (Fig. 17).

(6) Install exhaust manifold retaining nuts. Torque

nuts to 32.4N´m.

(7) Install exhaust manifold heat shield (Fig. 17).

Torque bolts to 27.5N´m.

(8) Install turbocharger outlet to charge air cooler

pipe (Fig. 16).

(9) Install thermostat housing to upper radiator

hose pipe (Fig. 16). Install retaining bolt and torque

to 47.1N´m.

(10) Install coolant recovery pressure container

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESS CONTAINER - INSTALLATION).

(11) Connect glow plug and coolant temperature

sensor electrical connectors.

(12) Install new cylinder head cover/intake mani-

fold gasket.

(13) Install rocker arm and lifter assemblies.Be

sure to put rocker arm and lifter assemblies in

same location as removed.

(14) Install cylinder head cover/intake manifold

(Fig. 15)(Refer to 9 - ENGINE/CYLINDER HEAD/

CYLINDER HEAD COVER(S) - INSTALLATION).

(15) Install timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(16) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(17) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(18)Remove crankshaft and both camshaft

locking pins at this time(Refer to 9 - ENGINE/

VALVE TIMING - STANDARD PROCEDURE).

(19) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(20) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(21) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(22) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(23) Install air cleaner housing assembly.

(24) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(25) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(26) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(27) Connect negative battery cable.CAMSHAFT(S)

DESCRIPTION

The camshafts are made of gray cast iron with

eight machined lobes and four bearing journals (Fig.

20).

OPERATION

When the camshaft rotates the lobes actuate the

hydraulic lifters and rocker arms, forcing downward

on the rocker arms which opens the valves.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(3) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(4) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(5) Remove air cleaner housing.

(6) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(8) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

(9) Support engine and remove right engine mount

(Refer to 9 - ENGINE/ENGINE MOUNTING/RIGHT

MOUNT - REMOVAL).

Fig. 20 CAMSHAFTS

1 - INTAKE CAMSHAFT

2 - EXHAUST CAMSHAFT

9a - 22 ENGINERG

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1384 of 2399

CAUTION: Before removing the cylinder head cover/

intake manifold or timing belt the engine must put

at 90É after TDC. Failure to do so could result in

valve and/or piston damage during reassembly.

(Refer to 9 - ENGINE/VALVE TIMING - STANDARD

PROCEDURE)

(10) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(11) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(12) Remove timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(13) Remove cylinder head cover/intake manifold

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(14) With cylinder head cover/intake manifold on

work bench, remove plugs at rear of cylinder head

cover/intake manifold.

(15) Remove camshaft oil seals (Fig. 21).

(16) Remove snapring and thrust washer from

camshaft (Fig. 21).

(17) Slide camshaft through access hole at rear of

cylinder head cover/intake manifold.

INSTALLATION

(1) Lubricate the camshafts with MopartEngine

Oil Supplement, or equivalent.

(2) Carefully install camshafts into access holes in

rear of cylinder head cover/intake manifold.

(3) Install thrust washer, snapring, and camshaft

oil seal (Fig. 21).

CHECKING CAMSHAFT ENDPLAY

(1) After camshafts are properly installed in cylin-

der head cover check end play of camshafts with a

dial indicator. The end play should be between .10

mm ± .30 mm.

NOTE: If the camshaft endplay is not within speci-

fication, measure thickness of the camshaft spacer.

Camshaft spacer thickness should be 2.8 .02mm.

(4) Install access hole plugs and gaskets at rear of

cylinder head cover/intake manifold. Torque plugs to

80N´m.

(5) Install cylinder head cover/intake manifold on

engine block (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

(6) Install timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).(7) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(8) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(9) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(10) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(11) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(12) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install air cleaner housing.

(14) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(15) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(16) Connect negative battery cable.

Fig. 21 CAMSHAFT ASSEMBLY

1 - INTAKE CAMSHAFT

2 - SNAPRING

3 - CAMSHAFT OIL SEAL

4 - THRUST WASHER

5 - CYLINDER HEAD COVER/INTAKE MANIFOLD

6 - EXHAUST CAMSHAFT

RGENGINE9a-23

CAMSHAFT(S) (Continued)

ProCarManuals.com