engine CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1415 of 2399

(9) Remove plug in cylinder head cover/intake

manifold and insert VM.1052 to lock intake camshaft

in position (Fig. 87).

(10) At this point the timing belt can be removed

for service.

(11) After engine service is completed and timing

belt reinstalled, remove both camshaft locking pins

from cylinder head cover/intake manifold.

(12) Install both camshaft access plugs.

(13) Remove 90É after TDC engine locking pin.

(14) Install starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - INSTALLA-

TION).

(15) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(16) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(17) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(18) Connect negative battery cable.BALANCE SHAFT

DESCRIPTION

The 2.5L Common Rail Diesel engine is equipped

with two nodular cast iron balance shafts in a cast

aluminum carrier. The balance shaft assembly is

mounted to the engine block (Fig. 88).

OPERATION

The balance shaft is driven by the crankshaft. The

balance shafts are connected by heelical gears. The

dual-counter rotating shafts decrease second order

vertical shaking forces caused by component move-

ment.

Fig. 87 INTAKE CAMSHAFT LOCKING PIN VM.1052

1 - TIMING BELT INNER COVER

2 - GLOW PLUG ELECTRICAL CONNECTOR

3 - CYLINDER HEAD COVER/INTAKE MANIFOLD

4 - FUEL RAIL

5 - INTAKE CAMSHAFT LOCKING PIN VM.1052

Fig. 88 BALANCE SHAFT ASSEMBLY

1 - BALANCE SHAFT

2 - OIL JET RETAINING BOLT

3 - OIL JET

4 - ENGINE BLOCK

5 - CRANKSHAFT

6 - BALANCE SHAFT RETAINING BOLTS

7 - OIL DIPSTICK TUBE RETAINER

8 - RUBBER BUSHING

9 - RETAINING BOLT

9a - 54 ENGINERG

VALVE TIMING (Continued)

ProCarManuals.com

Page 1416 of 2399

REMOVAL

(1) Disconnect negative battery cable.

(2) Raise vehicle on hoist.

(3) Remove oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

(4) Remove balance shaft assembly (Fig. 89).

INSTALLATION

(1)Before installation of the balance shaft assembly,

the # 1 cylinder must be brought to TDC. Using special

tool VM.1051, roll engine over by hand until tool can be

inserted into engine block locking flywheel from turning

(Fig. 90). Once the # 1 cylinder is brought to TDC, the

balance shaft assembly can be installed.

(2) With balance shaft assembly on work bench.

Insert special tool VM.1056 into balance shaft assem-bly (Fig. 91). This will ensure proper balance shaft

and crankshaft timing after assembly.

Fig. 89 BALANCE SHAFT ASSEMBLY

1 - BALANCE SHAFT

2 - OIL JET RETAINING BOLT

3 - OIL JET

4 - ENGINE BLOCK

5 - CRANKSHAFT

6 - BALANCE SHAFT RETAINING BOLTS

7 - OIL DIPSTICK TUBE RETAINER

8 - RUBBER BUSHING

9 - RETAINING BOLT

Fig. 90 TDC AND 90 DEGREES AFTER TDC

ALIGNMENT PIN LOCATION

1 - ENGINE BLOCK

2 - VM.1051 TDC PIN OR VM.1068 90 DEGREES ATDC PIN

3 - FLYWHEEL

Fig. 91 BALANCE SHAFT ALIGNMENT PIN VM.1056

1 - VM.1056

2 - BALANCE SHAFT ASSEMBLY

RGENGINE9a-55

BALANCE SHAFT (Continued)

ProCarManuals.com

Page 1417 of 2399

(3) Install balance shaft assembly and retaining

bolts (Fig. 89). Torque bolts to 32.4N´m.

(4) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(5) Refill engine oil to proper level.

(6) Connect negative battery cable.

TIMING BELT / CHAIN

COVER(S)

REMOVAL

REMOVAL - TIMING BELT OUTER COVER

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine mount

and bracket.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover retaining bolts

and remove cover (Fig. 92).

REMOVAL - TIMING BELT INNER COVER

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine mount

and bracket.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(9) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).(10) Remove timing belt idler pulleys (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT IDLER

PULLEY - REMOVAL).

(11) Using special tool VM.1055, remove camshaft

sprockets (Fig. 93).

(12) Remove timing belt tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TMNG BELT/CHAIN

TENSIONER&PULLEY - REMOVAL) .

(13) Remove injection pump sprocket (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(14) Remove timing belt inner cover retaining bolts

and remove cover (Fig. 94).

INSTALLATION

INSTALLATION - TIMING BELT OUTER COVER

(1) Install timing belt outer cover seal and cover

(Fig. 92). Torque 3mm bolts to 10.8N´m and 8mm

bolts to 10.8N´m.

(2) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

Fig. 92 TIMING BELT COVER (OUTER)

1 - SEAL

2 - TIMING BELT OUTER COVER

3 - RETAINING BOLTS

9a - 56 ENGINERG

BALANCE SHAFT (Continued)

ProCarManuals.com

Page 1418 of 2399

(3) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(4) Install power steering belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(5) Install right engine mount.

(6) Install air cleaner housing.

(7) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(8) Connect negative battery cable.

INSTALLATION - TIMING BELT INNER COVER

(1) Install timing belt inner cover to engine front

cover seal (Fig. 94).

(2) Install timing belt inner cover to cylinder head

cover gaskets (Fig. 94).

(3) Install timing belt inner cover and retaining

bolts (Fig. 94). Torque 10mm bolts to 47.1N´m and

8mm bolts to 10.8N´m.

(4) Install injection pump sprocket (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - INSTALLATION).

(5) Install camshaft sprockets (Fig. 93). Torque

bolts to 108N´m.(6) Install timing belt idler pulleys (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT IDLER

PULLEY - INSTALLATION).

(7) Install timing belt and tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION) .

(8) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

Fig. 93 CAMSHAFT SPROCKET REMOVAL/

INSTALLATION

1 - TIMING BELT INNER COVER

2 - CAMSHAFT SPROCKET

3 - IDLER PULLEYS

4 - CAMSHAFT SPROCKET

5 - VM.1055

Fig. 94 TIMING BELT COVER - INNER

1 - TIMING BELT COVER TO CYLINDER HEAD COVER GASKET

2 - TIMING BELT COVER TO FRONT ENGINE COVER SEAL

3 - RUBBER GROMMET

4 - BUSHING

5 - TIMING BELT COVER - INNER

6 - RETAINING BOLT

7 - RETAINING BOLT

8 - RETAINING BOLT

9 - BUSHING

10 - RUBBER GROMMET

RGENGINE9a-57

TIMING BELT / CHAIN COVER(S) (Continued)

ProCarManuals.com

Page 1419 of 2399

(9) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(10) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(11) Install power steering belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(12) Install right engine mount assembly.

(13) Install air cleaner housing.

(14) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(15) Connect negative battery cable.

TIMING BELT IDLER PULLEY

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine

mount.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(9) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

NOTE: Idler pulley retaining bolts are LHD thread.

(10) Remove timing belt idler pulleys (Fig. 95).

INSTALLATION

(1) Install timing belt idler pulleys (Fig. 95).

Torque bolts to 47.1N´m.

(2) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(3) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(4) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).(5) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(6) Install power steering belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(7) Install right engine mount.

(8) Install air cleaner housing.

(9) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(10) Connect negative battery cable.

Fig. 95 TIMING BELT AND SPROCKETS

1 -CAMSHAFT SPROCKETS

2 - INJECTION PUMP SPROCKET

3 - INJECTION PUMP SPROCKET RETAINING NUT

4 - TIMING BELT

5 - TIMING BELT TENSIONER RETAINING BOLT

6 - TIMING BELT TENSIONER

7 - TENSIONER ALIGNMENT PIN

8 - IDLER PULLEY

9 - CAMSHAFT SPROCKET RETAINING BOLT

9a - 58 ENGINERG

TIMING BELT / CHAIN COVER(S) (Continued)

ProCarManuals.com

Page 1420 of 2399

TMNG BELT/CHAIN

TENSIONER

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine

mount.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(9) Loosen and remove timing belt tensioner (Fig.

96).

INSTALLATION

(1) Install timing belt tensioner and retaining bolt

(Fig. 96).

(2) Adjust timing belt tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TMNG BELT/CHAIN

TENSIONER&PULLEY - ADJUSTMENTS) .

(3) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(4) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(5) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).(6) Install power steering belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(7) Install right engine mount.

(8) Install air cleaner housing.

(9) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(10) Connect negative battery cable.Fig. 96 TIMING BELT AND SPROCKETS

1 -CAMSHAFT SPROCKETS

2 - INJECTION PUMP SPROCKET

3 - INJECTION PUMP SPROCKET RETAINING NUT

4 - TIMING BELT

5 - TIMING BELT TENSIONER RETAINING BOLT

6 - TIMING BELT TENSIONER

7 - TENSIONER ALIGNMENT PIN

8 - IDLER PULLEY

9 - CAMSHAFT SPROCKET RETAINING BOLT

RGENGINE9a-59

ProCarManuals.com

Page 1421 of 2399

ADJUSTMENTS

ADJUSTMENT - TIMING BELT TENSIONER

(1) With timing belt outer cover removed and tim-

ing belt installed.

(2) Loosen timing belt tensioner (Fig. 97).

(3) Align timing belt tensioner spring stop with

tensioner as shown (Fig. 98) and torque timing belt

tensioner retaining bolt to 34.7N´m.

(4) Rotate engine 2 complete revolution and then

recheck tensioner alignment. Readjust tensioner

alignment as necessary.

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

CAUTION: Before removing the timing belt, the

engine must put at 90É after TDC. Failure to do so

could result in valve and/or piston damage during

reassembly. (Refer to 9 - ENGINE/VALVE TIMING -

STANDARD PROCEDURE)

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing assembly.

(4) Support engine and remove right engine

mount.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

Fig. 97 TIMING BELT TENSIONER ADJUSTMENT

1 - TIMING BELT IDLER PULLEY

2 - ENGINE FRONT COVER

3 - CRANKSHAFT HUB

4 - TIMING BELT TENSIONER

5 - TIMING BELT

Fig. 98 TIMING BELT TENSIONER ALIGNMENT

1 - TENSIONER SPRING STOP

2 - TIMING BELT TENSIONER

3 - TIMING BELT TENSIONER

4 - TIMING BELT

5 - TIMING BELT INNER COVER

9a - 60 ENGINERG

ProCarManuals.com

Page 1422 of 2399

(8) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(9) Loosen timing belt tensioner and remove tim-

ing belt (Fig. 99).

INSTALLATION

(1) With both camshaft alignment pins still

installed and the engine locked at 90É after TDC.

(2) Align timing mark on injection pump sprocket

with timing mark on timing belt (Fig. 100).(3) Install timing belt.

(4) Adjust the timing belt tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TMNG BELT/CHAIN

TENSIONER&PULLEY - ADJUSTMENTS) .

(5) Remove both camshaft alignment pins from cyl-

inder head cover/intake manifold and engine locking

pin from engine block (Refer to 9 - ENGINE/VALVE

TIMING - STANDARD PROCEDURE).

(6) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(7) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(8) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(9) Install power steering belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(10) Install right engine mount.

(11) Install air cleaner housing.

(12) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(13) Connect negative battery cable.

Fig. 99 TIMING BELT AND SPROCKETS

1 -CAMSHAFT SPROCKETS

2 - INJECTION PUMP SPROCKET

3 - INJECTION PUMP SPROCKET RETAINING NUT

4 - TIMING BELT

5 - TIMING BELT TENSIONER RETAINING BOLT

6 - TIMING BELT TENSIONER

7 - TENSIONER ALIGNMENT PIN

8 - IDLER PULLEY

9 - CAMSHAFT SPROCKET RETAINING BOLT

Fig. 100 INJECTION PUMP GEAR TIMING MARKS

1 - TIMING MARK ON COVER

2 - TIMING MARK ON INJECTION PUMP SPROCKET

3 - INJECTION PUMP SPROCKET

RGENGINE9a-61

TIMING BELT/CHAIN AND SPROCKETS (Continued)

ProCarManuals.com

Page 1424 of 2399

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EXCESSIVE

EXHAUST SYSTEM NOISE...............2

DIAGNOSIS AND TESTING - EXHAUST

SYSTEM RESTRICTION CHECK...........2

INSPECTION...........................3

ADJUSTMENTS.........................3

SPECIFICATIONS

TORQUE.............................3

SPECIAL TOOLS

EXHAUST SYSTEM.....................4

CATALYTIC CONVERTER

DESCRIPTION..........................4

OPERATION............................4REMOVAL.............................5

INSPECTION...........................6

INSTALLATION..........................6

CROSS-OVER PIPE - 3.3/3.8L

REMOVAL.............................6

INSTALLATION..........................6

HEAT SHIELDS

DESCRIPTION..........................6

OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................7

MUFFLER

REMOVAL.............................7

INSTALLATION..........................8

RESONATOR

REMOVAL.............................9

INSTALLATION..........................9

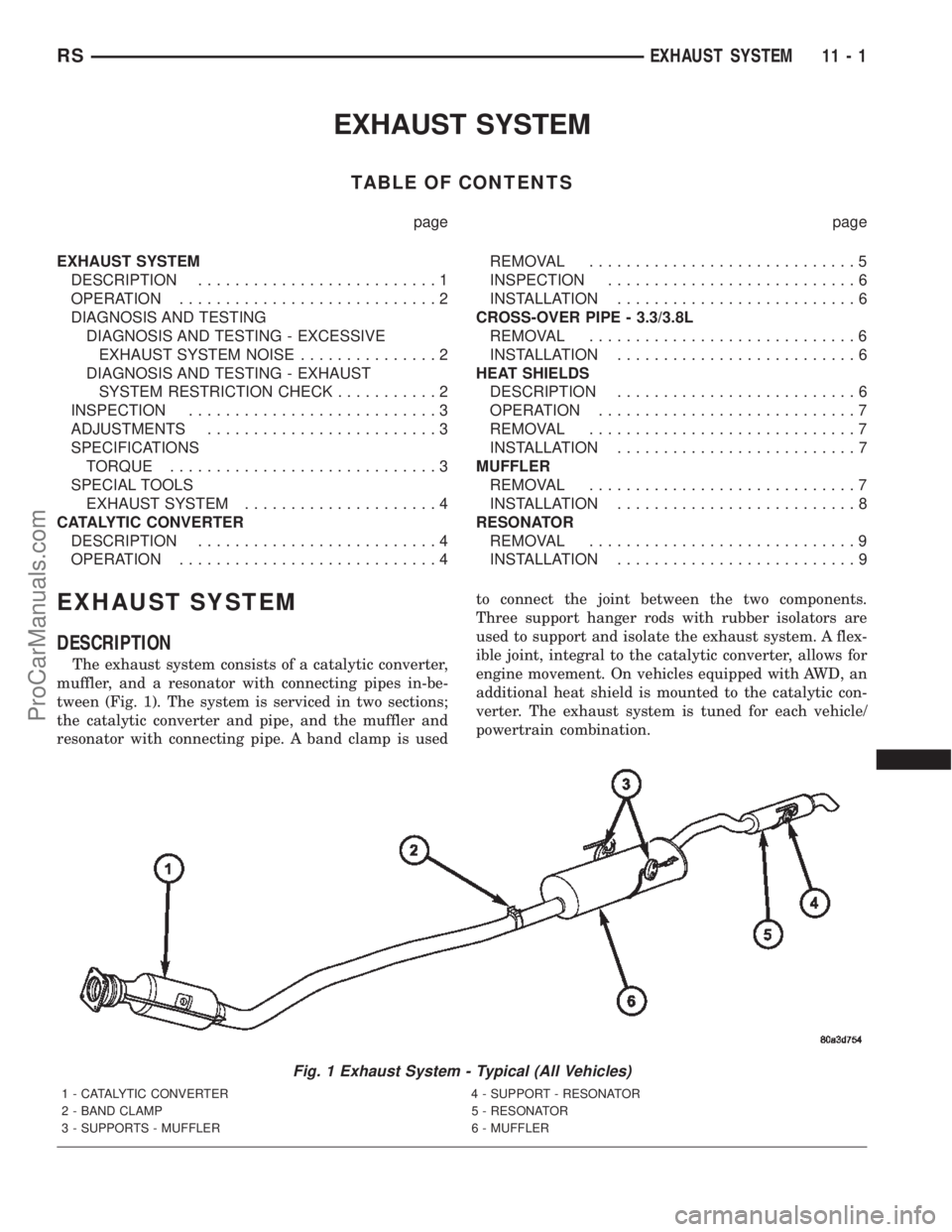

EXHAUST SYSTEM

DESCRIPTION

The exhaust system consists of a catalytic converter,

muffler, and a resonator with connecting pipes in-be-

tween (Fig. 1). The system is serviced in two sections;

the catalytic converter and pipe, and the muffler and

resonator with connecting pipe. A band clamp is usedto connect the joint between the two components.

Three support hanger rods with rubber isolators are

used to support and isolate the exhaust system. A flex-

ible joint, integral to the catalytic converter, allows for

engine movement. On vehicles equipped with AWD, an

additional heat shield is mounted to the catalytic con-

verter. The exhaust system is tuned for each vehicle/

powertrain combination.

Fig. 1 Exhaust System - Typical (All Vehicles)

1 - CATALYTIC CONVERTER 4 - SUPPORT - RESONATOR

2 - BAND CLAMP 5 - RESONATOR

3 - SUPPORTS - MUFFLER 6 - MUFFLER

RSEXHAUST SYSTEM11-1

ProCarManuals.com

Page 1425 of 2399

OPERATION

The exhaust system contains, quiets, and cleans

the exhaust gases generated by the engine.

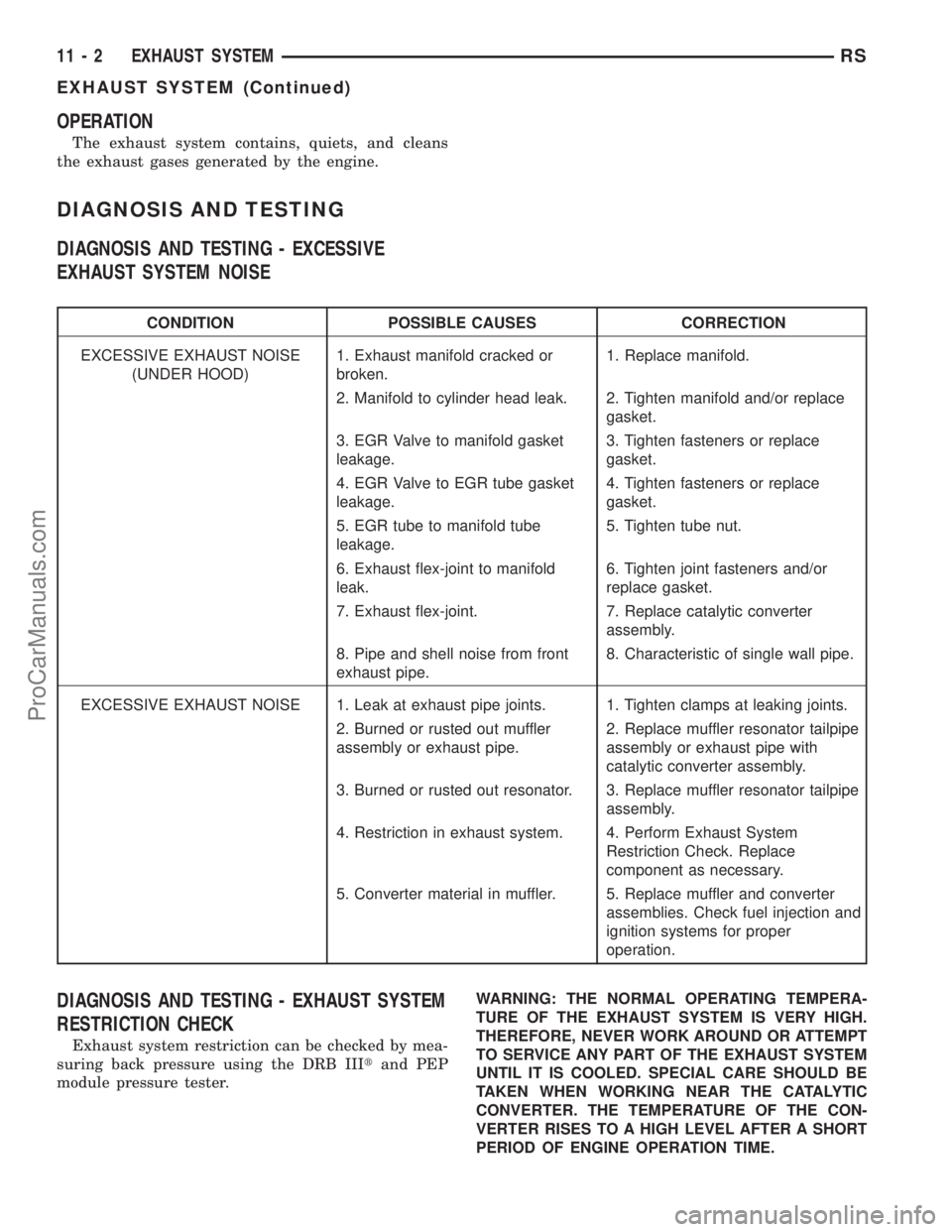

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EXCESSIVE

EXHAUST SYSTEM NOISE

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE EXHAUST NOISE

(UNDER HOOD)1. Exhaust manifold cracked or

broken.1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace

gasket.

3. EGR Valve to manifold gasket

leakage.3. Tighten fasteners or replace

gasket.

4. EGR Valve to EGR tube gasket

leakage.4. Tighten fasteners or replace

gasket.

5. EGR tube to manifold tube

leakage.5. Tighten tube nut.

6. Exhaust flex-joint to manifold

leak.6. Tighten joint fasteners and/or

replace gasket.

7. Exhaust flex-joint. 7. Replace catalytic converter

assembly.

8. Pipe and shell noise from front

exhaust pipe.8. Characteristic of single wall pipe.

EXCESSIVE EXHAUST NOISE 1. Leak at exhaust pipe joints. 1. Tighten clamps at leaking joints.

2. Burned or rusted out muffler

assembly or exhaust pipe.2. Replace muffler resonator tailpipe

assembly or exhaust pipe with

catalytic converter assembly.

3. Burned or rusted out resonator. 3. Replace muffler resonator tailpipe

assembly.

4. Restriction in exhaust system. 4. Perform Exhaust System

Restriction Check. Replace

component as necessary.

5. Converter material in muffler. 5. Replace muffler and converter

assemblies. Check fuel injection and

ignition systems for proper

operation.

DIAGNOSIS AND TESTING - EXHAUST SYSTEM

RESTRICTION CHECK

Exhaust system restriction can be checked by mea-

suring back pressure using the DRB IIItand PEP

module pressure tester.WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

11 - 2 EXHAUST SYSTEMRS

EXHAUST SYSTEM (Continued)

ProCarManuals.com