Shift cable CHRYSLER VOYAGER 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1660 of 2399

(4) Connect PRNDL cable to gear shift lever (Fig.

177). Adjust if necessary.

(5) Install knee bolster (Fig. 178).

(6) Install instrument panel lower silencer (Fig.

179).

(7) Install gear shift cable to transaxle upper

mount bracket (Fig. 180). An audible ªclickº should

be heard.

(8) Connect gear shift cable end to transaxle man-

ual valve lever (Fig. 180).(9) Adjust gearshift cable. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 31TH/GEAR

SHIFT CABLE - ADJUSTMENTS)

Fig. 177 PRNDL Cable

1 - PRNDL CABLE

2 - GEAR SHIFT LEVER

Fig. 178 Knee Bolster

1 - KNEE BOLSTER

Fig. 179 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 180 Gearshift Cable at Transaxle

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

RS31TH AUTOMATIC TRANSAXLE21 - 103

GEAR SHIFT CABLE (Continued)

ProCarManuals.com

Page 1661 of 2399

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT

Lift and rotate the gearshift hand lever into the

park (P) gate position and remove the ignition key.

This confirms the shift lever is in the gated park (P)

position.

After confirming the park gate position, turn the

ignition switch . If the starter will operate, the park

gate position is correct. Move the shift lever into the

neutral (N) position. If the starter will operate in this

position, the linkage is properly adjusted. If the

starter fails to operate in either position, linkage

adjustment is required.

(1) Park the vehicle on level ground and set the

parking brake.

(2) Place the gearshift lever in park (P) gate posi-

tion and remove key.

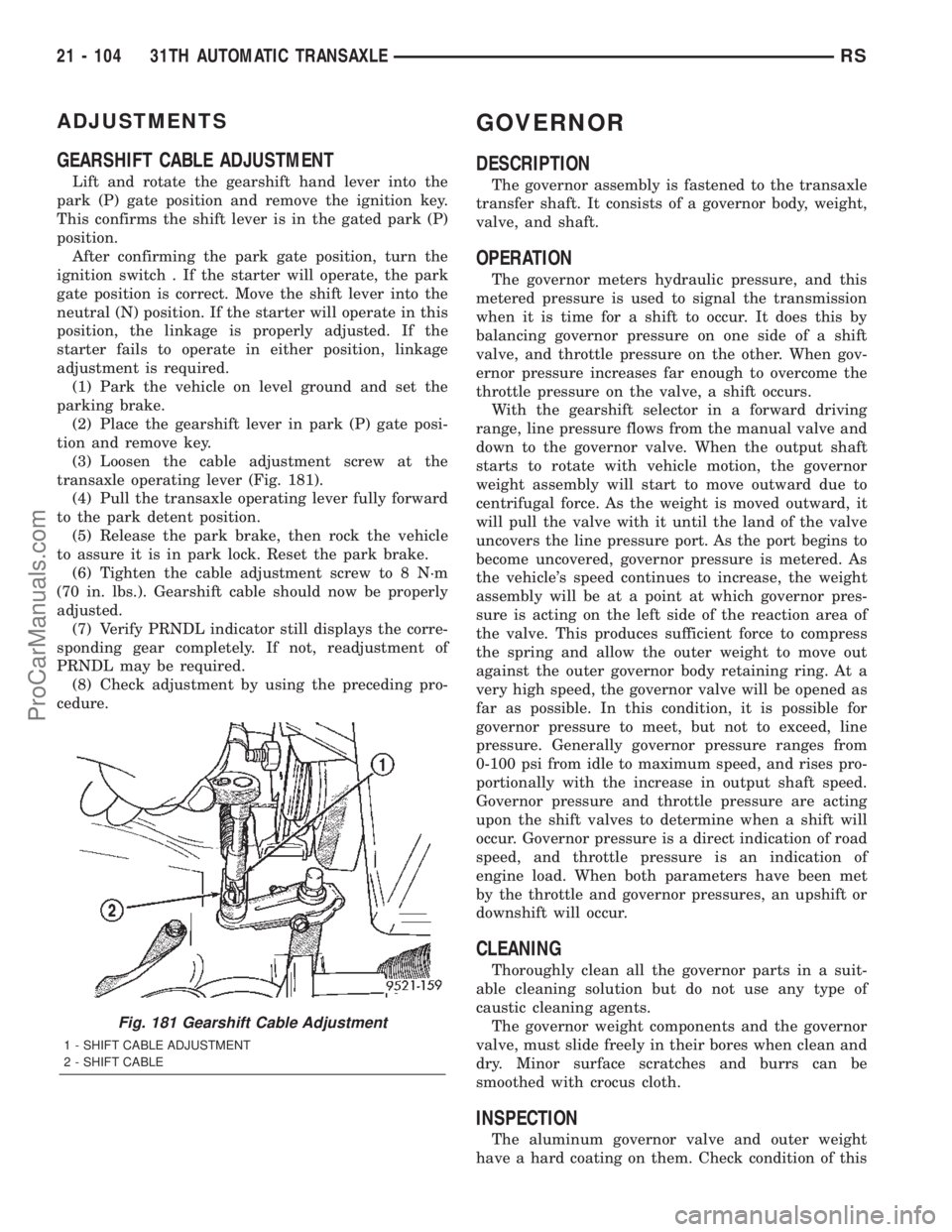

(3) Loosen the cable adjustment screw at the

transaxle operating lever (Fig. 181).

(4) Pull the transaxle operating lever fully forward

to the park detent position.

(5) Release the park brake, then rock the vehicle

to assure it is in park lock. Reset the park brake.

(6) Tighten the cable adjustment screw to 8 N´m

(70 in. lbs.). Gearshift cable should now be properly

adjusted.

(7) Verify PRNDL indicator still displays the corre-

sponding gear completely. If not, readjustment of

PRNDL may be required.

(8) Check adjustment by using the preceding pro-

cedure.

GOVERNOR

DESCRIPTION

The governor assembly is fastened to the transaxle

transfer shaft. It consists of a governor body, weight,

valve, and shaft.

OPERATION

The governor meters hydraulic pressure, and this

metered pressure is used to signal the transmission

when it is time for a shift to occur. It does this by

balancing governor pressure on one side of a shift

valve, and throttle pressure on the other. When gov-

ernor pressure increases far enough to overcome the

throttle pressure on the valve, a shift occurs.

With the gearshift selector in a forward driving

range, line pressure flows from the manual valve and

down to the governor valve. When the output shaft

starts to rotate with vehicle motion, the governor

weight assembly will start to move outward due to

centrifugal force. As the weight is moved outward, it

will pull the valve with it until the land of the valve

uncovers the line pressure port. As the port begins to

become uncovered, governor pressure is metered. As

the vehicle's speed continues to increase, the weight

assembly will be at a point at which governor pres-

sure is acting on the left side of the reaction area of

the valve. This produces sufficient force to compress

the spring and allow the outer weight to move out

against the outer governor body retaining ring. At a

very high speed, the governor valve will be opened as

far as possible. In this condition, it is possible for

governor pressure to meet, but not to exceed, line

pressure. Generally governor pressure ranges from

0-100 psi from idle to maximum speed, and rises pro-

portionally with the increase in output shaft speed.

Governor pressure and throttle pressure are acting

upon the shift valves to determine when a shift will

occur. Governor pressure is a direct indication of road

speed, and throttle pressure is an indication of

engine load. When both parameters have been met

by the throttle and governor pressures, an upshift or

downshift will occur.

CLEANING

Thoroughly clean all the governor parts in a suit-

able cleaning solution but do not use any type of

caustic cleaning agents.

The governor weight components and the governor

valve, must slide freely in their bores when clean and

dry. Minor surface scratches and burrs can be

smoothed with crocus cloth.

INSPECTION

The aluminum governor valve and outer weight

have a hard coating on them. Check condition of this

Fig. 181 Gearshift Cable Adjustment

1 - SHIFT CABLE ADJUSTMENT

2 - SHIFT CABLE

21 - 104 31TH AUTOMATIC TRANSAXLERS

ProCarManuals.com

Page 1664 of 2399

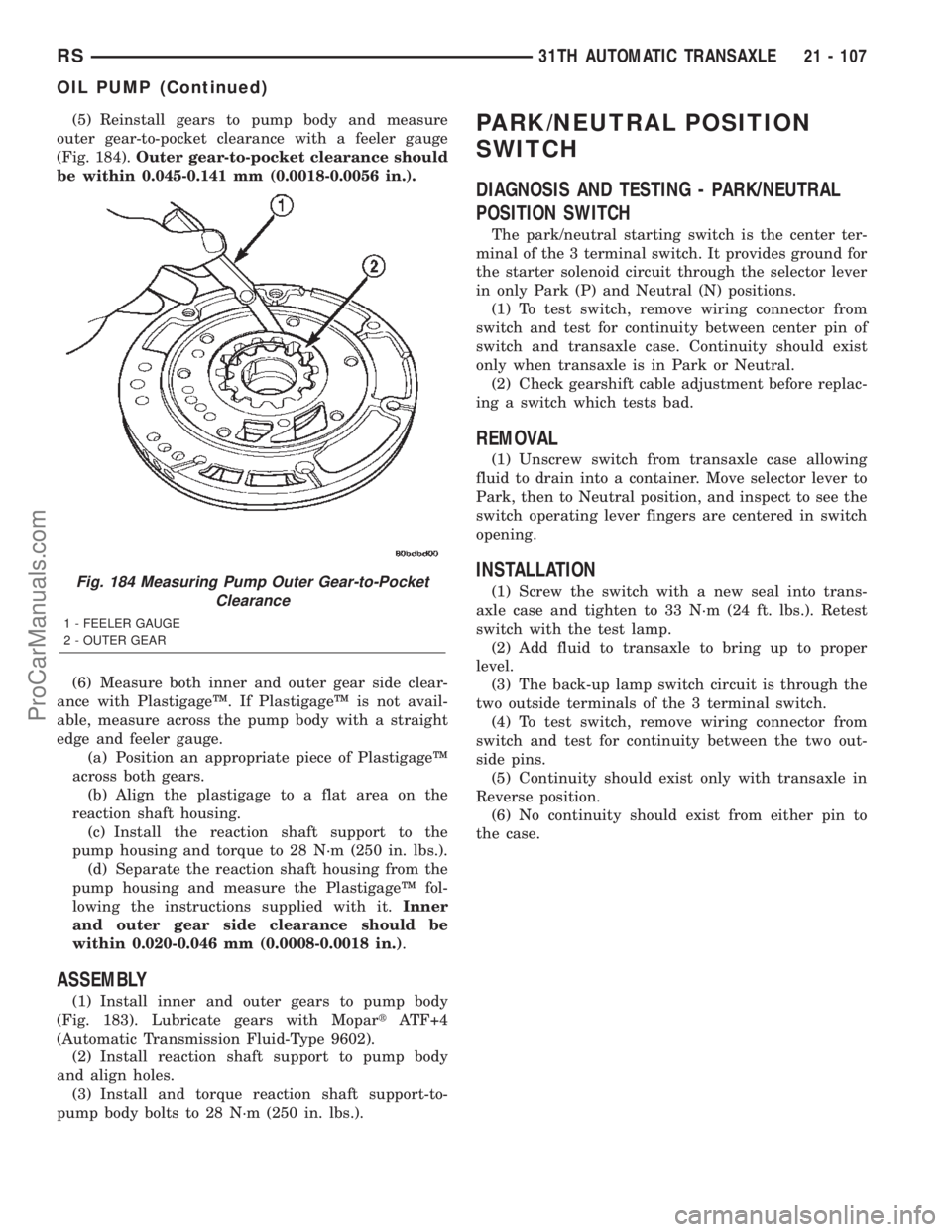

(5) Reinstall gears to pump body and measure

outer gear-to-pocket clearance with a feeler gauge

(Fig. 184).Outer gear-to-pocket clearance should

be within 0.045-0.141 mm (0.0018-0.0056 in.).

(6) Measure both inner and outer gear side clear-

ance with PlastigageŸ. If PlastigageŸ is not avail-

able, measure across the pump body with a straight

edge and feeler gauge.

(a) Position an appropriate piece of PlastigageŸ

across both gears.

(b) Align the plastigage to a flat area on the

reaction shaft housing.

(c) Install the reaction shaft support to the

pump housing and torque to 28 N´m (250 in. lbs.).

(d) Separate the reaction shaft housing from the

pump housing and measure the PlastigageŸ fol-

lowing the instructions supplied with it.Inner

and outer gear side clearance should be

within 0.020-0.046 mm (0.0008-0.0018 in.).

ASSEMBLY

(1) Install inner and outer gears to pump body

(Fig. 183). Lubricate gears with MopartATF+4

(Automatic Transmission Fluid-Type 9602).

(2) Install reaction shaft support to pump body

and align holes.

(3) Install and torque reaction shaft support-to-

pump body bolts to 28 N´m (250 in. lbs.).

PARK/NEUTRAL POSITION

SWITCH

DIAGNOSIS AND TESTING - PARK/NEUTRAL

POSITION SWITCH

The park/neutral starting switch is the center ter-

minal of the 3 terminal switch. It provides ground for

the starter solenoid circuit through the selector lever

in only Park (P) and Neutral (N) positions.

(1) To test switch, remove wiring connector from

switch and test for continuity between center pin of

switch and transaxle case. Continuity should exist

only when transaxle is in Park or Neutral.

(2) Check gearshift cable adjustment before replac-

ing a switch which tests bad.

REMOVAL

(1) Unscrew switch from transaxle case allowing

fluid to drain into a container. Move selector lever to

Park, then to Neutral position, and inspect to see the

switch operating lever fingers are centered in switch

opening.

INSTALLATION

(1) Screw the switch with a new seal into trans-

axle case and tighten to 33 N´m (24 ft. lbs.). Retest

switch with the test lamp.

(2) Add fluid to transaxle to bring up to proper

level.

(3) The back-up lamp switch circuit is through the

two outside terminals of the 3 terminal switch.

(4) To test switch, remove wiring connector from

switch and test for continuity between the two out-

side pins.

(5) Continuity should exist only with transaxle in

Reverse position.

(6) No continuity should exist from either pin to

the case.Fig. 184 Measuring Pump Outer Gear-to-Pocket

Clearance

1 - FEELER GAUGE

2 - OUTER GEAR

RS31TH AUTOMATIC TRANSAXLE21 - 107

OIL PUMP (Continued)

ProCarManuals.com

Page 1674 of 2399

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK SOLENOID

For intended BTSI system operation, refer to the

following chart:

ACTION EXPECTED RESPONSE

1. Turn key to the9OFF9

position.1. Shifter CAN be shifted

out of park with brake

pedal applied.

2. Turn key to the

9ON/RUN9position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

9ON/RUN9position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the9LOCK9or9ACC9

position.4. Key cannot be

returned to the9LOCK9or

9ACC9position.

5. Return shifter to

9PARK9and try to remove

the key.5. Key can be removed

(after returning to9LOCK9

position).

6. With the key removed,

try to shift out of9PARK9.6. Shifter cannot be

shifted out of9PARK9.

NOTE: Any failure to meet these expected

responses requires system repair. Refer to the

appropriate Diagnostic Information.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower shroud (Fig.

214).(3) Remove knee bolster (Fig. 215).

(4) Remove steering column lower shroud.

(5) Disconnect brake/transmission shift interlock

(BTSI) solenoid connector (Fig. 216).

Fig. 214 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 215 Knee Bolster

1 - KNEE BOLSTER

Fig. 216 BTSI Solenoid Connector

1 - BTSI SOLENOID

2 - SOLENOID CONNECTOR

RS31TH AUTOMATIC TRANSAXLE21 - 117

SHIFT INTERLOCK SOLENOID (Continued)

ProCarManuals.com

Page 1676 of 2399

(5) Install instrument panel lower silencer (Fig.

221).

(6) Connect battery negative cable.

(7) Verify proper shift interlock system operation.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 31TH/SHIFT INTERLOCK SOLENOID -

OPERATION)

SOLENOID - TCC

DESCRIPTION

The torque converter clutch (TCC) solenoid is fas-

tened to the transaxle valve body, and its connector

protrudes through the transaxle case (Fig. 222).

OPERATION

The torque converter clutch solenoid is responsible

for controlling application of the torque converter

clutch. It is controlled by the Powertrain Control

Module (PCM), which determines when conditions

are acceptable for torque converter lock-up.

REMOVAL

(1) Remove valve body from transaxle. (Refer to 21

- TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/VALVE BODY - REMOVAL)

(2) Remove three (3) torque converter clutch sole-

noid-to-valve body screws (Fig. 223).

(3) Remove torque converter clutch solenoid (Fig.

223). Note orientation of plug and spring.

Fig. 221 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 222 Torque Converter Clutch Solenoid

1 - TCC SOLENOID WIRING CONNECTOR

RS31TH AUTOMATIC TRANSAXLE21 - 119

SHIFT INTERLOCK SOLENOID (Continued)

ProCarManuals.com

Page 1679 of 2399

ADJUSTMENTS

THROTTLE VALVE LINKAGE ADJUSTMENT

The throttle valve linkage adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too short, early shifts and slippage

between shifts may occur. If the setting is too long,

shifts may be delayed and part throttle downshifts

may be very sensitive.

LINKAGE ADJUSTMENT PROCEDURE

(1) Perform transaxle throttle valve linkage

adjustment while engine is at normal operating tem-

perature.

(2) Using small screwdriver, disengage adjustment

lock at transaxle.

(3) Rotate lever at transaxle all the way to the left

side of vehicle against stop.

(4) Slide cable adjuster until cable core end

touches clip at throttle valve lever.

(5) Press adjuster lock (Fig. 228) to retain setting.

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 229) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid. If the fluid

is contaminated, flush the fluid cooler and lines.

Fig. 228 Throttle Valve Cable Adjustment Lock

1 - ADJUSTER LOCK

Fig. 229 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - CONVERTER CLUTCH DISC

6 - DRIVE PLATE

21 - 122 31TH AUTOMATIC TRANSAXLERS

THROTTLE VALVE CABLE (Continued)

ProCarManuals.com

Page 1703 of 2399

VALVE BODY

REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect throttle valve cable from throttle

valve lever at transaxle.

(3) Disconnect gearshift cable from gearshift lever

at transaxle.

(4) Disconnect torque converter clutch solenoid

connector.

(5) Raise vehicle on hoist.

(6) Remove transaxle oil pan bolts (Fig. 297).

(7) Separate oil pan from case and drain fluid into

suitable container (Fig. 298).(8) Remove oil filter-to-valve body screws (Fig.

299).

(9) Remove oil filter and gasket (Fig. 300).

Fig. 297 Transaxle Oil Pan Bolts

1 - TRANSAXLE OIL PAN

2 - OIL PAN BOLTS

Fig. 298 Transaxle Oil Pan

1 - TRANSAXLE OIL PAN

2 - OIL FILTER

Fig. 299 Oil Filter Screws

1 - SCREWDRIVER HANDLE

2 - SPECIAL TOOL L-4553

3 - OIL FILTER SCREWS (2)

4 - OIL FILTER

Fig. 300 Oil Filter and Gasket

1 - OIL FILTER

2 - GASKET

3 - VALVE BODY

21 - 146 31TH AUTOMATIC TRANSAXLERS

ProCarManuals.com

Page 1717 of 2399

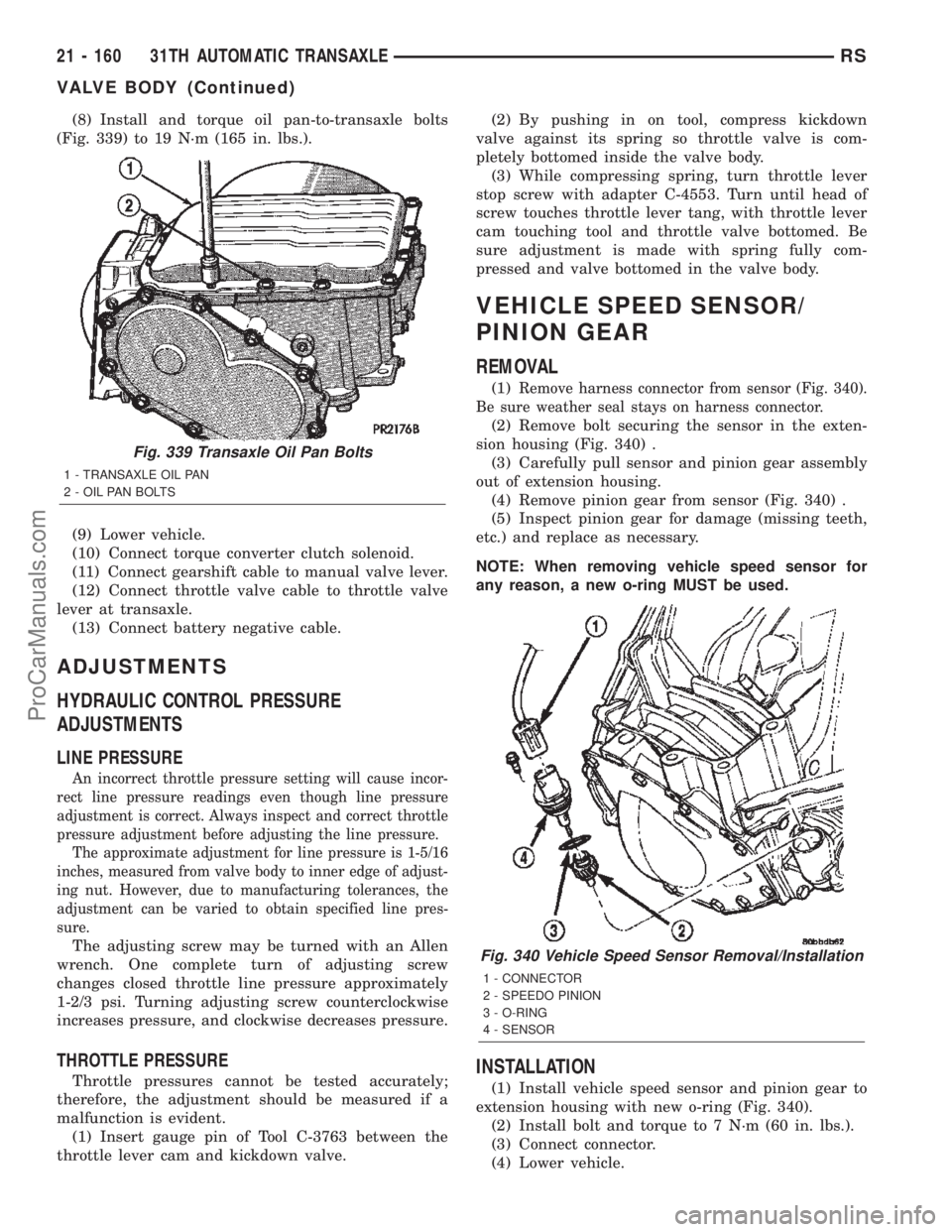

(8) Install and torque oil pan-to-transaxle bolts

(Fig. 339) to 19 N´m (165 in. lbs.).

(9) Lower vehicle.

(10) Connect torque converter clutch solenoid.

(11) Connect gearshift cable to manual valve lever.

(12) Connect throttle valve cable to throttle valve

lever at transaxle.

(13) Connect battery negative cable.

ADJUSTMENTS

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS

LINE PRESSURE

An incorrect throttle pressure setting will cause incor-

rect line pressure readings even though line pressure

adjustment is correct. Always inspect and correct throttle

pressure adjustment before adjusting the line pressure.

The approximate adjustment for line pressure is 1-5/16

inches, measured from valve body to inner edge of adjust-

ing nut. However, due to manufacturing tolerances, the

adjustment can be varied to obtain specified line pres-

sure.

The adjusting screw may be turned with an Allen

wrench. One complete turn of adjusting screw

changes closed throttle line pressure approximately

1-2/3 psi. Turning adjusting screw counterclockwise

increases pressure, and clockwise decreases pressure.

THROTTLE PRESSURE

Throttle pressures cannot be tested accurately;

therefore, the adjustment should be measured if a

malfunction is evident.

(1) Insert gauge pin of Tool C-3763 between the

throttle lever cam and kickdown valve.(2) By pushing in on tool, compress kickdown

valve against its spring so throttle valve is com-

pletely bottomed inside the valve body.

(3) While compressing spring, turn throttle lever

stop screw with adapter C-4553. Turn until head of

screw touches throttle lever tang, with throttle lever

cam touching tool and throttle valve bottomed. Be

sure adjustment is made with spring fully com-

pressed and valve bottomed in the valve body.

VEHICLE SPEED SENSOR/

PINION GEAR

REMOVAL

(1)Remove harness connector from sensor (Fig. 340).

Be sure weather seal stays on harness connector.

(2) Remove bolt securing the sensor in the exten-

sion housing (Fig. 340) .

(3) Carefully pull sensor and pinion gear assembly

out of extension housing.

(4) Remove pinion gear from sensor (Fig. 340) .

(5) Inspect pinion gear for damage (missing teeth,

etc.) and replace as necessary.

NOTE: When removing vehicle speed sensor for

any reason, a new o-ring MUST be used.

INSTALLATION

(1) Install vehicle speed sensor and pinion gear to

extension housing with new o-ring (Fig. 340).

(2) Install bolt and torque to 7 N´m (60 in. lbs.).

(3) Connect connector.

(4) Lower vehicle.

Fig. 339 Transaxle Oil Pan Bolts

1 - TRANSAXLE OIL PAN

2 - OIL PAN BOLTS

Fig. 340 Vehicle Speed Sensor Removal/Installation

1 - CONNECTOR

2 - SPEEDO PINION

3 - O-RING

4 - SENSOR

21 - 160 31TH AUTOMATIC TRANSAXLERS

VALVE BODY (Continued)

ProCarManuals.com

Page 1718 of 2399

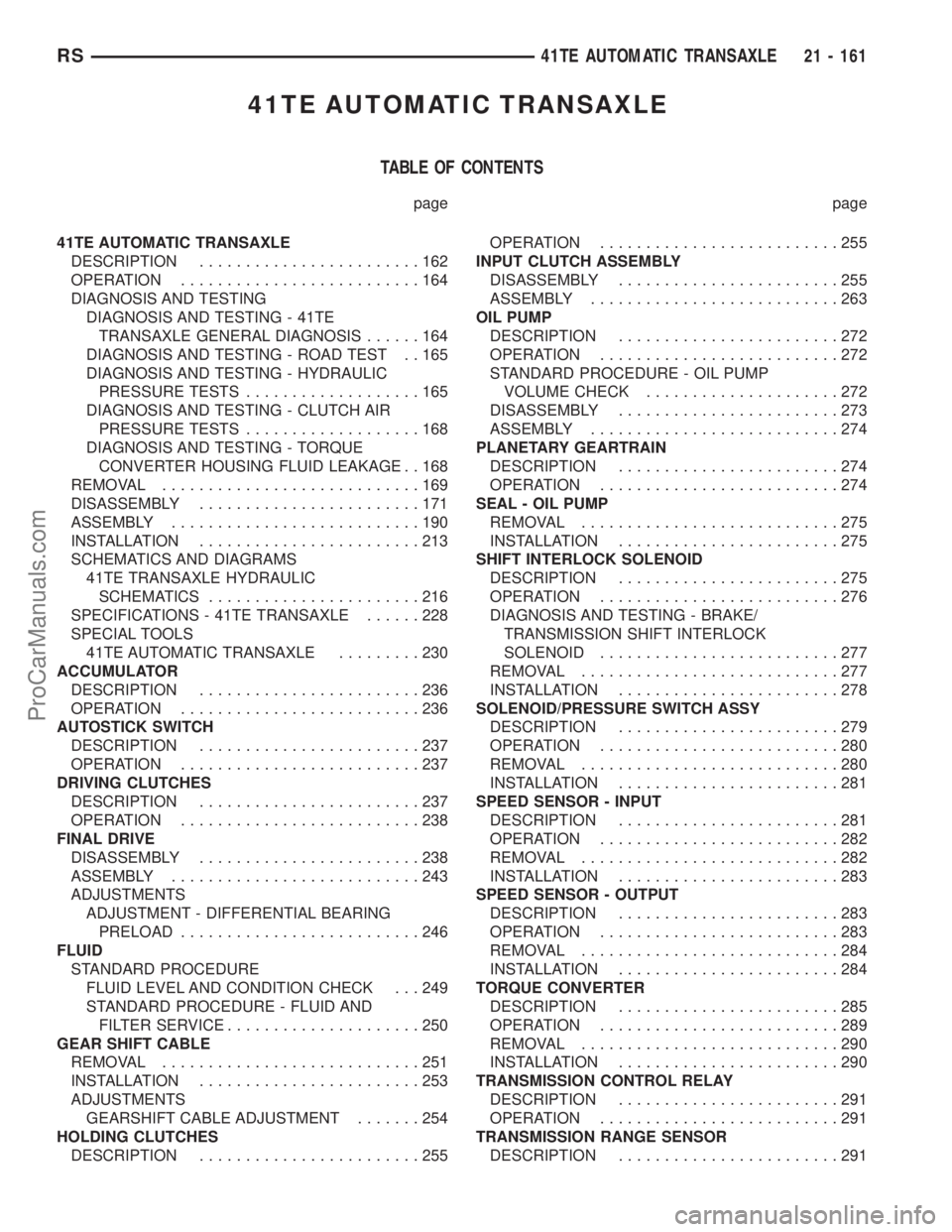

41TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

41TE AUTOMATIC TRANSAXLE

DESCRIPTION........................162

OPERATION..........................164

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 41TE

TRANSAXLE GENERAL DIAGNOSIS......164

DIAGNOSIS AND TESTING - ROAD TEST . . 165

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TESTS...................165

DIAGNOSIS AND TESTING - CLUTCH AIR

PRESSURE TESTS...................168

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE . . 168

REMOVAL............................169

DISASSEMBLY........................171

ASSEMBLY...........................190

INSTALLATION........................213

SCHEMATICS AND DIAGRAMS

41TE TRANSAXLE HYDRAULIC

SCHEMATICS.......................216

SPECIFICATIONS - 41TE TRANSAXLE......228

SPECIAL TOOLS

41TE AUTOMATIC TRANSAXLE.........230

ACCUMULATOR

DESCRIPTION........................236

OPERATION..........................236

AUTOSTICK SWITCH

DESCRIPTION........................237

OPERATION..........................237

DRIVING CLUTCHES

DESCRIPTION........................237

OPERATION..........................238

FINAL DRIVE

DISASSEMBLY........................238

ASSEMBLY...........................243

ADJUSTMENTS

ADJUSTMENT - DIFFERENTIAL BEARING

PRELOAD..........................246

FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK . . . 249

STANDARD PROCEDURE - FLUID AND

FILTER SERVICE.....................250

GEAR SHIFT CABLE

REMOVAL............................251

INSTALLATION........................253

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT.......254

HOLDING CLUTCHES

DESCRIPTION........................255OPERATION..........................255

INPUT CLUTCH ASSEMBLY

DISASSEMBLY........................255

ASSEMBLY...........................263

OIL PUMP

DESCRIPTION........................272

OPERATION..........................272

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................272

DISASSEMBLY........................273

ASSEMBLY...........................274

PLANETARY GEARTRAIN

DESCRIPTION........................274

OPERATION..........................274

SEAL - OIL PUMP

REMOVAL............................275

INSTALLATION........................275

SHIFT INTERLOCK SOLENOID

DESCRIPTION........................275

OPERATION..........................276

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK

SOLENOID..........................277

REMOVAL............................277

INSTALLATION........................278

SOLENOID/PRESSURE SWITCH ASSY

DESCRIPTION........................279

OPERATION..........................280

REMOVAL............................280

INSTALLATION........................281

SPEED SENSOR - INPUT

DESCRIPTION........................281

OPERATION..........................282

REMOVAL............................282

INSTALLATION........................283

SPEED SENSOR - OUTPUT

DESCRIPTION........................283

OPERATION..........................283

REMOVAL............................284

INSTALLATION........................284

TORQUE CONVERTER

DESCRIPTION........................285

OPERATION..........................289

REMOVAL............................290

INSTALLATION........................290

TRANSMISSION CONTROL RELAY

DESCRIPTION........................291

OPERATION..........................291

TRANSMISSION RANGE SENSOR

DESCRIPTION........................291

RS41TE AUTOMATIC TRANSAXLE21 - 161

ProCarManuals.com

Page 1721 of 2399

TRANSAXLE IDENTIFICATION

The 41TE transaxle is identified by a barcode label

that is fixed to the transaxle case as shown in (Fig.

2).

The label contains a series of digits that can be

translated into useful information such as transaxle

part number, date of manufacture, manufacturing

origin, plant shift number, build sequence number,

etc. Refer to (Fig. 3) for identification label break-

down.

If the tag is not legible or missing, the ªPKº num-

ber, which is stamped into the transaxle case behind

the transfer gear cover, can be referred to for identi-

fication. This number differs slightly in that it con-

tains the entire transaxle part number, rather than

the last three digits.

OPERATION

Transmission output is directed to an integral dif-

ferential by a transfer gear system in the following

input-to-output ratios:

First...............................2.84 : 1

Second.............................1.57 : 1

Third..............................1.00 : 1

Overdrive...........................0.69 : 1

Reverse............................2.21 : 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 41TE TRANSAXLE

GENERAL DIAGNOSIS

NOTE: Before attempting any repair on a 41TE four-

speed automatic transaxle, check for diagnostic

trouble codes (DTC's) using the DRB scan tool.

Refer to the Transmission Diagnostic Procedures

Manual.

Transaxle malfunctions may be caused by these

general conditions:

²Poor engine performance

²Improper adjustments

²Hydraulic malfunctions

²Mechanical malfunctions

²Electronic malfunctions

Diagnosis of these problems should always begin

by checking the easily accessible variables: fluid level

and condition, gearshift cable adjustment. Then per-

Fig. 2 Transaxle Identification Label

1 - IDENTIFICATION LABEL

Fig. 3 Identification Label Breakdown

1 - T=TRACEABILITY

2 - SUPPLIER CODE (PK=KOKOMO)

3 - COMPONENT CODE (TK=KOKOMO TRANSMISSION)

4 - BUILD DAY (344=DEC. 9)

5 - BUILD YEAR (9=1999)

6 - LINE/SHIFT CODE (3=3RD SHIFT)

7 - BUILD SEQUENCE NUMBER

8 - LAST THREE OF P/N

9 - NIK

10 - TRANSAXLE PART NUMBER

11 - P=PART NUMBER

21 - 164 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com