Shift cable CHRYSLER VOYAGER 2002 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1929 of 2399

(6) Install coolant recovery bottle to bracket.

(7) Connect battery temperature sensor to battery

tray. Install battery tray into position (Fig. 174).

(8) Install battery, hold-down clamp, and nut (Fig.

175).(9) Install battery thermal shield (Fig. 176).

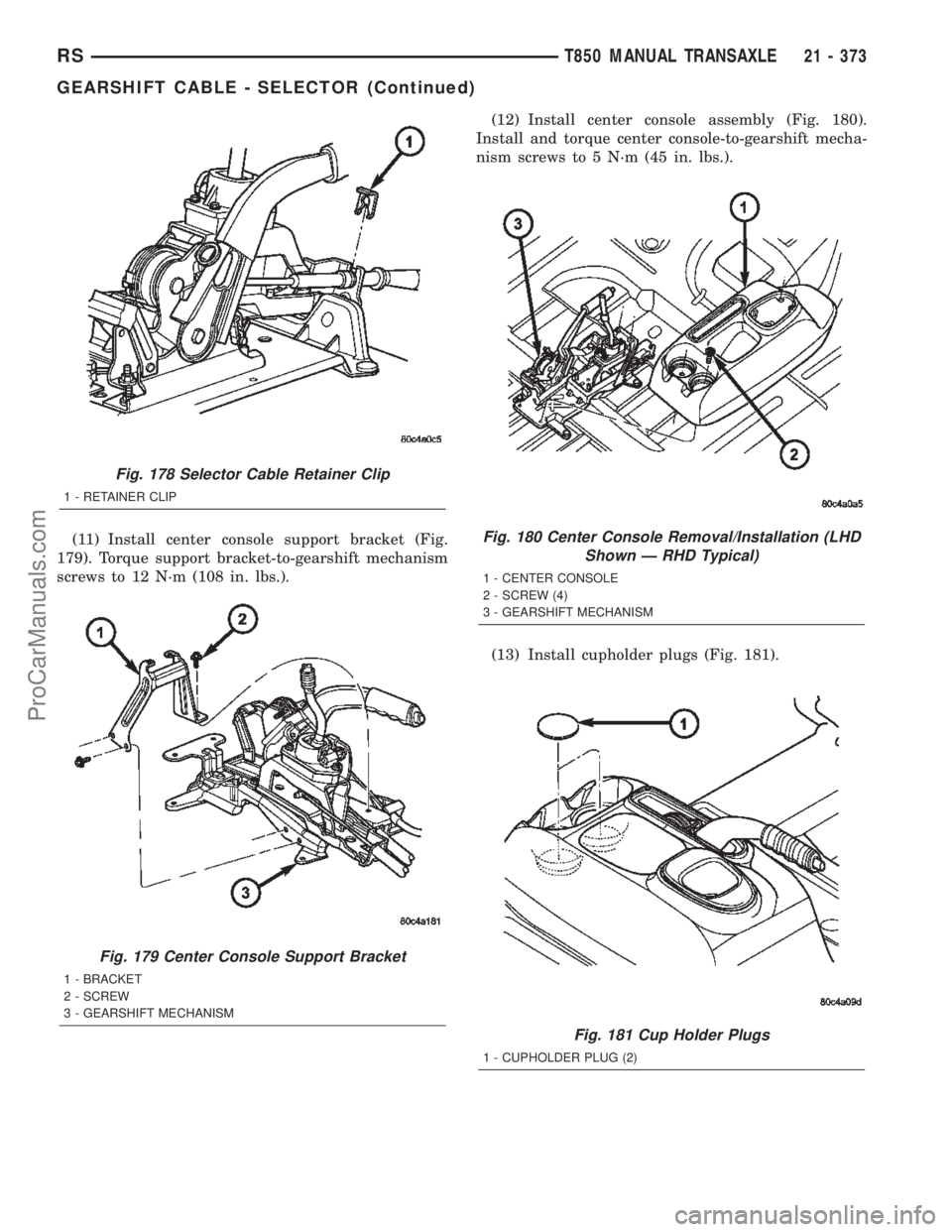

(10) Install selector cable to gearshift mechanism

(Fig. 177). Install retainer clip (Fig. 178).

Fig. 174 Battery Tray

1 - BATTERY TRAY

Fig. 175 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

Fig. 176 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

Fig. 177 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

21 - 372 T850 MANUAL TRANSAXLERS

GEARSHIFT CABLE - SELECTOR (Continued)

ProCarManuals.com

Page 1930 of 2399

(11) Install center console support bracket (Fig.

179). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).(12) Install center console assembly (Fig. 180).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(13) Install cupholder plugs (Fig. 181).

Fig. 178 Selector Cable Retainer Clip

1 - RETAINER CLIP

Fig. 179 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 180 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 181 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

RST850 MANUAL TRANSAXLE21 - 373

GEARSHIFT CABLE - SELECTOR (Continued)

ProCarManuals.com

Page 1931 of 2399

(14) Install gearshift boot to console (Fig. 182).

Secure with three (3) retainer clips.

(15) Install gearshift knob to gearshift lever (Fig.

183). Orient shift pattern

1¤4-turn clockwise, push

down and rotate1¤4-turn counter-clockwise and

release. Secure boot to knob.

(16) Connect battery negative cable.

GEARSHIFT KNOB

REMOVAL

(1) Separate gearshift boot from base of knob.

(2) Remove gearshift knob by pushing down and

rotating

1¤4-turn clockwise (Fig. 184).

INSTALLATION

(1) Install gearshift knob pattern1¤4-turn clock-

wise, press down, and rotate1¤4-turn counter clock-

wise (Fig. 184).

(2) Secure gearshift boot to base of knob.

Fig. 182 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 183 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 184 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

21 - 374 T850 MANUAL TRANSAXLERS

GEARSHIFT CABLE - SELECTOR (Continued)

ProCarManuals.com

Page 1932 of 2399

GEARSHIFT MECHANISM

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating

1¤4turn clock-wise (Fig. 185).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 186).(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

187).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

188).

Fig. 185 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 186 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 187 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 188 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

RST850 MANUAL TRANSAXLE21 - 375

ProCarManuals.com

Page 1933 of 2399

(7) Remove center console support bracket (Fig.

189).

(8) Remove crossover cable retainer clip (Fig. 190).(9) Remove crossover cable from gearshift mecha-

nism (Fig. 191).

(10) Remove selector cable retainer clip (Fig. 192).

Fig. 189 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 190 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 191 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

Fig. 192 Selector Cable Retainer Clip

1 - RETAINER CLIP

21 - 376 T850 MANUAL TRANSAXLERS

GEARSHIFT MECHANISM (Continued)

ProCarManuals.com

Page 1934 of 2399

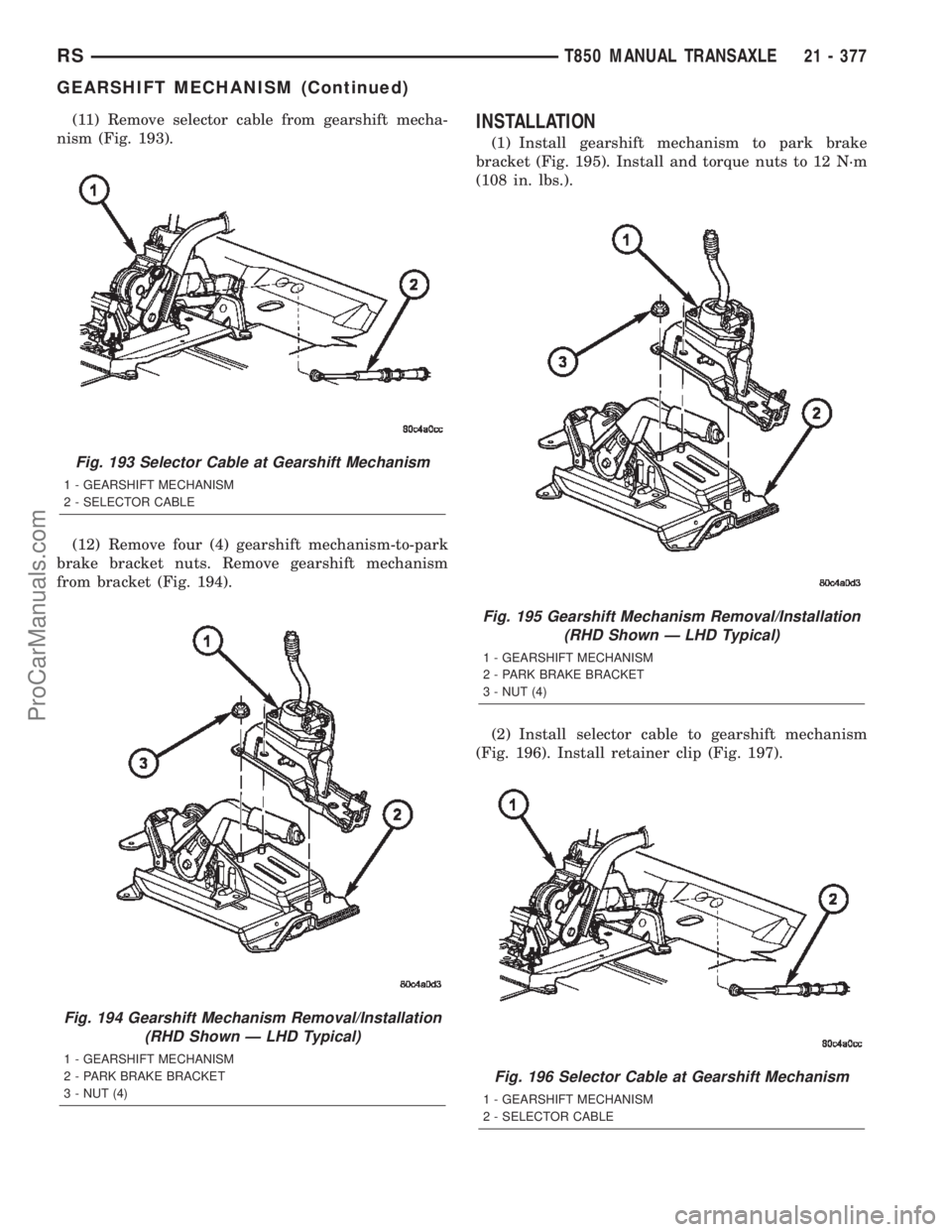

(11) Remove selector cable from gearshift mecha-

nism (Fig. 193).

(12) Remove four (4) gearshift mechanism-to-park

brake bracket nuts. Remove gearshift mechanism

from bracket (Fig. 194).INSTALLATION

(1) Install gearshift mechanism to park brake

bracket (Fig. 195). Install and torque nuts to 12 N´m

(108 in. lbs.).

(2) Install selector cable to gearshift mechanism

(Fig. 196). Install retainer clip (Fig. 197).

Fig. 193 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

Fig. 194 Gearshift Mechanism Removal/Installation

(RHD Shown Ð LHD Typical)

1 - GEARSHIFT MECHANISM

2 - PARK BRAKE BRACKET

3 - NUT (4)

Fig. 195 Gearshift Mechanism Removal/Installation

(RHD Shown Ð LHD Typical)

1 - GEARSHIFT MECHANISM

2 - PARK BRAKE BRACKET

3 - NUT (4)

Fig. 196 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

RST850 MANUAL TRANSAXLE21 - 377

GEARSHIFT MECHANISM (Continued)

ProCarManuals.com

Page 1935 of 2399

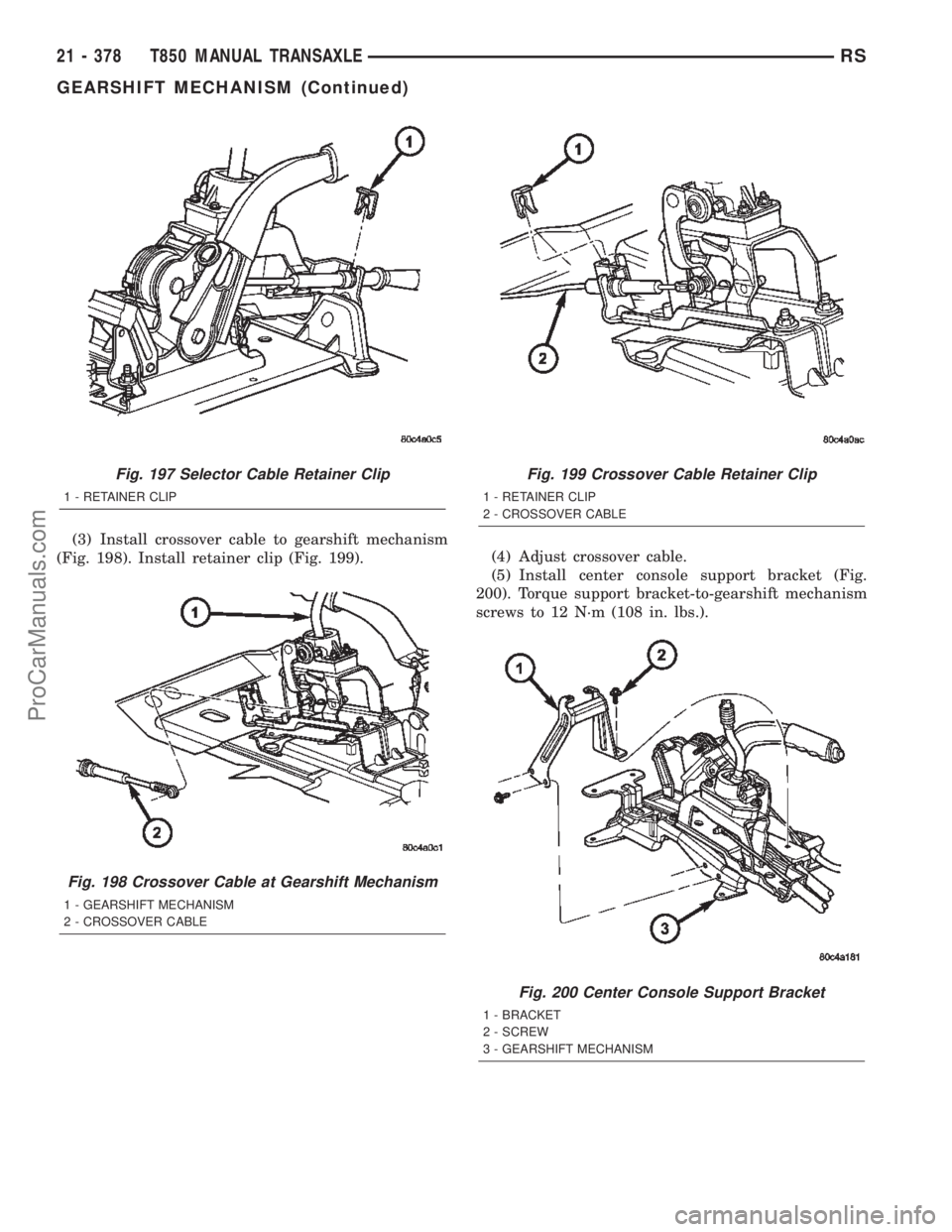

(3) Install crossover cable to gearshift mechanism

(Fig. 198). Install retainer clip (Fig. 199).(4) Adjust crossover cable.

(5) Install center console support bracket (Fig.

200). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

Fig. 197 Selector Cable Retainer Clip

1 - RETAINER CLIP

Fig. 198 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

Fig. 199 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 200 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

21 - 378 T850 MANUAL TRANSAXLERS

GEARSHIFT MECHANISM (Continued)

ProCarManuals.com

Page 1936 of 2399

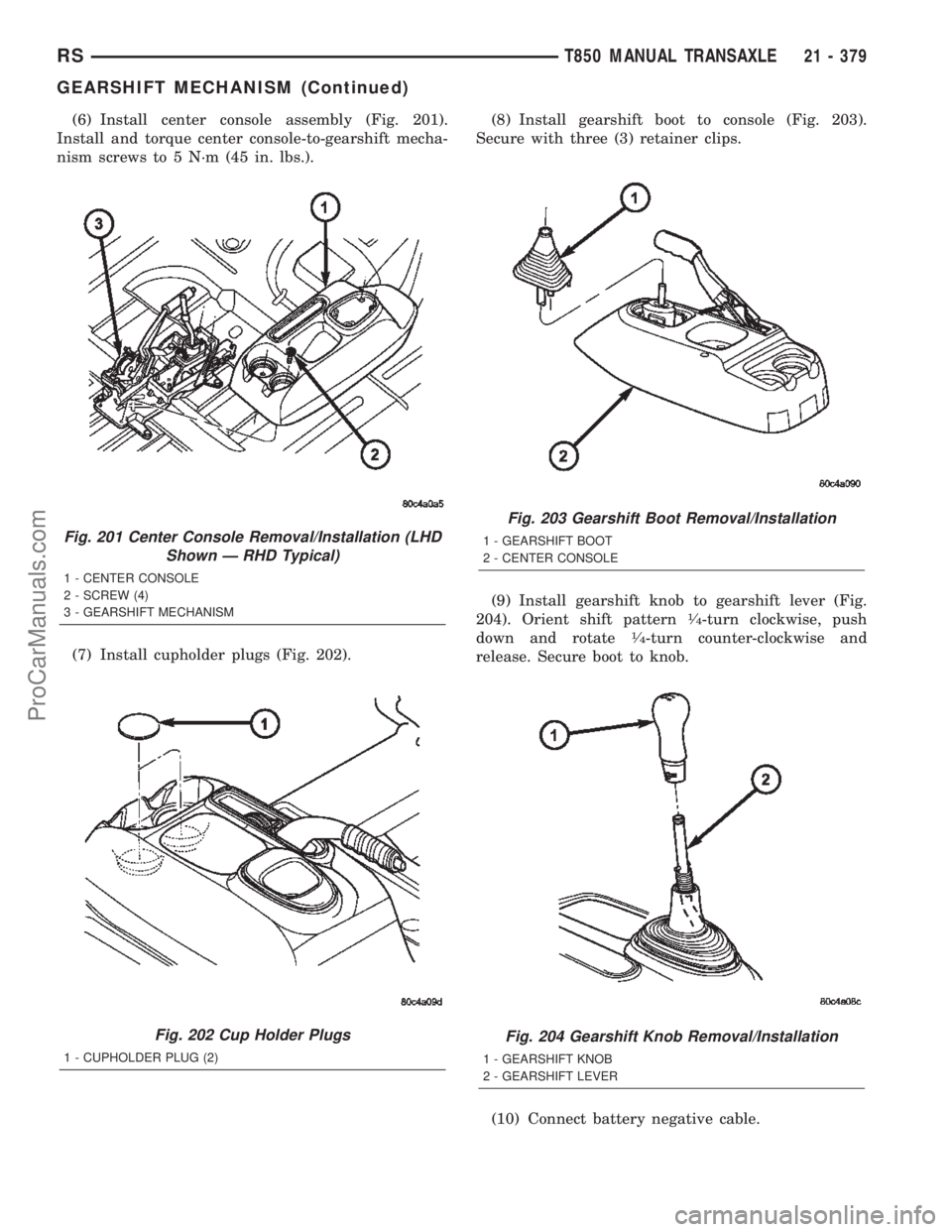

(6) Install center console assembly (Fig. 201).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(7) Install cupholder plugs (Fig. 202).(8) Install gearshift boot to console (Fig. 203).

Secure with three (3) retainer clips.

(9) Install gearshift knob to gearshift lever (Fig.

204). Orient shift pattern

1¤4-turn clockwise, push

down and rotate1¤4-turn counter-clockwise and

release. Secure boot to knob.

(10) Connect battery negative cable.

Fig. 201 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 202 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 203 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 204 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

RST850 MANUAL TRANSAXLE21 - 379

GEARSHIFT MECHANISM (Continued)

ProCarManuals.com

Page 1958 of 2399

(22) InstallNEWintermediate shaft sealed bear-

ing snap ring (Fig. 273).

SHIFT COVER

DESCRIPTION

The shift cover assembly (Fig. 274) (Fig. 275) is

operated by the gearshift crossover and selector

cables, and operates the shift fork/shaft system. It

consists of crossover and selector lever mechanisms,

transaxle vent, a main shift selector shaft, and the

5-R blockout mechanism. The shift cover is only ser-

viced as an assembly.

Fig. 274 Shift Lever Identification

1 - SHIFT COVER ASSEMBLY

2 - VENT

3 - CROSSOVER LEVER

4 - SELECTOR LEVER

Fig. 273 Intermediate Shaft Bearing Snap Ring

1 - SNAP RING

2 - BEARING

Fig. 275 Shift Cover Assembly Components

1 - SHAFT

2 - 5-R BLOCKOUT PIN/CAM

3 - SHIFT SELECTOR

4 - SHIFT BLOCKER

5 - SELECTOR LEVER/DETENT

RST850 MANUAL TRANSAXLE21 - 401

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1959 of 2399

SHIFT FORK AND SHAFT

DESCRIPTION

The T850 utilizes a unique shift fork and shaft

arrangement consisting of three shift forks and two

shafts as shown in (Fig. 276). This system is oper-

ated by the shift cover assembly, which combined

with a unique gearshift cable design, offers a higher

mechanical advantage over traditional shift systems.

This arrangement results in less friction and lower

shift cable loads for smoother, more positive opera-

tion. The shift fork assemblies are constructed of

brass, float about the shafts with the aid of needle

bearings, and are serviced only as fork/bearing

assemblies.

SYNCHRONIZER

DESCRIPTION

The T850 transaxle uses two styles of synchronizer

assemblies; a conventional single-cone style is used

for the 5th/Reverse and 3rd/4th applications (Fig.

277), and a dual-cone style for the 1st/2nd gear appli-

cation (Fig. 278).

DISASSEMBLY

Place synchronizer in a clean shop towel and wrap.

Press on inner hub. Carefully open up shop towel

and remove springs, balls, keys, hub, and sleeve.

CLEANING

CLEAN

Do not attempt to clean the blocking rings in sol-

vent. The friction material will become contaminated.

Place synchronizer components in a suitable holder

and clean with solvent. Air dry.

INSPECTION

INSPECT

Proper inspection of components involve:

²Teeth, for wear, scuffed, nicked, burred, or bro-

ken teeth

²Keys, for wear or distortion

²Balls and springs, for distortion, cracks, or wear

Fig. 276 Shift Fork/Shaft Components

1 - 5/R FORK

2 - SHAFT/LINK ASSEMBLY

3 - LINK

4 - 3/4 FORK

5 - 1/2 FORK

Fig. 277 3/4-5/R Synchronizer Assembly

1 - SLEEVE

2 - HUB

3 - BLOCKER RING (2)

4 - SPRING (3)

5 - KEY (3)

6 - BALL (3)

21 - 402 T850 MANUAL TRANSAXLERS

ProCarManuals.com