tow CHRYSLER VOYAGER 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 455 of 2399

The electrically heated Rear Window Defogger (Fig.

1), Heated Power Side View Mirrors, and Heated

Windshield Wiper De-icer (Fig. 2)is available on

select models.

OPERATION

The Rear Window Defogger(Refer to 8 - ELECTRI-

CAL/HEATED GLASS - DESCRIPTION) system con-

sists of two vertical bus bars linked by a series of

grid lines on the inside surface of the rear window.

The electrical circuit consists of the rear defogger

switch in the HVAC control assembly and a relay

with timer switch to turn OFF the system after ten

minutes. The main feed circuit is protected by fuse

13 (40 amp) in the Power Distribution Center (PDC)

which is connected directly to the front control mod-

ule (FCM) to form an integrated unit called an Inte-

grated Power Module (IPM). The rear defogger

switch and relay also activates the heated power side

view mirrors. The rear defogger switch also activates

the heated windshield wiper de-icer which is powered

by the RUN/ACC relay in the IPM and feed thru fuse

#11 (20 amp) in the PDC. The heated mirror circuit

is protected by a non-servicable Positive Temperature

Coefficient (PTC) located inside the PDC. The heated

windshield wiper de-icer circuit is protected by fuse

11 (20 amp) in the PDC.

The Heated Windshield Wiper Deicer is also acti-

vated when the DEFROST mode is selected on the

HVAC. In the DEFROST mode the rear defogger

timout is bypassed, the heated windshield wiper de-

icer will stay ON until the another mode is selected.

For circuit information and component location refer

to appropriate section for Wiring Diagrams.

CAUTION:

Since grid lines can be damaged or scraped off

with sharp instruments, care should be taken in

cleaning the glass or removing foreign materials,

decals or stickers. Normal glass cleaning solvents

or hot water used with rags or toweling is recom-

mended.

DEFOGGER RELAY

DESCRIPTION

There is no heated windshield wiper de-icer relay.

The grid is powered directly from fuse #11 in the

PDC and is controlled directly from the HVAC con-

trol assembly.

REAR WINDOW DEFOGGER

GRID

STANDARD PROCEDURE - GRID LINE REPAIR

REAR

For Grid repair procedure for the rear window

defogger (Refer to 8 - ELECTRICAL/HEATED

GLASS/WINDSHIELD GRID - STANDARD PROCE-

DURE).

REAR WINDOW DEFOGGER

SWITCH

DESCRIPTION

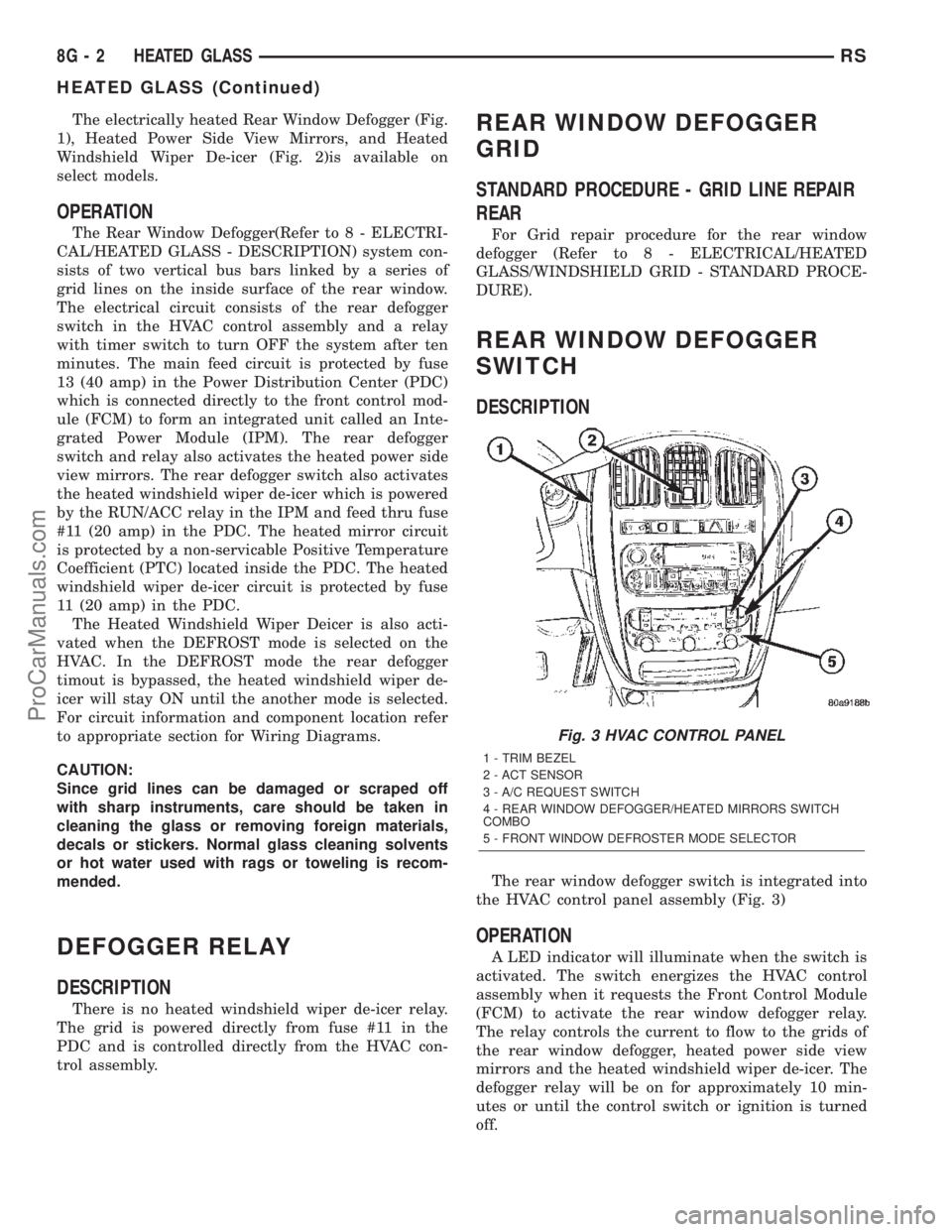

The rear window defogger switch is integrated into

the HVAC control panel assembly (Fig. 3)

OPERATION

A LED indicator will illuminate when the switch is

activated. The switch energizes the HVAC control

assembly when it requests the Front Control Module

(FCM) to activate the rear window defogger relay.

The relay controls the current to flow to the grids of

the rear window defogger, heated power side view

mirrors and the heated windshield wiper de-icer. The

defogger relay will be on for approximately 10 min-

utes or until the control switch or ignition is turned

off.

Fig. 3 HVAC CONTROL PANEL

1 - TRIM BEZEL

2 - ACT SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

COMBO

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

8G - 2 HEATED GLASSRS

HEATED GLASS (Continued)

ProCarManuals.com

Page 461 of 2399

²Heated Seat Switch- Two heated seat

switches are used per vehicle, one for the driver and

one for the passenger side front seats. The switches

are mounted to in the instrument panel center stack.

Refer to the description of the heated seat switch

later in this section for additional information.

Hard wired circuitry connects the heated seat sys-

tem components to each other through the electrical

system of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system and to the

heated seat system components through the use of a

combination of soldered splices and splice block con-

nectors. Refer to Wiring for complete system wiring

schematics. The wiring information also includes the

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

OPERATION

The heated seat system components operate on

battery current received through a fuse in the Inte-

grated Power Module (IPM) on a fused ignition

switch output (run-acc) circuit so that the system willonly operate when the ignition switch is in the On or

Accessory positions. The heated seat system will be

turned Off automatically whenever the ignition

switch is turned to any position except On or Acces-

sory. Also, the heated seat system will not operate

when the surface temperature of the seat cushion

cover at either heated seat sensor is above the

designed temperature set points of the system. The

heated seat system has a self-diagnostic capability.

When certain failures are detected within the heated

seat system, the system will provide a visual indica-

tion of the failure by flashing the Light Emitting

Diode (LED) indicator lamps located in the heated

seat switches. See the owner's manual in the vehicle

glove box for more information on the features, use

and operation of the heated seat system.

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM

Refer toWiring Diagramsfor complete wiring

schematics. The wiring information also includes the

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

HEATED SEAT SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO HEATED SEAT SWITCH

ILLUMINATION WITH

IGNITION ON (SYSTEM ON)1. Faulty fuse 1. Check heated seat fuse in Integrated Power

Module. Replace fuse, repair short if required.

2. Faulty components 2. Refer to individual Heated Seat System

components for the proper diagnosis and testing

procedures.

3. Ground faulty 3. Check for ground at heated seat switch and

module. Repair, if required.

4. Wiring faulty 4. Check fused ignition switch output (run-acc)

circuits at switch and module. Repair, if required.

8G - 8 HEATED SEAT SYSTEMRS

HEATED SEAT SYSTEM (Continued)

ProCarManuals.com

Page 462 of 2399

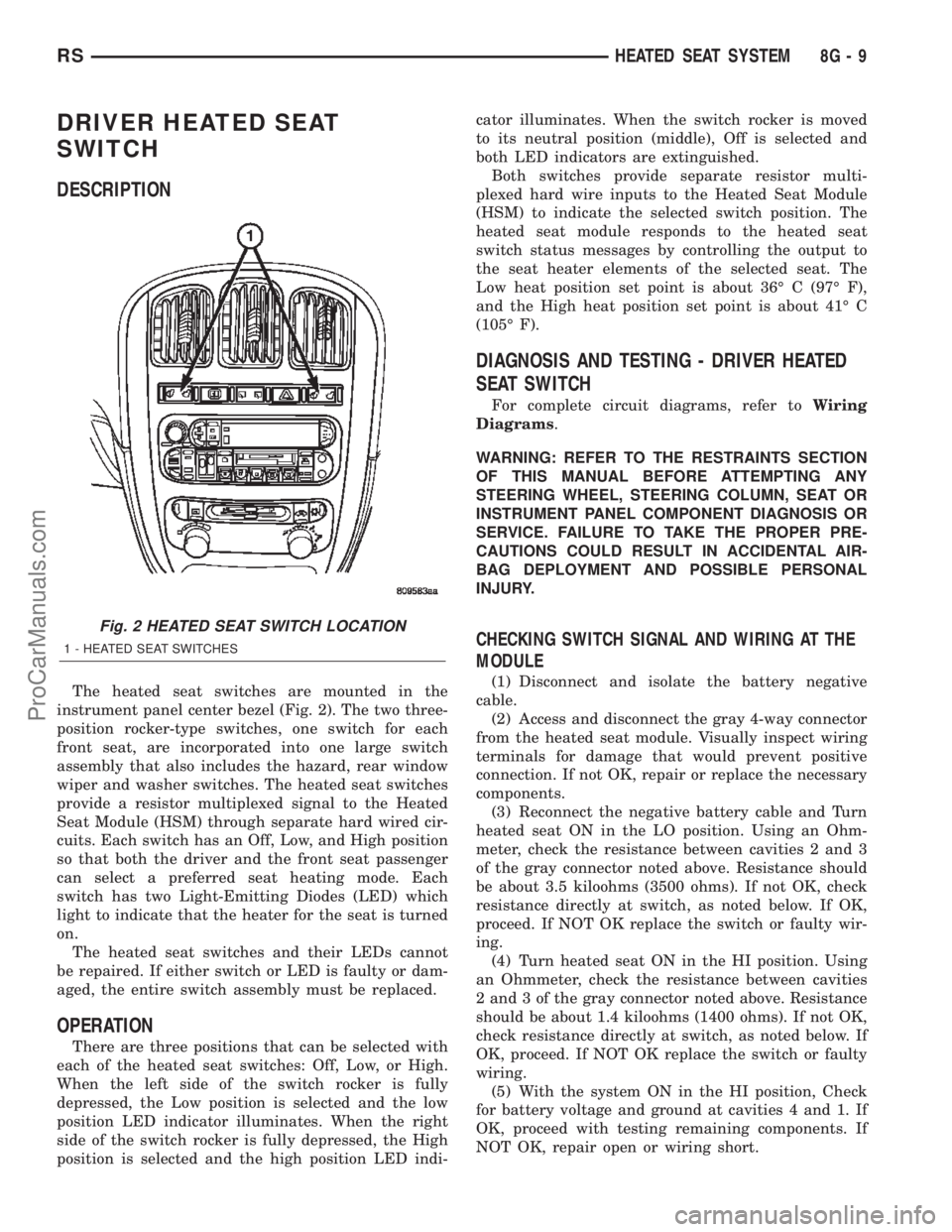

DRIVER HEATED SEAT

SWITCH

DESCRIPTION

The heated seat switches are mounted in the

instrument panel center bezel (Fig. 2). The two three-

position rocker-type switches, one switch for each

front seat, are incorporated into one large switch

assembly that also includes the hazard, rear window

wiper and washer switches. The heated seat switches

provide a resistor multiplexed signal to the Heated

Seat Module (HSM) through separate hard wired cir-

cuits. Each switch has an Off, Low, and High position

so that both the driver and the front seat passenger

can select a preferred seat heating mode. Each

switch has two Light-Emitting Diodes (LED) which

light to indicate that the heater for the seat is turned

on.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch assembly must be replaced.

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the left side of the switch rocker is fully

depressed, the Low position is selected and the low

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the high position LED indi-cator illuminates. When the switch rocker is moved

to its neutral position (middle), Off is selected and

both LED indicators are extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the Heated Seat Module

(HSM) to indicate the selected switch position. The

heated seat module responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CHECKING SWITCH SIGNAL AND WIRING AT THE

MODULE

(1) Disconnect and isolate the battery negative

cable.

(2) Access and disconnect the gray 4-way connector

from the heated seat module. Visually inspect wiring

terminals for damage that would prevent positive

connection. If not OK, repair or replace the necessary

components.

(3) Reconnect the negative battery cable and Turn

heated seat ON in the LO position. Using an Ohm-

meter, check the resistance between cavities 2 and 3

of the gray connector noted above. Resistance should

be about 3.5 kiloohms (3500 ohms). If not OK, check

resistance directly at switch, as noted below. If OK,

proceed. If NOT OK replace the switch or faulty wir-

ing.

(4) Turn heated seat ON in the HI position. Using

an Ohmmeter, check the resistance between cavities

2 and 3 of the gray connector noted above. Resistance

should be about 1.4 kiloohms (1400 ohms). If not OK,

check resistance directly at switch, as noted below. If

OK, proceed. If NOT OK replace the switch or faulty

wiring.

(5) With the system ON in the HI position, Check

for battery voltage and ground at cavities 4 and 1. If

OK, proceed with testing remaining components. If

NOT OK, repair open or wiring short.

Fig. 2 HEATED SEAT SWITCH LOCATION

1 - HEATED SEAT SWITCHES

RSHEATED SEAT SYSTEM8G-9

ProCarManuals.com

Page 465 of 2399

REMOVAL

Do not remove the OEM heating element from the

seat or seat back cushion/trim covers. The original

element is permanently attached and cannot be

removed without permanent damage. The service

replacement heating element is designed to be

applied directly on the seat cushion.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate seat cushion or seat

back trim cover. Refer to the Body section of the ser-

vice manual for the procedures.

(3) Disconnect the inoperative heated seat cushion

or seat back element electrical connectors.

(4) Locate the wires leading from the inoperative

heating element and cut them off flush with the edge

of the original heating element.

INSTALLATION

(1) Peel off the adhesive backing on the back of the

replacement heating element and stick directly on

the foam cushion.

CAUTION: During the installation of the replace-

ment heating element, be careful not to fold or

crease the element assembly. Folds or creases will

cause premature failure.

(2) Connect the new heating element electrical

connectors (Fig. 5).

(3) Connect the negative battery cable.

(4) Verify heated seat system operation.

(5) Install the appropriate seat cushion or seat

back trim cover. Make certain the seat wire harness

is correctly routed through the seat and seat back.

The excess wire between the cushion and back ele-

ments should be securely tucked between the rear of

the cushion foam and the rear carpet flap of the trim

cover.

HEATED SEAT SENSOR

DESCRIPTION

Two heated seat sensors are used per vehicle, one

in each front seat cushion heating element. The

heated seat temperature sensor is a Negative Tem-

perature Coefficient (NTC) thermistor.

The heated seat sensors cannot be repaired or

adjusted and if found to be faulty, the complete

heated seat cushion element must be replaced.

OPERATION

The temperature sensor is a NTC thermistor.

When the temperature of the seat cushion cover

rises, the resistance of the sensor decreases. The

heated seat module supplies a five-volt current to one

side of each sensor, and monitors the voltage drop

through the sensor on a return circuit. The heated

seat module uses this temperature sensor input to

monitor the temperature of the seat, and regulates

the current flow to the seat heating elements accord-

ingly.

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Disconnect and isolate the battery negative

cable. Disconnect the green 4-way heated seat mod-

ule wire harness connector.

(2) Using an ohmmeter, check the resistance

between cavities 2 and 3. The sensor resistance

should be between 2 kilohms at 15É C (60É F) and 50

kilohms at 30É C (85É F). If not OK, replace the

faulty seat element and sensor assembly.

Fig. 5 HEATING ELEMENT INSTALLED - TYPICAL

1 - SEAT BACK WIRE HARNESS

2 - HEATED SEAT WIRE HARNESS CONNECTOR

3 - HEATED SEAT CUSHION ELEMENT

8G - 12 HEATED SEAT SYSTEMRS

HEATED SEAT ELEMENT (Continued)

ProCarManuals.com

Page 466 of 2399

PASSENGER HEATED SEAT

SWITCH

DESCRIPTION

The heated seat switches are mounted in the

instrument panel center bezel (Fig. 6). The two three-

position rocker-type switches, one switch for each

front seat, are incorporated into one large switch

assembly that also includes the hazard, rear window

wiper and washer switches. The heated seat switches

provide a resistor multiplexed signal to the Heated

Seat Module (HSM) through separate hard wired cir-

cuits. Each switch has an Off, Low, and High position

so that both the driver and the front seat passenger

can select a preferred seat heating mode. Each

switch has two Light-Emitting Diodes (LED) which

light to indicate that the heater for the seat is turned

on.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch assembly must be replaced.

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the left side of the switch rocker is fully

depressed, the Low position is selected and the low

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the high position LED indi-cator illuminates. When the switch rocker is moved

to its neutral position (middle), Off is selected and

both LED indicators are extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the Heated Seat Module

(HSM) to indicate the selected switch position. The

heated seat module responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CHECKING SWITCH SIGNAL AND WIRING AT THE

MODULE

(1) Disconnect and isolate the battery negative

cable.

(2) Access and disconnect the gray 4-way connector

from the heated seat module. Visually inspect wiring

terminals for damage that would prevent positive

connection. If not OK, repair or replace the necessary

components.

(3) Reconnect the negative battery cable and Turn

heated seat ON in the LO position. Using an Ohm-

meter, check the resistance between cavities 2 and 3

of the gray connector noted above. Resistance should

be about 3.5 kiloohms (3500 ohms). If not OK, check

resistance directly at switch, as noted below. If OK,

proceed. If NOT OK replace the switch or faulty wir-

ing.

(4) Turn heated seat ON in the HI position. Using

an Ohmmeter, check the resistance between cavities

2 and 3 of the gray connector noted above. Resistance

should be about 1.4 kiloohms (1400 ohms). If not OK,

check resistance directly at switch, as noted below. If

OK, proceed. If NOT OK replace the switch or faulty

wiring.

(5) With the system ON in the HI position, Check

for battery voltage and ground at cavities 4 and 1. If

OK, proceed with testing remaining components. If

NOT OK, repair open or wiring short.

Fig. 6 HEATED SEAT SWITCH LOCATION

1 - HEATED SEAT SWITCHES

RSHEATED SEAT SYSTEM8G-13

ProCarManuals.com

Page 482 of 2399

REMOVAL

REMOVAL - 2.4L

The electronic ignition coil pack attaches directly

to the valve cover.

(1) Diconnect the negative battery cable.

(2) Disconnect electrical connector from coil pack(3) Remove coil pack mounting bolts.

(4) Remove coil pack and heat shield (Fig. 9).

REMOVAL - 3.3/3.8L

(1) Disconnect the negative battery cable.

(2) Remove the throttle and speed control cables

from clip.

(3) Remove 2 bolts from the Power steering reser-

voir to intake manifold.

(4) Loosen the lower nut for the power steering

reservoir from stud on ignition coil bracket.

(5) Reposition the Power steering reservoir (Fig.

11).

(6) Remove the ignition cables from the ignition

coil.

(7) Disconnect the electrical connector from the

ignition coil.

(8) Remove 2 nuts from the ignition coil studs.

(9) Remove 2 bolts from ignition coil, remove coil.

INSTALLATION

INSTALLATION - 2.4L

(1) Install ignition coil and heat shield to valve

cover and tighten bolts.

(2) Connect the electrical connector to the ignition

coil.

(3) Transfer spark plug cables to new coil pack.

The coil pack towers are numbered with the cylinder

identification. Be sure the ignition cables are fully

seated onto the towers.

(4) Connect the negative battery cable.

Fig. 9 IGNITION COIL - 2.4L

Fig. 10 IGNITION COIL - 3.3/3.8L

1 -Ignition Coil

Fig. 11 IGNITION COIL BRACKET 3.3/3.8L

RSIGNITION CONTROL8I-7

IGNITION COIL (Continued)

ProCarManuals.com

Page 522 of 2399

(4) Reconnect the battery negative cable.

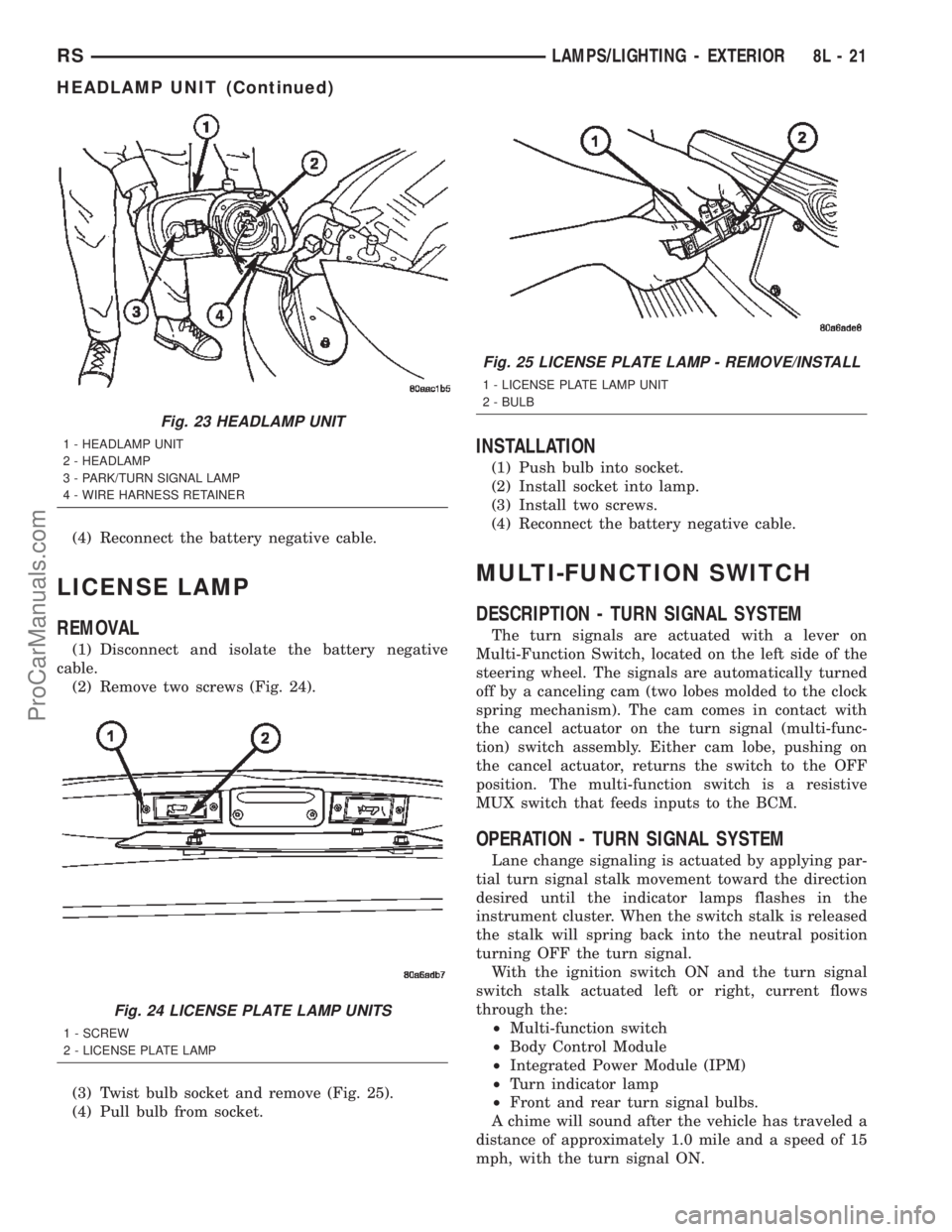

LICENSE LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two screws (Fig. 24).

(3) Twist bulb socket and remove (Fig. 25).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into lamp.

(3) Install two screws.

(4) Reconnect the battery negative cable.

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM

The turn signals are actuated with a lever on

Multi-Function Switch, located on the left side of the

steering wheel. The signals are automatically turned

off by a canceling cam (two lobes molded to the clock

spring mechanism). The cam comes in contact with

the cancel actuator on the turn signal (multi-func-

tion) switch assembly. Either cam lobe, pushing on

the cancel actuator, returns the switch to the OFF

position. The multi-function switch is a resistive

MUX switch that feeds inputs to the BCM.

OPERATION - TURN SIGNAL SYSTEM

Lane change signaling is actuated by applying par-

tial turn signal stalk movement toward the direction

desired until the indicator lamps flashes in the

instrument cluster. When the switch stalk is released

the stalk will spring back into the neutral position

turning OFF the turn signal.

With the ignition switch ON and the turn signal

switch stalk actuated left or right, current flows

through the:

²Multi-function switch

²Body Control Module

²Integrated Power Module (IPM)

²Turn indicator lamp

²Front and rear turn signal bulbs.

A chime will sound after the vehicle has traveled a

distance of approximately 1.0 mile and a speed of 15

mph, with the turn signal ON.

Fig. 23 HEADLAMP UNIT

1 - HEADLAMP UNIT

2 - HEADLAMP

3 - PARK/TURN SIGNAL LAMP

4 - WIRE HARNESS RETAINER

Fig. 24 LICENSE PLATE LAMP UNITS

1 - SCREW

2 - LICENSE PLATE LAMP

Fig. 25 LICENSE PLATE LAMP - REMOVE/INSTALL

1 - LICENSE PLATE LAMP UNIT

2 - BULB

RSLAMPS/LIGHTING - EXTERIOR8L-21

HEADLAMP UNIT (Continued)

ProCarManuals.com

Page 572 of 2399

LEFT B-PILLAR SWITCH

DESCRIPTION

Vehicles equipped with power sliding side door/s

utilize B-pillar switches. These switches are located

on the interior of the vehicle, on the B-pillar trim

panels. These switches serve as an open and close

command switch for the appropriate power side door.

The B-pillar switches are replaceable. Consult your

Mopar parts catalog for a specific part number.

OPERATION

When the Pillar switch is depressed a signal is

sent to the Body Control Module (BCM), this signal

is then sent to the Power Sliding Door Module, tell-

ing it to start a power open or close cycle. The child

lockout feature must be disabled and the side door

must be unlocked in order for the Pillar switch to

function.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Using a trim stick or other small flat-bladed

pry tool, gently pry the leading upper edge of the

B-pillar switch away from the B-pillar trim.

(3) Once the upper edge is free from pillar trim,

rock the switch out of the switch opening.

(4) Disconnect the B-pillar switch electrical con-

nector. First, slide the connector lock away from the

switch then, depress connector retaining tab while

pulling straight apart.

(5) Remove the B-pillar switch from the vehicle.

INSTALLATION

(1) Connect the B-pillar switch electrical connector.

Slide connector lock toward the switch to lock in

place.

(2) Hook the lower edge of the B-pillar switch on

the B-pillar trim and then push the switch firmly

into position.

(3) Connect the negative battery cable.

RIGHT B-PILLAR SWITCH

DESCRIPTION

Vehicles equipped with power sliding side door/s

utilize B-pillar switches. These switches are located

on the interior of the vehicle, on the B-pillar trim

panels. These switches serve as an open and close

command switch for the appropriate power side door.

The B-pillar switches are replaceable. Consult your

Mopar parts catalog for a specific part number.

OPERATION

When the Pillar switch is depressed a signal is

sent to the Body Control Module (BCM), this signal

is then sent to the Power Sliding Door Module, tell-

ing it to start a power open or close cycle. The child

lockout feature must be disabled and the side door

must be unlocked in order for the Pillar switch to

function.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Using a trim stick or other small flat-bladed

pry tool, gently pry the leading upper edge of the

B-pillar switch away from the B-pillar trim.

(3) Once the upper edge is free from pillar trim,

rock the switch out of the switch opening.

(4) Disconnect the B-pillar switch electrical con-

nector. First, slide the connector lock away from the

switch then, depress connector retaining tab while

pulling straight apart.

(5) Remove the B-pillar switch from the vehicle.

INSTALLATION

(1) Connect the B-pillar switch electrical connector.

Slide connector lock toward the switch to lock in

place.

(2) Hook the lower edge of the B-pillar switch on

the B-pillar trim and then push the switch firmly

into position.

(3) Connect the negative battery cable.

LOWER DRIVE UNIT

DESCRIPTION

Vehicles equipped with a power sliding side door

utilize a lower drive unit. The lower drive unit is

located on the sliding door lower hinge assembly

(Fig. 10). This drive unit is used to transfer the lat-

eral rotation of the flex drive assembly into longitu-

dinal movement via the drive unit gear and door

track rack teeth (Fig. 10).

The lower drive unit is a replaceable component.

Consult your Mopar parts catalog for specific part

numbers.

OPERATION

During a power open or close cycle, the power drive

unit is driven by the flex drive assembly. The lower

drive units main gear engages the lower door tracks

rack teeth, this moves the side door assembly accord-

ingly.

RSPOWER SLIDING DOOR SYSTEM8N-31

ProCarManuals.com

Page 581 of 2399

REMOTE KEYLESS ENTRY SYSTEM

The key fob transmitter (Fig. 1) has six buttons.

Three of them, LOCK, UNLOCK, and PANIC, are

used to actuate parts of, and program the Remote

Keyless Entry (RKE) system via the customer pro-

gramming mode. It is not necessary to use the

PANIC button with the DRB IIItscan tool mode of

programming.

OPERATION

POWER DOOR LOCK SYSTEM

The Body Control Module (BCM) locks or unlocks

the doors when an actuation input signal from a door

lock switch or Remote Keyless Entry Module (RKE)

is received. The BCM turns on the output drivers

and provides a voltage level to the door lock motor

for a specified time. The BCM locks the doors auto-

matically when the vehicle is driven beyond the

speed of 25.7 Km/h (16 mph). The rolling door lock

feature can be disabled if desired. All doors and lift-

gate can be locked or unlocked using mechanical but-

ton or key cylinder methods (Liftgate cylinder does

not lock/unlock vehicle. It only unlocks the liftgate).

AUTOMATIC DOOR LOCKS

The BCM is equipped with a disable feature to

stop the speed sensitive automatic door locks from

functioning. The DISABLE feature can be switched

ON or OFF as desired. When the system is DIS-

ABLED the door locks will operate normally, but will

not lock automatically when the vehicle is rolling.

When the door locks are ENABLED the door locks

will automatically lock when the vehicle is moving at

about 25.7 Km/h (16 mph). All doors are closed, the

PCM has set the ªOK TO LOCKº bit, and doors were

not previously locked.

DOOR LOCK INHIBIT

If the key is in the ignition, in any position, and

either front door is ajar, all power door lock function-

ing shall be disabled when activating either door lock

switch. Also, if the Vehicle Theft Alarm (VTA) is

armed, the door lock switch ªUNLOCKº feature will

be disabled until the vehicle is disarmed. Pressing

the RKE lock/unlock button under these conditions

will result in a normal lock/unlock activation.

After the key is removed from the Ignition Switch,

or the doors are closed, the power door locks will

operate normally.

CENTRAL LOCKING

If equipped with Vehicle Theft Security System

(VTSS), all the doors can be locked with the key by

using any of the door lock cylinders. Turning the key

to the LOCK position will lock all the doors.

When either of the front key cylinder switches is

detected active, the BCM will activate the illumi-

nated entry feature and the individual front doors

will become mechanically unlocked. To central unlock

all doors, a second transition from OFF to UNLOCK

has to occur within 2 seconds of the first complete

UNLOCK cycle.

To central unlock the driver door, turn the key to

the rear of the vehicle. This indicates an unlock sig-

nal to the BCM. For the passenger door, turn the key

toward the front of the vehicle. When either key cyl-

inder switch is detected as active, the BCM will acti-

vate the illuminated entry feature. The individual

doors will become mechanically unlocked.

To central lock the vehicle, the driver door lock cyl-

inder is turned toward the front of the vehicle. The

passenger door lock cylinder is turned toward the

rear of the vehicle. When a lock input from either

key cylinder is detected as active, the BCM will can-

cel the illuminated entry feature and perform the

central lock operation.

Fig. 1 KEY FOB

1 - LEFT SLIDING DOOR BUTTON

2 - RIGHT SLIDING DOOR BUTTON

3 - LIFTGATE SWITCH

8N - 40 POWER LOCKSRS

POWER LOCKS (Continued)

ProCarManuals.com

Page 582 of 2399

DOOR LOCK CIRCUIT PROTECTION

The BCM controls the door lock output drivers. If

the door lock switch is actuated continuously for

more than one second the BCM will turn the output

driver OFF (the BCM would consider the switch

stuck). The lock motors are protected with Positive

Temperature Coefficient (PTC) device that prevents

motor burn out.

REMOTE KEYLESS ENTRY SYSTEM

²LOCK: Pressing the LOCK button locks all

doors and sounds horn (chirp) and arm the Vehicle

Theft Security System, if equipped. The chirp verifies

that the RKE receiver has sent a message to the

BCM for door lock operation. If a door has not been

closed before pressing the LOCK button, the vehicle

may not be secured and the VTSS will not arm until

the door is closed.

²UNLOCK: Pressing the UNLOCK button once

will unlock the driver's side doors and activate the

illuminated entry system and disarm Vehicle Theft

Security System, if equipped. Pressing the UNLOCK

button twice within five seconds will unlock all doors

and activate the illuminated entry system.

²LEFT SLIDING DOOR: Pressing the LEFT

SLIDING DOOR BUTTON opens/closes the left

power sliding door remotely.

²RIGHT SLIDING DOOR: Pressing the RIGHT

SLIDING DOOR BUTTON opens/closes the right

power sliding door remotely.

²LIFTGATE:

Pressing the LIFTGATE BUTTON

opens/closes the liftgate remotely, if equipped.If not

equipped with power liftgate, pressing the liftgate but-

ton will allow a one time 30 second access to liftgate.

²PANIC: Pressing the PANIC button sounds the

horns at half second intervals, flashes the exterior

lamps, and turns ON the interior lamps. The panic

alarm will remain on for three minutes, or until the

PANIC button is actuated again or the ignition

switch is turned to the RUN position.

The Remote Keyless Entry Module is capable of

retaining the transmitter Vehicle Access Code(s)

(VAC) in its memory even after vehicle power has

been interrupted.

NOTE: Additional features available to the customer

are described in the Vehicle Owners Manual.

The RKE system activates the optional memory

seat, mirror system and adjustable pedals, if

equipped. Two primary key fob transmitters can be

programmed to actuate memory seat and mirror set-

ting 1 or 2. Two additional key fob transmitters can be

added, but they will not be able to operate the mem-

ory seat and mirror system (Refer to 8 - ELECTRI-

CAL/POWER SEATS - OPERATION) and (Refer to 8 -

ELECTRICAL/POWER MIRRORS - OPERATION).

DOOR CYLINDER LOCK

SWITCH

DESCRIPTION

The Door Cylinder Lock Switch is used to:

²Unlock/Lock all the doors via the Central Lock-

ing feature.

²Arm/Disarm the Vehicle Theft Security System.

²Trigger the Illuminated Entry feature.

The door cylinder lock switch is mounted to the

rear of the driver and passenger door lock cylinders.

When installed on the rear of the cylinder, there is a

tab on the lock cylinder that aligns with the switch

to prevent it from turning. An anti-rotating device.

The door cylinder lock switch is a one time use

switch. Once it is removed from the rear of the door

lock cylinder, it may not be reinstalled and a new

switch must be used.

OPERATION

When the Door Cylinder Lock Switch is turned

either way using the door key cylinder, the BCM

reads a direct message signal from the switch, via

the Programmable Communication Interface (PCI)

bus.

If turning the key cylinder once, toward the front

of the vehicle (for either driver or passenger doors),

this will:

(1) Mechanically unlock the door lock.

(2) Disarm the Vehicle Theft Security System (if

equipped).

(3) Turn on the Illuminated Entry (if equipped) for

approximately 30 seconds.

If the key cylinder is turned to the unlock position

(toward the front of vehicle) twice within two sec-

onds, all the doors and liftgate will unlock (if

equipped with the central locking feature).

To lock the vehicle using the door cylinder lock

switch, turn the key cylinder toward the rear of the

vehicle (either passenger or driver doors) once. This

will lock the door that you are using the key on. If

equipped with the central locking feature, this will

lock all the other doors and liftgate. Furthermore,

this will arm the vehicle theft security system and

turn off the illuminated entry.

DIAGNOSIS AND TESTING - DOOR CYLINDER

LOCK SWITCH

(1) Visually inspect the switch for proper installa-

tion. Make sure it is seated on the rear of the key

cylinder, with the tab of the door key cylinder prop-

erly aligned with the slot on the door cylinder lock

switch.

(2) Disconnect the switch at the harness connector

and check the resistance in each switch position.

RSPOWER LOCKS8N-41

POWER LOCKS (Continued)

ProCarManuals.com