tow CHRYSLER VOYAGER 2002 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1134 of 2399

RIGHT CINCH/RELEASE MOTOR (POWER SLIDING DOOR) - GRAY 4 WAY

CAV CIRCUIT FUNCTION

1 Q46 18TN/GY RIGHT CINCH/RELEASE MOTOR LATCH DRIVER

2 Z248 18BK/WT GROUND

3 Q44 18OR/GY RIGHT CINCH/RELEASE MOTOR CLUTCH DRIVER

4 Q48 18TN/WT RIGHT CINCH/RELEASE MOTOR UNLATCH DRIVER

RIGHT COMBINATION RELAY (TRAILER TOW) - BLACK 5 WAY

CAV CIRCUIT FUNCTION

1 L62 18WT/BR RIGHT REAR TURN SIGNAL DRIVER

1 L62 18WT/BR RIGHT REAR TURN SIGNAL DRIVER

2 Z1 18BK/DG GROUND

3 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

4 L605 18DG RIGHT COMBINATION SIGNAL

5- -

RIGHT CYLINDER LOCK SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z462 20BK/WT GROUND

2 G162 20VT/WT RIGHT CYLINDER LOCK SWITCH MUX

RIGHT DOOR SPEAKER - BLACK/RED 6 WAY

CAV CIRCUIT FUNCTION

1 X154 20GY/YL (HIGH LINE) RIGHT FRONT INSTRUMENT PANEL SPEAKER (+)

2 X15 16GY/DG (HIGH LINE) AMPLIFIED SPEAKER GROUND

3 X156 20GY/LB (HIGH LINE) RIGHT FRONT INSTRUMENT PANEL SPEAKER (-)

4 X54 20GY RIGHT FRONT SPEAKER (+)

5 X13 16DG/GY (HIGH LINE) RADIO CHOKE OUTPUT

6 X56 20GY/BR RIGHT FRONT SPEAKER (-)

RIGHT FOG LAMP (BUILT-UP-EXPORT) - WHITE 2 WAY

CAV CIRCUIT FUNCTION

1 L90 18WT/OR FRONT FOG LAMP RELAY OUTPUT

2 Z348 18BK/OR GROUND

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 103

ProCarManuals.com

Page 1141 of 2399

RIGHT SLIDING DOOR LOCK MOTOR (POWER SLIDING DOOR) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 P38 20TN/DB RIGHT SLIDING DOOR LOCK DRIVER

2 P34 20TN/LB RIGHT SLIDING DOOR UNLOCK DRIVER

3 Q34 20OR/GY RIGHT DOOR LOCK SENSE

4 Z76 20BK/YL GROUND

RIGHT SLIDING DOOR LOCK MOTOR/AJAR SWITCH (MANUAL SLIDING DOOR) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 P38 20BK/DB RIGHT SLIDING DOOR LOCK DRIVER

2 P34 20BK/TN RIGHT SLIDING DOOR UNLOCK DRIVER

3 G76 20BK/DG RIGHT SLIDING DOOR AJAR SWITCH SENSE

4 Z76 20BK GROUND

RIGHT SLIDING DOOR MOTOR (POWER SLIDING DOOR) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1- -

2 Q72 20TN/VT RIGHT DOOR MOTOR HALL EFFECT SUPPLY

3 Q68 16TN/BR RIGHT SLIDING DOOR OPEN DRIVER

4 Z164 18BK/TN GROUND

5 Q64 18OR/TN RIGHT DOOR MOTOR CLUTCH DRIVER

6 Q70 16TN/OR RIGHT SLIDING DOOR CLOSE DRIVER

7 Z34 20BK/TN GROUND

8 Q74 20TN/YL RIGHT DOOR MOTOR HALL EFFECT SIGNAL

RIGHT SPEED CONTROL SWITCH - WHITE 2 WAY

CAV CIRCUIT FUNCTION

A V37 20VT/TN (BUILT UP EXPORT) SPEED CONTROL SWITCH SIGNAL

A V37 20DG/VT (EXCEPT

BUILT-UP-EXPORT)SPEED CONTROL SWITCH SIGNAL

B Z23 20BK/VT RIGHT SPEED CONTROL SWITCH GROUND

RIGHT STOP/TURN SIGNAL RELAY (TRAILER TOW) - BLACK 5 WAY

CAV CIRCUIT FUNCTION

1 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

1 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

2 Z1 18BK/DG GROUND

2 Z1 18BK/DG GROUND

3 L74 18LG RIGHT STOP SIGNAL

4 L62 18WT/BR RIGHT REAR TURN SIGNAL DRIVER

5 L605 18DG RIGHT COMBINATION SIGNAL

8W - 80 - 110 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1144 of 2399

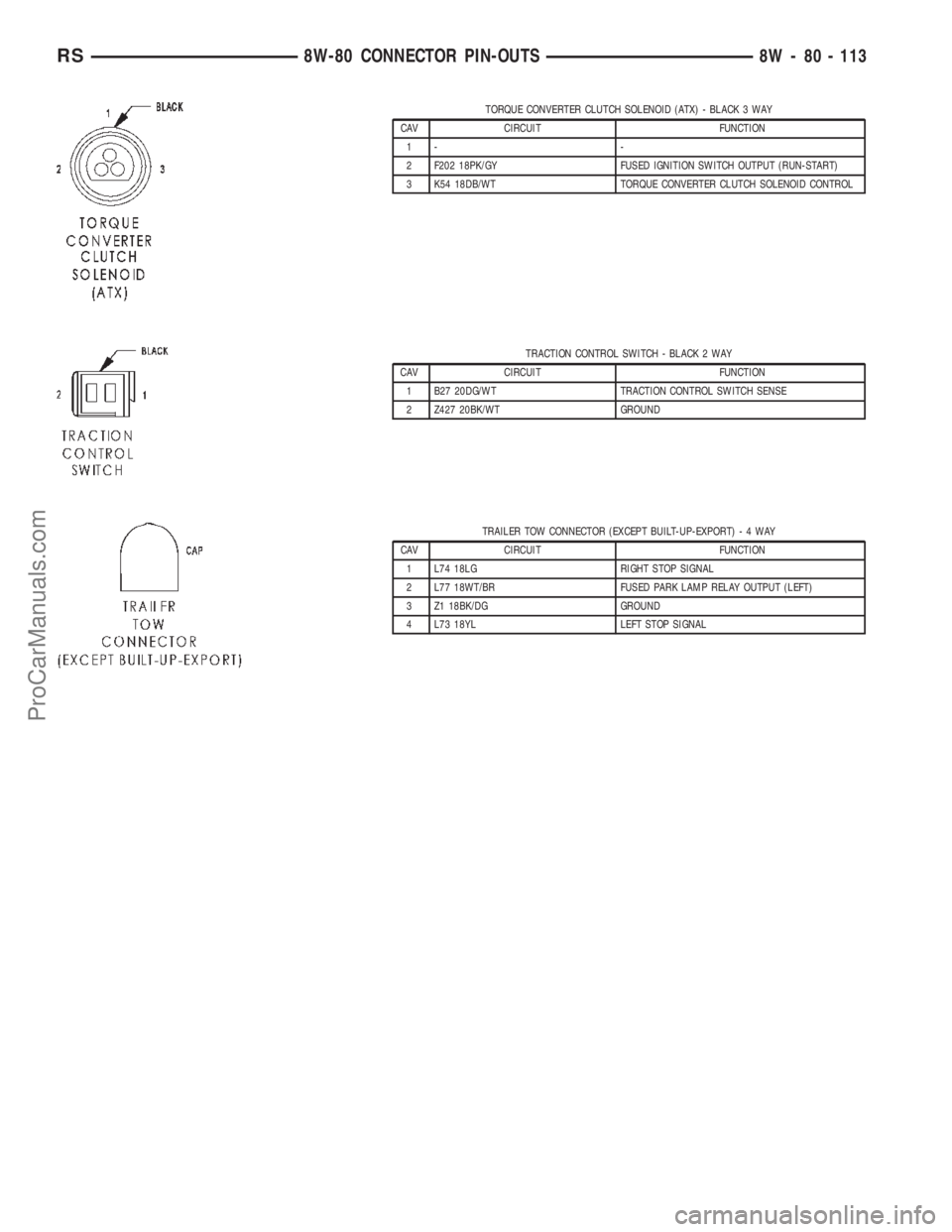

TORQUE CONVERTER CLUTCH SOLENOID (ATX) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1- -

2 F202 18PK/GY FUSED IGNITION SWITCH OUTPUT (RUN-START)

3 K54 18DB/WT TORQUE CONVERTER CLUTCH SOLENOID CONTROL

TRACTION CONTROL SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 B27 20DG/WT TRACTION CONTROL SWITCH SENSE

2 Z427 20BK/WT GROUND

TRAILER TOW CONNECTOR (EXCEPT BUILT-UP-EXPORT)-4WAY

CAV CIRCUIT FUNCTION

1 L74 18LG RIGHT STOP SIGNAL

2 L77 18WT/BR FUSED PARK LAMP RELAY OUTPUT (LEFT)

3 Z1 18BK/DG GROUND

4 L73 18YL LEFT STOP SIGNAL

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 113

ProCarManuals.com

Page 1149 of 2399

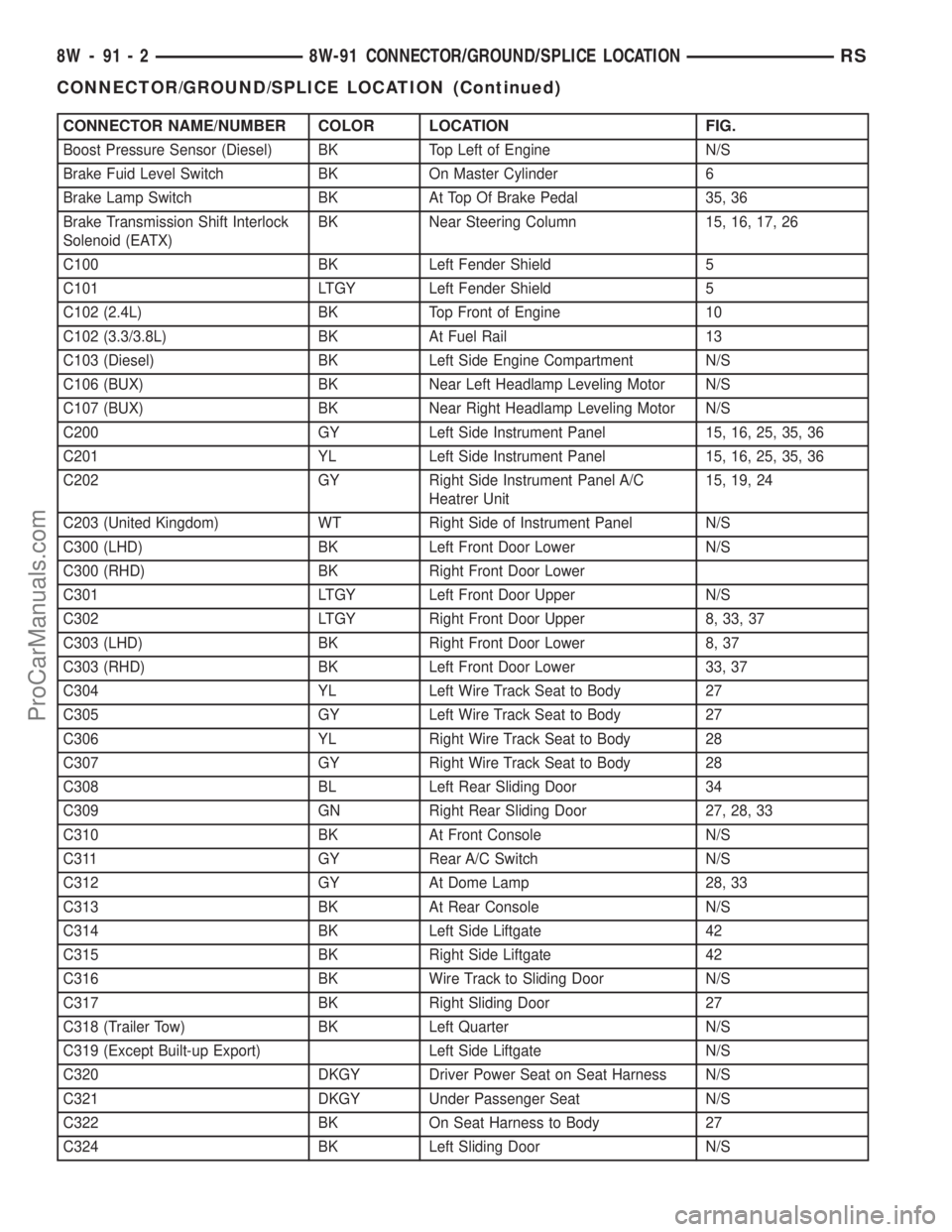

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Boost Pressure Sensor (Diesel) BK Top Left of Engine N/S

Brake Fuid Level Switch BK On Master Cylinder 6

Brake Lamp Switch BK At Top Of Brake Pedal 35, 36

Brake Transmission Shift Interlock

Solenoid (EATX)BK Near Steering Column 15, 16, 17, 26

C100 BK Left Fender Shield 5

C101 LTGY Left Fender Shield 5

C102 (2.4L) BK Top Front of Engine 10

C102 (3.3/3.8L) BK At Fuel Rail 13

C103 (Diesel) BK Left Side Engine Compartment N/S

C106 (BUX) BK Near Left Headlamp Leveling Motor N/S

C107 (BUX) BK Near Right Headlamp Leveling Motor N/S

C200 GY Left Side Instrument Panel 15, 16, 25, 35, 36

C201 YL Left Side Instrument Panel 15, 16, 25, 35, 36

C202 GY Right Side Instrument Panel A/C

Heatrer Unit15, 19, 24

C203 (United Kingdom) WT Right Side of Instrument Panel N/S

C300 (LHD) BK Left Front Door Lower N/S

C300 (RHD) BK Right Front Door Lower

C301 LTGY Left Front Door Upper N/S

C302 LTGY Right Front Door Upper 8, 33, 37

C303 (LHD) BK Right Front Door Lower 8, 37

C303 (RHD) BK Left Front Door Lower 33, 37

C304 YL Left Wire Track Seat to Body 27

C305 GY Left Wire Track Seat to Body 27

C306 YL Right Wire Track Seat to Body 28

C307 GY Right Wire Track Seat to Body 28

C308 BL Left Rear Sliding Door 34

C309 GN Right Rear Sliding Door 27, 28, 33

C310 BK At Front Console N/S

C311 GY Rear A/C Switch N/S

C312 GY At Dome Lamp 28, 33

C313 BK At Rear Console N/S

C314 BK Left Side Liftgate 42

C315 BK Right Side Liftgate 42

C316 BK Wire Track to Sliding Door N/S

C317 BK Right Sliding Door 27

C318 (Trailer Tow) BK Left Quarter N/S

C319 (Except Built-up Export) Left Side Liftgate N/S

C320 DKGY Driver Power Seat on Seat Harness N/S

C321 DKGY Under Passenger Seat N/S

C322 BK On Seat Harness to Body 27

C324 BK Left Sliding Door N/S

8W - 91 - 2 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1157 of 2399

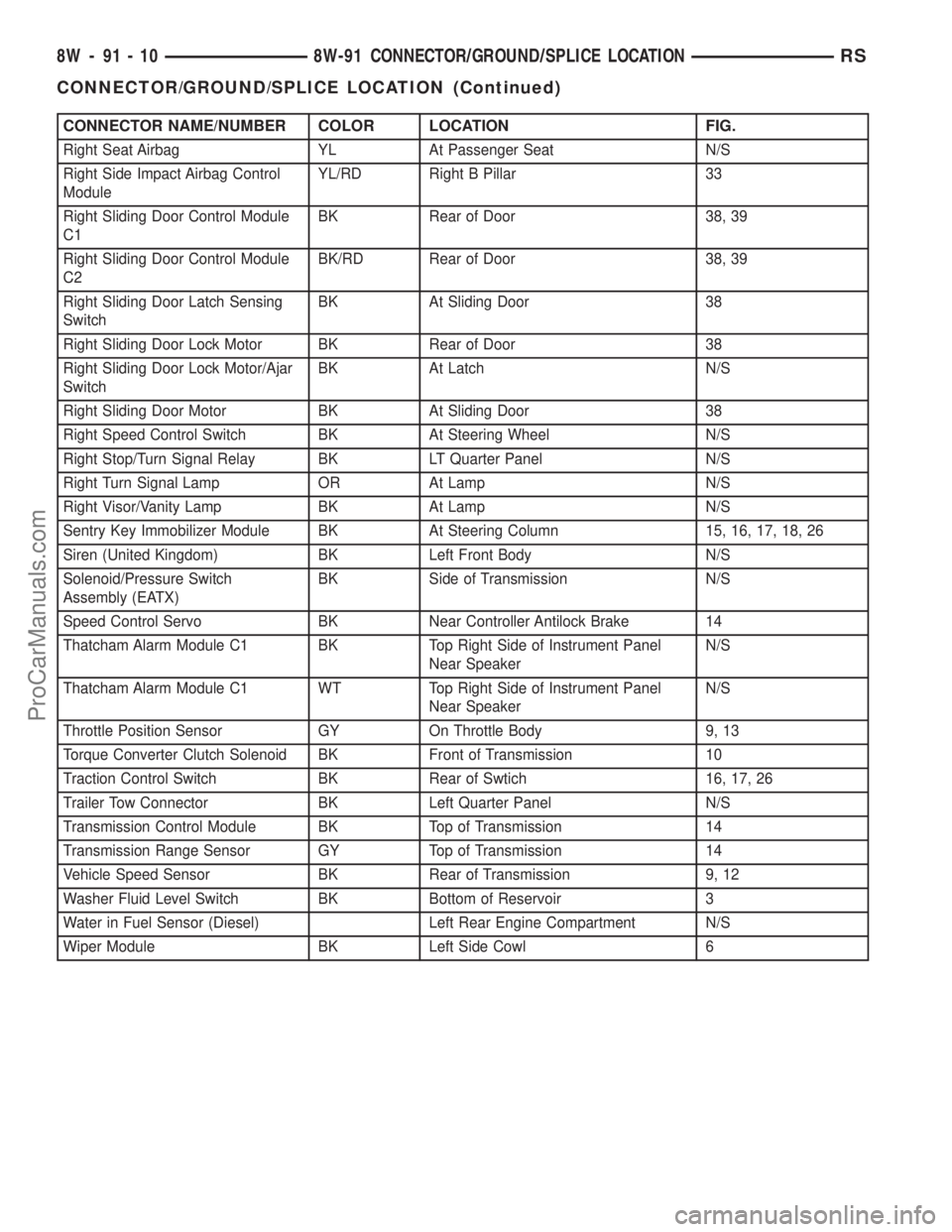

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Right Seat Airbag YL At Passenger Seat N/S

Right Side Impact Airbag Control

ModuleYL/RD Right B Pillar 33

Right Sliding Door Control Module

C1BK Rear of Door 38, 39

Right Sliding Door Control Module

C2BK/RD Rear of Door 38, 39

Right Sliding Door Latch Sensing

SwitchBK At Sliding Door 38

Right Sliding Door Lock Motor BK Rear of Door 38

Right Sliding Door Lock Motor/Ajar

SwitchBK At Latch N/S

Right Sliding Door Motor BK At Sliding Door 38

Right Speed Control Switch BK At Steering Wheel N/S

Right Stop/Turn Signal Relay BK LT Quarter Panel N/S

Right Turn Signal Lamp OR At Lamp N/S

Right Visor/Vanity Lamp BK At Lamp N/S

Sentry Key Immobilizer Module BK At Steering Column 15, 16, 17, 18, 26

Siren (United Kingdom) BK Left Front Body N/S

Solenoid/Pressure Switch

Assembly (EATX)BK Side of Transmission N/S

Speed Control Servo BK Near Controller Antilock Brake 14

Thatcham Alarm Module C1 BK Top Right Side of Instrument Panel

Near SpeakerN/S

Thatcham Alarm Module C1 WT Top Right Side of Instrument Panel

Near SpeakerN/S

Throttle Position Sensor GY On Throttle Body 9, 13

Torque Converter Clutch Solenoid BK Front of Transmission 10

Traction Control Switch BK Rear of Swtich 16, 17, 26

Trailer Tow Connector BK Left Quarter Panel N/S

Transmission Control Module BK Top of Transmission 14

Transmission Range Sensor GY Top of Transmission 14

Vehicle Speed Sensor BK Rear of Transmission 9, 12

Washer Fluid Level Switch BK Bottom of Reservoir 3

Water in Fuel Sensor (Diesel) Left Rear Engine Compartment N/S

Wiper Module BK Left Side Cowl 6

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1197 of 2399

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

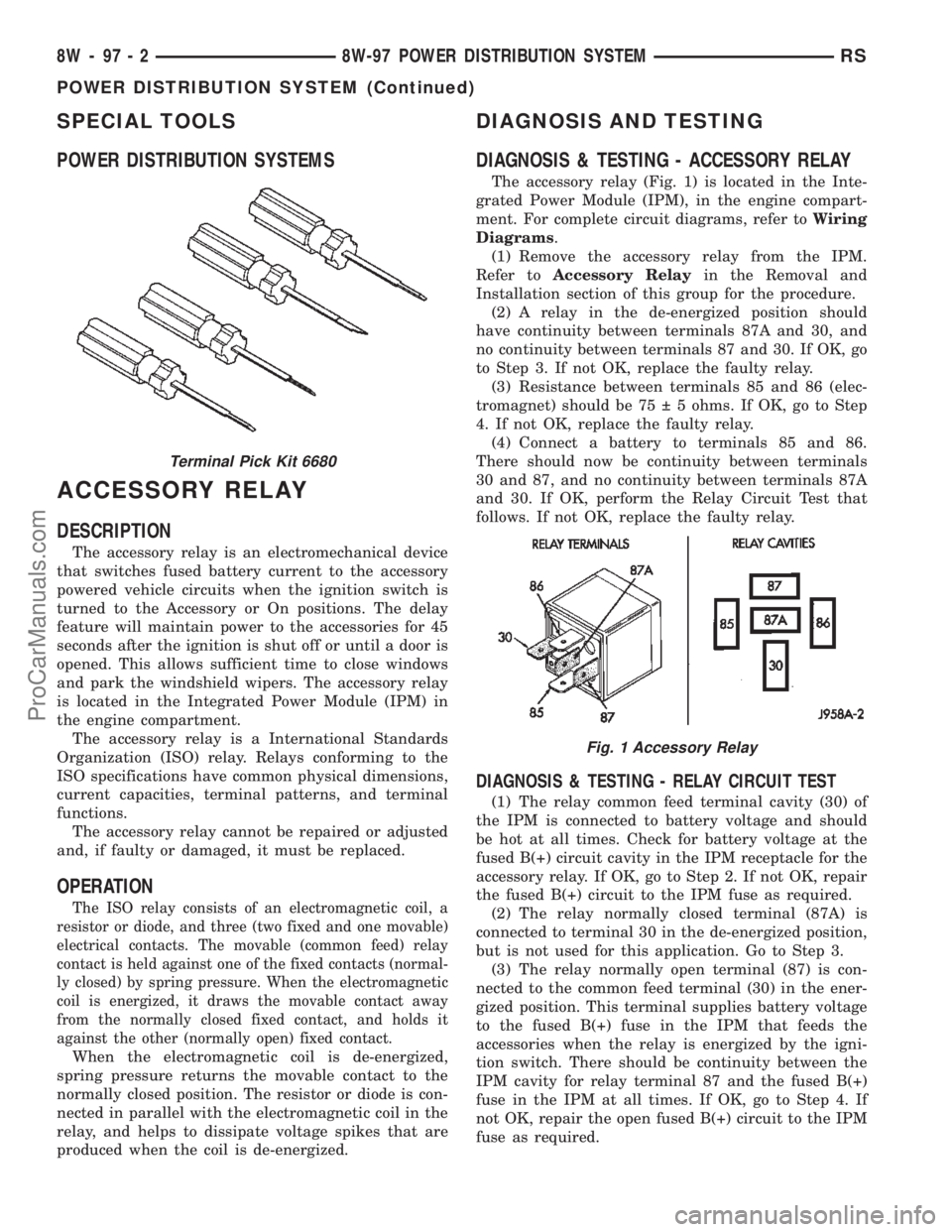

ACCESSORY RELAY

DESCRIPTION

The accessory relay is an electromechanical device

that switches fused battery current to the accessory

powered vehicle circuits when the ignition switch is

turned to the Accessory or On positions. The delay

feature will maintain power to the accessories for 45

seconds after the ignition is shut off or until a door is

opened. This allows sufficient time to close windows

and park the windshield wipers. The accessory relay

is located in the Integrated Power Module (IPM) in

the engine compartment.

The accessory relay is a International Standards

Organization (ISO) relay. Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions.

The accessory relay cannot be repaired or adjusted

and, if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one movable)

electrical contacts. The movable (common feed) relay

contact is held against one of the fixed contacts (normal-

ly closed) by spring pressure. When the electromagnetic

coil is energized, it draws the movable contact away

from the normally closed fixed contact, and holds it

against the other (normally open) fixed contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - ACCESSORY RELAY

The accessory relay (Fig. 1) is located in the Inte-

grated Power Module (IPM), in the engine compart-

ment. For complete circuit diagrams, refer toWiring

Diagrams.

(1) Remove the accessory relay from the IPM.

Refer toAccessory Relayin the Removal and

Installation section of this group for the procedure.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

DIAGNOSIS & TESTING - RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) of

the IPM is connected to battery voltage and should

be hot at all times. Check for battery voltage at the

fused B(+) circuit cavity in the IPM receptacle for the

accessory relay. If OK, go to Step 2. If not OK, repair

the fused B(+) circuit to the IPM fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the fused B(+) fuse in the IPM that feeds the

accessories when the relay is energized by the igni-

tion switch. There should be continuity between the

IPM cavity for relay terminal 87 and the fused B(+)

fuse in the IPM at all times. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit to the IPM

fuse as required.

Terminal Pick Kit 6680

Fig. 1 Accessory Relay

8W - 97 - 2 8W-97 POWER DISTRIBUTION SYSTEMRS

POWER DISTRIBUTION SYSTEM (Continued)

ProCarManuals.com

Page 1211 of 2399

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 2).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS

Damaged or worn threads (excluding spark plug

and camshaft bearing cap attaching threads) can be

repaired. Essentially, this repair consists of drilling

out worn or damaged threads, tapping the hole with

a special Heli-Coil Tap, (or equivalent) and installing

an insert into the tapped hole. This brings the hole

back to its original thread size.

CAUTION: Be sure that the tapped holes maintain

the original center line.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

STANDARD PROCEDURE - HYDROSTATIC

LOCKED ENGINE

When an engine is suspected to be hydrostatically

locked, regardless of what caused the problem, the

following steps should be used.

CAUTION: DO NOT use starter motor to rotate the

engine, severe damage may occur.

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.)

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

Fig. 2 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

9 - 10 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1212 of 2399

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Install a new oil filter.

(11) Fill engine with specified amount of approved

oil.

(12) Connect negative battery cable.

(13) Start engine and check for any leaks.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

anaerobic material is for use between two machined

surfaces. Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANTis a unique

(green-in-color) anaerobic type gasket material that

is specially made to seal the area between the bed-plate and cylinder block without disturbing the bear-

ing clearance or alignment of these components. The

material cures slowly in the absence of air when

torqued between two metallic surfaces, and will rap-

idly cure when heat is applied.

MOPARtGASKET SEALANTis a slow drying,

permanently soft sealer. This material is recom-

mended for sealing threaded fittings and gaskets

against leakage of oil and coolant. Can be used on

threaded and machined parts under all tempera-

tures. This material is used on engines with multi-

layer steel (MLS) cylinder head gaskets. This

material also will prevent corrosion. MopartGasket

Sealant is available in a 13 oz. aerosol can or 4oz./16

oz. can w/applicator.

SEALER APPLICATION

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 3)

RSENGINE 2.4L9-11

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1225 of 2399

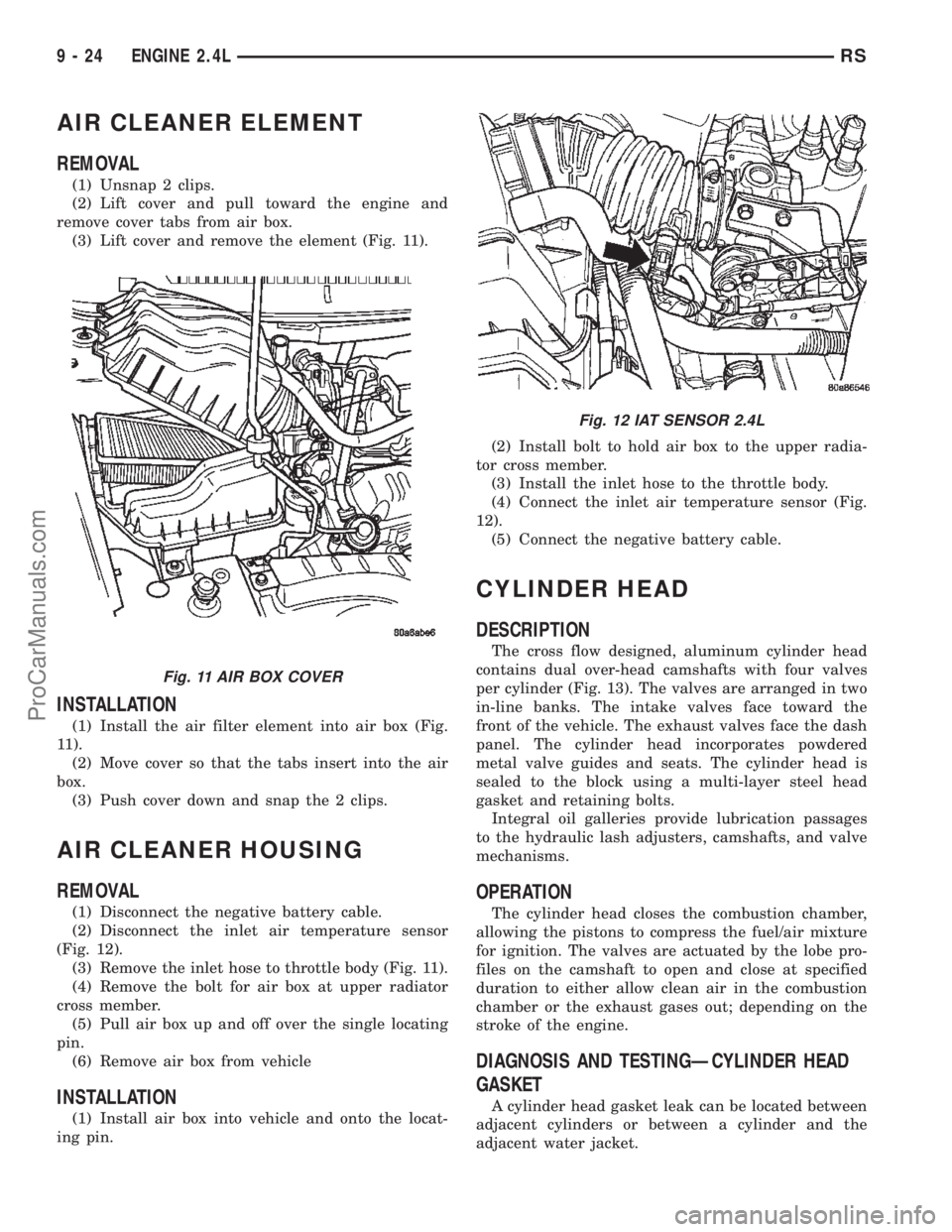

AIR CLEANER ELEMENT

REMOVAL

(1) Unsnap 2 clips.

(2) Lift cover and pull toward the engine and

remove cover tabs from air box.

(3) Lift cover and remove the element (Fig. 11).

INSTALLATION

(1) Install the air filter element into air box (Fig.

11).

(2) Move cover so that the tabs insert into the air

box.

(3) Push cover down and snap the 2 clips.

AIR CLEANER HOUSING

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect the inlet air temperature sensor

(Fig. 12).

(3) Remove the inlet hose to throttle body (Fig. 11).

(4) Remove the bolt for air box at upper radiator

cross member.

(5) Pull air box up and off over the single locating

pin.

(6) Remove air box from vehicle

INSTALLATION

(1) Install air box into vehicle and onto the locat-

ing pin.(2) Install bolt to hold air box to the upper radia-

tor cross member.

(3) Install the inlet hose to the throttle body.

(4) Connect the inlet air temperature sensor (Fig.

12).

(5) Connect the negative battery cable.

CYLINDER HEAD

DESCRIPTION

The cross flow designed, aluminum cylinder head

contains dual over-head camshafts with four valves

per cylinder (Fig. 13). The valves are arranged in two

in-line banks. The intake valves face toward the

front of the vehicle. The exhaust valves face the dash

panel. The cylinder head incorporates powdered

metal valve guides and seats. The cylinder head is

sealed to the block using a multi-layer steel head

gasket and retaining bolts.

Integral oil galleries provide lubrication passages

to the hydraulic lash adjusters, camshafts, and valve

mechanisms.

OPERATION

The cylinder head closes the combustion chamber,

allowing the pistons to compress the fuel/air mixture

for ignition. The valves are actuated by the lobe pro-

files on the camshaft to open and close at specified

duration to either allow clean air in the combustion

chamber or the exhaust gases out; depending on the

stroke of the engine.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Fig. 11 AIR BOX COVER

Fig. 12 IAT SENSOR 2.4L

9 - 24 ENGINE 2.4LRS

ProCarManuals.com

Page 1244 of 2399

(4) Using Tool 6771 to remove front crankshaft oil

seal (Fig. 58). Be careful not to damage the seal sur-

face of cover.

INSTALLATION

(1) Install new seal by using Special Tool 6780

(Fig. 59).

(2) Place seal into opening with seal spring

towards the inside of engine. Install seal until flush

with cover.

(3) Install crankshaft sprocket using Special Tool

6792 (Fig. 60).

(4) Install timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

(5) Install crankshaft vibration damper. (Refer to 9

- ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Remove transaxle. Refer to TRANSMISSION/

TRANSAXLE - REMOVAL for procedure.

(2) Remove flex plate.

(3) Insert a 3/16 flat bladed screwdriver between

the dust lip and the metal case of the crankshaft

seal. Angle the screwdriver (Fig. 61)through the dust

lip against metal case of the seal. Pry out seal.

CAUTION: Do not permit the screwdriver blade to

contact crankshaft seal surface. Contact of the

screwdriver blade against crankshaft edge (cham-

fer) is permitted.

Fig. 58 Front Crankshaft Oil Seal - Removal

1 - SPECIAL TOOL 6771

2 - REAR TIMING BELT COVER

Fig. 59 Crankshaft Front Oil Seal - Installation

1 - PROTECTOR

2 - SEAL

3 - SPECIAL TOOL 6780

Fig. 60 Crankshaft Sprocket - Installation

1 - SPECIAL TOOL 6792

2 - TIGHTEN NUT TO INSTALL

RSENGINE 2.4L9-43

CRANKSHAFT OIL SEAL - FRONT (Continued)

ProCarManuals.com