torque CHRYSLER VOYAGER 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 117 of 2399

OPERATION

In order to achieve all-wheel drive operation in

reverse, the overrunning clutch locking functional direc-

tion must be reversible. The bi-directional overrunning

clutch (BOC) changes the operational mode direction

depending on the propeller shaft direction. The propel-

ler shaft rotates in the clockwise (when viewed from the

front) direction when the vehicle is moving forward,

which indexes the BOC to the forward overrunning

position. When the vehicle is in reverse, the propeller

shaft will rotate counter-clockwise and index the BOC

to the reverse overrunning position.

The BOC acts as a mechanical stator. It is active

(transmitting torque), or it is not active and in over-

running mode (not transmitting torque). This ªall or

nothingº approach to torque transfer would cause a

sudden application of all available power to the rear

wheels, which is not desirable. Therefore it is run in

series with a viscous coupler to smooth, dampen, and

limit the transmission of torque to the rear axle and

to prevent a step style torque input to the rear axle.

STEADY STATE, LOW TO MODERATE SPEED, NO

FRONT WHEEL SLIP, FORWARD DIRECTION

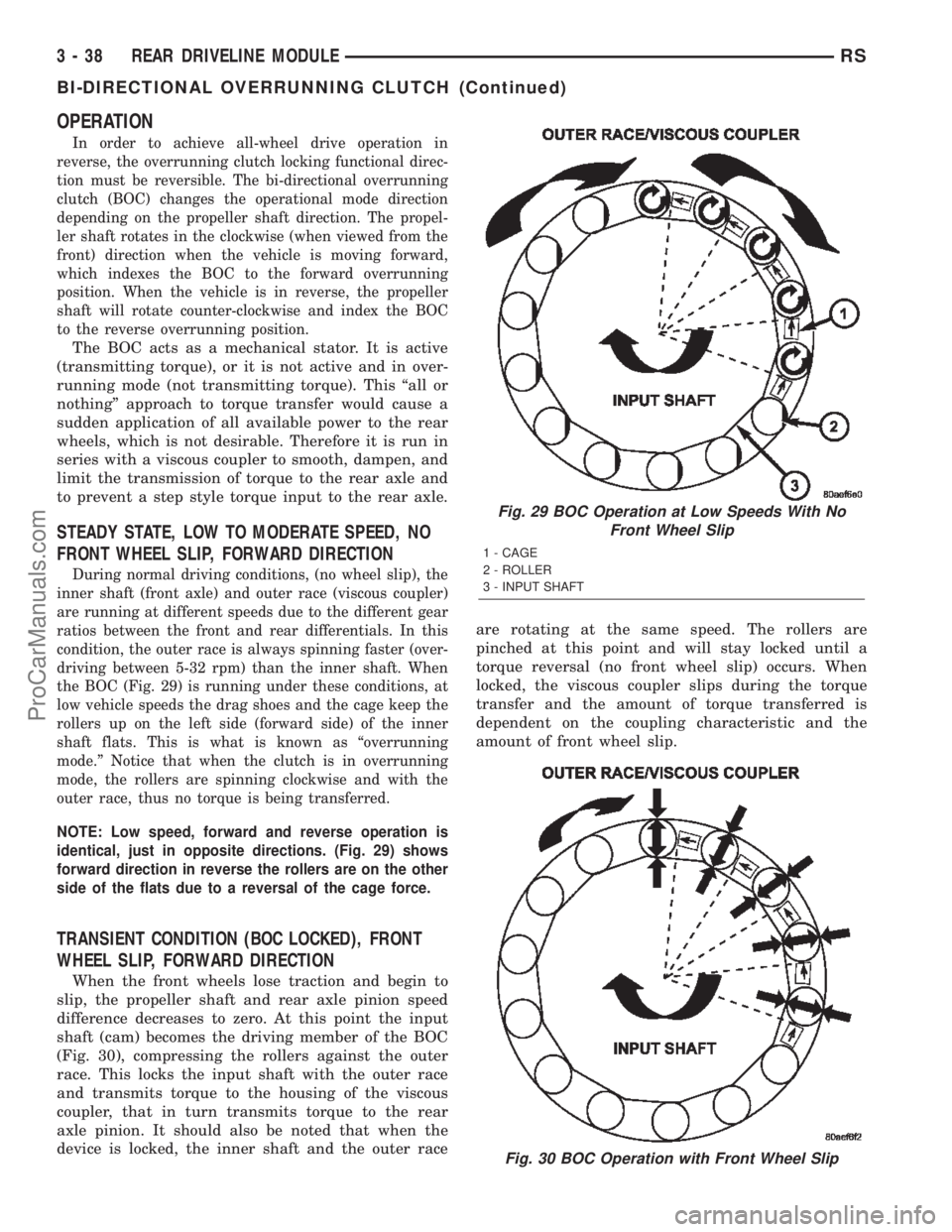

During normal driving conditions, (no wheel slip), the

inner shaft (front axle) and outer race (viscous coupler)

are running at different speeds due to the different gear

ratios between the front and rear differentials. In this

condition, the outer race is always spinning faster (over-

driving between 5-32 rpm) than the inner shaft. When

the BOC (Fig. 29) is running under these conditions, at

low vehicle speeds the drag shoes and the cage keep the

rollers up on the left side (forward side) of the inner

shaft flats. This is what is known as ªoverrunning

mode.º Notice that when the clutch is in overrunning

mode, the rollers are spinning clockwise and with the

outer race, thus no torque is being transferred.

NOTE: Low speed, forward and reverse operation is

identical, just in opposite directions. (Fig. 29) shows

forward direction in reverse the rollers are on the other

side of the flats due to a reversal of the cage force.

TRANSIENT CONDITION (BOC LOCKED), FRONT

WHEEL SLIP, FORWARD DIRECTION

When the front wheels lose traction and begin to

slip, the propeller shaft and rear axle pinion speed

difference decreases to zero. At this point the input

shaft (cam) becomes the driving member of the BOC

(Fig. 30), compressing the rollers against the outer

race. This locks the input shaft with the outer race

and transmits torque to the housing of the viscous

coupler, that in turn transmits torque to the rear

axle pinion. It should also be noted that when the

device is locked, the inner shaft and the outer raceare rotating at the same speed. The rollers are

pinched at this point and will stay locked until a

torque reversal (no front wheel slip) occurs. When

locked, the viscous coupler slips during the torque

transfer and the amount of torque transferred is

dependent on the coupling characteristic and the

amount of front wheel slip.

Fig. 29 BOC Operation at Low Speeds With No

Front Wheel Slip

1 - CAGE

2 - ROLLER

3 - INPUT SHAFT

Fig. 30 BOC Operation with Front Wheel Slip

3 - 38 REAR DRIVELINE MODULERS

BI-DIRECTIONAL OVERRUNNING CLUTCH (Continued)

ProCarManuals.com

Page 118 of 2399

STEADY STATE, HIGH SPEED, NO WHEEL SLIP

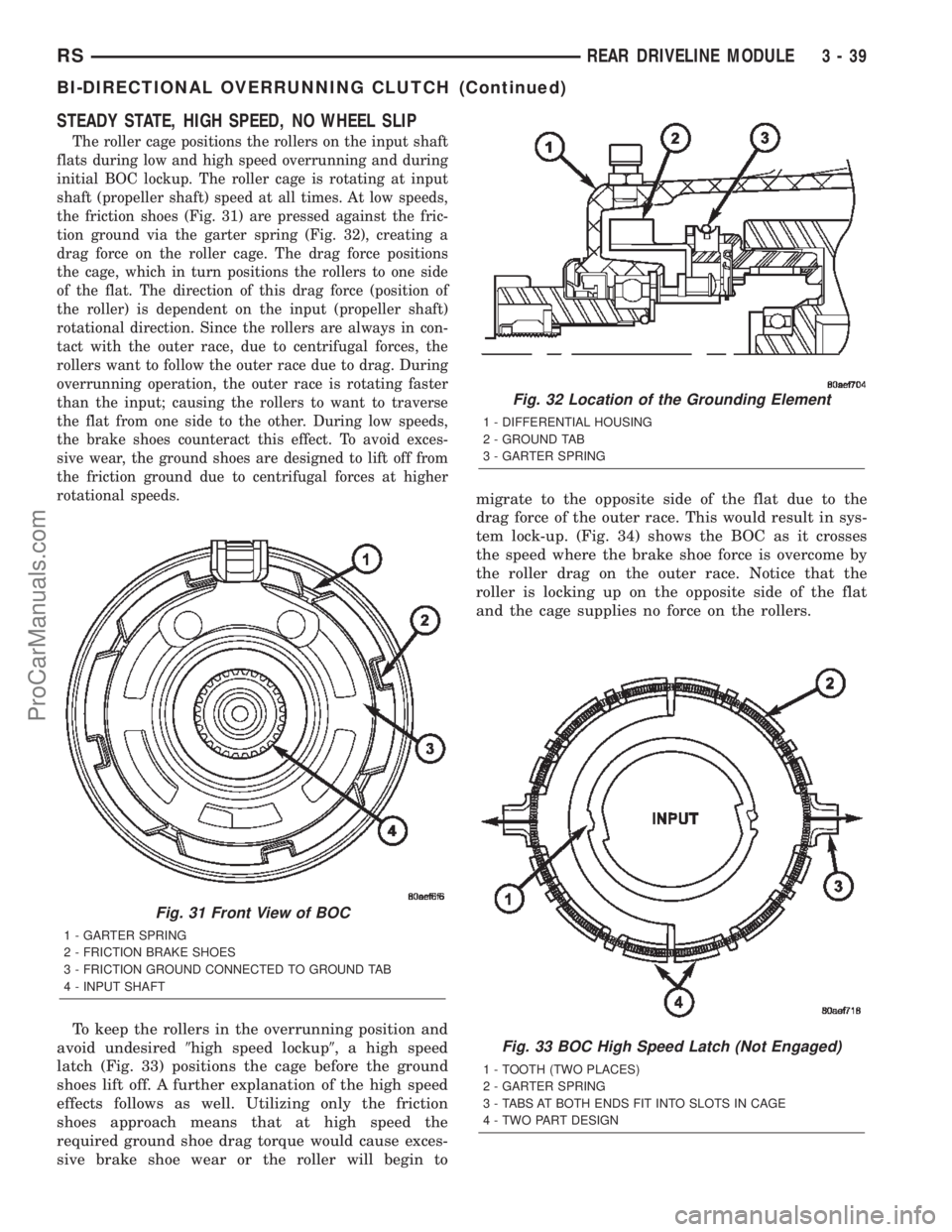

The roller cage positions the rollers on the input shaft

flats during low and high speed overrunning and during

initial BOC lockup. The roller cage is rotating at input

shaft (propeller shaft) speed at all times. At low speeds,

the friction shoes (Fig. 31) are pressed against the fric-

tion ground via the garter spring (Fig. 32), creating a

drag force on the roller cage. The drag force positions

the cage, which in turn positions the rollers to one side

of the flat. The direction of this drag force (position of

the roller) is dependent on the input (propeller shaft)

rotational direction. Since the rollers are always in con-

tact with the outer race, due to centrifugal forces, the

rollers want to follow the outer race due to drag. During

overrunning operation, the outer race is rotating faster

than the input; causing the rollers to want to traverse

the flat from one side to the other. During low speeds,

the brake shoes counteract this effect. To avoid exces-

sive wear, the ground shoes are designed to lift off from

the friction ground due to centrifugal forces at higher

rotational speeds.

To keep the rollers in the overrunning position and

avoid undesired9high speed lockup9, a high speed

latch (Fig. 33) positions the cage before the ground

shoes lift off. A further explanation of the high speed

effects follows as well. Utilizing only the friction

shoes approach means that at high speed the

required ground shoe drag torque would cause exces-

sive brake shoe wear or the roller will begin tomigrate to the opposite side of the flat due to the

drag force of the outer race. This would result in sys-

tem lock-up. (Fig. 34) shows the BOC as it crosses

the speed where the brake shoe force is overcome by

the roller drag on the outer race. Notice that the

roller is locking up on the opposite side of the flat

and the cage supplies no force on the rollers.

Fig. 31 Front View of BOC

1 - GARTER SPRING

2 - FRICTION BRAKE SHOES

3 - FRICTION GROUND CONNECTED TO GROUND TAB

4 - INPUT SHAFT

Fig. 32 Location of the Grounding Element

1 - DIFFERENTIAL HOUSING

2 - GROUND TAB

3 - GARTER SPRING

Fig. 33 BOC High Speed Latch (Not Engaged)

1 - TOOTH (TWO PLACES)

2 - GARTER SPRING

3 - TABS AT BOTH ENDS FIT INTO SLOTS IN CAGE

4 - TWO PART DESIGN

RSREAR DRIVELINE MODULE3-39

BI-DIRECTIONAL OVERRUNNING CLUTCH (Continued)

ProCarManuals.com

Page 119 of 2399

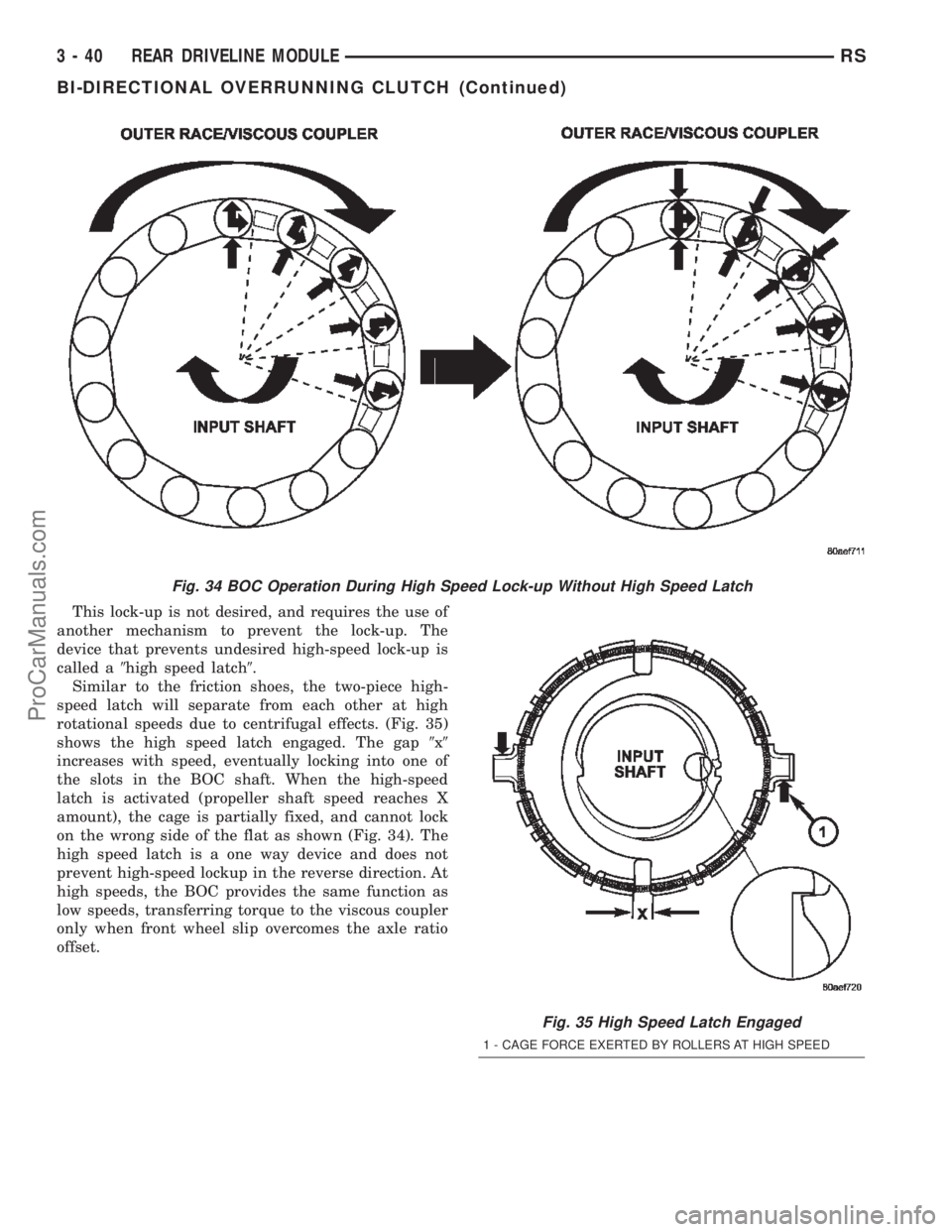

This lock-up is not desired, and requires the use of

another mechanism to prevent the lock-up. The

device that prevents undesired high-speed lock-up is

called a9high speed latch9.

Similar to the friction shoes, the two-piece high-

speed latch will separate from each other at high

rotational speeds due to centrifugal effects. (Fig. 35)

shows the high speed latch engaged. The gap9x9

increases with speed, eventually locking into one of

the slots in the BOC shaft. When the high-speed

latch is activated (propeller shaft speed reaches X

amount), the cage is partially fixed, and cannot lock

on the wrong side of the flat as shown (Fig. 34). The

high speed latch is a one way device and does not

prevent high-speed lockup in the reverse direction. At

high speeds, the BOC provides the same function as

low speeds, transferring torque to the viscous coupler

only when front wheel slip overcomes the axle ratio

offset.

Fig. 34 BOC Operation During High Speed Lock-up Without High Speed Latch

Fig. 35 High Speed Latch Engaged

1 - CAGE FORCE EXERTED BY ROLLERS AT HIGH SPEED

3 - 40 REAR DRIVELINE MODULERS

BI-DIRECTIONAL OVERRUNNING CLUTCH (Continued)

ProCarManuals.com

Page 120 of 2399

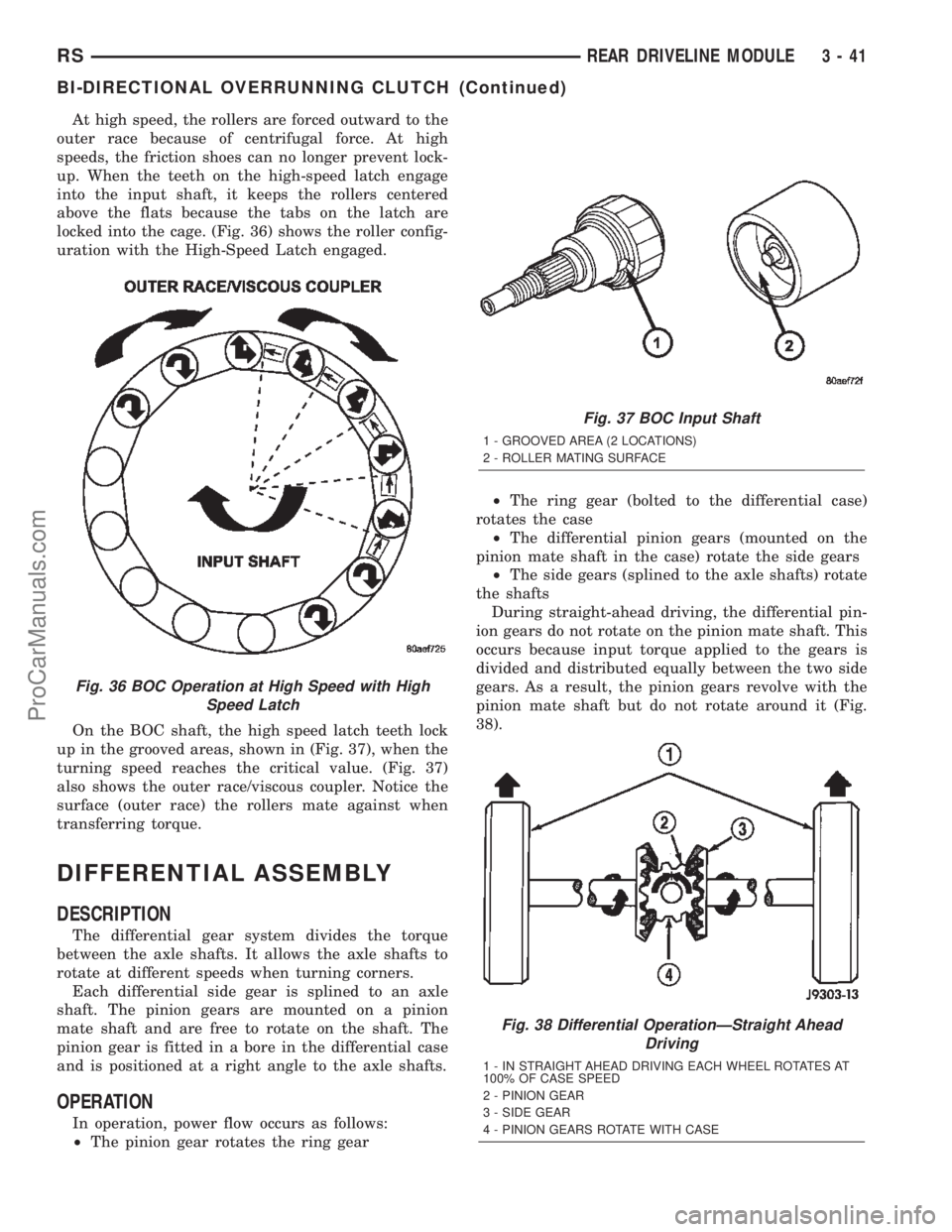

At high speed, the rollers are forced outward to the

outer race because of centrifugal force. At high

speeds, the friction shoes can no longer prevent lock-

up. When the teeth on the high-speed latch engage

into the input shaft, it keeps the rollers centered

above the flats because the tabs on the latch are

locked into the cage. (Fig. 36) shows the roller config-

uration with the High-Speed Latch engaged.

On the BOC shaft, the high speed latch teeth lock

up in the grooved areas, shown in (Fig. 37), when the

turning speed reaches the critical value. (Fig. 37)

also shows the outer race/viscous coupler. Notice the

surface (outer race) the rollers mate against when

transferring torque.

DIFFERENTIAL ASSEMBLY

DESCRIPTION

The differential gear system divides the torque

between the axle shafts. It allows the axle shafts to

rotate at different speeds when turning corners.

Each differential side gear is splined to an axle

shaft. The pinion gears are mounted on a pinion

mate shaft and are free to rotate on the shaft. The

pinion gear is fitted in a bore in the differential case

and is positioned at a right angle to the axle shafts.

OPERATION

In operation, power flow occurs as follows:

²The pinion gear rotates the ring gear²The ring gear (bolted to the differential case)

rotates the case

²The differential pinion gears (mounted on the

pinion mate shaft in the case) rotate the side gears

²The side gears (splined to the axle shafts) rotate

the shafts

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig.

38).

Fig. 36 BOC Operation at High Speed with High

Speed Latch

Fig. 37 BOC Input Shaft

1 - GROOVED AREA (2 LOCATIONS)

2 - ROLLER MATING SURFACE

Fig. 38 Differential OperationÐStraight Ahead

Driving

1 - IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

RSREAR DRIVELINE MODULE3-41

BI-DIRECTIONAL OVERRUNNING CLUTCH (Continued)

ProCarManuals.com

Page 121 of 2399

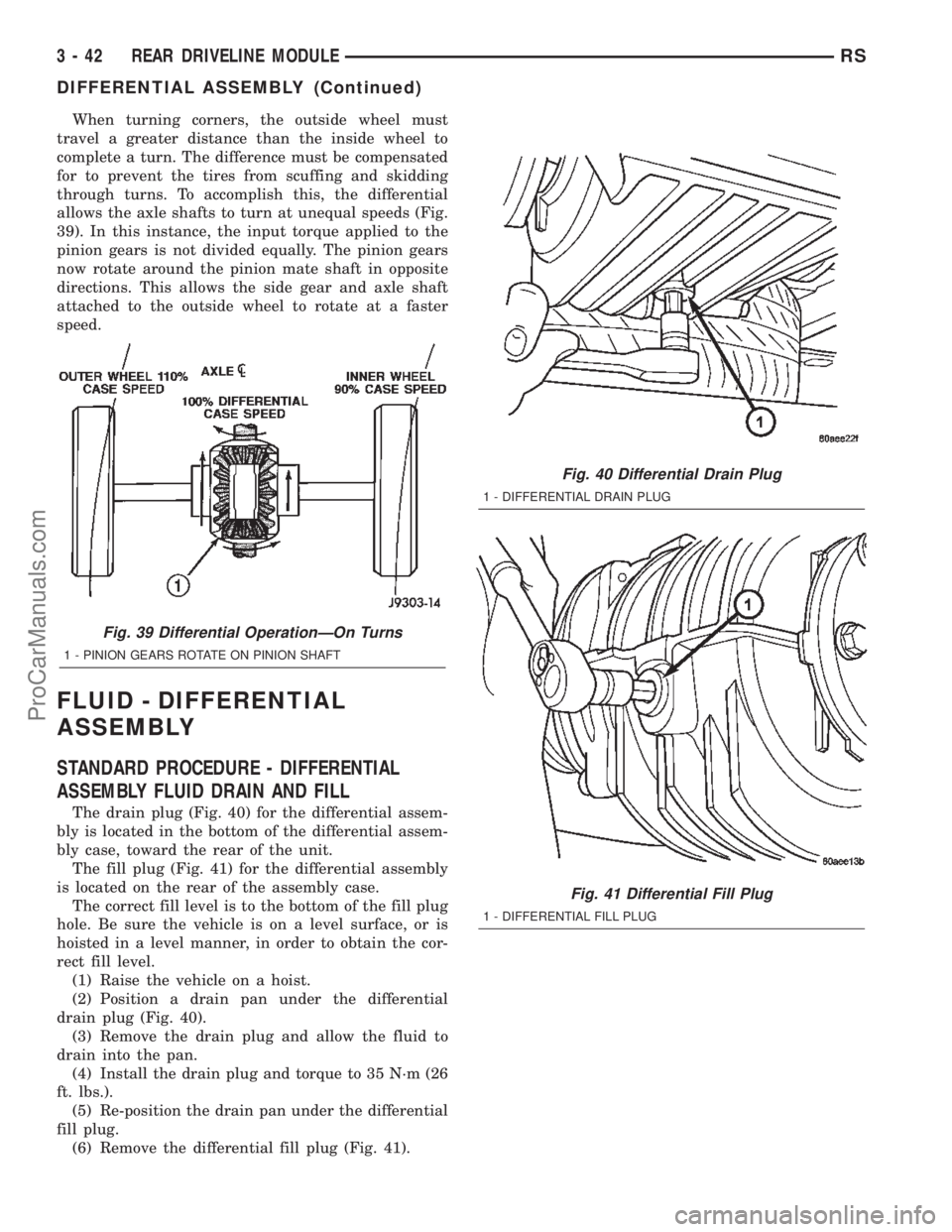

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. The difference must be compensated

for to prevent the tires from scuffing and skidding

through turns. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

39). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

FLUID - DIFFERENTIAL

ASSEMBLY

STANDARD PROCEDURE - DIFFERENTIAL

ASSEMBLY FLUID DRAIN AND FILL

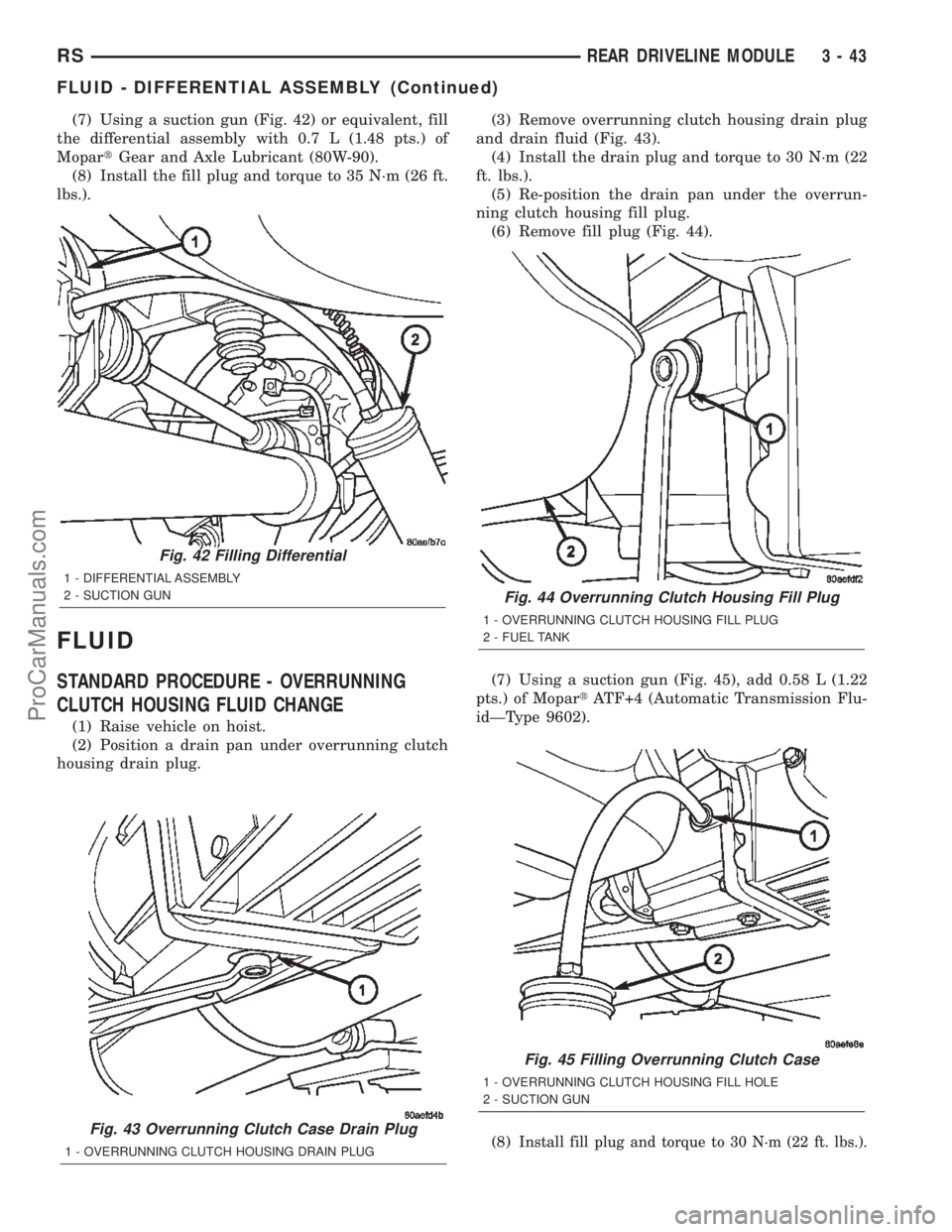

The drain plug (Fig. 40) for the differential assem-

bly is located in the bottom of the differential assem-

bly case, toward the rear of the unit.

The fill plug (Fig. 41) for the differential assembly

is located on the rear of the assembly case.

The correct fill level is to the bottom of the fill plug

hole. Be sure the vehicle is on a level surface, or is

hoisted in a level manner, in order to obtain the cor-

rect fill level.

(1) Raise the vehicle on a hoist.

(2) Position a drain pan under the differential

drain plug (Fig. 40).

(3) Remove the drain plug and allow the fluid to

drain into the pan.

(4) Install the drain plug and torque to 35 N´m (26

ft. lbs.).

(5) Re-position the drain pan under the differential

fill plug.

(6) Remove the differential fill plug (Fig. 41).

Fig. 39 Differential OperationÐOn Turns

1 - PINION GEARS ROTATE ON PINION SHAFT

Fig. 40 Differential Drain Plug

1 - DIFFERENTIAL DRAIN PLUG

Fig. 41 Differential Fill Plug

1 - DIFFERENTIAL FILL PLUG

3 - 42 REAR DRIVELINE MODULERS

DIFFERENTIAL ASSEMBLY (Continued)

ProCarManuals.com

Page 122 of 2399

(7) Using a suction gun (Fig. 42) or equivalent, fill

the differential assembly with 0.7 L (1.48 pts.) of

MopartGear and Axle Lubricant (80W-90).

(8) Install the fill plug and torque to 35 N´m (26 ft.

lbs.).

FLUID

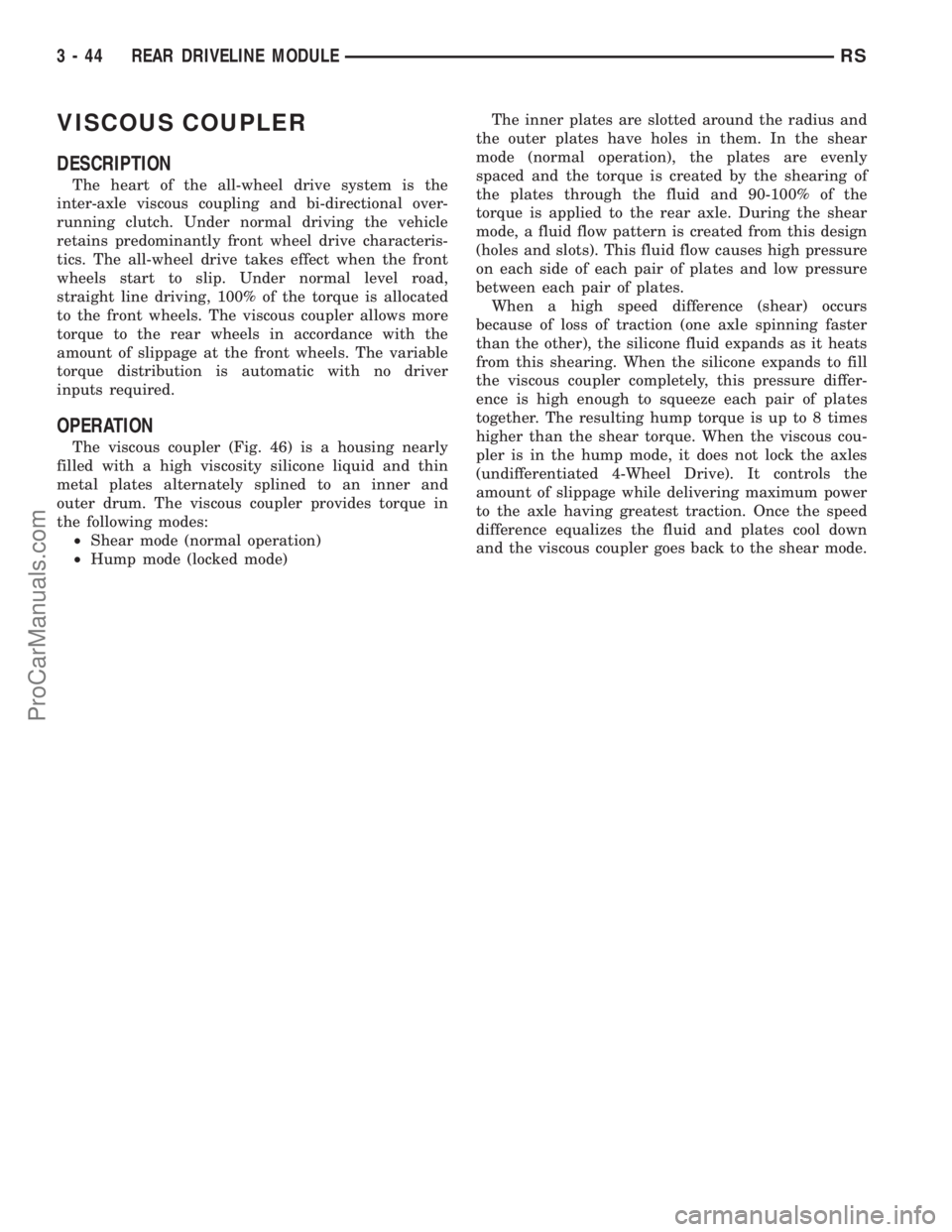

STANDARD PROCEDURE - OVERRUNNING

CLUTCH HOUSING FLUID CHANGE

(1) Raise vehicle on hoist.

(2) Position a drain pan under overrunning clutch

housing drain plug.(3) Remove overrunning clutch housing drain plug

and drain fluid (Fig. 43).

(4) Install the drain plug and torque to 30 N´m (22

ft. lbs.).

(5) Re-position the drain pan under the overrun-

ning clutch housing fill plug.

(6) Remove fill plug (Fig. 44).

(7) Using a suction gun (Fig. 45), add 0.58 L (1.22

pts.) of MopartATF+4 (Automatic Transmission Flu-

idÐType 9602).

(8)

Install fill plug and torque to 30 N´m (22 ft. lbs.).Fig. 43 Overrunning Clutch Case Drain Plug

1 - OVERRUNNING CLUTCH HOUSING DRAIN PLUG

Fig. 42 Filling Differential

1 - DIFFERENTIAL ASSEMBLY

2 - SUCTION GUN

Fig. 44 Overrunning Clutch Housing Fill Plug

1 - OVERRUNNING CLUTCH HOUSING FILL PLUG

2 - FUEL TANK

Fig. 45 Filling Overrunning Clutch Case

1 - OVERRUNNING CLUTCH HOUSING FILL HOLE

2 - SUCTION GUN

RSREAR DRIVELINE MODULE3-43

FLUID - DIFFERENTIAL ASSEMBLY (Continued)

ProCarManuals.com

Page 123 of 2399

VISCOUS COUPLER

DESCRIPTION

The heart of the all-wheel drive system is the

inter-axle viscous coupling and bi-directional over-

running clutch. Under normal driving the vehicle

retains predominantly front wheel drive characteris-

tics. The all-wheel drive takes effect when the front

wheels start to slip. Under normal level road,

straight line driving, 100% of the torque is allocated

to the front wheels. The viscous coupler allows more

torque to the rear wheels in accordance with the

amount of slippage at the front wheels. The variable

torque distribution is automatic with no driver

inputs required.

OPERATION

The viscous coupler (Fig. 46) is a housing nearly

filled with a high viscosity silicone liquid and thin

metal plates alternately splined to an inner and

outer drum. The viscous coupler provides torque in

the following modes:

²Shear mode (normal operation)

²Hump mode (locked mode)The inner plates are slotted around the radius and

the outer plates have holes in them. In the shear

mode (normal operation), the plates are evenly

spaced and the torque is created by the shearing of

the plates through the fluid and 90-100% of the

torque is applied to the rear axle. During the shear

mode, a fluid flow pattern is created from this design

(holes and slots). This fluid flow causes high pressure

on each side of each pair of plates and low pressure

between each pair of plates.

When a high speed difference (shear) occurs

because of loss of traction (one axle spinning faster

than the other), the silicone fluid expands as it heats

from this shearing. When the silicone expands to fill

the viscous coupler completely, this pressure differ-

ence is high enough to squeeze each pair of plates

together. The resulting hump torque is up to 8 times

higher than the shear torque. When the viscous cou-

pler is in the hump mode, it does not lock the axles

(undifferentiated 4-Wheel Drive). It controls the

amount of slippage while delivering maximum power

to the axle having greatest traction. Once the speed

difference equalizes the fluid and plates cool down

and the viscous coupler goes back to the shear mode.

3 - 44 REAR DRIVELINE MODULERS

ProCarManuals.com

Page 125 of 2399

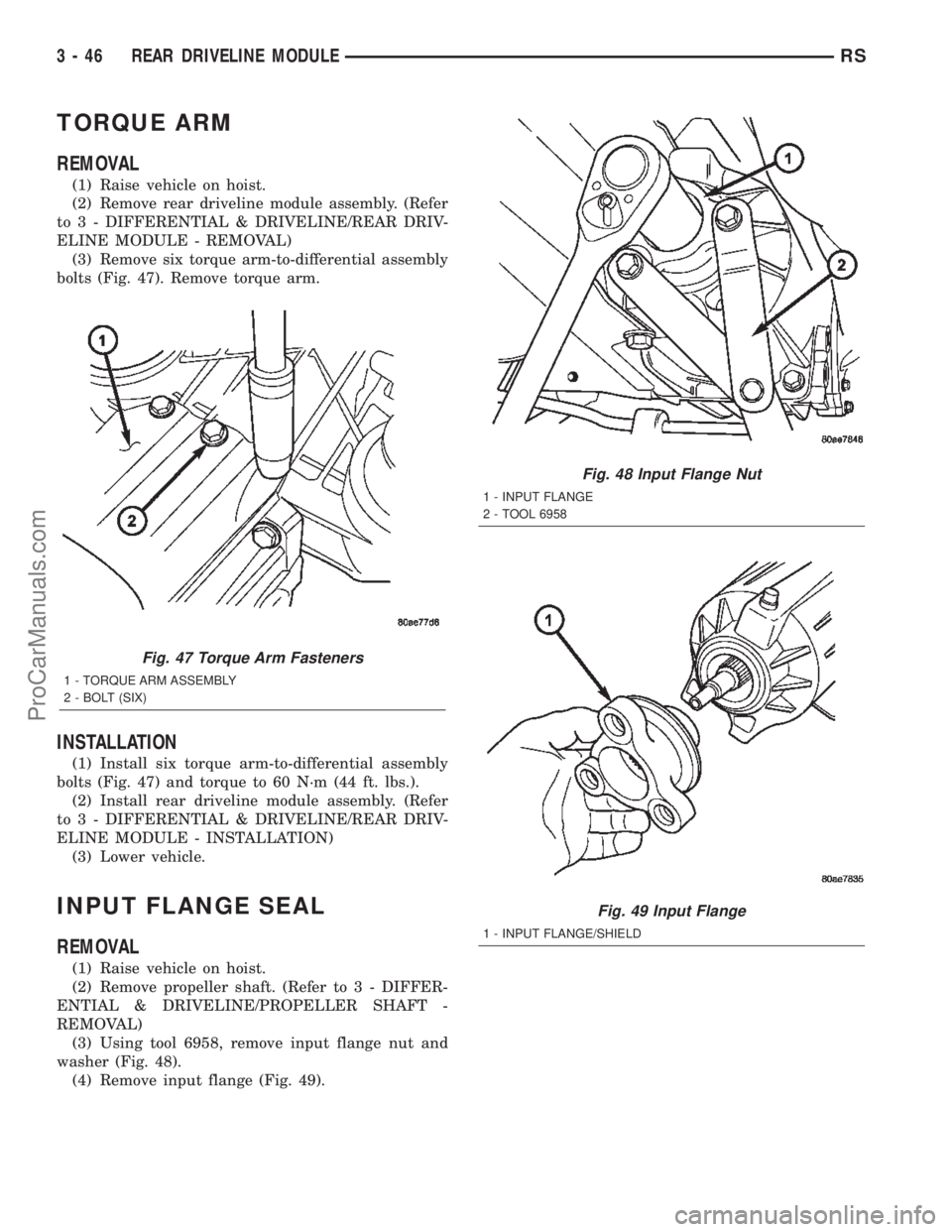

TORQUE ARM

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove rear driveline module assembly. (Refer

to 3 - DIFFERENTIAL & DRIVELINE/REAR DRIV-

ELINE MODULE - REMOVAL)

(3) Remove six torque arm-to-differential assembly

bolts (Fig. 47). Remove torque arm.

INSTALLATION

(1) Install six torque arm-to-differential assembly

bolts (Fig. 47) and torque to 60 N´m (44 ft. lbs.).

(2) Install rear driveline module assembly. (Refer

to 3 - DIFFERENTIAL & DRIVELINE/REAR DRIV-

ELINE MODULE - INSTALLATION)

(3) Lower vehicle.

INPUT FLANGE SEAL

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT -

REMOVAL)

(3) Using tool 6958, remove input flange nut and

washer (Fig. 48).

(4) Remove input flange (Fig. 49).

Fig. 47 Torque Arm Fasteners

1 - TORQUE ARM ASSEMBLY

2 - BOLT (SIX)

Fig. 48 Input Flange Nut

1 - INPUT FLANGE

2 - TOOL 6958

Fig. 49 Input Flange

1 - INPUT FLANGE/SHIELD

3 - 46 REAR DRIVELINE MODULERS

ProCarManuals.com

Page 126 of 2399

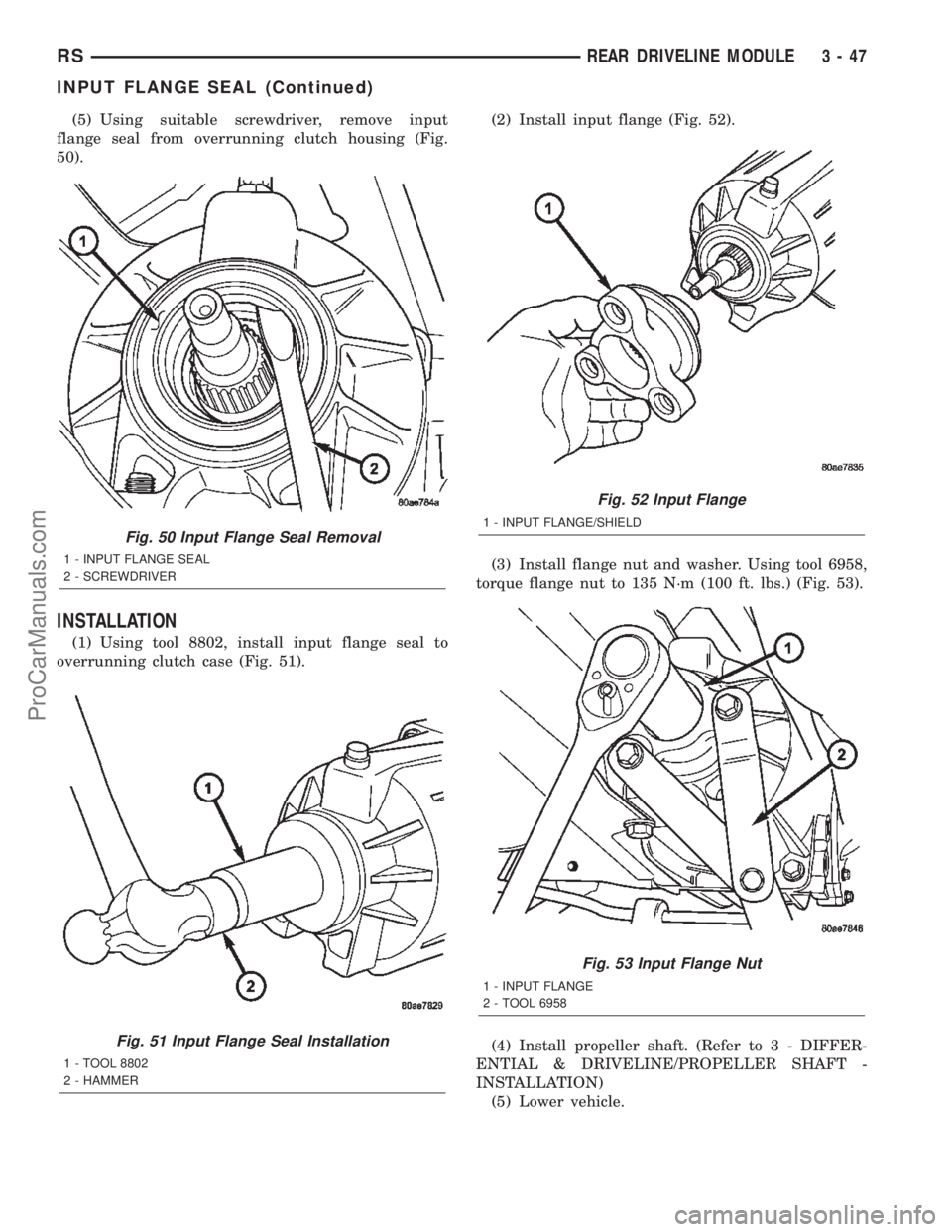

(5) Using suitable screwdriver, remove input

flange seal from overrunning clutch housing (Fig.

50).

INSTALLATION

(1) Using tool 8802, install input flange seal to

overrunning clutch case (Fig. 51).(2) Install input flange (Fig. 52).

(3) Install flange nut and washer. Using tool 6958,

torque flange nut to 135 N´m (100 ft. lbs.) (Fig. 53).

(4) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT -

INSTALLATION)

(5) Lower vehicle.

Fig. 50 Input Flange Seal Removal

1 - INPUT FLANGE SEAL

2 - SCREWDRIVER

Fig. 51 Input Flange Seal Installation

1 - TOOL 8802

2 - HAMMER

Fig. 52 Input Flange

1 - INPUT FLANGE/SHIELD

Fig. 53 Input Flange Nut

1 - INPUT FLANGE

2 - TOOL 6958

RSREAR DRIVELINE MODULE3-47

INPUT FLANGE SEAL (Continued)

ProCarManuals.com

Page 128 of 2399

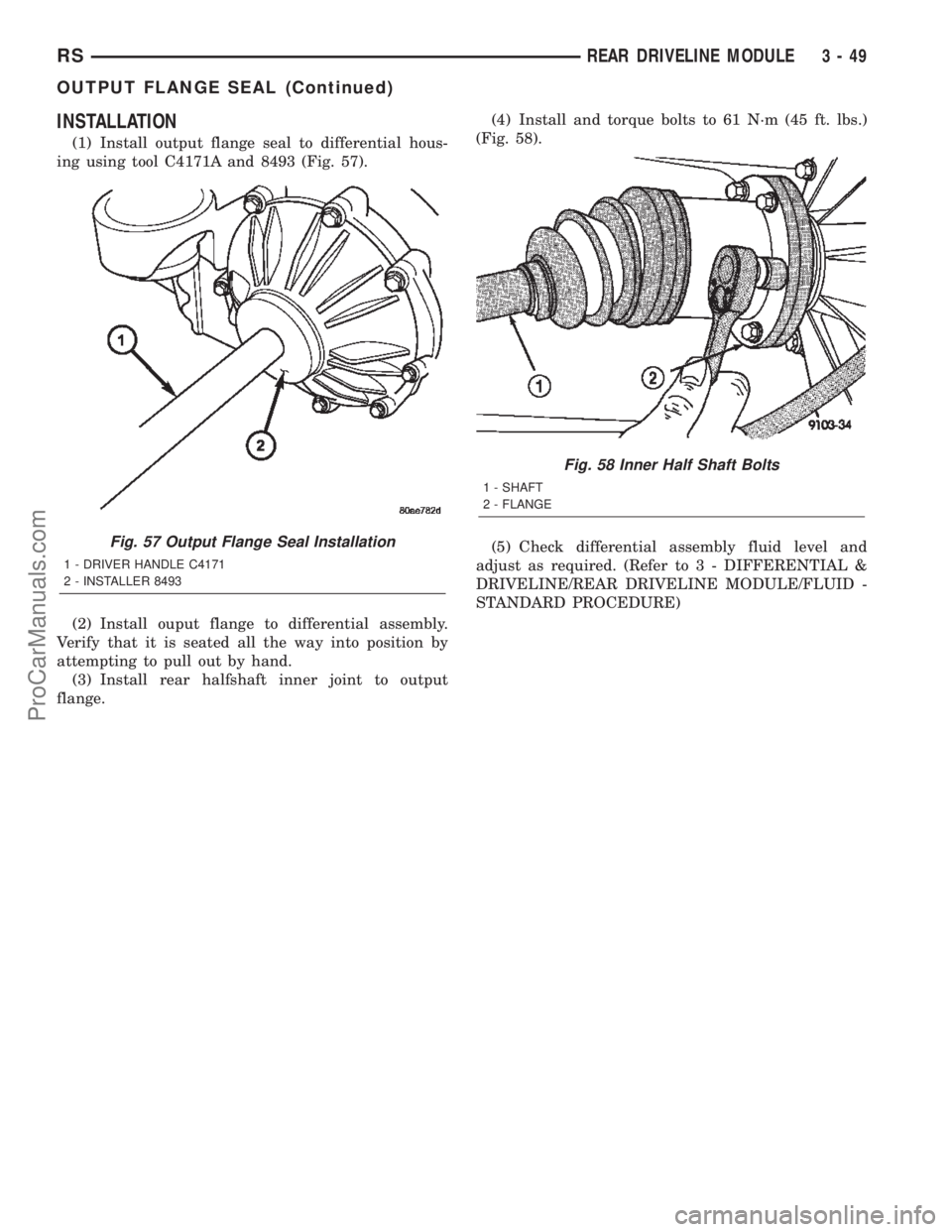

INSTALLATION

(1) Install output flange seal to differential hous-

ing using tool C4171A and 8493 (Fig. 57).

(2) Install ouput flange to differential assembly.

Verify that it is seated all the way into position by

attempting to pull out by hand.

(3) Install rear halfshaft inner joint to output

flange.(4) Install and torque bolts to 61 N´m (45 ft. lbs.)

(Fig. 58).

(5) Check differential assembly fluid level and

adjust as required. (Refer to 3 - DIFFERENTIAL &

DRIVELINE/REAR DRIVELINE MODULE/FLUID -

STANDARD PROCEDURE)

Fig. 57 Output Flange Seal Installation

1 - DRIVER HANDLE C4171

2 - INSTALLER 8493

Fig. 58 Inner Half Shaft Bolts

1 - SHAFT

2 - FLANGE

RSREAR DRIVELINE MODULE3-49

OUTPUT FLANGE SEAL (Continued)

ProCarManuals.com