engine CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1657 of 2399

(8) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

(9) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ªADDº mark on the dip-

stick (Fig. 168).

(10) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.).

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 31TH/FLUID - STANDARD PROCEDURE)(11) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

DIPSTICK TUBE FLUID SUCTION METHOD

(ALTERNATIVE)

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature.

(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (VaculaŸ

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

(6) Pour four quarts of MopartATF+4 (Automatic

Transmission FluidÐType 9602) through the dipstick

opening.

(7) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

(8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ªADDº mark on the dip-

stick (Fig. 168).

(9) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.).

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 31TH/FLUID - STANDARD PROCEDURE)

(10) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

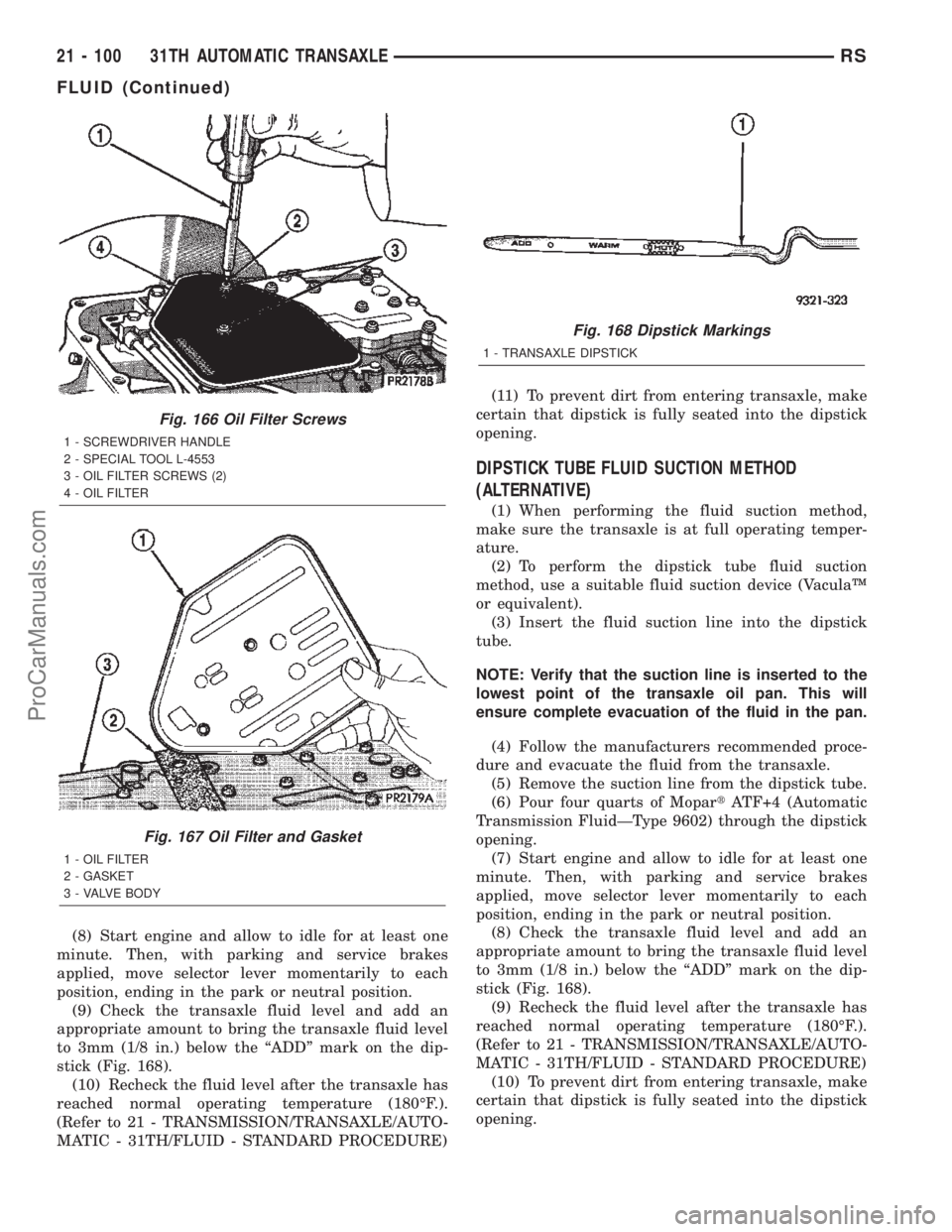

Fig. 166 Oil Filter Screws

1 - SCREWDRIVER HANDLE

2 - SPECIAL TOOL L-4553

3 - OIL FILTER SCREWS (2)

4 - OIL FILTER

Fig. 167 Oil Filter and Gasket

1 - OIL FILTER

2 - GASKET

3 - VALVE BODY

Fig. 168 Dipstick Markings

1 - TRANSAXLE DIPSTICK

21 - 100 31TH AUTOMATIC TRANSAXLERS

FLUID (Continued)

ProCarManuals.com

Page 1659 of 2399

(7) Disconnect gear shift cable from gear shift

lever (Fig. 173).

(8) Remove gear shift cable from column bracket

(Fig. 173).

(9) Disengage grommet from dash panel and

remove gear shift cable from inside vehicle (Fig. 174).INSTALLATION

(1) Fish gear shift cable dash panel opening into

engine compartment and secure grommet (Fig. 175).

(2) Install gear shift cable through column bracket

(Fig. 176) until audible ªclickº is heard.

(3) Connect gear shift cable to gear shift lever (Fig.

176).

Fig. 173 Gearshift Cable at Column

1 - GEAR SHIFT CABLE

Fig. 174 Gearshift Cable/Grommet at Dash Panel

1 - CABLE GROMMET

2 - DASH PANEL

Fig. 175 Gearshift Cable/Grommet at Dash Panel

1 - CABLE GROMMET

2 - DASH PANEL

Fig. 176 Gearshift Cable at Column

1 - GEAR SHIFT CABLE

21 - 102 31TH AUTOMATIC TRANSAXLERS

GEAR SHIFT CABLE (Continued)

ProCarManuals.com

Page 1661 of 2399

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT

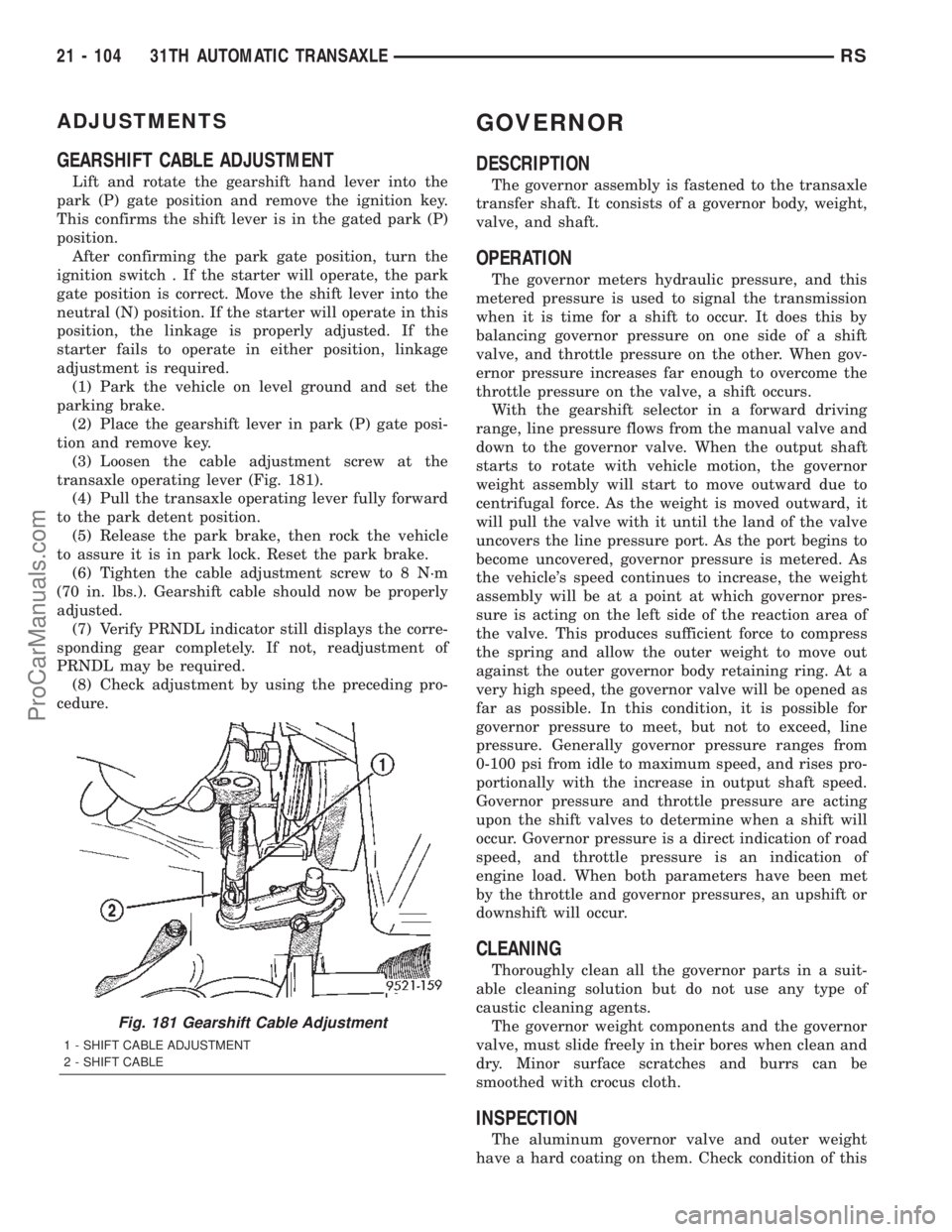

Lift and rotate the gearshift hand lever into the

park (P) gate position and remove the ignition key.

This confirms the shift lever is in the gated park (P)

position.

After confirming the park gate position, turn the

ignition switch . If the starter will operate, the park

gate position is correct. Move the shift lever into the

neutral (N) position. If the starter will operate in this

position, the linkage is properly adjusted. If the

starter fails to operate in either position, linkage

adjustment is required.

(1) Park the vehicle on level ground and set the

parking brake.

(2) Place the gearshift lever in park (P) gate posi-

tion and remove key.

(3) Loosen the cable adjustment screw at the

transaxle operating lever (Fig. 181).

(4) Pull the transaxle operating lever fully forward

to the park detent position.

(5) Release the park brake, then rock the vehicle

to assure it is in park lock. Reset the park brake.

(6) Tighten the cable adjustment screw to 8 N´m

(70 in. lbs.). Gearshift cable should now be properly

adjusted.

(7) Verify PRNDL indicator still displays the corre-

sponding gear completely. If not, readjustment of

PRNDL may be required.

(8) Check adjustment by using the preceding pro-

cedure.

GOVERNOR

DESCRIPTION

The governor assembly is fastened to the transaxle

transfer shaft. It consists of a governor body, weight,

valve, and shaft.

OPERATION

The governor meters hydraulic pressure, and this

metered pressure is used to signal the transmission

when it is time for a shift to occur. It does this by

balancing governor pressure on one side of a shift

valve, and throttle pressure on the other. When gov-

ernor pressure increases far enough to overcome the

throttle pressure on the valve, a shift occurs.

With the gearshift selector in a forward driving

range, line pressure flows from the manual valve and

down to the governor valve. When the output shaft

starts to rotate with vehicle motion, the governor

weight assembly will start to move outward due to

centrifugal force. As the weight is moved outward, it

will pull the valve with it until the land of the valve

uncovers the line pressure port. As the port begins to

become uncovered, governor pressure is metered. As

the vehicle's speed continues to increase, the weight

assembly will be at a point at which governor pres-

sure is acting on the left side of the reaction area of

the valve. This produces sufficient force to compress

the spring and allow the outer weight to move out

against the outer governor body retaining ring. At a

very high speed, the governor valve will be opened as

far as possible. In this condition, it is possible for

governor pressure to meet, but not to exceed, line

pressure. Generally governor pressure ranges from

0-100 psi from idle to maximum speed, and rises pro-

portionally with the increase in output shaft speed.

Governor pressure and throttle pressure are acting

upon the shift valves to determine when a shift will

occur. Governor pressure is a direct indication of road

speed, and throttle pressure is an indication of

engine load. When both parameters have been met

by the throttle and governor pressures, an upshift or

downshift will occur.

CLEANING

Thoroughly clean all the governor parts in a suit-

able cleaning solution but do not use any type of

caustic cleaning agents.

The governor weight components and the governor

valve, must slide freely in their bores when clean and

dry. Minor surface scratches and burrs can be

smoothed with crocus cloth.

INSPECTION

The aluminum governor valve and outer weight

have a hard coating on them. Check condition of this

Fig. 181 Gearshift Cable Adjustment

1 - SHIFT CABLE ADJUSTMENT

2 - SHIFT CABLE

21 - 104 31TH AUTOMATIC TRANSAXLERS

ProCarManuals.com

Page 1662 of 2399

coating carefully. Do not reuse either part if the coat-

ing is damaged.

Inspect the governor weight spring for distortion.

Replace the spring, if distorted, collapsed, or broken.

Clean the filter in solvent and dry it with compressed

air. Replace the filter, if damaged. Inspect the park

gear for chipped or worn gear teeth or damaged ring

grooves. Replace the gear, if damaged.

Check the teeth on the park gear for wear or dam-

age. Replace the gear if necessary. Inspect the metal

seal rings on the park gear hub. Replace the rings

only if severely worn, or broken.

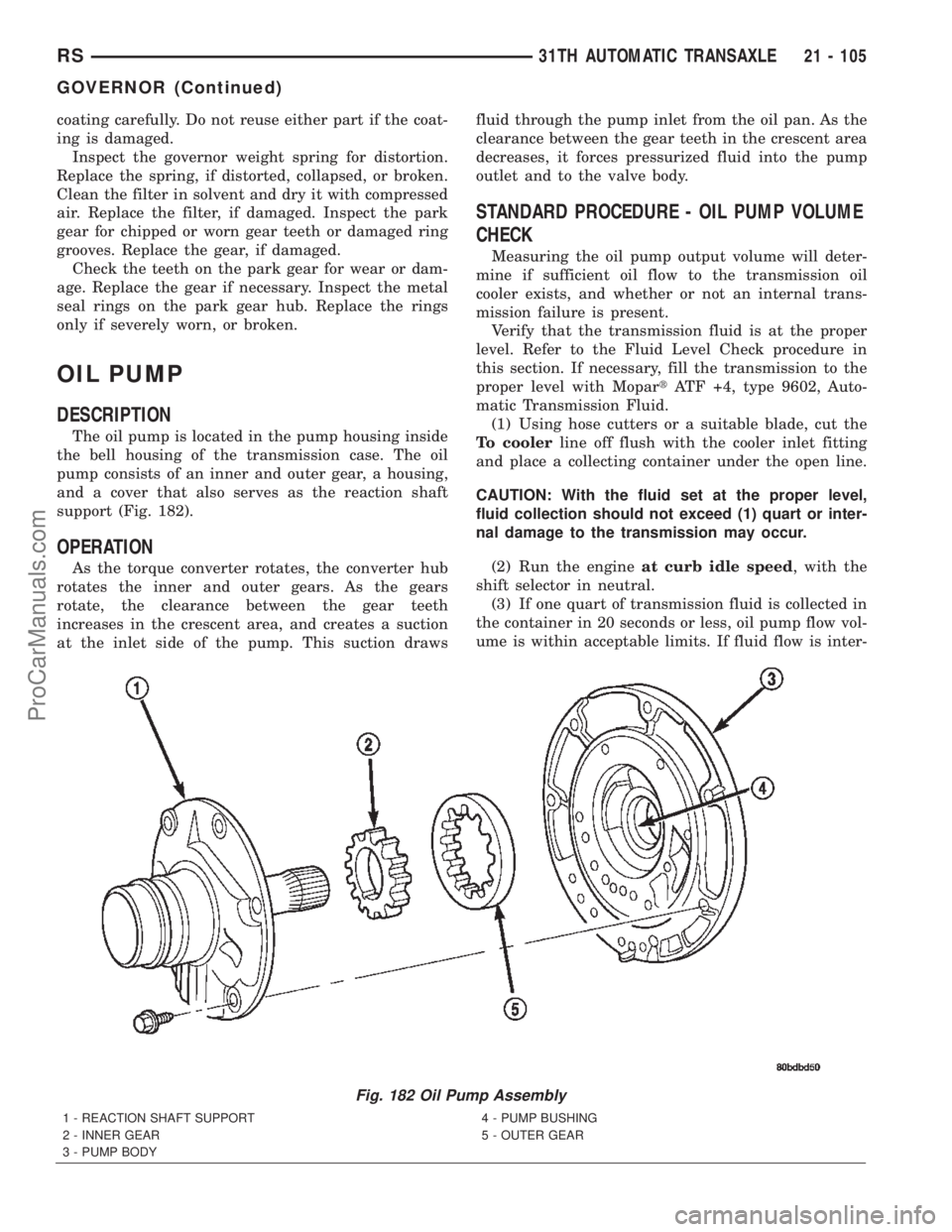

OIL PUMP

DESCRIPTION

The oil pump is located in the pump housing inside

the bell housing of the transmission case. The oil

pump consists of an inner and outer gear, a housing,

and a cover that also serves as the reaction shaft

support (Fig. 182).

OPERATION

As the torque converter rotates, the converter hub

rotates the inner and outer gears. As the gears

rotate, the clearance between the gear teeth

increases in the crescent area, and creates a suction

at the inlet side of the pump. This suction drawsfluid through the pump inlet from the oil pan. As the

clearance between the gear teeth in the crescent area

decreases, it forces pressurized fluid into the pump

outlet and to the valve body.

STANDARD PROCEDURE - OIL PUMP VOLUME

CHECK

Measuring the oil pump output volume will deter-

mine if sufficient oil flow to the transmission oil

cooler exists, and whether or not an internal trans-

mission failure is present.

Verify that the transmission fluid is at the proper

level. Refer to the Fluid Level Check procedure in

this section. If necessary, fill the transmission to the

proper level with MopartATF +4, type 9602, Auto-

matic Transmission Fluid.

(1) Using hose cutters or a suitable blade, cut the

To coolerline off flush with the cooler inlet fitting

and place a collecting container under the open line.

CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(2) Run the engineat curb idle speed, with the

shift selector in neutral.

(3) If one quart of transmission fluid is collected in

the container in 20 seconds or less, oil pump flow vol-

ume is within acceptable limits. If fluid flow is inter-

Fig. 182 Oil Pump Assembly

1 - REACTION SHAFT SUPPORT

2 - INNER GEAR

3 - PUMP BODY4 - PUMP BUSHING

5 - OUTER GEAR

RS31TH AUTOMATIC TRANSAXLE21 - 105

GOVERNOR (Continued)

ProCarManuals.com

Page 1668 of 2399

SERVO - KICKDOWN

DESCRIPTION

The kickdown servo (Fig. 196) consists of a two-

land piston with an inner piston, a piston rod and

guide, and a return spring. The dual-land piston uses

seal rings on its outer diameters and an O-ring for

the inner piston.

OPERATION

The application of the piston is accomplished by

applying pressure between the two lands of the pis-

ton. The pressure acts against the larger lower land

to push the piston downward, allowing the piston rod

to extend though its guide against the apply lever.

Release of the servo at the 2-3 upshift is accom-

plished by a combination of spring and line pressure,

acting on the bottom of the larger land of the piston.

The small piston is used to cushion the application of

the band by bleeding oil through a small orifice in

the larger piston. The release timing of the kickdown

servo is very important to obtain a smooth but firm

shift. The release has to be very quick, just as the

front clutch application is taking place. Otherwise,

engine runaway or a shift hesitation will occur. To

accomplish this, the band retains its holding capacity

until the front clutch is applied, giving a small

amount of overlap between them.

DISASSEMBLY

(1) Remove kickdown servo snap ring (Fig. 197).

(2) Remove kickdown servo rod guide and snap

ring (Fig. 198).

Fig. 196 Front Servo

1 - VENT

2 -PISTON ROD

3 - PISTON

4 - SPRING

5 - RELEASE PRESSURE

6 - APPLY PRESSURE

Fig. 197 Kickdown Servo Snap Ring

1 - SNAP RING

2 - SNAP RING PLIERS

3 - ACCUMULATOR PLATE

4 - KICKDOWN LEVER

5 - KICKDOWN PISTON ROD GUIDE

Fig. 198 Kickdown Servo Rod Guide and Snap Ring

1 - SNAP RING

2 - ACCUMULATOR PLATE

3 - RETURN SPRING

4 - O-RING

5 - PISTON ROD GUIDE

RS31TH AUTOMATIC TRANSAXLE21 - 111

ProCarManuals.com

Page 1679 of 2399

ADJUSTMENTS

THROTTLE VALVE LINKAGE ADJUSTMENT

The throttle valve linkage adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too short, early shifts and slippage

between shifts may occur. If the setting is too long,

shifts may be delayed and part throttle downshifts

may be very sensitive.

LINKAGE ADJUSTMENT PROCEDURE

(1) Perform transaxle throttle valve linkage

adjustment while engine is at normal operating tem-

perature.

(2) Using small screwdriver, disengage adjustment

lock at transaxle.

(3) Rotate lever at transaxle all the way to the left

side of vehicle against stop.

(4) Slide cable adjuster until cable core end

touches clip at throttle valve lever.

(5) Press adjuster lock (Fig. 228) to retain setting.

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 229) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid. If the fluid

is contaminated, flush the fluid cooler and lines.

Fig. 228 Throttle Valve Cable Adjustment Lock

1 - ADJUSTER LOCK

Fig. 229 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - CONVERTER CLUTCH DISC

6 - DRIVE PLATE

21 - 122 31TH AUTOMATIC TRANSAXLERS

THROTTLE VALVE CABLE (Continued)

ProCarManuals.com

Page 1680 of 2399

IMPELLER

The impeller (Fig. 230) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving member of the system.

Fig. 230 Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

RS31TH AUTOMATIC TRANSAXLE21 - 123

TORQUE CONVERTER (Continued)

ProCarManuals.com

Page 1681 of 2399

TURBINE

The turbine (Fig. 231) is the output, or driven,

member of the converter. The turbine is mounted

within the housing opposite the impeller, but is not

attached to the housing. The input shaft is inserted

through the center of the impeller and splined into

the turbine. The design of the turbine is similar to

the impeller, except the blades of the turbine are

curved in the opposite direction.

Fig. 231 Turbine

1 - TURBINE VANE

2 - ENGINE ROTATION

3 - INPUT SHAFT

4 - PORTION OF TORQUE CONVERTER COVER5 - ENGINE ROTATION

6 - OIL FLOW WITHIN TURBINE SECTION

21 - 124 31TH AUTOMATIC TRANSAXLERS

TORQUE CONVERTER (Continued)

ProCarManuals.com

Page 1683 of 2399

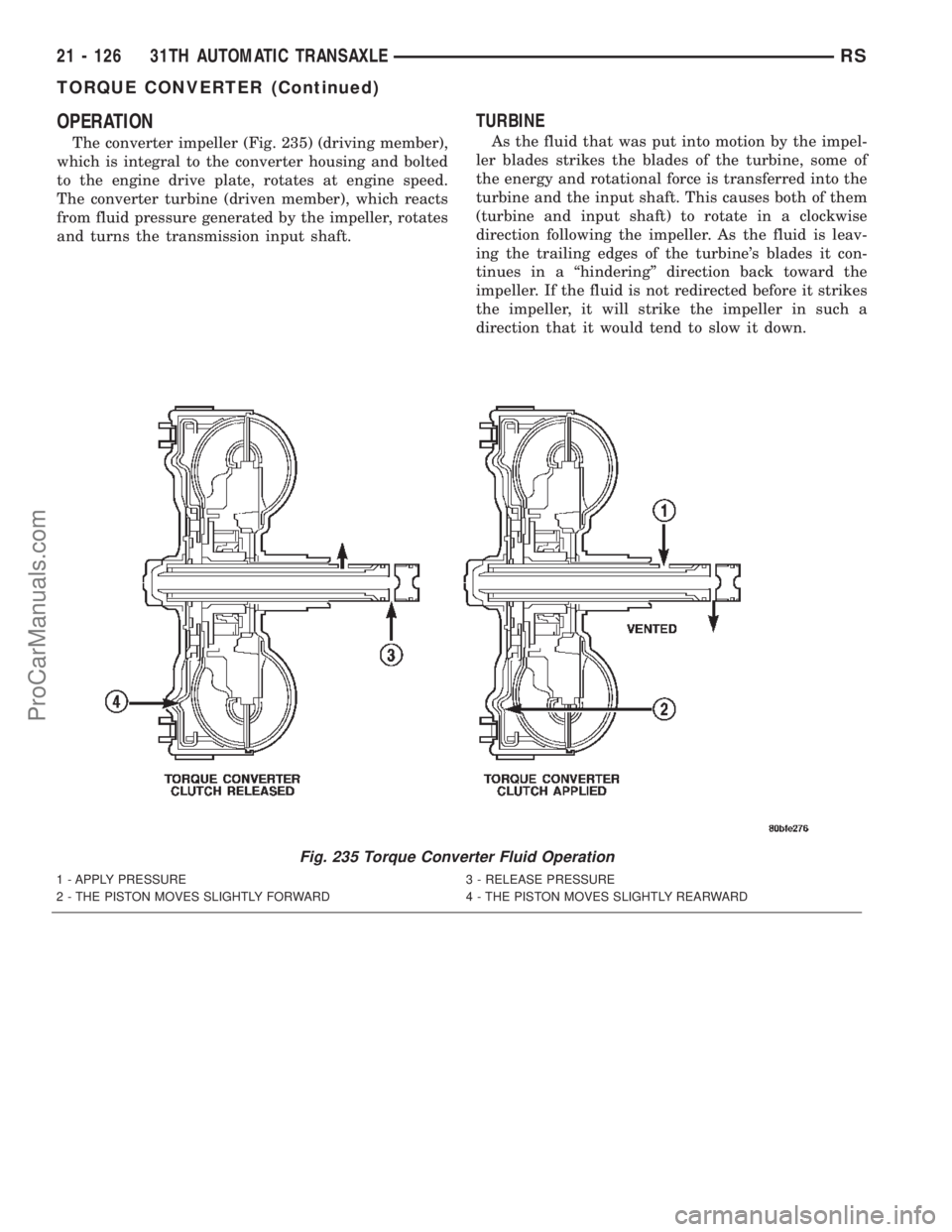

OPERATION

The converter impeller (Fig. 235) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

Fig. 235 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

21 - 126 31TH AUTOMATIC TRANSAXLERS

TORQUE CONVERTER (Continued)

ProCarManuals.com

Page 1684 of 2399

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 236).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the over±run-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock±up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

In a standard torque converter, the impeller and

turbine are rotating at about the same speed and the

stator is freewheeling, providing no torque multipli-

cation. By applying the turbine's piston to the front

cover's friction material, a total converter engage-

ment can be obtained. The result of this engagement

is a direct 1:1 mechanical link between the engine

and the transmission.

The engagement and disengagement of the TCC

are automatic and controlled by the Powertrain Con-

trol Module (PCM). The engagement cannot be acti-

vated in the lower gears because it eliminates the

torque multiplication effect of the torque converternecessary for acceleration. Inputs that determine

clutch engagement are: coolant temperature, vehicle

speed and throttle position. The torque converter

clutch is engaged by the clutch solenoid on the valve

body. The clutch will engage at approximately 56

km/h (35 mph) with light throttle, after the shift to

third gear.

REMOVAL

(1) Remove transmission and torque converter

from vehicle. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 31TH - REMOVAL)

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate converter hub and oil pump seal lip

with transmission fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 237). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

Fig. 236 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

RS31TH AUTOMATIC TRANSAXLE21 - 127

TORQUE CONVERTER (Continued)

ProCarManuals.com