CHRYSLER VOYAGER 2002 Service Manual

Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 611 of 2399

RESTRAINTS

DESCRIPTION

This vehicle is equipped with a Frontal Impact Air-

bag System, which utilizes the driver/passenger air-

bags and seatbelt pretensioners. This system is

designed to protect occupants in the event of a front

impact collision. These airbags and seatbelt preten-

sioners are all serviceable parts. If these pyrotechnics

are deployed or defective, they must be replaced, as

well as the Occupant Restraint Controller (ORC)

must be diagnosed following procedures outlined in

the service/diagnostic manuals.

Vehicles equipped with the Side Impact Airbag

System, the seat back assembly must be replaced, as

well as the Side Impact Airbag Control Module

(SIACM) must be diagnosed following procedures

outlined in the service/diagnostic manuals.

OPERATION

The Occupant Restraint Controller (ORC) controls

the driver/passenger airbags and seatbelt pretension-

ers. If the ORC determines the impact is severe

enough, the driver/passenger airbags and seatbelt

pretensioners will inflate. Once a deployment occurs,

these devices, and all damaged parts must be

replaced, as well as the ORC must be diagnosed fol-

lowing procedures outlined in the service/diagnostic

manuals.

The Side Impact Airbag Control Module (SIACM),

the seat back assemblies and all damaged parts must

be replaced, as well as the SIACM must be diagnosed

following procedures outlined in the service/diagnos-

tic manuals.

WARNING

WARNING: THIS SYSTEM IS A SENSITIVE, COM-

PLEX ELECTRO±MECHANICAL UNIT. DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE CABLE

BEFORE BEGINNING AIRBAG SYSTEM COMPO-

NENT REMOVAL OR INSTALLATION PROCEDURES.

THIS WILL DISABLE THE AIRBAG SYSTEM. FAIL-

URE TO DISCONNECT THE BATTERY COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE FOR

TWO MINUTES BEFORE REMOVING AIRBAG COM-

PONENTS.

DO NOT PLACE AN INTACT UNDEPLOYED AIRBAG

FACE DOWN ON A SOLID SURFACE, THE AIRBAG

WILL PROPEL INTO THE AIR IF ACCIDENTALLY

DEPLOYED AND COULD RESULT IN PERSONAL

INJURY. WHEN CARRYING OR HANDLING AN

UNDEPLOYED AIRBAG MODULE, THE TRIM SIDE

OF THE AIRBAG SHOULD BE POINTING AWAYFROM THE BODY TO MINIMIZE POSSIBILITY OF

INJURY IF ACCIDENTAL DEPLOYMENT OCCURS.

REPLACE AIRBAG SYSTEM COMPONENTS WITH

MOPARTREPLACEMENT PARTS. SUBSTITUTE

PARTS MAY APPEAR INTERCHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN INFE-

RIOR OCCUPANT PROTECTION.

WEAR SAFETY GLASSES, RUBBER GLOVES, AND

LONG SLEEVED CLOTHING WHEN CLEANING

POWDER RESIDUE FROM VEHICLE AFTER AIRBAG

DEPLOYMENT. SODIUM HYDROXIDE POWDER

RESIDUE EMITTED FROM A DEPLOYED AIRBAG

CAN CAUSE SKIN IRRITATION. FLUSH AFFECTED

AREA WITH COOL WATER IF IRRITATION IS EXPE-

RIENCED. IF NASAL OR THROAT IRRITATION IS

EXPERIENCED, EXIT THE VEHICLE FOR FRESH AIR

UNTIL THE IRRITATION CEASES. IF IRRITATION

CONTINUES, SEE A PHYSICIAN.

DO NOT USE A REPLACEMENT AIRBAG THAT IS

NOT IN THE ORIGINAL PACKAGING, IMPROPER

DEPLOYMENT AND PERSONAL INJURY CAN

RESULT.

THE FACTORY INSTALLED FASTENERS, SCREWS

AND BOLTS USED TO FASTEN AIRBAG COMPO-

NENTS HAVE A SPECIAL COATING AND ARE SPE-

CIFICALLY DESIGNED FOR THE AIRBAG SYSTEM.

DO NOT USE SUBSTITUTE FASTENERS, USE ONLY

ORIGINAL EQUIPMENT FASTENERS LISTED IN THE

PARTS CATALOG WHEN FASTENER REPLACE-

MENT IS REQUIRED.

CAUTION:

Deployed and Nondeployed Air Bags may or may

not have live pyrotechnic material within the air bag

inflator. Do not dispose of Driver and Passenger

Airbags unless you are sure of complete deploy-

ment. Please refer to the Hazardous Substance

Control System for Proper Disposal. Dispose of

deployed air bags in a manner consistent with

state, provincial, local, and federal regulations.

DIAGNOSIS AND TESTING - AIRBAG SYSTEM

(1) Connect a DRB llltscan tool to the Data Link

Connector (DLC), located at left side of the steering

column and at the lower edge of the lower instru-

ment panel.

(2) Turn the ignition key to ON position. Exit vehi-

cle with scan tool. Use the latest version of the

proper cartridge.

(3) After checking that no one is inside the vehicle,

connect the battery negative terminal.

(4) Using the DRB llltscan tool, read and record

active diagnostic code data.

(5) Read and record any stored diagnostic codes.

8O - 2 RESTRAINTSRS

ProCarManuals.com

Page 612 of 2399

(6) Refer to the proper Body Diagnostic Procedures

manual if any diagnostic codes are found in Step 4 or

Step 5.

(7) Erase stored diagnostic codes if there are no

active diagnostic codes. If problems remain, diagnos-

tic codes will not erase. Refer to the Proper Body

Diagnostic Procedures Manual to diagnose the prob-

lem.If airbag warning lamp either fails to light,

or goes on and stays on, there is a system mal-

function. Refer to the proper Body Diagnostic

Procedures manual to diagnose the problem.

CLOCK SPRING

DESCRIPTION

The clock spring is screwed to a plastic mounting

platform on the steering column behind the steering

wheel. The clock spring is used to maintain a contin-

uous electrical circuit between the wiring harness

and the drivers airbag.

OPERATION

This assembly consists of a flat ribbon like electri-

cally conductive tape which winds and unwinds with

the steering wheel rotation. The clock spring cannot

be repaired. If the clock spring is faulty, damaged, or

if the airbag has been deployed, the clock spring

must be replaced.

STANDARD PROCEDURE - CLOCK SPRING

CENTERING

If the rotating tape (wire coil) in the clock spring is

not positioned properly with the steering wheel and

the front wheels, the clock spring may fail. The fol-

lowing procedure MUST BE USED to center the

clock spring if it is not known to be properly posi-

tioned, or if the front wheels were moved from the

straight ahead position.

(1) Adjust the steering wheel so that the tires are

in a straight ahead position.

(2) Remove Driver Airbag from steering wheel.

(3) Disconnect wire connectors from back of airbag.

(4) Remove steering wheel.

(5) Rotate the clock spring rotor clockwise until

the rotor stops. Do not apply excessive force.

(6) From the end of travel, rotate the rotor two

turns counterclockwise until the wires end up at the

top.

(7) Install steering wheel and airbag.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood. Disconnect

and isolate the battery negative cable.

(3) Remove driver airbag from steering wheel.

(4) Disconnect wire connectors from back of driver

airbag.

(5) Disconnect the 2±way connector from remote

radio control harness and the 4-way connector from

the speed control/horn harness.

(6) Remove steering wheel.

(7) Remove steering column shrouds.

(8) Disconnect 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(9) Remove clock spring from housing assembly by

removing the two retaining screws retaining the

clock spring.

INSTALLATION

(1) Position the clock spring into the housing.

Install the two retaining screws to clock spring.

(2) Connect the 4-way and 6-way harness between

the clock spring and the instrument panel.

(3) Install the steering wheel. Refer to Steering,

Column, Steering Wheel, Installation.

(4) Connect the harness connector to the driver

airbag.

(5) Connect the remote radio control harness and

the speed control/horn harness.

(6) Install the driver airbag into the steering

wheel.

(7) Install the steering column upper and lower

shrouds.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

DRIVER AIRBAG

DESCRIPTION

The Driver Airbag is located in the center of the

steering wheel. The most visible part of the airbag is

the cover/horn switch.

OPERATION

The Driver Airbag cover contains the horn switch,

inflator device, and a fabric bag. The airbag cover/

horn switch is serviced separately from the inflator

and bag components.

RSRESTRAINTS8O-3

RESTRAINTS (Continued)

ProCarManuals.com

Page 613 of 2399

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly.

²Lower Steering Column Coupler.

²Steering Wheel.

²Clock Spring.

²Driver Airbag

²Passenger Airbag

²Upper Instrument Panel with Pad.

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

STANDARD PROCEDURE - CLEAN UP

Roll or fold the driver airbag towards the steering

wheel and then tape the bag to the steering wheel.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well. If

HVAC was in RECIRC mode at time of airbag

deployment, operate HVAC blower on low speed/heat

and vacuum powder residue expelled from the heat

outlets. Multiple vacuum cleaning may be necessary

to decontaminate the interior of the vehicle.

REMOVAL

DEPLOYED AIRBAG

The Driver Airbag and Driver Airbag Cover/Horn

Pad are serviced separately from each other.

(1) Clean powder residue from interior of vehicle,

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - STANDARD PROCEDURE ) Cleanup.

(2) Remove two screws attaching Driver Airbag to

steering wheel.

(3) Remove the driver airbag from steering wheel.

(4) Disconnect wire connectors from Airbag and

Clock Spring.

(5) Adjust the steering wheel so that the tires are

in a straight ahead position. Remove steering wheel,

(Refer to 19 - STEERING/COLUMN/STEERING

WHEEL - REMOVAL)

(6) Disconnect the 2-way and 4-way connectors

between the clock spring and the instrument panel

wiring harness.(7) Remove upper and lower steering column

shrouds.

(8) Remove clock spring from the housing assem-

bly by depressing the 2 tabs on the clock spring.

UNDEPLOYED AIRBAG

(1) Remove screws attaching airbag/horn switch to

steering wheel.

(2) Remove Driver Airbag from steering wheel.

(3) Disconnect wire connectors from driver airbag

and clock spring.

INSTALLATION

DEPLOYED AIRBAG

(1) Perform cleanup procedure.(Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - STAN-

DARD PROCEDURE)

(2) Install a new steering column assembly and

lower steering column coupler. Refer to Steering, Col-

umn, Installation.

(3) Install the clock spring.

(4) Install the driver airbag and the two screws

retaining the airbag. Tighten screws to 10 N´m (90

in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

UNDEPLOYED AIRBAG

(1) Position a new airbag into the airbag cavity.

(2) Install the two screws retaining the airbag.

Tighten screws to 10 N´m (90 in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

DRIVER AIRBAG TRIM COVER

REMOVAL

The horn switch is integral to the driver airbag

trim cover. If either component is faulty or damaged,

the entire driver airbag trim cover and horn switch

unit must be replaced.

(1) Disconnect and isolate the battery negative

cable.

WARNING: WAIT TWO MINUTES FOR THE AIRBAG

SYSTEM RESERVE CAPACITOR TO DISCHARGE.

8O - 4 RESTRAINTSRS

DRIVER AIRBAG (Continued)

ProCarManuals.com

Page 614 of 2399

(2) Remove the driver airbag from the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) Remove the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing.

(4) Remove the four nuts that secure the upper

and lower trim cover retainers to the studs on the

back of the driver airbag housing.

(5) Remove the upper and lower trim cover retain-

ers from the airbag housing studs.

(6) Remove the horn switch ground pigtail wire

eyelet terminal from the upper right airbag housing

stud.

(7) Disengage the six trim cover locking blocks

from the lip around the outside edge of the driver

airbag housing and remove the housing from the

cover.

INSTALLATION

(1) Install the housing into the cover. Engage the

six trim cover locking blocks to the lip around the

outside edge of the driver airbag housing.

(2) Install the horn switch ground pigtail wire eye-

let terminal to the upper right airbag housing stud.

(3) Install the upper and lower trim cover retain-

ers to the airbag housing studs.

(4) Install the four nuts that secure the upper and

lower trim cover retainers to the studs on the back of

the driver airbag housing.

(5) Install the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing.

(6) Install the driver airbag onto the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. FIRST (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DIAGNOSIS AND TESTING - AIRBAG

SYSTEM).

OCCUPANT RESTRAINT

CONTROLLER

DESCRIPTION

The front driver and passenger airbag system is

designed to reduce the risk of fatality or serious

injury, caused by a frontal impact of the vehicle.

The Occupant Restraint Controller (ORC) contains

the impact sensor and energy reserve capacitor. It is

mounted on a bracket, under the instrument panel,just forward of the storage bin. The ORC monitors

the system to determine the system readiness. The

ORC contains on-board diagnostics and will light the

AIRBAG warning lamp in the message center when a

problem occurs.

OPERATION

The impact sensor provides verification of the

direction and severity of the impact. One impact sen-

sor is used. It is located inside the Occupant

Restraint Controller (ORC). The impact sensor is an

accelerometer that senses deceleration. The decelera-

tion pulses are sent to a microprocessor which con-

tains a decision algorithm. When an impact is severe

enough to require airbag protection, the ORC micro-

processor sends a signal that completes the electrical

circuit to the driver and passenger airbags. The

impact sensor is calibrated for the specific vehicle

and reacts to the severity and direction of an impact.

REMOVAL

NOTE: Diagnose the ORC using the service/diag-

nostic manual.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove storage bin from instrument panel.

Refer to Body, Instrument Panel, Storage Bin,

Removal.

(3) Remove three bolts holding ORC to floor

bracket.

(4) Disconnect the wire connector from ORC.

(5) Remove the ORC assembly from vehicle.

INSTALLATION

WARNING: DO NOT INSTALL ORC IF MOUNTING

LOCATION IS DEFORMED OR DAMAGED.

CAUTION: Use correct screws when installing the

ORC.

(1) Install the ORC assembly into vehicle.

(2) Connect the wire connector to the ORC.

(3) Install three bolts holding ORC to floor

bracket. Torque bolts to 7.3 - 9.6 N´m (65 to 85 in.

lbs.)

(4) Install the storage bin onto the instrument

panel. Refer to Body, Instrument Panel, Storage Bin,

Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

RSRESTRAINTS8O-5

DRIVER AIRBAG TRIM COVER (Continued)

ProCarManuals.com

Page 615 of 2399

PASSENGER AIRBAG

DESCRIPTION

WARNING: NEVER DISASSEMBLE THE PASSEN-

GER AIRBAG, THE PASSENGER AIRBAG HAS NO

SERVICEABLE PARTS.

The Passenger Airbag is located beneath the

instrument panel and pad assembly. The airbag is

mounted to the back side of the instrument panel

reinforcement.

The instrument panel top pad is the most visible

part of the passenger airbag system. Located under

the instrument panel top pad are the airbag door, the

passenger airbag cushion and the airbag cushion

supporting components.

The passenger airbag includes a magnesium hous-

ing within which the cushion and inflator are

mounted and sealed.

Following a passenger airbag deployment, the pas-

senger airbag and the instrument panel must be

replaced. The passenger airbag cannot be repaired,

and must be replaced if deployed or damaged in any

way.

OPERATION

The passenger airbag is equipped with two infla-

tors, each with three levels of pressure output. The

inflators seal the hole in the airbag cushion so it can

discharge the gas it produces directly into the cush-

ion when supplied with the proper electrical signal.

Following an airbag deployment, the airbag cushion

quickly deflates by venting this gas through the

cushion material towards the instrument panel.

The passenger airbag is secured with screws to the

instrument panel beneath the instrument panel top

pad and above the glove box opening. The instrument

panel top pad above the glove box opening conceals

the airbag door and a predetermined hinge line

beneath its decorative cover. Upon airbag deploy-

ment, the top pad will bend at the hinge line and the

door will fold back out of the way onto the top of the

instrument panel.

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly.

²Lower Steering Column Coupler.

²Steering Wheel.

²Clock Spring.

²Driver Airbag.

²Passenger Airbag.

²Upper Instrument Panel with Pad.

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

STANDARD PROCEDURE - CLEAN UP

Roll or fold the passenger airbag towards the

instrument panel surface and close the door over the

folded bag. Then tape the door shut.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well. If

HVAC was in RECIRC mode at time of airbag

deployment, operate HVAC blower on low speed/heat

and vacuum powder residue expelled from the heat

outlets. Multiple vacuum cleaning may be necessary

to decontaminate the interior of the vehicle.

REMOVAL

DEPLOYED AIRBAG

(1) Clean powder residue from interior of vehicle.

Refer to Electrical, Restraints, Passenger Airbag,

Standard Procedure - Passenger Airbag Clean Up.

(2) Remove instrument panel. Refer to Body,

Instrument Panel, Removal.

(3) Remove all reusable components from the

upper instrument panel and transfer to the new

instrument panel.

UNDEPLOYED AIRBAG

(1) Remove instrument panel. Refer to Body,

Instrument Panel, Removal.

(2) De-trim the instrument panel enough to gain

access to the passenger airbag fasteners.

(3) Disconnect yellow wire connector from passen-

ger airbag.

(4) Remove three bolts to the passenger airbag.

(5) Remove airbag from instrument panel through

rear of instrument panel.

INSTALLATION

DEPLOYED AIRBAG

Transfer all reusable components to the new

instrument panel.

(1) Install new Passenger Airbag into instrument

panel.

8O - 6 RESTRAINTSRS

ProCarManuals.com

Page 616 of 2399

(2) Install airbag attaching bolts to the instrument

panel.

(3) Connect yellow wire connector from passenger

airbag.

(4) Install Instrument panel. Refer to Body, Instru-

ment Panel, Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

UNDEPLOYED AIRBAG

(1) Install Passenger Airbag into instrument panel.

(2) Install airbag attaching bolts to the instrument

panel.

(3) Connect yellow wire connector from passenger

airbag.

(4) Install Instrument panel. Refer to Body, Instru-

ment Panel, Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

SEAT AIRBAG

DESCRIPTION

The side impact airbag system Seat Airbags are

located in the outboard side of the front seat backs.One in each front seat. The seat airbag inflator

assembly is within the airbag housing (Fig. 1). Each

airbag is mounted to the seat back frame. If deployed

or defective, the entire seat back assembly must be

replaced.

OPERATION

Only the Side Impact Airbag Control Module

(SIACM) can deploy the side airbags. When supplied

with the proper electrical signal, the seat airbag

inflator will produce a gas and discharge the bag

directly between the occupant and the side of the

vehicle, protecting the occupant. Upon deployment,

the seat back trim cover will tear open and allow the

side airbag to fully inflate and quickly deflate.

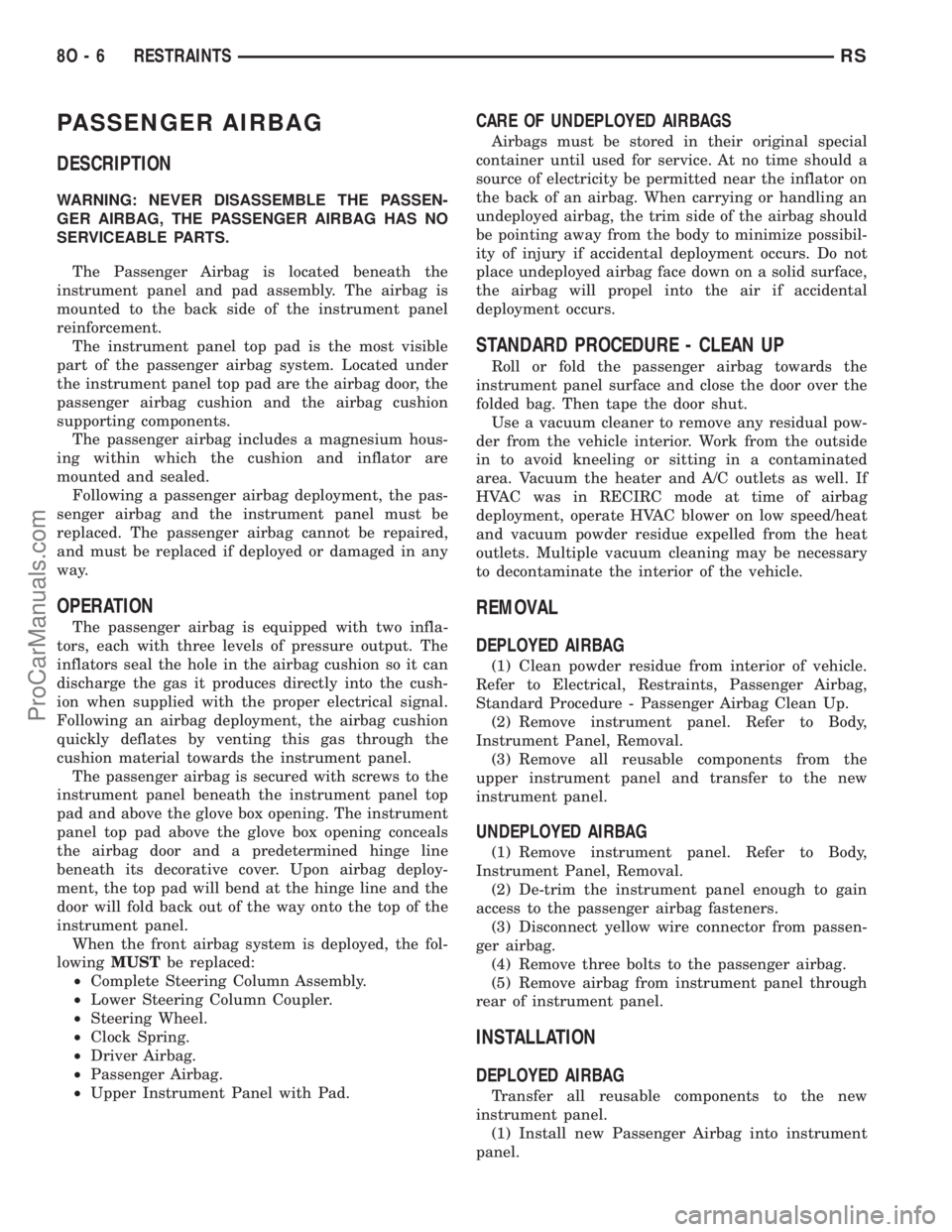

SEAT BELT OUTBOARD

FRONT

REMOVAL

Inspect the condition of the shoulder belt and lap

belt. Replace any belt that is cut, frayed, torn, or

damaged in any way. Also, replace the shoulder belt

if the retractor is either damaged or inoperative.

(1) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(2) Remove cover from seat belt turning loop.

(3) Remove bolt attaching turning loop to shoulder

belt height adjuster (Fig. 2).

(4) Remove turning loop from B-pillar.

(5) Remove lower B-pillar trim cover or quarter

trim panel.

(6) Remove bolt attaching seat belt retractor to

B-pillar (Fig. 2).

(7) Lift retractor upward and disengage arrow

head retainer attaching retractor to B-pillar.

(8) Remove seat belt from vehicle.

INSTALLATION

Inspect the condition of the shoulder belt and lap

belt. Replace any belt that is cut, frayed, torn, or

damaged in any way. Also, replace the shoulder belt

if the retractor is either damaged or inoperative.

(1) Place seat belt into position.

(2) Lower retractor into position B-pillar.

(3) Install bolt attaching seat belt retractor to

B-pillar. Tighten all seat belt anchor bolts to 39 N´m

(29 ft. lbs.) torque.

(4) Install turning loop onto B-pillar.

(5) Install lower B-pillar trim cover or quarter

trim panel.

(6) Install bolt attaching turning loop to shoulder

belt height adjuster. Tighten all seat belt anchor

bolts to 39 N´m (29 ft. lbs.) torque.

(7) Press cover onto the seat belt turning loop.

Fig. 1 SEAT AIRBAG - TYPICAL

RSRESTRAINTS8O-7

PASSENGER AIRBAG (Continued)

ProCarManuals.com

Page 617 of 2399

(8) Install shoulder harness height adjuster knob

by pushing onto the adjuster.

SEAT BELT FIRST ROW

ANCHOR BRACKET - LWB

REMOVAL

(1) Remove lower quarter trim panel.

(2) Remove bolt attaching first row seat belt

anchor bracket to floor.

(3) Remove bracket from vehicle.

INSTALLATION

(1) Position bracket to vehicle.

(2) Install bolt attaching first row seat belt anchor

bracket to floor.

(3) Install lower quarter trim panel.

NOTE: The tightening specification for all seat belt

anchor bolts is 39 N´m (29 ft. lbs.) torque.

SEAT BELT LEFT FIRST ROW

OUTBOARD - SWB THREE

DOOR

REMOVAL

(1) Remove first and second row seats. Refer to

Owner's manual for proper procedures.

(2) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(3) Slide floor anchor cover from over the anchor

bolt.

(4) Remove floor anchor bolt (Fig. 3).

(5) Remove anchor from floor.

(6) Open clam shell cover from over seat belt turn-

ing loop.

(7) Remove bolt attaching turning loop to shoulder

belt height adjuster.

(8) Remove turning loop from C-pillar.

(9) Remove B-pillar upper trim cover.

(10) Remove C-pillar upper trim cover.

(11) Remove lower quarter trim panel.

(12) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(13) Remove bolt attaching seat belt retractor to

quarter panel.

(14) Lift retractor upward and disengage arrow

head retainer attaching retractor to quarter panel

(Fig. 3).

(15) Remove seat belt from vehicle.

INSTALLATION

(1) Install seat belt into position.

(2) Lower retractor into position to quarter panel.

(3) Install bolt attaching seat belt retractor to

quarter panel. Tighten all seat belt anchor bolts to 39

N´m (29 ft. lbs.) torque.

(4) Install lower quarter trim panel.

(5) Install C-pillar upper trim cover.

(6) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(7) Install B-pillar upper trim cover.

(8) Install turning loop onto C-pillar. Tighten all

seat belt anchor bolts to 39 N´m (29 ft. lbs.) torque.

(9) Press clam shell cover over seat belt turning

loop.

(10) Install anchor to floor.

(11) Slide floor anchor cover over the anchor bolt.

(12) Install shoulder harness height adjuster knob

by pushing it onto adjuster.

Fig. 2 SEAT BELT - OUTBOARD FRONT

1 - B-PILLAR TRIM LOWER

2 - BELT

3 - B-PILLAR TRIM UPPER

4 - HEIGHT ADJUSTER

5 - KNOB

6 - B-PILLAR TRIM LOWER

7 - FLOOR ANCHOR

8 - FLOOR ANCHOR

9 - 30É OUTBOARD

10 - RETRACTOR

8O - 8 RESTRAINTSRS

SEAT BELT OUTBOARD FRONT (Continued)

ProCarManuals.com

Page 618 of 2399

(13) Install first and second row seats.

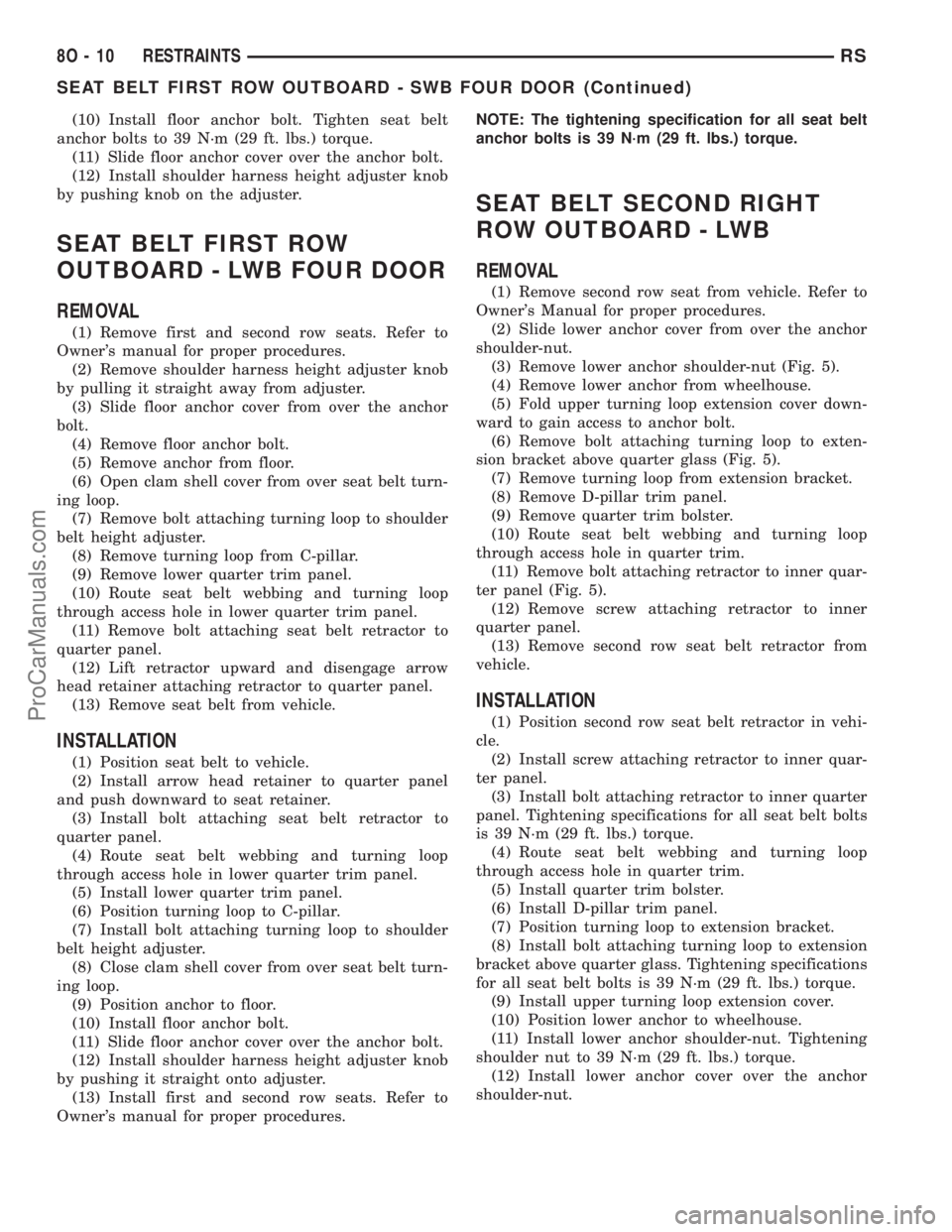

SEAT BELT FIRST ROW

OUTBOARD - SWB FOUR

DOOR

REMOVAL

(1) Remove first and second row seats. Refer to

Owner's manual for proper procedures.

(2) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(3) Slide floor anchor cover from over the anchor

bolt.

(4) Remove floor anchor bolt (Fig. 4).

(5) Remove anchor from floor.

(6) Open clam shell cover from over seat belt turn-

ing loop.

(7) Remove bolt attaching turning loop to shoulder

belt height adjuster (Fig. 4).

(8) Remove turning loop from C-pillar.

(9) Remove lower quarter trim panel.

(10) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.(11) Remove bolt attaching seat belt retractor to

quarter panel (Fig. 4).

(12) Lift retractor upward and disengage arrow

head retainer holding retractor to quarter panel.

(13) Remove seat belt from vehicle.

INSTALLATION

(1) Install seat belt into position.

(2) Lower retractor into position to quarter panel.

(3) Install bolt attaching seat belt retractor to

quarter panel. Tighten seat belt anchor bolts to 39

N´m (29 ft. lbs.) torque.

(4) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(5) Install lower quarter trim panel.

(6) Install turning loop in position on C-pillar.

Tighten seat belt anchor bolts to 39 N´m (29 ft. lbs.)

torque.

(7) Install bolt attaching turning loop to shoulder

belt height adjuster. Tighten seat belt anchor bolts to

39 N´m (29 ft. lbs.) torque.

(8) Close clam shell cover over seat belt turning

loop.

(9) Place anchor in position on floor.

Fig. 3 SEAT BELT LEFT FIRST ROW OUTBOARD ±

SWB THREE DOOR

1 - C-PILLAR TRIM

2 - KNOB

3 - RETRACTOR

4 - LOWER ANCHOR

5 - QUARTER TRIM

Fig. 4 SEAT BELT FIRST ROW OUTBOARD - SWB

FOUR DOOR

1 - UPPER C-PILLAR TRIM

2 - KNOB

3 - HEIGHT ADJUSTER

4 - C-PILLAR

5 - RETRACTOR

6 - FLOOR ANCHOR

7 - QUARTER TRIM PANEL

8 - TURNING LOOP

RSRESTRAINTS8O-9

SEAT BELT LEFT FIRST ROW OUTBOARD - SWB THREE DOOR (Continued)

ProCarManuals.com

Page 619 of 2399

(10) Install floor anchor bolt. Tighten seat belt

anchor bolts to 39 N´m (29 ft. lbs.) torque.

(11) Slide floor anchor cover over the anchor bolt.

(12) Install shoulder harness height adjuster knob

by pushing knob on the adjuster.

SEAT BELT FIRST ROW

OUTBOARD - LWB FOUR DOOR

REMOVAL

(1) Remove first and second row seats. Refer to

Owner's manual for proper procedures.

(2) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(3) Slide floor anchor cover from over the anchor

bolt.

(4) Remove floor anchor bolt.

(5) Remove anchor from floor.

(6) Open clam shell cover from over seat belt turn-

ing loop.

(7) Remove bolt attaching turning loop to shoulder

belt height adjuster.

(8) Remove turning loop from C-pillar.

(9) Remove lower quarter trim panel.

(10) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(11) Remove bolt attaching seat belt retractor to

quarter panel.

(12) Lift retractor upward and disengage arrow

head retainer attaching retractor to quarter panel.

(13) Remove seat belt from vehicle.

INSTALLATION

(1) Position seat belt to vehicle.

(2) Install arrow head retainer to quarter panel

and push downward to seat retainer.

(3) Install bolt attaching seat belt retractor to

quarter panel.

(4) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(5) Install lower quarter trim panel.

(6) Position turning loop to C-pillar.

(7) Install bolt attaching turning loop to shoulder

belt height adjuster.

(8) Close clam shell cover from over seat belt turn-

ing loop.

(9) Position anchor to floor.

(10) Install floor anchor bolt.

(11) Slide floor anchor cover over the anchor bolt.

(12) Install shoulder harness height adjuster knob

by pushing it straight onto adjuster.

(13) Install first and second row seats. Refer to

Owner's manual for proper procedures.NOTE: The tightening specification for all seat belt

anchor bolts is 39 N´m (29 ft. lbs.) torque.

SEAT BELT SECOND RIGHT

ROW OUTBOARD - LWB

REMOVAL

(1) Remove second row seat from vehicle. Refer to

Owner's Manual for proper procedures.

(2) Slide lower anchor cover from over the anchor

shoulder-nut.

(3) Remove lower anchor shoulder-nut (Fig. 5).

(4) Remove lower anchor from wheelhouse.

(5) Fold upper turning loop extension cover down-

ward to gain access to anchor bolt.

(6) Remove bolt attaching turning loop to exten-

sion bracket above quarter glass (Fig. 5).

(7) Remove turning loop from extension bracket.

(8) Remove D-pillar trim panel.

(9) Remove quarter trim bolster.

(10) Route seat belt webbing and turning loop

through access hole in quarter trim.

(11) Remove bolt attaching retractor to inner quar-

ter panel (Fig. 5).

(12) Remove screw attaching retractor to inner

quarter panel.

(13) Remove second row seat belt retractor from

vehicle.

INSTALLATION

(1) Position second row seat belt retractor in vehi-

cle.

(2) Install screw attaching retractor to inner quar-

ter panel.

(3) Install bolt attaching retractor to inner quarter

panel. Tightening specifications for all seat belt bolts

is 39 N´m (29 ft. lbs.) torque.

(4) Route seat belt webbing and turning loop

through access hole in quarter trim.

(5) Install quarter trim bolster.

(6) Install D-pillar trim panel.

(7) Position turning loop to extension bracket.

(8) Install bolt attaching turning loop to extension

bracket above quarter glass. Tightening specifications

for all seat belt bolts is 39 N´m (29 ft. lbs.) torque.

(9) Install upper turning loop extension cover.

(10) Position lower anchor to wheelhouse.

(11) Install lower anchor shoulder-nut. Tightening

shoulder nut to 39 N´m (29 ft. lbs.) torque.

(12) Install lower anchor cover over the anchor

shoulder-nut.

8O - 10 RESTRAINTSRS

SEAT BELT FIRST ROW OUTBOARD - SWB FOUR DOOR (Continued)

ProCarManuals.com

Page 620 of 2399

(13) Install second row seat to vehicle. Refer to

Owner's Manual for proper procedures.

SEAT BELT SECOND RIGHT

ROW OUTBOARD - LBW WITH

REAR HVAC

REMOVAL

(1) Remove second row seat from vehicle. Refer to

Owner's Manual for proper procedures.

(2) Slide lower anchor cover from over the anchor

shoulder-nut.

(3) Remove lower anchor shoulder-nut.

(4) Remove lower anchor from wheelhouse.

(5) Fold upper turning loop extension cover down-

ward to gain access to anchor bolt.

(6) Remove bolt attaching turning loop to exten-

sion bracket above quarter glass.

(7) Remove turning loop from extension bracket.

(8) Remove D-pillar trim panel.

(9) Remove quarter trim bolster.(10) Remove quarter trim panel as necessary to

gain access to HVAC unit.

(11) Route seat belt webbing and turning loop

through access hole in quarter trim.

(12) Loosen HVAC unit enough to gain access to

seat belt retractor fasteners.

(a) Remove bracket around HVAC unit (Fig. 6).

(b) Remove air duct (Fig. 7).

(c) Remove fasteners attaching HVAC unit to

inner quarter panel (Fig. 8).

(d) Remove screws attaching upper evaporator

housing to lower evaporator housing.

(e) Remove coolant line retaining bracket hold

down bolt.

(13) Remove bolts attaching seat belt guide loop to

inner quarter panel.

(14) Pull outward on HVAC unit and remove bolt

attaching retractor to inner quarter panel.

(15) Remove screw attaching retractor to inner

quarter panel.

(16) Remove second row seat belt retractor from

vehicle.INSTALLATION

(1) Position second row seat belt retractor to vehi-

cle.

(2) Install screw attaching retractor to inner quar-

ter panel.

(3) Pull outward on HVAC unit and install bolt

attaching retractor to inner quarter panel. Tighten-

ing specifications for all seat belt bolts is 39 N´m (29

ft. lbs.) torque.

(4) Install bolts attaching seat belt guide loop to

inner quarter panel.

(5) Install coolant line retaining bracket hold down

bolt.

Fig. 5 SECOND RIGHT ROW OUTBOARD SEAT

BELT - LWB

1 - TURNING LOOP GUIDE

2 - RETRACTOR 2nd REAR

3 - LOWER QUARTER TRIM

4 - LOWER ANCHOR

5 - RETRACTOR 1st REAR

6 - ANCHOR BRACKET

7 - QUARTER PANEL

8 - C-PILLAR TRIM

9 - HEIGHT ADJUSTER

Fig. 6 TRIM PANEL MOUNTING BRACKET

1 - TRIM PANEL MOUNTING BRACKET

RSRESTRAINTS8O-11

SEAT BELT SECOND RIGHT ROW OUTBOARD - LWB (Continued)

ProCarManuals.com