rear light CHRYSLER VOYAGER 2002 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1847 of 2399

clutch is engaged by the clutch solenoid on the valve

body. The clutch will engage at approximately 56

km/h (35 mph) with light throttle, after the shift to

third gear.

REMOVAL

(1) Remove transmission and torque converter

from vehicle. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE - REMOVAL)

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate converter hub and oil pump seal lip

with transmission fluid.(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 335). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE - INSTALLATION)

(9) Fill the transmission with the recommended

fluid. (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 41TE/FLUID - STANDARD PROCE-

DURE)

Fig. 334 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

Fig. 335 Checking Torque Converter Seating

1 - SCALE

2 - STRAIGHTEDGE

21 - 290 41TE AUTOMATIC TRANSAXLERS

TORQUE CONVERTER (Continued)

ProCarManuals.com

Page 1963 of 2399

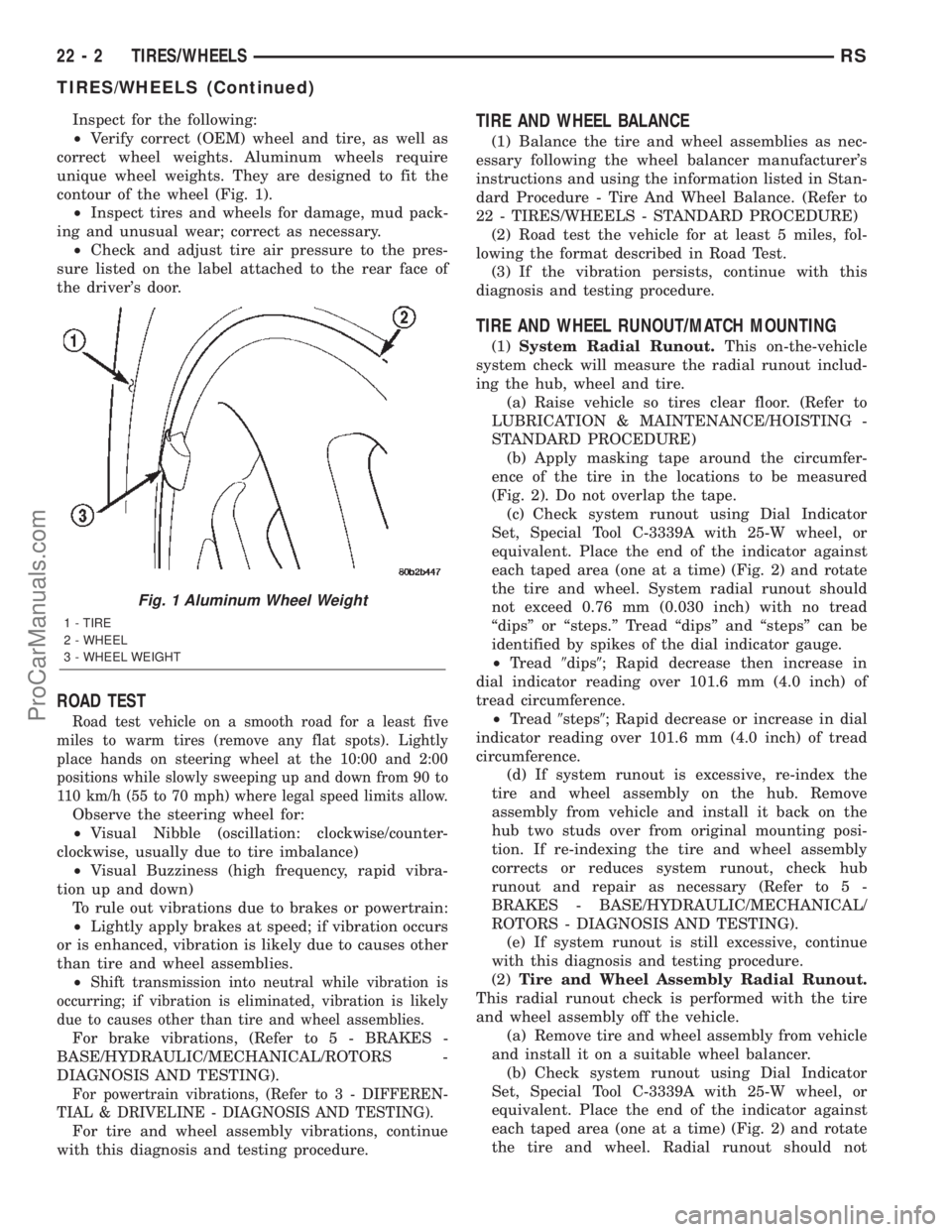

Inspect for the following:

²Verify correct (OEM) wheel and tire, as well as

correct wheel weights. Aluminum wheels require

unique wheel weights. They are designed to fit the

contour of the wheel (Fig. 1).

²Inspect tires and wheels for damage, mud pack-

ing and unusual wear; correct as necessary.

²Check and adjust tire air pressure to the pres-

sure listed on the label attached to the rear face of

the driver's door.

ROAD TEST

Road test vehicle on a smooth road for a least five

miles to warm tires (remove any flat spots). Lightly

place hands on steering wheel at the 10:00 and 2:00

positions while slowly sweeping up and down from 90 to

110 km/h (55 to 70 mph) where legal speed limits allow.

Observe the steering wheel for:

²Visual Nibble (oscillation: clockwise/counter-

clockwise, usually due to tire imbalance)

²Visual Buzziness (high frequency, rapid vibra-

tion up and down)

To rule out vibrations due to brakes or powertrain:

²Lightly apply brakes at speed; if vibration occurs

or is enhanced, vibration is likely due to causes other

than tire and wheel assemblies.

²

Shift transmission into neutral while vibration is

occurring; if vibration is eliminated, vibration is likely

due to causes other than tire and wheel assemblies.

For brake vibrations, (Refer to 5 - BRAKES -

BASE/HYDRAULIC/MECHANICAL/ROTORS -

DIAGNOSIS AND TESTING).

For powertrain vibrations, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE - DIAGNOSIS AND TESTING).

For tire and wheel assembly vibrations, continue

with this diagnosis and testing procedure.

TIRE AND WHEEL BALANCE

(1) Balance the tire and wheel assemblies as nec-

essary following the wheel balancer manufacturer's

instructions and using the information listed in Stan-

dard Procedure - Tire And Wheel Balance. (Refer to

22 - TIRES/WHEELS - STANDARD PROCEDURE)

(2) Road test the vehicle for at least 5 miles, fol-

lowing the format described in Road Test.

(3) If the vibration persists, continue with this

diagnosis and testing procedure.

TIRE AND WHEEL RUNOUT/MATCH MOUNTING

(1)System Radial Runout.This on-the-vehicle

system check will measure the radial runout includ-

ing the hub, wheel and tire.

(a) Raise vehicle so tires clear floor. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(b) Apply masking tape around the circumfer-

ence of the tire in the locations to be measured

(Fig. 2). Do not overlap the tape.

(c) Check system runout using Dial Indicator

Set, Special Tool C-3339A with 25-W wheel, or

equivalent. Place the end of the indicator against

each taped area (one at a time) (Fig. 2) and rotate

the tire and wheel. System radial runout should

not exceed 0.76 mm (0.030 inch) with no tread

ªdipsº or ªsteps.º Tread ªdipsº and ªstepsº can be

identified by spikes of the dial indicator gauge.

²Tread9dips9; Rapid decrease then increase in

dial indicator reading over 101.6 mm (4.0 inch) of

tread circumference.

²Tread9steps9; Rapid decrease or increase in dial

indicator reading over 101.6 mm (4.0 inch) of tread

circumference.

(d) If system runout is excessive, re-index the

tire and wheel assembly on the hub. Remove

assembly from vehicle and install it back on the

hub two studs over from original mounting posi-

tion. If re-indexing the tire and wheel assembly

corrects or reduces system runout, check hub

runout and repair as necessary (Refer to 5 -

BRAKES - BASE/HYDRAULIC/MECHANICAL/

ROTORS - DIAGNOSIS AND TESTING).

(e) If system runout is still excessive, continue

with this diagnosis and testing procedure.

(2)Tire and Wheel Assembly Radial Runout.

This radial runout check is performed with the tire

and wheel assembly off the vehicle.

(a) Remove tire and wheel assembly from vehicle

and install it on a suitable wheel balancer.

(b) Check system runout using Dial Indicator

Set, Special Tool C-3339A with 25-W wheel, or

equivalent. Place the end of the indicator against

each taped area (one at a time) (Fig. 2) and rotate

the tire and wheel. Radial runout should not

Fig. 1 Aluminum Wheel Weight

1 - TIRE

2 - WHEEL

3 - WHEEL WEIGHT

22 - 2 TIRES/WHEELSRS

TIRES/WHEELS (Continued)

ProCarManuals.com

Page 1970 of 2399

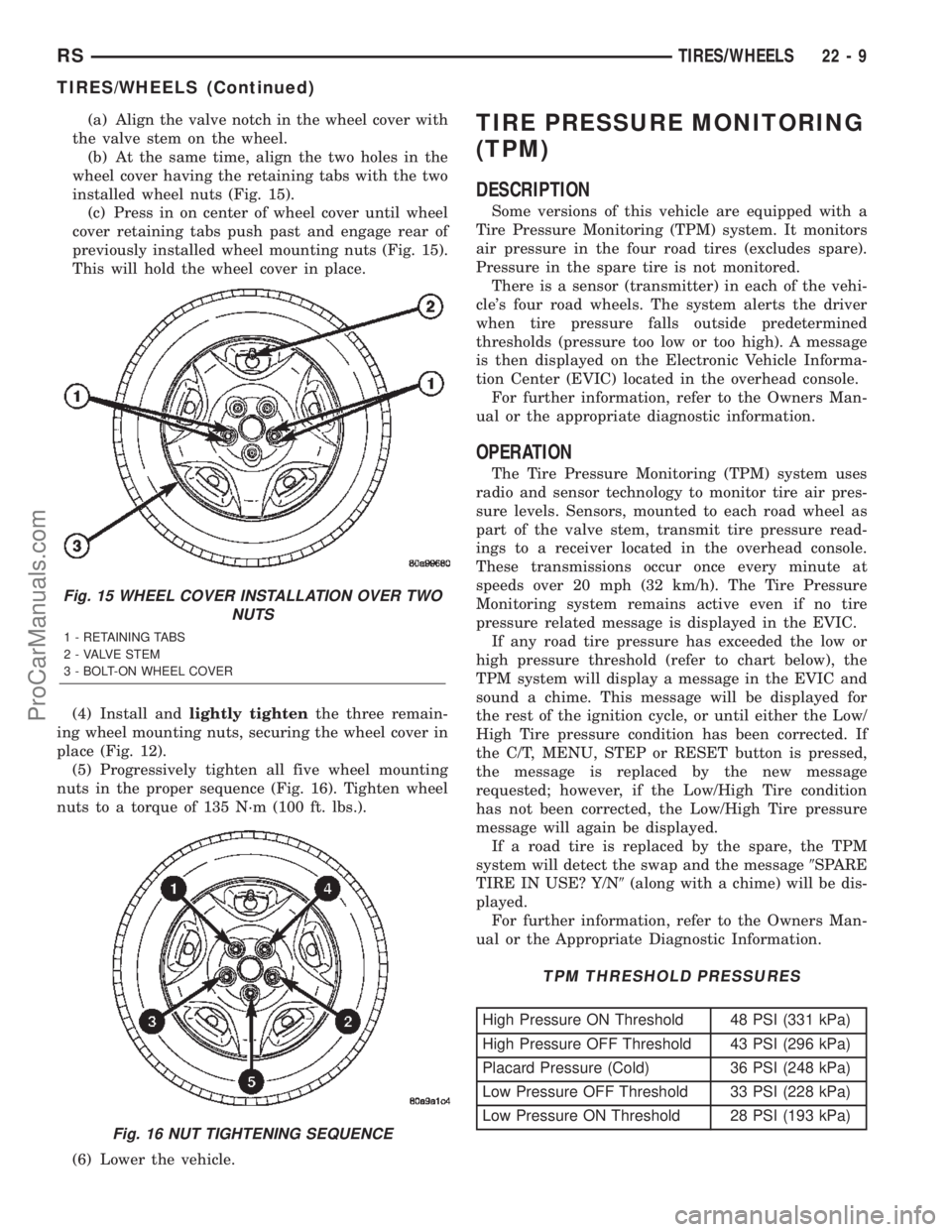

(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 15).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 15).

This will hold the wheel cover in place.

(4) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 12).

(5) Progressively tighten all five wheel mounting

nuts in the proper sequence (Fig. 16). Tighten wheel

nuts to a torque of 135 N´m (100 ft. lbs.).

(6) Lower the vehicle.TIRE PRESSURE MONITORING

(TPM)

DESCRIPTION

Some versions of this vehicle are equipped with a

Tire Pressure Monitoring (TPM) system. It monitors

air pressure in the four road tires (excludes spare).

Pressure in the spare tire is not monitored.

There is a sensor (transmitter) in each of the vehi-

cle's four road wheels. The system alerts the driver

when tire pressure falls outside predetermined

thresholds (pressure too low or too high). A message

is then displayed on the Electronic Vehicle Informa-

tion Center (EVIC) located in the overhead console.

For further information, refer to the Owners Man-

ual or the appropriate diagnostic information.

OPERATION

The Tire Pressure Monitoring (TPM) system uses

radio and sensor technology to monitor tire air pres-

sure levels. Sensors, mounted to each road wheel as

part of the valve stem, transmit tire pressure read-

ings to a receiver located in the overhead console.

These transmissions occur once every minute at

speeds over 20 mph (32 km/h). The Tire Pressure

Monitoring system remains active even if no tire

pressure related message is displayed in the EVIC.

If any road tire pressure has exceeded the low or

high pressure threshold (refer to chart below), the

TPM system will display a message in the EVIC and

sound a chime. This message will be displayed for

the rest of the ignition cycle, or until either the Low/

High Tire pressure condition has been corrected. If

the C/T, MENU, STEP or RESET button is pressed,

the message is replaced by the new message

requested; however, if the Low/High Tire condition

has not been corrected, the Low/High Tire pressure

message will again be displayed.

If a road tire is replaced by the spare, the TPM

system will detect the swap and the message9SPARE

TIRE IN USE? Y/N9(along with a chime) will be dis-

played.

For further information, refer to the Owners Man-

ual or the Appropriate Diagnostic Information.

TPM THRESHOLD PRESSURES

High Pressure ON Threshold 48 PSI (331 kPa)

High Pressure OFF Threshold 43 PSI (296 kPa)

Placard Pressure (Cold) 36 PSI (248 kPa)

Low Pressure OFF Threshold 33 PSI (228 kPa)

Low Pressure ON Threshold 28 PSI (193 kPa)

Fig. 15 WHEEL COVER INSTALLATION OVER TWO

NUTS

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 16 NUT TIGHTENING SEQUENCE

RSTIRES/WHEELS22-9

TIRES/WHEELS (Continued)

ProCarManuals.com

Page 1980 of 2399

SPECIFICATIONS

WHEEL

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Wheel Mounting (Lug)

Nut Hex Size19 mm

Wheel Mounting Stud

SizeM12 x 1.5 mm

TORQUE SPECIFICATIONS

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Wheel Mounting (Lug ) Nut 135 100 Ð

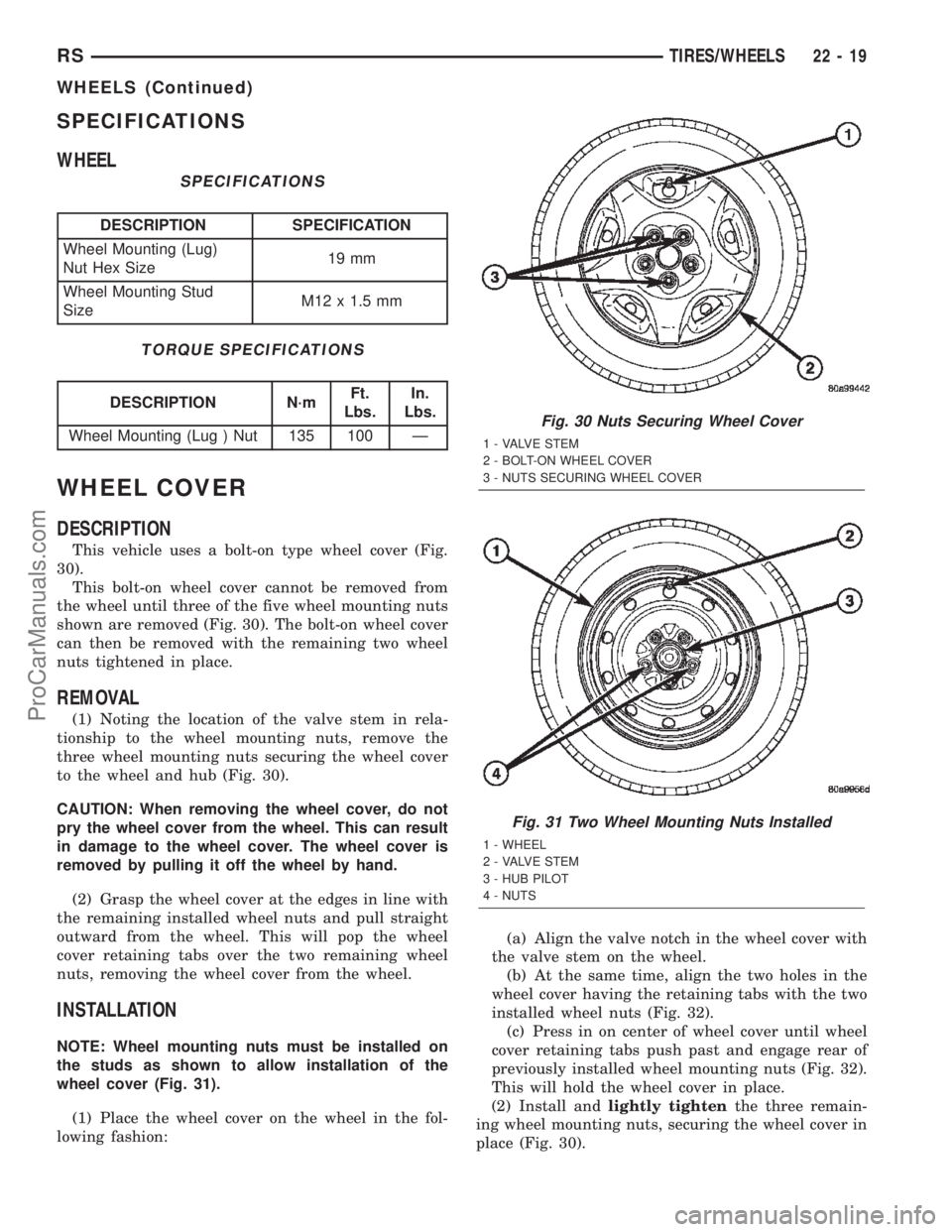

WHEEL COVER

DESCRIPTION

This vehicle uses a bolt-on type wheel cover (Fig.

30).

This bolt-on wheel cover cannot be removed from

the wheel until three of the five wheel mounting nuts

shown are removed (Fig. 30). The bolt-on wheel cover

can then be removed with the remaining two wheel

nuts tightened in place.

REMOVAL

(1) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 30).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can result

in damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

(2) Grasp the wheel cover at the edges in line with

the remaining installed wheel nuts and pull straight

outward from the wheel. This will pop the wheel

cover retaining tabs over the two remaining wheel

nuts, removing the wheel cover from the wheel.

INSTALLATION

NOTE: Wheel mounting nuts must be installed on

the studs as shown to allow installation of the

wheel cover (Fig. 31).

(1) Place the wheel cover on the wheel in the fol-

lowing fashion:(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 32).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 32).

This will hold the wheel cover in place.

(2) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 30).

Fig. 30 Nuts Securing Wheel Cover

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 31 Two Wheel Mounting Nuts Installed

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

RSTIRES/WHEELS22-19

WHEELS (Continued)

ProCarManuals.com

Page 2057 of 2399

(5) Disengage hidden clips attaching lower trim

cover to B-pillar.

(6) Remove lower B-pillar trim cover from vehicle.

INSTALLATION

(1) Place lower B-pillar trim cover in position on

vehicle (Fig. 3).

(2) Insert seat belt through hole in lower B-pillar

trim.

(3) Engage hidden clips attaching lower trim cover

to B-pillar.

(4) Install access cover.

(5) Install upper B-pillar trim cover.

(6) Place seat belt anchor in position on floor so

webbing is pointed rearward and slightly outboard.

(7) Install bolt attaching lower seat belt anchor to

floor. Tighten all seat belt bolts to 39 N´m (29 ft. lbs.)

torque.

(8) Verify that seat belt anchor does not interfere

with seat track travel.

B-PILLAR UPPER TRIM

REMOVAL

(1) Remove bolt attaching lower seat belt anchor to

floor.(2) Lower shoulder belt height adjuster to the bot-

tom of travel.

(3) Remove shoulder belt turning loop from height

adjuster.

(4) Use a Snap-ontTrim Pad Remover tool

(A179A), or equivalent, and remove shoulder belt

height adjuster knob.

(5) Remove shoulder belt bezel from trim cover

(Fig. 3).

(6) Remove screw attaching trim cover to B-pillar

from inside bezel cavity.

(7) Disengage hidden clips attaching trim cover to

B-pillar.

(8) Remove B-pillar trim cover from vehicle.

INSTALLATION

(1) Insert seat belt through B-pillar trim and web

guide (Fig. 3).

(2) Place B-pillar trim cover in position on vehicle.

(3) Engage hidden clips attaching trim cover to

B-pillar.

(4) Install shoulder belt bezel into trim cover.

(5) Install height adjuster knob.

(6) Install shoulder belt turning loop onto height

adjuster. Tighten bolt to 39 N´m (29 ft. lbs.) torque.

(7) Place seat anchor in position on floor so web-

bing is pointed rearward and slightly outboard.

(8) Install bolt attaching lower seat belt anchor to

floor. Tighten seat belt bolt to 39 N´m (29 ft. lbs.)

torque.

CARPETS AND FLOOR MATS

REMOVAL

(1) Remove front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL)

(2) Remove front center console.

(3) Remove the remaining seats. Refer to the Own-

er's Manual for the proper procedures.

(4) Remove front cowl panels and sill plates.

(5) Remove sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(6) Remove the cargo organizer, if equipped.

(7) Remove liftgate scuff plate. (Refer to 23 -

BODY/INTERIOR/LIFTGATE SCUFF PLATE -

REMOVAL)

(8) Remove lower B-pillar trim covers.

(9) Remove D-pillar trim covers.

(10) Remove Quarter trim panels.

(11) Remove floor escutcheons (Fig. 4).

(12) Remove the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

REMOVAL)

Fig. 3 LOWER B-PILLAR TRIM COVER

1 - B-PILLAR UPPER TRIM

2 - B-PILLAR UPPER PLUG

3 - POWER SLIDING DOOR SWITCH AND BEZEL

4 - BELT ASSEMBLY

5 - B-PILLAR LOWER TRIM

23 - 74 INTERIORRS

B-PILLAR LOWER TRIM (Continued)

ProCarManuals.com

Page 2247 of 2399

REAR CONTROL PANEL

With the rear control active, temperature selection

dictates indirectly the mode (floor or overhead air) of

the rear unit: a low temperature setting directs flow

to the overhead outlets and a high temperature set-

ting to the floor.

OPERATION - THREE ZONE ATC

Comfort temperature or perceived temperature is

affected by air flow, sun impinging on exposed skin,

etc. The air temperature may be higher or lower than

the comfort temperature. Three infrared sensors, two

in the instrument panel center stack, and one in the

overhead-mounted rear control panel, independently

measure the temperature of the driver, front passen-

ger, and rear compartment occupants to determine

their comfort level relative to the selected comfort

temperature. The HVAC computer in the control

module adjusts the air flow rate and temperature to

maintain the customer-perceived comfort tempera-

ture. The air temperature in the passenger compart-

ment at any time may be slightly higher or lower

than the comfort temperature. For instance, on

sunny summer days the air flow will probably be

cooler than the comfort temperature; on cold or

cloudy days and at night it will probably be slightly

warmer. Infrared Three-Zone Temperature Control

provides side-to-side and front-to-rear variation in

comfort temperature settings. The Infrared Three-

Zone Automatic Temperature Control fan provides a

continuously variable air flow rate to meet occupant

comfort requirements.

FRONT CONTROL PANEL

²AUTO HI/LO± This system features two sets of

automatic control logic that allow either a rapid cool-

down rate or a somewhat slower cool-down rate with

less fan noise. HI-AUTO controls the system to reach

its assigned temperature quickly with a higher fan

speed. LO-AUTO controls the system to reach its

assigned temperature somewhat slower with less fan

noise. Both modes will automatically engage auto

recirculation.

²DE-FROST± The front de-frost function is

active when the rear window defogger function is

active or when the defog/defrost mode is selected.

²RECIRC± The RECIRC button will close the

air inlet door. If the system is in auto recirc (indica-

tor being displayed automatically), pressing the man-

ual recirc button will disable the auto recirc function

until one of the auto keys are pressed or the ignition

is cycled. If Auto HI/LO is pressed while manual

recirc is active, manual recirc will be deactivated.

²REAR WINDOW DEFOGGER± Pushing the

button sends a PCI bus message to the Intelligent

Power Module which controls the Rear WindowDefogger and side view mirror (if equipped) circuitry.

The defogger function will be active for 10 minutes

and can be turned off by a switch press. The defogger

will function while the control is in the OFF mode.

²FAN/MODE± The Fan and Mode knobs have

17 manual selectable positions. Manually changing

either of the rotary knobs for mode or fan speed set-

tings makes control of that function alone manual for

as long as the ignition is on. If only one is changed

manually, the other remains under automatic control.

Pressing the HI-AUTO/LO-AUTO rocker switch

restores full automatic control.

²REAR CONTROL± When the Rear System

control knob is moved to the OFF position, there will

be a delay of approximately 1 second before the sys-

tem actually turns off. This delay is to prevent an

undesired blower dropout if the knob is moved

through OFF to the other selections.

²BLOWER DELAY TIMER± The word DELAY

is displayed at start-up to signify that the system is

waiting so that cold air will not be blowing. This tells

the operator that it is unnecessary to turn the sys-

tem off, raise the temperature setting or turn the fan

speed setting down to prevent cold air from blowing.

A countdown in minutes and seconds until the engine

is warm enough to begin delivering heat to the pas-

sengers alternates with the DELAY message at 25

second intervals. This countdown is based on actual

measurement of the rate of engine coolant tempera-

ture change. During the delay time, Defrost mode is

selected and the fan operates at a low speed to keep

the windshield fog free.

REAR CONTROL PANEL

Primary control of the rear compartment unit is in

the instrument panel center stack. The rear unit con-

trol knob there allows the driver to turn the rear

unit off, allow control by the intermediate seat occu-

pants by switching to the REAR position, or provide

fully automatic control based on the temperature set-

ting shown on the front control display.

²REAR CONTROL± Selecting automatic control

of the rear unit at the instrument panel, illuminates

a Locked Padlock in the rear control panel display.

Selecting REAR activates the rear control panel and

the Padlock then appears unlocked.

²FAN KNOB± The rear fan control has Off and

AUTO positions and a range of manual speed set-

tings that override the AUTO setting.

²MODE KNOB± The mode control allows inter-

mediate seat occupants to manually override the

automatic mode and select any balance of air flow

between overhead and floor outlets from full over-

head to full floor.

²SET TEMP± The rear set temp control will

operate identical to the front controls. If the front

24 - 4 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

ProCarManuals.com

Page 2251 of 2399

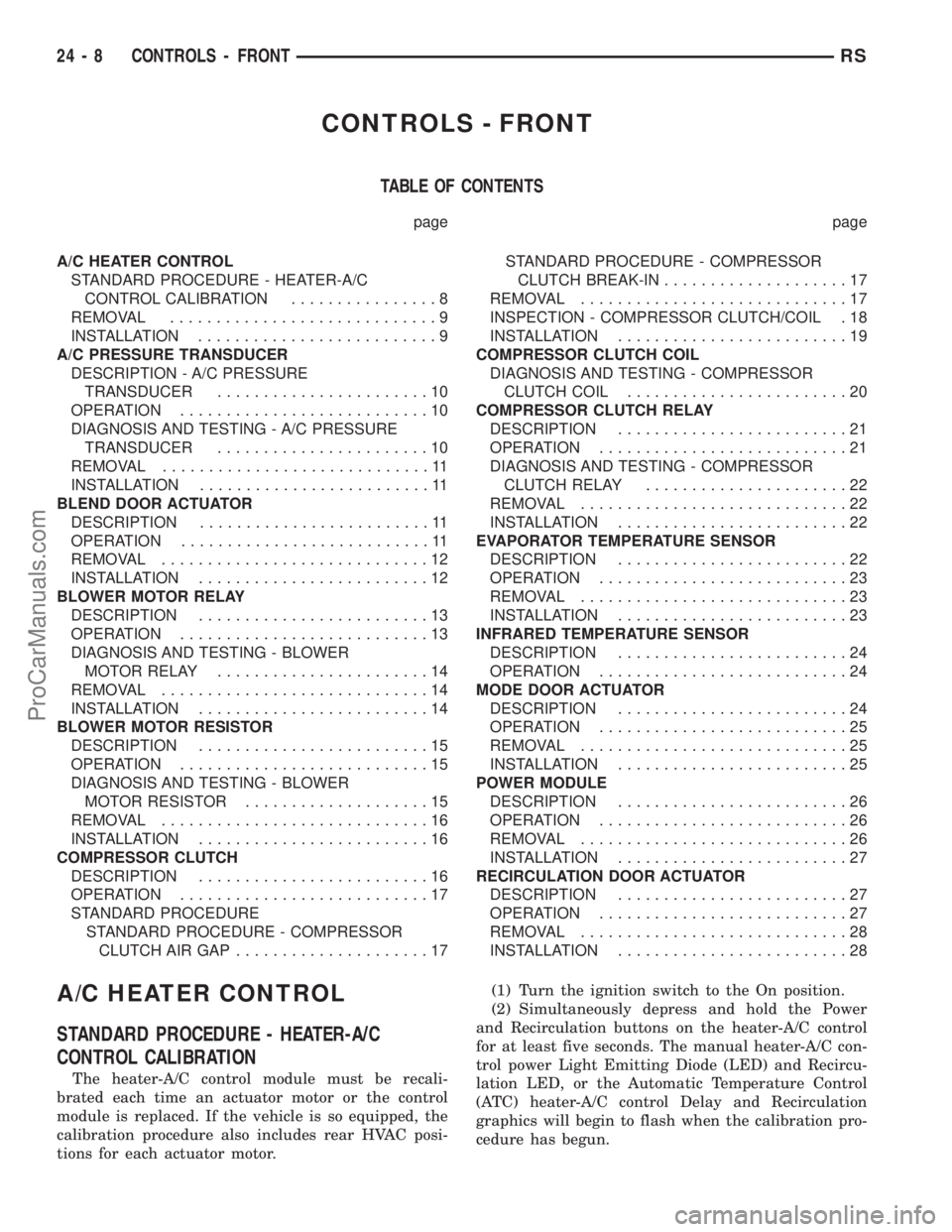

CONTROLS - FRONT

TABLE OF CONTENTS

page page

A/C HEATER CONTROL

STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION................8

REMOVAL.............................9

INSTALLATION..........................9

A/C PRESSURE TRANSDUCER

DESCRIPTION - A/C PRESSURE

TRANSDUCER.......................10

OPERATION...........................10

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER.......................10

REMOVAL.............................11

INSTALLATION.........................11

BLEND DOOR ACTUATOR

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................12

INSTALLATION.........................12

BLOWER MOTOR RELAY

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING - BLOWER

MOTOR RELAY.......................14

REMOVAL.............................14

INSTALLATION.........................14

BLOWER MOTOR RESISTOR

DESCRIPTION.........................15

OPERATION...........................15

DIAGNOSIS AND TESTING - BLOWER

MOTOR RESISTOR....................15

REMOVAL.............................16

INSTALLATION.........................16

COMPRESSOR CLUTCH

DESCRIPTION.........................16

OPERATION...........................17

STANDARD PROCEDURE

STANDARD PROCEDURE - COMPRESSOR

CLUTCH AIR GAP.....................17STANDARD PROCEDURE - COMPRESSOR

CLUTCH BREAK-IN....................17

REMOVAL.............................17

INSPECTION - COMPRESSOR CLUTCH/COIL . 18

INSTALLATION.........................19

COMPRESSOR CLUTCH COIL

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL........................20

COMPRESSOR CLUTCH RELAY

DESCRIPTION.........................21

OPERATION...........................21

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH RELAY......................22

REMOVAL.............................22

INSTALLATION.........................22

EVAPORATOR TEMPERATURE SENSOR

DESCRIPTION.........................22

OPERATION...........................23

REMOVAL.............................23

INSTALLATION.........................23

INFRARED TEMPERATURE SENSOR

DESCRIPTION.........................24

OPERATION...........................24

MODE DOOR ACTUATOR

DESCRIPTION.........................24

OPERATION...........................25

REMOVAL.............................25

INSTALLATION.........................25

POWER MODULE

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................26

INSTALLATION.........................27

RECIRCULATION DOOR ACTUATOR

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................28

INSTALLATION.........................28

A/C HEATER CONTROL

STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION

The heater-A/C control module must be recali-

brated each time an actuator motor or the control

module is replaced. If the vehicle is so equipped, the

calibration procedure also includes rear HVAC posi-

tions for each actuator motor.(1) Turn the ignition switch to the On position.

(2) Simultaneously depress and hold the Power

and Recirculation buttons on the heater-A/C control

for at least five seconds. The manual heater-A/C con-

trol power Light Emitting Diode (LED) and Recircu-

lation LED, or the Automatic Temperature Control

(ATC) heater-A/C control Delay and Recirculation

graphics will begin to flash when the calibration pro-

cedure has begun.

24 - 8 CONTROLS - FRONTRS

ProCarManuals.com

Page 2255 of 2399

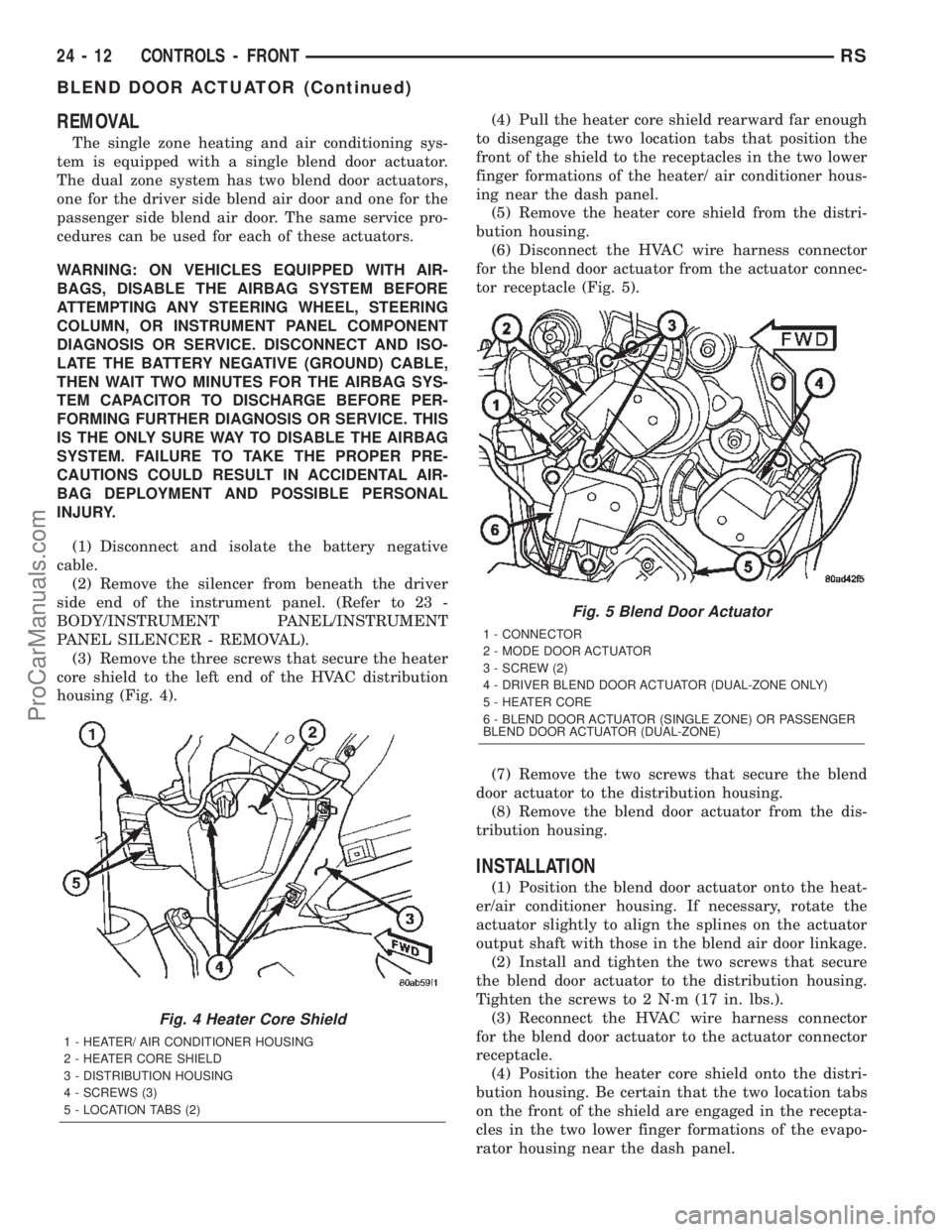

REMOVAL

The single zone heating and air conditioning sys-

tem is equipped with a single blend door actuator.

The dual zone system has two blend door actuators,

one for the driver side blend air door and one for the

passenger side blend air door. The same service pro-

cedures can be used for each of these actuators.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the silencer from beneath the driver

side end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL SILENCER - REMOVAL).

(3) Remove the three screws that secure the heater

core shield to the left end of the HVAC distribution

housing (Fig. 4).(4) Pull the heater core shield rearward far enough

to disengage the two location tabs that position the

front of the shield to the receptacles in the two lower

finger formations of the heater/ air conditioner hous-

ing near the dash panel.

(5) Remove the heater core shield from the distri-

bution housing.

(6) Disconnect the HVAC wire harness connector

for the blend door actuator from the actuator connec-

tor receptacle (Fig. 5).

(7) Remove the two screws that secure the blend

door actuator to the distribution housing.

(8) Remove the blend door actuator from the dis-

tribution housing.

INSTALLATION

(1) Position the blend door actuator onto the heat-

er/air conditioner housing. If necessary, rotate the

actuator slightly to align the splines on the actuator

output shaft with those in the blend air door linkage.

(2) Install and tighten the two screws that secure

the blend door actuator to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the HVAC wire harness connector

for the blend door actuator to the actuator connector

receptacle.

(4) Position the heater core shield onto the distri-

bution housing. Be certain that the two location tabs

on the front of the shield are engaged in the recepta-

cles in the two lower finger formations of the evapo-

rator housing near the dash panel.

Fig. 4 Heater Core Shield

1 - HEATER/ AIR CONDITIONER HOUSING

2 - HEATER CORE SHIELD

3 - DISTRIBUTION HOUSING

4 - SCREWS (3)

5 - LOCATION TABS (2)

Fig. 5 Blend Door Actuator

1 - CONNECTOR

2 - MODE DOOR ACTUATOR

3 - SCREW (2)

4 - DRIVER BLEND DOOR ACTUATOR (DUAL-ZONE ONLY)

5 - HEATER CORE

6 - BLEND DOOR ACTUATOR (SINGLE ZONE) OR PASSENGER

BLEND DOOR ACTUATOR (DUAL-ZONE)

24 - 12 CONTROLS - FRONTRS

BLEND DOOR ACTUATOR (Continued)

ProCarManuals.com

Page 2261 of 2399

(1) Disconnect and isolate the battery negative

cable.

(2) Raise and support the vehicle.

(3) Remove the serpentine drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

2.4L - REMOVAL) or (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - 3.3/3.8L - REMOV-

AL).

(4) Disconnect the engine wire harness connector

for the compressor clutch coil from the clutch coil pig-

tail wire connector on the top of the compressor.

(5) On models with the 3.3L and 3.8L engines, dis-

engage the retainer on the engine wire harness com-

pressor clutch coil take out from the bracket on the

top of the compressor.

(6) On models with the 2.4L engine, remove all of

the compressor mounting screws except the upper

left (rear of the compressor) screw, which should only

be loosened. Allow the front (pulley end) of the com-

pressor to tilt downward far enough to access the

clutch for removal, then tighten the loosened upper

left compressor mounting screw.

(7) On models with the 3.3L and 3.8L engines,

remove the three screws and one nut that secure the

compressor to the engine. Disengage the mounting

ear at the front of the compressor from the stud on

the engine, allow the front (pulley end) of the com-

pressor to tilt downward far enough to access the

clutch for removal, then reinstall and tighten the

upper left compressor mounting screw.

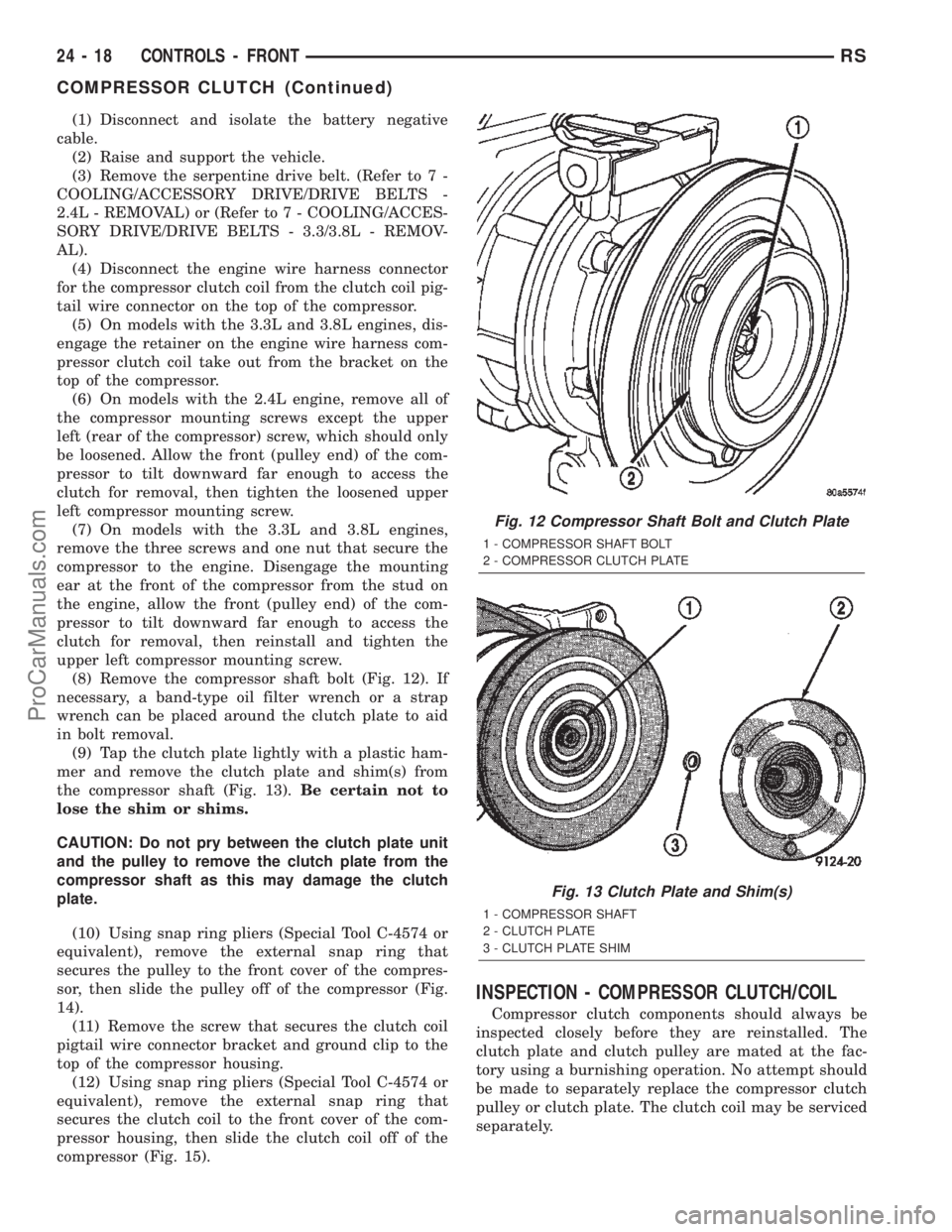

(8) Remove the compressor shaft bolt (Fig. 12). If

necessary, a band-type oil filter wrench or a strap

wrench can be placed around the clutch plate to aid

in bolt removal.

(9) Tap the clutch plate lightly with a plastic ham-

mer and remove the clutch plate and shim(s) from

the compressor shaft (Fig. 13).Be certain not to

lose the shim or shims.

CAUTION: Do not pry between the clutch plate unit

and the pulley to remove the clutch plate from the

compressor shaft as this may damage the clutch

plate.

(10) Using snap ring pliers (Special Tool C-4574 or

equivalent), remove the external snap ring that

secures the pulley to the front cover of the compres-

sor, then slide the pulley off of the compressor (Fig.

14).

(11) Remove the screw that secures the clutch coil

pigtail wire connector bracket and ground clip to the

top of the compressor housing.

(12) Using snap ring pliers (Special Tool C-4574 or

equivalent), remove the external snap ring that

secures the clutch coil to the front cover of the com-

pressor housing, then slide the clutch coil off of the

compressor (Fig. 15).

INSPECTION - COMPRESSOR CLUTCH/COIL

Compressor clutch components should always be

inspected closely before they are reinstalled. The

clutch plate and clutch pulley are mated at the fac-

tory using a burnishing operation. No attempt should

be made to separately replace the compressor clutch

pulley or clutch plate. The clutch coil may be serviced

separately.

Fig. 12 Compressor Shaft Bolt and Clutch Plate

1 - COMPRESSOR SHAFT BOLT

2 - COMPRESSOR CLUTCH PLATE

Fig. 13 Clutch Plate and Shim(s)

1 - COMPRESSOR SHAFT

2 - CLUTCH PLATE

3 - CLUTCH PLATE SHIM

24 - 18 CONTROLS - FRONTRS

COMPRESSOR CLUTCH (Continued)

ProCarManuals.com

Page 2274 of 2399

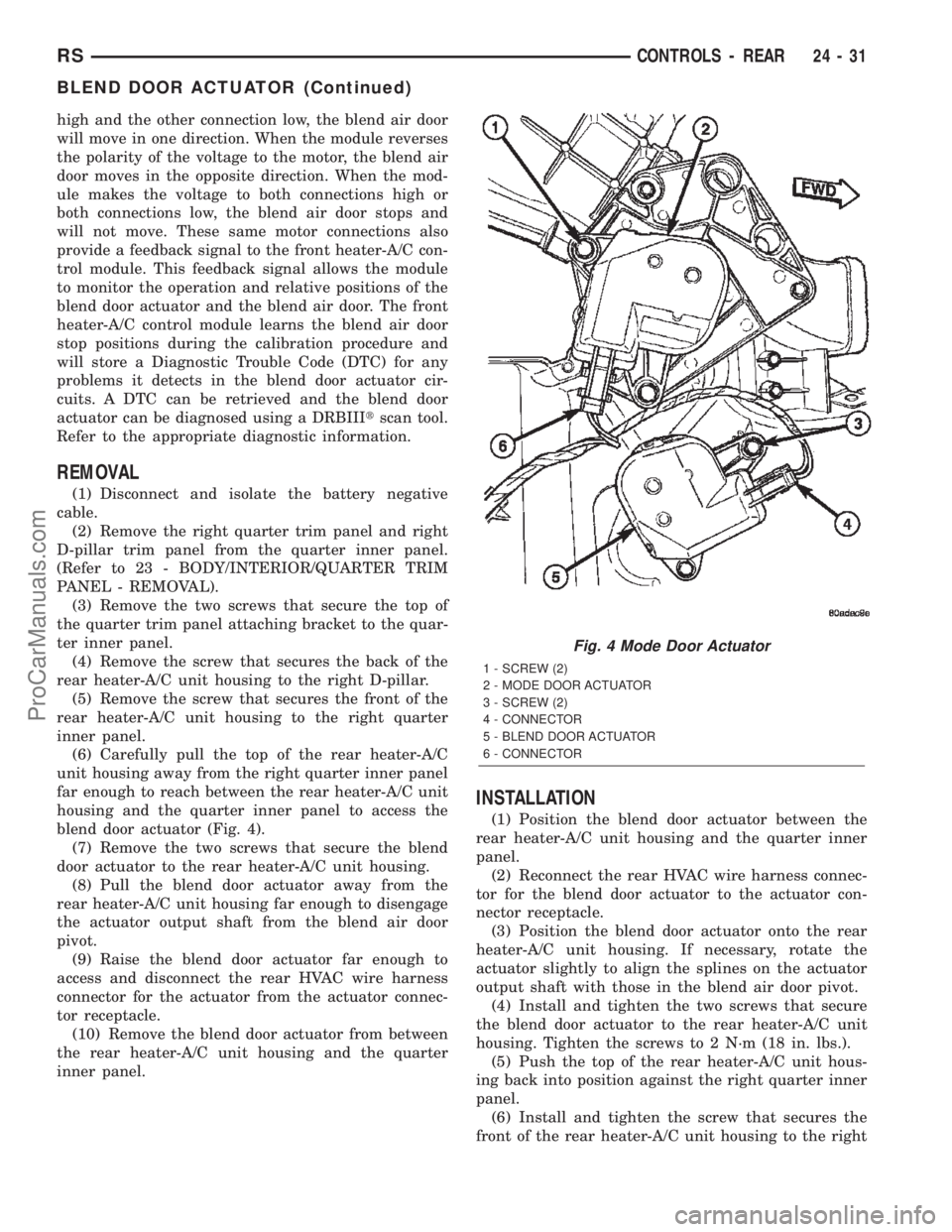

high and the other connection low, the blend air door

will move in one direction. When the module reverses

the polarity of the voltage to the motor, the blend air

door moves in the opposite direction. When the mod-

ule makes the voltage to both connections high or

both connections low, the blend air door stops and

will not move. These same motor connections also

provide a feedback signal to the front heater-A/C con-

trol module. This feedback signal allows the module

to monitor the operation and relative positions of the

blend door actuator and the blend air door. The front

heater-A/C control module learns the blend air door

stop positions during the calibration procedure and

will store a Diagnostic Trouble Code (DTC) for any

problems it detects in the blend door actuator cir-

cuits. A DTC can be retrieved and the blend door

actuator can be diagnosed using a DRBIIItscan tool.

Refer to the appropriate diagnostic information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right quarter trim panel and right

D-pillar trim panel from the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

(3) Remove the two screws that secure the top of

the quarter trim panel attaching bracket to the quar-

ter inner panel.

(4) Remove the screw that secures the back of the

rear heater-A/C unit housing to the right D-pillar.

(5) Remove the screw that secures the front of the

rear heater-A/C unit housing to the right quarter

inner panel.

(6) Carefully pull the top of the rear heater-A/C

unit housing away from the right quarter inner panel

far enough to reach between the rear heater-A/C unit

housing and the quarter inner panel to access the

blend door actuator (Fig. 4).

(7) Remove the two screws that secure the blend

door actuator to the rear heater-A/C unit housing.

(8) Pull the blend door actuator away from the

rear heater-A/C unit housing far enough to disengage

the actuator output shaft from the blend air door

pivot.

(9) Raise the blend door actuator far enough to

access and disconnect the rear HVAC wire harness

connector for the actuator from the actuator connec-

tor receptacle.

(10) Remove the blend door actuator from between

the rear heater-A/C unit housing and the quarter

inner panel.

INSTALLATION

(1) Position the blend door actuator between the

rear heater-A/C unit housing and the quarter inner

panel.

(2) Reconnect the rear HVAC wire harness connec-

tor for the blend door actuator to the actuator con-

nector receptacle.

(3) Position the blend door actuator onto the rear

heater-A/C unit housing. If necessary, rotate the

actuator slightly to align the splines on the actuator

output shaft with those in the blend air door pivot.

(4) Install and tighten the two screws that secure

the blend door actuator to the rear heater-A/C unit

housing. Tighten the screws to 2 N´m (18 in. lbs.).

(5) Push the top of the rear heater-A/C unit hous-

ing back into position against the right quarter inner

panel.

(6) Install and tighten the screw that secures the

front of the rear heater-A/C unit housing to the right

Fig. 4 Mode Door Actuator

1 - SCREW (2)

2 - MODE DOOR ACTUATOR

3 - SCREW (2)

4 - CONNECTOR

5 - BLEND DOOR ACTUATOR

6 - CONNECTOR

RSCONTROLS - REAR24-31

BLEND DOOR ACTUATOR (Continued)

ProCarManuals.com