radio controls CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 320 of 2399

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - AUDIO..........1

ANTENNA BODY AND CABLE

DESCRIPTION..........................4

OPERATION............................4

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE..........................4

REMOVAL.............................4

INSTALLATION..........................5

ANTENNA MODULE - EXPORT

DESCRIPTION..........................6

OPERATION............................6

DIAGNOSIS AND TESTING - ANTENNA

MODULE - EXPORT....................6

REMOVAL.............................7

INSTALLATION..........................7

CD CHANGER

DESCRIPTION..........................7

OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................7

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL.............................8INSTALLATION..........................8

QUARTER GLASS INTEGRAL ANTENNA -

EXPORT

DESCRIPTION..........................8

OPERATION............................8

DIAGNOSIS AND TESTING - QUARTER

GLASS INTEGRAL ANTENNA - EXPORT.....8

RADIO

DIAGNOSIS AND TESTING - RADIO..........9

REMOVAL.............................9

INSTALLATION.........................10

RADIO NOISE SUPPRESSION COMPONENTS

DESCRIPTION.........................10

OPERATION...........................10

REMOTE SWITCHES

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - REMOTE

SWITCHES..........................11

REMOVAL.............................12

INSTALLATION.........................12

SPEAKER

DIAGNOSIS AND TESTING - SPEAKER......12

REMOVAL.............................13

INSTALLATION.........................14

AUDIO

DESCRIPTION

There are four different system combinations avail-

able on this model. The available radio options are:

²AM/FM Cassette

²AM/FM Compact Disc with Compact Disc

changer controls

²AM/FM Cassette with single Compact Disc

Player and Compact Disc changer controls

²AM/FM Cassette with Compact Disc changer

controls

²AM/FM Cassette with Compact Disc player, rear

seat audio system and Compact Disc changer con-

trols.

The rear seat audio system allows passengers to

listen to a different music source, through head-

phones, other than what is playing through the vehi-

cles speaker system. A remote control is provided for

functions such as changing stations, tracks, disc and

modes while listening to rear seat audio. The radiomust be turned ON to use the rear seat audio sys-

tem.

All factory installed radio receivers are stereo Elec-

tronically Tuned Radios (ETR) and include and elec-

tronic digital clock function.

OPERATION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with this vehicle.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

RSAUDIO8A-1

ProCarManuals.com

Page 330 of 2399

REMOTE SWITCHES

DESCRIPTION

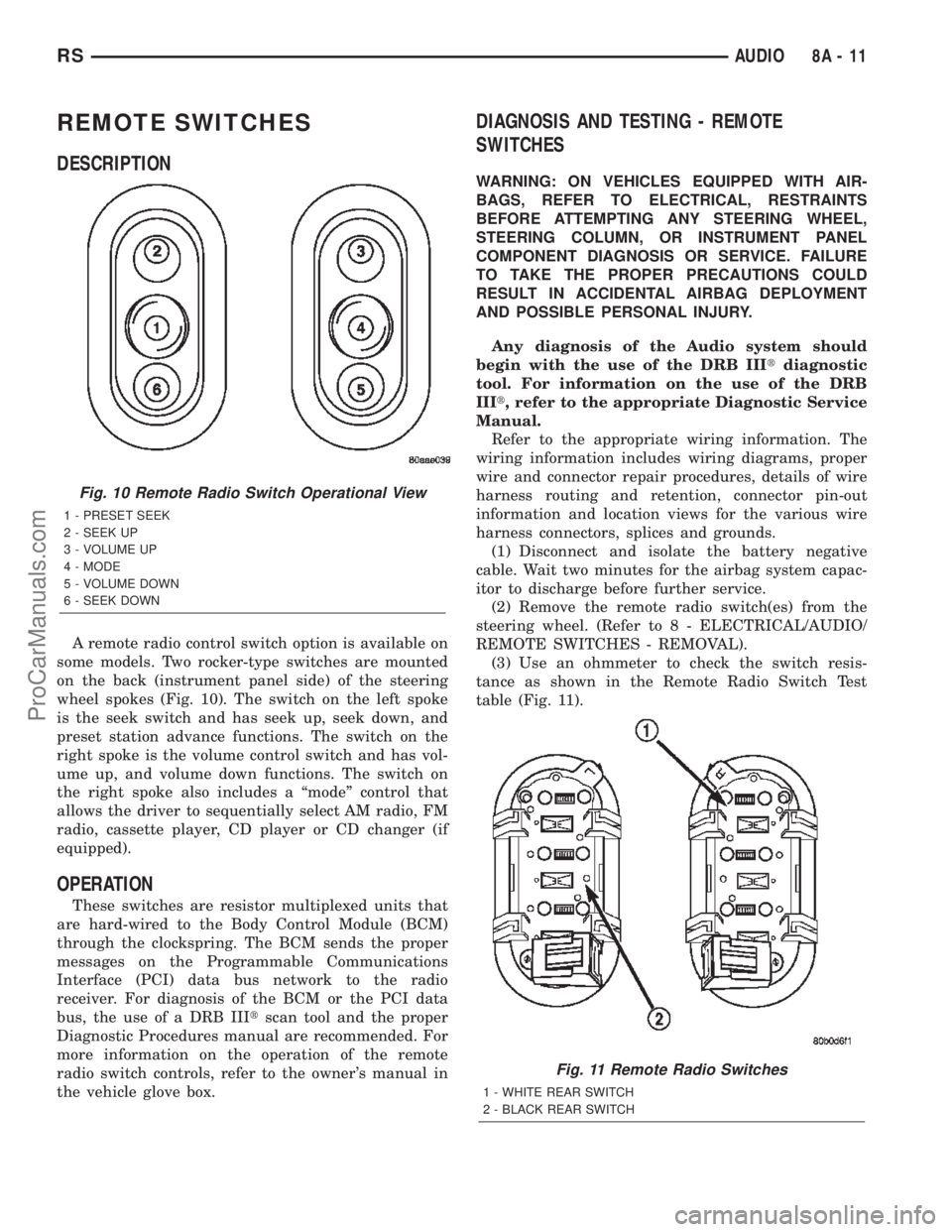

A remote radio control switch option is available on

some models. Two rocker-type switches are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 10). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Programmable Communications

Interface (PCI) data bus network to the radio

receiver. For diagnosis of the BCM or the PCI data

bus, the use of a DRB IIItscan tool and the proper

Diagnostic Procedures manual are recommended. For

more information on the operation of the remote

radio switch controls, refer to the owner's manual in

the vehicle glove box.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the airbag system capac-

itor to discharge before further service.

(2) Remove the remote radio switch(es) from the

steering wheel. (Refer to 8 - ELECTRICAL/AUDIO/

REMOTE SWITCHES - REMOVAL).

(3) Use an ohmmeter to check the switch resis-

tance as shown in the Remote Radio Switch Test

table (Fig. 11).

Fig. 10 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

Fig. 11 Remote Radio Switches

1 - WHITE REAR SWITCH

2 - BLACK REAR SWITCH

RSAUDIO8A-11

ProCarManuals.com

Page 332 of 2399

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) If all speakers are inoperative, check the radio

fuses in the junction block. If OK, go to Step 2. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the ON position.

Turn the radio receiver ON. Adjust the balance and

fader control controls to check the performance of

each individual speaker. Note the speaker locations

that are not performing correctly. Go to Step 3.

(3) Turn the radio receiver OFF. Turn the ignition

OFF. Disconnect and isolate the battery negative

cable. Remove the radio receiver.

(4) Check both the speaker feed (+) circuit and

return (-) circuit cavities for the inoperative speaker

at the radio receiver wire harness connector for con-

tinuity to ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted

speaker feed (+) and/or return (-) circuits(s) to the

speaker as required.

(5) Disconnect wire harness connector at the inop-

erative speaker. Check for continuity between the

speaker feed (+) circuit cavities of the radio receiver

wire harness connector. Repeat the check between

the speaker return (-) circuit cavities of the radio

receiver wire harness connector and the speaker wire

harness connector. In each case, there should be con-

tinuity. If OK, replace the faulty speaker. If not OK,

repair the open speaker feed (+) and/or return (-) cir-

cuits(s) as required.

REMOVAL

D-PILLAR SPEAKER

(1)Disconnect and isolate the battery negative cable.

(2) Remove rear header trim (right side speaker).

(3) Remove jack cover (left side speaker).

(4) Remove liftgate scuff plate.

(5) Remove upper seat belt bolt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT OUT-

BOARD FRONT - REMOVAL).(6) Partially remove quarter trim panel to access

the D-pillar speaker.

(7) Slide the speaker from the retainer (Fig. 12).

(8) Disconnect the wire harness connector from the

speaker.

FRONT DOOR SPEAKER

(1)Disconnect and isolate the battery negative cable.

(2)Remove the front door trim panel. (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove the speaker mounting screws (Fig. 13).

(4) Disconnect wire harness connector and remove

speaker from door.

Fig. 12 D-PILLAR SPEAKER

1 - SPEAKER

2 - RETAINER

3 - TRIM PANEL

Fig. 13 DOOR SPEAKER

1 - SPEAKER

2 - WIRE HARNESS CONNECTOR

RSAUDIO8A-13

SPEAKER (Continued)

ProCarManuals.com

Page 340 of 2399

(5) Obtain ignition keys to be programmed from

customer (8 keys maximum).

(6) Using the DRB III, erase all ignition keys by

selecting MISCELLANEOUS and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all ignition keys.

Learned Key In Ignition - Ignition key transponder

ID is currently programmed in SKIM memory.

ADJUSTABLE PEDAL MODULE

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL MODULE

Refer to Appropriate Diagnostic Information.

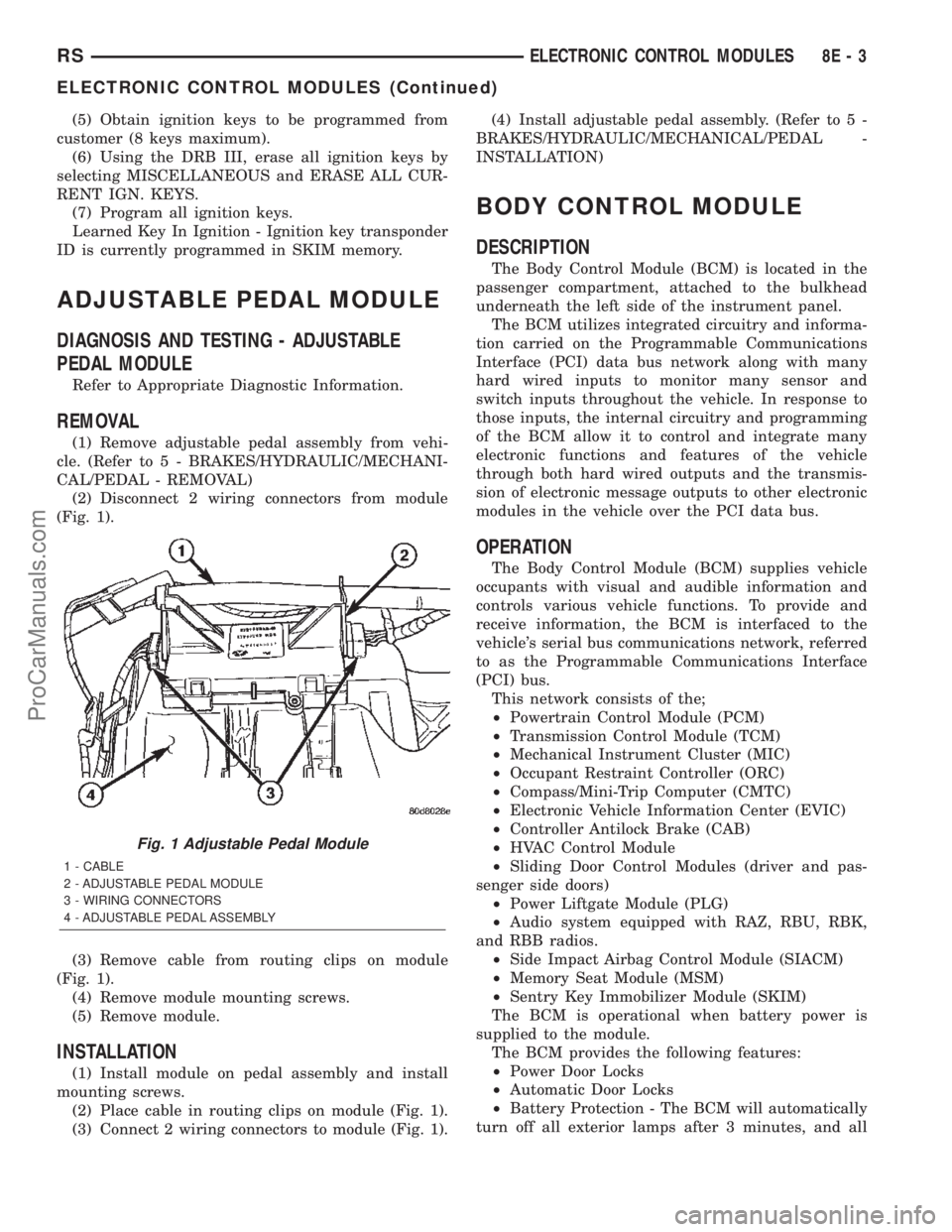

REMOVAL

(1) Remove adjustable pedal assembly from vehi-

cle. (Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/PEDAL - REMOVAL)

(2) Disconnect 2 wiring connectors from module

(Fig. 1).

(3) Remove cable from routing clips on module

(Fig. 1).

(4) Remove module mounting screws.

(5) Remove module.

INSTALLATION

(1) Install module on pedal assembly and install

mounting screws.

(2) Place cable in routing clips on module (Fig. 1).

(3) Connect 2 wiring connectors to module (Fig. 1).(4) Install adjustable pedal assembly. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/PEDAL -

INSTALLATION)

BODY CONTROL MODULE

DESCRIPTION

The Body Control Module (BCM) is located in the

passenger compartment, attached to the bulkhead

underneath the left side of the instrument panel.

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

OPERATION

The Body Control Module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the BCM is interfaced to the

vehicle's serial bus communications network, referred

to as the Programmable Communications Interface

(PCI) bus.

This network consists of the;

²Powertrain Control Module (PCM)

²Transmission Control Module (TCM)

²Mechanical Instrument Cluster (MIC)

²Occupant Restraint Controller (ORC)

²Compass/Mini-Trip Computer (CMTC)

²Electronic Vehicle Information Center (EVIC)

²Controller Antilock Brake (CAB)

²HVAC Control Module

²Sliding Door Control Modules (driver and pas-

senger side doors)

²Power Liftgate Module (PLG)

²Audio system equipped with RAZ, RBU, RBK,

and RBB radios.

²Side Impact Airbag Control Module (SIACM)

²Memory Seat Module (MSM)

²Sentry Key Immobilizer Module (SKIM)

The BCM is operational when battery power is

supplied to the module.

The BCM provides the following features:

²Power Door Locks

²Automatic Door Locks

²Battery Protection - The BCM will automatically

turn off all exterior lamps after 3 minutes, and all

Fig. 1 Adjustable Pedal Module

1 - CABLE

2 - ADJUSTABLE PEDAL MODULE

3 - WIRING CONNECTORS

4 - ADJUSTABLE PEDAL ASSEMBLY

RSELECTRONIC CONTROL MODULES8E-3

ELECTRONIC CONTROL MODULES (Continued)

ProCarManuals.com

Page 341 of 2399

interior lamps after 15 minutes after the ignition is

turned off, if they are not turned off by the driver.

²Chime Driver

²Compass/Mini-Trip support.

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Headlamp Time Delay (with/without Automatic

Headlamps)

²Illuminated Entry

²Fade to Off Interior Lamps - This feature dims

the interior lighting (courtesy lamps) gradually if theBCM does not receive any new inputs that would

cause the interior lamps to remain on.

²Pulse Width Modulated Instrument Panel Dim-

ming

²Door Lock Inhibit - This feature disables the

door lock functions if the key is in the ignition and

either front door is ajar. Pressing the Remote Keyless

Entry (RKE) lock/unlock button under these condi-

tions result in normal lock/unlock activation.

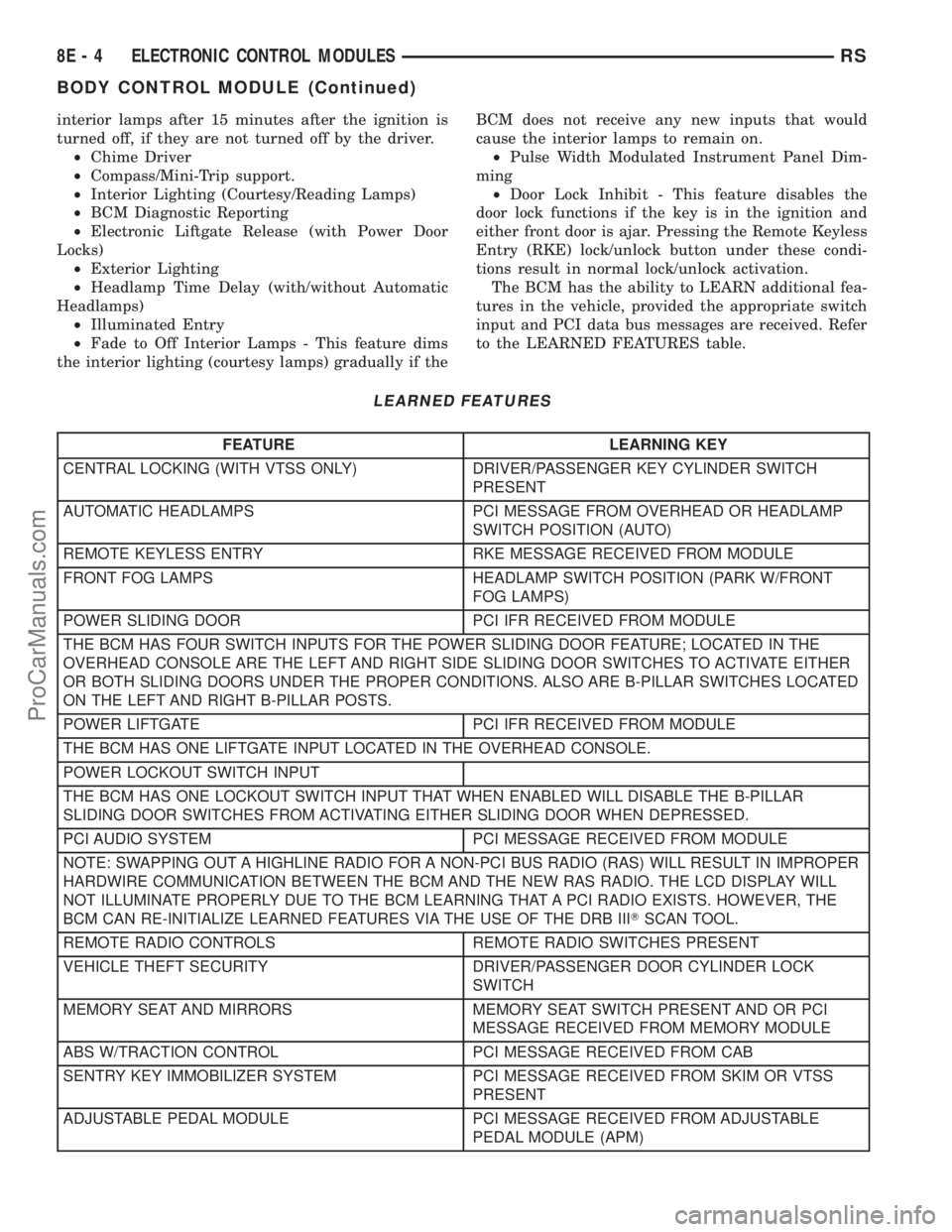

The BCM has the ability to LEARN additional fea-

tures in the vehicle, provided the appropriate switch

input and PCI data bus messages are received. Refer

to the LEARNED FEATURES table.

LEARNED FEATURES

FEATURE LEARNING KEY

CENTRAL LOCKING (WITH VTSS ONLY) DRIVER/PASSENGER KEY CYLINDER SWITCH

PRESENT

AUTOMATIC HEADLAMPS PCI MESSAGE FROM OVERHEAD OR HEADLAMP

SWITCH POSITION (AUTO)

REMOTE KEYLESS ENTRY RKE MESSAGE RECEIVED FROM MODULE

FRONT FOG LAMPS HEADLAMP SWITCH POSITION (PARK W/FRONT

FOG LAMPS)

POWER SLIDING DOOR PCI IFR RECEIVED FROM MODULE

THE BCM HAS FOUR SWITCH INPUTS FOR THE POWER SLIDING DOOR FEATURE; LOCATED IN THE

OVERHEAD CONSOLE ARE THE LEFT AND RIGHT SIDE SLIDING DOOR SWITCHES TO ACTIVATE EITHER

OR BOTH SLIDING DOORS UNDER THE PROPER CONDITIONS. ALSO ARE B-PILLAR SWITCHES LOCATED

ON THE LEFT AND RIGHT B-PILLAR POSTS.

POWER LIFTGATE PCI IFR RECEIVED FROM MODULE

THE BCM HAS ONE LIFTGATE INPUT LOCATED IN THE OVERHEAD CONSOLE.

POWER LOCKOUT SWITCH INPUT

THE BCM HAS ONE LOCKOUT SWITCH INPUT THAT WHEN ENABLED WILL DISABLE THE B-PILLAR

SLIDING DOOR SWITCHES FROM ACTIVATING EITHER SLIDING DOOR WHEN DEPRESSED.

PCI AUDIO SYSTEM PCI MESSAGE RECEIVED FROM MODULE

NOTE: SWAPPING OUT A HIGHLINE RADIO FOR A NON-PCI BUS RADIO (RAS) WILL RESULT IN IMPROPER

HARDWIRE COMMUNICATION BETWEEN THE BCM AND THE NEW RAS RADIO. THE LCD DISPLAY WILL

NOT ILLUMINATE PROPERLY DUE TO THE BCM LEARNING THAT A PCI RADIO EXISTS. HOWEVER, THE

BCM CAN RE-INITIALIZE LEARNED FEATURES VIA THE USE OF THE DRB IIITSCAN TOOL.

REMOTE RADIO CONTROLS REMOTE RADIO SWITCHES PRESENT

VEHICLE THEFT SECURITY DRIVER/PASSENGER DOOR CYLINDER LOCK

SWITCH

MEMORY SEAT AND MIRRORS MEMORY SEAT SWITCH PRESENT AND OR PCI

MESSAGE RECEIVED FROM MEMORY MODULE

ABS W/TRACTION CONTROL PCI MESSAGE RECEIVED FROM CAB

SENTRY KEY IMMOBILIZER SYSTEM PCI MESSAGE RECEIVED FROM SKIM OR VTSS

PRESENT

ADJUSTABLE PEDAL MODULE PCI MESSAGE RECEIVED FROM ADJUSTABLE

PEDAL MODULE (APM)

8E - 4 ELECTRONIC CONTROL MODULESRS

BODY CONTROL MODULE (Continued)

ProCarManuals.com

Page 346 of 2399

(4) Install the battery in the vehicle. Refer to the

procedure in Battery Systems.

(5) Connect the positive and negative battery

cables.

(6) Using the DRB IIIt, under ªFRONT CON-

TROL MODULEº then ªMISCº program the EQ

curve of the radio into the Front Control Module.

Refer to the appropriate diagnostic manual.

NOTE: If the vehicle is not equipped with Name

Brand Speakers (Infinity, etc.) or Headlamp Washers

the DRB IIITmust be used to Disable the appropri-

ate relays in the Intelligent Power Module Assembly.

HEATED SEAT MODULE

DESCRIPTION

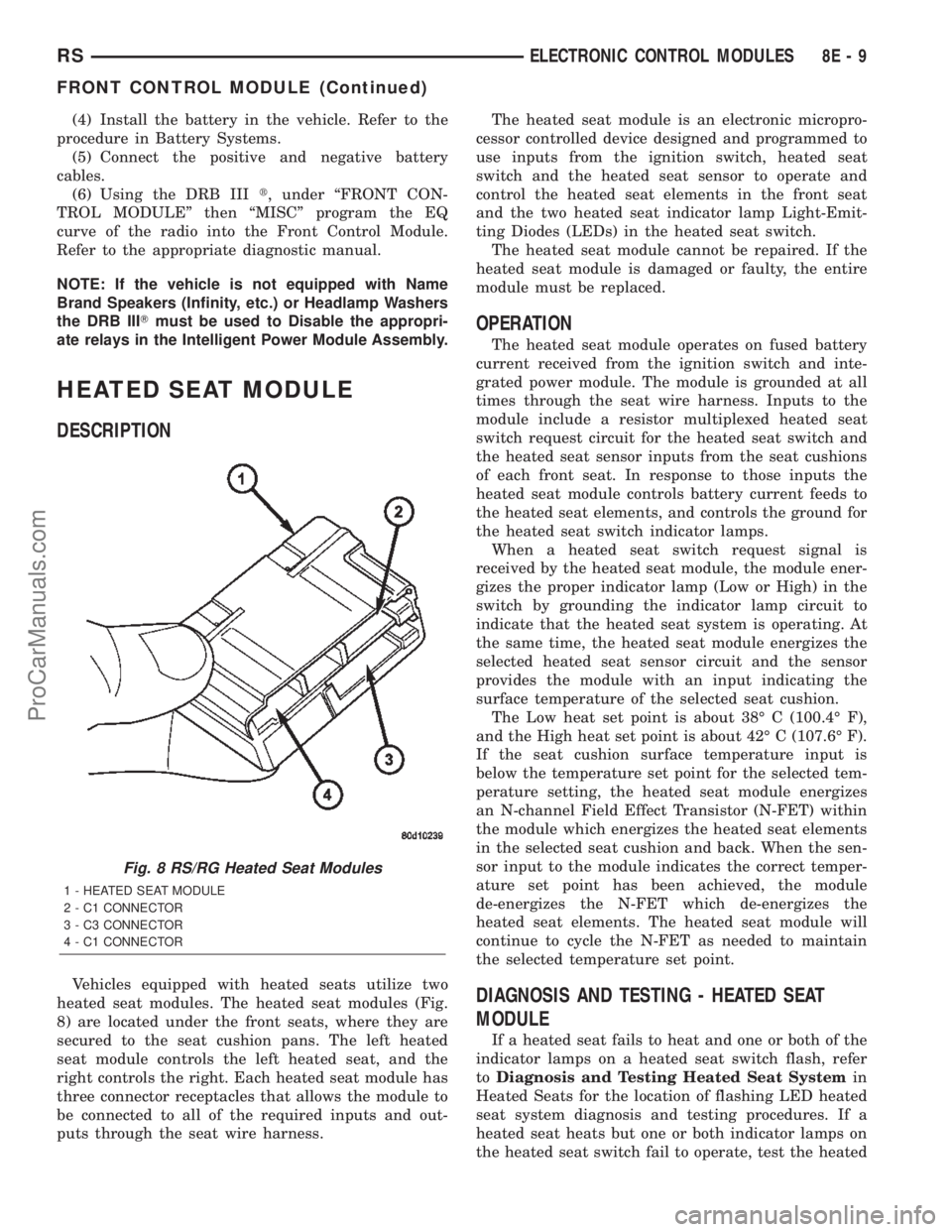

Vehicles equipped with heated seats utilize two

heated seat modules. The heated seat modules (Fig.

8) are located under the front seats, where they are

secured to the seat cushion pans. The left heated

seat module controls the left heated seat, and the

right controls the right. Each heated seat module has

three connector receptacles that allows the module to

be connected to all of the required inputs and out-

puts through the seat wire harness.The heated seat module is an electronic micropro-

cessor controlled device designed and programmed to

use inputs from the ignition switch, heated seat

switch and the heated seat sensor to operate and

control the heated seat elements in the front seat

and the two heated seat indicator lamp Light-Emit-

ting Diodes (LEDs) in the heated seat switch.

The heated seat module cannot be repaired. If the

heated seat module is damaged or faulty, the entire

module must be replaced.

OPERATION

The heated seat module operates on fused battery

current received from the ignition switch and inte-

grated power module. The module is grounded at all

times through the seat wire harness. Inputs to the

module include a resistor multiplexed heated seat

switch request circuit for the heated seat switch and

the heated seat sensor inputs from the seat cushions

of each front seat. In response to those inputs the

heated seat module controls battery current feeds to

the heated seat elements, and controls the ground for

the heated seat switch indicator lamps.

When a heated seat switch request signal is

received by the heated seat module, the module ener-

gizes the proper indicator lamp (Low or High) in the

switch by grounding the indicator lamp circuit to

indicate that the heated seat system is operating. At

the same time, the heated seat module energizes the

selected heated seat sensor circuit and the sensor

provides the module with an input indicating the

surface temperature of the selected seat cushion.

The Low heat set point is about 38É C (100.4É F),

and the High heat set point is about 42É C (107.6É F).

If the seat cushion surface temperature input is

below the temperature set point for the selected tem-

perature setting, the heated seat module energizes

an N-channel Field Effect Transistor (N-FET) within

the module which energizes the heated seat elements

in the selected seat cushion and back. When the sen-

sor input to the module indicates the correct temper-

ature set point has been achieved, the module

de-energizes the N-FET which de-energizes the

heated seat elements. The heated seat module will

continue to cycle the N-FET as needed to maintain

the selected temperature set point.

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE

If a heated seat fails to heat and one or both of the

indicator lamps on a heated seat switch flash, refer

toDiagnosis and Testing Heated Seat Systemin

Heated Seats for the location of flashing LED heated

seat system diagnosis and testing procedures. If a

heated seat heats but one or both indicator lamps on

the heated seat switch fail to operate, test the heated

Fig. 8 RS/RG Heated Seat Modules

1 - HEATED SEAT MODULE

2 - C1 CONNECTOR

3 - C3 CONNECTOR

4 - C1 CONNECTOR

RSELECTRONIC CONTROL MODULES8E-9

FRONT CONTROL MODULE (Continued)

ProCarManuals.com

Page 539 of 2399

ules push buttons located just rearward of the dis-

play screen in the overhead console. The three

universal transmitter push buttons are identified

with one, two or three light indicators so that they be

easily identified by sight or by feel.

Each of the three universal transmitter push but-

tons controls an independent radio transmitter chan-

nel. Each of these three channels can be trained to

transmit a different radio frequency signal for the

remote operation of garage door openers, motorized

gate openers, home or office lighting, security sys-

tems or just about any other device that can be

equipped with a radio receiver in the 286 to 399

MegaHertz (MHz) frequency range for remote opera-

tion. The universal transmitter is capable of operat-

ing systems using either rolling code or non-rolling

code technology.

The electronics module displays messages and a

small house-shaped icon with one, two or three dots

corresponding to the three transmitter buttons to

indicate the status of the universal transmitter. The

EVIC messages are:

²Cleared Channels- Indicates that all of the

transmitter codes stored in the universal transmitter

have been successfully cleared.

²Training- Indicates that the universal trans-

mitter is in its transmitter learning mode.

²Trained- Indicates that the universal transmit-

ter has successfully acquired a new transmitter code.

²Transmit- Indicates that a trained universal

transmitter button has been depressed and that the

universal transmitter is transmitting.

The universal transmitter cannot be repaired, and

is available for service only as a unit with the EVIC

or CMTC modules. If any of these components is

faulty or damaged, the complete EVIC or CMTC

module must be replaced.

OPERATION

The universal transmitter operates on a non-

switched source of battery current so the unit will

remain functional, regardless of the ignition switch

position. For more information on the features, pro-

gramming procedures and operation of the universal

transmitter, see the owner's manual in the vehicle

glove box.

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER

If the universal transmitter is inoperative, but the

Electronic Vehicle Information Center (EVIC) or

Compass Mini-Trip Computer is operating normally,

see the owner's manual in the vehicle glove box for

instructions on training the universal transmitter.

Retrain the universal transmitter with a known good

transmitter as instructed in the owner's manual andtest the universal transmitter operation again. If the

unit is still inoperative, replace the faulty universal

transmitter and EVIC/CMTC module as a unit. If

both the universal transmitter and the EVIC/CMTC

module are inoperative, refer toOverhead Console

Diagnosis and Testingearlier in this group for fur-

ther diagnosis. For complete circuit diagrams, refer

toOverhead Consolein Wiring Diagrams.

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the over-

head console through ambient temperature messages

received from the Front Control Module (FCM) over

the Programmable Communications Interface (PCI)

J1850 data bus circuit. The FCM receives a hard

wired input from the ambient temperature sensor.

The ambient temperature sensor is a variable resis-

tor mounted to a bracket that is secured with a screw

to the right side of the headlamp mounting module

grille opening, behind the radiator grille and in front

of the engine compartment.

Refer toFront Control Modulein Electronic

Control Modules. For complete circuit diagrams, refer

to the appropriate wiring information. The ambient

temperature sensor cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the Front Control Module. The resis-

tance in the sensor changes as temperature changes,

changing the temperature sensor signal circuit volt-

age to the Front Control Module. Based upon the

resistance in the sensor, the Front Control Module

senses a specific voltage on the temperature sensor

signal circuit, which it is programmed to correspond

to a specific temperature. The Front Control Module

then sends the proper ambient temperature mes-

sages to the EVIC, CMTC over the PCI J1850 data

bus.

The thermometer function is supported by the

ambient temperature sensor, a wiring circuit, the

Front Control Module, the Programmable Communi-

cations Interface (PCI) data bus, and a portion of the

Electronics module. If any portion of the ambient

temperature sensor circuit fails, the Front Control

Module will self-diagnose the circuit.

The ambient temperature sensor circuit can also be

diagnosed by referring toDiagnosis and Testing -

Ambient Temperature Sensor, and Diagnosis

and Testing - Ambient Temperature Sensor Cir-

cuit. If the temperature sensor and circuit are con-

8M - 10 MESSAGE SYSTEMSRS

UNIVERSAL TRANSMITTER (Continued)

ProCarManuals.com

Page 1527 of 2399

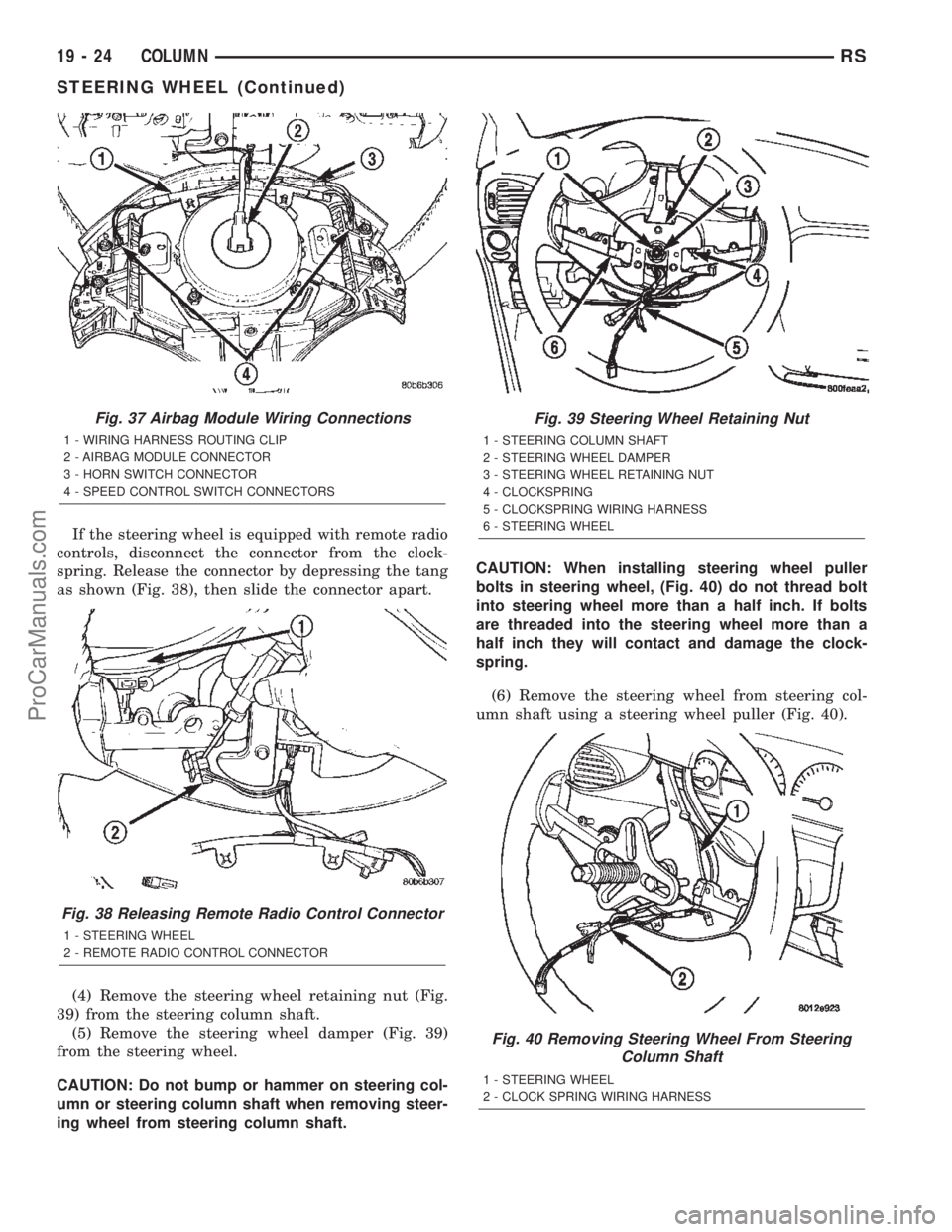

If the steering wheel is equipped with remote radio

controls, disconnect the connector from the clock-

spring. Release the connector by depressing the tang

as shown (Fig. 38), then slide the connector apart.

(4) Remove the steering wheel retaining nut (Fig.

39) from the steering column shaft.

(5) Remove the steering wheel damper (Fig. 39)

from the steering wheel.

CAUTION: Do not bump or hammer on steering col-

umn or steering column shaft when removing steer-

ing wheel from steering column shaft.CAUTION: When installing steering wheel puller

bolts in steering wheel, (Fig. 40) do not thread bolt

into steering wheel more than a half inch. If bolts

are threaded into the steering wheel more than a

half inch they will contact and damage the clock-

spring.

(6) Remove the steering wheel from steering col-

umn shaft using a steering wheel puller (Fig. 40).

Fig. 37 Airbag Module Wiring Connections

1 - WIRING HARNESS ROUTING CLIP

2 - AIRBAG MODULE CONNECTOR

3 - HORN SWITCH CONNECTOR

4 - SPEED CONTROL SWITCH CONNECTORS

Fig. 38 Releasing Remote Radio Control Connector

1 - STEERING WHEEL

2 - REMOTE RADIO CONTROL CONNECTOR

Fig. 39 Steering Wheel Retaining Nut

1 - STEERING COLUMN SHAFT

2 - STEERING WHEEL DAMPER

3 - STEERING WHEEL RETAINING NUT

4 - CLOCKSPRING

5 - CLOCKSPRING WIRING HARNESS

6 - STEERING WHEEL

Fig. 40 Removing Steering Wheel From Steering

Column Shaft

1 - STEERING WHEEL

2 - CLOCK SPRING WIRING HARNESS

19 - 24 COLUMNRS

STEERING WHEEL (Continued)

ProCarManuals.com