child lock CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 16 of 2399

GEAR LUBRICANTS

SAE ratings also apply to multigrade gear lubri-

cants. In addition, API classification defines the

lubricants usage. Such as API GL-5 and SAE 75W-

90.

LUBRICANTS AND GREASES

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 4) on the label. At the bottom of the

NLGI symbol is the usage and quality identification

letters. Wheel bearing lubricant is identified by the

letter ªGº. Chassis lubricant is identified by the letter

ªLº. The letter following the usage letter indicates

the quality of the lubricant. The following symbols

indicate the highest quality.

SPECIALIZED LUBRICANTS AND OILS

Some maintenance or repair procedures may

require the use of specialized lubricants or oils. Con-

sult the appropriate sections in this manual for the

correct application of these lubricants.

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHENENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less boiling protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with hybrid organic

corrosion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

The green coolantMUST NOT BE MIXEDwith

the orange or magenta coolants. When replacing cool-

ant the complete system flush must be performed

before using the replacement coolant.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Doing so

will reduce the corrosion protection and may result

in premature water pump seal failure. If non-HOAT

coolant is introduced into the cooling system in an

emergency, it should be replaced with the specified

coolant as soon as possible.DESCRIPTION - FLEXIBLE FUEL ENGINE OIL

The information in this section is for Flexible Fuel

Vehicles (FFV) only. These vehicles can be identified

by the unique Fuel Filler Door Label that states

Ethanol (E-85) or Unleaded Gasoline Only. This sec-

tion only covers those subjects that are unique to

these vehicles. Please refer to the other sections of

this manual for information on features that are

common between Flexible Fuel and gasoline only

powered vehicles.

ETHANOL FUEL (E-85)

E-85 is a mixture of approximately 85% fuel etha-

nol and 15% unleaded gasoline.

Fig. 4 NLGI SYMBOL

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

RSLUBRICATION & MAINTENANCE0-3

FLUID TYPES (Continued)

ProCarManuals.com

Page 559 of 2399

POWER SLIDING DOOR SYSTEM

TABLE OF CONTENTS

page page

POWER SLIDING DOOR SYSTEM

DESCRIPTION.........................18

OPERATION...........................20

DIAGNOSIS AND TESTING - POWER SLIDING

DOOR SYSTEM.......................21

STANDARD PROCEDURE

STANDARD PROCEDURE - WELLNUT

REPLACEMENT.......................27

STANDARD PROCEDURE - POWER DOOR

LEARN CYCLE.......................27

STANDARD PROCEDURE - SLIDING DOOR

ADJUSTMENT........................27

LATCH

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................28

INSTALLATION.........................29

SLIDING DOOR MOTOR

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................29

INSTALLATION.........................30

FULL OPEN SWITCH

DESCRIPTION.........................30

OPERATION...........................30

LEFT B-PILLAR SWITCH

DESCRIPTION.........................31

OPERATION...........................31

REMOVAL.............................31

INSTALLATION.........................31RIGHT B-PILLAR SWITCH

DESCRIPTION.........................31

OPERATION...........................31

REMOVAL.............................31

INSTALLATION.........................31

LOWER DRIVE UNIT

DESCRIPTION.........................31

OPERATION...........................31

REMOVAL.............................32

INSTALLATION.........................32

LOWER DRIVE UNIT TRACK & RACK

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................33

INSTALLATION.........................33

WIRING HARNESS

DESCRIPTION.........................34

OPERATION...........................34

REMOVAL.............................34

INSTALLATION.........................35

FLEX DRIVE

DESCRIPTION.........................35

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................36

SLIDING DOOR MODULE

DESCRIPTION.........................37

OPERATION...........................37

REMOVAL.............................38

INSTALLATION.........................38

POWER SLIDING DOOR

SYSTEM

DESCRIPTION

Some vehicles are equipped with a power opening

and closing sliding door system (Fig. 1). Depending

on how the vehicle is ordered it may be equipped

with only a right side power door or right and left

side power doors. This power sliding door system is a

complex system consisting of many components.

Some of these components are the door motor, latch

assembly, sliding door control module, lower drive

unit, flex drive assembly, wire harness and track,

lower drive unit track and rack assembly, full open

switch, B-pillar switch, overhead console switch, key

fob switches (Fig. 2), pawl switch, ratchet switch and

child lockout and handle switches.Each power side door has its own door control mod-

ule, located in the center of the door behind the door

trim panel. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/DOOR CONTROL

MODULE - DESCRIPTION) The power side door

motor is located in the front portion of the door, on

the inner door panel sheet metal. The latch assembly

is located in the rear of the power side door, near the

body line. The lower drive unit is attached to the

lower door hinge. The flex drive assembly connects

the door motor to the lower drive unit. The wire har-

ness and track and the lower drive unit track are vis-

ible with the door open in the lower door sill area.

The power side door full open switch is located under

the lower drive unit and is part of the hold open

latch assembly. The pawl, ratchet, handle and child

lockout switches are all located on the power side

door latch assembly. The B-pillar switch, as it will be

8N - 18 POWER SLIDING DOOR SYSTEMRS

ProCarManuals.com

Page 560 of 2399

referred to, is an open and close command switch

located on the vehicles interior body side B-pillar

trim. The overhead console switch, is an open and

close command switch located in the vehicle's over-

head console. More detailed information can be found

on these components later in this section.

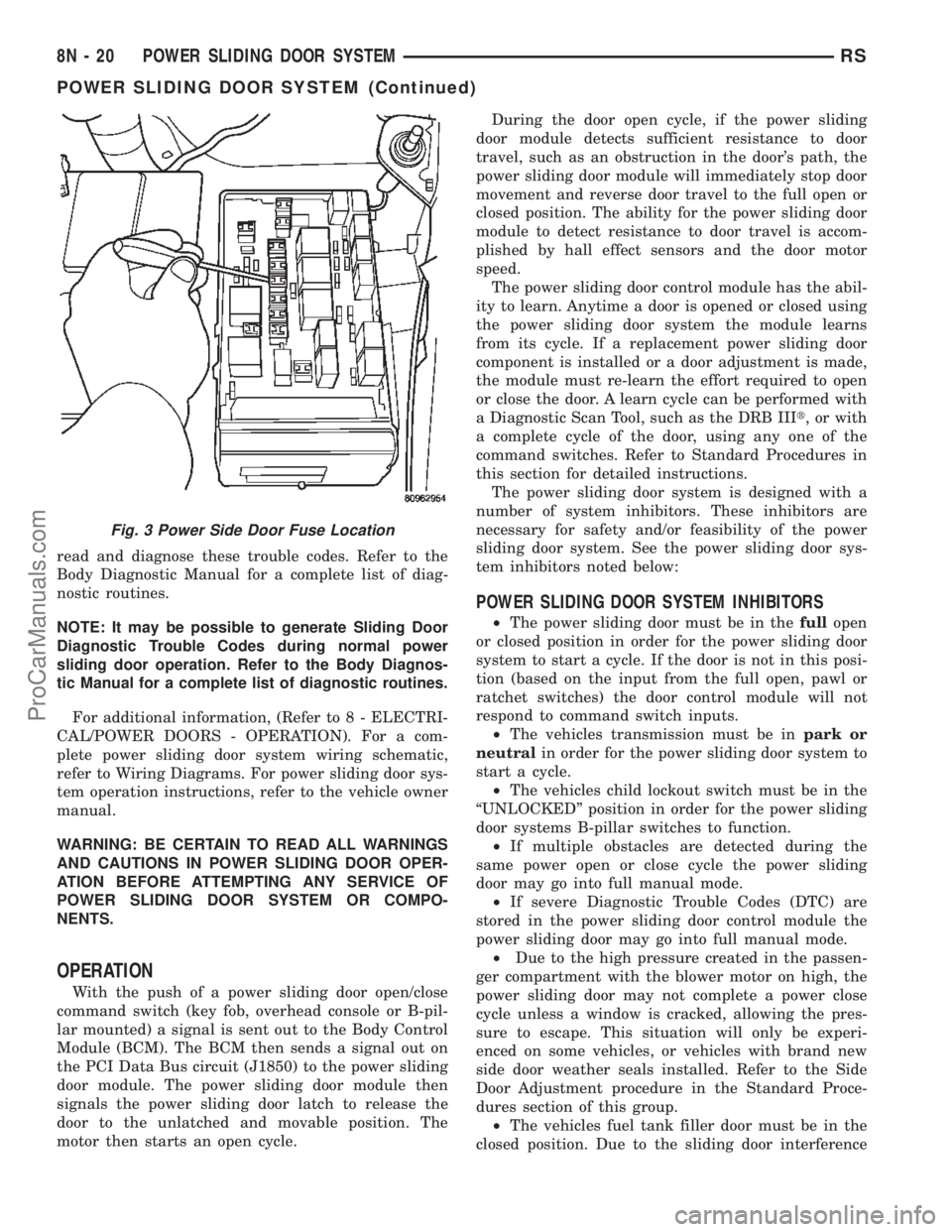

Safety is of the utmost concern with the power

sliding door system. Software technology has enabled

the power sliding door control module to detect resis-

tance to door travel. This allows the power sliding

door to stop and reverse direction any time an

obstruction is felt or any of the command switches

are operated (while closing only). Battery voltage is

supplied to the power sliding door system through a

40 amp fuse, located in the Intelligent Power Module

(IPM) assembly (Fig. 3). The child lockout switch pre-

vents children from opening or actuating the power

sliding door system when desired. In the unlikely

event that the power sliding door system develops a

fault, the power sliding door can still be operated

manually from the interior or exterior door handle,

just like a standard manual sliding door.

The power sliding door control module communi-

cates on the J1850 PCI Data Bus Circuit. Therefore,

the power sliding door control module can generate

and store its own diagnostic trouble codes (DTC). A

diagnostic scan tool, such as the DRB IIItis used to

Fig. 1 Power Sliding Door Introduction

Fig. 2 Key Fob

1 - Left Sliding Door Switch

2 - Right Sliding Door Switch

3 - Liftgate Switch

RSPOWER SLIDING DOOR SYSTEM8N-19

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 561 of 2399

read and diagnose these trouble codes. Refer to the

Body Diagnostic Manual for a complete list of diag-

nostic routines.

NOTE: It may be possible to generate Sliding Door

Diagnostic Trouble Codes during normal power

sliding door operation. Refer to the Body Diagnos-

tic Manual for a complete list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). For a com-

plete power sliding door system wiring schematic,

refer to Wiring Diagrams. For power sliding door sys-

tem operation instructions, refer to the vehicle owner

manual.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS IN POWER SLIDING DOOR OPER-

ATION BEFORE ATTEMPTING ANY SERVICE OF

POWER SLIDING DOOR SYSTEM OR COMPO-

NENTS.

OPERATION

With the push of a power sliding door open/close

command switch (key fob, overhead console or B-pil-

lar mounted) a signal is sent out to the Body Control

Module (BCM). The BCM then sends a signal out on

the PCI Data Bus circuit (J1850) to the power sliding

door module. The power sliding door module then

signals the power sliding door latch to release the

door to the unlatched and movable position. The

motor then starts an open cycle.During the door open cycle, if the power sliding

door module detects sufficient resistance to door

travel, such as an obstruction in the door's path, the

power sliding door module will immediately stop door

movement and reverse door travel to the full open or

closed position. The ability for the power sliding door

module to detect resistance to door travel is accom-

plished by hall effect sensors and the door motor

speed.

The power sliding door control module has the abil-

ity to learn. Anytime a door is opened or closed using

the power sliding door system the module learns

from its cycle. If a replacement power sliding door

component is installed or a door adjustment is made,

the module must re-learn the effort required to open

or close the door. A learn cycle can be performed with

a Diagnostic Scan Tool, such as the DRB IIIt, or with

a complete cycle of the door, using any one of the

command switches. Refer to Standard Procedures in

this section for detailed instructions.

The power sliding door system is designed with a

number of system inhibitors. These inhibitors are

necessary for safety and/or feasibility of the power

sliding door system. See the power sliding door sys-

tem inhibitors noted below:

POWER SLIDING DOOR SYSTEM INHIBITORS

²The power sliding door must be in thefullopen

or closed position in order for the power sliding door

system to start a cycle. If the door is not in this posi-

tion (based on the input from the full open, pawl or

ratchet switches) the door control module will not

respond to command switch inputs.

²The vehicles transmission must be inpark or

neutralin order for the power sliding door system to

start a cycle.

²The vehicles child lockout switch must be in the

ªUNLOCKEDº position in order for the power sliding

door systems B-pillar switches to function.

²If multiple obstacles are detected during the

same power open or close cycle the power sliding

door may go into full manual mode.

²If severe Diagnostic Trouble Codes (DTC) are

stored in the power sliding door control module the

power sliding door may go into full manual mode.

²Due to the high pressure created in the passen-

ger compartment with the blower motor on high, the

power sliding door may not complete a power close

cycle unless a window is cracked, allowing the pres-

sure to escape. This situation will only be experi-

enced on some vehicles, or vehicles with brand new

side door weather seals installed. Refer to the Side

Door Adjustment procedure in the Standard Proce-

dures section of this group.

²The vehicles fuel tank filler door must be in the

closed position. Due to the sliding door interference

Fig. 3 Power Side Door Fuse Location

8N - 20 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 569 of 2399

Use a known good vehicle for side door comparison

data. Refer to the Side Door Adjustment procedure in

the Body section of the service manual for detailed

instructions.

LATCH

DESCRIPTION

Vehicles equipped with a power side door or doors

utilize a power latch. One power latch is used for

each power door. The latch is located on the trailing

edge of the side door assembly (Fig. 5). This power

latch assembly is comprised of many different compo-

nents which have the ability to perform the power

cinch, release, lock, unlock and safety related opera-

tions. These components are the door latch, lock/un-

lock actuator, cinch/release actuator and child

lockout, pawl, ratchet and handle switches. The pawl

and ratchet switches are used to indicate the primary

and secondary latched positions. The cinch latch also

provides a connection point for the interior handle,

exterior handle and hold open latch cables.

The power latch is a replaceable component. Con-

sult your Mopar parts catalog for specific part num-

bers.

OPERATION

The power latch performs the same operation as a

full manual door latch as well as power cinch,

release, lock and unlock operations. The power latch

mounted actuator cinches the door closed and latches

it in its primary latched position. During a power

close cycle, the power cinch actuator will not operate

until the side door has reached its secondary latch

position (determined by pawl and ratchet switches).

During a power open cycle, the power release actua-

tor will stop once the side door has moved from pri-

mary latch position.

The power latch uses inputs from the lock/unlock

actuator, power side door control module and child

lockout, pawl, ratchet and handle switches to provide

safe power cinch and release operations. Refer to

Power Side Door Operation for additional informa-

tion.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate side door trim panel.

Refer to the Body section for the procedure.

(3) Remove the weather shield if necessary. Refer

to the Body section for the procedure.

(4) Open the side door all the way and remove the

door latch retaining bolts (Fig. 6).

Fig. 5 Removing/Installing Power Latch in Sliding

Door

1 - Power Latch Assembly

Fig. 6 Removing Latch Retaining Bolts

1 - Latch Retaining Bolts

2 - Side Door

8N - 28 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 572 of 2399

LEFT B-PILLAR SWITCH

DESCRIPTION

Vehicles equipped with power sliding side door/s

utilize B-pillar switches. These switches are located

on the interior of the vehicle, on the B-pillar trim

panels. These switches serve as an open and close

command switch for the appropriate power side door.

The B-pillar switches are replaceable. Consult your

Mopar parts catalog for a specific part number.

OPERATION

When the Pillar switch is depressed a signal is

sent to the Body Control Module (BCM), this signal

is then sent to the Power Sliding Door Module, tell-

ing it to start a power open or close cycle. The child

lockout feature must be disabled and the side door

must be unlocked in order for the Pillar switch to

function.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Using a trim stick or other small flat-bladed

pry tool, gently pry the leading upper edge of the

B-pillar switch away from the B-pillar trim.

(3) Once the upper edge is free from pillar trim,

rock the switch out of the switch opening.

(4) Disconnect the B-pillar switch electrical con-

nector. First, slide the connector lock away from the

switch then, depress connector retaining tab while

pulling straight apart.

(5) Remove the B-pillar switch from the vehicle.

INSTALLATION

(1) Connect the B-pillar switch electrical connector.

Slide connector lock toward the switch to lock in

place.

(2) Hook the lower edge of the B-pillar switch on

the B-pillar trim and then push the switch firmly

into position.

(3) Connect the negative battery cable.

RIGHT B-PILLAR SWITCH

DESCRIPTION

Vehicles equipped with power sliding side door/s

utilize B-pillar switches. These switches are located

on the interior of the vehicle, on the B-pillar trim

panels. These switches serve as an open and close

command switch for the appropriate power side door.

The B-pillar switches are replaceable. Consult your

Mopar parts catalog for a specific part number.

OPERATION

When the Pillar switch is depressed a signal is

sent to the Body Control Module (BCM), this signal

is then sent to the Power Sliding Door Module, tell-

ing it to start a power open or close cycle. The child

lockout feature must be disabled and the side door

must be unlocked in order for the Pillar switch to

function.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Using a trim stick or other small flat-bladed

pry tool, gently pry the leading upper edge of the

B-pillar switch away from the B-pillar trim.

(3) Once the upper edge is free from pillar trim,

rock the switch out of the switch opening.

(4) Disconnect the B-pillar switch electrical con-

nector. First, slide the connector lock away from the

switch then, depress connector retaining tab while

pulling straight apart.

(5) Remove the B-pillar switch from the vehicle.

INSTALLATION

(1) Connect the B-pillar switch electrical connector.

Slide connector lock toward the switch to lock in

place.

(2) Hook the lower edge of the B-pillar switch on

the B-pillar trim and then push the switch firmly

into position.

(3) Connect the negative battery cable.

LOWER DRIVE UNIT

DESCRIPTION

Vehicles equipped with a power sliding side door

utilize a lower drive unit. The lower drive unit is

located on the sliding door lower hinge assembly

(Fig. 10). This drive unit is used to transfer the lat-

eral rotation of the flex drive assembly into longitu-

dinal movement via the drive unit gear and door

track rack teeth (Fig. 10).

The lower drive unit is a replaceable component.

Consult your Mopar parts catalog for specific part

numbers.

OPERATION

During a power open or close cycle, the power drive

unit is driven by the flex drive assembly. The lower

drive units main gear engages the lower door tracks

rack teeth, this moves the side door assembly accord-

ingly.

RSPOWER SLIDING DOOR SYSTEM8N-31

ProCarManuals.com

Page 1109 of 2399

LEFT SEAT AIRBAG - YELLOW 2 WAY

CAV CIRCUIT FUNCTION

1 R31 18LG/OR (EXCEPT

BUILT-UP-EXPORT)LEFT SEAT SQUIB LINE 1

1 R33 18WT/BK (BUILT-UP-EXPORT) LEFT SEAT SQUIB LINE 2

2 R33 18LG/WT (EXCEPT

BUILT-UP-EXPORT)LEFT SEAT SQUIB LINE 2

2 R31 18DG/WT (BUILT-UP-EXPORT) LEFT SEAT SQUIB LINE 1

LEFT SIDE IMPACT AIRBAG CONTROL MODULE - YELLOW/RED 7 WAY

CAV CIRCUIT FUNCTION

1 R31 18LG/OR LEFT SEAT SQUIB LINE 1

2 R33 18LG/WT LEFT SEAT SQUIB LINE 2

3- -

4 D25 20WT/VT PCI BUS

5 F214 18PK/LG FCM OUTPUT (SIACM RUN-START DRIVER)

6 Z104 18BK/LG GROUND

7 Z104 18BK/LG GROUND

LEFT SLIDING DOOR CONTROL MODULE C1 (POWER SLIDING DOOR) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1 Q45 18OR/GY LEFT CINCH/RELEASE MOTOR CLUTCH DRIVER

2 Q67 16TN/BR LEFT SLIDING DOOR OPEN DRIVER

3 Q69 16TN/OR LEFT SLIDING DOOR CLOSE DRIVER

4- -

5 A113 14WT/RD FUSED B(+)

6- -

7- -

8 Z123 14BK/WT GROUND

LEFT SLIDING DOOR CONTROL MODULE C2 (POWER SLIDING DOOR) - BLACK/RED 20 WAY

CAV CIRCUIT FUNCTION

1 Q71 20TN/VT LEFT DOOR MOTOR HALL EFFECT SUPPLY

2- -

3 Q35 20OR/GY LEFT DOOR LOCK SENSE

4 Q55 20OR/BR LEFT DOOR IN/OUT HANDLE SWITCH SENSE

5- -

6- -

7 Q63 18OR/TN LEFT DOOR MOTOR CLUTCH DRIVER

8 Q47 18TN/GY LEFT CINCH/RELEASE MOTOR LATCH DRIVER

9 Q49 18TN/WT LEFT CINCH/RELEASE MOTOR UNLATCH DRIVER

10 - -

11 D25 20WT/VT PCI BUS

12 G77 20TN/OR LEFT SLIDING DOOR AJAR SWITCH SENSE

13 Q59 20OR/YL LEFT PAWL SWITCH SENSE

14 Q53 20OR LEFT FULL OPEN SWITCH SENSE

15 Z25 20BK/TN GROUND-DRIVER SIDE IDENTIFIER (LHD/RHD)

16 Q57 20OR/VT LEFT DOOR CHILD LOCKOUT SWITCH SENSE

17 Q73 20TN/YL LEFT DOOR MOTOR HALL EFFECT SIGNAL

18 - -

19 G151 20VT/BR LEFT SLIDING DOOR WAKE UP SIGNAL

20 Z25 20BK/TN GROUND

8W - 80 - 78 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1110 of 2399

LEFT SLIDING DOOR LATCH SENSING SWITCH (POWER SLIDING DOOR) - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 Z77 20BK/GY GROUND

2 Q59 20OR/YL LEFT PAWL SWITCH SENSE

3 G77 20TN/OR LEFT SLIDING DOOR AJAR SWITCH SENSE

4 Z77 20BK/GY GROUND

5 Q55 20OR/BR LEFT DOOR IN/OUT HANDLE SWITCH SENSE

6 Q57 20OR/VT LEFT DOOR CHILD LOCKOUT SWITCH SENSE

LEFT SLIDING DOOR LOCK MOTOR (POWER SLIDING DOOR) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 P5 20TN/OR LEFT SLIDING DOOR LOCK UNLOCK DRIVER

2 P32 20TN/VT LEFT SLIDING DOOR LOCK DRIVER

3 Q35 20OR/GY LEFT DOOR LOCK SENSE

4 Z77 20BK/GY GROUND

LEFT SLIDING DOOR LOCK MOTOR/AJAR SWITCH (MANUAL SLIDING DOOR) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 P5 20BK/DB LEFT SLIDING DOOR UNLOCK DRIVER

2 P32 20BK/TN LEFT SLIDING DOOR LOCK DRIVER

3 G77 20BK/DG LEFT SLIDING DOOR AJAR SWITCH SENSE

4 Z77 20BK GROUND

LEFT SLIDING DOOR MOTOR (POWER SLIDING DOOR) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1- -

2 Q71 20TN/VT LEFT DOOR MOTOR HALL EFFECT SUPPLY

3 Q69 16TN/OR LEFT SLIDING DOOR CLOSE DRIVER

4 Z163 18BK/TN GROUND

5 Q63 18OR/TN LEFT DOOR MOTOR CLUTCH DRIVER

6 Q67 16TN/BR LEFT SLIDING DOOR OPEN DRIVER

7 Z33 20BK/TN GROUND

8 Q73 20TN/YL LEFT DOOR MOTOR HALL EFFECT SIGNAL

LEFT SPEED CONTROL SWITCH - WHITE 2 WAY

CAV CIRCUIT FUNCTION

A V37 20VT/TN (BUILT-UP-EXPORT) SPEED CONTROL SWITCH SIGNAL

A V37 20DG/VT (EXCEPT

BUILT-UP-EXPORT)SPEED CONTROL SWITCH SIGNAL

B Z23 20BK/VT LEFT SPEED CONTROL SWITCH GROUND

RS8W-80 CONNECTOR PIN-OUTS8W-80-79

ProCarManuals.com

Page 1140 of 2399

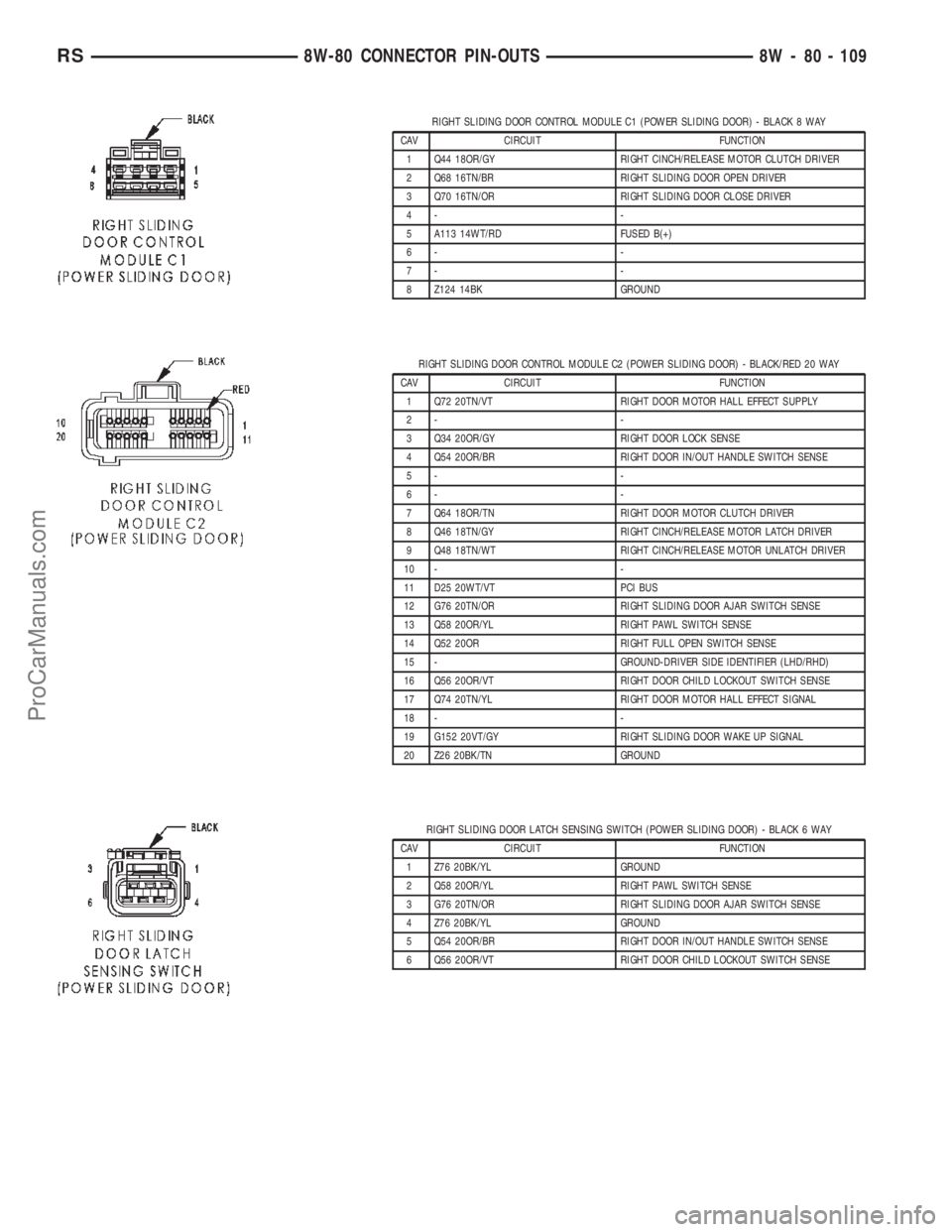

RIGHT SLIDING DOOR CONTROL MODULE C1 (POWER SLIDING DOOR) - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1 Q44 18OR/GY RIGHT CINCH/RELEASE MOTOR CLUTCH DRIVER

2 Q68 16TN/BR RIGHT SLIDING DOOR OPEN DRIVER

3 Q70 16TN/OR RIGHT SLIDING DOOR CLOSE DRIVER

4- -

5 A113 14WT/RD FUSED B(+)

6- -

7- -

8 Z124 14BK GROUND

RIGHT SLIDING DOOR CONTROL MODULE C2 (POWER SLIDING DOOR) - BLACK/RED 20 WAY

CAV CIRCUIT FUNCTION

1 Q72 20TN/VT RIGHT DOOR MOTOR HALL EFFECT SUPPLY

2- -

3 Q34 20OR/GY RIGHT DOOR LOCK SENSE

4 Q54 20OR/BR RIGHT DOOR IN/OUT HANDLE SWITCH SENSE

5- -

6- -

7 Q64 18OR/TN RIGHT DOOR MOTOR CLUTCH DRIVER

8 Q46 18TN/GY RIGHT CINCH/RELEASE MOTOR LATCH DRIVER

9 Q48 18TN/WT RIGHT CINCH/RELEASE MOTOR UNLATCH DRIVER

10 - -

11 D25 20WT/VT PCI BUS

12 G76 20TN/OR RIGHT SLIDING DOOR AJAR SWITCH SENSE

13 Q58 20OR/YL RIGHT PAWL SWITCH SENSE

14 Q52 20OR RIGHT FULL OPEN SWITCH SENSE

15 - GROUND-DRIVER SIDE IDENTIFIER (LHD/RHD)

16 Q56 20OR/VT RIGHT DOOR CHILD LOCKOUT SWITCH SENSE

17 Q74 20TN/YL RIGHT DOOR MOTOR HALL EFFECT SIGNAL

18 - -

19 G152 20VT/GY RIGHT SLIDING DOOR WAKE UP SIGNAL

20 Z26 20BK/TN GROUND

RIGHT SLIDING DOOR LATCH SENSING SWITCH (POWER SLIDING DOOR) - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 Z76 20BK/YL GROUND

2 Q58 20OR/YL RIGHT PAWL SWITCH SENSE

3 G76 20TN/OR RIGHT SLIDING DOOR AJAR SWITCH SENSE

4 Z76 20BK/YL GROUND

5 Q54 20OR/BR RIGHT DOOR IN/OUT HANDLE SWITCH SENSE

6 Q56 20OR/VT RIGHT DOOR CHILD LOCKOUT SWITCH SENSE

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 109

ProCarManuals.com

Page 2069 of 2399

BENCH SEAT BACK

REMOVAL............................102

INSTALLATION........................103

BENCH SEAT BACK COVER

REMOVAL............................103

INSTALLATION........................103

BENCH SEAT TRACK

REMOVAL............................103

INSTALLATION........................104

PLASTIC GROCERY BAG RETAINER

REMOVAL............................104

INSTALLATION........................104UNDER SEAT STORAGE BIN

REMOVAL............................104

INSTALLATION........................105

UNDER SEAT STORAGE BIN GUIDE

REMOVAL............................105

INSTALLATION........................105

UNDER SEAT STORAGE BIN LOCK/LATCH

REMOVAL............................105

INSTALLATION........................105

LUMBAR SUPPORT

REMOVAL............................106

INSTALLATION........................106

CHILD SEAT MODULE

REMOVAL

(1) Close child restraint seat.

(2) Remove seat back cover.

(3) Remove screws attaching child restraint seat

module hinges to seat back frame lower rail (Fig. 1).

(4) Return seat back to upright position.

(5) Disengage push in fasteners attaching upper

bolster to child restraint seat module (Fig. 2).

(6) Remove screws attaching top of module to seat

back frame upper rail (Fig. 3).

(7) Remove child restraint seat module from seat

back (Fig. 4).

Fig. 1 CHILD RESTRAINT SEAT LOWER HINGE

1 - CHILD RESTRAINT SEAT MODULE

2 - LOWER HINGE

Fig. 2 CHILD RESTRAINT SEAT UPPER BOLSTER

1 - UPPER BOLSTER

2 - CHILD RESTRAINT SEAT MODULE

3 - PUSH-IN FASTENER

Fig. 3 CHILD RESTRAINT SEAT UPPER SCREWS

1 - UPPER BOLSTER

2 - CHILD RESTRAINT SEAT MODULE

23 - 86 SEATSRS

ProCarManuals.com