ignition CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1 of 2399

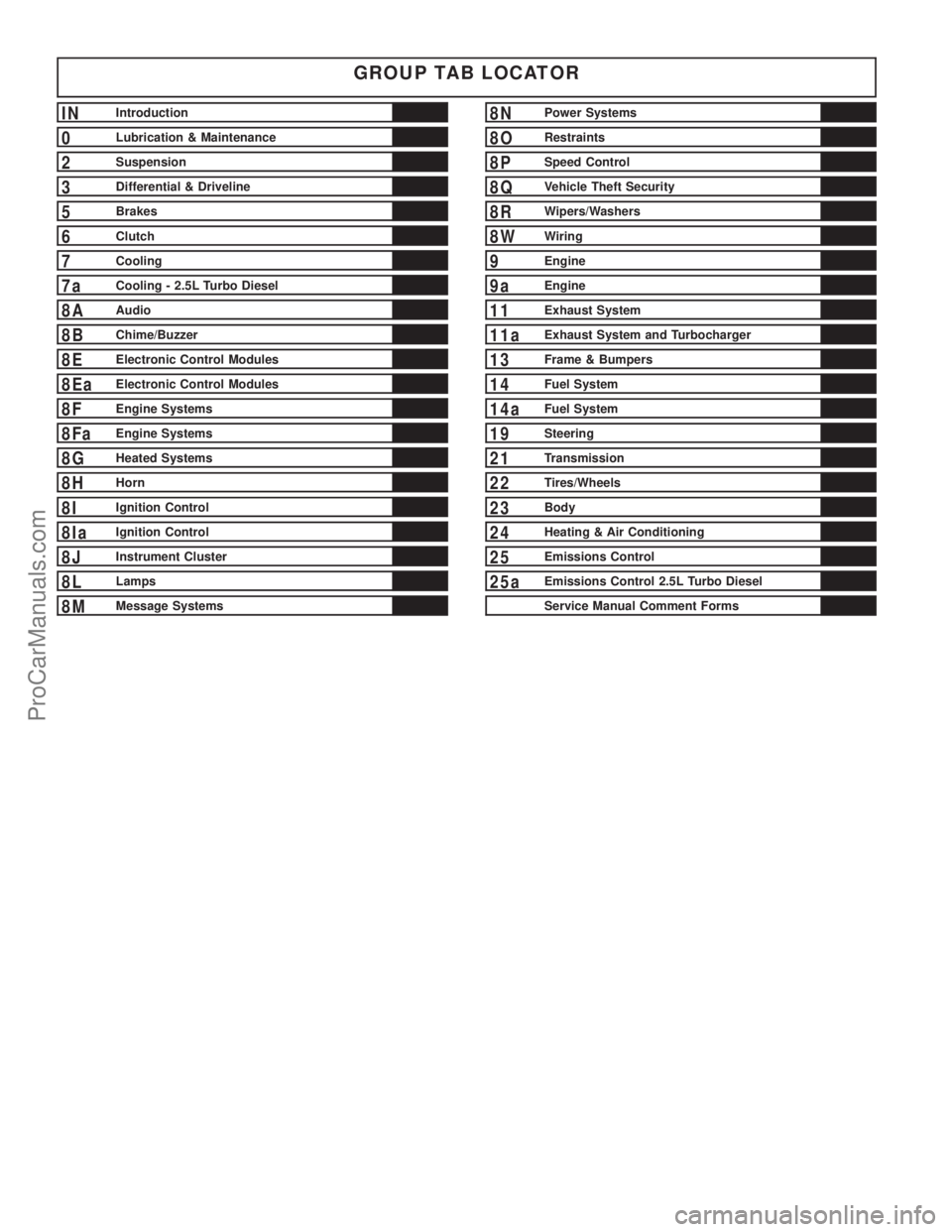

GROUP TAB LOCATOR

INIntroduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

6Clutch

7Cooling

7aCooling - 2.5L Turbo Diesel

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8EaElectronic Control Modules

8FEngine Systems

8FaEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8IaIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

9aEngine

11Exhaust System

11aExhaust System and Turbocharger

13Frame & Bumpers

14Fuel System

14aFuel System

19Steering

21Transmission

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

25aEmissions Control 2.5L Turbo Diesel

Service Manual Comment Forms

ProCarManuals.com

Page 18 of 2399

Light spark knock at low engine speeds is not

harmful to your engine. However, continued heavy

spark knock at high speeds can cause damage and

immediate service is required. Engine damage result-

ing from operation with a heavy spark knock may

not be covered by the new vehicle warranty.

Poor quality gasoline can cause problems such as

hard starting, stalling and hesitations. If you experi-

ence these symptoms, try another brand of gasoline

before considering service for the vehicle.

Over 40 auto manufacturers world-wide have

issued and endorsed consistent gasoline specifications

(the Worldwide Fuel Charter, WWFC) to define fuel

properties necessary to deliver enhanced emissions,

performance and durability for your vehicle. We rec-

ommend the use of gasolines that meet the WWFC

specifications if they are available.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner burning gasoline referred to as ªreformulat-

edº gasoline. Reformulated gasoline contain oxygen-

ates, and are specifically blended to reduce vehicle

emissions and improve air quality.

We strongly support the use of reformulated gaso-

line. Properly blended reformulated gasoline will pro-

vide excellent performance and durability for the

engine and fuel system components.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as 10% ethanol, MTBE, and ETBE.

Oxygenates are required in some areas of the country

during the winter months to reduce carbon monoxide

emissions. Fuels blended with these oxygenates may

be used in your vehicle.

CAUTION: DO NOT use gasoline containing METH-

ANOL. Gasoline containing methanol may damage

critical fuel system components.

MMT IN GASOLINE

MMT is a manganese-containing metallic additive

that is blended into some gasoline to increase octane.

Gasoline blended with MMT provide no performance

advantage beyond gasoline of the same octane num-

ber without MMT. Gasoline blended with MMT

reduce spark plug life and reduce emission system

performance in some vehicles. We recommend that

gasoline free of MMT be used in your vehicle. The

MMT content of gasoline may not be indicated on the

gasoline pump; therefore, you should ask your gaso-

line retailer whether or not his/her gasoline contains

MMT.

It is even more important to look for gasoline with-

out MMT in Canada because MMT can be used atlevels higher than allowed in the United States.

MMT is prohibited in Federal and California refor-

mulated gasoline.

SULFUR IN GASOLINE

If you live in the northeast United States, your

vehicle may have been designed to meet California

low emission standards with Cleaner-Burning Cali-

fornia reformulated gasoline with low sulfur. If such

fuels are not available in states adopting California

emission standards, your vehicles will operate satis-

factorily on fuels meeting federal specifications, but

emission control system performance may be

adversely affected. Gasoline sold outside of California

is permitted to have higher sulfur levels which may

affect the performance of the vehicle's catalytic con-

verter. This may cause the Malfunction Indicator

Lamp (MIL), Check Engine or Service Engine Soon

light to illuminate. We recommend that you try a dif-

ferent brand of unleaded gasoline having lower sulfur

to determine if the problem is fuel related prior to

returning your vehicle to an authorized dealer for

service.

CAUTION: If the Malfunction Indicator Lamp (MIL),

Check Engine or Service Engine Soon light is flash-

ing, immediate service is required; see on-board

diagnostics system section.

MATERIALS ADDED TO FUEL

All gasoline sold in the United States and Canada

are required to contain effective detergent additives.

Use of additional detergents or other additives is not

needed under normal conditions.

FUEL SYSTEM CAUTIONS

CAUTION: Follow these guidelines to maintain your

vehicle's performance:

²The use of leaded gas is prohibited by Federal

law. Using leaded gasoline can impair engine perfor-

mance, damage the emission control system, and

could result in loss of warranty coverage.

²An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your dealer for service assistance.

²When pulling a heavy load or driving a fully

loaded vehicle when the humidity is low and the tem-

perature is high, use a premium unleaded fuel to

help prevent spark knock. If spark knock persists,

lighten the load, or engine piston damage may result.

RSLUBRICATION & MAINTENANCE0-5

FLUID TYPES (Continued)

ProCarManuals.com

Page 21 of 2399

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

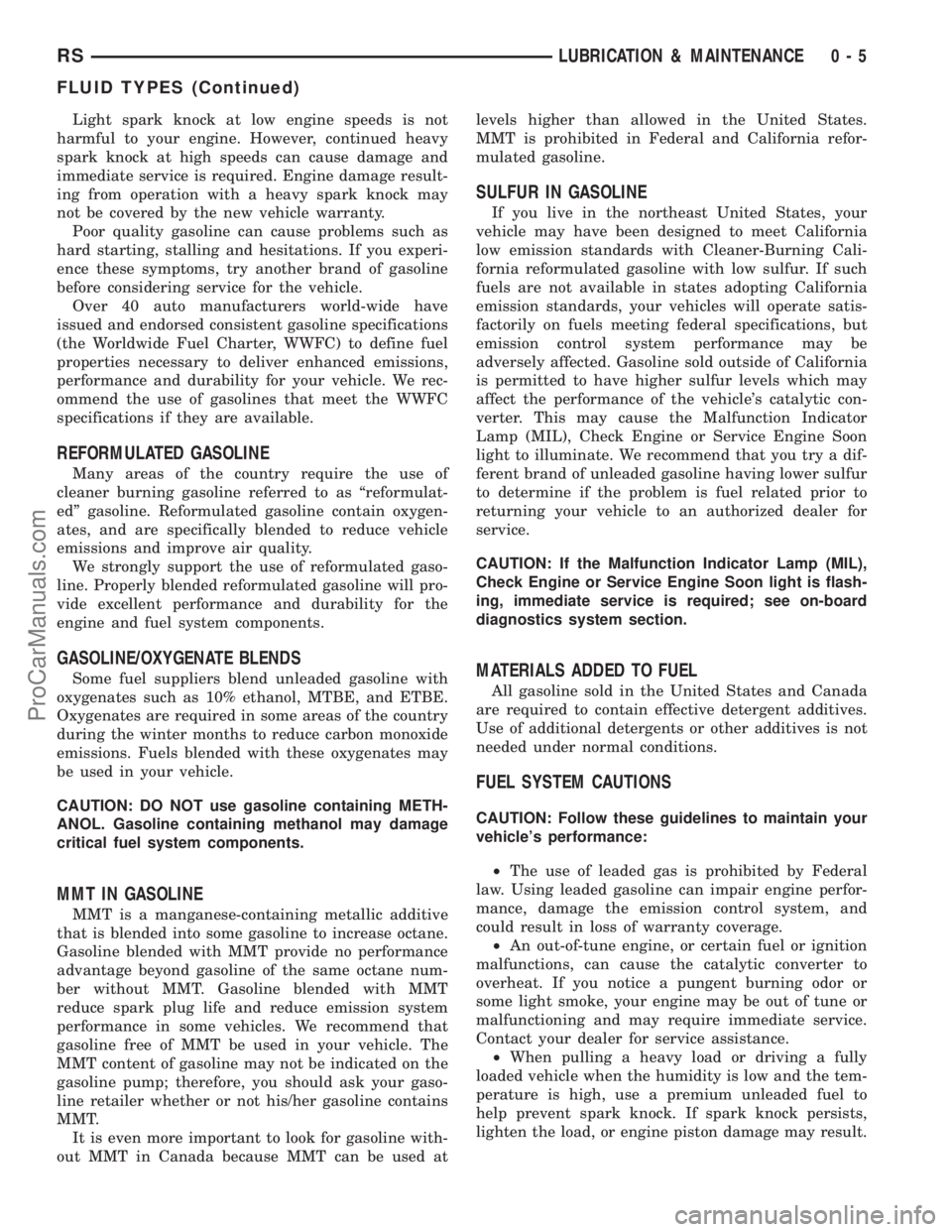

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 6).

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - STANDARD PROCEDURE).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter may over-

heat and could fail.

(7) If engine does not start within 15 seconds, stop

cranking engine and allow starter to cool (15 min-

utes), before cranking again.DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

STANDARD PROCEDURE - TOWING

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use:

²FWD vehicles, use of a flat bed towing device or

a wheel lift is recommended (Fig. 7).

²AWD vehicles, a flat bed towing device or a

wheel lift and towing dolly is recommended (Fig. 7).

When using a wheel lift towing device, be sure the

disabled vehicle has at least 100 mm (4 in.) ground

clearance. If minimum ground clearance cannot be

reached, use a towing dolly. If a flat bed device is

used, the approach angle should not exceed 15

degrees.

Fig. 6 JUMPER CABLE CLAMP CONNECTIONS

1 - BATTERY NEGATIVE TERMINAL

2 - POSITIVE JUMPER CABLE

3 - TEST INDICATOR (IF EQUIPPED)

4 - BATTERY POSITIVE TERMINAL

5 - BATTERY

6 - NEGATIVE JUMPER CABLE

0 - 8 LUBRICATION & MAINTENANCERS

JUMP STARTING (Continued)

ProCarManuals.com

Page 141 of 2399

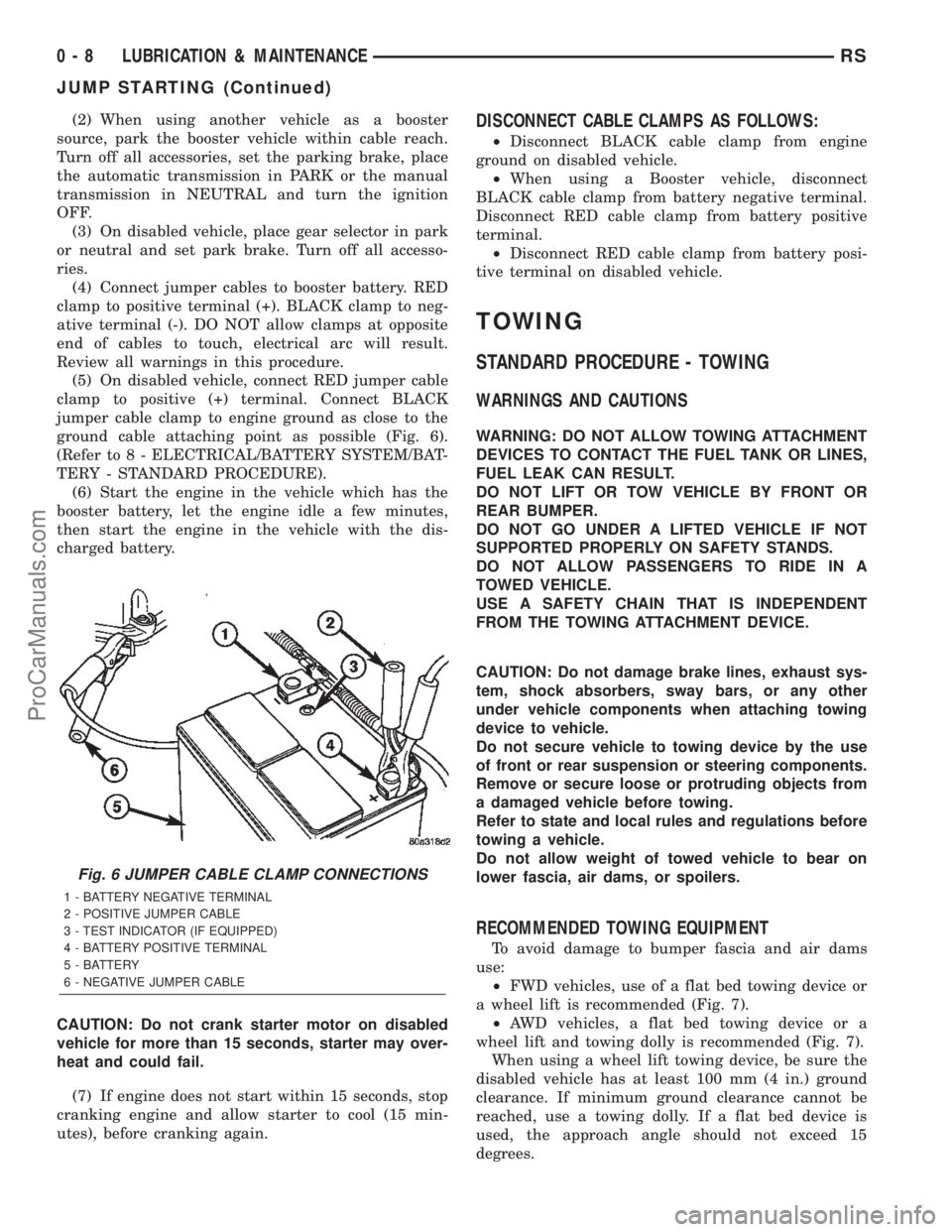

(9) Depress retainers on rear of adjustable pedal

switch, then remove switch from lower shroud (Fig.

9).

INSTALLATION

(1) Guide adjustable pedal switch wiring through

mounting hole in lower shroud.

(2) Align switch retainers with notches in mount-

ing hole and snap the switch into place (Fig. 9).

(3) Connect adjustable pedal switch wiring connec-

tor along left side of column (Fig. 8).(4) Install the lower shroud with adjustable pedal

switch. Install screws fastening steering column

shrouds to steering column (Fig. 7).

(5) Install knee blocker reinforcement plate (Fig.

6).

(6) Connect parking brake release link to release

handle.

(7) Install data link diagnostic connector to mount-

ing hole in reinforcement plate.

(8) Install lower steering column cover/knee

blocker (Fig. 6).

(9) Install silencer panel below lower steering col-

umn cover/knee blocker.

(10) Connect ground cable to negative post of bat-

tery.

(11) Connect scan tool (DRBIIIt) to data link diag-

nostic connector located below steering column.

(12) Turn ignition key to ON position.

(13) Using scan tool, check for and clear any exist-

ing adjustable pedal fault codes.

(14) Test operation of adjustable pedals, memory

sets and RKE (if equipped). If applicable, reset radio

and clock.

(15) Recheck for any fault codes.

(16) Turn key to OFF and remove scan tool from

vehicle.

PEDAL POSITION SENSOR

DESCRIPTION

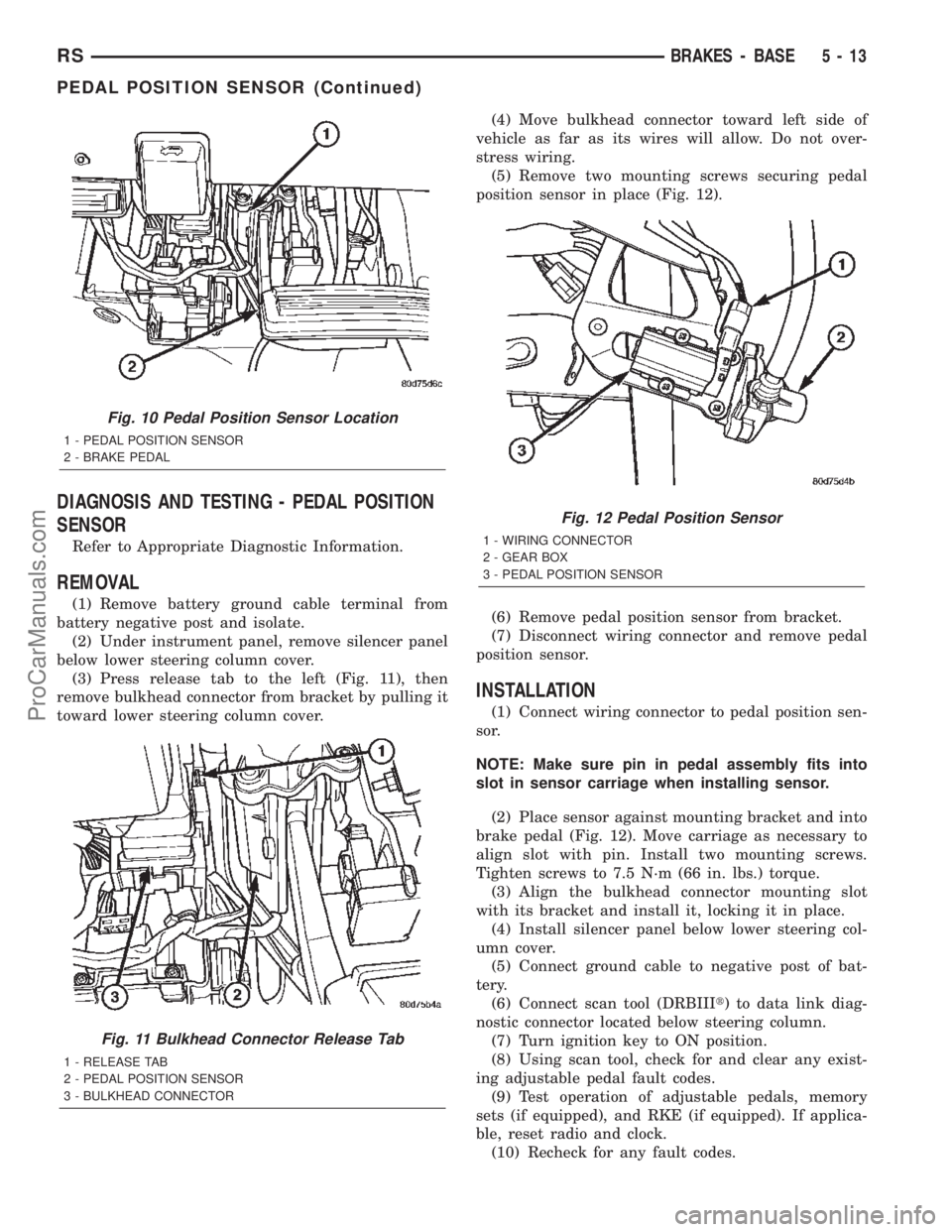

The pedal position sensor is part of the adjustable

pedal assembly. It is mounted to the left of the brake

pedal (Fig. 10). It senses the fore and aft position of

the brake pedal.

Fig. 7 Steering Column Shrouds

1 - FIXED SHROUD

2 - UPPER SHROUD

3 - CLOCKSPRING

4 - LOWER SHROUD

5 - STEERING COLUMN

Fig. 8 Pedal Switch Wiring Connector

1 - STEERING COLUMN FIXED SHROUD

2 - BRAKE TRANSMISSION SHIFT INTERLOCK

3 - B.T.S.I. WIRING CONNECTOR

4 - PEDAL SWITCH WIRING CONNECTOR

Fig. 9 Pedal Switch Retainers

1 - LOWER SHROUD INTERIOR

2 - RETAINERS

5 - 12 BRAKES - BASERS

ADJUSTABLE PEDAL SWITCH (Continued)

ProCarManuals.com

Page 142 of 2399

DIAGNOSIS AND TESTING - PEDAL POSITION

SENSOR

Refer to Appropriate Diagnostic Information.

REMOVAL

(1) Remove battery ground cable terminal from

battery negative post and isolate.

(2) Under instrument panel, remove silencer panel

below lower steering column cover.

(3) Press release tab to the left (Fig. 11), then

remove bulkhead connector from bracket by pulling it

toward lower steering column cover.(4) Move bulkhead connector toward left side of

vehicle as far as its wires will allow. Do not over-

stress wiring.

(5) Remove two mounting screws securing pedal

position sensor in place (Fig. 12).

(6) Remove pedal position sensor from bracket.

(7) Disconnect wiring connector and remove pedal

position sensor.

INSTALLATION

(1) Connect wiring connector to pedal position sen-

sor.

NOTE: Make sure pin in pedal assembly fits into

slot in sensor carriage when installing sensor.

(2) Place sensor against mounting bracket and into

brake pedal (Fig. 12). Move carriage as necessary to

align slot with pin. Install two mounting screws.

Tighten screws to 7.5 N´m (66 in. lbs.) torque.

(3) Align the bulkhead connector mounting slot

with its bracket and install it, locking it in place.

(4) Install silencer panel below lower steering col-

umn cover.

(5) Connect ground cable to negative post of bat-

tery.

(6) Connect scan tool (DRBIIIt) to data link diag-

nostic connector located below steering column.

(7) Turn ignition key to ON position.

(8) Using scan tool, check for and clear any exist-

ing adjustable pedal fault codes.

(9) Test operation of adjustable pedals, memory

sets (if equipped), and RKE (if equipped). If applica-

ble, reset radio and clock.

(10) Recheck for any fault codes.

Fig. 10 Pedal Position Sensor Location

1 - PEDAL POSITION SENSOR

2 - BRAKE PEDAL

Fig. 11 Bulkhead Connector Release Tab

1 - RELEASE TAB

2 - PEDAL POSITION SENSOR

3 - BULKHEAD CONNECTOR

Fig. 12 Pedal Position Sensor

1 - WIRING CONNECTOR

2 - GEAR BOX

3 - PEDAL POSITION SENSOR

RSBRAKES - BASE5-13

PEDAL POSITION SENSOR (Continued)

ProCarManuals.com

Page 172 of 2399

ing pedal adjustment, the APM will monitor pedal

position sensor voltage. If the APM does not detect

expected voltage change within 3 seconds, it will cut

power to the adjustable pedal motor.

An optional memory feature is available. This

allows storing of one or two preferred pedal positions

in the APS. A preferred position can be stored and

recalled using the door-mounted switches. A stored

pedal position can be recalled (but not stored) using

the Remote Keyless Entry (RKE) if equipped with

the memory feature.

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL SYSTEM

Refer to Appropriate Diagnostic Information.

REMOVAL

NOTE: Before proceeding, review all Steering Col-

umn and Airbag Warnings and Cautions. (Refer to

19 - STEERING/COLUMN - WARNING)(Refer to 8 -

ELECTRICAL/RESTRAINTS - WARNING)

(1) Remove battery ground cable terminal from

battery negative post and isolate.

(2) Under instrument panel, remove silencer panel

below lower steering column cover.

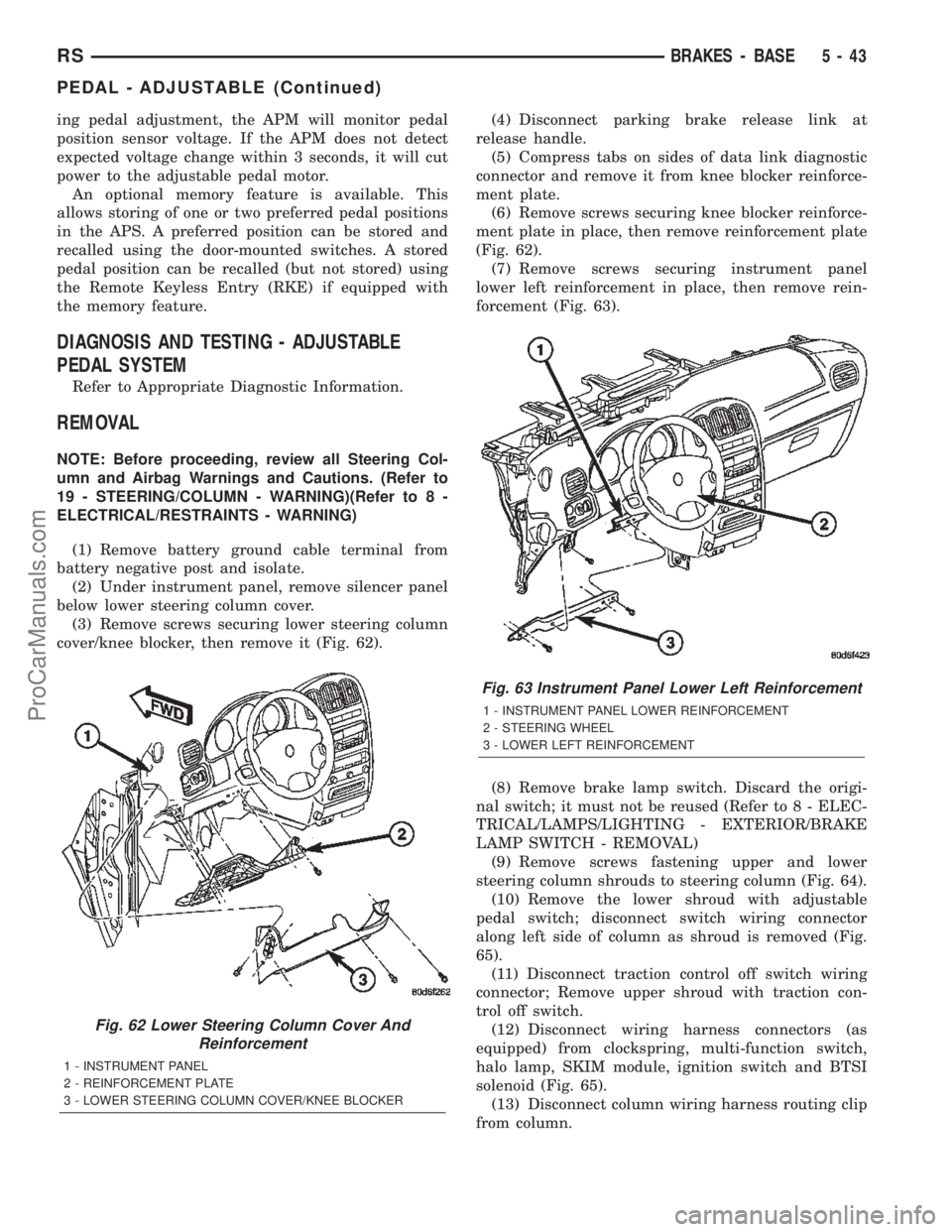

(3) Remove screws securing lower steering column

cover/knee blocker, then remove it (Fig. 62).(4) Disconnect parking brake release link at

release handle.

(5) Compress tabs on sides of data link diagnostic

connector and remove it from knee blocker reinforce-

ment plate.

(6) Remove screws securing knee blocker reinforce-

ment plate in place, then remove reinforcement plate

(Fig. 62).

(7) Remove screws securing instrument panel

lower left reinforcement in place, then remove rein-

forcement (Fig. 63).

(8) Remove brake lamp switch. Discard the origi-

nal switch; it must not be reused (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE

LAMP SWITCH - REMOVAL)

(9) Remove screws fastening upper and lower

steering column shrouds to steering column (Fig. 64).

(10) Remove the lower shroud with adjustable

pedal switch; disconnect switch wiring connector

along left side of column as shroud is removed (Fig.

65).

(11) Disconnect traction control off switch wiring

connector; Remove upper shroud with traction con-

trol off switch.

(12) Disconnect wiring harness connectors (as

equipped) from clockspring, multi-function switch,

halo lamp, SKIM module, ignition switch and BTSI

solenoid (Fig. 65).

(13) Disconnect column wiring harness routing clip

from column.

Fig. 62 Lower Steering Column Cover And

Reinforcement

1 - INSTRUMENT PANEL

2 - REINFORCEMENT PLATE

3 - LOWER STEERING COLUMN COVER/KNEE BLOCKER

Fig. 63 Instrument Panel Lower Left Reinforcement

1 - INSTRUMENT PANEL LOWER REINFORCEMENT

2 - STEERING WHEEL

3 - LOWER LEFT REINFORCEMENT

RSBRAKES - BASE5-43

PEDAL - ADJUSTABLE (Continued)

ProCarManuals.com

Page 175 of 2399

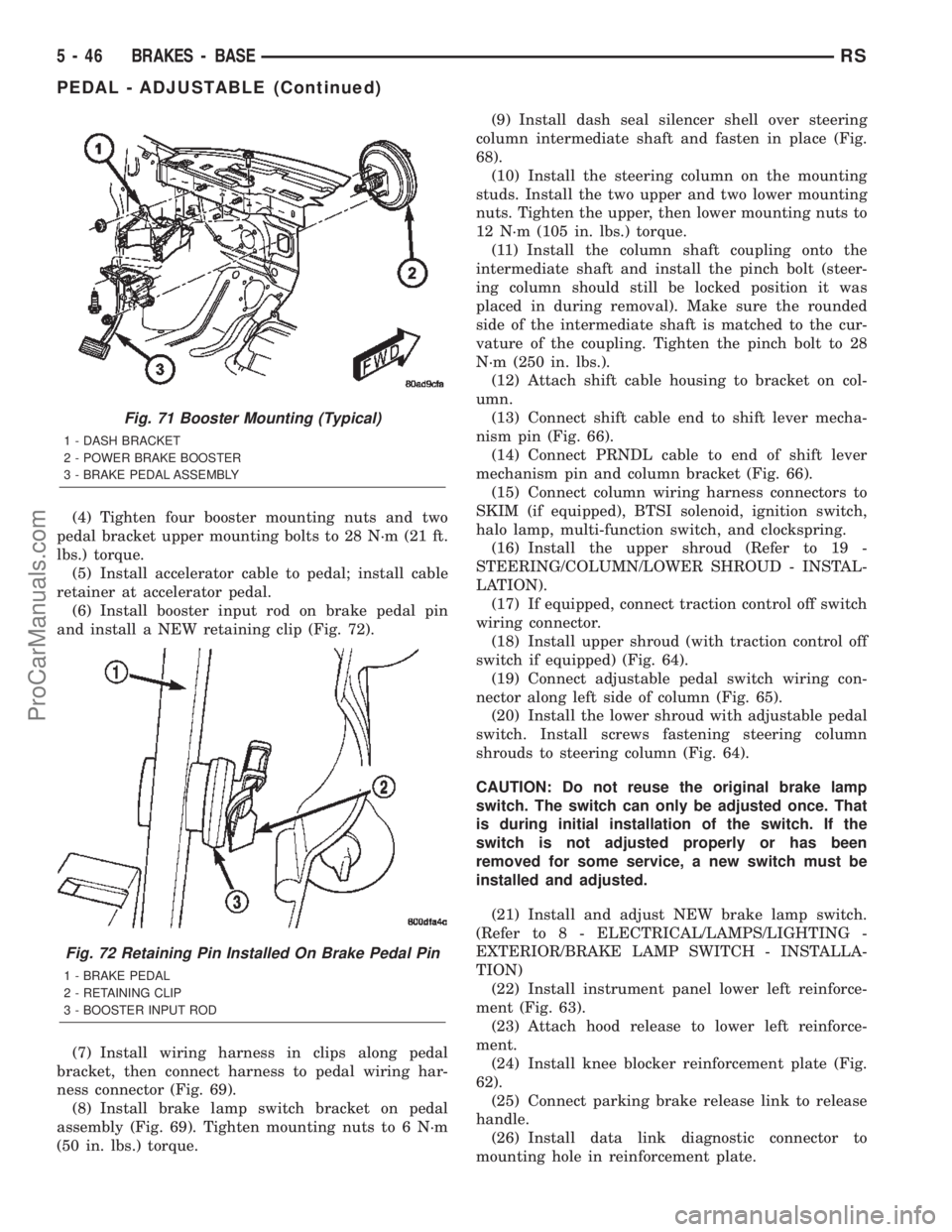

(4) Tighten four booster mounting nuts and two

pedal bracket upper mounting bolts to 28 N´m (21 ft.

lbs.) torque.

(5) Install accelerator cable to pedal; install cable

retainer at accelerator pedal.

(6) Install booster input rod on brake pedal pin

and install a NEW retaining clip (Fig. 72).

(7) Install wiring harness in clips along pedal

bracket, then connect harness to pedal wiring har-

ness connector (Fig. 69).

(8) Install brake lamp switch bracket on pedal

assembly (Fig. 69). Tighten mounting nuts to 6 N´m

(50 in. lbs.) torque.(9) Install dash seal silencer shell over steering

column intermediate shaft and fasten in place (Fig.

68).

(10) Install the steering column on the mounting

studs. Install the two upper and two lower mounting

nuts. Tighten the upper, then lower mounting nuts to

12 N´m (105 in. lbs.) torque.

(11) Install the column shaft coupling onto the

intermediate shaft and install the pinch bolt (steer-

ing column should still be locked position it was

placed in during removal). Make sure the rounded

side of the intermediate shaft is matched to the cur-

vature of the coupling. Tighten the pinch bolt to 28

N´m (250 in. lbs.).

(12) Attach shift cable housing to bracket on col-

umn.

(13) Connect shift cable end to shift lever mecha-

nism pin (Fig. 66).

(14) Connect PRNDL cable to end of shift lever

mechanism pin and column bracket (Fig. 66).

(15) Connect column wiring harness connectors to

SKIM (if equipped), BTSI solenoid, ignition switch,

halo lamp, multi-function switch, and clockspring.

(16) Install the upper shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - INSTAL-

LATION).

(17) If equipped, connect traction control off switch

wiring connector.

(18) Install upper shroud (with traction control off

switch if equipped) (Fig. 64).

(19) Connect adjustable pedal switch wiring con-

nector along left side of column (Fig. 65).

(20) Install the lower shroud with adjustable pedal

switch. Install screws fastening steering column

shrouds to steering column (Fig. 64).

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(21) Install and adjust NEW brake lamp switch.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/BRAKE LAMP SWITCH - INSTALLA-

TION)

(22) Install instrument panel lower left reinforce-

ment (Fig. 63).

(23) Attach hood release to lower left reinforce-

ment.

(24) Install knee blocker reinforcement plate (Fig.

62).

(25) Connect parking brake release link to release

handle.

(26) Install data link diagnostic connector to

mounting hole in reinforcement plate.

Fig. 71 Booster Mounting (Typical)

1 - DASH BRACKET

2 - POWER BRAKE BOOSTER

3 - BRAKE PEDAL ASSEMBLY

Fig. 72 Retaining Pin Installed On Brake Pedal Pin

1 - BRAKE PEDAL

2 - RETAINING CLIP

3 - BOOSTER INPUT ROD

5 - 46 BRAKES - BASERS

PEDAL - ADJUSTABLE (Continued)

ProCarManuals.com

Page 176 of 2399

(27) Install lower steering column cover/knee

blocker (Fig. 62).

(28) Install silencer panel below lower steering col-

umn cover/knee blocker.

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(29) Reconnect ground cable to negative post of

battery in following manor:

(a) Connect scan tool (DRBIIIt) to data link

diagnostic connector located below steering column.

(b) Turn ignition key to ON position. Exit vehi-

cle with scan tool leaving scan tool harness

plugged in.

(c) Ensuring that there are no occupants in vehi-

cle, connect ground (-) cable to the negative post of

the battery.

(d) Using scan tool, read and record any airbag

fault codes. Refer to Appropriate Diagnostic Infor-

mation if any faults are found.

(e) Through drivers open window, Reach around

back of steering wheel (between steering wheel and

instrument cluster) and turn ignition key to OFF,

then back ON while observing instrument cluster

airbag indicator lamp. It should go on for six to

eight seconds, then go out. This action indicates

that airbag system is functioning normally. If air-

bag indicator lamp fails to light, blinks on and off,

or goes on and stays on, there is an airbag system

malfunction. Refer to Appropriate Diagnostic Infor-

mation to diagnose the system malfunction.

(30) Using scan tool (DRBIIIt), check for and clear

any existing adjustable pedal fault codes. The adjust-

able pedal system is now activated.

(31) Turn key to OFF and remove scan tool from

vehicle.

(32) Test operation of adjustable pedals, memory

seats (if equipped), RKE (if equipped), and all func-

tions that are steering column operated. If applica-

ble, reset the radio and the clock.

(33) Road test the vehicle to ensure proper opera-

tion of the steering and brake systems.

PEDAL TORQUE SHAFT - RHD

REMOVAL

(1) Remove the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL)

(2) Remove the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL)

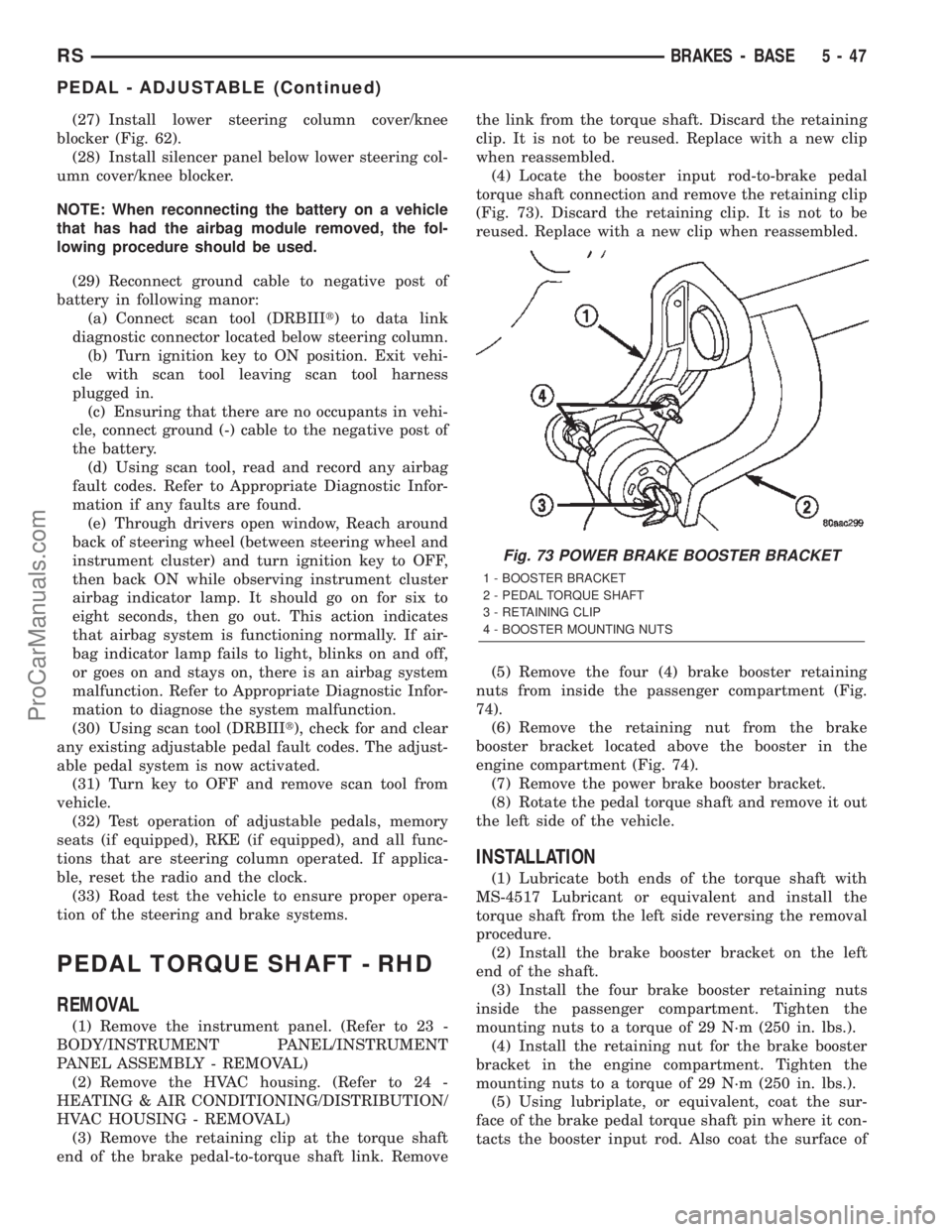

(3) Remove the retaining clip at the torque shaft

end of the brake pedal-to-torque shaft link. Removethe link from the torque shaft. Discard the retaining

clip. It is not to be reused. Replace with a new clip

when reassembled.

(4) Locate the booster input rod-to-brake pedal

torque shaft connection and remove the retaining clip

(Fig. 73). Discard the retaining clip. It is not to be

reused. Replace with a new clip when reassembled.

(5) Remove the four (4) brake booster retaining

nuts from inside the passenger compartment (Fig.

74).

(6) Remove the retaining nut from the brake

booster bracket located above the booster in the

engine compartment (Fig. 74).

(7) Remove the power brake booster bracket.

(8) Rotate the pedal torque shaft and remove it out

the left side of the vehicle.

INSTALLATION

(1) Lubricate both ends of the torque shaft with

MS-4517 Lubricant or equivalent and install the

torque shaft from the left side reversing the removal

procedure.

(2) Install the brake booster bracket on the left

end of the shaft.

(3) Install the four brake booster retaining nuts

inside the passenger compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(4) Install the retaining nut for the brake booster

bracket in the engine compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(5) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod. Also coat the surface of

Fig. 73 POWER BRAKE BOOSTER BRACKET

1 - BOOSTER BRACKET

2 - PEDAL TORQUE SHAFT

3 - RETAINING CLIP

4 - BOOSTER MOUNTING NUTS

RSBRAKES - BASE5-47

PEDAL - ADJUSTABLE (Continued)

ProCarManuals.com

Page 216 of 2399

black tire marks since the wheel never reaches a

fully locked condition. However, tire marks may be

noticeable as light patched marks.

START-UP CYCLE

When the ignition is turned on, a popping sound

and a slight brake pedal movement may be noticed.

The ABS warning lamp will also be on for up to 5

seconds after the ignition is turned on. When the

vehicle is first driven off, a humming may be heard

or felt by the driver at approximately 20±40 kph

(12±25 mph). All of these conditions are a normal

function of ABS as the system is performing a diag-

nosis check.

PREMATURE ABS CYCLING

Symptoms of premature ABS cycling include: click-

ing sounds from the solenoid valves; pump/motor

running; and pulsations in the brake pedal. Prema-

ture ABS cycling can occur at any braking rate of the

vehicle and on any type of road surface. Neither the

red BRAKE warning lamp, nor the amber ABS warn-

ing lamp, illuminate and no fault codes are stored in

the CAB.

Premature ABS cycling is a condition that needs to

be correctly assessed when diagnosing problems with

the antilock brake system. It may be necessary to use

a DRB scan tool to detect and verify premature ABS

cycling.

Check the following common causes when diagnos-

ing premature ABS cycling: damaged tone wheels;

incorrect tone wheels; damaged steering knuckle

wheel speed sensor mounting bosses; loose wheel

speed sensor mounting bolts; excessive tone wheel

runout; or an excessively large tone wheel-to-wheel

speed sensor air gap. Give special attention to these

components when diagnosing a vehicle exhibiting

premature ABS cycling.

After diagnosing the defective component, repair or

replace it as required. When the component repair or

replacement is completed, test drive the vehicle to

verify that premature ABS cycling has been cor-

rected.

OPERATION - ELECTRONIC VARIABLE BRAKE

PROPORTIONING

Upon entry into EVBP the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

hydraulic control unit (HCU) resulting in a drop in

fluid pressure to the rear brakes. In order to increase

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases thepressure to the rear brakes. This back-and-forth pro-

cess will continue until the required slip difference is

obtained. At the end of EVBP braking (brakes

released) the fluid in the LPA drains back to the

master cylinder by switching on the outlet valve and

draining through the inlet valve check valve. At the

same time the inlet valve is switched on in case of

another brake application.

The EVBP will remain functional during many

ABS fault modes. If both the red BRAKE and amber

ABS warning indicators are illuminated, the EVBP

may not be functioning.

OPERATION - TRACTION CONTROL SYSTEM

The traction control module monitors wheel speed.

During acceleration, if the module detects front

(drive) wheel slip and the brakes are not applied, the

module enters traction control mode. Traction control

operation proceeds in the following order:

(1) Close the normally open isolation valves.

(2) Start the pump/motor and supply volume and

pressure to the front (drive) hydraulic circuit. (The

pump/motor runs continuously during traction con-

trol operation.)

(3) Open and close the build and decay valves to

maintain minimum wheel slip and maximum trac-

tion.

The cycling of the build and decay valves during

traction control is similar to that during antilock

braking, except the valves work to control wheel spin

by applying the brakes, whereas the ABS function is

to control wheel skid by releasing the brakes.

If the brakes are applied at anytime during a trac-

tion control cycle, the brake lamp switch triggers the

controller to switch off traction control.

HYDRAULIC SHUTTLE VALVES

Two pressure relief hydraulic shuttle valves allow

pressure and volume to return to the master cylinder

reservoir when not consumed by the build and decay

valves. These valves are necessary because the

pump/motor supplies more volume than the system

requires.

TRACTION CONTROL LAMP

The traction control system is enabled at each igni-

tion cycle. It may be turned off by depressing the

Traction Control Off switch button when the ignition

is in the ON position. The traction control function

lamp (TRAC OFF) illuminates immediately upon

depressing the button.

The traction control function lamp illuminates dur-

ing a traction control cycle, displaying TRAC.

If the CAB calculates that the brake temperatures

are high, the traction control system becomes inoper-

ative until a time-out period has elapsed. During this

RSBRAKES - ABS5-87

BRAKES - ABS (Continued)

ProCarManuals.com

Page 217 of 2399

ªthermo-protection mode,º the traction control func-

tion lamp illuminates TRAC OFF; note that no trou-

ble code is registered.

CAUTION

CAUTIONS

The ABS uses an electronic control module, the

CAB. This module is designed to withstand normal

current draws associated with vehicle operation.

Care must be taken to avoid overloading the CAB

circuits.

CAUTION: In testing for open or short circuits, do

not ground or apply voltage to any of the circuits

unless instructed to do so for a diagnostic proce-

dure.

CAUTION: These circuits should only be tested

using a high impedance multi-meter or the DRBIIIT

scan tool as described in this section. Power

should never be removed or applied to any control

module with the ignition in the ON position. Before

removing or connecting battery cables, fuses, or

connectors, always turn the ignition to the OFF

position.

CAUTION: The CAB 24-way connector should never

be connected or disconnected with the ignition

switch in the ON position.

CAUTION: This vehicle utilizes active wheel speed

sensors. Do not apply voltage to wheel speed sen-

sors at any time.

CAUTION: Use only factory wiring harnesses. Do

not cut or splice wiring to the brake circuits. The

addition of aftermarket electrical equipment (car

phone, radar detector, citizen band radio, trailer

lighting, trailer brakes, etc.) on a vehicle equipped

with antilock brakes may affect the function of the

antilock brake system.

CAUTION: When performing any service procedure

on a vehicle equipped with ABS, do not apply a

12-volt power source to the ground circuit of the

pump motor in the HCU. Doing this will damage the

pump motor and will require replacement of the

entire HCU.CAUTION: An attempt to remove or disconnect cer-

tain system components may result in improper

system operation. Only those components with

approved removal and installation procedures in

this manual should be serviced.

CAUTION: If welding work is to be performed on the

vehicle, using an electric arc welder, the CAB con-

nector should be disconnected during the welding

operation.

CAUTION: Many components of the ABS System

are not serviceable and must be replaced as an

assembly. Do not disassemble any component

which is not designed to be serviced.

CAUTION: Only the recommended jacking or hoist-

ing positions for this vehicle are to be used when-

ever it is necessary to lift a vehicle. Failure to raise

a vehicle from the recommended locations could

result in lifting a vehicle by the hydraulic control

unit mounting bracket. Lifting a vehicle by the

hydraulic control unit mounting bracket will result

in damage to the mounting bracket and the hydrau-

lic control unit.

CAUTION: Brake fluid will damage painted surfaces.

If brake fluid is spilled on any painted surface,

wash off with water immediately.

STANDARD PROCEDURE - ANTILOCK BRAKE

SYSTEM BLEEDING

The base brake's hydraulic system must be bled

anytime air enters the hydraulic system. The ABS

though, particularly the ICU (HCU), should only be

bled when the HCU is replaced or removed from the

vehicle. The ABS must always be bled anytime it is

suspected that the HCU has ingested air. Under

most circumstances that require the bleeding of the

brakes hydraulic system, only the base brake

hydraulic system needs to be bled.

It is important to note that excessive air in the

brake system will cause a soft or spongy feeling

brake pedal.

During the brake bleeding procedure, be sure the

brake fluid level remains close to the FULL level in

the master cylinder fluid reservoir. Check the fluid

level periodically during the bleeding procedure and

add DOT 3 brake fluid as required.

The ABS must be bled as two independent braking

systems. The non-ABS portion of the brake system

with ABS is to be bled the same as any non-ABS sys-

tem.

5 - 88 BRAKES - ABSRS

BRAKES - ABS (Continued)

ProCarManuals.com