tow CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 10 of 2399

VEHICLE IDENTIFICATION

NUMBER

DESCRIPTION

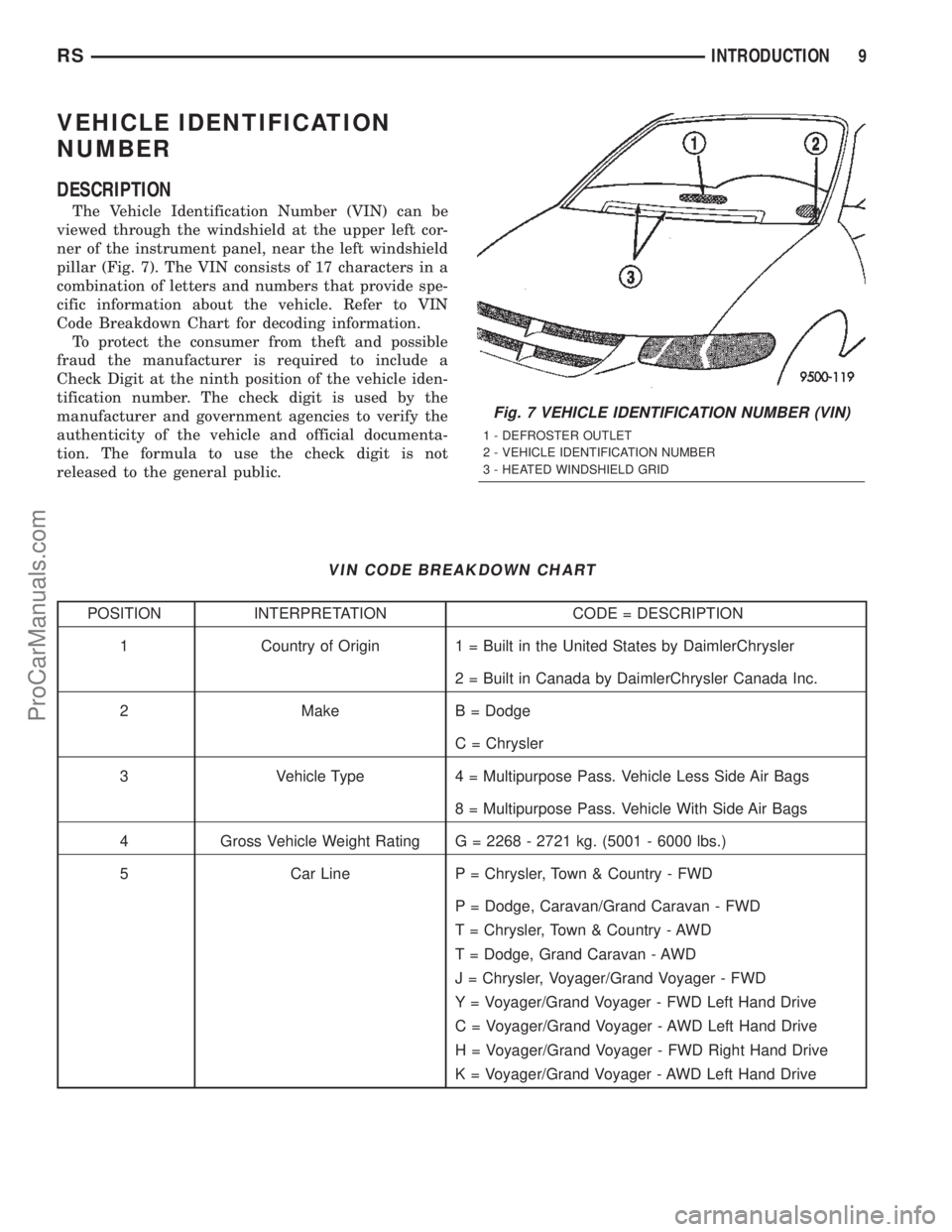

The Vehicle Identification Number (VIN) can be

viewed through the windshield at the upper left cor-

ner of the instrument panel, near the left windshield

pillar (Fig. 7). The VIN consists of 17 characters in a

combination of letters and numbers that provide spe-

cific information about the vehicle. Refer to VIN

Code Breakdown Chart for decoding information.

To protect the consumer from theft and possible

fraud the manufacturer is required to include a

Check Digit at the ninth position of the vehicle iden-

tification number. The check digit is used by the

manufacturer and government agencies to verify the

authenticity of the vehicle and official documenta-

tion. The formula to use the check digit is not

released to the general public.

VIN CODE BREAKDOWN CHART

POSITION INTERPRETATION CODE = DESCRIPTION

1 Country of Origin 1 = Built in the United States by DaimlerChrysler

2 = Built in Canada by DaimlerChrysler Canada Inc.

2 Make B = Dodge

C = Chrysler

3 Vehicle Type 4 = Multipurpose Pass. Vehicle Less Side Air Bags

8 = Multipurpose Pass. Vehicle With Side Air Bags

4 Gross Vehicle Weight Rating G = 2268 - 2721 kg. (5001 - 6000 lbs.)

5 Car Line P = Chrysler, Town & Country - FWD

P = Dodge, Caravan/Grand Caravan - FWD

T = Chrysler, Town & Country - AWD

T = Dodge, Grand Caravan - AWD

J = Chrysler, Voyager/Grand Voyager - FWD

Y = Voyager/Grand Voyager - FWD Left Hand Drive

C = Voyager/Grand Voyager - AWD Left Hand Drive

H = Voyager/Grand Voyager - FWD Right Hand Drive

K = Voyager/Grand Voyager - AWD Left Hand Drive

Fig. 7 VEHICLE IDENTIFICATION NUMBER (VIN)

1 - DEFROSTER OUTLET

2 - VEHICLE IDENTIFICATION NUMBER

3 - HEATED WINDSHIELD GRID

RSINTRODUCTION9

ProCarManuals.com

Page 14 of 2399

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

LUBRICATION & MAINTENANCE

SPECIFICATIONS - FLUID CAPACITIES.......1

INTERNATIONAL SYMBOLS

DESCRIPTION..........................2

FLUID TYPES

DESCRIPTION

DESCRIPTION - ENGINE OIL AND

LUBRICANTS.........................2

DESCRIPTION - ENGINE COOLANT........3

DESCRIPTION - FLEXIBLE FUEL ENGINE

OIL .................................3

DESCRIPTION - AUTOMATIC

TRANSMISSION FLUID..................4

DESCRIPTION - FUEL REQUIREMENTS.....4

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE.......................6DESCRIPTION - ENGINE OIL - DIESEL

ENGINES............................6

FLUID FILL/CHECK LOCATIONS

DESCRIPTION..........................6

LUBRICATION POINTS

DESCRIPTION..........................6

MAINTENANCE SCHEDULES

DESCRIPTION..........................6

HOISTING

STANDARD PROCEDURE - HOISTING........6

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING . . 7

TOWING

STANDARD PROCEDURE - TOWING.........8

LUBRICATION &

MAINTENANCE

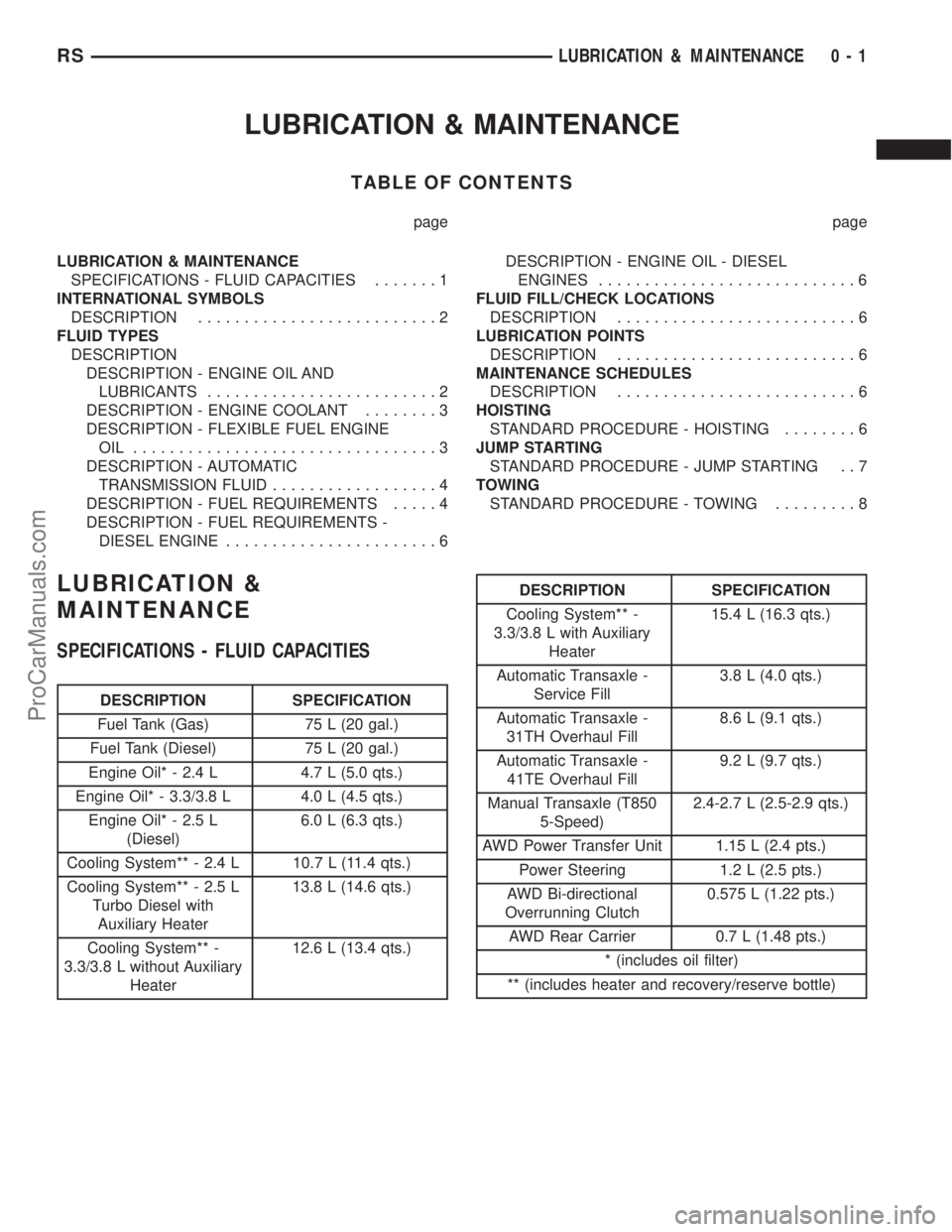

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

Fuel Tank (Gas) 75 L (20 gal.)

Fuel Tank (Diesel) 75 L (20 gal.)

Engine Oil* - 2.4 L 4.7 L (5.0 qts.)

Engine Oil* - 3.3/3.8 L 4.0 L (4.5 qts.)

Engine Oil* - 2.5 L

(Diesel)6.0 L (6.3 qts.)

Cooling System** - 2.4 L 10.7 L (11.4 qts.)

Cooling System** - 2.5 L

Turbo Diesel with

Auxiliary Heater13.8 L (14.6 qts.)

Cooling System** -

3.3/3.8 L without Auxiliary

Heater12.6 L (13.4 qts.)

DESCRIPTION SPECIFICATION

Cooling System** -

3.3/3.8 L with Auxiliary

Heater15.4 L (16.3 qts.)

Automatic Transaxle -

Service Fill3.8 L (4.0 qts.)

Automatic Transaxle -

31TH Overhaul Fill8.6 L (9.1 qts.)

Automatic Transaxle -

41TE Overhaul Fill9.2 L (9.7 qts.)

Manual Transaxle (T850

5-Speed)2.4-2.7 L (2.5-2.9 qts.)

AWD Power Transfer Unit 1.15 L (2.4 pts.)

Power Steering 1.2 L (2.5 pts.)

AWD Bi-directional

Overrunning Clutch0.575 L (1.22 pts.)

AWD Rear Carrier 0.7 L (1.48 pts.)

* (includes oil filter)

** (includes heater and recovery/reserve bottle)

RSLUBRICATION & MAINTENANCE0-1

ProCarManuals.com

Page 20 of 2399

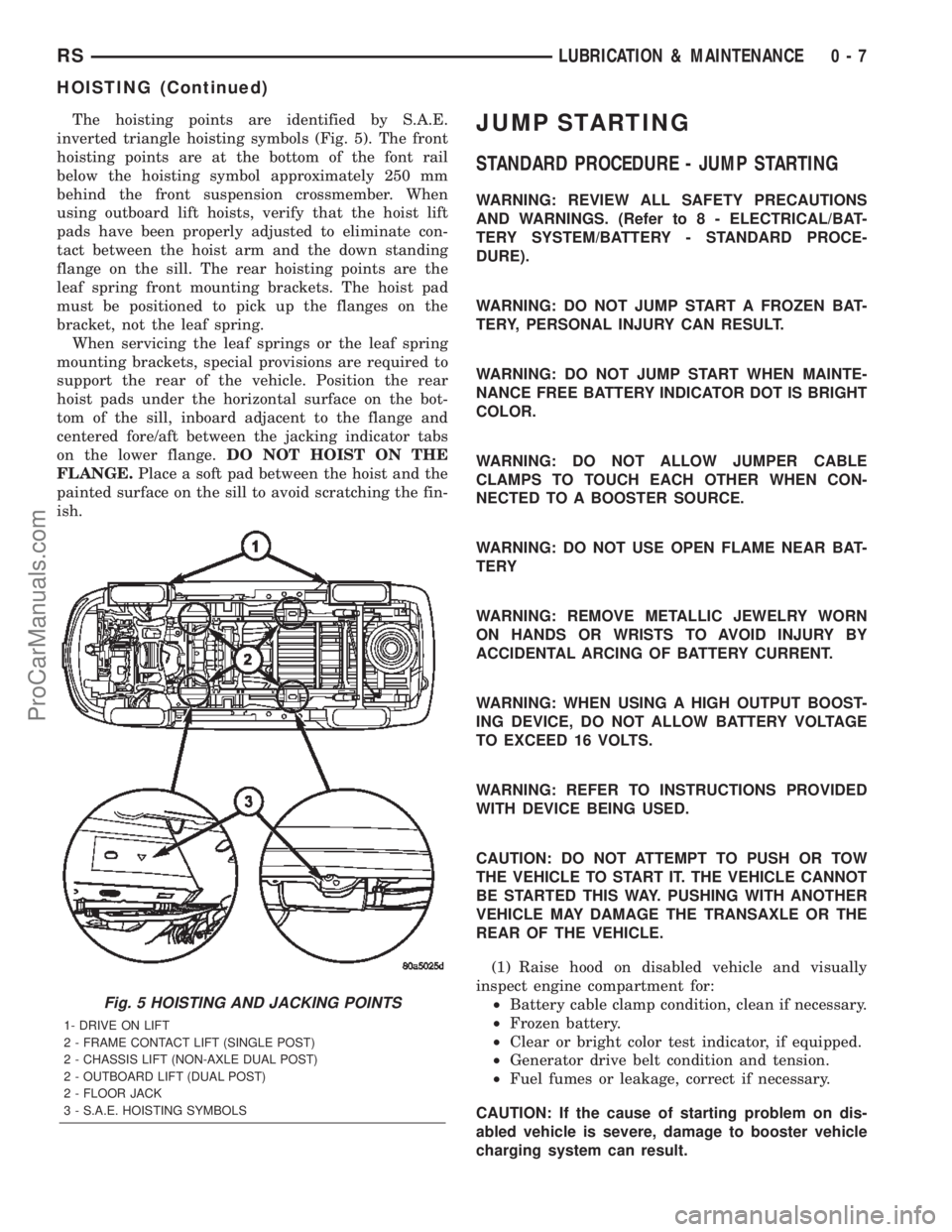

The hoisting points are identified by S.A.E.

inverted triangle hoisting symbols (Fig. 5). The front

hoisting points are at the bottom of the font rail

below the hoisting symbol approximately 250 mm

behind the front suspension crossmember. When

using outboard lift hoists, verify that the hoist lift

pads have been properly adjusted to eliminate con-

tact between the hoist arm and the down standing

flange on the sill. The rear hoisting points are the

leaf spring front mounting brackets. The hoist pad

must be positioned to pick up the flanges on the

bracket, not the leaf spring.

When servicing the leaf springs or the leaf spring

mounting brackets, special provisions are required to

support the rear of the vehicle. Position the rear

hoist pads under the horizontal surface on the bot-

tom of the sill, inboard adjacent to the flange and

centered fore/aft between the jacking indicator tabs

on the lower flange.DO NOT HOIST ON THE

FLANGE.Place a soft pad between the hoist and the

painted surface on the sill to avoid scratching the fin-

ish.JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS. (Refer to 8 - ELECTRICAL/BAT-

TERY SYSTEM/BATTERY - STANDARD PROCE-

DURE).

WARNING: DO NOT JUMP START A FROZEN BAT-

TERY, PERSONAL INJURY CAN RESULT.

WARNING: DO NOT JUMP START WHEN MAINTE-

NANCE FREE BATTERY INDICATOR DOT IS BRIGHT

COLOR.

WARNING: DO NOT ALLOW JUMPER CABLE

CLAMPS TO TOUCH EACH OTHER WHEN CON-

NECTED TO A BOOSTER SOURCE.

WARNING: DO NOT USE OPEN FLAME NEAR BAT-

TERY

WARNING: REMOVE METALLIC JEWELRY WORN

ON HANDS OR WRISTS TO AVOID INJURY BY

ACCIDENTAL ARCING OF BATTERY CURRENT.

WARNING: WHEN USING A HIGH OUTPUT BOOST-

ING DEVICE, DO NOT ALLOW BATTERY VOLTAGE

TO EXCEED 16 VOLTS.

WARNING: REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: DO NOT ATTEMPT TO PUSH OR TOW

THE VEHICLE TO START IT. THE VEHICLE CANNOT

BE STARTED THIS WAY. PUSHING WITH ANOTHER

VEHICLE MAY DAMAGE THE TRANSAXLE OR THE

REAR OF THE VEHICLE.

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Clear or bright color test indicator, if equipped.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

Fig. 5 HOISTING AND JACKING POINTS

1- DRIVE ON LIFT

2 - FRAME CONTACT LIFT (SINGLE POST)

2 - CHASSIS LIFT (NON-AXLE DUAL POST)

2 - OUTBOARD LIFT (DUAL POST)

2 - FLOOR JACK

3 - S.A.E. HOISTING SYMBOLS

RSLUBRICATION & MAINTENANCE0-7

HOISTING (Continued)

ProCarManuals.com

Page 21 of 2399

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

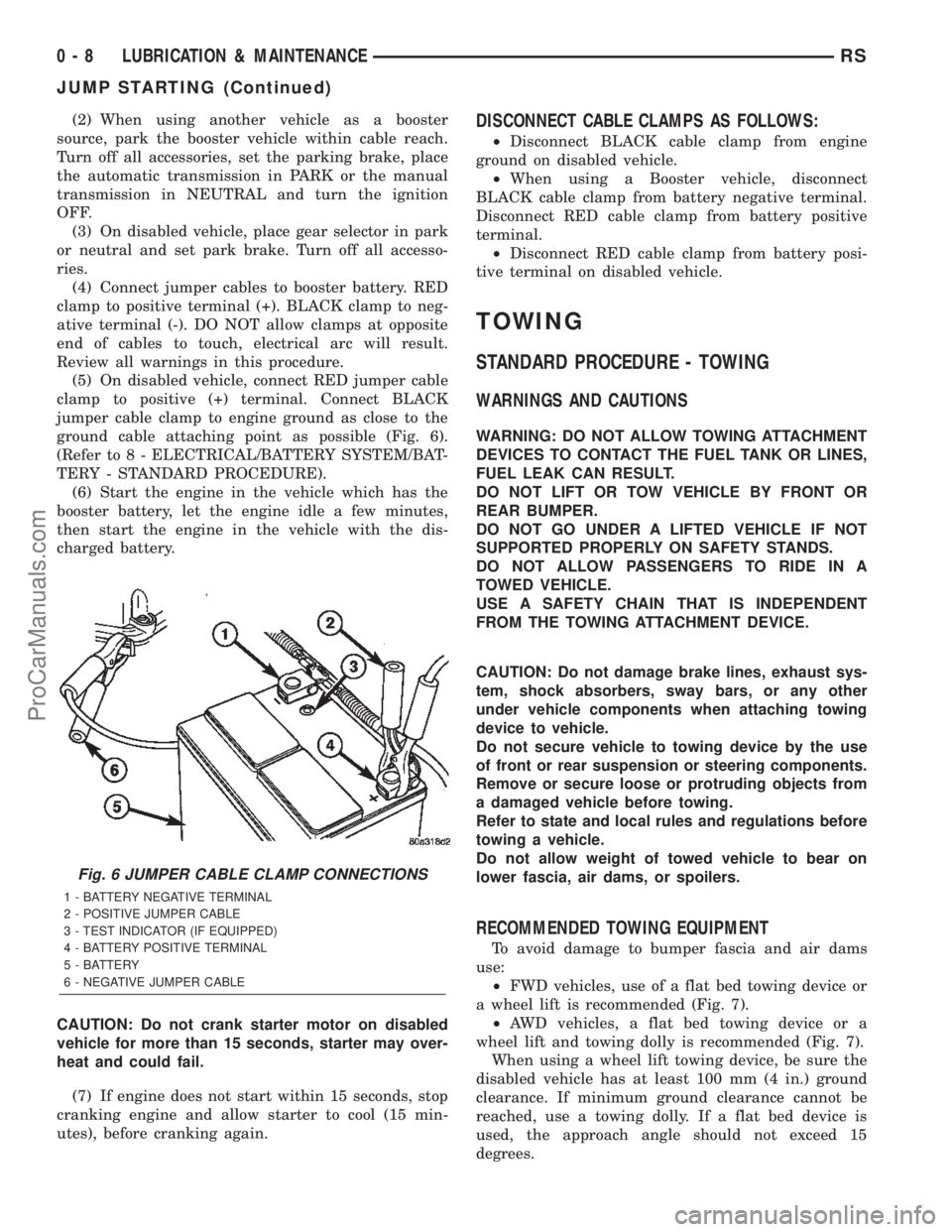

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 6).

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - STANDARD PROCEDURE).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter may over-

heat and could fail.

(7) If engine does not start within 15 seconds, stop

cranking engine and allow starter to cool (15 min-

utes), before cranking again.DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

STANDARD PROCEDURE - TOWING

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

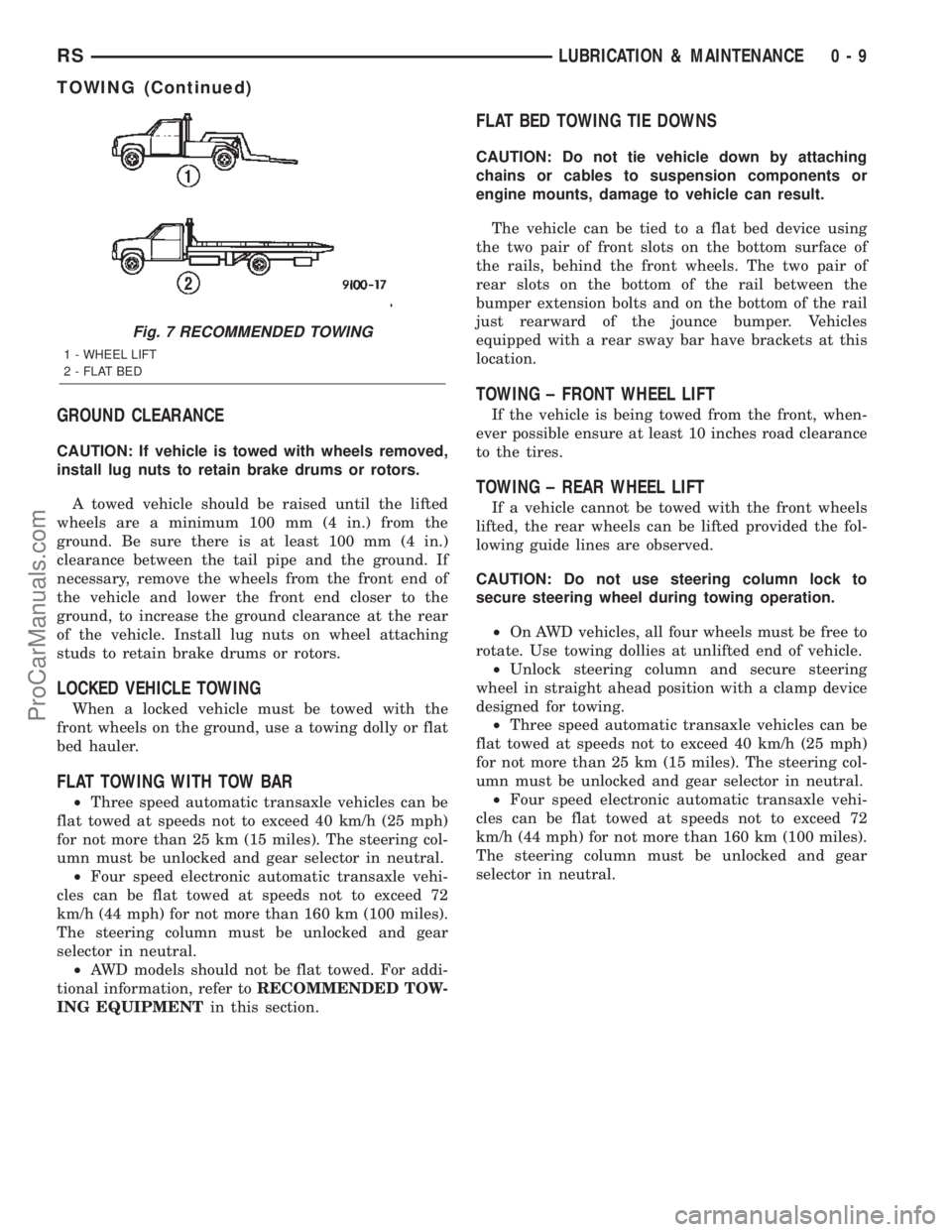

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use:

²FWD vehicles, use of a flat bed towing device or

a wheel lift is recommended (Fig. 7).

²AWD vehicles, a flat bed towing device or a

wheel lift and towing dolly is recommended (Fig. 7).

When using a wheel lift towing device, be sure the

disabled vehicle has at least 100 mm (4 in.) ground

clearance. If minimum ground clearance cannot be

reached, use a towing dolly. If a flat bed device is

used, the approach angle should not exceed 15

degrees.

Fig. 6 JUMPER CABLE CLAMP CONNECTIONS

1 - BATTERY NEGATIVE TERMINAL

2 - POSITIVE JUMPER CABLE

3 - TEST INDICATOR (IF EQUIPPED)

4 - BATTERY POSITIVE TERMINAL

5 - BATTERY

6 - NEGATIVE JUMPER CABLE

0 - 8 LUBRICATION & MAINTENANCERS

JUMP STARTING (Continued)

ProCarManuals.com

Page 22 of 2399

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the front end of

the vehicle and lower the front end closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

²AWD models should not be flat towed. For addi-

tional information, refer toRECOMMENDED TOW-

ING EQUIPMENTin this section.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

The vehicle can be tied to a flat bed device using

the two pair of front slots on the bottom surface of

the rails, behind the front wheels. The two pair of

rear slots on the bottom of the rail between the

bumper extension bolts and on the bottom of the rail

just rearward of the jounce bumper. Vehicles

equipped with a rear sway bar have brackets at this

location.

TOWING ± FRONT WHEEL LIFT

If the vehicle is being towed from the front, when-

ever possible ensure at least 10 inches road clearance

to the tires.

TOWING ± REAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²On AWD vehicles, all four wheels must be free to

rotate. Use towing dollies at unlifted end of vehicle.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

Fig. 7 RECOMMENDED TOWING

1 - WHEEL LIFT

2 - FLAT BED

RSLUBRICATION & MAINTENANCE0-9

TOWING (Continued)

ProCarManuals.com

Page 25 of 2399

FRONT SUSPENSION

DESCRIPTION - FRONT SUSPENSION

This vehicle has a MacPherson Strut type front

suspension (Fig. 1).

OPERATION - FRONT SUSPENSION

The front suspension allows each wheel on a vehi-

cle to adapt to different road surfaces and conditions

without greatly affecting the opposite wheel and the

ability to control the vehicle. Each side of the front

suspension is allowed to pivot so the vehicle can be

steered in the direction preferred.

A strut assembly is used in place of the front sus-

pension upper control arm and upper ball joint.

When a vehicle strikes a bump, the force is trans-

ferred through the hub, bearing, and knuckle, into

the strut assembly to absorb the force and dampen it.

The top of the strut is mounted directly to the strut

tower of the vehicle. During steering maneuvers, thestrut assembly (through a pivot bearing in the upper

strut mount) and steering knuckle (through the lower

ball joint) turn as an assembly.

STANDARD PROCEDURE - LUBRICATION

There are no serviceable lubrication points on the

front suspension. The ball joints are sealed-for-life

and require no maintenance. The lower ball joints

have special grease fitting caps that prevent normal

grease gun attachment. This has been done to elimi-

nate the possibility of over-filling, damaging the non-

vented seal. Do not attempt to remove the special

grease fitting cap and replace it with a normal grease

zirc fitting.

CAUTION: No attempt should be made to replace

the ball joint grease fitting cap with a normal zirc

fitting or fill the ball joint with grease. Damage to

the grease seal can result.

Fig. 1 Front Suspension

1 - TOWER

2 - CROSSMEMBER TAPPING PLATES

3 - LEFT STRUT ASSEMBLY

4 - LEFT STEERING KNUCKLE (WITH HUB AND BEARING)

5 - STABILIZER BAR LINK

6 - STABILIZER BAR

7 - LEFT LOWER CONTROL ARM

8 - CRADLE/CROSSMEMBER9 - CRADLE/CROSSMEMBER REINFORCEMENT

10 - BALL JOINT

11 - ISOLATOR BUSHING

12 - STEERING GEAR TIE ROD

13 - RIGHT STEERING KNUCKLE

14 - RIGHT HUB AND BEARING

15 - RIGHT STRUT ASSEMBLY

2 - 2 FRONT SUSPENSIONRS

ProCarManuals.com

Page 26 of 2399

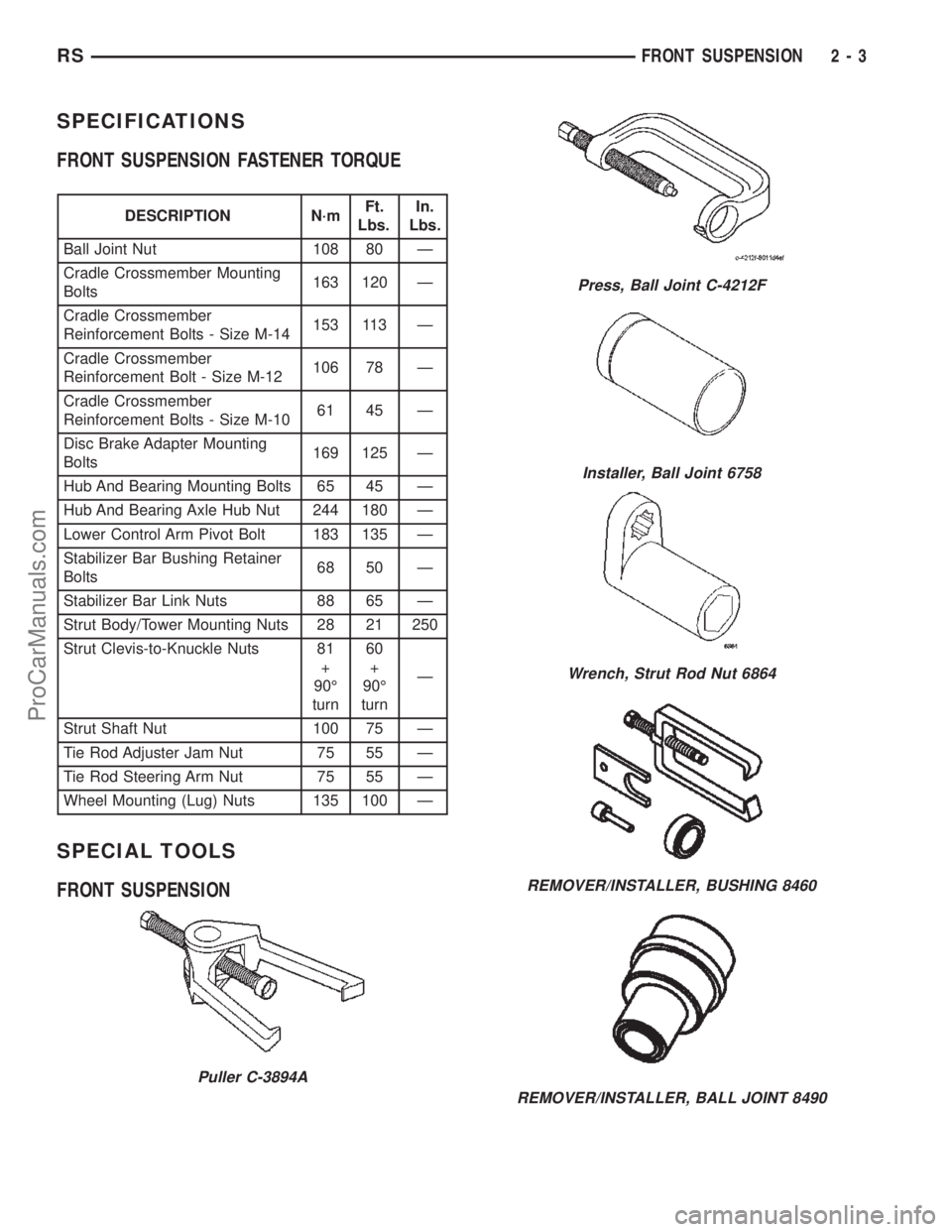

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Ball Joint Nut 108 80 Ð

Cradle Crossmember Mounting

Bolts163 120 Ð

Cradle Crossmember

Reinforcement Bolts - Size M-14153 113 Ð

Cradle Crossmember

Reinforcement Bolt - Size M-12106 78 Ð

Cradle Crossmember

Reinforcement Bolts - Size M-1061 45 Ð

Disc Brake Adapter Mounting

Bolts169 125 Ð

Hub And Bearing Mounting Bolts 65 45 Ð

Hub And Bearing Axle Hub Nut 244 180 Ð

Lower Control Arm Pivot Bolt 183 135 Ð

Stabilizer Bar Bushing Retainer

Bolts68 50 Ð

Stabilizer Bar Link Nuts 88 65 Ð

Strut Body/Tower Mounting Nuts 28 21 250

Strut Clevis-to-Knuckle Nuts 81

+

90É

turn60

+

90É

turnÐ

Strut Shaft Nut 100 75 Ð

Tie Rod Adjuster Jam Nut 75 55 Ð

Tie Rod Steering Arm Nut 75 55 Ð

Wheel Mounting (Lug) Nuts 135 100 Ð

SPECIAL TOOLS

FRONT SUSPENSION

Puller C-3894A

Press, Ball Joint C-4212F

Installer, Ball Joint 6758

Wrench, Strut Rod Nut 6864

REMOVER/INSTALLER, BUSHING 8460

REMOVER/INSTALLER, BALL JOINT 8490

RSFRONT SUSPENSION2-3

ProCarManuals.com

Page 35 of 2399

(4) Wipe any grease off the ball joint stem using a

clean shop towel with MopartBrake Parts Cleaner

applied to it.

CAUTION: Do not attempt to install a normal grease

zirc in the ball joint an lubricate the joint through

the zirc fitting.

(5) Reinstall steering knuckle on vehicle. (Refer to

2 - SUSPENSION/FRONT/KNUCKLE - INSTALLA-

TION)

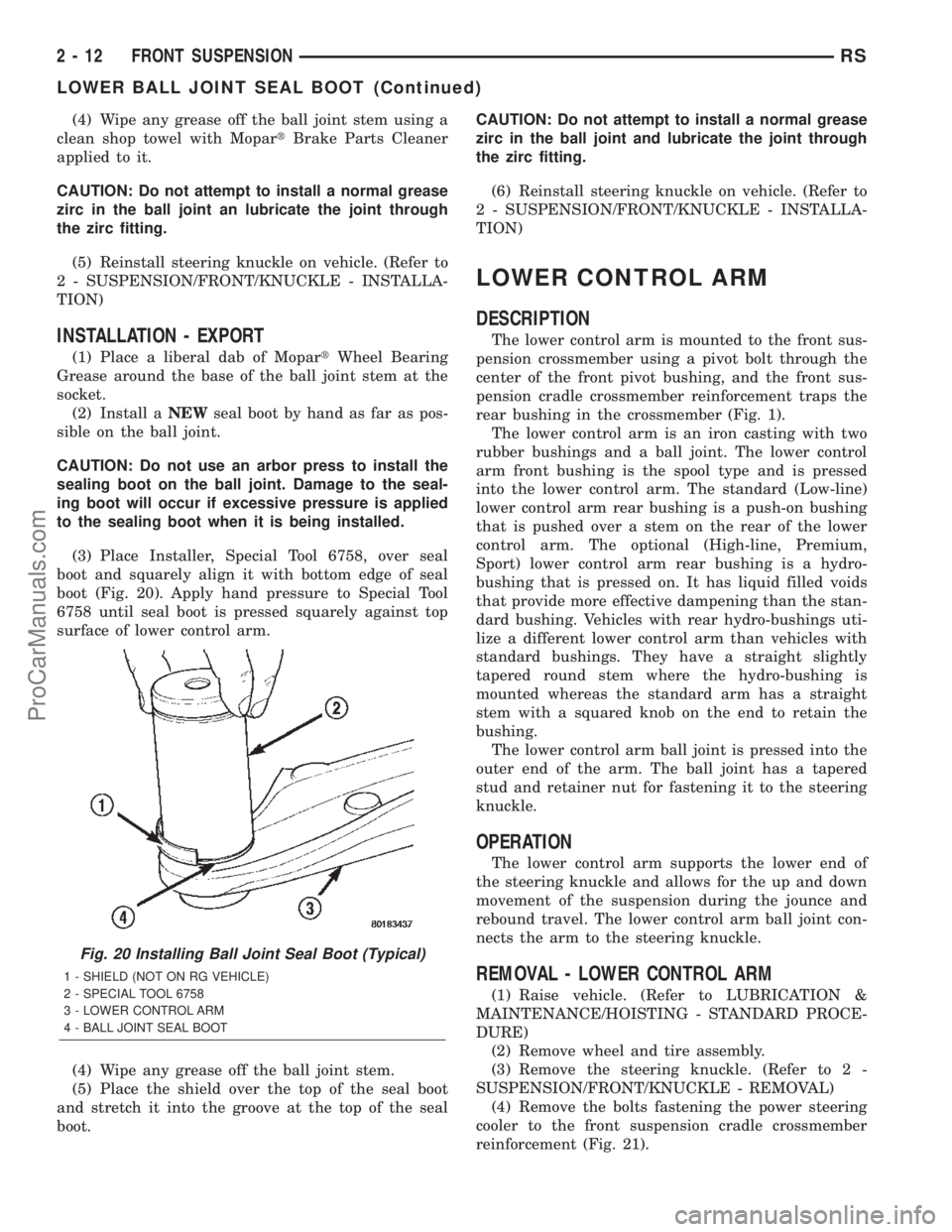

INSTALLATION - EXPORT

(1) Place a liberal dab of MopartWheel Bearing

Grease around the base of the ball joint stem at the

socket.

(2) Install aNEWseal boot by hand as far as pos-

sible on the ball joint.

CAUTION: Do not use an arbor press to install the

sealing boot on the ball joint. Damage to the seal-

ing boot will occur if excessive pressure is applied

to the sealing boot when it is being installed.

(3) Place Installer, Special Tool 6758, over seal

boot and squarely align it with bottom edge of seal

boot (Fig. 20). Apply hand pressure to Special Tool

6758 until seal boot is pressed squarely against top

surface of lower control arm.

(4) Wipe any grease off the ball joint stem.

(5) Place the shield over the top of the seal boot

and stretch it into the groove at the top of the seal

boot.CAUTION: Do not attempt to install a normal grease

zirc in the ball joint and lubricate the joint through

the zirc fitting.

(6) Reinstall steering knuckle on vehicle. (Refer to

2 - SUSPENSION/FRONT/KNUCKLE - INSTALLA-

TION)

LOWER CONTROL ARM

DESCRIPTION

The lower control arm is mounted to the front sus-

pension crossmember using a pivot bolt through the

center of the front pivot bushing, and the front sus-

pension cradle crossmember reinforcement traps the

rear bushing in the crossmember (Fig. 1).

The lower control arm is an iron casting with two

rubber bushings and a ball joint. The lower control

arm front bushing is the spool type and is pressed

into the lower control arm. The standard (Low-line)

lower control arm rear bushing is a push-on bushing

that is pushed over a stem on the rear of the lower

control arm. The optional (High-line, Premium,

Sport) lower control arm rear bushing is a hydro-

bushing that is pressed on. It has liquid filled voids

that provide more effective dampening than the stan-

dard bushing. Vehicles with rear hydro-bushings uti-

lize a different lower control arm than vehicles with

standard bushings. They have a straight slightly

tapered round stem where the hydro-bushing is

mounted whereas the standard arm has a straight

stem with a squared knob on the end to retain the

bushing.

The lower control arm ball joint is pressed into the

outer end of the arm. The ball joint has a tapered

stud and retainer nut for fastening it to the steering

knuckle.

OPERATION

The lower control arm supports the lower end of

the steering knuckle and allows for the up and down

movement of the suspension during the jounce and

rebound travel. The lower control arm ball joint con-

nects the arm to the steering knuckle.

REMOVAL - LOWER CONTROL ARM

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove wheel and tire assembly.

(3) Remove the steering knuckle. (Refer to 2 -

SUSPENSION/FRONT/KNUCKLE - REMOVAL)

(4) Remove the bolts fastening the power steering

cooler to the front suspension cradle crossmember

reinforcement (Fig. 21).

Fig. 20 Installing Ball Joint Seal Boot (Typical)

1 - SHIELD (NOT ON RG VEHICLE)

2 - SPECIAL TOOL 6758

3 - LOWER CONTROL ARM

4 - BALL JOINT SEAL BOOT

2 - 12 FRONT SUSPENSIONRS

LOWER BALL JOINT SEAL BOOT (Continued)

ProCarManuals.com

Page 39 of 2399

(2) Install NEW pivot bolt attaching front bushing

of lower control arm to front suspension cradle cross-

member (Fig. 29).Do not tighten or torque pivot

bolt at this time.

(3) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 22). Tighten the M-14 size bolts to a torque of

153 N´m (113 ft. lbs.). Tighten the M-12 size bolts to

a torque of 106 N´m (78 ft. lbs.).

(4) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten these

M-10 size bolts to a torque of 61 N´m (45 ft. lbs.).

(5) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 22). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(6) Install the power steering cooler (Fig. 21).

Tighten bolts to a torque of 11 N´m (100 in. lbs.).

(7) Reinstall steering knuckle, brake rotor and cal-

iper. (Refer to 2 - SUSPENSION/FRONT/KNUCKLE

- INSTALLATION)

CAUTION: When locating jack stands under lower

control arms, do not place the jack stands under

the ball joints (Fig. 30).

(8) Position jack stands under the lower control

arms as close to the ball joints as possible (Fig. 30).

Lower the vehicle onto the jack stands until the jack

stands are supporting the total weight of the vehicle.

(9) Tighten front lower control arm pivot bolt to a

torque of 183 N´m (135 ft. lbs.).(10) Install the wheel and tire assembly. Install

and tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(11) Raise vehicle, remove jack stands and lower

vehicle to the ground.

(12) Perform front wheel alignment as necessary.

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE)

STABILIZER BAR

DESCRIPTION

The stabilizer bar interconnects both front struts of

the vehicle and is attached to the front crossmember

(Fig. 1) .

Attachment of the stabilizer bar to the front cross-

member is through 2 rubber-isolator cushion bush-

ings and retainers. A double ball jointed stabilizer

bar link is used to attach each end of the stabilizer

bar to the front strut assemblies. All parts of the sta-

bilizer bar are replaceable as individual components.

The stabilizer bar to front crossmember cushion

bushings are split for easy removal and installation.

The split in the bushings should be positioned toward

the rear of the vehicle, with the square corner facing

down, when the stabilizer bar is installed.

OPERATION

Jounce and rebound movements affecting one

wheel are partially transmitted to the opposite wheel

of the vehicle through the stabilizer bar. This helps

Fig. 29 Lower Control Arm Bushing Pivot Bolt

Correctly Installed

1 - PIVOT BOLT

2 - LOWER CONTROL ARM

3 - FRONT SUSPENSION CRADLE CROSSMEMBER

Fig. 30 Jack Stands Supporting Vehicle Weight

1 - LOWER CONTROL ARMS

2 - BALL JOINT

3 - JACK STANDS

4 - BALL JOINT

2 - 16 FRONT SUSPENSIONRS

LOWER CONTROL ARM (Continued)

ProCarManuals.com

Page 41 of 2399

INSTALLATION

NOTE: Two different diameter stabilizer bars are

available for this vehicle. Therefore, two different

size bushings/cushions are also used. Use the cor-

rect bushing/cushion on the correct stabilizer bar.(1) If the stabilizer bar to front suspension cradle

bushings require replacement at time of inspection,

install new bushings before installing stabilizer bar.

Bushings are replaced by opening slit on bushings

and peeling them off stabilizer bar. Install new bush-

ings on stabilizer bar by spreading bushing at slit

and forcing them on the stabilizer bar.Bushings

must be installed on stabilizer bar so slit in

bushing will be facing toward the rear of vehi-

cle with the square corner toward the ground,

when the stabilizer bar is installed on the vehi-

cle (Fig. 35).

(2) Position stabilizer bar into front suspension

cradle so stabilizer bar bushings are aligned with

depressions in cradle. Install stabilizer bar bushing

retainers onto crossmember aligning raised bead on

retainer with cutouts in bushings (Fig. 36).Do not

tighten Stabilizer bar bushing retainers bolts at

this time.

(3) Check position of the stabilizer bar in the front

suspension cradle. The center of the curved section of

the stabilizer bar must be aligned with the raised

line in the center of the front suspension cradle (Fig.

37).

(4) Install the stabilizer bar link mounting stud

through the hole in each end of the stabilizer bar

(Fig. 33).

CAUTION: When installing the nut on the mounting

stud of the stabilizer bar link, do not allow the stud

to rotate in it's socket. Hold the stud from rotating

by placing an open-end wrench on the flat

machined into the stud (Fig. 33).

Fig. 33 Stabilizer Bar Link To Stabilizer Bar

Attachment

1 - RATCHET

2 - WRENCH

3 - STRUT

4 - STABILIZER BAR LINK

5 - NUT

6 - STABILIZER BAR

Fig. 34 Front Stabilizer Bar Retainers

1 - STEERING GEAR

2 - STABILIZER BAR

3 - RAISED BEAD

4 - FRONT CRADLE CROSSMEMBER

5 - RETAINERS

Fig. 35 Correctly Installed Stabilizer Bar To Cradle

Bushing

1 - SWAY BAR ISOLATOR BUSHING

2 - SLIT IN SWAY BAR BUSHING

3-SWAYBAR

2 - 18 FRONT SUSPENSIONRS

STABILIZER BAR (Continued)

ProCarManuals.com