sunroof CHRYSLER VOYAGER 2003 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 1077 of 2177

MULTI-FUNCTION SWITCH - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 W52 22BR/YL FRONT WIPER SWITCH MUX

2 G902 22VT/LB MULTI-FUNCTION SWITCH MUX RETURN

3 L305 20WT/LB TURN SIGNAL SWITCH MUX

4 G194 22VT/LG HIGH BEAM/FRONT WASHER SWITCH MUX

NATURAL VACUUM LEAK DETECTION ASSEMBLY (2.4L EXCEPT EXPORT) - LT. GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 Z166 18BK/WT GROUND

2 K107 20VT/WT NVLD SWITCH SIGNAL

3 K106 20VT/LB NVLD SOL CONTROL

OUTPUT SPEED SENSOR (EATX) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 T13 18DG/VT SPEED SENSOR GROUND

2 T14 18DG/BR OUTPUT SPEED SENSOR SIGNAL

OVERHEAD CONSOLE (EXCEPT BASE) - BLACK 12 WAY

CAV CIRCUIT FUNCTION

1 G23 20VT/DB (EXCEPT SUNROOF) SLIDING DOORS OVERHEAD SWITCH MUX

1 G23 22VT/DB (SUNROOF) SLIDING DOORS OVERHEAD SWITCH MUX

2 G25 20VT/TN (EXCEPT SUNROOF) LIFTGATE SWITCH MUX

2 G25 22VT/TN (SUNROOF) LIFTGATE SWITCH MUX

3 D25 20WT/VT PCI BUS

4 Z113 20BK/DB GROUND

5 A114 20GY/RD FUSED B(+) (I.O.D.)

6 F503 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

7 Z13 20BK/WT GROUND

8 E15 20OR/DB ASH/RECEIVER LAMP FEED

9- -

10 - -

11 L24 20BK/GY (EXCEPT EXPORT/

PREMIUM/LUXURY)AUTOMATIC HEADLAMP SWITCH SENSOR

12 L1 20BK/WT (PREMIUM/LUXURY) BACK-UP LAMP FEED

8W - 80 - 96 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1112 of 2177

SUNROOF MODULE (EXCEPT EXPORT) - BLACK 12 WAY

CAV CIRCUIT FUNCTION

1 Q3 20OR/TN SUNROOF VENT

2 Q5 20OR/LB SUNROOF CLOSE

3 Q4 20OR/YL SUNROOF OPEN

4 F302 18GY/PK FUSED ACCESSORY RELAY OUTPUT

5 A115 14YL/RD FUSED B(+)

6 Z138 14BK/DB GROUND

7- -

8- -

9- -

10 - -

11 - -

12 - -

SUNROOF SWITCH (EXCEPT EXPORT) - NATURAL 4 WAY

CAV CIRCUIT FUNCTION

1 Q3 20OR/TN SUNROOF VENT

2 Q4 20OR/YL SUNROOF OPEN

3 Z137 20BK/DB GROUND

4 Q5 20OR/LB SUNROOF CLOSE

THATCHAM ALARM MODULE (UNITED KINGDOM) - BLACK 16 WAY

CAV CIRCUIT FUNCTION

1 A645 20RD/VT REAR INTRUSION SENSOR SIGNAL

2 G640 20DG/VT FRONT INTRUSION SENSOR SIGNAL

3 G22 20YL VTSS INDICATOR SUPPLY

4- -

5 D97 20WT/OR SIREN SIGNAL OUTPUT

6 D96 20WT/LB SIREN SIGNAL CONTROL

7 F20 20PK/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

8 G944 20LB/BR SIREN SIGNAL RETURN

9 G945 20VT/DG SENSOR GROUND

10 G946 20LG/VT SENSOR GROUND

11 G922 20GY VTSS INDICATOR DRIVER

12 - -

13 D25 20WT/VT PCI BUS

14 - -

15 L91 22WT/DB HAZARD SWITCH SENSE

16 A600 20RD/LB SIREN SUPPLY

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 131

ProCarManuals.com

Page 1126 of 2177

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Right Sliding Door Lock

Motor/Ajar SwitchBK At Latch N/S

Right Sliding Door Motor BK At Sliding Door 44

Right Speed Control Switch BK At Steering Wheel N/S

Right Stop/Turn Signal Relay BK LT Quarter Panel N/S

Right Turn Signal Lamp OR At Lamp N/S

Right Visor/Vanity Lamp BK At Lamp N/S

Sentry Key Immobilizer Module BK At Steering Column 19, 20, 21, 22, 30

Siren (United Kingdom) BK Left Front Body N/S

Solenoid/Pressure Switch

Assembly (EATX)BK Side of Transmission 14, 18

Speed Control Servo BK Near Controller Antilock Brake 11, 18

Sunroof Module BK At Sunroof N/S

Sunroof Switch Nat Near Overhead Console N/S

Thatcham Alarm Module C1 BK Top Right Side of Instrument Panel

Near SpeakerN/S

Thatcham Alarm Module C1 WT Top Right Side of Instrument Panel

Near SpeakerN/S

Throttle Position Sensor GY On Throttle Body 10, 11, 17

Torque Converter Clutch Solenoid BK Front of Transmission 11

Traction Control Switch BK Rear of Swtich 20, 21, 30

Trailer Tow Connector BK Left Quarter Panel N/S

Transmission Control Module BK Left Engine Compartment 5

Transmission Range Sensor GY Top of Transmission 14, 18

Turbo boost Pressure Sensor On Cylinder Block 15

Vehicle Speed Sensor BK Rear of Transmission 10, 16

Washer Fluid Level Switch BK Bottom of Reservoir 3

Water in Fuel Sensor (Diesel) Left Rear Engine Compartment N/S

Wiper Module BK Left Side Cowl 6

GROUNDS

GROUND NUMBER LOCATION FIG.

G100 Body Ground Near Powertrain Control Module N/S

G101 Above Starter 11, 13

G102 Left Headlamp Area 1

G103 Above Starter 11, 13

G200 Right Side of Instrument Panel 19, 23, 28

G201 Right Side of Instrument Panel 19, 23, 28

G202 Near Radio N/S

G300 Left B Pillar 31

G301 Right B Pillar 32, 38

G302 Left Rear Quarter 46

G400 Liftgate Ground N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-11

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1734 of 2177

BODY

TABLE OF CONTENTS

page page

BODY

DESCRIPTION - VEHICLE IDENTIFICATION....1

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 2

DIAGNOSIS AND TESTING - WIND NOISE . . . 3

STANDARD PROCEDURE

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR........................3

STANDARD PROCEDURE - HEAT STAKING . 10

SPECIFICATIONS

TORQUE............................11

BODY LUBRICATION...................12

SPECIAL TOOLS

BODY..............................13DOOR - FRONT.........................14

DOORS - SLIDING.......................24

DECKLID/HATCH/LIFTGATE/TAILGATE.......39

EXTERIOR.............................44

HOOD.................................59

INSTRUMENT PANEL.....................62

INTERIOR..............................72

PAINT.................................83

SEATS................................85

STATIONARY GLASS....................105

WEATHERSTRIP/SEALS..................110

SUNROOF.............................113

BODY STRUCTURE.....................121

BODY

DESCRIPTION - VEHICLE IDENTIFICATION

Throughout this group, references to the

DaimlerChrysler Corporation vehicle family identifi-

cation code are used when describing a procedure

that is unique to that vehicle. Refer to Introduction

Group of this manual for detailed information on

vehicle identification. If a procedure is common to all

vehicles covered in this manual, no reference will be

made to a vehicle family code.

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE THATIS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.

Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to fin-

ish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

RSBODY23-1

ProCarManuals.com

Page 1745 of 2177

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Luggage rack crossbar fasteners 4 Ð 35

Lumbar support handle screw 1 Ð 9

Pivot bolt to the body half of hood hinge 28 21 Ð

Prop assembly to lifgate bolts 28 21 Ð

Rear door glass to regulator bolt 11 8 Ð

Rear door hinge to B-pillar bolt 28 20 Ð

Rear door hinge to door bolt 28 20 Ð

Rear door latch striker 28 20 Ð

Rear latch to sliding door end frame 28 20 Ð

Rear seat back to seat cushion bolt 27 19 Ð

Recliner to seat back frame 12 9 Ð

Seatback frame upper rail 8 Ð 71

Seatback hinge bolt 48 35 Ð

Seatback hinge cover screws 2.3 Ð 20

Shoulder belt turning loop onto height adjuster 39 29 Ð

Side view mirror bolts 10 Ð 85

Sliding door center hinge adjusting bolt 15 Ð 130

Sliding door glass nuts 3.4 Ð 30

Sliding door latch striker 28 21 Ð

Sliding door to roller arm bracket 12 9 Ð

Storage bin track guide to seat riser 3.5 Ð 31

Sunroof opening panel to lifter arm screws 5 44

Sunroof opening panel motor screws 4 35

Sunroof trough bracket to roof bolts 6 53

Sunroof trough to trough bracket bolts 6 53

Sunroof trough bracket bolts 6 53

Support cylinders to liftgate 28 21 Ð

BODY LUBRICATION

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a com-

ponent, any excess oil or grease should be removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

23 - 12 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1846 of 2177

SUNROOF

TABLE OF CONTENTS

page page

SUNROOF

DESCRIPTION........................113

DIAGNOSIS AND TESTING - SUNROOF.....113

DRAIN TUBE

REMOVAL............................116

INSTALLATION........................117

GLASS PANEL

REMOVAL............................117

INSTALLATION........................117

ADJUSTMENTS

SUNROOF GLASS PANEL ADJUSTMENT . . 117

SUNROOF ASSEMBLY

REMOVAL............................117

INSTALLATION........................117

SUNSHADE

REMOVAL............................117INSTALLATION........................118

WIND DEFLECTOR

REMOVAL............................118

INSTALLATION........................118

WATER CHANNEL

REMOVAL............................118

INSTALLATION........................118

SUNROOF MOTOR

REMOVAL............................118

INSTALLATION........................118

ADJUSTMENTS

ADJUSTMENT.......................119

SUNROOF SWITCH

REMOVAL............................120

INSTALLATION........................120

SUNROOF

DESCRIPTION

WARNING: Keep fingers and other body parts out

of sunroof opening at all times.

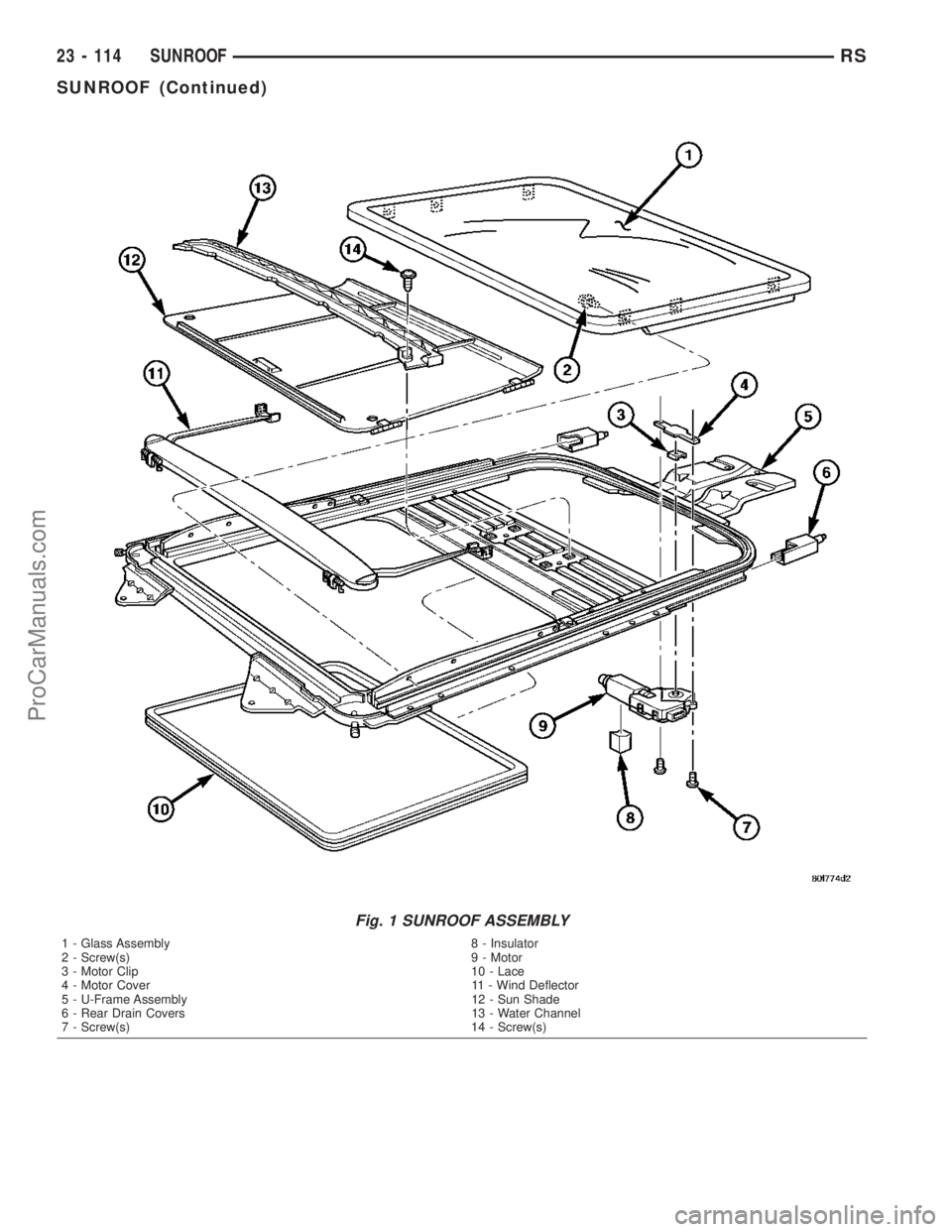

The sun roof features consists of: (Fig. 1)

²Sun roof glass

²Sun roof sun shade

The sunroof power sliding glass panel and sun-

shade can be positioned anywhere along its travel,

rearward of glass panel front edge.

The sunroof is electrically operated from a switch

located in the overhead console. To operate the sun-

roof the ignition switch must be in the Accessory or

On/Run position. Both switchs are a rocker style

design that open or close the sunroof. When pressing

and releasing the open button once, the sunroof will

express open to the comfort stop and the wind deflec-

tor will raise. If the button is pressed a second time,

the sunroof will continue to open to full travel unless

the button is released, at which time it will stop in

that position. Pressing and holding the close button

will close the sunroof. If the close button is released

before the glass fully closes, the sunroof will stop in

that position. The vent switch operates in a similar

manor. The sunroof will also operate for up to fifteen

minutes after the ignition key is turned off for cus-

tomer comfort and convenance while parking.

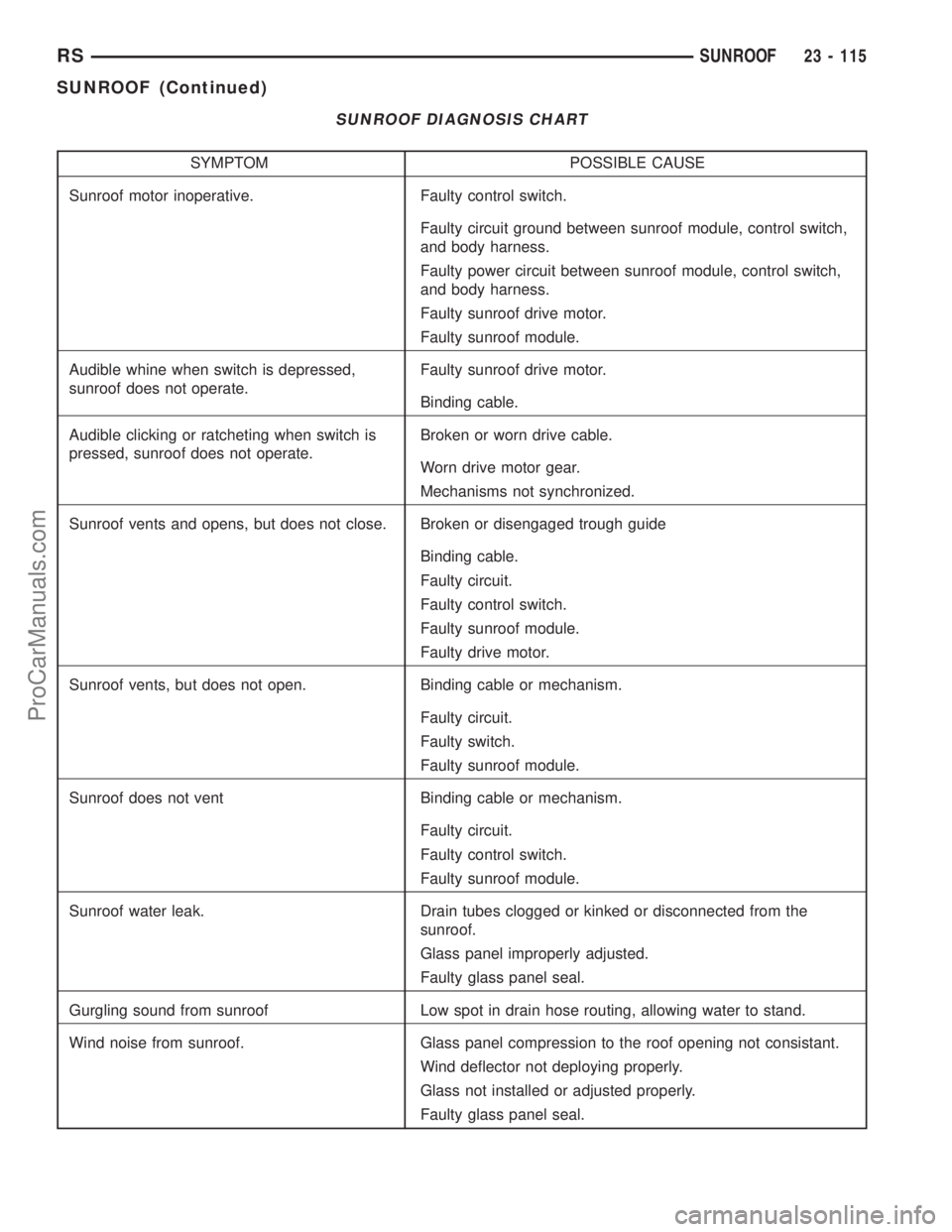

DIAGNOSIS AND TESTING - SUNROOF

Refer to Sunroof Diagnostic Chart for possible

causes. Before beginning sunroof diagnostics verify

that all other power accessories are in proper operat-

ing condition. If not, a common electrical problem

may exist. Refer to Wiring Diagrams, in this publica-

tion for circuit, splice and component descriptions.

Check the condition of the circuit protection (20 amp

circuit breaker in the Junction Block). Inspect all

wiring connector pins for proper engagement and

continuity. Check for battery voltage at the power

sunroof controller, refer to Wiring Diagrams, for cir-

cuit information. If battery voltage of more than 10

volts is detected at the controller, proceed with the

following tests (the controller will not operate at less

than 10 volts).

Before beginning diagnosis for wind noise or water

leaks, verify that the problem was not caused by

releasing the control switch before the sunroof was

fully closed. The sunroof module has a water-man-

agement system. If however, the sunroof glass is in a

partial closed position, high pressure water may be

forced beyond the water management system bound-

aries and onto the headlining.

RSSUNROOF23 - 113

ProCarManuals.com

Page 1847 of 2177

Fig. 1 SUNROOF ASSEMBLY

1 - Glass Assembly 8 - Insulator

2 - Screw(s) 9 - Motor

3 - Motor Clip 10 - Lace

4 - Motor Cover 11 - Wind Deflector

5 - U-Frame Assembly 12 - Sun Shade

6 - Rear Drain Covers 13 - Water Channel

7 - Screw(s) 14 - Screw(s)

23 - 114 SUNROOFRS

SUNROOF (Continued)

ProCarManuals.com

Page 1848 of 2177

SUNROOF DIAGNOSIS CHART

SYMPTOM POSSIBLE CAUSE

Sunroof motor inoperative. Faulty control switch.

Faulty circuit ground between sunroof module, control switch,

and body harness.

Faulty power circuit between sunroof module, control switch,

and body harness.

Faulty sunroof drive motor.

Faulty sunroof module.

Audible whine when switch is depressed,

sunroof does not operate.Faulty sunroof drive motor.

Binding cable.

Audible clicking or ratcheting when switch is

pressed, sunroof does not operate.Broken or worn drive cable.

Worn drive motor gear.

Mechanisms not synchronized.

Sunroof vents and opens, but does not close. Broken or disengaged trough guide

Binding cable.

Faulty circuit.

Faulty control switch.

Faulty sunroof module.

Faulty drive motor.

Sunroof vents, but does not open. Binding cable or mechanism.

Faulty circuit.

Faulty switch.

Faulty sunroof module.

Sunroof does not vent Binding cable or mechanism.

Faulty circuit.

Faulty control switch.

Faulty sunroof module.

Sunroof water leak. Drain tubes clogged or kinked or disconnected from the

sunroof.

Glass panel improperly adjusted.

Faulty glass panel seal.

Gurgling sound from sunroof Low spot in drain hose routing, allowing water to stand.

Wind noise from sunroof. Glass panel compression to the roof opening not consistant.

Wind deflector not deploying properly.

Glass not installed or adjusted properly.

Faulty glass panel seal.

RSSUNROOF23 - 115

SUNROOF (Continued)

ProCarManuals.com

Page 1849 of 2177

SYMPTOM POSSIBLE CAUSE

Buzz, Squeak,Rattles from sunroof Loose or broken attaching hardware.

No lubracation in track.

Worn or broken mechanism.

Cables bunched or kinked

Sunshade will not function or does not

operate smoothlySunshade feet are missing, broken or loose.

No lubracation in track.

Track obstructions or interference.

Glass movement not consistant or glass does

not operate smoothlyGlass and Track timing.

Glass and Track alignment

Cables and Guide alignment

WATER DRAINAGE AND WIND NOISE DIAGNOSIS

The sliding glass panel is designed to seal water

entry with a snug fit between the roof and the seal.

The fit can be checked by inserting a piece of paper

between the roof and the seal. The piece of paper

should have some resistance when pulled out when

the glass panel is in the closed position. The sunroof

housing will drain off a minimum amount of water.

Excessive wind noise could result if the gap clear-

ances are exceeded. The sunroof glass panel may

need to be adjusted. Refer to Sunroof Glass Panel

Adjustment for proper procedures.

Adequate drainage is provided by a drain trough in

the sunroof housing which encircles the sliding glass

panel and leads to drain hoses. If a wet headliner or

other water leak complaints are encountered, before

performing any adjustments, first ensure that the

drainage system is not plugged or disconnected. Use

a pint container to pour water into the sunroof hous-

ing drain trough. If water flow is restricted, use com-

pressed air to blow out any material plugging the

drain system. Retest system again.

To further check for a disconnected drain hose:

(1) Remove A-pillar trim, sun visors, and map

lamps/mini console.

(2) Remove sunroof opening trim lace. Refer to

Sunroof Opening Trim Lace.

NOTE: Care must be taken not to fold or kink the

headliner upon removal.

(3) Lower headliner as necessary to gain access to

sunroof housing drain tubes. Refer to Headlining

Removal and Installation for proper procedures.

(4) Repair as necessary.

DRAIN TUBE

REMOVAL

FRONT HOSES

NOTE: Front A-pillars are filled with sound deaden-

ing foam and the front drain tubes are sealed into

the pillars.

(1) Move glass panel to the fully closed position.

(2) Disconnect negative battery cable.

(3) Remove headliner (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL).

(4) Disconnect the drain hose from the sunroof

housing (Fig. 1).

(5) Drain any liquid from hose connection, repair

as necessary.

REAR HOUSING HOSE

(1) Move glass panel to the fully closed position.

(2) Disconnect negative battery cable.

(3) Remove headliner (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL).

(4) Remove third seat or seats from vehicle.

(5) Remove second seat belt lower anchor.

(6) Remove third seat lower anchor.

(7) Remove quarter trim bolster.

(8) Remove trim panel screws.

(9) Remove quarter trim panel

(10) Disconnect the drain hose from the sunroof

housing. (Fig. 1).

(11) Drain any liquid from hose connection, if nec-

essary, and remove tube.

23 - 116 SUNROOFRS

SUNROOF (Continued)

ProCarManuals.com

Page 1850 of 2177

INSTALLATION

FRONT HOSES

(1) Connect the new drain hose to the sunroof

housing and test drainage (Fig. 1).

(2) Install headliner (Refer to 23 - BODY/INTERI-

OR/HEADLINER - INSTALLATION).

(3) Install sunroof opening trim lace.

(4) Connect the control switch wire connector and

install control switch.

(5) Verify sunroof operation and alignment.

REAR HOUSING HOSE

(1) Connect the new drain hose to the sunroof

housing and test drainage (Fig. 1).

(2) Install headliner(Refer to 23 - BODY/INTERI-

OR/HEADLINER - INSTALLATION).

(3) Install sunroof opening trim lace.

(4) Connect the control switch wire connector and

install control switch.

(5) Verify sunroof operation and alignment.

GLASS PANEL

REMOVAL

(1) Move the glass panel to the vent position.

(2) Slide sunshade rearward to the open position.

(3) Remove the glass panel screws (Fig. 1).

(4) Lift off glass panel and remove from vehicle.

INSTALLATION

(1) Position glass panel on to mechanism lift arms.

(2) Start the attaching screws, and hand tighten

(Fig. 1).

(3) Adjust sunroof glass to fit flush with roof

line(Refer to 23 - BODY/SUNROOF/GLASS PANEL -

ADJUSTMENTS).

(4) Verify sunroof operation and alignment.

ADJUSTMENTS

SUNROOF GLASS PANEL ADJUSTMENT

(1) Move the sunshade rearward to the open posi-

tion.

(2) Move the sunroof glass panel to the fully closed

position.

(3) Loosen the forward attaching screws on each

side enough to make the front of the glass to adjust

up or down.

(4) Adjust the front surface of the sunroof glass

panel 0.00 mm to 1.75 mm (0.00 in. to 0.07 in.) below

the top surface of the roof.

(5) Tighten the front glass panel attaching screws

to 3.5 N´m (31 in. lbs.) torque (Fig. 1).(6) Loosen the rear screws on each side enough to

make the rear adjustment (Fig. 1).

(7) Adjust the rear surface of the sunroof glass

panel 0.00 mm to 1.75 mm (0.03 in. to 0.07 in.) above

the top surface of the roof.

(8) Tighten the rear glass panel attaching screws

to 3.5 N´m (31 in. lbs.) torque (Fig. 1).

(9) Check for proper fit. If not OK, repeat glass

panel adjustment.

SUNROOF ASSEMBLY

REMOVAL

(1) Move glass panel to the fully closed position.

(2) Disconnect battery negative cable.

(3) Remove headliner (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL).

(4) Disconnect the four drain tubes from sunroof

housing (Fig. 1).

(5) Loosen fasteners attaching sunroof assembly

(Fig. 1).

(6) With the aid of a helper, support the sunroof

and remove the fasteners attaching sunroof assembly

to roof panel (Fig. 1).

(7) Remove sunroof from vehicle.

INSTALLATION

(1) Raise sunroof module assembly and guide it

carefully into position.

(2) While supporting the sunroof assembly tighten

the attaching screws (Fig. 1). Tighten to 6 N´m (53

in. lbs.) torque.

(3) Connect the drain tubes to the sunroof (Fig. 1).

(4) Connect battery negative cable.

(5) Test sunroof operation, adjust as necessary(Re-

fer to 23 - BODY/SUNROOF/GLASS PANEL -

ADJUSTMENTS).

(6) Install headliner (Refer to 23 - BODY/INTERI-

OR/HEADLINER - INSTALLATION).

(7) Install sunroof opening trim lace position(Refer

to 23 - BODY/SUNROOF/OPENING TRIM LACE -

INSTALLATION).

SUNSHADE

REMOVAL

(1) Place the sunroof glass panel in the vent posi-

tion.

(2) Remove glass panel (Refer to 23 - BODY/SUN-

ROOF/GLASS PANEL - REMOVAL).

(3) Remove water channel (Fig. 1).

(4) Cycle sunroof motor to the open position.

(5) Move sunshade towards the closed position

stopping three to four inches from the closed position.

RSSUNROOF23 - 117

DRAIN TUBE (Continued)

ProCarManuals.com