ESP inoperative CHRYSLER VOYAGER 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 333 of 2177

Refer to the appropriate Powertrain Diagnostic Man-

ual and the DRBIIItscan tool.

(1) Install PCM module to the mounting bracket.

(2) Install electrical connectors and lock.

(3) Install the splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.

(6) Using DRBIIItscan tool, program mileage and

vehicle identification number (VIN) into PCM. Refer

to the DRBIIItscan tool and the appropriate Power-

train Diagnostic Manual.

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a

microprocessor. The SKIM retains in memory the ID

numbers of any Sentry Key that is programmed to it.

The maximum number of keys that may be pro-

grammed to each module is eight (8). The SKIM also

communicates over the Programmable Communica-

tion Interface (PCI) data bus with the Powertrain

Control Module (PCM), the Body Control Module

(BCM), the Mechanical Instrument Cluster (MIC),

and the DRB IIItscan tool. The SKIM transmits and

receives RF signals through a tuned antenna

enclosed within a molded plastic ring formation that

is integral to the SKIM housing. When the SKIM is

properly installed on the steering column, the

antenna ring fits snugly around the circumference of

the ignition lock cylinder housing. If this ring is not

mounted properly, communication problems may

arise in the form of transponder-related faults.

For added system security, each SKIM is pro-

grammed with a unique9Secret Key9code. This code

is stored in memory and is sent over the PCI bus to

the PCM and to each key that is programmed to

work with the vehicle. The9Secret Key9code is there-

fore a common element found in all components of

the Sentry Key Immobilizer System (SKIS). In the

event that a SKIM replacement is required, the

9Secret Key9code can be restored from the PCM by

following the SKIM replacement procedure found in

the DRB IIItscan tool. Proper completion of this

task will allow the existing ignition keys to be repro-

grammed. Therefore, new keys will NOT be needed.

In the event that the original9Secret Key9code can

not be recovered, new ignition keys will be required.

The DRB IIItscan tool will alert the technician if

key replacement is necessary. Another security code,

called a PIN, is used to gain secured access to the

SKIM for service. The SKIM also stores in its mem-

ory the Vehicle Identification Number (VIN), which itlearns through a bus message from the assembly

plant tester. The SKIS scrambles the information

that is communicated between its components in

order to reduce the possibility of unauthorized SKIM

access and/or disabling.

OPERATION

When the ignition switch is moved to the RUN

position, the Sentry Key Immobilizer Module (SKIM)

transmits an Radio Frequency (RF) signal to the

transponder in the ignition key. The SKIM then

waits for a response RF signal from the transponder

in the key. If the response received identifies the key

as valid, the SKIM sends a9valid key9message to

the Powertrain Control Module (PCM) over the Pro-

grammable Communication Interface (PCI) data bus.

If the response received identifies the key as invalid

or no response is received from the transponder in

the ignition key, the SKIM sends an9invalid key9

message to the PCM. The PCM will enable or disable

engine operation based upon the status of the SKIM

messages. It is important to note that the default

condition in the PCM is9invalid key.9Therefore, if no

response is received by the PCM, the engine will be

immobilized after two (2) seconds of running.

The SKIM also sends indicator light status mes-

sages to the Mechanical Instrument Cluster (MIC) to

operate the light. This is the method used to turn the

light ON solid or to flash it after the indicator light

test is complete to signify a fault in the SKIS. If the

light comes ON and stays ON solid after the indica-

tor light test, this signifies that the SKIM has

detected a system malfunction and/or that the SKIS

has become inoperative. If the SKIM detects an

invalid keyORa key-related fault exists, the indica-

tor light will flash following the indicator light test.

The SKIM may also request an audible chime if the

customer key programming feature is available and

the procedure is being utilized (Refer to 8 - ELEC-

TRICAL/VEHICLE THEFT SECURITY/TRANSPON-

DER KEY - STANDARD PROCEDURE).

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove Lower Instrument Panel Cover. Refer

to Body, Instrument Panel, Lower Instrument Panel

Cover, Removal.

(3) Remove the steering column upper and lower

shrouds. Refer to Steering, Column, Column Shroud,

Removal.

(4) Disengage the steering column wire harness

from the Sentry Key Immobilizer Module (SKIM).

(5) Remove the one screws securing the SKIM to

the steering column.

8E - 18 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 408 of 2177

INSTRUMENT CLUSTER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

INSTRUMENT CLUSTER

INOPERATIVE. NO

RESPONSE FROM

INSTRUMENT CLUSTER.NO PCI BUS MESSAGES

FROM THE BCM.USE A DRB IIITSCAN TOOL TO CHECK THE BCM.

IF OK, LOOK FOR ANOTHER POSSIBLE CAUSE

FOR CLUSTER FAILURE. IF NOT OK, REFER TO

THE PROPER BODY DIAGNOSTIC PROCEDURES

MANUAL.

SPREAD TERMINAL(S)

ON WIRING HARNESS

CLUSTER CONNECTOR.REMOVE CLUSTER FROM INSTRUMENT PANEL

AND CHECK WIRING HARNESS CONNECTOR FOR

SPREAD TERMINAL. IF OK, LOOK FOR ANOTHER

POSSIBLE CAUSE FOR THE CLUSTER FAILURE. IF

NOT OK, REPAIR CONNECTOR.

BCM IS NOT RECEIVING

PROPER INPUT FROM

THE IGNITION SWITCH.1. USE A DRB IIITSCAN TOOL TO VERIFY IGNITION

SWITCH STATUS INTO THE BCM. IF NOT OK, GO

TO STEP (2). IF OK, LOOK AT ANOTHER POSSIBLE

CAUSE OF FAILURE.

2. CHECK IGNITION SWITCH FUNCTION AND

WIRING.

INTERNAL CLUSTER

FAILURE.REPLACE CLUSTER.

WAKE UP CIRCUIT

FAULTY.VERIFY CONTINUITY OF WAKE UP CIRCUIT FROM

BCM TO MIC. CIRCUIT SHALL BE LOW WHENEVER

BCM IS AWAKE.

POWER OR GROUND

MISSING.IF NO RESPONSE FROM THE MIC, CHECK FOR

POWER AND GROUND AT THE MIC CONNECTOR.

REFER TO WIRING DIAGRAMS FOR CONNECTOR

CALL OUTS.

RSINSTRUMENT CLUSTER8J-3

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 453 of 2177

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER

Compass Mini-Trip Computer (CMTC) and Com-

pass Temperature (CT) data is obtained from the

Body Control Module (BCM) on the J1850 Data Bus

circuit. The CMTC and CT will display dashes (- -)

for any of the screens it did not receive the bus mes-

sages. The label corresponding to the missing infor-

mation will be lit. If no compass mini-trip computer

data is displayed, check the J1850 Data Bus circuit

communications and the BCM. If the brightness level

is improper check the J1850 Data Bus circuit.

The DRB IIItis recommended for checking the

J1850 Data Bus circuit and the BCM. Perform the

CMTC, CT self diagnosis before replacing the CMTC

or CT module.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove overhead console(Refer to 8 - ELEC-

TRICAL/OVERHEAD CONSOLE - REMOVAL).

(3) Remove the screws holding Compass Mini-Trip

Computer module in the overhead console.

(4) Remove CMTC module from console assembly.

INSTALLATION

(1) Position the compass mini-trip computer mod-

ule in the overhead console.

(2) Install the ten screws holding the compass

mini-trip computer module in the overhead console.

(3) Install the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - INSTALLA-

TION).

(4) Connect the battery negative cable.

NOTE: If a new EVIC module has been installed, the

compass will have to be calibrated and the variance

set. Refer to compass variation adjustment and

compass calibration in standard procedures.

UNIVERSAL TRANSMITTER

DESCRIPTION

On some RS models a Universal Transmitter trans-

ceiver is standard factory-installed equipment. The

universal transmitter transceiver is integral to the

Electronic Vehicle Information Center (EVIC) and the

Compass Mini-Trip Computer (CMTC) modules,

which is located in the overhead console. The only

visible component of the universal transmitter are

the three transmitter push buttons centered between

the modules push buttons located just rearward of

the display screen in the overhead console. The threeuniversal transmitter push buttons are identified

with one, two or three light indicators so that they be

easily identified by sight or by feel.

Each of the three universal transmitter push but-

tons controls an independent radio transmitter chan-

nel. Each of these three channels can be trained to

transmit a different radio frequency signal for the

remote operation of garage door openers, motorized

gate openers, home or office lighting, security sys-

tems or just about any other device that can be

equipped with a radio receiver in the 286 to 399

MegaHertz (MHz) frequency range for remote opera-

tion. The universal transmitter is capable of operat-

ing systems using either rolling code or non-rolling

code technology.

The electronics module displays messages and a

small house-shaped icon with one, two or three dots

corresponding to the three transmitter buttons to

indicate the status of the universal transmitter. The

EVIC messages are:

²Cleared Channels- Indicates that all of the

transmitter codes stored in the universal transmitter

have been successfully cleared.

²Training- Indicates that the universal trans-

mitter is in its transmitter learning mode.

²Trained- Indicates that the universal transmit-

ter has successfully acquired a new transmitter code.

²Transmit- Indicates that a trained universal

transmitter button has been depressed and that the

universal transmitter is transmitting.

The universal transmitter cannot be repaired, and

is available for service only as a unit with the EVIC

or CMTC modules. If any of these components is

faulty or damaged, the complete EVIC or CMTC

module must be replaced.

OPERATION

The universal transmitter operates on a non-

switched source of battery current so the unit will

remain functional, regardless of the ignition switch

position. For more information on the features, pro-

gramming procedures and operation of the universal

transmitter, see the owner's manual in the vehicle

glove box.

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER

If the Universal Transmitter is inoperative, but the

Electronic Vehicle Information Center (EVIC) is oper-

ating normally, see the owner's manual in the vehicle

glove box for instructions on training the Transmit-

ter. Retrain the Transmitter with a known good

transmitter as instructed in the owner's manual and

test the Transmitter operation again. If the unit is

still inoperative, test the universal transmitter with

Radio Frequency Detector special tool. If both the

8M - 10 MESSAGE SYSTEMSRS

COMPASS/MINI-TRIP COMPUTER (Continued)

ProCarManuals.com

Page 454 of 2177

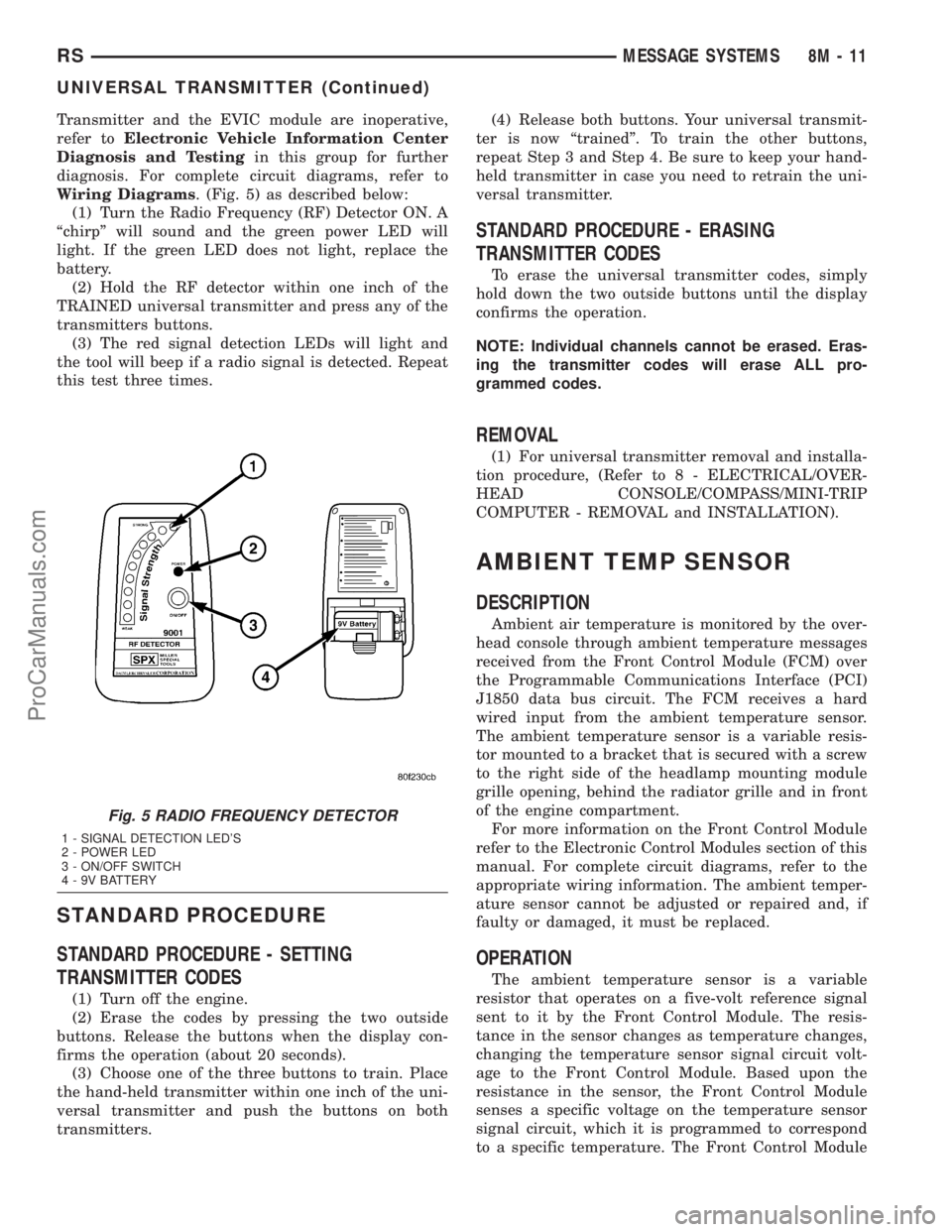

Transmitter and the EVIC module are inoperative,

refer toElectronic Vehicle Information Center

Diagnosis and Testingin this group for further

diagnosis. For complete circuit diagrams, refer to

Wiring Diagrams. (Fig. 5) as described below:

(1) Turn the Radio Frequency (RF) Detector ON. A

ªchirpº will sound and the green power LED will

light. If the green LED does not light, replace the

battery.

(2) Hold the RF detector within one inch of the

TRAINED universal transmitter and press any of the

transmitters buttons.

(3) The red signal detection LEDs will light and

the tool will beep if a radio signal is detected. Repeat

this test three times.

STANDARD PROCEDURE

STANDARD PROCEDURE - SETTING

TRANSMITTER CODES

(1) Turn off the engine.

(2) Erase the codes by pressing the two outside

buttons. Release the buttons when the display con-

firms the operation (about 20 seconds).

(3) Choose one of the three buttons to train. Place

the hand-held transmitter within one inch of the uni-

versal transmitter and push the buttons on both

transmitters.(4) Release both buttons. Your universal transmit-

ter is now ªtrainedº. To train the other buttons,

repeat Step 3 and Step 4. Be sure to keep your hand-

held transmitter in case you need to retrain the uni-

versal transmitter.

STANDARD PROCEDURE - ERASING

TRANSMITTER CODES

To erase the universal transmitter codes, simply

hold down the two outside buttons until the display

confirms the operation.

NOTE: Individual channels cannot be erased. Eras-

ing the transmitter codes will erase ALL pro-

grammed codes.

REMOVAL

(1) For universal transmitter removal and installa-

tion procedure, (Refer to 8 - ELECTRICAL/OVER-

HEAD CONSOLE/COMPASS/MINI-TRIP

COMPUTER - REMOVAL and INSTALLATION).

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the over-

head console through ambient temperature messages

received from the Front Control Module (FCM) over

the Programmable Communications Interface (PCI)

J1850 data bus circuit. The FCM receives a hard

wired input from the ambient temperature sensor.

The ambient temperature sensor is a variable resis-

tor mounted to a bracket that is secured with a screw

to the right side of the headlamp mounting module

grille opening, behind the radiator grille and in front

of the engine compartment.

For more information on the Front Control Module

refer to the Electronic Control Modules section of this

manual. For complete circuit diagrams, refer to the

appropriate wiring information. The ambient temper-

ature sensor cannot be adjusted or repaired and, if

faulty or damaged, it must be replaced.

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the Front Control Module. The resis-

tance in the sensor changes as temperature changes,

changing the temperature sensor signal circuit volt-

age to the Front Control Module. Based upon the

resistance in the sensor, the Front Control Module

senses a specific voltage on the temperature sensor

signal circuit, which it is programmed to correspond

to a specific temperature. The Front Control Module

Fig. 5 RADIO FREQUENCY DETECTOR

1 - SIGNAL DETECTION LED'S

2 - POWER LED

3 - ON/OFF SWITCH

4 - 9V BATTERY

RSMESSAGE SYSTEMS8M-11

UNIVERSAL TRANSMITTER (Continued)

ProCarManuals.com

Page 542 of 2177

AUTOMATIC SPEED CONTROL OVERSPEED

REDUCTION

DESCRIPTION

Transmission control software includes an auto-

matic speed control overspeed reduction feature. This

maintains vehicle speed at the selected set point

when descending a grade.

OPERATION

The TCM (on SBEC vehicles) (PCM on NGC vehi-

cles) first senses that the speed control is set. If the

set speed is exceeded by more than 4 mph (6.5

km/hr) and the throttle is closed, the TCM (on SBEC

vehicles) (PCM on NGC vehicles) causes the trans-

axle to downshift to THIRD gear. After downshifting,

the automatic speed control resumes normal opera-

tion. To ensure that an upshift is appropriate after

the set speed is reached, the TCM (on SBEC vehi-

cles) (PCM on NGC vehicles) waits until the speed

control system opens the throttle at least 6 degrees

before upshifting to OVERDRIVE again.

If the driver applies the brakes, canceling auto-

matic speed control operation with the transaxle still

in THIRD gear, the TCM (on SBEC vehicles) (PCM

on NGC vehicles) maintains this gear until the driver

opens the throttle at least 6 degrees to avoid an inap-

propriate upshift. The upshift is also delayed for 2.5

seconds after reaching the 6 degrees throttle opening

in anticipation that the driver might open the throt-

tle enough to require THIRD gear. This will avoid

unnecessary and disturbing transmission cycling. If

the automatic speed control RESUME feature is used

after braking, the upshift is delayed until the set

speed is achieved to reduce cycling and provide bet-

ter response.

DIAGNOSIS AND TESTING - ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road test

should include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to the Instru-

ment Cluster for speedometer diagnosis.

If a road test verifies an inoperative system, and

the speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose or corroded electrical connections at the

servo. Corrosion should be removed from electrical

terminals and a light coating of Mopar Multipurpose

Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment at both ends of the speed

control servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Conduct electrical test at PCM.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SPECIFICATIONS - TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Servo Mounting Bracket

Nuts14 10.3 123.9

Servo Mounting Bracket

Bolts14 10.3 123.9

Servo Mounting Nuts 6.7 60

RSSPEED CONTROL8P-3

SPEED CONTROL (Continued)

ProCarManuals.com

Page 1569 of 2177

(3) Clutch circuit leaks are indicated if pressures

do not fall within the specified pressure range.

(4)

If the overdrive clutch pressure is greater than 5

psi in Step 4 of Test Three, a worn reaction shaft seal

ring or a defective solenoid assembly is indicated.

(5) If the underdrive clutch pressure is greater

than 5 psi in Step 4 of Test Two A, a defective sole-

noid assembly or PCM/TCM is the cause.

PRESSURE CHECK SPECIFICATIONS

Gear Selector

PositionActual GearPressure Taps

Underdrive

ClutchOverdrive

ClutchReverse

ClutchTorque

Converter

Clutch

Off2/4

ClutchLow/

Reverse

Clutch

Park *

PARK 0-2 0-5 0-2 60-110 0-2 115-145

0 mph

REVERSE *

REVERSE 0-2 0-7 165-235 50-100 0-2 165-235

0 mph

NEUTRAL *

NEUTRAL 0-2 0-5 0-2 60-110 0-2 115-145

0 mph

L#

FIRST 110-145 0-5 0-2 60-110 0-2 115-145

20 mph

3#

SECOND 110-145 0-5 0-2 60-110 115-145 0-2

30 mph

3#

DIRECT 75-95 75-95 0-2 60-90 0-2 0-2

45 mph

OD #

OVERDRIVE 0-2 75-95 0-2 60-90 75-95 0-2

30 mph

OD #

OVERDRIVE

WITH TCC0-2 75-95 0-2 0-5 75-95 0-2

50 mph

* Engine speed at 1500 rpm

# CAUTION: Both front wheels must be turning at the same speed.

DIAGNOSIS AND TESTING - CLUTCH AIR

PRESSURE TESTS

Inoperative clutches can be located using a series

of tests by substituting air pressure for fluid pressure

(Fig. 5) (Fig. 6). The clutches may be tested by apply-

ing air pressure to their respective passages. The

valve body must be removed and Tool 6056 installed.

To make air pressure tests, proceed as follows:

NOTE: The compressed air supply must be free of

all dirt and moisture. Use a pressure of 30 psi.

Remove oil pan and valve body. See Valve body

removal.

OVERDRIVE CLUTCH

Apply air pressure to the overdrive clutch apply

passage and watch for the push/pull piston to moveforward. The piston should return to its starting

position when the air pressure is removed.

REVERSE CLUTCH

Apply air pressure to the reverse clutch apply pas-

sage and watch for the push/pull piston to move rear-

ward. The piston should return to its starting

position when the air pressure is removed.

2/4 CLUTCH

Apply air pressure to the feed hole located on the

2/4 clutch retainer. Look in the area where the 2/4

piston contacts the first separator plate and watch

carefully for the 2/4 piston to move rearward. The

piston should return to its original position after the

air pressure is removed.

21 - 122 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 2116 of 2177

period the switch ratio reaches a predetermined

value, a counter is incremented by one. The monitor

is enabled to run another test during that trip. When

the test fails 6 times, the counter increments to 3, a

malfunction is entered, and a Freeze Frame is stored,

the code is matured and the MIL is illuminated. If

the first test passes, no further testing is conducted

during that trip.

The MIL is extinguished after three consecutive

good trips. The good trip criteria for the catalyst

monitor is more stringent than the failure criteria. In

order to pass the test and increment one good trip,

the downstream sensor switch rate must be less than

45% of the upstream rate. The failure percentages

are 59% respectively.

Enabling ConditionsÐThe following conditions

must typically be met before the PCM runs the cat-

alyst monitor. Specific times for each parameter may

be different from engine to engine.

²Accumulated drive time

²Enable time

²Ambient air temperature

²Barometric pressure

²Catalyst warm-up counter

²Engine coolant temperature

²Vehicle speed

²MAP

²RPM

²Engine in closed loop

²Fuel level

Pending ConditionsÐ

²Misfire DTC

²Front Oxygen Sensor Response

²Front Oxygen Sensor Heater Monitor

²Front Oxygen Sensor Electrical

²Rear Oxygen Sensor Rationality (middle check)

²Rear Oxygen Sensor Heater Monitor

²Rear Oxygen Sensor Electrical

²Fuel System Monitor

²All TPS faults

²All MAP faults

²All ECT sensor faults

²Purge flow solenoid functionality

²Purge flow solenoid electrical

²All PCM self test faults

²All CMP and CKP sensor faults

²All injector and ignition electrical faults

²Idle Air Control (IAC) motor functionality

²Vehicle Speed Sensor

²Brake switch (auto trans only)

²Intake air temperature

ConflictÐThe catalyst monitor does not run if any

of the following are conditions are present:

²EGR Monitor in progress (if equipped)

²Fuel system rich intrusive test in progress

²EVAP Monitor in progress²Time since start is less than 60 seconds

²Low fuel level-less than 15 %

²Low ambient air temperature

²Ethanol content learn is taking place and the

ethanol used once flag is set

SuspendÐThe Task Manager does not mature a

catalyst fault if any of the following are present:

²Oxygen Sensor Monitor, Priority 1

²Oxygen Sensor Heater, Priority 1

²EGR Monitor, Priority 1 (if equipped)

²EVAP Monitor, Priority 1

²Fuel System Monitor, Priority 2

²Misfire Monitor, Priority 2

OPERATION - NON-MONITORED CIRCUITS

The PCM does not monitor all circuits, systems

and conditions that could have malfunctions causing

driveability problems. However, problems with these

systems may cause the PCM to store diagnostic trou-

ble codes for other systems or components. For exam-

ple, a fuel pressure problem will not register a fault

directly, but could cause a rich/lean condition or mis-

fire. This could cause the PCM to store an oxygen

sensor or misfire diagnostic trouble code.

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor, fuel system, or mis-

fire diagnostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables. The misfire will however,

increase the oxygen content in the exhaust, deceiving

the PCM in to thinking the fuel system is too lean.

Also see misfire detection.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression. Low compression lowers O2

content in the exhaust. Leading to fuel system, oxy-

gen sensor, or misfire detection fault.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR (if

equipped) or Fuel system or O2S fault.

RSEMISSIONS CONTROL25-5

EMISSIONS CONTROL (Continued)

ProCarManuals.com