engine CHRYSLER VOYAGER 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 1274 of 2177

SPECIFICATIONS - TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Camshaft SprocketÐBolt 54 40 Ð

Camshaft Thrust

PlateÐBolts12 Ð 105

Connecting Rod

CapÐBolts54 +

1¤4

turn40

+1¤4

turnÐ

Crankshaft Main Bearing

CapÐBolts41 +

1¤4

turn30

+1¤4

turnÐ

Crankshaft Main Bearing

Cap Cross Bolts (3.8L)61 45 Ð

Crankshaft Oil Seal

Retainer RearÐBolts12 Ð 105

Crankshaft DamperÐBolt 54 40 Ð

Cylinder Block Drain

Plugs20 15 Ð

Cylinder HeadÐBolts (Refer to 9 - ENGINE/

CYLINDER HEAD -

INSTALLATION)

Cylinder Head CoverÐ

Bolts12 Ð 105

Flex Plate to Crankshaft 95 70 Ð

Engine Mounting (Refer to 9 - ENGINE/

ENGINE MOUNTING)

Exhaust ManifoldÐBolts 23 Ð 200

Exhaust Crossover

PipeÐBolts54 40 Ð

Intake Manifold -

LowerÐBolts23 Ð 200

Intake Manifold - Lower

Gasket RetainerÐBolts12 Ð 105

Intake Manifold

UpperÐBolts12 Ð 105

Lifter Yoke RetainerÐ

Bolts12 Ð 105

Oil Filter Attaching Fitting 54 40 Ð

Oil Cooler Attaching

Fitting27 20 Ð

Oil Filter 20 15 Ð

Oil Filter AdapterÐBolts 28 Ð 250

Oil Gallery Plug 27 20 Ð

Oil PanÐBolts 12 Ð 105

Oil Pan DrainÐPlug 27 20 Ð

Oil Pressure Switch 23 Ð 200

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Oil Pump Cover

PlateÐScrews12 Ð 105

Oil Pump Pick-up

TubeÐBolt28 Ð 250

Oil Dipstick HousingÐ

Bolts48 35 Ð

Rocker Arm ShaftÐBolts 23 Ð 200

Spark Plug 16 12 Ð

Timing Chain Case Cover

ÐM8 Bolt 27 20 Ð

ÐM10 Bolt 54 40 Ð

Water PumpÐBolts 12 Ð 105

Water Pump PulleyÐ

Bolts28 Ð 250

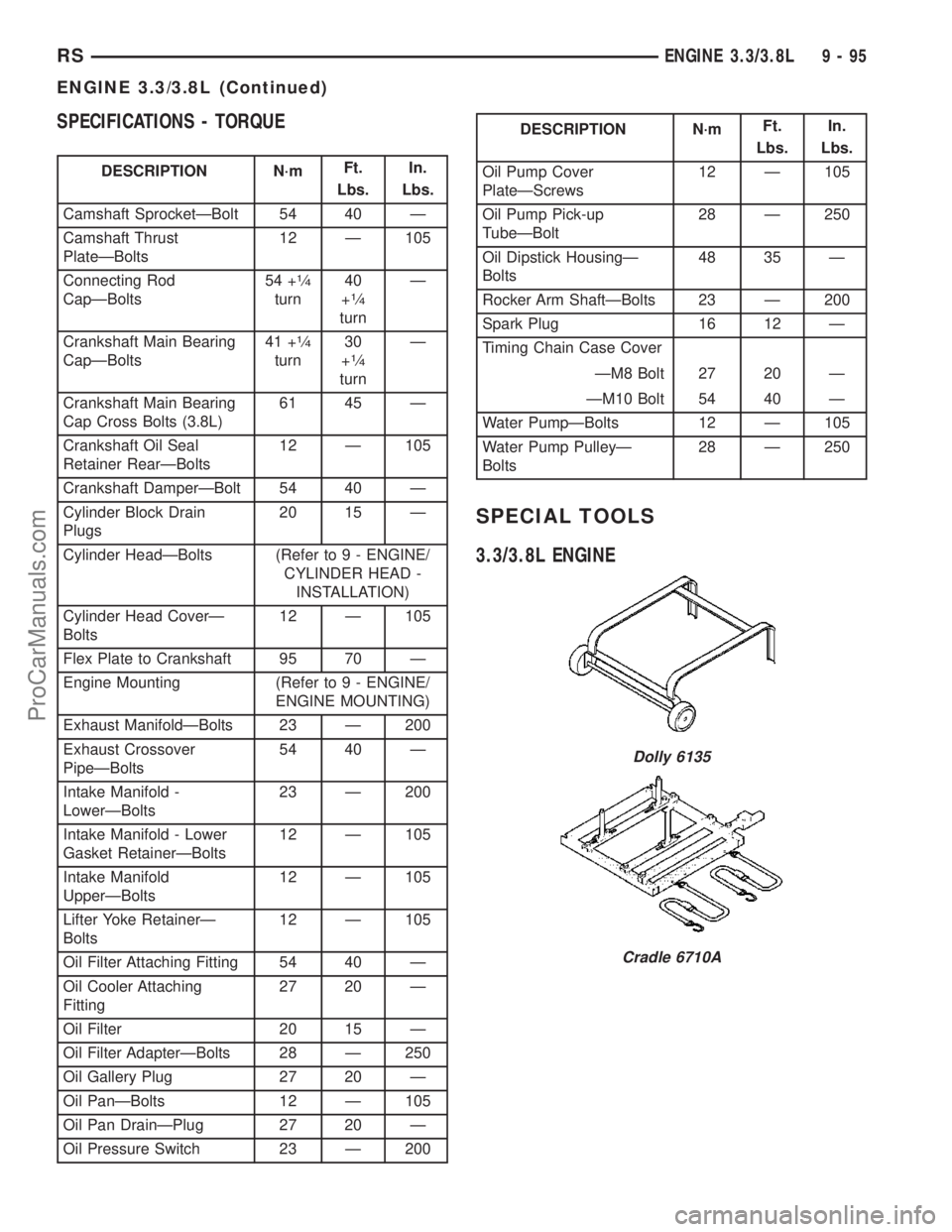

SPECIAL TOOLS

3.3/3.8L ENGINE

Dolly 6135

Cradle 6710A

RSENGINE 3.3/3.8L9-95

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1275 of 2177

Adapter 6909A

Adapter 8444

Adapter 6912

Puller 1026

Insert, Crankshaft 8450

Crankshaft Damper/Sprocket Installer 8452

Indicator, Cylinder Bore C-119

Tester - Valve Spring C-647

9 - 96 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1276 of 2177

Compressor, Valve Spring In-vehicle 8453

Valve Spring Compressor Off-vehicle C-3422-D

Adapter, Valve Spring Compressor Off-vehicle 8464

Remover, Valve Tappet C-4129-A

Remover, Crankshaft Front Seal 6341A

Installer, Crankshaft Front Seal C-4992

Remover and Installer, Crankshaft Main Bearing

C-3059

Rear Crankshaft Oil Seal Installer 6926

Oil Pressure Gauge C-3292

RSENGINE 3.3/3.8L9-97

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1277 of 2177

AIR CLEANER ELEMENT

REMOVAL

(1) Unsnap 2 clips.

(2) Lift cover and pull toward the engine and

remove cover tabs from air box.

(3) Lift cover and remove the element (Fig. 15).

INSTALLATION

(1) Install the air filter element into air box (Fig.

15).

(2) Move cover so that the tabs insert into the air

box.

(3) Push cover down and snap the 2 clips.

Adapter 8406

Cooling System Tester 7700

Combustion Leak Tester C-3685-A

Pressure Transducer CH7059

Compression Test Adapter 8116

DRB IIITwith PEP Module OT-CH6010A

Fig. 15 AIR BOX COVER

9 - 98 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1278 of 2177

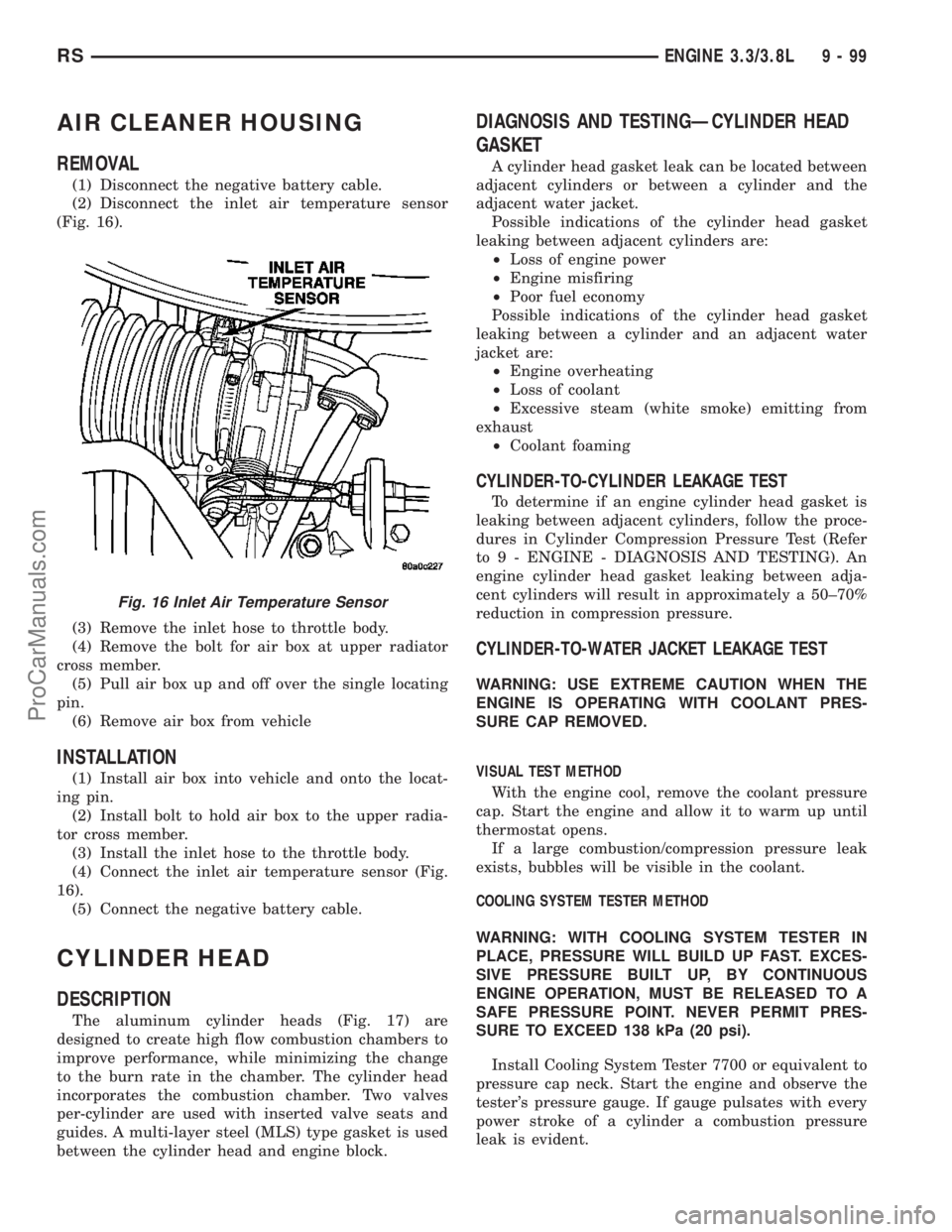

AIR CLEANER HOUSING

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect the inlet air temperature sensor

(Fig. 16).

(3) Remove the inlet hose to throttle body.

(4) Remove the bolt for air box at upper radiator

cross member.

(5) Pull air box up and off over the single locating

pin.

(6) Remove air box from vehicle

INSTALLATION

(1) Install air box into vehicle and onto the locat-

ing pin.

(2) Install bolt to hold air box to the upper radia-

tor cross member.

(3) Install the inlet hose to the throttle body.

(4) Connect the inlet air temperature sensor (Fig.

16).

(5) Connect the negative battery cable.

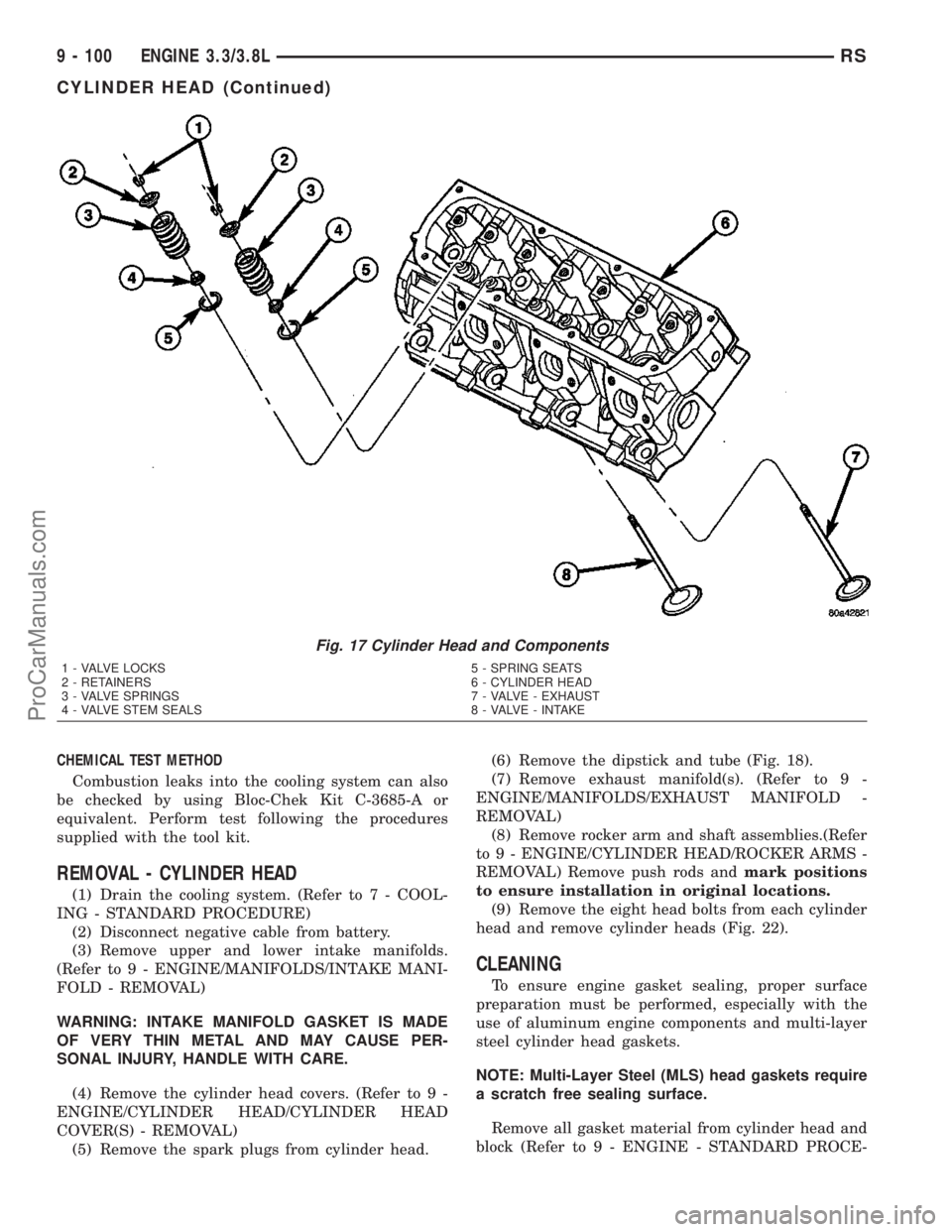

CYLINDER HEAD

DESCRIPTION

The aluminum cylinder heads (Fig. 17) are

designed to create high flow combustion chambers to

improve performance, while minimizing the change

to the burn rate in the chamber. The cylinder head

incorporates the combustion chamber. Two valves

per-cylinder are used with inserted valve seats and

guides. A multi-layer steel (MLS) type gasket is used

between the cylinder head and engine block.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

Fig. 16 Inlet Air Temperature Sensor

RSENGINE 3.3/3.8L9-99

ProCarManuals.com

Page 1279 of 2177

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL - CYLINDER HEAD

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Disconnect negative cable from battery.

(3) Remove upper and lower intake manifolds.

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - REMOVAL)

WARNING: INTAKE MANIFOLD GASKET IS MADE

OF VERY THIN METAL AND MAY CAUSE PER-

SONAL INJURY, HANDLE WITH CARE.

(4) Remove the cylinder head covers. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(5) Remove the spark plugs from cylinder head.(6) Remove the dipstick and tube (Fig. 18).

(7) Remove exhaust manifold(s). (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

REMOVAL)

(8) Remove rocker arm and shaft assemblies.(Refer

to 9 - ENGINE/CYLINDER HEAD/ROCKER ARMS -

REMOVAL) Remove push rods andmark positions

to ensure installation in original locations.

(9) Remove the eight head bolts from each cylinder

head and remove cylinder heads (Fig. 22).

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Remove all gasket material from cylinder head and

block (Refer to 9 - ENGINE - STANDARD PROCE-

Fig. 17 Cylinder Head and Components

1 - VALVE LOCKS 5 - SPRING SEATS

2 - RETAINERS 6 - CYLINDER HEAD

3 - VALVE SPRINGS 7 - VALVE - EXHAUST

4 - VALVE STEM SEALS 8 - VALVE - INTAKE

9 - 100 ENGINE 3.3/3.8LRS

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1280 of 2177

DURE). Be careful not to gouge or scratch the alumi-

num head sealing surface.

Clean all engine oil passages.

INSPECTION

(1) Before cleaning, check for leaks, damage and

cracks.

(2) Clean cylinder head and oil passages.

(3) Check cylinder head for flatness (Fig. 19).

(4) Cylinder head must be flat within:

²Standard dimension = less than 0.05 mm (0.002

inch.)

²Service Limit = 0.2 mm (0.008 inch.)

²Grinding Limit = Maximum of 0.2 mm (0.008

inch.) is permitted.

CAUTION: 0.20 mm (0.008 in.) MAX is a combined

total dimension of the stock removal limit from cyl-

inder head and block top surface (Deck) together.

INSTALLATION - CYLINDER HEAD

(1) Clean all sealing surfaces of engine block and

cylinder heads. (Refer to 9 - ENGINE - STANDARD

PROCEDURE)

(2) Position new gasket(s) on engine block (Fig.

20). The left bank gasket is identified with the ªLºstamped in the exposed area of the gasket located at

front of engine (shown in (Fig. 20)). The right bank

gasket is identified with a ªRº stamped in the

exposed area of the gasket also, but is located at the

rear of the engine.

(3)The cylinder head bolts are torqued using

the torque yield method, they should be exam-

ined BEFORE reuse. If the threads are necked

down, the bolts must be replaced(Fig. 21).

(4) Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale the bolt should be replaced.

(5)

Tighten the cylinder head bolts 1±8 in the

sequence shown in (Fig. 22). Using the 4 step torque

turn method, tighten according to the following values:

²Step 1: Bolts1±8to61N´m(45ft.lbs.)

²Step 2: Bolts1±8to88N´m(65ft.lbs.)

²Step 3: Bolts1±8(again) to 88 N´m (65 ft. lbs.)

²Step 4: Bolts1±8turn an additional 1/4 Turn.

(Do not use a torque wrench for this step.)

Fig. 18 DIPSTICK & TUBE

1 - DIPSTICK

2 - BOLT

3 - TUBE

Fig. 19 Checking Cylinder Head FlatnessÐTypical

Fig. 20 Head Gasket Installation

1 - CYLINDER HEAD GASKET

2 - LOCATION IDENTIFICATION (L = LEFT BANK, R = RIGHT

BANK)

RSENGINE 3.3/3.8L9 - 101

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1281 of 2177

NOTE: Bolt torque after 1/4 turn should be over 122

N´m (90 ft. lbs.). If not, replace the bolt.

(6) Inspect push rods and replace worn or bent

rods.

(7) Install the push rods.

(8) Install the rocker arm and shaft assemblies.

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARMS - INSTALLATION)

(9) Install the cylinder head covers. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(10) Install the exhaust manifolds. (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

INSTALLATION)

(11) Install new O-ring on dipstick tube. Install

dipstick tube assembly (Fig. 18).

(12) Install the spark plugs.

(13) Install upper and lower intake manifolds.

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - INSTALLATION)

(14) Fill the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(15) Connect negative cable to battery.

CYLINDER HEAD COVER(S)

DESCRIPTION

The cylinder head covers are made of stamped

steel. The covers are sealed with steel reinforced sil-

icon rubber gaskets. The cylinder head cover uses

rubber isolators at each fastener location (Fig. 23).

NOTE: Due to the tight packaging near the cylinder

head covers, which makes spill clean-up difficult, a

spill during an engine oil change may be misinter-

preted as an oil leak. When investigating an oil leak

in the location of the cylinder head covers and

intake manifold, follow the procedure found in Oil

Leak Diagnosis (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING) for determining the source of a leak.

CYLINDER HEAD COVER -

RIGHT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL)

(3) Disconnect spark plug wires from plugs.

(4) Disconnect PCV hose from cylinder head cover

(Fig. 24).

(5) Remove cylinder head cover bolts.

(6) Remove cylinder head cover and gasket (Fig.

23).

Fig. 21 Checking Bolts for Stretching (Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 22 CYLINDER HEAD TIGHTENING SEQUENCE

Fig. 23 Cylinder Head Cover

1 - CYLINDER HEAD COVER

2 - BOLT

9 - 102 ENGINE 3.3/3.8LRS

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1282 of 2177

INSTALLATION

(1) Clean cylinder head and cover mating surfaces.

Inspect cylinder head cover surface for flatness.

Replace gasket as necessary.

(2) Inspect seal on the cover bolt for wear or dam-

age (Fig. 25). Replace bolt assembly as necessary.

NOTE: The cylinder head cover bolts contain a

torque limiter sleeve and a seal (Fig. 25). The seal

and torque sleeve is replaced with the bolt.

(3) Assemble gasket to cylinder cover by inserting

the bolt assemblies through each bolt hole on the

cover and gasket (Fig. 25).

(4) Install cylinder head cover and bolts (Fig. 26).

(5) Tighten cylinder head cover bolts to 12 N´m

(105 in. lbs.) (Fig. 26).

(6) Connect PCV hose to cylinder head cover.

(7) Connect spark plug wires to spark plugs.

(8) Install wiper module. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION)

(9) Connect negative cable to battery.

CYLINDER HEAD COVER -

LEFT

REMOVAL

(1) Disconnect spark plug wires from spark plugs.

(2) Disconnect crankcase vent hose from cylinder

head cover.

(3) Remove cylinder head cover bolts.

(4) Remove cylinder head cover and gasket.

INSTALLATION

(1) Clean cylinder head and cover mating surfaces.

Inspect cylinder head cover surface for flatness.

Replace gasket as necessary.

Fig. 24 PCV Hose

1 - HOSE - PCV

2 - P C V VA LV E

Fig. 25 CYLINDER HEAD COVER GASKET

1 - CYLINDER HEAD COVER

2 - BOLT

3 - SEAL (SERVICED WITH BOLT)

4 - GASKET

Fig. 26 Cylinder Head Cover

1 - CYLINDER HEAD COVER

2 - BOLT

RSENGINE 3.3/3.8L9 - 103

CYLINDER HEAD COVER - RIGHT (Continued)

ProCarManuals.com

Page 1283 of 2177

(2) Assemble gasket to cylinder cover by inserting

the fasteners through each bolt hole on cover and

gasket (Fig. 25).

(3) Install the cylinder head cover and bolts (Fig.

26).

(4) Tighten cylinder head cover bolts to 12 N´m

(105 in. lbs.) (Fig. 26).

(5) Connect crankcase vent hose.

(6) Connect spark plug wires to spark plugs.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves have chrome plated valve stems with

four-bead lock grooves. The valve stem seals are

made of Viton rubber.

OPERATION

The two valves per cylinder are opened using

hydraulic lifters, push rods, and rocker arms.

STANDARD PROCEDURE - REFACING VALVES

AND VALVE SEATS

The intake and exhaust valves and seats are

machined to specific angles (Fig. 27).

VALVES

(1) Inspect the remaining margin after the valves

are refaced (Fig. 28). (Refer to 9 - ENGINE - SPEC-

IFICATIONS)

VALVE SEATS

CAUTION: Remove metal from valve seat only. Do

not remove material from cylinder head (Fig. 29).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-ing stones. A true and complete surface must be

obtained.

(2) Measure the concentricity of valve seat using

dial indicator (Fig. 30). Total runout should not

exceed 0.051 mm (0.002 in.) total indicator reading.

(3) Inspect the valve seat using Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of valve face, lower valve seat with

a 15 degree stone. If the blue is transferred to the

bottom edge of valve face raise valve seat with a 65

degrees stone.

NOTE: Valve seats which are worn or burned can

be reworked, provided that correct angle and seat

width are maintained. Otherwise cylinder head must

be replaced.

Fig. 27 Valve Face and Seat

1 - SEAT WIDTH

2 - FACE ANGLE

3 - SEAT ANGLE

4 - SEAT CONTACT AREA

Fig. 28 Valve Margin

1 - VALVE FACE

2 - VALVE MARGIN

Fig. 29 Refacing Valve Seats

1 - REFACING STONE MUST NOT CUT INTO CYLINDER HEAD

2-STONE

3 - PILOT

4 - SEAT

9 - 104 ENGINE 3.3/3.8LRS

CYLINDER HEAD COVER - LEFT (Continued)

ProCarManuals.com