engine CHRYSLER VOYAGER 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 1304 of 2177

(1) For main bearing fitting procedure, (Refer to 9

- ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE)

(2) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 71).

(3) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

(4) Inspect main cap bolts for stretching (Fig. 72).

Replace bolts that are stretched.

NOTE: The main cap bolts should be examined

before reuse. Bolt stretch can be checked by hold-

ing a scale or straight edge against the threads. If

all the threads do not contact the scale the bolt

must be replaced (Fig. 72).

(5) Install each main cap and tighten bolts finger

tight.

(6) Tighten number 1, 3 and 4 main cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn).

(7) Rotate the crankshaft until the number 6 pis-

ton is at TDC.

(8) To ensure correct thrust bearing alignment the

following procedure must be done:

a. Move crankshaft all the way to the rear of its

travel.

b. Then, move crankshaft all the way to the front

of its travel.

c. Wedge an appropriate tool between the rear of

the cylinder block and rear crankshaft counter-

weight. This will hold the crankshaft in it's most for-

ward position.

d. Tighten the #2 Thrust Bearing cap bolts to 41

N´m + 1/4 Turn (30 ft. lbs.+ 1/4 Turn). Remove the

holding tool.

(9) Install oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION)

(10) Fill engine crankcase with proper oil to cor-

rect level.CRANKSHAFT

DESCRIPTION

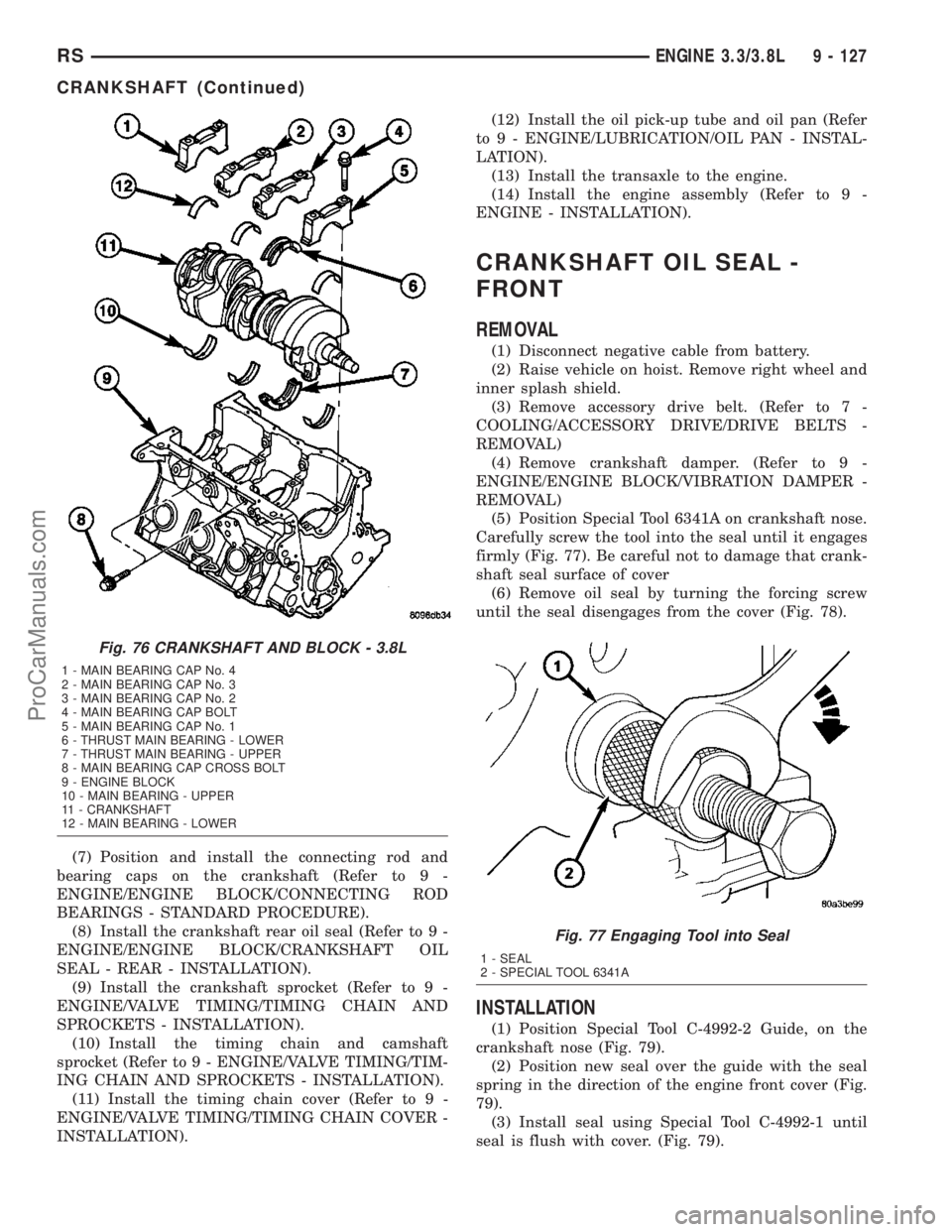

DESCRIPTION - 3.3L

The nodular iron crankshaft is supported by four

main bearings, with number two position the thrust

bearing (Fig. 75). Crankshaft end sealing is provided

by front and rear rubber seals.

DESCRIPTION - 3.8L

The nodular iron crankshaft is supported by four

main bearings, with number two position providing

thrust bearing location (Fig. 76). Each main bearing

cap has two vertical retaining bolts. The two center

main caps have horizontal bolts to add increased

rigidity to the lower engine block (Fig. 76). Crank-

shaft end sealing is provided by front and rear rub-

ber seals.

STANDARD PROCEDURE - MEASURING

CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine with

the locating probe on nose of crankshaft (Fig. 73).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. (Refer to 9 - ENGINE -

SPECIFICATIONS) for end play specification.

REMOVAL

(1) Remove the engine assembly (Refer to 9 -

ENGINE - REMOVAL).

(2) Separate transaxle from engine.

(3) Mount engine on an engine stand.

(4) Remove the oil filter.

Fig. 72 Check for Stretched (Necked) Bolts

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 73 Checking Crankshaft End PlayÐTypical

RSENGINE 3.3/3.8L9 - 125

CRANKSHAFT MAIN BEARINGS (Continued)

ProCarManuals.com

Page 1305 of 2177

(5)Remove the oil pan and oil pick-up tube (Refer to

9 - ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(6) Remove the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING CHAIN COVER -

REMOVAL).

(7) Remove timing chain and sprockets (Refer to 9

- ENGINE/VALVE TIMING/TIMING CHAIN AND

SPROCKETS - REMOVAL).

(8) Remove crankshaft rear oil seal and retainer

(Refer to 9 - ENGINE/ENGINE BLOCK/CRANK-

SHAFT OIL SEAL - REAR - REMOVAL).

(9) Rotate the crankshaft until connecting rod cap

is accessible.

(10) Mark connecting rod cap position using a suit-

able marker/scribe tool.

(11)

Remove connecting rod bearing cap. Use care to

prevent damage to the crankshaft bearing surfaces.

(12) Repeat removal procedure for each connecting

rod cap.

(13) Remove and discard the main bearing cross

bolts and washers (3.8L engine only) (Fig. 76).

NOTE: Install new cross bolt and washer assembly

(3.8L engine only) upon reassembly.

(14) Remove the main bearing cap bolts

(15) Remove the main bearing caps.

(16) Remove the crankshaft from engine block

(Fig. 75) or (Fig. 76).

INSTALLATION

(1) For main bearing identification, refer to (Fig.

68). Lubricate with engine oil and install the crank-

shaft main bearing halves in the engine block.

(2) Position the crankshaft in engine block (Fig.

75) or (Fig. 76).

(3) Perform main bearing fitting procedure (Refer

to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT

MAIN BEARINGS - STANDARD PROCEDURE).

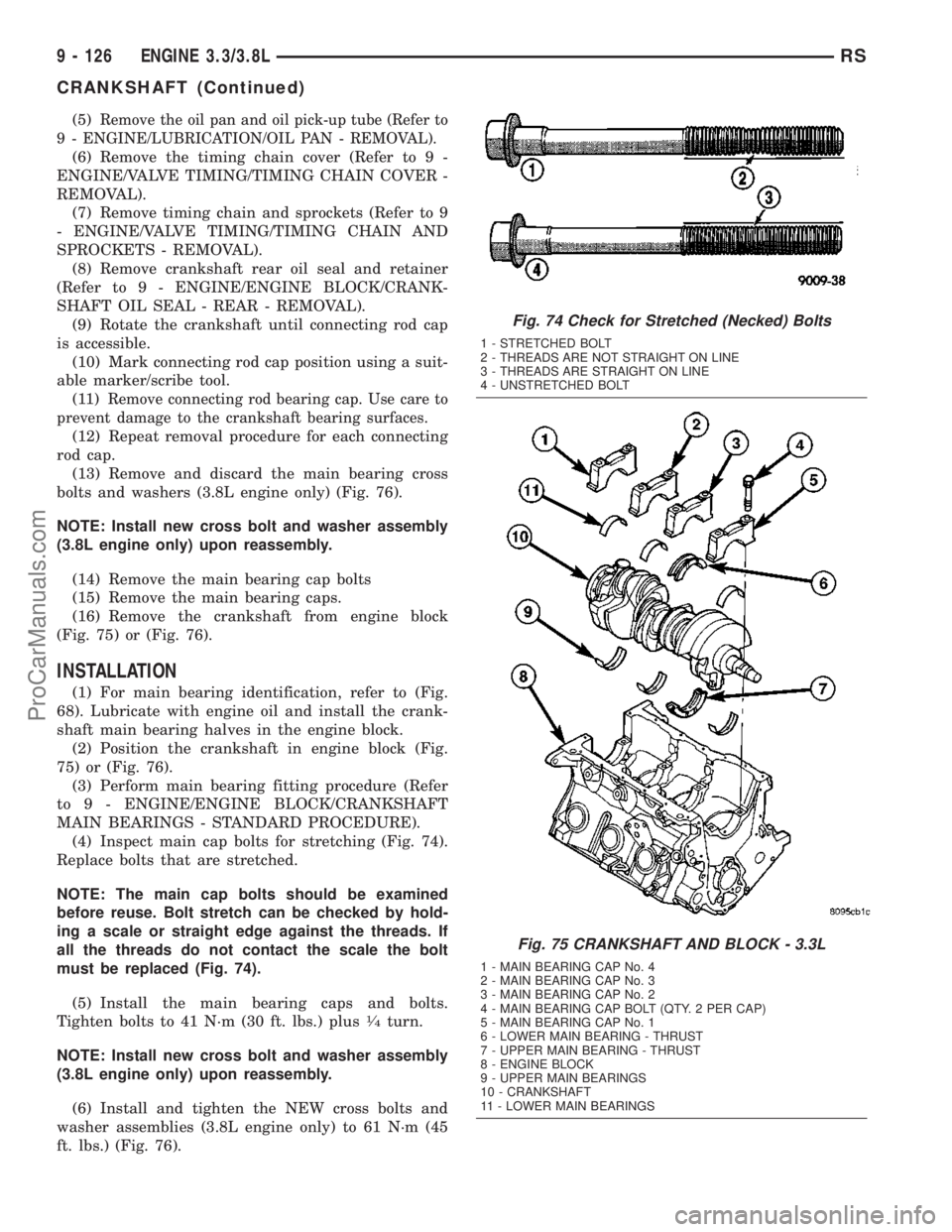

(4) Inspect main cap bolts for stretching (Fig. 74).

Replace bolts that are stretched.

NOTE: The main cap bolts should be examined

before reuse. Bolt stretch can be checked by hold-

ing a scale or straight edge against the threads. If

all the threads do not contact the scale the bolt

must be replaced (Fig. 74).

(5) Install the main bearing caps and bolts.

Tighten bolts to 41 N´m (30 ft. lbs.) plus

1¤4turn.

NOTE: Install new cross bolt and washer assembly

(3.8L engine only) upon reassembly.

(6) Install and tighten the NEW cross bolts and

washer assemblies (3.8L engine only) to 61 N´m (45

ft. lbs.) (Fig. 76).

Fig. 74 Check for Stretched (Necked) Bolts

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 75 CRANKSHAFT AND BLOCK - 3.3L

1 - MAIN BEARING CAP No. 4

2 - MAIN BEARING CAP No. 3

3 - MAIN BEARING CAP No. 2

4 - MAIN BEARING CAP BOLT (QTY. 2 PER CAP)

5 - MAIN BEARING CAP No. 1

6 - LOWER MAIN BEARING - THRUST

7 - UPPER MAIN BEARING - THRUST

8 - ENGINE BLOCK

9 - UPPER MAIN BEARINGS

10 - CRANKSHAFT

11 - LOWER MAIN BEARINGS

9 - 126 ENGINE 3.3/3.8LRS

CRANKSHAFT (Continued)

ProCarManuals.com

Page 1306 of 2177

(7) Position and install the connecting rod and

bearing caps on the crankshaft (Refer to 9 -

ENGINE/ENGINE BLOCK/CONNECTING ROD

BEARINGS - STANDARD PROCEDURE).

(8) Install the crankshaft rear oil seal (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - INSTALLATION).

(9) Install the crankshaft sprocket (Refer to 9 -

ENGINE/VALVE TIMING/TIMING CHAIN AND

SPROCKETS - INSTALLATION).

(10) Install the timing chain and camshaft

sprocket (Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING CHAIN AND SPROCKETS - INSTALLATION).

(11) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING CHAIN COVER -

INSTALLATION).(12) Install the oil pick-up tube and oil pan (Refer

to 9 - ENGINE/LUBRICATION/OIL PAN - INSTAL-

LATION).

(13) Install the transaxle to the engine.

(14) Install the engine assembly (Refer to 9 -

ENGINE - INSTALLATION).

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist. Remove right wheel and

inner splash shield.

(3) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(4) Remove crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL)

(5) Position Special Tool 6341A on crankshaft nose.

Carefully screw the tool into the seal until it engages

firmly (Fig. 77). Be careful not to damage that crank-

shaft seal surface of cover

(6) Remove oil seal by turning the forcing screw

until the seal disengages from the cover (Fig. 78).

INSTALLATION

(1) Position Special Tool C-4992-2 Guide, on the

crankshaft nose (Fig. 79).

(2) Position new seal over the guide with the seal

spring in the direction of the engine front cover (Fig.

79).

(3) Install seal using Special Tool C-4992-1 until

seal is flush with cover. (Fig. 79).

Fig. 76 CRANKSHAFT AND BLOCK - 3.8L

1 - MAIN BEARING CAP No. 4

2 - MAIN BEARING CAP No. 3

3 - MAIN BEARING CAP No. 2

4 - MAIN BEARING CAP BOLT

5 - MAIN BEARING CAP No. 1

6 - THRUST MAIN BEARING - LOWER

7 - THRUST MAIN BEARING - UPPER

8 - MAIN BEARING CAP CROSS BOLT

9 - ENGINE BLOCK

10 - MAIN BEARING - UPPER

11 - CRANKSHAFT

12 - MAIN BEARING - LOWER

Fig. 77 Engaging Tool into Seal

1 - SEAL

2 - SPECIAL TOOL 6341A

RSENGINE 3.3/3.8L9 - 127

CRANKSHAFT (Continued)

ProCarManuals.com

Page 1307 of 2177

(4) Install crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

(5) Install accessory drive belt. (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION)

(6) Install inner splash shield and right front

wheel.

(7) Lower vehicle and connect negative cable to

battery.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Remove the transaxle. Refer to TRANSAXLE

AND POWER TRANSFER UNIT for procedure.

(2) Remove the flex plate. (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL)

(3) Insert a 3/16 flat bladed pry tool between the

dust lip and the metal case of the crankshaft seal.

Angle the pry tool (Fig. 80) through the dust lip

against metal case of the seal. Pry out seal.

CAUTION: Do not permit the pry tool blade to con-

tact crankshaft seal surface. Contact of the pry tool

blade against crankshaft edge (chamfer) is permit-

ted.

Fig. 78 Crankshaft Front Seal Removal

1 - SEAL

2 - SPECIAL TOOL 6341A

Fig. 79 CRANKSHAFT FRONT SEAL INSTALLATION

1 - SPECIAL TOOL C-4992-1

2 - SEAL

3 - SPECIAL TOOL C-4992-2

4 - CRANKSHAFT

Fig. 80 Crankshaft Rear Oil Seal - Removal

1 - REAR CRANKSHAFT SEAL

2 - ENGINE BLOCK

3 - ENGINE BLOCK

4 - REAR CRANKSHAFT SEAL METAL CASE

5 - PRY IN THIS DIRECTION

6 - CRANKSHAFT

7 - SCREWDRIVER

8 - REAR CRANKSHAFT SEAL DUST LIP

9 - SCREWDRIVER

9 - 128 ENGINE 3.3/3.8LRS

CRANKSHAFT OIL SEAL - FRONT (Continued)

ProCarManuals.com

Page 1308 of 2177

INSTALLATION

CAUTION: If burr or scratch is present on the

crankshaft edge (chamfer), cleanup with 400 grit

sand paper to prevent seal damage during installa-

tion of new seal.

(1) Place Special Tool 6926-1 magnetic pilot tool on

crankshaft (Fig. 81).

(2) Place seal over Special Tool 6926-1 Pilot. Using

Special Tool 6926-2 Installer with C-4171 Handle,

drive seal into the retainer housing (Fig. 81).

(3) Install the flex plate. (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - INSTALLATION)

(4) Install transaxle. Refer to TRANSAXLE AND

POWER TRANSFER UNIT for procedure.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Remove crankshaft rear oil seal (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

(2) Remove oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

(3) Remove oil seal retainer screws (Fig. 82).

(4) Remove oil seal retainer (Fig. 82).

(5) Clean engine block and retainer of oil and gas-

ket material. Make sure surfaces are clean and free

of oil.

INSTALLATION

(1) Position new gasket and install retainer on

block (Fig. 82). Tighten attaching screws to 12 N´m

(105 in. lbs.).

(2) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(3) Install oil seal (Refer to 9 - ENGINE/ENGINE

BLOCK/CRANKSHAFT OIL SEAL - REAR -

INSTALLATION).

Fig. 81 Rear Crankshaft Oil SealÐInstallation

1 - SPECIAL TOOLS:

2 - C-4171 HANDLE

3 - 6926±2 INSTALLER

4 - 6926±1 GUIDE

5 - SEAL

Fig. 82 CRANKSHAFT REAR OIL SEAL

1 - OIL SEAL

2 - BOLT

3 - RETAINER - OIL SEAL

4 - GASKET

RSENGINE 3.3/3.8L9 - 129

CRANKSHAFT OIL SEAL - REAR (Continued)

ProCarManuals.com

Page 1309 of 2177

VIBRATION DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Remove the right front wheel and inner splash

shield.

(4) Remove the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(5) Remove vibration damper bolt.

(6) Insert Special Tool 8450 into crankshaft nose

(Fig. 83).

(7) Position 3-jaw puller Special Tool 1026 on

damper as shown in (Fig. 83). Turn puller forcing

screw until damper releases from crankshaft.

(8) Remove the crankshaft vibration damper.

INSTALLATION

(1) Install crankshaft vibration damper using the

forcing screw, nut, and thrust bearing/washer from

Special Tool 8452 (Fig. 84).NOTE: To minimize friction and prolong tool life,

lubricate the threads on the forcing screw of Spe-

cial Tool 8452.

(2) Position vibration damper on crankshaft.

(3) Screw Special Tool 8452 into crankshaft until

the bolt seats. Turn the nut to install damper until it

seats fully.

(4) Remove Special Tool 8452.

(5) Install vibration damper bolt. Torque bolt to 54

N´m (40 ft. lbs.).

(6) Install the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(7) Install inner splash shield and right front

wheel.

(8) Connect negative cable to battery.

Fig. 83 Vibration Damper - Removal

1 - SPECIAL TOOL 8450 - INSERT

2 - SPECIAL TOOL 1026-3JAWPULLER

Fig. 84 Vibration Damper - Installation

1 - FORCING SCREW / NUT FROM SPECIAL TOOL 8452

2 - VIBRATION DAMPER

3 - THRUST BEARING / WASHER

9 - 130 ENGINE 3.3/3.8LRS

ProCarManuals.com

Page 1310 of 2177

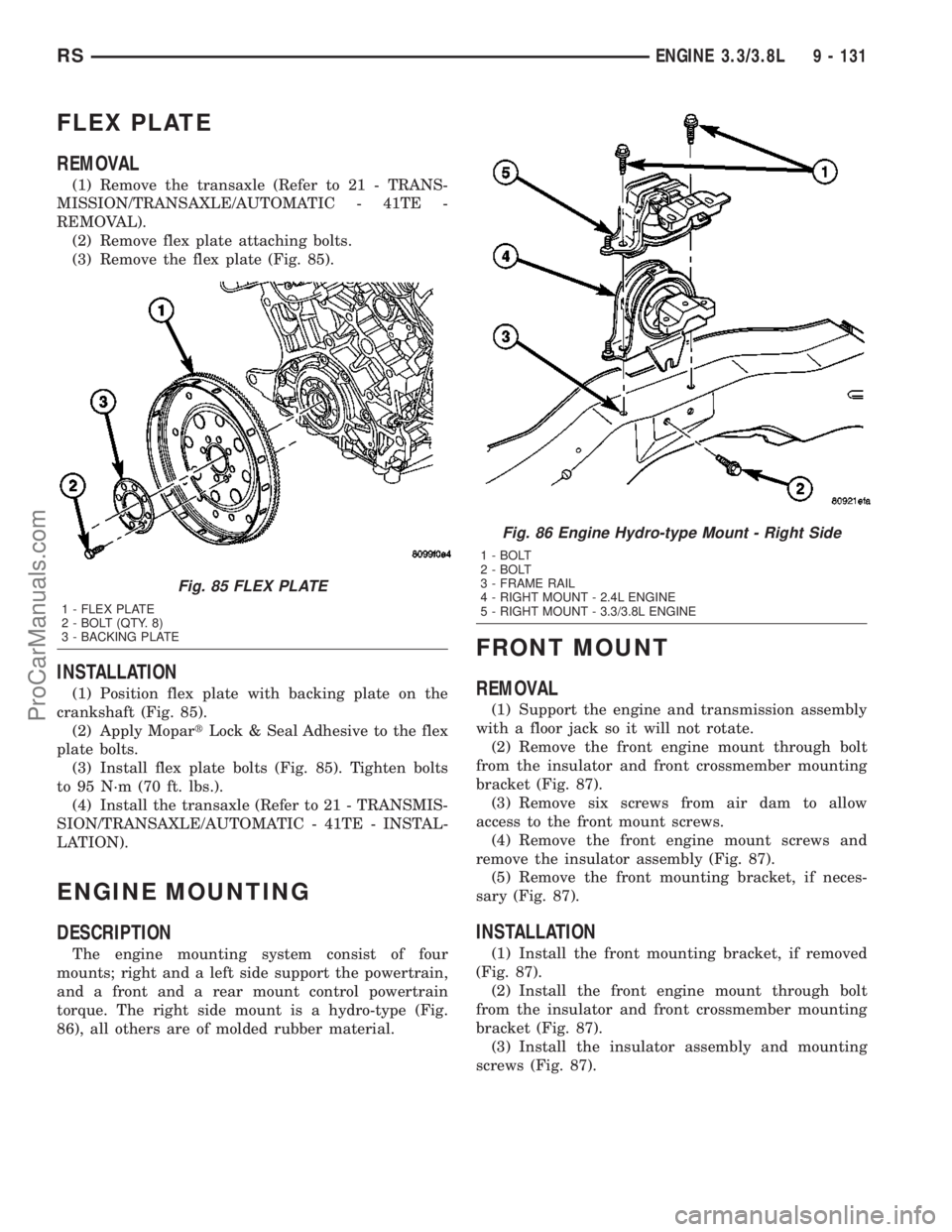

FLEX PLATE

REMOVAL

(1) Remove the transaxle (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 41TE -

REMOVAL).

(2) Remove flex plate attaching bolts.

(3) Remove the flex plate (Fig. 85).

INSTALLATION

(1) Position flex plate with backing plate on the

crankshaft (Fig. 85).

(2) Apply MopartLock & Seal Adhesive to the flex

plate bolts.

(3) Install flex plate bolts (Fig. 85). Tighten bolts

to 95 N´m (70 ft. lbs.).

(4) Install the transaxle (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 41TE - INSTAL-

LATION).

ENGINE MOUNTING

DESCRIPTION

The engine mounting system consist of four

mounts; right and a left side support the powertrain,

and a front and a rear mount control powertrain

torque. The right side mount is a hydro-type (Fig.

86), all others are of molded rubber material.

FRONT MOUNT

REMOVAL

(1) Support the engine and transmission assembly

with a floor jack so it will not rotate.

(2) Remove the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 87).

(3) Remove six screws from air dam to allow

access to the front mount screws.

(4) Remove the front engine mount screws and

remove the insulator assembly (Fig. 87).

(5) Remove the front mounting bracket, if neces-

sary (Fig. 87).

INSTALLATION

(1) Install the front mounting bracket, if removed

(Fig. 87).

(2) Install the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 87).

(3) Install the insulator assembly and mounting

screws (Fig. 87).

Fig. 85 FLEX PLATE

1 - FLEX PLATE

2 - BOLT (QTY. 8)

3 - BACKING PLATE

Fig. 86 Engine Hydro-type Mount - Right Side

1 - BOLT

2 - BOLT

3 - FRAME RAIL

4 - RIGHT MOUNT - 2.4L ENGINE

5 - RIGHT MOUNT - 3.3/3.8L ENGINE

RSENGINE 3.3/3.8L9 - 131

ProCarManuals.com

Page 1311 of 2177

Fig. 87 Engine Mounting - Front

1 - CROSSMEMBER 5 - BOLT 54 N´m (40 ft. lbs.)

2 - BOLT - 68 N´m (50 ft. lbs.) 6 - NUT - 68 N´m (50 ft. lbs.)

3 - BOLT - 102 N´m (75 ft. lbs.) 7 - MOUNT - ENGINE FRONT

4 - BOLT - 68 N´m (50 ft. lbs.) 8 - BRACKET - ENGINE FRONT MOUNT

9 - 132 ENGINE 3.3/3.8LRS

FRONT MOUNT (Continued)

ProCarManuals.com

Page 1312 of 2177

LEFT MOUNT

REMOVAL

(1) Raise the vehicle on hoist.

(2) Remove the left front wheel.

(3) Remove the left mount through bolt access

cover.

(4) Support the transaxle with a suitable jack.

(5) Remove the engine front mount through bolt to

allow left mount removal clearance (Fig. 87).

(6) Remove the left mount through frame rail bolt

(Fig. 88).

(7) Lower transaxle for access to horizontal bolts.

(8) Remove the horizontal bolts from the mount to

the transaxle (Fig. 89).

NOTE: To remove mount, additional lowering of

transaxle may be required.

(9) Remove left mount.

INSTALLATION

(1) Install left mount on transaxle (Fig. 89).

(2) Raise transaxle with jack until left mount is in

position.

(3) Install left mount through bolt (Fig. 88).

(4) Install left mount through bolt access cover.

(5) Install front mount through bolt (Fig. 87).

(6) Install left front wheel.

(7) Lower vehicle.

REAR MOUNT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the rear mount heat shield (Fig. 90).

(3) Remove the through bolt from the mount and

rear mount bracket (Fig. 91).

(4) Remove the mount bolts (Fig. 91).

(5) Remove the rear mount (Fig. 91).

(6) For rear mount bracket removal, remove the

bolts attaching bracket to transaxle (Fig. 92).

(7) Remove rear mount bracket.

Fig. 88 LEFT MOUNT TO BRACKET

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

Fig. 89 LEFT MOUNT - 41TE TRANSAXLE

1 - LEFT MOUNT ASSEMBLY

2 - BOLT - 54 N´m (40 ft. lbs.)

3 - TRANSAXLE - 41TE

Fig. 90 REAR MOUNT HEAT SHIELD

1 - BOLT - HEAT SHIELD 11 N´m (100 in. lbs.)

2 - HEAT SHIELD

3 - CLIP

4 - REAR MOUNT

RSENGINE 3.3/3.8L9 - 133

ProCarManuals.com

Page 1313 of 2177

INSTALLATION

(1) Install rear mount bracket, if removed (Fig.

92).

(2) Install the rear mount and bolts (Fig. 91).

Tighten bolts to 54 N´m (40 ft. lbs.).

(3) Install the mount through bolt to the mount

and bracket (Fig. 91). Tighten through bolt to 54 N´m

(40 ft. lbs.).

(4) Install the rear mount heat shield (Fig. 90).

(5) Lower vehicle on hoist.

Fig. 91 REAR MOUNT

1 - BOLT 54 N´m (40 ft. lbs.)

2 - REAR MOUNT BRACKET

3 - THRU-BOLT 54 N´m (40 ft. lbs.)

4 - REAR MOUNT

Fig. 92 REAR MOUNT BRACKET - (all engines)

1 - BOLT - VERTICAL 102 N´m (75 ft. lbs.)

2 - BRACKET - REAR MOUNT

3 - BOLT - HORIZONTAL 102 N´m (75 ft. lbs.)

9 - 134 ENGINE 3.3/3.8LRS

REAR MOUNT (Continued)

ProCarManuals.com