torque CHRYSLER VOYAGER 2003 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2003Pages: 2177, PDF Size: 59.81 MB

Page 121 of 2177

INSTALLATION

CAUTION: Propeller shaft installation is a two-man

operation. Never allow propeller shaft to hang while

connected to power transfer unit (PTU) or rear driv-

eline module flanges. A helper is required.

(1) Make sure transaxle is in Neutral (N) position.

(2) Obtain a helper and lift propeller shaft assem-

bly into position (Fig. 1).

(3) While helper supports front half of shaft level

to underbody, align paint marks at driveline module

flange and install three propeller shaft rubber cou-pler-to-rear driveline module bolts by hand. Do not

torque at this time.

(4) While helper supports front half of shaft level

to underbody, align chalk marks at PTU flange.

Install six propeller shaft-to-PTU flange bolts and

torque to 30 N´m (22 ft. lbs.). Torque bolts alternately

to ensure proper flange mating.

(5) Place center bearing into position. Install and

torque center bearing-to-crossmember bolts to 54

N´m (40 ft. lbs.).

(6) Torque propeller shaft rubber coupler-to-rear

driveline module assembly to 54 N´m (40 ft. lbs.).

SPECIFICATIONS - PROPELLER SHAFT

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, Propeller Shaft Front Flange-to-PTU Flange 30 22 Ð

Bolt, Propeller Shaft Rear Flange-to-Driveline

Module Flange54 40 Ð

Bolt, Center Support Bearing-to-Body 54 40 Ð

Fig. 1 Propeller Shaft Removal/Installation

1 - PTU FLANGE 3 - REAR DRIVELINE MODULE 5 - BOLT-CENTER SUPPORT BEARING-TO-

CROSSMEMBER

2 - CROSSMEMBER 4 - BOLT-PROPELLER SHAFT COUPLER-

T0-DRIVELINE MODULE6 - PROPELLER SHAFT ASSEMBLY

3 - 22 PROPELLER SHAFTRS

PROPELLER SHAFT (Continued)

ProCarManuals.com

Page 122 of 2177

REAR DRIVELINE MODULE

TABLE OF CONTENTS

page page

REAR DRIVELINE MODULE

DESCRIPTION.........................23

OPERATION...........................23

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REAR

DRIVELINE MODULE NOISE.............24

DIAGNOSIS AND TESTING - REAR

DRIVELINE MODULE OPERATION........26

REMOVAL.............................26

DISASSEMBLY.........................27

ASSEMBLY............................29

INSTALLATION.........................33

SPECIFICATIONS - REAR DRIVELINE

MODULE............................34

SPECIAL TOOLS.......................34

BI-DIRECTIONAL OVERRUNNING CLUTCH

DESCRIPTION.........................34

OPERATION...........................36

DIFFERENTIAL ASSEMBLY

DESCRIPTION.........................39OPERATION...........................39

FLUID - DIFFERENTIAL ASSEMBLY

STANDARD PROCEDURE - DIFFERENTIAL

ASSEMBLY FLUID CHANGE.............40

FLUID - OVERRUNNING CLUTCH HOUSING

STANDARD PROCEDURE - OVERRUNNING

CLUTCH HOUSING FLUID CHANGE.......41

VISCOUS COUPLER

DESCRIPTION.........................41

OPERATION...........................42

TORQUE ARM

REMOVAL.............................44

INSTALLATION.........................44

INPUT FLANGE SEAL

REMOVAL.............................44

INSTALLATION.........................45

OUTPUT FLANGE SEAL

REMOVAL.............................45

INSTALLATION.........................46

REAR DRIVELINE MODULE

DESCRIPTION

The rear driveline module assembly (Fig. 1) con-

sists of four main components:

²Bi-Directional Overrunning Clutch (BOC)

²Viscous Coupling

²Differential Assembly

²Torque Arm

The viscous coupling and bi-directional overrun-

ning clutch are contained within an overrunning

clutch housing, which fastens to the differential

assembly. The overrunning clutch housing and differ-

ential assembly have unique fluid sumps, each

requiring their own type and capacity of fluid. The

overrunning clutch housing requires MopartATF+4

(Automatic Transmission FluidÐType 9602) or equiv-

alent. The differential assembly requires Mopart

80W-90 Gear and Axle Lubricant.

Driveline module service is limited to the following

components:

²Differential Assembly (serviced only as assem-

bly)

²Viscous Coupling

²Bi-Directional Overrunning Clutch (BOC)

²Overrunning Clutch Housing²Seals (Input Flange, Output Flange, Overrun-

ning Clutch Housing O-rings)

²Input Flange/Shield

²Torque Arm

²Vents

²Fasteners

OPERATION

The primary benefits of All Wheel Drive are:

²Superior straight line acceleration, and corner-

ing on all surfaces

²Better traction and handling under adverse con-

ditions, resulting in improved hill climbing ability

and safer driving.

The heart of the system is an inter-axle viscous

coupling. The vehicle retains predominantly front-

wheel drive characteristics, but the All Wheel Drive

capability takes effect when the front wheels start to

slip. Under normal level road, straight line driving,

100% of the torque is allocated to the front wheels.

The viscous coupling controls and distributes torque/

power to the rear wheels. The viscous coupling trans-

mits torque to the rear wheels in proportion of the

amount of the slippage at the front wheels. Thais

variable torque distribution is automatic with no

driver inputs required. The coupling is similar to a

multi-plate clutch. It consists of a series of closely

spaced discs, which are alternately connected to the

RSREAR DRIVELINE MODULE3-23

ProCarManuals.com

Page 123 of 2177

front and rear drive units. The unit is totally sealed

and partially filled with silicone fluid. There is no

adjustment, maintenance or fluid checks required

during the life of the unit.

The overrunning clutch allows the rear wheels to

overrun the front wheels during a rapid front wheel

lock braking maneuver. The overrunning action pre-

vents any feed-back of front wheel braking torque to

the rear wheels. It also allows the braking system to

control the braking behavior as a two wheel drive

(2WD) vehicle.

The overrunning clutch housing has a separate oil

sump and is filled independently from the differen-

tial. The fill plug is located on the side of the over-

running clutch case. When filling the overrunning

clutch with lubricant use MopartATF+4 (Automatic

Transmission FluidÐType 9602) or equivalent.

The differential assembly contains a conventional

open differential with hypoid ring gear and pinion

gear set. The hypoid gears are lubricated by SAE

80W-90 gear lubricant.DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE NOISE

Different sources can be the cause of noise that the

rear driveline module assembly is suspected of mak-

ing. Refer to the following causes for noise diagnosis.

DRIVELINE MODULE ASSEMBLY NOISE

The most important part of driveline module ser-

vice is properly identifying the cause of failures and

noise complaints. The cause of most driveline module

failures is relatively easy to identify. The cause of

driveline module noise is more difficult to identify.

If vehicle noise becomes intolerable, an effort

should be made to isolate the noise. Many noises that

are reported as coming from the driveline module

may actually originate at other sources. For example:

²Tires

²Road surfaces

²Wheel bearings

Fig. 1 AWD Driveline Module Assembly

1 - TORQUE ARM 8 - WASHER 15 - PLUG-OVERRUNNING CLUTCH

HOUSING DRAIN

2 - INPUT FLANGE 9 - BI-DIRECTIONAL OVERRUNNING

CLUTCH (BOC)16 - SNAP RING

3 - FLANGE NUT 10 - VISCOUS COUPLER 17 - BEARING

4 - WASHER 11 - SHIM (SELECT) 18 - OVERRUNING CLUTCH HOUSING

5 - SHIELD 12 - O-RING 19 - SEAL-INPUT FLANGE

6 - VENT 13 - DIFFERENTIAL ASSEMBLY

7 - O-RING 14 - PLUG-DIFFERENTIAL FILL

3 - 24 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 125 of 2177

DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE OPERATION

Driveline module operation requires relatively

straight-forward diagnosis. Refer to the following

chart:

DRIVELINE MODULE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Rear wheels not

overrunning1) Bi-directional overrunning clutch

failure1) Replace overrunning clutch

components as required

No AWD in forward or

reverse directions, propeller

shaft turning1) Bi-directional overrunning clutch

failure1) Replace overrunning clutch

components as required

2) Viscous coupling failure 2) Replace viscous coupling

3) Rear differential failure 3) Replace the rear differential

assembly

No AWD in forward or

reverse directions, propeller

shaft not turning1) Power transfer unit failure. 1) Replace power transfer unit

components as necessary

Vibration at all speeds,

continuous torque transfer1) Mis-matched tires, worn tires on

front axle.1) Replace worn or incorrect

(mis-matched) tires with same

make and size

REMOVAL

(1) Raise vehicle on hoist.

(2) Drain fluid from overrunning clutch housing

and/or differential assembly if necessary.

(3) Remove propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT -

REMOVAL)

(4) Disconnect left and right rear halfshafts from

output flanges (Fig. 2).

(5) Remove torque arm mount to body bolts.(6) Position transmission jack to driveline module

assembly and secure assembly to jack.

(7) Remove two driveline module-to-body bolts

(Fig. 3).

(8) Lower driveline module from vehicle and

remove from jack.

Fig. 2 Half Shaft Mounting Bolts

1 - SHAFT

2 - FLANGE

Fig. 3 Rear Drive Line Module Assembly Mounting

Bolts

1 - DRIVELINE MODULE RETAINING BOLT (2)

2 - RUBBER ISOLATOR

3 - WASHER

3 - 26 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 126 of 2177

DISASSEMBLY

WARNING: Differential is only to be serviced as an

assembly, and no disassembly is required.

(1) Remove six torque arm-to-differential case

bolts and remove torque arm assembly (Fig. 4).

(2) Remove input flange nut and washer using

Tool 6958 and a breaker bar (Fig. 5).(3) Remove input flange (Fig. 6).

(4) Remove input flange seal from overrunning

clutch housing using suitable screwdriver (Fig. 7).

Fig. 4 Torque Arm Fasteners

1 - TORQUE ARM ASSEMBLY

2 - BOLT (SIX)

Fig. 5 Input Flange Nut

1 - INPUT FLANGE

2 - TOOL 6958

Fig. 6 Input Flange

1 - INPUT FLANGE/SHIELD

Fig. 7 Input Flange Seal Removal

1 - INPUT FLANGE SEAL

2 - SCREWDRIVER

RSREAR DRIVELINE MODULE3-27

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 131 of 2177

(10) Install and torque overrunning clutch hous-

ing-to-differential assembly bolts (Fig. 21) to 60 N´m

(44 ft. lbs.).

(11) Install input flange seal using tool 8802 (Fig.

22).(12) Install flange/shield assembly (Fig. 23).

(13) Install input flange washer and nut. Using

tool 6958 (Fig. 24), torque nut to 135 N´m (100 ft.

lbs.).

Fig. 21 Overrunning Clutch Housing Bolts

1 - OVERRUNNING CLUTCH HOUSING

2 - BOLT (FOUR)

Fig. 22 Input Flange Seal Installation

1 - TOOL 8802

2 - HAMMER

Fig. 23 Input Flange/Shield

1 - INPUT FLANGE/SHIELD

Fig. 24 Input Flange Nut

1 - INPUT FLANGE

2 - TOOL 6958

3 - 32 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 132 of 2177

(14) Install torque arm assembly into position.

Install and torque torque arm-to-differential assem-

bly bolts (Fig. 25) to 60 N´m (44 ft. lbs.).

INSTALLATION

(1) Install rear driveline module assembly to

transmission jack and secure.

(2) Raise rear driveline module into position and

install and torque mounting bolts (Fig. 26) to 54 N´m

(40 ft. lbs.).(3) Remove transmission jack.

(4) Install and torque torque arm mount-to-body

bolts to 54 N´m (40 ft. lbs.).

(5) Install halfshafts to differential output flanges

and torque bolts (Fig. 27) to 61 N´m (45 ft. lbs.).

(6) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT -

INSTALLATION)

(7) Lower vehicle.

Fig. 25 Torque Arm Fasteners

1 - TORQUE ARM ASSEMBLY

2 - BOLT (SIX)

Fig. 26 Rear Drive Line Module Assembly Rear

Mounting Bolts

1 - DRIVELINE MODULE RETAINING BOLT (2)

2 - RUBBER ISOLATOR

3 - WASHER

Fig. 27 Half Shaft Mounting Bolts

1 - SHAFT

2 - FLANGE

RSREAR DRIVELINE MODULE3-33

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 133 of 2177

SPECIFICATIONS - REAR DRIVELINE MODULE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, Driveline Module-to-Body 54 40 Ð

Bolt, Halfshaft-to-Ouput Flange 61 45 Ð

Bolt, Overrunning Clutch Housing-to-Differential 60 44 Ð

Bolt, Torque Arm-to-Differential Assembly 60 44 Ð

Bolt, Torque Arm Mount-to-Body 54 40 Ð

Nut, Input Flange 135 100 Ð

Plug, Differential Drain/Fill 35 26 Ð

Plug, Overrunning Clutch Housing Drain/Fill 30 22 Ð

Vent, Differential/Overrunning Clutch Housing 12 Ð 110

SPECIAL TOOLSBI-DIRECTIONAL

OVERRUNNING CLUTCH

DESCRIPTION

The bi-directional overrunning clutch (BOC) (Fig.

28) works as a mechanical disconnect between the

front and rear axles, preventing torque from being

transferred from the rear axle to the front. The BOC

is a simply an overrunning clutch which works in

both clockwise and counter-clockwise rotations. This

means that when the output (the rear axle) is rotat-

ing faster in one direction than the input (front axle),

there is no torque transmission. But when the input

speed is equal to the output speed, the unit becomes

locked. The BOC provides significant benefits regard-

ing braking stability, handling, and driveline durabil-

ity. Disconnecting the front and the rear driveline

during braking helps to maintain the braking stabil-

ity of an AWD vehicle. In an ABS/braking event, the

locking of the rear wheels must be avoided for stabil-

ity reasons. Therefore brake systems are designed to

lock the front wheels first. Any torque transfer from

the rear axle to the front axle disturbs the ABS/brak-

ing system and causes potential instabilities on a

slippery surface. The BOC de-couples the rear driv-

eline as soon the rear wheels begin to spin faster

than the front wheels (front wheels locked) in order

to provide increased braking stability. Furthermore

the BOC also reduces the likelihood of throttle off

over-steer during cornering. In a throttle off maneu-

ver, the BOC once again de-couples the rear driveline

forcing all the engine brake torque to the front

wheels. This eliminates the chance of lateral slip on

the rear axle and increases it on the front. The vehi-

cle will therefore tend to understeer, a situation

which is considered easier to manage in most circum-

stances. During this maneuver, and during the ABS

braking event, the BOC does not transmit torque

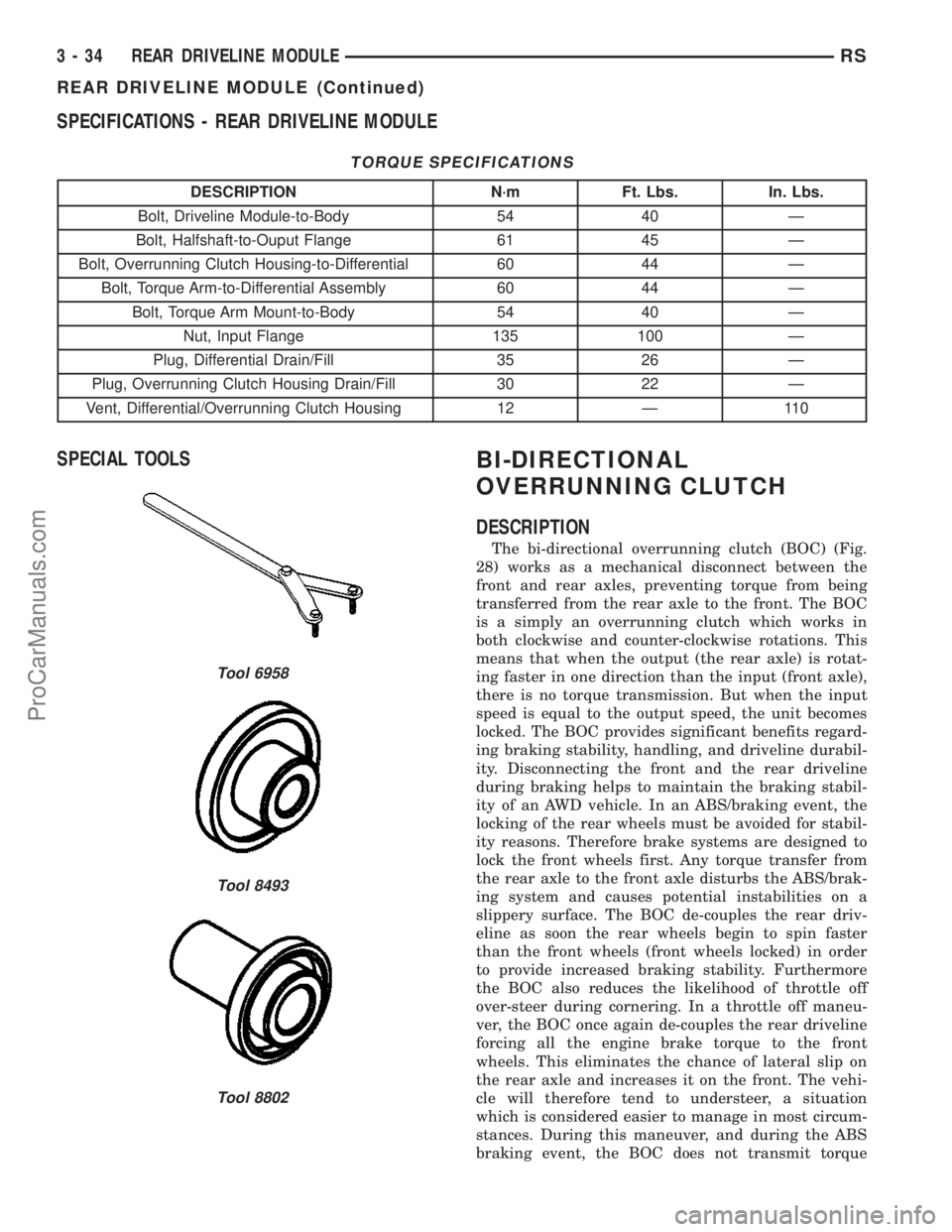

Tool 6958

Tool 8493

Tool 8802

3 - 34 REAR DRIVELINE MODULERS

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 135 of 2177

OPERATION

In order to achieve all-wheel drive operation in

reverse, the overrunning clutch locking functional

direction must be reversible. The bi-directional over-

running clutch (BOC) changes the operational mode

direction depending on the propeller shaft direction.

The propeller shaft rotates in the clockwise (when

viewed from the front) direction when the vehicle is

moving forward, which indexes the BOC to the for-

ward overrunning position. When the vehicle is in

reverse, the propeller shaft will rotate counter-clock-

wise and index the BOC to the reverse overrunning

position.

The BOC acts as a mechanical stator. It is active

(transmitting torque), or it is not active and in over-

running mode (not transmitting torque). This ªall or

nothingº approach to torque transfer would cause a

sudden application of all available power to the rear

wheels, which is not desirable. Therefore it is run in

series with a viscous coupler to smooth, dampen, and

limit the transmission of torque to the rear axle and

to prevent a step style torque input to the rear axle.

STEADY STATE, LOW TO MODERATE SPEED, NO

FRONT WHEEL SLIP, FORWARD DIRECTION

During normal driving conditions, (no wheel slip),

the inner shaft (front axle) and outer race (viscous

coupler) are running at different speeds due to the

different gear ratios between the front and rear dif-

ferentials. In this condition, the outer race is always

spinning faster (overdriving between 5-32 rpm) than

the inner shaft. When the BOC (Fig. 29) is running

under these conditions, at low vehicle speeds the

drag shoes and the cage keep the rollers up on the

left side (forward side) of the inner shaft flats. This is

what is known as ªoverrunning mode.º Notice that

when the clutch is in overrunning mode, the rollers

are spinning clockwise and with the outer race, thus

no torque is being transferred.

NOTE: Low speed, forward and reverse operation is

identical, just in opposite directions. (Fig. 29)

shows forward direction in reverse the rollers are

on the other side of the flats due to a reversal of

the cage force.

TRANSIENT CONDITION (BOC LOCKED), FRONT

WHEEL SLIP, FORWARD DIRECTION

When the front wheels lose traction and begin to

slip, the propeller shaft and rear axle pinion speed

difference decreases to zero. At this point the input

shaft (cam) becomes the driving member of the BOC

(Fig. 30), compressing the rollers against the outer

race. This locks the input shaft with the outer race

and transmits torque to the housing of the viscous

coupler, that in turn transmits torque to the rear

axle pinion. It should also be noted that when the

device is locked, the inner shaft and the outer race

are rotating at the same speed. The rollers are

pinched at this point and will stay locked until a

torque reversal (no front wheel slip) occurs. When

locked, the viscous coupler slips during the torque

transfer and the amount of torque transferred is

dependent on the coupling characteristic and the

amount of front wheel slip.

Fig. 29 BOC Operation at Low Speeds With No

Front Wheel Slip

1 - CAGE

2 - ROLLER

3 - INPUT SHAFT

3 - 36 REAR DRIVELINE MODULERS

BI-DIRECTIONAL OVERRUNNING CLUTCH (Continued)

ProCarManuals.com

Page 136 of 2177

STEADY STATE, HIGH SPEED, NO WHEEL SLIP

The roller cage positions the rollers on the input

shaft flats during low and high speed overrunning

and during initial BOC lockup. The roller cage is

rotating at input shaft (propeller shaft) speed at all

times. At low speeds, the friction shoes (Fig. 31) are

pressed against the friction ground via the garter

spring (Fig. 32), creating a drag force on the roller

cage. The drag force positions the cage, which in turn

positions the rollers to one side of the flat. The direc-

tion of this drag force (position of the roller) is depen-

dent on the input (propeller shaft) rotational

direction. Since the rollers are always in contact with

the outer race, due to centrifugal forces, the rollers

want to follow the outer race due to drag. During

overrunning operation, the outer race is rotating

faster than the input; causing the rollers to want to

traverse the flat from one side to the other. During

low speeds, the brake shoes counteract this effect. To

avoid excessive wear, the ground shoes are designed

to lift off from the friction ground due to centrifugal

forces at higher rotational speeds.

To keep the rollers in the overrunning position and

avoid undesired9high speed lockup9, a high speed

latch (Fig. 33) positions the cage before the ground

shoes lift off. A further explanation of the high speed

effects follows as well. Utilizing only the friction

shoes approach means that at high speed the

required ground shoe drag torque would cause exces-

sive brake shoe wear or the roller will begin to

migrate to the opposite side of the flat due to the

drag force of the outer race. This would result in sys-

tem lock-up. (Fig. 34) shows the BOC as it crossesthe speed where the brake shoe force is overcome by

the roller drag on the outer race. Notice that the

roller is locking up on the opposite side of the flat

and the cage supplies no force on the rollers.

Fig. 30 BOC Operation with Front Wheel SlipFig. 31 Front View of BOC

1 - GARTER SPRING

2 - FRICTION BRAKE SHOES

3 - FRICTION GROUND CONNECTED TO GROUND TAB

4 - INPUT SHAFT

Fig. 32 Location of the Grounding Element

1 - DIFFERENTIAL HOUSING

2 - GROUND TAB

3 - GARTER SPRING

RSREAR DRIVELINE MODULE3-37

BI-DIRECTIONAL OVERRUNNING CLUTCH (Continued)

ProCarManuals.com