seats CHRYSLER VOYAGER 2004 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2230 of 2585

SYMPTOM POSSIBLE CAUSE

Buzz, Squeak,Rattles from sunroof Loose or broken attaching hardware.

No lubracation in track.

Worn or broken mechanism.

Cables bunched or kinked

Sunshade will not function or does not

operate smoothlySunshade feet are missing, broken or loose.

No lubracation in track.

Track obstructions or interference.

Glass movement not consistant or glass does

not operate smoothlyGlass and Track timing.

Glass and Track alignment

Cables and Guide alignment

WATER DRAINAGE AND WIND NOISE DIAGNOSIS

The sliding glass panel is designed to seal water

entry with a snug fit between the roof and the seal.

The fit can be checked by inserting a piece of paper

between the roof and the seal. The piece of paper

should have some resistance when pulled out when

the glass panel is in the closed position. The sunroof

housing will drain off a minimum amount of water.

Excessive wind noise could result if the gap clear-

ances are exceeded. The sunroof glass panel may

need to be adjusted. Refer to Sunroof Glass Panel

Adjustment for proper procedures.

Adequate drainage is provided by a drain trough in

the sunroof housing which encircles the sliding glass

panel and leads to drain hoses. If a wet headliner or

other water leak complaints are encountered, before

performing any adjustments, first ensure that the

drainage system is not plugged or disconnected. Use

a pint container to pour water into the sunroof hous-

ing drain trough. If water flow is restricted, use com-

pressed air to blow out any material plugging the

drain system. Retest system again.

To further check for a disconnected drain hose:

(1) Remove A-pillar trim, sun visors, and map

lamps/mini console.

(2) Remove sunroof opening trim lace. Refer to

Sunroof Opening Trim Lace.

NOTE: Care must be taken not to fold or kink the

headliner upon removal.

(3) Lower headliner as necessary to gain access to

sunroof housing drain tubes. Refer to Headlining

Removal and Installation for proper procedures.

(4) Repair as necessary.

DRAIN TUBE

REMOVAL

FRONT HOSES

NOTE: Front A-pillars are filled with sound deaden-

ing foam and the front drain tubes are sealed into

the pillars.

(1) Move glass panel to the fully closed position.

(2) Disconnect negative battery cable.

(3) Remove headliner (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL).

(4) Disconnect the drain hose from the sunroof

housing (Fig. 1).

(5) Drain any liquid from hose connection, repair

as necessary.

REAR HOUSING HOSE

(1) Move glass panel to the fully closed position.

(2) Disconnect negative battery cable.

(3) Remove headliner (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL).

(4) Remove third seat or seats from vehicle.

(5) Remove second seat belt lower anchor.

(6) Remove third seat lower anchor.

(7) Remove quarter trim bolster.

(8) Remove trim panel screws.

(9) Remove quarter trim panel

(10) Disconnect the drain hose from the sunroof

housing. (Fig. 1).

(11) Drain any liquid from hose connection, if nec-

essary, and remove tube.

RSSUNROOF23 - 119

SUNROOF (Continued)

Page 2451 of 2585

DISTRIBUTION - REAR

TABLE OF CONTENTS

page page

AIR OUTLETS

DESCRIPTION.........................56

REMOVAL.............................56

INSTALLATION.........................56

DISTRIBUTION DUCT

REMOVAL.............................57

INSTALLATION.........................57

BLOWER MOTOR

DESCRIPTION.........................57

OPERATION...........................57DIAGNOSIS AND TESTING - REAR BLOWER

MOTOR .............................58

REMOVAL.............................58

INSTALLATION.........................58

HVAC HOUSING

REMOVAL.............................60

INSTALLATION.........................61

REAR FLOOR HEAT DUCT

REMOVAL.............................62

INSTALLATION.........................63

AIR OUTLETS

DESCRIPTION

Based upon the system mode selected, conditioned

air can exit the rear HVAC housing through one or a

combination of the two main housing outlets: air con-

ditioner, or heater. Once the conditioned air exits the

unit housing, it is directed through molded plastic

ducts to the various outlets in the vehicle interior.

These outlets and their locations are as follows:

²Floor Outlets- Three floor outlets with fixed

vanes are located in the right quarter trim panel,

near the floor. These outlets distribute air from the

rear floor heat duct to the intermediate and rear seat

occupants. The floor outlets are integral to the right

quarter trim panel and, if faulty or damaged, the

quarter trim panel must be replaced.

²Overhead Outlets- Four (two right side and

two left side) fully adjustable outlets along the roof

rails distribute air from the rear distribution duct

and the headliner ducts to the intermediate and rear

seat occupants. The headliner ducts are integral to

the headliner panel. Each overhead outlet is housed

in a headliner bezel. The two forward headliner

bezels also feature a courtesy lamp, a fold-away coat

hook, and a fold-away assist handle. The overhead

outlets can be removed from the headliner bezels

individually for service replacement.

REMOVAL

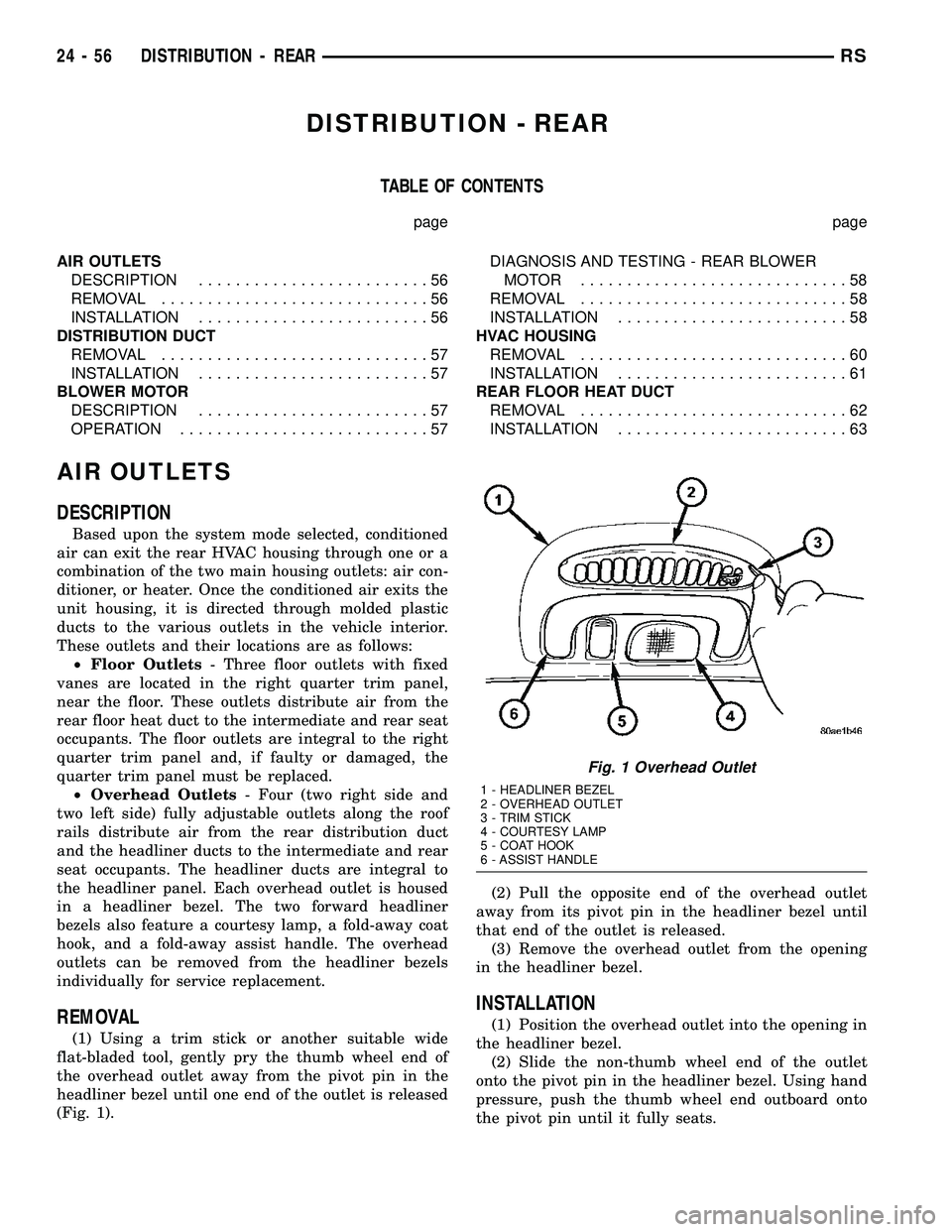

(1) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the thumb wheel end of

the overhead outlet away from the pivot pin in the

headliner bezel until one end of the outlet is released

(Fig. 1).(2) Pull the opposite end of the overhead outlet

away from its pivot pin in the headliner bezel until

that end of the outlet is released.

(3) Remove the overhead outlet from the opening

in the headliner bezel.

INSTALLATION

(1) Position the overhead outlet into the opening in

the headliner bezel.

(2) Slide the non-thumb wheel end of the outlet

onto the pivot pin in the headliner bezel. Using hand

pressure, push the thumb wheel end outboard onto

the pivot pin until it fully seats.

Fig. 1 Overhead Outlet

1 - HEADLINER BEZEL

2 - OVERHEAD OUTLET

3 - TRIM STICK

4 - COURTESY LAMP

5 - COAT HOOK

6 - ASSIST HANDLE

24 - 56 DISTRIBUTION - REARRS

Page 2468 of 2585

CHARGING PROCEDURE

CAUTION: A small amount of refrigerant oil is

removed from the A/C system each time the refrig-

erant system is recovered and evacuated. Before

charging the A/C system, you MUST replenish any

oil lost during the recovery process. Refer the

equipment manufacturer instructions for more infor-

mation.

(1) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(2) A manifold gauge set and a R-134a refrigerant

recovery/recycling/charging station that meets SAE

Standard J2210 should still be connected to the

refrigerant system.

(3) Measure the proper amount of refrigerant and

heat it to 52É C (125É F) with the charging station.

See the operating instructions supplied by the equip-

ment manufacturer for proper use of this equipment.

(4) Open both the suction and discharge valves,

then open the charge valve to allow the heated

refrigerant to flow into the system.

(5) When the transfer of refrigerant has stopped,

close both the suction and discharge valves.

(6) If all of the refrigerant charge did not transfer

from the dispensing device, open all of the windows

in the vehicle and set the heater-air conditioner con-

trols so that the compressor is engaged and the

blower motor is operating at its lowest speed setting.

Run the engine at a steady high idle (about 1400

rpm). If the compressor will not engage, test the com-

pressor clutch control circuit and repair as required.

(7) Open the suction valve to allow the remaining

refrigerant to transfer to the refrigerant system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH PRESSURE) VALVE AT THIS TIME.

(8) Close the suction valve and test the system

performance. (Refer to 24 - HEATING & AIR CON-

DITIONING - STANDARD PROCEDURE - A/C PER-

FORMANCE TEST).

(9) Disconnect the charging station and manifold

gauge set from the refrigerant system service ports.

(10) Reinstall the caps onto the refrigerant system

service ports.

(11) Run the HVAC Control Cooldown test to ver-

ify proper operation(Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND TESTING).A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR

Vehicles equipped with the 2.5L diesel, 3.3L and

3.8L gasoline engines use the Denso 10S20 A/C com-

pressor. Vehicles equipped with the 2.4L gasoline

engine use the Denso 10S17 A/C compressor. Both

A/C compressors include an integral high pressure

relief valve. The A/C compressor is secured to a

mounting bracket on the 2.4L gasoline engine and

directly to the cylinder block on the 2.5L diesel, 3.3L

and 3.8L gasoline engines.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the rear

of the A/C compressor. This mechanical valve is

designed to vent refrigerant from the A/C system to

protect against damage to the compressor and other

system components, caused by condenser air flow

restriction or an overcharge of refrigerant.

OPERATION

OPERATION - A/C COMPRESSOR

The A/C compressor is driven by the engine

through an electric clutch, drive pulley and belt

arrangement. The compressor is lubricated by refrig-

erant oil that is circulated throughout the refrigerant

system with the refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor. The compressor

pumps the high-pressure refrigerant vapor to the

condenser through the compressor discharge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

when a minimum discharge pressure of 2756 kPa

(400 psi) is reached.

The high pressure relief valve vents only enough

refrigerant to reduce the system pressure, and then

re-seats itself. The majority of the refrigerant is con-

served in the system. If the valve vents refrigerant, it

does not mean that the valve is faulty.

RSPLUMBING - FRONT24-73

PLUMBING - FRONT (Continued)

Page 2561 of 2585

INBOARD - 50/50 BENCH - REMOVAL,

SEAT BELT BUCKLE - SECOND ROW.....8O-13

INBOARD - INSTALLATION, SEAT BELT

BUCKLE - FRONT....................8O-12

INBOARD - QUAD BUCKET -

INSTALLATION, SEAT BELT BUCKLE -

FIRST ROW.........................8O-12

INBOARD - QUAD BUCKET - REMOVAL,

SEAT BELT BUCKLE - FIRST ROW.......8O-12

INBOARD - REMOVAL, SEAT BELT

BUCKLE - FRONT....................8O-12

INDICATOR LAMP - DESCRIPTION,

VTSS/SKIS..........................8Q-7

INDICATOR LAMP - OPERATION,

VTSS/SKIS..........................8Q-8

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR..........22-16,22s-8

INFLATION PRESSURES - STANDARD

PROCEDURE, TIRE..............22-16,22s-8

INFO CENTER - DESCRIPTION,

ELECTRONIC VEHICLE.................8M-6

INFO CENTER - INSTALLATION,

ELECTRONIC VEHICLE.................8M-9

INFO CENTER - OPERATION,

ELECTRONIC VEHICLE.................8M-7

INFO CENTER - REMOVAL, ELECTRONIC

VEHICLE............................8M-9

INFRARED TEMPERATURE SENSOR -

DESCRIPTION.......................24-29

INFRARED TEMPERATURE SENSOR -

OPERATION.........................24-29

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP.............................19-37

INJECTION SYSTEM - OPERATION.......14-18

INJECTOR - DESCRIPTION, FUEL........14-26

INJECTOR - OPERATION, FUEL..........14-26

INLET AIR TEMPERATURE SENSOR -

DESCRIPTION.......................14-30

INLET FILTER - INSTALLATION..........14-13

INLET FILTER - REMOVAL..............14-13

INLET HOSE - INSTALLATION, HEATER....24-86

INLET HOSE - REMOVAL, HEATER.......24-85

INLET TUBE - 2.4L - DESCRIPTION,

WATER PUMP........................7-35

INLET TUBE - 2.4L - INSTALLATION,

WATER PUMP........................7-35

INLET TUBE - 2.4L - REMOVAL, WATER

PUMP..............................7-35

INLET TUBE - 3.3/3.8L - INSTALLATION,

WATER PUMP........................7-36

INLET TUBE - 3.3/3.8L - REMOVAL,

WATER PUMP........................7-36

INNER - INSTALLATION, CV BOOT.........3-6

INNER - REMOVAL, CV BOOT.............3-6

INNER BELT MOLDING - INSTALLATION,

FRONT DOOR......................23-115

INNER BELT MOLDING - REMOVAL,

FRONT DOOR......................23-115

INNER SEAL - INSTALLATION, HALF

SHAFT.............................21-12

INNER SEAL - REMOVAL, HALF SHAFT . . . 21-12

INNER/OUTER - INSTALLATION, CV

BOOT...............................3-17

INNER/OUTER - REMOVAL, CV BOOT......3-15

INPUT - DESCRIPTION, SPEED SENSOR . 21-239,

21s-140

INPUT - INSTALLATION, SPEED

SENSOR....................21-240,21s-141

INPUT - OPERATION, DATA BUS

COMMUNICATION RECEIVE - PCM.......8E-15

INPUT - OPERATION, IGNITION SENSE -

PCM...............................8E-15

INPUT - OPERATION, SENSOR RETURN -

PCM...............................8E-15

INPUT - OPERATION, SPEED SENSOR . . . 21-240,

21s-140

INPUT - REMOVAL, SPEED SENSOR....21-240,

21s-141

INPUT CLUTCH ASSEMBLY - ASSEMBLY . 21-216,

21s-116

INPUT CLUTCH ASSEMBLY -

DISASSEMBLY...............21-208,21s-107

INPUT FLANGE SEAL - INSTALLATION

.....3-45

INPUT FLANGE SEAL - REMOVAL

.........3-44

INPUT SHAFT - ASSEMBLY

........21-96,21s-5

INPUT SHAFT - DESCRIPTION

.....21-93,21s-1

INPUT SHAFT - DISASSEMBLY

.....21-93,21s-1INPUT SHAFT COVER SEAL -

INSTALLATION.......................21-14

INPUT SHAFT COVER SEAL - REMOVAL . . . 21-13

INPUT SHAFT END SEAL -

INSTALLATION.......................21-16

INPUT SHAFT END SEAL - REMOVAL.....21-15

INPUT SHAFT SEAL - INSTALLATION.....21-18

INPUT SHAFT SEAL - REMOVAL.........21-17

INSIDE HANDLE ACTUATOR -

INSTALLATION.......................23-27

INSIDE HANDLE ACTUATOR - REMOVAL . . 23-27

INSIDE HANDLE CABLE - INSTALLATION . . 23-38

INSIDE HANDLE CABLE - REMOVAL......23-37

INSIDE LATCH HANDLE - INSTALLATION . . 23-34

INSIDE LATCH HANDLE - REMOVAL......23-34

INSPECT, INSPECTION...............21-114

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-1

INSTRUMENT CLUSTER - OPERATION.....8J-1

INSTRUMENT PANEL - INSTALLATION,

LOWER............................23-69

INSTRUMENT PANEL - REMOVAL,

LOWER............................23-69

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-9

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-8

INSTRUMENT PANEL ASSEMBLY -

INSTALLATION.......................23-66

INSTRUMENT PANEL ASSEMBLY -

REMOVAL............................23-65

INSTRUMENT PANEL CENTER BEZEL -

INSTALLATION.......................23-68

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL..........................23-68

INSTRUMENT PANEL DEMISTER DUCTS

- INSTALLATION.....................24-55

INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL.........................24-55

INSTRUMENT PANEL DUCTS -

INSTALLATION.......................24-55

INSTRUMENT PANEL DUCTS - REMOVAL . 24-55

INSTRUMENT PANEL END CAP -

INSTALLATION.......................23-68

INSTRUMENT PANEL END CAP -

REMOVAL..........................23-68

INSTRUMENT PANEL OUTLET -

INSTALLATION.......................24-46

INSTRUMENT PANEL OUTLET -

REMOVAL..........................24-45

INSTRUMENT PANEL TOP COVER -

INSTALLATION.......................23-69

INSTRUMENT PANEL TOP COVER -

REMOVAL..........................23-68

INSTRUMENT PANEL TOP PAD

ASSEMBLY - INSTALLATION............23-72

INSTRUMENT PANEL TOP PAD

ASSEMBLY - REMOVAL................23-71

INTAKE MANIFOLD - DESCRIPTION . . 9-144,9-58

INTAKE MANIFOLD - INSTALLATION,

LOWER............................9-149

INTAKE MANIFOLD - INSTALLATION,

UPPER.............................9-147

INTAKE MANIFOLD - LOWER -

CLEANING..........................9-148

INTAKE MANIFOLD - LOWER -

INSPECTION....................9-148,9-60

INTAKE MANIFOLD - LOWER -

INSTALLATION........................9-60

INTAKE MANIFOLD - LOWER - REMOVAL . . 9-60

INTAKE MANIFOLD - REMOVAL, LOWER . . 9-148

INTAKE MANIFOLD - REMOVAL, UPPER . . . 9-145

INTAKE MANIFOLD - UPPER -

INSPECTION.........................9-59

INTAKE MANIFOLD - UPPER -

INSTALLATION........................9-59

INTAKE MANIFOLD - UPPER - REMOVAL . . . 9-58

INTAKE MANIFOLD LEAKS - DIAGNOSIS

AND TESTING...................9-145,9-58

INTAKE MANIFOLD VACUUM PORT

REPAIR - STANDARD PROCEDURE.......9-145

INTAKE PIPE - INSTALLATION, AIR

......24-114

INTAKE PIPE - REMOVAL, AIR

.........24-113

INTAKE/EXHAUST VALVES & SEATS -

CLEANING

.................9-105,9-32,9s-22

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION

..............9-104,9-32,9s-21

INTAKE/EXHAUST VALVES & SEATS -

INSPECTION

...................9-105,9s-22INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION..................9-106,9s-23

INTAKE/EXHAUST VALVES & SEATS -

OPERATION....................9-104,9s-21

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL.....................9-105,9s-22

INTEGRAL ANTENNA - EXPORT -

DESCRIPTION, QUARTER GLASS.........8A-9

INTEGRAL ANTENNA - EXPORT -

DIAGNOSIS AND TESTING, QUARTER

GLASS..............................8A-9

INTEGRAL ANTENNA - EXPORT -

OPERATION, QUARTER GLASS...........8A-9

INTEGRATED POWER MODULE -

DESCRIPTION.....................8W-97-2

INTEGRATED POWER MODULE -

INSTALLATION....................8W-97-3

INTEGRATED POWER MODULE -

OPERATION.......................8W-97-2

INTEGRATED POWER MODULE -

REMOVAL........................8W-97-2

INTERACTIVE SPEED CONTROL (4

SPEED EATX ONLY) - OPERATION........8P-2

INTERFACE (PCI) BUS, OPERATION -

PROGRAMMABLE COMMUNICATIONS....14-21

INTERIOR LAMPS, SPECIFICATIONS......8L-20

INTERLOCK - DESCRIPTION, IGNITION....19-17

INTERLOCK SOLENOID - DESCRIPTION,

SHIFT......................21-233,21s-133

INTERLOCK SOLENOID - DIAGNOSIS

AND TESTING, BRAKE/TRANSMISSION

SHIFT......................21-235,21s-135

INTERLOCK SOLENOID - INSTALLATION,

SHIFT.......................21-236,21s-136

INTERLOCK SOLENOID - OPERATION,

SHIFT......................21-233,21s-134

INTERLOCK SOLENOID - REMOVAL,

SHIFT......................21-235,21s-135

INTERLOCK SWITCH - INSTALLATION,

CLUTCH PEDAL.......................6-14

INTERLOCK SWITCH - REMOVAL,

CLUTCH PEDAL.......................6-13

INTERMEDIATE SHAFT - ASSEMBLY....21-107,

21s-17

INTERMEDIATE SHAFT - DESCRIPTION . . 21-100,

21s-9

INTERMEDIATE SHAFT - DISASSEMBLY . 21-100,

21s-10

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-5

INTERNATIONAL SYMBOLS -

DESCRIPTION.........................0-1

INTRODUCTION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS........9-3,9-76

IOD FUSE - DESCRIPTION...........8W-97-3

IOD FUSE - OPERATION.............8W-97-3

JOINT - DESCRIPTION, LOWER BALL......2-10

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL........................2-10

JOINT - OPERATION, LOWER BALL.......2-10

JOINT MOLDING - INSTALLATION, ROOF . . 23-58

JOINT MOLDING - REMOVAL, ROOF......23-58

JOUNCE BUMPER - DESCRIPTION........2-36

JOUNCE BUMPER - OPERATION..........2-36

JUMP STARTING - STANDARD

PROCEDURE.........................0-27

JUNCTION BLOCK - DESCRIPTION,

NON-ABS.......................5-33,5s-32

JUNCTION BLOCK - INSTALLATION,

NON-ABS.......................5-33,5s-32

JUNCTION BLOCK - OPERATION,

NON-ABS.......................5-33,5s-32

JUNCTION BLOCK - REMOVAL, NON-ABS . . 5-33,

5s-32

KEY - DESCRIPTION, TRANSPONDER.....8Q-6

KEY - OPERATION, TRANSPONDER.......8Q-6

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY................8E-18

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY

...............8E-19

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY

.................8E-18

KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY

............................8E-18

KEY REMOTE ENTRY MODULE -

DESCRIPTION, SENTRY

................8Q-3

KEY REMOTE ENTRY MODULE -

DIAGNOSIS AND TESTING, SENTRY

.......8Q-5

18 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2571 of 2585

RECOVERY CONTAINER - DESCRIPTION,

COOLANT............................7-19

RECOVERY CONTAINER - INSTALLATION,

COOLANT............................7-20

RECOVERY CONTAINER - OPERATION,

COOLANT............................7-19

RECOVERY CONTAINER - REMOVAL,

COOLANT............................7-20

RECOVERY SYSTEM - DIAGNOSIS AND

TESTING, COOLANT...................7-20

REFACING VALVES AND VALVE SEATS -

STANDARD PROCEDURE..........9-104,9s-21

REFERENCES - DESCRIPTION, TORQUE . . Intro.-8

REFRIGERANT - DESCRIPTION..........24-92

REFRIGERANT - OPERATION............24-92

REFRIGERANT LINE - DESCRIPTION......24-65

REFRIGERANT LINES - INSTALLATION,

UNDERBODY.......................24-111

REFRIGERANT LINES - OPERATION......24-65

REFRIGERANT LINES - REMOVAL,

UNDERBODY.......................24-110

REFRIGERANT OIL - DESCRIPTION......24-92

REFRIGERANT OIL - OPERATION........24-92

REFRIGERANT OIL LEVEL - STANDARD

PROCEDURE........................24-93

REFRIGERANT RECOVERY - STANDARD

PROCEDURE........................24-71

REFRIGERANT SYSTEM CHARGE -

STANDARD PROCEDURE...............24-72

REFRIGERANT SYSTEM EVACUATE -

STANDARD PROCEDURE...............24-72

REFRIGERANT SYSTEM LEAKS -

DIAGNOSIS AND TESTING.............24-66

REFRIGERANT SYSTEM SERVICE

EQUIPMENT - STANDARD PROCEDURE . . . 24-70

REGULATOR - DESCRIPTION, VOLTAGE . . . 8F-27,

8F-29

REGULATOR - INSTALLATION, FUEL

PRESSURE..........................14-7

REGULATOR - MANUAL - INSTALLATION,

WINDOW...........................23-23

REGULATOR - MANUAL - REMOVAL,

WINDOW...........................23-22

REGULATOR - OPERATION, FUEL

PRESSURE..........................14-7

REGULATOR - OPERATION, VOLTAGE....8F-27,

8F-29

REGULATOR - POWER - INSTALLATION,

WINDOW...........................23-22

REGULATOR - POWER - REMOVAL,

WINDOW...........................23-22

REGULATOR - REMOVAL, FUEL

PRESSURE..........................14-7

REINFORCEMENT - INSTALLATION,

FRONT BUMPER......................13-2

REINFORCEMENT - INSTALLATION,

GRILLE OPENING....................23-54

REINFORCEMENT - INSTALLATION, REAR

BUMPER............................13-3

REINFORCEMENT - REMOVAL, FRONT

BUMPER............................13-2

REINFORCEMENT - REMOVAL, GRILLE

OPENING...........................23-54

REINFORCEMENT - REMOVAL, REAR

BUMPER............................13-3

RELAY - DESCRIPTION, A/C

COMPRESSOR CLUTCH

...............24-19

RELAY - DESCRIPTION, AUTO SHUT

DOWN

..............................8I-3

RELAY - DESCRIPTION, BLOWER

MOTOR

.......................24-24,24-37

RELAY - DESCRIPTION, FUEL PUMP

.....14-28

RELAY - DESCRIPTION, RADIATOR FAN

....7-30

RELAY - DESCRIPTION, REAR WINDOW

DEFOGGER

..........................8G-3

RELAY - DESCRIPTION, TRANSMISSION

CONTROL

...................21-247,21s-150

RELAY - INSTALLATION, A/C

COMPRESSOR CLUTCH

...............24-20

RELAY - INSTALLATION, BLOWER

MOTOR

.......................24-25,24-38

RELAY - INSTALLATION, RADIATOR FAN

. . . 7-30

RELAY - INSTALLATION, REAR WINDOW

DEFOGGER

..........................8G-3

RELAY - OPERATION, A/C COMPRESSOR

CLUTCH

............................24-19

RELAY - OPERATION, AUTO SHUT DOWN

. . . 8I-3RELAY - OPERATION, BLOWER MOTOR . . 24-24,

24-37

RELAY - OPERATION, FUEL PUMP.......14-28

RELAY - OPERATION, RADIATOR FAN......7-30

RELAY - OPERATION, REAR WINDOW

DEFOGGER..........................8G-3

RELAY - OPERATION, TRANSMISSION

CONTROL...................21-248,21s-150

RELAY - REMOVAL, A/C COMPRESSOR

CLUTCH............................24-20

RELAY - REMOVAL, BLOWER MOTOR....24-25,

24-38

RELAY - REMOVAL, RADIATOR FAN.......7-30

RELAY - REMOVAL, REAR WINDOW

DEFOGGER..........................8G-3

RELEASE - STANDARD PROCEDURE,

PARKING BRAKE AUTOMATIC

ADJUSTER TENSION..............5-58,5s-61

RELEASE CABLE - INSTALLATION, LATCH . 23-62

RELEASE CABLE - REMOVAL, LATCH.....23-61

RELEASE LEVER AND BEARING -

INSTALLATION, CLUTCH.................6-7

RELEASE LEVER AND BEARING -

REMOVAL, CLUTCH.....................6-6

RELEASE PROCEDURE - STANDARD

PROCEDURE, FUEL SYSTEM

PRESSURE..........................14-2

RELIEF VALVE - DESCRIPTION, HIGH

PRESSURE.........................24-73

RELIEF VALVE - INSTALLATION, OIL

PRESSURE.........................9-141

RELIEF VALVE - OPERATION, HIGH

PRESSURE...........................24-73

RELIEF VALVE - REMOVAL, OIL

PRESSURE.........................9-141

REMOTE ENTRY MODULE -

DESCRIPTION, SENTRY KEY.............8Q-3

REMOTE ENTRY MODULE - DIAGNOSIS

AND TESTING, SENTRY KEY.............8Q-5

REMOTE ENTRY MODULE -

INSTALLATION, SENTRY KEY............8Q-6

REMOTE ENTRY MODULE - OPERATION,

SENTRY KEY.........................8Q-4

REMOTE ENTRY MODULE - REMOVAL,

SENTRY KEY.........................8Q-5

REMOTE ENTRY SYSTEM - DIAGNOSIS

AND TESTING, SENTRY KEY.............8Q-3

REMOTE KEYLESS ENTRY MODULE -

DESCRIPTION.......................8N-43

REMOTE KEYLESS ENTRY MODULE -

DIAGNOSIS AND TESTING.............8N-43

REMOTE KEYLESS ENTRY MODULE -

INSTALLATION......................8N-44

REMOTE KEYLESS ENTRY MODULE -

OPERATION.........................8N-43

REMOTE KEYLESS ENTRY MODULE -

REMOVAL..........................8N-44

REMOTE KEYLESS ENTRY

TRANSMITTER PROGRAMMING -

STANDARD PROCEDURE...............8N-5

REMOTE SWITCH - DIAGNOSIS AND

TESTING...........................8N-49

REMOTE SWITCH - INSTALLATION......8N-49

REMOTE SWITCH - REMOVAL..........8N-49

REMOTE SWITCHES - DESCRIPTION.....8A-12

REMOTE SWITCHES - DIAGNOSIS AND

TESTING...........................8A-12

REMOTE SWITCHES - INSTALLATION.....8A-14

REMOTE SWITCHES - OPERATION.......8A-12

REMOTE SWITCHES - REMOVAL........8A-13

REPAIR - DESCRIPTION, FRONT CRADLE

CROSSMEMBER THREAD...............13-9

REPAIR - DESCRIPTION, THREADED

HOLE.............................Intro.-5

REPAIR - STANDARD PROCEDURE, GRID

LINE AND TERMINAL..................8G-4

REPAIR - STANDARD PROCEDURE,

INTAKE MANIFOLD VACUUM PORT......9-145

REPAIR - STANDARD PROCEDURE,

MANIFOLD STRIPPED THREAD

..........9-145

REPAIR - STANDARD PROCEDURE,

PLASTIC BODY PANEL

.................23-3

REPAIR OF DAMAGED OR WORN

THREADS - STANDARD PROCEDURE

. . 9-10,9-86

REPAIRING - STANDARD PROCEDURE,

TIRE LEAK

.....................22-17,22s-9

REQUIREMENTS - DESCRIPTION,

ENGINE COOLING SYSTEM

..............24-1REQUIREMENTS - DESCRIPTION, FUEL.....0-4

REQUIREMENTS - DIESEL ENGINE -

DESCRIPTION, FUEL....................0-6

RESERVOIR - DESCRIPTION, VACUUM....8P-6

RESERVOIR - INSTALLATION, VACUUM....8P-6

RESERVOIR - INSTALLATION, WASHER . . . 8R-13

RESERVOIR - OPERATION, VACUUM......8P-6

RESERVOIR - REMOVAL, VACUUM........8P-6

RESERVOIR - REMOVAL, WASHER......8R-13

RESET - STANDARD PROCEDURE,

PARKING BRAKE AUTOMATIC

ADJUSTER TENSION..............5-59,5s-61

RESISTANCE, SPECIFICATIONS - SPARK

PLUG CABLE.........................8I-2

RESISTANCE TEST - DIAGNOSIS AND

TESTING, FEED CIRCUIT..........8F-32,8F-34

RESISTOR - DESCRIPTION, BLOWER

MOTOR............................24-38

RESISTOR - INSTALLATION, BLOWER

MOTOR............................24-39

RESISTOR - OPERATION, BLOWER

MOTOR............................24-38

RESISTOR - REMOVAL, BLOWER

MOTOR............................24-39

RESISTOR BLOCK - DESCRIPTION,

BLOWER MOTOR....................24-26

RESISTOR BLOCK - DIAGNOSIS AND

TESTING, BLOWER MOTOR............24-26

RESISTOR BLOCK - DIAGNOSIS AND

TESTING, REAR BLOWER MOTOR.......24-38

RESISTOR BLOCK - INSTALLATION,

BLOWER MOTOR......................24-27

RESISTOR BLOCK - OPERATION,

BLOWER MOTOR....................24-26

RESISTOR BLOCK - REMOVAL, BLOWER

MOTOR............................24-26

RESONATOR - INSTALLATION............11-9

RESONATOR - REMOVAL...............11-9

RESTRAINT ANCHOR - DESCRIPTION,

CHILD..............................8O-4

RESTRAINT ANCHOR - OPERATION,

CHILD..............................8O-4

RESTRAINT CONTROLLER -

DESCRIPTION, OCCUPANT..............8O-8

RESTRAINT CONTROLLER -

INSTALLATION, OCCUPANT.............8O-8

RESTRAINT CONTROLLER - OPERATION,

OCCUPANT..........................8O-8

RESTRAINT CONTROLLER - REMOVAL,

OCCUPANT..........................8O-8

RESTRAINTS - DESCRIPTION............8O-2

RESTRAINTS - OPERATION.............8O-2

RESTRAINTS - WARNING...............8O-2

RESTRICTION CHECK - DIAGNOSIS AND

TESTING, EXHAUST SYSTEM............11-2

RETAINER - INSTALLATION,

CRANKSHAFT REAR OIL SEAL..........9-129

RETAINER - INSTALLATION, PLASTIC

GROCERY BAG

.....................23-105

RETAINER - REMOVAL, CRANKSHAFT

REAR OIL SEAL

......................9-129

RETAINER - REMOVAL, PLASTIC

GROCERY BAG

.....................23-104

RETRACTOR - FIRST ROW - OUTBOARD

- INSTALLATION, SEAT BELT

...........8O-14

RETRACTOR - FIRST ROW - OUTBOARD

- REMOVAL, SEAT BELT

...............8O-14

RETRACTOR - OUTBOARD - FRONT -

INSTALLATION, SEAT BELT

.............8O-14

RETRACTOR - OUTBOARD - FRONT -

REMOVAL, SEAT BELT

................8O-14

RETRACTOR - SECOND ROW - LEFT

OUTBOARD - INSTALLATION, SEAT

BELT

..............................8O-17

RETRACTOR - SECOND ROW - LEFT

OUTBOARD - REMOVAL, SEAT BELT

.....8O-17

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD - INSTALLATION, SEAT

BELT

..............................8O-15

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD - REMOVAL, SEAT BELT

.....8O-15

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC - LWB -

INSTALLATION, SEAT BELT

.............8O-16

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC - LWB -

REMOVAL, SEAT BELT

................8O-16

28 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2574 of 2585

SEAT TRACK MANUAL ADJUSTER -

INSTALLATION, FRONT................23-95

SEAT TRACK MANUAL ADJUSTER -

REMOVAL, FRONT....................23-95

SEAT TRACK POWER ADJUSTER -

INSTALLATION, FRONT................23-95

SEAT TRACK POWER ADJUSTER -

REMOVAL, FRONT....................23-95

SEATBACK ASSIST STRAP -

INSTALLATION, FRONT................23-92

SEATBACK ASSIST STRAP - REMOVAL,

FRONT.............................23-92

SEATBACK COVER - INSTALLATION,

FRONT.............................23-93

SEATBACK COVER - REMOVAL, FRONT . . . 23-93

SEATBACK PANEL - INSTALLATION,

BENCH.............................23-99

SEATBACK PANEL - INSTALLATION,

FRONT.............................23-93

SEATBACK PANEL - REMOVAL, BENCH . . . 23-99

SEATBACK PANEL - REMOVAL, FRONT....23-92

SEAT/MIRROR MODULE - DESCRIPTION,

MEMORY...........................8E-10

SEAT/MIRROR MODULE - DIAGNOSIS

AND TESTING, MEMORY...............8E-10

SEAT/MIRROR MODULE -

INSTALLATION, MEMORY..............8E-10

SEAT/MIRROR MODULE - OPERATION,

MEMORY...........................8E-10

SEAT/MIRROR MODULE - REMOVAL,

MEMORY...........................8E-10

SEATS - CLEANING, INTAKE/EXHAUST

VALVES.....................9-105,9-32,9s-22

SEATS - DESCRIPTION, INTAKE/

EXHAUST VALVES...........9-104,9-32,9s-21

SEATS - INSPECTION, INTAKE/EXHAUST

VALVES .......................9-105,9s-22

SEATS - INSTALLATION, INTAKE/

EXHAUST VALVES...............9-106,9s-23

SEATS - OPERATION, INTAKE/EXHAUST

VALVES .......................9-104,9s-21

SEATS - REMOVAL, INTAKE/EXHAUST

VALVES .......................9-105,9s-22

SEATS - STANDARD PROCEDURE,

REFACING VALVES AND VALVE.....9-104,9s-21

SECOND ROW - INSTALLATION, BENCH

SEAT RISER........................23-101

SECOND ROW - LEFT OUTBOARD -

INSTALLATION, SEAT BELT &

RETRACTOR........................8O-17

SECOND ROW - LEFT OUTBOARD -

REMOVAL, SEAT BELT & RETRACTOR....8O-17

SECOND ROW - REMOVAL, BENCH SEAT

RISER............................23-101

SECOND ROW - RIGHT OUTBOARD -

INSTALLATION, SEAT BELT &

RETRACTOR........................8O-15

SECOND ROW - RIGHT OUTBOARD -

REMOVAL, SEAT BELT & RETRACTOR

....8O-15

SECOND ROW - RIGHT OUTBOARD

WITH REAR HVAC - LWB -

INSTALLATION, SEAT BELT &

RETRACTOR

........................8O-16

SECOND ROW - RIGHT OUTBOARD

WITH REAR HVAC - LWB - REMOVAL,

SEAT BELT & RETRACTOR

.............8O-16

SECOND ROW - THREE PASSENGER

BENCH - INSTALLATION, SEAT BELT

BUCKLE

............................8O-15

SECOND ROW - THREE PASSENGER

BENCH - REMOVAL, SEAT BELT

BUCKLE

............................8O-15

SECOND ROW INBOARD - 50/50 BENCH

- INSTALLATION, SEAT BELT BUCKLE

....8O-13

SECOND ROW INBOARD - 50/50 BENCH

- REMOVAL, SEAT BELT BUCKLE

........8O-13

SECTION IDENTIFICATION AND

INFORMATION - DESCRIPTION

........8W-01-6

SECURITY - DESCRIPTION, VEHICLE

THEFT

..............................8Q-1

SECURITY - OPERATION, VEHICLE THEFT

. . 8Q-1

SECURITY SYSTEM - DIAGNOSIS AND

TESTING, VEHICLE THEFT

..............8Q-3

SELECTION, ADJUSTMENTS - OUTPUT

FLANGE SHIM

........................21-7

SELECTOR - INSTALLATION, GEARSHIFT

CABLE

.............................21-84SELECTOR - REMOVAL, GEARSHIFT

CABLE.............................21-81

SELF-DIAGNOSTICS - DIAGNOSIS AND

TESTING............................8J-2

SENDING UNIT / SENSOR -

DESCRIPTION, FUEL LEVEL.............14-5

SENDING UNIT / SENSOR -

INSTALLATION, FUEL LEVEL.............14-5

SENDING UNIT / SENSOR - OPERATION,

FUEL LEVEL..........................14-5

SENDING UNIT / SENSOR - REMOVAL,

FUEL LEVEL..........................14-5

SENSE - PCM INPUT - OPERATION,

IGNITION...........................8E-15

SENSITIVE DEVICES - STANDARD

PROCEDURE, ELECTROSTATIC

DISCHARGE (ESD).................8W-01-8

SENSOR - 2.4L - DESCRIPTION, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - 2.4L - INSTALLATION, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - 2.4L - REMOVAL, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - 3.3/3.8L - DESCRIPTION,

ENGINE COOLANT TEMPERATURE........7-21

SENSOR - 3.3/3.8L - INSTALLATION,

ENGINE COOLANT TEMPERATURE........7-22

SENSOR - 3.3/3.8L - REMOVAL, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - AWD - INSTALLATION, REAR

WHEEL SPEED........................5-80

SENSOR - AWD - REMOVAL, REAR

WHEEL SPEED........................5-80

SENSOR - DESCRIPTION, AMBIENT

TEMP.............................8M-11

SENSOR - DESCRIPTION, BATTERY

TEMPERATURE......................8F-23

SENSOR - DESCRIPTION, CAMSHAFT

POSITION............................8I-4

SENSOR - DESCRIPTION, CRANKSHAFT

POSITION..........................14-25

SENSOR - DESCRIPTION, ENGINE SPEED . 14-26

SENSOR - DESCRIPTION, EVAPORATOR

TEMPERATURE......................24-27

SENSOR - DESCRIPTION, FUEL LEVEL

SENDING UNIT.......................14-5

SENSOR - DESCRIPTION, HEATED SEAT . . 8G-12

SENSOR - DESCRIPTION, INFRARED

TEMPERATURE......................24-29

SENSOR - DESCRIPTION, INLET AIR

TEMPERATURE......................14-30

SENSOR - DESCRIPTION, KNOCK.........8I-8

SENSOR - DESCRIPTION, MAP..........14-30

SENSOR - DESCRIPTION, O2...........14-32

SENSOR - DESCRIPTION, PINCH........8N-17

SENSOR - DESCRIPTION, THROTTLE

POSITION..........................14-36

SENSOR - DESCRIPTION,

TRANSMISSION RANGE.......21-248,21s-150

SENSOR - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE..............8M-12

SENSOR - DIAGNOSIS AND TESTING,

HEATED SEAT .......................8G-12

SENSOR - DIAGNOSIS AND TESTING,

TIRE PRESSURE

................22-10,22s-2

SENSOR - FWD - INSTALLATION, REAR

WHEEL SPEED

........................5-81

SENSOR - FWD - REMOVAL, REAR

WHEEL SPEED

........................5-81

SENSOR - INPUT - DESCRIPTION,

SPEED

.....................21-239,21s-140

SENSOR - INPUT - INSTALLATION,

SPEED

.....................21-240,21s-141

SENSOR - INPUT - OPERATION, SPEED

. 21-240,

21s-140

SENSOR - INPUT - REMOVAL, SPEED

. . . 21-240,

21s-141

SENSOR - INSTALLATION, FRONT

WHEEL SPEED

........................5-80

SENSOR - INSTALLATION, FUEL LEVEL

SENDING UNIT

.......................14-5

SENSOR - INSTALLATION, PINCH

........8N-17

SENSOR - INSTALLATION,

TRANSMISSION RANGE

.......21-249,21s-152

SENSOR - INSTALLATION, VEHICLE

SPEED

............................21-115

SENSOR - OPERATION, AMBIENT TEMP

. . 8M-11SENSOR - OPERATION, BATTERY

TEMPERATURE......................8F-23

SENSOR - OPERATION, CAMSHAFT

POSITION............................8I-4

SENSOR - OPERATION, CRANKSHAFT

POSITION..........................14-25

SENSOR - OPERATION, ENGINE SPEED . . . 14-26

SENSOR - OPERATION, EVAPORATOR

TEMPERATURE......................24-28

SENSOR - OPERATION, FUEL LEVEL

SENDING UNIT.......................14-5

SENSOR - OPERATION, HEATED SEAT....8G-12

SENSOR - OPERATION, INFRARED

TEMPERATURE......................24-29

SENSOR - OPERATION, KNOCK...........8I-8

SENSOR - OPERATION, MAP...........14-30

SENSOR - OPERATION, O2.............14-32

SENSOR - OPERATION, PINCH..........8N-17

SENSOR - OPERATION, THROTTLE

POSITION..........................14-36

SENSOR - OPERATION, TRANSMISSION

RANGE.....................21-248,21s-151

SENSOR - OUTPUT - DESCRIPTION,

SPEED.....................21-241,21s-142

SENSOR - OUTPUT - INSTALLATION,

SPEED.....................21-242,21s-143

SENSOR - OUTPUT - OPERATION,

SPEED.....................21-241,21s-142

SENSOR - OUTPUT - REMOVAL, SPEED . 21-241,

21s-143

SENSOR - REMOVAL, BATTERY

TEMPERATURE........................8F-23

SENSOR - REMOVAL, CRANKSHAFT

POSITION..........................14-25

SENSOR - REMOVAL, FRONT WHEEL

SPEED..............................5-79

SENSOR - REMOVAL, FUEL LEVEL

SENDING UNIT.......................14-5

SENSOR - REMOVAL, PINCH...........8N-17

SENSOR - REMOVAL, TRANSMISSION

RANGE.....................21-249,21s-151

SENSOR - REMOVAL, VEHICLE SPEED . . . 21-115

SENSOR - SPECIFICATIONS, BATTERY

TEMPERATURE......................8F-22

SENSOR - TPM - CAUTION........22-10,22s-2

SENSOR - TPM - DESCRIPTION....22-10,22s-1

SENSOR - TPM - INSTALLATION....22-12,22s-3

SENSOR - TPM - OPERATION......22-10,22s-2

SENSOR - TPM - REMOVAL.......22-11,22s-2

SENSOR AIR GAP, SPECIFICATIONS -

WHEEL SPEED........................5-79

SENSOR CIRCUIT - DIAGNOSIS AND

TESTING, AMBIENT TEMPERATURE......8M-12

SENSOR RETRAIN - STANDARD

PROCEDURE, TIRE PRESSURE.....22-10,22s-2

SENSOR RETURN - PCM INPUT -

OPERATION.........................8E-15

SENTRY KEY IMMOBILIZER MODULE -

DESCRIPTION.......................8E-18

SENTRY KEY IMMOBILIZER MODULE -

INSTALLATION.......................8E-19

SENTRY KEY IMMOBILIZER MODULE -

OPERATION.........................8E-18

SENTRY KEY IMMOBILIZER MODULE -

REMOVAL..........................8E-18

SENTRY KEY REMOTE ENTRY MODULE -

DESCRIPTION

........................8Q-3

SENTRY KEY REMOTE ENTRY MODULE -

DIAGNOSIS AND TESTING

..............8Q-5

SENTRY KEY REMOTE ENTRY MODULE -

INSTALLATION

.......................8Q-6

SENTRY KEY REMOTE ENTRY MODULE -

OPERATION

..........................8Q-4

SENTRY KEY REMOTE ENTRY MODULE -

REMOVAL

...........................8Q-5

SENTRY KEY REMOTE ENTRY SYSTEM -

DIAGNOSIS AND TESTING

..............8Q-3

SERVO - DESCRIPTION

.................8P-4

SERVO - INSTALLATION

................8P-5

SERVO - OPERATION

..................8P-4

SERVO - REMOVAL

....................8P-5

SET SWITCH - DESCRIPTION,

MEMORY

.....................8N-12,8N-55

SET SWITCH - INSTALLATION,

MEMORY

.....................8N-13,8N-56

SET SWITCH - OPERATION,

MEMORY

.....................8N-13,8N-56

RSINDEX31

Description Group-Page Description Group-Page Description Group-Page

Page 2581 of 2585

VALVE (HEIGHT SENSING) -

DESCRIPTION, PROPORTIONING....5-48,5s-51

VALVE (HEIGHT SENSING) - DIAGNOSIS

AND TESTING, PROPORTIONING....5-49,5s-52

VALVE (HEIGHT SENSING) -

INSTALLATION, PROPORTIONING....5-51,5s-53

VALVE (HEIGHT SENSING) - OPERATION,

PROPORTIONING.................5-48,5s-51

VALVE (HEIGHT SENSING) - REMOVAL,

PROPORTIONING.................5-50,5s-53

VALVE SEATS - STANDARD PROCEDURE,

REFACING VALVES...............9-104,9s-21

VALVE SPRINGS - DESCRIPTION . . . 9-106,9s-23

VALVE SPRINGS - OPERATION.....9-106,9s-23

VALVE STEM SEALS - DESCRIPTION.....9-111,

9s-29

VALVE STEM SEALS - INSTALLATION....9-112,

9s-29

VALVE STEM SEALS - REMOVAL . . . 9-112,9s-29

VALVE TIMING VERIFICATION -

STANDARD PROCEDURE...............9-153

VALVES - OPERATION, HYDRAULIC

CIRCUITS............................5-83

VALVES & SEATS - CLEANING,

INTAKE/EXHAUST...........9-105,9-32,9s-22

VALVES & SEATS - DESCRIPTION,

INTAKE/EXHAUST...........9-104,9-32,9s-21

VALVES & SEATS - INSPECTION,

INTAKE/EXHAUST...............9-105,9s-22

VALVES & SEATS - INSTALLATION,

INTAKE/EXHAUST...............9-106,9s-23

VALVES & SEATS - OPERATION,

INTAKE/EXHAUST.................9-104,9s-21

VALVES & SEATS - REMOVAL,

INTAKE/EXHAUST...............9-105,9s-22

VALVES AND VALVE SEATS - STANDARD

PROCEDURE, REFACING..........9-104,9s-21

VANITY LAMP - INSTALLATION.........8L-24

VANITY LAMP - REMOVAL.............8L-24

VAPOR CANISTER - DESCRIPTION.......25-18

VAPOR CANISTER - OPERATION.........25-18

VARIABLE BRAKE PROPORTIONING -

DESCRIPTION, ELECTRONIC.............5-75

VARIABLE BRAKE PROPORTIONING -

OPERATION, ELECTRONIC...............5-77

VARIATION ADJUSTMENT - STANDARD

PROCEDURE, COMPASS...............8M-5

VECI LABEL - DESCRIPTION..........Intro.-11

VEHICLE CERTIFICATION LABEL -

DESCRIPTION.....................Intro.-11

VEHICLE DOES NOT FILL - DIAGNOSIS

AND TESTING.......................25-16

VEHICLE EMISSION CONTROL

INFORMATION LABEL - DESCRIPTION.....25-1

VEHICLE IDENTIFICATION -

DESCRIPTION........................23-1

VEHICLE IDENTIFICATION NUMBER -

DESCRIPTION......................Intro.-9

VEHICLE INFO CENTER - DESCRIPTION,

ELECTRONIC........................8M-6

VEHICLE INFO CENTER - INSTALLATION,

ELECTRONIC........................8M-9

VEHICLE INFO CENTER - OPERATION,

ELECTRONIC........................8M-7

VEHICLE INFO CENTER - REMOVAL,

ELECTRONIC........................8M-9

VEHICLE INFORMATION CENTER -

DIAGNOSIS AND TESTING,

ELECTRONIC........................8M-7

VEHICLE INFORMATION CENTER

PROGRAMMING - STANDARD

PROCEDURE, ELECTRONIC.............8M-7

VEHICLE SPEED SENSOR -

INSTALLATION......................21-115

VEHICLE SPEED SENSOR - REMOVAL . . . 21-115

VEHICLE THEFT SECURITY -

DESCRIPTION........................8Q-1

VEHICLE THEFT SECURITY - OPERATION . . 8Q-1

VEHICLE THEFT SECURITY SYSTEM -

DIAGNOSIS AND TESTING..............8Q-3

VENT WINDOW MOTOR - DIAGNOSIS

AND TESTING

.......................8N-63

VENT WINDOW MOTOR - INSTALLATION

. . 8N-64

VENT WINDOW MOTOR - REMOVAL

.....8N-63

VERIFICATION - STANDARD

PROCEDURE, VALVE TIMING

...........9-153

VIBRATION - DIAGNOSIS AND TESTING,

TIRE AND WHEEL

.....................22-1VIBRATION DAMPER - INSTALLATION....9-130,

9-47

VIBRATION DAMPER - REMOVAL....9-130,9-47

VIDEO SCREEN - DESCRIPTION.........8A-16

VIDEO SCREEN - INSTALLATION........8A-16

VIDEO SCREEN - OPERATION...........8A-16

VIDEO SCREEN - REMOVAL............8A-16

VIEW MIRROR - INSTALLATION, REAR . . . 23-81

VIEW MIRROR - INSTALLATION, SIDE....23-59

VIEW MIRROR - REMOVAL, REAR.......23-81

VIEW MIRROR - REMOVAL, SIDE........23-59

VIEW MIRROR GLASS - INSTALLATION,

SIDE..............................23-59

VIEW MIRROR GLASS - REMOVAL, SIDE . . 23-59

VISCOUS COUPLER - DESCRIPTION.......3-41

VISCOUS COUPLER - OPERATION........3-42

VISOR - INSTALLATION, SUN...........23-82

VISOR - REMOVAL, SUN...............23-82

VISOR SUPPORT - INSTALLATION, SUN . . . 23-83

VISOR SUPPORT - REMOVAL, SUN......23-83

VOLT SUPPLY - PCM OUTPUT -

OPERATION, 5.......................8E-15

VOLTAGE DROP - STANDARD

PROCEDURE, TESTING FOR A.......8W-01-10

VOLTAGE POTENTIAL - STANDARD

PROCEDURE, TESTING OF...........8W-01-9

VOLTAGE REGULATOR - DESCRIPTION . . . 8F-27,

8F-29

VOLTAGE REGULATOR - OPERATION.....8F-27,

8F-29

VOLTAGE TEST - STANDARD

PROCEDURE, OPEN-CIRCUIT...........8F-13

VTSS/SKIS INDICATOR LAMP -

DESCRIPTION........................8Q-7

VTSS/SKIS INDICATOR LAMP -

OPERATION..........................8Q-8

WARNING - A/C SYSTEM..............24-65

WARNING - ENGINE COOLING SYSTEM . . . 24-65

WARNING - INSTALLATION............23-109

WARNING - INSTALLATION.............19-13

WARNING - REMOVAL...............23-108

WARNING - REMOVAL................19-12

WARNING - SAFETY PRECAUTIONS AND

WARNINGS..........................23-1

WARNING - WARNINGS AND CAUTIONS . . 19-10,

19-27

WARNING - WINDSHIELD SAFETY

PRECAUTIONS......................23-108

WARNING, CHIME/BUZZER..............8B-1

WARNING, DESCRIPTION............5-4,5s-3

WARNING, DESCRIPTION..............19-37

WARNING, LAMPS/LIGHTING -

EXTERIOR...........................8L-3

WARNING, RESTRAINTS................8O-2

WARNINGS AND CAUTIONS, WARNING . . 19-10,

19-27

WARNINGS, GENERAL..............8W-01-7

WARNINGS, WARNING - SAFETY

PRECAUTIONS........................23-1

WASHER FLUID LEVEL SWITCH -

INSTALLATION......................8R-12

WASHER FLUID LEVEL SWITCH -

REMOVAL..........................8R-12

WASHER HOSES - INSTALLATION.......8R-13

WASHER HOSES - REMOVAL...........8R-13

WASHER PUMP MOTOR -

INSTALLATION, FRONT.................8R-8

WASHER PUMP MOTOR -

INSTALLATION, REAR.................8R-10

WASHER PUMP MOTOR - REMOVAL,

FRONT..............................8R-8

WASHER PUMP MOTOR - REMOVAL,

REAR..............................8R-10

WASHER RESERVOIR - INSTALLATION . . . 8R-13

WASHER RESERVOIR - REMOVAL.......8R-13

WASHER SYSTEM - DIAGNOSIS AND

TESTING............................8R-4

WATER CHANNEL - INSTALLATION......23-121

WATER CHANNEL - REMOVAL.........23-121

WATER LEAKS - DIAGNOSIS AND

TESTING............................23-1

WATER PUMP - 2.4L - CLEANING........7-32

WATER PUMP - 2.4L - DESCRIPTION......7-31

WATER PUMP - 2.4L - INSPECTION

.......7-32

WATER PUMP - 2.4L - INSTALLATION

.....7-32

WATER PUMP - 2.4L - REMOVAL

.........7-31

WATER PUMP - 3.3/3.8L - CLEANING

.....7-34

WATER PUMP - 3.3/3.8L - DESCRIPTION

. . . 7-33WATER PUMP - 3.3/3.8L - INSPECTION....7-34

WATER PUMP - 3.3/3.8L -

INSTALLATION........................7-34

WATER PUMP - 3.3/3.8L - REMOVAL......7-33

WATER PUMP INLET TUBE - 2.4L -

DESCRIPTION........................7-35

WATER PUMP INLET TUBE - 2.4L -

INSTALLATION........................7-35

WATER PUMP INLET TUBE - 2.4L -

REMOVAL...........................7-35

WATER PUMP INLET TUBE - 3.3/3.8L -

INSTALLATION........................7-36

WATER PUMP INLET TUBE - 3.3/3.8L -

REMOVAL...........................7-36

WATERSHIELD - INSTALLATION.........23-21

WATERSHIELD - REMOVAL.............23-21

WEAR - STANDARD PROCEDURE,

MEASURING TIMING CHAIN............9-153

WEAR INDICATORS - DIAGNOSIS AND

TESTING, TREAD................22-16,22s-8

WEAR PATTERNS - DIAGNOSIS AND

TESTING, TIRE..................22-16,22s-8

WEATHERSTRIP - INSTALLATION, FRONT

DOOR............................23-114

WEATHERSTRIP - INSTALLATION, FRONT

DOOR GLASS RUN..................23-113

WEATHERSTRIP - INSTALLATION,

SLIDING DOOR.....................23-115

WEATHERSTRIP - REMOVAL, FRONT

DOOR............................23-114

WEATHERSTRIP - REMOVAL, FRONT

DOOR GLASS RUN..................23-113

WEATHERSTRIP - REMOVAL, SLIDING

DOOR............................23-115

WELD LOCATIONS - SPECIFICATIONS . . . 23-166

WHEEL - DESCRIPTION...............22-18

WHEEL - INSPECTION, TONE............5-82

WHEEL - INSTALLATION, STEERING......19-24

WHEEL - REMOVAL, STEERING.........19-23

WHEEL ALIGNMENT - DESCRIPTION......2-47

WHEEL ALIGNMENT - STANDARD

PROCEDURE.........................2-52

WHEEL ALIGNMENT, SPECIFICATIONS.....2-56

WHEEL ASSEMBLY (ALUMINUM WHEEL)

- INSTALLATION, TIRE.................22-8

WHEEL ASSEMBLY (ALUMINUM WHEEL)

- REMOVAL, TIRE.....................22-7

WHEEL ASSEMBLY (STEEL WHEEL) -

INSTALLATION, TIRE...................22-8

WHEEL ASSEMBLY (STEEL WHEEL) -

REMOVAL, TIRE......................22-8

WHEEL BALANCE - STANDARD

PROCEDURE, TIRE....................22-5

WHEEL CARE - CLEANING, ALUMINUM . . . 22-18

WHEEL COVER - DESCRIPTION.........22-19

WHEEL COVER - INSTALLATION.........22-19

WHEEL COVER - REMOVAL............22-19

WHEEL CYLINDERS - INSPECTION . . . 5-57,5s-59

WHEEL CYLINDERS - INSTALLATION . 5-57,5s-60

WHEEL CYLINDERS - REMOVAL.....5-57,5s-59

WHEEL INSPECTION - DIAGNOSIS AND

TESTING...........................22-18

WHEEL MATCH MOUNTING - STANDARD

PROCEDURE, TIRE

....................22-7

WHEEL MOUNTING STUDS - FRONT -

INSTALLATION

.......................22-21

WHEEL MOUNTING STUDS - FRONT -

REMOVAL

..........................22-20

WHEEL MOUNTING STUDS - REAR -

INSTALLATION

.......................22-22

WHEEL MOUNTING STUDS - REAR -

REMOVAL

..........................22-21

WHEEL ROTATION - STANDARD

PROCEDURE, TIRE

....................22-7

WHEEL RUNOUT, SPECIFICATIONS -

TONE

...............................5-79

WHEEL, SPECIFICATIONS

..............22-19

WHEEL SPEED SENSOR - AWD -

INSTALLATION, REAR

..................5-80

WHEEL SPEED SENSOR - AWD -

REMOVAL, REAR

......................5-80

WHEEL SPEED SENSOR - FWD -

INSTALLATION, REAR

..................5-81

WHEEL SPEED SENSOR - FWD -

REMOVAL, REAR

......................5-81

WHEEL SPEED SENSOR -

INSTALLATION, FRONT

.................5-80

38 INDEXRS

Description Group-Page Description Group-Page Description Group-Page