steering wheel CHRYSLER VOYAGER 2004 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 662 of 2585

(7) Disconnect the 4±way harness connector from

the speed control/horn harness to the clock spring.

INSTALLATION

DEPLOYED AIRBAG

(1) Perform clean up procedure (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- SERVICE AFTER AN AIRBAG DEPLOYMENT).

(2) Install a new steering column assembly and

lower steering column coupler (Refer to 19 - STEER-

ING/COLUMN - INSTALLATION).

(3) Install the new clock spring.

(4) Connect the 4-way and 6-way connectors

between the clock spring and the instrument panel

wiring harness.

(5) Install the steering column shrouds and con-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - INSTALLATION).

(6) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(7) Connect the 4±way harness connector to the

speed control/horn harness to the clock spring.

(8) Connect the 2±way connector to the remote

radio control harness.

(9) Install the driver airbag and the two screws

retaining the airbag. Tighten screws to 10 N´m (90

in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

UNDEPLOYED AIRBAG

(1) Connect the harness connector on the DAB

cover (horn, speed controls) to the clock spring.

(2) Connect the squib connectors to the DAB.

(3) Position a new airbag into the airbag cavity.

(4) Install the two screws retaining the airbag.

Tighten screws to 10 N´m (90 in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

DRIVER AIRBAG TRIM COVER

REMOVAL

The horn switch is integral to the driver airbag

trim cover. If either component is faulty or damaged,

the entire driver airbag trim cover and horn switch

unit must be replaced.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge.

(2) Remove the driver airbag from the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) Remove the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing and disconnect the speed con-

trol switches (if equipped).

(4) Remove the four nuts that secure the trim

cover retainer to the studs on the back of the driver

airbag housing.

(5) Remove the horn switch ground pigtail wire

eyelet terminal from the upper left airbag housing

stud.

(6) Remove the trim cover retainer from the airbag

housing studs.

(7) Disengage the six trim cover locking blocks

from the lip around the outside edge of the driver

airbag housing and remove the housing from the

cover.

INSTALLATION

(1) Install the housing into the cover. Engage the

six trim cover locking blocks to the lip around the

outside edge of the driver airbag housing.

(2) Install the trim cover retainer to the airbag

housing studs.

(3) Install the horn switch ground pigtail wire eye-

let terminal to the upper left airbag housing stud.

(4) Install the four nuts that secure the upper and

lower trim cover retainers to the studs on the back of

the driver airbag housing. Torque nuts to 6.8 N´m (60

in. lbs.).

(5) Install the plastic wire retainer that captures

the horn switch feed pigtail wire between the upper

left inflator stud and the inflator on the back of the

driver airbag housing.

(6) Connect speed control switches (if equipped).

(7) Install the driver airbag onto the steering

wheel (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

RSRESTRAINTS8O-7

DRIVER AIRBAG (Continued)

Page 664 of 2585

OPERATION

The passenger airbag is equipped with two infla-

tors, each with three levels of pressure output. The

inflators seal the hole in the airbag cushion so it can

discharge the gas it produces directly into the cush-

ion when supplied with the proper electrical signal.

Following an airbag deployment, the airbag cushion

quickly deflates by venting this gas through the

cushion material towards the instrument panel.

The passenger airbag is secured with screws to the

instrument panel beneath the instrument panel top

pad and above the glove box opening. The instrument

panel top pad above the glove box opening conceals

the airbag door and a predetermined hinge line

beneath its decorative cover. Upon airbag deploy-

ment, the top pad will bend at the hinge line and the

door will fold back out of the way onto the top of the

instrument panel.

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly.

²Lower Steering Column Coupler.

²Steering Wheel.

²Clock Spring.

²Driver Airbag.

²Passenger Airbag.

²Upper Instrument Panel with Pad.

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

REMOVAL

DEPLOYED AIRBAG

(1) Clean powder residue from interior of vehicle

(Refer to 8 - ELECTRICAL/RESTRAINTS - STAN-

DARD PROCEDURE - SERVICE AFTER AN AIR-

BAG DEPLOYMENT).

(2) Remove instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - REMOVAL).

(3) Remove all reusable components from the

upper instrument panel and transfer to the new

instrument panel.

UNDEPLOYED AIRBAG

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Wait two minutes for the airbag system reserve

capacitor to discharge before attempting any airbag

or instrument panel service.

(4) Remove center console bin between front seats.

(5) Remove left front door sill plate using a trim

stick (special tool #C-4755) or equivalent, and gently

prying up on sill plate.

(6) Remove left cowl panel using a trim stick or

equivalent, and gently prying out on cowl panel.

(7) Remove four screws to lower steering column

cover and remove cover.

(8) Unsnap parking brake lever from knee blocker

reinforcement.

(9) Remove Data Link Connector (DLC) from knee

blocker.

(10) Remove screws to knee blocker.

(11) Unsnap left A-pillar lower extension trim

using a trim stick or equivalent.

(12) Remove three left side instrument panel A-pil-

lar retaining bolts and loosen the instrument panel

roll down bolt.

(13) Remove four nuts at brake pedal support

bracket to instrument panel.

(14) Using a trim stick or equivalent, gently pry

off left side upper A-pillar trim.

(15) Remove six screws and two wiring connectors

to lower instrument panel cubby bin at bottom of

center stack.

(16) Remove two left side nuts at instrument panel

center stack support to floor.

(17) Remove two right side nuts at instrument

panel center stack support to floor.

(18) Remove right front door sill plate using a trim

stick or equivalent, and gently prying up on sill

plate.

(19) Remove right cowl panel using a trim stick or

equivalent, and gently prying out on cowl panel.

(20) Using a trim stick or equivalent, gently pry

out on right instrument panel end cap.

(21) Unsnap right A-pillar lower extension trim

using a trim stick or equivalent.

(22) Remove three right side instrument panel

A-pillar retaining bolts and loosen the instrument

panel roll down bolt.

(23) Using a trim stick or equivalent, gently pry

off right side upper A-pillar trim.

(24) Open glove box, pinch in sides and roll down

towards floor. With a firm pull, snap glove box door

off hinges and remove.

(25) Using a trim stick or equivalent, gently pry

up on rear of instrument panel top cover and then

pull rearward and out.

RSRESTRAINTS8O-9

PASSENGER AIRBAG (Continued)

Page 674 of 2585

SPEED CONTROL

TABLE OF CONTENTS

page page

SPEED CONTROL

DESCRIPTION..........................1

OPERATION

OPERATION..........................1

OPERATION - INTERACTIVE SPEED

CONTROL (4 Speed EATX Only)...........2

DIAGNOSIS AND TESTING - ROAD TEST.....3

SPECIFICATIONS - TORQUE...............3

CABLE

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

SERVO

DESCRIPTION..........................4OPERATION............................4

REMOVAL.............................5

INSTALLATION..........................5

SWITCH

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

VACUUM RESERVOIR

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

SPEED CONTROL

DESCRIPTION

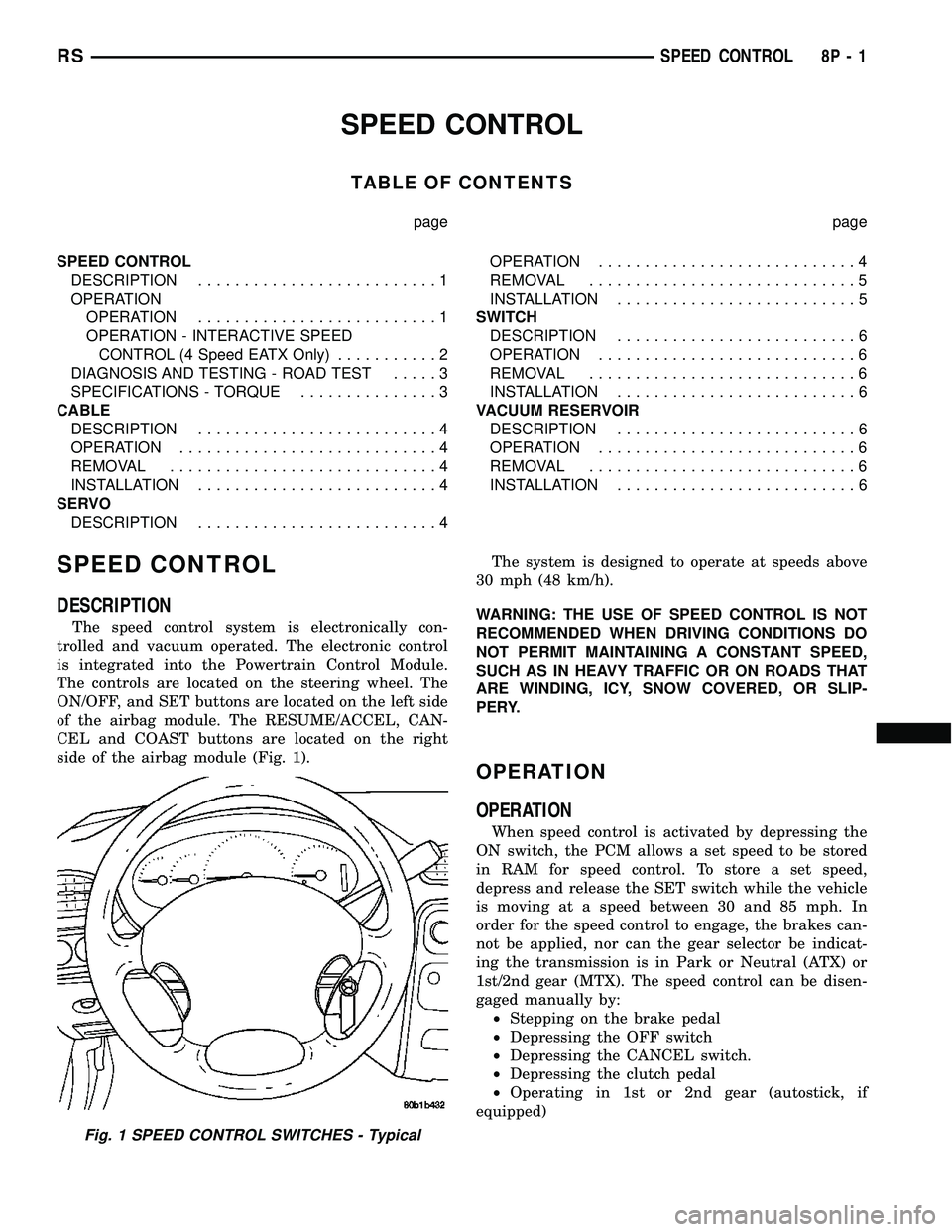

The speed control system is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the Powertrain Control Module.

The controls are located on the steering wheel. The

ON/OFF, and SET buttons are located on the left side

of the airbag module. The RESUME/ACCEL, CAN-

CEL and COAST buttons are located on the right

side of the airbag module (Fig. 1).The system is designed to operate at speeds above

30 mph (48 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

OPERATION

When speed control is activated by depressing the

ON switch, the PCM allows a set speed to be stored

in RAM for speed control. To store a set speed,

depress and release the SET switch while the vehicle

is moving at a speed between 30 and 85 mph. In

order for the speed control to engage, the brakes can-

not be applied, nor can the gear selector be indicat-

ing the transmission is in Park or Neutral (ATX) or

1st/2nd gear (MTX). The speed control can be disen-

gaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal

²Operating in 1st or 2nd gear (autostick, if

equipped)

Fig. 1 SPEED CONTROL SWITCHES - Typical

RSSPEED CONTROL8P-1

Page 679 of 2585

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system and are located on the

steering wheel.

OPERATION

The speed control system has five separate resis-

tive switches that provide a single multiplexed

(MUX) voltage inputs to the PCM.The switch names

are: ON, OFF, SET, COAST, RESUME, ACCEL, TAP-

UP, COAST, and CANCEL. Based on conditions when

the buttons are pushed (and released), the five volt-

ages ranges provided to the PCM result in the follow-

ing functions: ON, OFF, SET, COAST, RESUME,

ACCEL, TAP-UP, TAP-DOWN, COAST, and CAN-

CEL. Refer to the Speed Control Section for more

information

Also the PCM receives an input from the brake

switch to sense whether the brake pedal has been

depressed. When the PCM receives the brake

depressed input, it turns off power to the speed con-

trol servo and disengages speed control. Also the

power to the servo is supplied through the brake

switch, which opens the circuit when the brake pedal

is depressed.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

REMOVAL

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Remove the negative battery cable.

(2) Turn off ignition.

(3) Remove the air bag, refer to the restraint sec-

tion for more information.

(4) Remove the screw from bottom of the switch.

(5) Remove switch from steering wheel.

(6) Disconnect two-way electrical connector.

(7) Repeat for the other switch.

INSTALLATION

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Connect two-way electrical connector.

(2) Install switch.

(3) Install screw for the switch.

(4) Repeat for the other switch.

(5) Install the air bag, refer to the restraint section

for more information.

(6) Install the negative battery cable.

VACUUM RESERVOIR

DESCRIPTION

The vacuum reservoir is located in the engine com-

partment. It is made of plastic.

OPERATION

The reservoir stores engine vacuum. Manifold vac-

uum is supplied from the brake booster check valve.

The speed control vacuum supply hose has a check

valve at the source (brake booster) to maintain the

highest available vacuum level in the servo, reservoir

and vacuum hoses. When engine vacuum drops, as in

climbing a grade while driving, the reservoir supplies

the vacuum needed to maintain proper speed control

operation. The vacuum reservoir cannot be repaired

and must be replaced if faulty.

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect the negative battery cable.

(3) Disconnect the vacuum line to the battery tray/

vacuum reservoir.

(4) Remove battery tray/vacuum reservoir, refer to

the Battery section for more information.

INSTALLATION

(1) Install battery tray/vacuum reservoir, refer to

the Battery section for more information.

(2) Connect vacuum line that leads to the battery

tray/vacuum reservoir.

(3) Connect the negative battery cable.

8P - 6 SPEED CONTROLRS

Page 683 of 2585

message must be sent to the Powertrain Control

Module (PCM) within two seconds of ignition ON to

free the engine from immobilization.

The SKREEM contains a Radio Frequency (RF)

transceiver and a microprocessor. The SKREEM

retains in memory the ID numbers of any Sentry Key

that is programmed to it. The maximum number of

keys that may be programmed to each module is

eight (8). The SKREEM also communicates over the

Programmable Communication Interface (PCI) data

bus with the Powertrain Control Module (PCM), the

Body Control Module (BCM), the Mechanical Instru-

ment Cluster (MIC), and the DRB IIItscan tool. The

SKREEM transmits and receives RF signals through

a tuned antenna enclosed within a molded plastic

ring formation that is integral to the SKREEM hous-

ing. When the SKREEM is properly installed on the

steering column, the antenna ring fits snugly around

the circumference of the ignition lock cylinder hous-

ing. If this ring is not mounted properly, communica-

tion problems may arise in the form of transponder-

related faults.

For added system security, each SKREEM is pro-

grammed with a unique9Secret Key9code. This code

is stored in memory and is sent over the PCI bus to

the PCM and to each key that is programmed to

work with the vehicle. The9Secret Key9code is there-

fore a common element found in all components of

the Sentry Key Immobilizer System (SKIS). In the

event that a SKREEM replacement is required, the

9Secret Key9code can be restored from the PCM by

following the SKIM replacement procedure found in

the DRB IIItscan tool. Proper completion of this

task will allow the existing ignition keys to be repro-

grammed. Therefore, new keys will NOT be needed.

In the event that the original9Secret Key9code can

not be recovered, new ignition keys will be required.

The DRB IIItscan tool will alert the technician if

key replacement is necessary. Another security code,

called a PIN, is used to gain secured access to the

SKREEM for service. The SKREEM also stores in its

memory the Vehicle Identification Number (VIN),

which it learns through a bus message from the

assembly plant tester. The SKIS scrambles the infor-

mation that is communicated between its components

in order to reduce the possibility of unauthorized

SKREEM access and/or disabling.

REMOTE KEYLESS ENTRY (RKE)

The RKE transmitter uses radio frequency signals

to communicate with the SKREEM. The SKREEM is

on the PCI bus. When the operator presses a button

on the transmitter, it sends a specific request to the

SKREEM. In turn the SKREEM sends the appropri-

ate request over the PCI Bus to the:²Body Control Module (BCM) to control the door

lock and unlock functions, the liftgate lock and

unlock functions, the arming and disarming of the

Vehicle Theft Security System (VTSS) (if equipped),

and the activation of illuminated entry.

²Integrated Power Module (IPM) to activate the

park lamps, the headlamps, and the horn for horn

chirp. If requested, the BCM sends a request over

the PCI Bus to the:

TIRE PRESSURE MONITORING (TPM)

If equipped with the Tire Pressure Monitoring

(TPM) System, each of the vehicles four wheels will

have a valve stem with a pressure sensor and radio

transmitter built in. Signals from the tire pressure

sensor/transmitter are received and interpreted by

the SKREEM.

A sensor/transmitter in a mounted wheel will

broadcast its detected pressure once per minute

when the vehicle is moving faster than 15 mph (24

km/h). Each sensor/transmitter's broadcast is

uniquely coded so that the SKREEM can determine

the location.

OPERATION

SENTRY KEY IMMOBILIZER

The Sentry Key Remote Entry Module (SKREEM)

receives an encrypted Radio Frequency (RF) signal

from the transponder key. The SKREEM then

decrypts the signal and broadcasts the requested

remote commands to the appropriate modules in the

vehicle over the Programmable Communication

Interface (PCI) data bus. A valid transponder key ID

must be incorporated into the RF signal in order for

the SKREEM to pass the message on to the appro-

priate modules.

Automatic transponder key synchronization is done

by the SKREEM if a valid transponder key is

inserted into the ignition cylinder, and the ignition is

turned ON. This provides a maximum operation win-

dow for RKE functions.

Each Sentry Key Remote Entry System (SKREES)

consists of a SKREEM and a transponder key. Each

system has a secret key code unique to that system.

The secret key is electronically coded in the

SKREEM and in all programmed transponder keys.

It is used for immobilization and RKE functions for

data security. In addition, each transponder key will

have a unique identification.

When the ignition switch is moved to the RUN

position, the SKREEM transmits an Radio Frequency

(RF) signal to the transponder in the ignition key.

The SKREEM then waits for a response RF signal

from the transponder in the key. If the response

received identifies the key as valid, the SKREEM

8Q - 4 VEHICLE THEFT SECURITYRS

SENTRY KEY REMOTE ENTRY MODULE (Continued)

Page 1237 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Ignition Coil (2.4L) BK Top of Valve Cover 10, 11

Ignition Coil (3.3L/ 3.8L) DKGY Top of Engine 17, 18

Ignition Switch BK Rear of Switch at Steering Column 20, 21, 22, 23, 31

Inlet Air Temperature Sensor BK Top Left of Engine 9, 10, 11, 17

Input Speed Sensor GY Front of Transmission 14, 19

Instrument Cluster BK Rear of Cluster 20, 21, 28

Instrument Panel Switch Bank

(Heated Seats)BK Right Center of Instrument Panel 20, 23, 25

Instrument Panel Switch Bank

(Except Heated Seats)Right Center of Instrument Panel 20, 23, 25

Integrated Power Module C1 Left Fender Shield 6, 7

Integrated Power Module C2 GN/BL Left Fender Shield 6, 7

Integrated Power Module C3 Left Fender Shield 6, 7, 11

Integrated Power Module C4 BL Left Fender Shield 6, 7, 11

Integrated Power Module C5 BK Left Fender Shield 6, 7

Integrated Power Module C6 NAT Left Fender Shield 6, 7

Integrated Power Module C7 Left Fender Shield 6, 7

Integrated Power Module C8 OR Left Fender Shield 6, 7

Integrated Power Module C9 BK Left Fender Shield 6, 7

Knock Sensor (2.4L) BK At Engine Block N/S

Knock Sensor (3.3L/3.8L ABS

Except Export)GY Front of Cylinder Block 11

Left B Pillar Switch (Power

Sliding Door)GY Left B Pillar 40

Left Cinch/Release Motor (Power

Sliding Door)GY Left Sliding Door N/S

Left Cylinder Lock Switch BK At Switch 43

Left Door Speaker (Highline) BK/RD At Speaker 43

Left Door Speaker (Lowline) In Door N/S

Left Fog Lamp (Except Export) BK At Lamp N/S

Left Fog Lamp (Export) WT At Lamp 5

Left Front Door Ajar Switch

(Base)BK At Switch N/S

Left Front Door Lock Motor/Ajar

Switch (Except Base)BK Left Door 43

Left Front Impact Sensor (Except

Export)BK Near T/O for C300 N/S

Left Front Park/Turn Signal Lamp

(Except Export)DKGY At Lamp 1

Left Front Wheel Speed Sensor GY Left Fender Side Shield 5, 11

Left Full Open Switch (Power

Sliding Door)BK Left Sliding Door N/S

Left Headlamp (Except Export) BK At Lamp 1

Left Headlamp Leveling Motor

(Export)WT At Motor N/S

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONRS

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1238 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Left High Beam Lamp (Export) BK At Lamp N/S

Left Instrument Panel Speaker BK At Speaker 20, 21, 27

Left Liftgate Flood Lamp GY At Lamp 49

Left Low Beam Lamp (Export) BK At Lamp N/S

Left Mid Reading Lamp

(Premium/Luxury)GY At Lamp N/S

Left Park Lamp (Export) BK At Lamp 5

Left Power Mirror BK At Mirror 27

Left Rear Lamp Assembly BK At Lamp 47

Left Rear Pillar Speaker BK Left of Liftgate 47

Left Rear Reading Lamp (Luxury) GY At Lamp N/S

Left Rear Speaker (Highline) BK/RD At Speaker 47

Left Rear Speaker (Lowline) At Speaker N/S

Left Rear Vent Motor NAT At Motor 46, 47

Left Rear Wheel Speed Sensor BK Center Rear of Floor Pan 47

Left Remote Radio Switch BK Steering Wheel N/S

Left Repeater Lamp (Export) GY Left Front Fender 4, 36

Left Seat Airbag YL Left Seat N/S

Left Side Impact Sensor

1(Premium ORC)DKGY Left B Pillar 40

Left Sliding Door Control Module

C1BK Left Sliding Door N/S

Left Sliding Door Control Module

C2Left Sliding Door N/S

Left Sliding Door Latch Sensing

SwitchBK Left Sliding Door N/S

Left Sliding Door Lock Motor BK Left Sliding Door N/S

Left Sliding Door Lock Motor/Ajar

Switch (Manual Sliding Door)BK Left Sliding Door N/S

Left Sliding Door Motor BK Left Sliding Door N/S

Left Speed Control Switch WT Steering Wheel N/S

Left Turn Signal Lamp (Export) OR AT Lamp N/S

Left Visor/Vanity Lamp (Except

Base)BK At Lamp N/S

License Lamp DKGY At Lamp 49

Lift Pump Motor (Diesel) BK Left Rear Engine Compartment N/S

Liftgate Ajar Switch (Manual

Release)BK At Latch 49

Liftgate Ajar Switch (Power

Release)BK Lower Liftgate 49

Liftgate Cinch/Release Motor

(Power Liftgate)BL Liftgate 49

Liftgate Left Pinch Sensor (Power

Liftgate)BK Left Side of Liftgate 49

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1242 of 2585

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Right Front Park/Turn Signal

Lamp (Except Export)BK At Lamp 1, 3

Right Front Wheel Speed Sensor GY Right Fender Side Shield 3,10, 16, 17

Right Full Open Switch (Power

Sliding Door)BK Right Sliding Door 45

Right Headlamp (Except Export) BK At Lamp 1, 3

Right Headlamp Leveling Motor

(Export)WT At Right Headlamp N/S

Right High Beam Lamp (Export) BK At Right Headlamp N/S

Right Instrument Panel Speaker BK At Speaker 20, 23, 24

Right Liftgate Flood Lamp GY At Lamp 49

Right Low Beam Lamp (Export) BK At Right Headlamp N/S

Right Mid Reading Lamp

(Premium/ Luxury)GY At Lamp N/S

Right Park Lamp (Export) BK AT Lamp N/S

Right Power Mirror BK At Mirror 20, 24, 28

Right Rear Lamp Assembly BK At Lamp 48

Right Rear Pillar Speaker BK At Speaker 48

Right Rear Reading Lamp

(Luxury)GY At Lamp N/S

Right Rear Speaker (Highline) BK/RD At Speaker 48

Right Rear Speaker (Lowline) At Speaker N/S

Right Rear Vent Motor NAT At Motor 48

Right Rear Wheel Speed Sensor BK Right Rear of Floor Pan 48

Right Remote Radio Switch BK At Steering Wheel N/S

Right Repeater Lamp (Export) GY Right Front Fender 39

Right Seat Airbag YL At Passenger Seat N/S

Right Side Impact Sensor 1

(Premium ORC)DKGY Right B Pillar 39

Right Sliding Door Control

Module C1BK Rear of Door 45, 46

Right Sliding Door Control

Module C2Rear of Door 45, 46

Right Sliding Door Latch Sensing

SwitchBK At Sliding Door 45

Right Sliding Door Lock Motor BK Rear of Door 45

Right Sliding Door Lock

Motor/Ajar Switch (Manual Sliding

Door)BK At Latch N/S

Right Sliding Door Motor BK At Sliding Door 45

Right Speed Control Switch BK At Steering Wheel N/S

Right Stop/Turn Signal Relay BK LT Quarter Panel N/S

Right Turn Signal Lamp OR At Lamp N/S

Right Visor/Vanity Lamp BK At Lamp N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-11

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1295 of 2585

POWER OUTLET

DESCRIPTION

Accessory power outlets are standard equipment on

this model. Two power outlets are installed in the

instrument panel center lower bezel, which is located

near the bottom of the instrument panel center stack

area. Two additional power outlets are also incorpo-

rated into the vehicle, one on the left rear C-pillar

trim and the other in the center console, if equipped.

The power outlets bases are secured by a snap fit in

the appropriate bezels. A hinged plug flips closed to

conceal and protect the power outlet base when the

power outlet is not being used.

The power outlet receptacle unit and the power

outlet plugs are each available for service replace-

ment.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the on position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

For complete circuit diagrams, refer toCigar

Lighter/Power Outletin Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the IPM. If OK, go to Step 3. If not OK, repair the

open fused B(+) circuit to the IPM fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

outlet receptacle and a good ground. There should be

continuity. If OK, go to Step 4. If not OK, go to Step

5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the appropriate bezel. Check for conti-

nuity between the ground circuit cavity of the power

outlet wire harness connector and a good ground.

There should be continuity. If OK, go to Step 6. If not

OK, repair the open ground circuit to ground as

required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the IPM fuse as

required.

8W - 97 - 4 8W-97 POWER DISTRIBUTION SYSTEMRS

Page 1313 of 2585

INSTALLATION - ENGINE ASSEMBLY

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

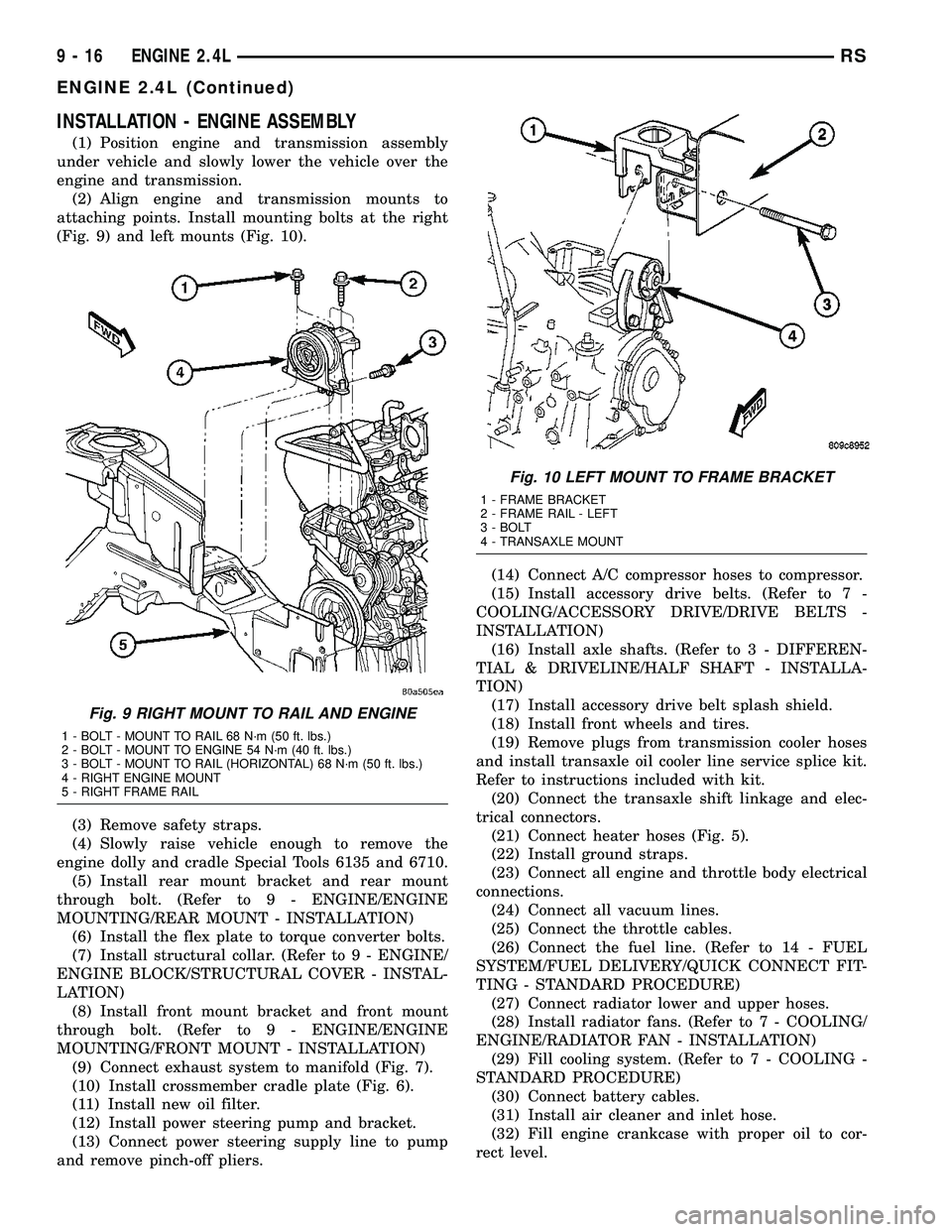

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

(Fig. 9) and left mounts (Fig. 10).

(3) Remove safety straps.

(4) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(5) Install rear mount bracket and rear mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/REAR MOUNT - INSTALLATION)

(6) Install the flex plate to torque converter bolts.

(7) Install structural collar. (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION)

(8) Install front mount bracket and front mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/FRONT MOUNT - INSTALLATION)

(9) Connect exhaust system to manifold (Fig. 7).

(10) Install crossmember cradle plate (Fig. 6).

(11) Install new oil filter.

(12) Install power steering pump and bracket.

(13) Connect power steering supply line to pump

and remove pinch-off pliers.(14) Connect A/C compressor hoses to compressor.

(15) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(16) Install axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(17) Install accessory drive belt splash shield.

(18) Install front wheels and tires.

(19) Remove plugs from transmission cooler hoses

and install transaxle oil cooler line service splice kit.

Refer to instructions included with kit.

(20) Connect the transaxle shift linkage and elec-

trical connectors.

(21) Connect heater hoses (Fig. 5).

(22) Install ground straps.

(23) Connect all engine and throttle body electrical

connections.

(24) Connect all vacuum lines.

(25) Connect the throttle cables.

(26) Connect the fuel line. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(27) Connect radiator lower and upper hoses.

(28) Install radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION)

(29) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(30) Connect battery cables.

(31) Install air cleaner and inlet hose.

(32) Fill engine crankcase with proper oil to cor-

rect level.

Fig. 9 RIGHT MOUNT TO RAIL AND ENGINE

1 - BOLT - MOUNT TO RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO ENGINE 54 N´m (40 ft. lbs.)

3 - BOLT - MOUNT TO RAIL (HORIZONTAL) 68 N´m (50 ft. lbs.)

4 - RIGHT ENGINE MOUNT

5 - RIGHT FRAME RAIL

Fig. 10 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

9 - 16 ENGINE 2.4LRS

ENGINE 2.4L (Continued)