ECU CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 624 of 2585

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) If the vehicle is equipped with the memory sys-

tem and the driver side power seat exhibits a inter-

rupted or jerky motion, there is a possibility that the

wires leading from the memory seat module to the

memory seat motor are mis-wired. To check the con-

cern, obtain a DRBIIItscan tool and energize each

axis one at a time. If any axis stops in approximately

2 seconds (without hitting the end of travel), the

feedback for that axis may have an open, short or be

mis-wired. Check the wiring to that axis (module to

motor). Fix any wiring problems and retry that axis.

(2) If any power seat is not operational in any

direction, check the power seat circuit breaker,

located under the trailing edge of the driver side

power seat. Refer to the Power Distribution section of

this service manual for the circuit breaker diagnosis

and testing procedure.

(3) If the power seat circuit breaker is OK, check

for proper battery and ground connections at the

power seat switch and/or memory seat module. Fix

any wiring problems and retry.

(4) Check the power seat system wire harness con-

nections and pins to ensure proper circuit continuity

and ground paths. For complete circuit diagrams,

refer toWiring Diagrams.

(5) With the dome lamp on, apply the power seat

switch in the direction of the failure. If the dome

lamp dims, the seat may be jamming. Check under

and behind the seat for binding or obstructions. If

the dome lamp does not dim, proceed with testing of

the individual components and circuits in the power

seat system.

DIAGNOSIS AND TESTING - MEMORY SYSTEM

In order to obtain conclusive testing of the memory

system, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the memory system requires the use of a

DRB IIItscan tool and the proper Diagnostic Proce-

dures manual. The DRB IIItscan tool can provideconfirmation that the PCI data bus is functional, that

all of the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus, and

that the memory system is receiving the proper hard

wired inputs and relaying the proper hard wired out-

puts to perform its functions.

(1) If the driver power seat exhibits a interrupted

or jerky motion, there is a possibility that the wires

leading from the memory seat module to the memory

seat motor are mis-wired. To check the concern,

obtain a DRB IIItscan tool and energize each axis

one at a time. If any axis stops in approximately 2

seconds (without hitting the end of travel), the feed-

back for that axis may have an open, short or be mis-

wired. Check the wiring to that axis (module to

motor). Fix any wiring problems and retry that axis.

Refer to Wiring Diagrams for complete circuit sche-

matic or connector pin-out information.

DRIVER SEAT SWITCH

DESCRIPTION

Vehicles equipped with a driver side power seat

utilize an eight-way power seat switch. This eight-

way power seat switch features two knobs ganged

together on the outboard seat cushion side shield

(Fig. 2).

The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

Fig. 2 Power Seat Switch Location

1 - Power Seat Switch

2 - Seat Cushion Side Shield

RSPOWER SEAT SYSTEM8N-53

POWER SEAT SYSTEM (Continued)

Page 625 of 2585

knobs for the seat switch unit must be removed

before the seat switch can be removed from the side

shield.

The power seat switch cannot be repaired. If one

switch is damaged or faulty, the entire power seat

switch unit must be replaced.

OPERATION

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged. See the owner's

manual in the vehicle glove box for more information

on the power seat switch functions and the seat

adjusting procedures.

DIAGNOSIS AND TESTING - DRIVER SEAT

SWITCH

(1) Remove the power seat switch, refer to the

Switch Removal and Installation procedures in this

section.

(2) Using an ohmmeter, check pin #1 in the power

seat switch connector receptacle for continuity to

ground. It should be present. If OK, go to Step 3. If

not OK, repair the open ground circuit as required.

(3) Using an voltmeter, check pin #5 of the wire

harness connector for the power seat switch for bat-

tery current. It should be present. If OK, go to Step

4. If not OK, repair the open voltage supply circuit as

required.

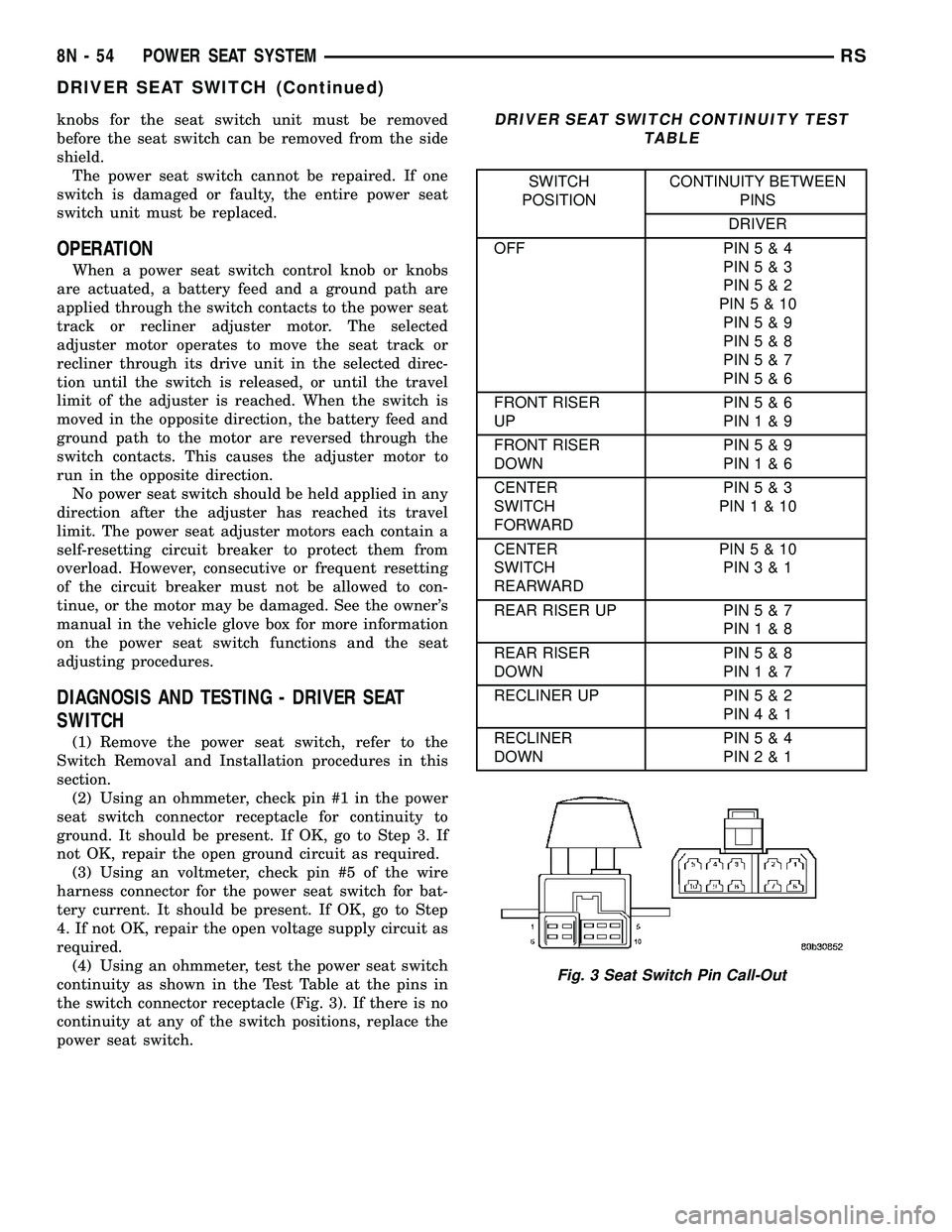

(4) Using an ohmmeter, test the power seat switch

continuity as shown in the Test Table at the pins in

the switch connector receptacle (Fig. 3). If there is no

continuity at any of the switch positions, replace the

power seat switch.

DRIVER SEAT SWITCH CONTINUITY TEST

TABLE

SWITCH

POSITIONCONTINUITY BETWEEN

PINS

DRIVER

OFF PIN5&4

PIN5&3

PIN5&2

PIN5&10

PIN5&9

PIN5&8

PIN5&7

PIN5&6

FRONT RISER

UPPIN5&6

PIN1&9

FRONT RISER

DOWNPIN5&9

PIN1&6

CENTER

SWITCH

FORWARDPIN5&3

PIN1&10

CENTER

SWITCH

REARWARDPIN5&10

PIN3&1

REAR RISER UP PIN5&7

PIN1&8

REAR RISER

DOWNPIN5&8

PIN1&7

RECLINER UP PIN5&2

PIN4&1

RECLINER

DOWNPIN5&4

PIN2&1

Fig. 3 Seat Switch Pin Call-Out

8N - 54 POWER SEAT SYSTEMRS

DRIVER SEAT SWITCH (Continued)

Page 626 of 2585

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

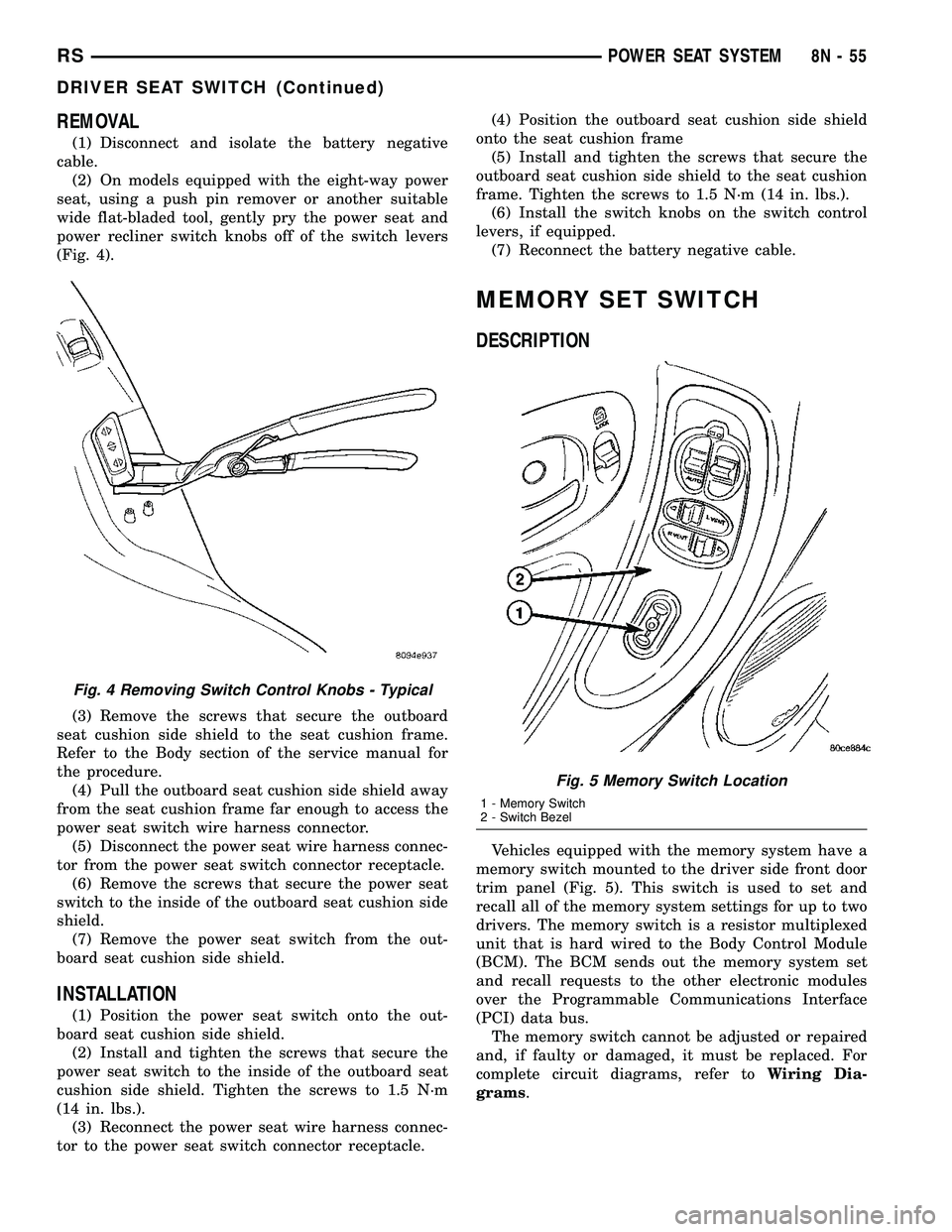

(2) On models equipped with the eight-way power

seat, using a push pin remover or another suitable

wide flat-bladed tool, gently pry the power seat and

power recliner switch knobs off of the switch levers

(Fig. 4).

(3) Remove the screws that secure the outboard

seat cushion side shield to the seat cushion frame.

Refer to the Body section of the service manual for

the procedure.

(4) Pull the outboard seat cushion side shield away

from the seat cushion frame far enough to access the

power seat switch wire harness connector.

(5) Disconnect the power seat wire harness connec-

tor from the power seat switch connector receptacle.

(6) Remove the screws that secure the power seat

switch to the inside of the outboard seat cushion side

shield.

(7) Remove the power seat switch from the out-

board seat cushion side shield.

INSTALLATION

(1) Position the power seat switch onto the out-

board seat cushion side shield.

(2) Install and tighten the screws that secure the

power seat switch to the inside of the outboard seat

cushion side shield. Tighten the screws to 1.5 N´m

(14 in. lbs.).

(3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.(4) Position the outboard seat cushion side shield

onto the seat cushion frame

(5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.).

(6) Install the switch knobs on the switch control

levers, if equipped.

(7) Reconnect the battery negative cable.

MEMORY SET SWITCH

DESCRIPTION

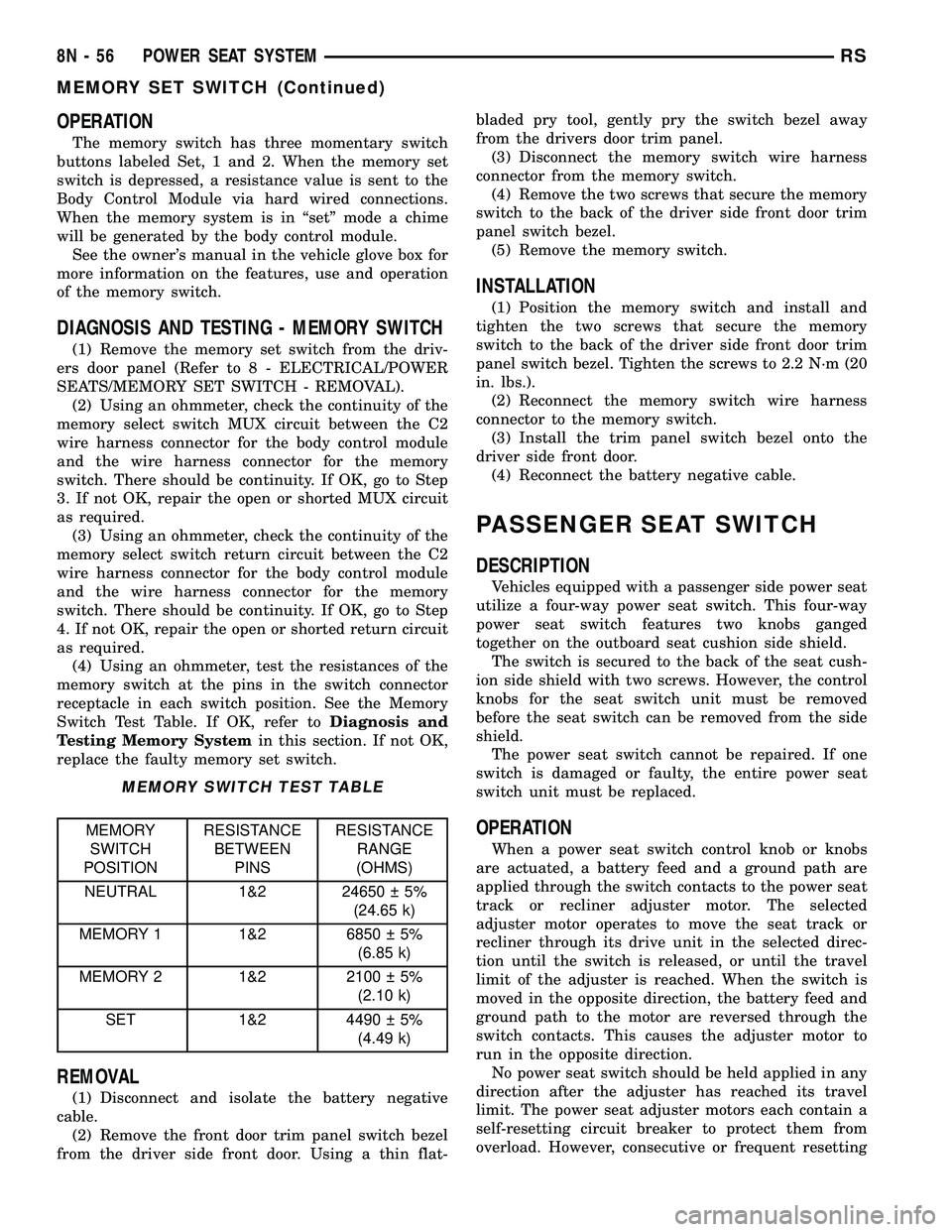

Vehicles equipped with the memory system have a

memory switch mounted to the driver side front door

trim panel (Fig. 5). This switch is used to set and

recall all of the memory system settings for up to two

drivers. The memory switch is a resistor multiplexed

unit that is hard wired to the Body Control Module

(BCM). The BCM sends out the memory system set

and recall requests to the other electronic modules

over the Programmable Communications Interface

(PCI) data bus.

The memory switch cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced. For

complete circuit diagrams, refer toWiring Dia-

grams.

Fig. 4 Removing Switch Control Knobs - Typical

Fig. 5 Memory Switch Location

1 - Memory Switch

2 - Switch Bezel

RSPOWER SEAT SYSTEM8N-55

DRIVER SEAT SWITCH (Continued)

Page 627 of 2585

OPERATION

The memory switch has three momentary switch

buttons labeled Set, 1 and 2. When the memory set

switch is depressed, a resistance value is sent to the

Body Control Module via hard wired connections.

When the memory system is in ªsetº mode a chime

will be generated by the body control module.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory switch.

DIAGNOSIS AND TESTING - MEMORY SWITCH

(1) Remove the memory set switch from the driv-

ers door panel (Refer to 8 - ELECTRICAL/POWER

SEATS/MEMORY SET SWITCH - REMOVAL).

(2) Using an ohmmeter, check the continuity of the

memory select switch MUX circuit between the C2

wire harness connector for the body control module

and the wire harness connector for the memory

switch. There should be continuity. If OK, go to Step

3. If not OK, repair the open or shorted MUX circuit

as required.

(3) Using an ohmmeter, check the continuity of the

memory select switch return circuit between the C2

wire harness connector for the body control module

and the wire harness connector for the memory

switch. There should be continuity. If OK, go to Step

4. If not OK, repair the open or shorted return circuit

as required.

(4) Using an ohmmeter, test the resistances of the

memory switch at the pins in the switch connector

receptacle in each switch position. See the Memory

Switch Test Table. If OK, refer toDiagnosis and

Testing Memory Systemin this section. If not OK,

replace the faulty memory set switch.

MEMORY SWITCH TEST TABLE

MEMORY

SWITCH

POSITIONRESISTANCE

BETWEEN

PINSRESISTANCE

RANGE

(OHMS)

NEUTRAL 1&2 24650 5%

(24.65 k)

MEMORY 1 1&2 6850 5%

(6.85 k)

MEMORY 2 1&2 2100 5%

(2.10 k)

SET 1&2 4490 5%

(4.49 k)

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front door trim panel switch bezel

from the driver side front door. Using a thin flat-bladed pry tool, gently pry the switch bezel away

from the drivers door trim panel.

(3) Disconnect the memory switch wire harness

connector from the memory switch.

(4) Remove the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel.

(5) Remove the memory switch.

INSTALLATION

(1) Position the memory switch and install and

tighten the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel. Tighten the screws to 2.2 N´m (20

in. lbs.).

(2) Reconnect the memory switch wire harness

connector to the memory switch.

(3) Install the trim panel switch bezel onto the

driver side front door.

(4) Reconnect the battery negative cable.

PASSENGER SEAT SWITCH

DESCRIPTION

Vehicles equipped with a passenger side power seat

utilize a four-way power seat switch. This four-way

power seat switch features two knobs ganged

together on the outboard seat cushion side shield.

The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

knobs for the seat switch unit must be removed

before the seat switch can be removed from the side

shield.

The power seat switch cannot be repaired. If one

switch is damaged or faulty, the entire power seat

switch unit must be replaced.

OPERATION

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

8N - 56 POWER SEAT SYSTEMRS

MEMORY SET SWITCH (Continued)

Page 628 of 2585

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged. See the owner's

manual in the vehicle glove box for more information

on the power seat switch functions and the seat

adjusting procedures.

DIAGNOSIS AND TESTING - PASSENGER SEAT

SWITCH

(1) Remove the power seat switch, refer to the

Switch Removal and Installation procedures in this

section.

(2) Using an ohmmeter, check pin #1 of the power

seat switch connector for continuity to ground. It

should be present, If OK go to Step3,IfNOTOK

repair the open ground circuit as required.

(3) Using a voltmeter, check pin #5 of the power

seat switch connector for battery voltage. If OK, go to

Step 4. If not OK, repair the open voltage supply cir-

cuit as required.

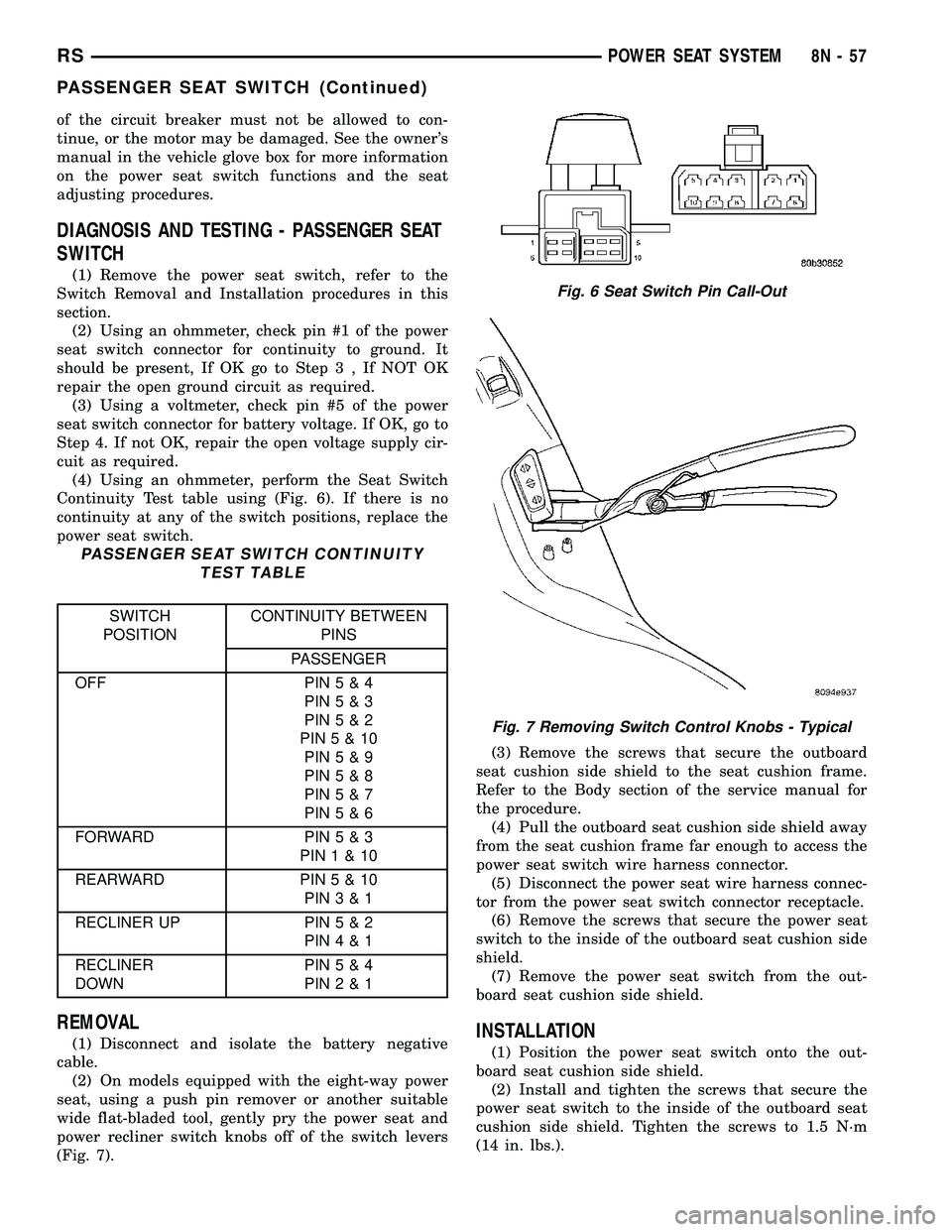

(4) Using an ohmmeter, perform the Seat Switch

Continuity Test table using (Fig. 6). If there is no

continuity at any of the switch positions, replace the

power seat switch.

PASSENGER SEAT SWITCH CONTINUITY

TEST TABLE

SWITCH

POSITIONCONTINUITY BETWEEN

PINS

PASSENGER

OFF PIN5&4

PIN5&3

PIN5&2

PIN5&10

PIN5&9

PIN5&8

PIN5&7

PIN5&6

FORWARD PIN5&3

PIN1&10

REARWARD PIN5&10

PIN3&1

RECLINER UP PIN5&2

PIN4&1

RECLINER

DOWNPIN5&4

PIN2&1

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) On models equipped with the eight-way power

seat, using a push pin remover or another suitable

wide flat-bladed tool, gently pry the power seat and

power recliner switch knobs off of the switch levers

(Fig. 7).(3) Remove the screws that secure the outboard

seat cushion side shield to the seat cushion frame.

Refer to the Body section of the service manual for

the procedure.

(4) Pull the outboard seat cushion side shield away

from the seat cushion frame far enough to access the

power seat switch wire harness connector.

(5) Disconnect the power seat wire harness connec-

tor from the power seat switch connector receptacle.

(6) Remove the screws that secure the power seat

switch to the inside of the outboard seat cushion side

shield.

(7) Remove the power seat switch from the out-

board seat cushion side shield.INSTALLATION

(1) Position the power seat switch onto the out-

board seat cushion side shield.

(2) Install and tighten the screws that secure the

power seat switch to the inside of the outboard seat

cushion side shield. Tighten the screws to 1.5 N´m

(14 in. lbs.).

Fig. 6 Seat Switch Pin Call-Out

Fig. 7 Removing Switch Control Knobs - Typical

RSPOWER SEAT SYSTEM8N-57

PASSENGER SEAT SWITCH (Continued)

Page 629 of 2585

(3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.

(4) Position the outboard seat cushion side shield

onto the seat cushion frame

(5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.).

(6) Install the switch knobs on the switch control

levers, if equipped.

(7) Reconnect the battery negative cable.

DRIVER POWER SEAT TRACK

DESCRIPTION

The eight-way driver side power seat option

includes a electrically operated power seat track

located under the driver side front seat. The front

power seat track on the driver side of the vehicle also

provides the mounting location for the Memory Seat/

Mirror Module (MSMM). The power seat circuit

breakers are mounted on the rear of the driver side

power seat track, just behind the seat rear trim

panel. The lower half of the power seat track is

secured to the floor panel via four studs and nuts

that must be accessed from the underside of the vehi-

cle. Four bolts secure the bottom of the seat cushion

pan to the upper half of the power seat track unit.

Four additional bolts secure the seat back frame to

the power seat track unit.

The power seat track unit includes four reversible

electric motors that are secured to the upper half of

the track unit. Each motor moves the seat adjuster

through a combination of worm-drive gearboxes and

screw-type drive units. Each of the four power seat

track motors used on models equipped with the

optional memory system incorporates a position

potentiometer integral to the motor assembly, which

electronically monitors the motor position. This

enables the memory system to function by referenc-

ing the motor positions programmed into the memory

seat/mirror module.

The front and rear of the seat are operated by two

separate vertical adjustment motors. These motors

can be operated independently of each other, tilting

the entire seat assembly forward or rearward; or,

they can be operated in unison by selecting the

proper power seat switch functions, which will raise

or lower the entire seat assembly. A third motor is

the horizontal adjustment motor, which moves the

seat track in the forward and rearward directions.

The forth motor is the recliner adjustment motor,

which moves the seat back in the forward and rear-

ward directions.

The power seat track unit cannot be repaired, and

is serviced only as a complete unit. If any componentin this unit is faulty or damaged, the entire power

seat track unit must be replaced.

OPERATION

When the driver side power seat switch control

knob or knobs are actuated, a battery feed and a

ground path are applied through the switch contacts

to the power seat track or recliner adjuster motor.

The selected adjuster motor operates to move the

seat track or recliner through its drive unit in the

selected direction until the switch is released, or

until the travel limit of the adjuster is reached.

When the switch is moved in the opposite direction,

the battery feed and ground path to the motor are

reversed through the switch contacts. This causes the

adjuster motor to run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

See the owner's manual in the vehicle glove box for

more information on the power seat switch functions

and the seat adjusting procedures.

DIAGNOSIS AND TESTING - DRIVER POWER

SEAT TRACK

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Actuate the driver side power seat switch to move

all three power seat track adjusters in each direction.

The power seat track adjusters should move in each

of the selected directions. If a power seat track

adjuster fails to operate in only one direction, move

the adjuster a short distance in the opposite direction

and test again to be certain that the adjuster is not

at its travel limit. If the power seat track adjuster

still fails to operate in only one direction, refer to

Diagnosis and Testing Power Seat Switchin this

section. If the power seat track adjuster fails to oper-

ate in more than one direction, perform the following

tests. For complete circuit diagrams, refer toWiring

Diagrams.

8N - 58 POWER SEAT SYSTEMRS

PASSENGER SEAT SWITCH (Continued)

Page 630 of 2585

TESTING POWER SEAT TRACK MOTORS

(1) Check the power seat circuit breaker under the

seat. If OK, go to Step 2. If not OK, replace the

faulty power seat circuit breaker.

(2) Check for battery voltage at the power seat cir-

cuit breaker under the seat. If OK, go to Step 3. If

not OK, repair the open fused B(+) circuit to the fuse

in the Intelligent Power Module as required.

(3) Remove the outboard seat cushion side shield

from the seat. Disconnect the seat wire harness con-

nector from the power seat switch connector recepta-

cle. Check for battery voltage at the fused B(+)

circuit cavity of the power seat wire harness connec-

tor for the power seat switch. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit to the

power seat circuit breaker under the seat as

required.

(4) Check for continuity between the ground cir-

cuit cavity of the power seat wire harness connector

for the power seat switch and a good ground. There

should be continuity. If OK, go to Step 5. If not OK,

repair the open ground circuit to ground as required.

(5) Test the power seat switch. Refer toDiagnosis

and Testing Power Seat Switchin this section. If

the switch tests OK, test the circuits of the power

seat wire harness between the inoperative power seat

track adjuster motor and the power seat switch for

shorts or opens. If the circuits check OK, replace the

faulty power seat track unit. If the circuits are not

OK, repair the power seat wire harness as required.

REMOVAL

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Remove the appropriate seat from the vehicle

and place it on a clean work surface(Refer to 23 -

BODY/SEATS/SEAT - REMOVAL).

(2) If the vehicle is so equipped, remove the Mem-

ory Seat/Mirror Module (MSMM) retaining screws.

(3) If the vehicle is so equipped, disconnect the

MSMM electrical connectors and remove the MSMM

from the power seat track.

(4) Remove the rear fabric blocker trim panel from

the rear of the front seat.(5) Remove the seat side cover and power seat

switch as an assembly (Refer to 23 - BODY/SEATS/

SEAT CUSHION SIDE COVERS - REMOVAL).

(6) Disconnect all electrical connectors connecting

the power seat track to the seat assembly.

(7) Pull the seat back trim cover up slightly to

access and remove the two seat back frame mounting

bolts and also remove two seat back recliner bolts.

(8) Remove four seat track mounting bolts from

the seat cushion pan.

(9) Remove the power seat track from the seat.

INSTALLATION

(1) Position the seat cushion on the seat track.

(2) Install the four seat track retaining bolts in the

seat cushion pan. Torque the bolts to 28.5 N´m.

(3) Position the seat back and install the two seat

back frame mounting bolts and the two seat back

recliner bolts. Torque the bolts to 55 N´m.

(4) Route and connect the electrical connectors

between the power seat track and the seat assembly.

(5) Install the seat side cover and power seat

switch as an assembly (Refer to 23 - BODY/SEATS/

SEAT CUSHION SIDE COVERS - INSTALLATION).

(6) Install the rear fabric blocker trim panel on the

rear of the front seat.

(7) If the vehicle is so equipped, position the Mem-

ory Seat/Mirror Module (MSMM) and connect the

MSMM electrical connectors.

(8) Install the MSMM retaining screws.

(9) Install the seat assembly in the vehicle (Refer

to 23 - BODY/SEATS/SEAT - INSTALLATION).

PASSENGER POWER SEAT

TRACK

DESCRIPTION

The four-way passenger side power seat option

includes a electrically operated power seat track unit

located under the passenger side front seat. The

power seat circuit breaker is mounted on the rear of

the power seat track, just behind the seat rear trim

panel. The lower half of the power seat track is

secured to the floor panel via four studs and nuts

that must be accessed from the underside of the vehi-

cle. Four bolts secure the bottom of the seat cushion

frame to the upper half of the power seat track unit.

Four additional bolts secure the seat back frame to

the power seat track unit.

The passenger side power seat track unit includes

two reversible electric motors that are secured to the

upper half of the track unit. Each motor moves the

seat adjuster through a combination of worm-drive

gearboxes and screw-type drive units. The horizontal

adjustment motor moves the seat track in the for-

RSPOWER SEAT SYSTEM8N-59

DRIVER POWER SEAT TRACK (Continued)

Page 631 of 2585

ward and rearward directions. The recliner adjust-

ment motor moves the seat back in the forward and

rearward directions.

The power seat track unit cannot be repaired, and

is serviced only as a complete unit. If any component

in this unit is faulty or damaged, the entire power

seat track unit must be replaced.

OPERATION

When a passenger side power seat switch control

knob or knobs are actuated, a battery feed and a

ground path are applied through the switch contacts

to the power seat track or recliner adjuster motor.

The selected adjuster motor operates to move the

seat track or recliner through its drive unit in the

selected direction until the switch is released, or

until the travel limit of the adjuster is reached.

When the switch is moved in the opposite direction,

the battery feed and ground path to the motor are

reversed through the switch contacts. This causes the

adjuster motor to run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

See the owner's manual in the vehicle glove box for

more information on the power seat switch functions

and the seat adjusting procedures.

DIAGNOSIS AND TESTING - POWER SEAT

TRACK

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Actuate the passenger side power seat switch to

move the power seat track adjuster in each direction.

The power seat track adjuster should move in each of

the selected directions. If a power seat track adjuster

fails to operate in only one direction, move the

adjuster a short distance in the opposite direction

and test again to be certain that the adjuster is not

at its travel limit. If the power seat track adjuster

still fails to operate in only one direction, refer to

Diagnosis and Testing Power Seat Switchin this

section. If the power seat track adjuster fails to oper-

ate in more than one direction, perform the following

tests. For complete circuit diagrams, refer toWiring

Diagrams.

(1) Check the power seat circuit breaker under the

seat. If OK, go to Step 2. If not OK, replace the

faulty power seat circuit breaker.

(2) Check for battery voltage at the power seat cir-

cuit breaker under the seat. If OK, go to Step 3. If

not OK, repair the open fused B(+) circuit to the fuse

in the Intelligent Power Module as required.

(3) Remove the outboard seat cushion side shield

from the seat. Disconnect the seat wire harness con-

nector from the power seat switch connector recepta-

cle. Check for battery voltage at the fused B(+)

circuit cavity of the power seat wire harness connec-

tor for the power seat switch. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit to the

power seat circuit breaker under the seat as

required.

(4) Check for continuity between the ground cir-

cuit cavity of the power seat wire harness connector

for the power seat switch and a good ground. There

should be continuity. If OK, go to Step 5. If not OK,

repair the open ground circuit to ground as required.

(5) Test the power seat switch. Refer toDiagnosis

and Testing Power Seat Switchin this section. If

the switch tests OK, test the circuits of the power

seat wire harness between the inoperative power seat

track adjuster motor and the power seat switch for

shorts or opens. If the circuits check OK, replace the

faulty power seat track unit. If the circuits are not

OK, repair the power seat wire harness as required.

8N - 60 POWER SEAT SYSTEMRS

PASSENGER POWER SEAT TRACK (Continued)

Page 639 of 2585

DOOR LOCK INHIBIT

When the key is in the ignition (in any switch posi-

tion) and either front door is opened, the door lock

switches LOCK functions are disabled. The

UN-LOCK functions are still functional. This protects

against locking the vehicle with the key still in the

ignition. The RKE key fob will still lock the doors.

After the key is removed from the ignition or the

doors are closed, the power door locks will operate

normally.

REMOTE KEYLESS ENTRY

The Remote Keyless Entry (RKE) system allows

the use of a remote battery-powered radio transmit-

ter to communicate with the BCM to actuate the

power lock system. The RKE transmitters are also equipped with a

Panic button. If the Panic button on the RKE trans-

mitter is depressed, the horn will sound and the

exterior lights will flash on the vehicle for about

three minutes, or until the Panic button is depressed

a second time. Pressing the Panic button also acti-

vates the courtesy lamps. Pressing the Panic button

again stops the exterior lamps from flashing and the

horn from sounding. However, the courtesy lamps

will remain illuminated until either the BCM times

out lamp operation or until the turning of the igni-

tion. The panic feature will operate if the ignition is

ON, but only if the Panic button is pressed prior to

starting the vehicle. A vehicle speed of about 25.7

km/h (15 miles-per-hour) will also cancel the panic

event. The RKE system can also perform other functions

on this vehicle. If the vehicle is equipped with the

optional Vehicle Theft Security System (VTSS), the

RKE transmitter will arm the VTSS when the Lock

button is depressed, and disarm the VTSS when the

Unlock button is depressed. The RKE system includes two transmitters when

the vehicle is shipped from the factory, but the sys-

tem can retain the vehicle access codes of up to a

total of eight transmitters. If an RKE transmitter is

inoperative or lost, new transmitter vehicle access

codes can be programmed into the system using a

DRB III tscan tool.

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-

ences. Customer programmable feature options

affecting the RKE system include: ² Automatic Door Lock - Customer programma-

ble feature that allows the BCM to perform an auto-

matic door lock if the vehicle speed is above 25.7

km/h (15 miles-per-hour). ² Automatic Door Unlock On Exit - Customer

programmable feature that allows the BCM to per- form an automatic door unlock if the vehicle speed is

0, vehicle in park and driver door is opened.

² Flash Lights with Lock and Unlock - Allows

the option of having the park lamps flash as an opti-

cal verification that the RKE system received a valid

Lock request or Unlock request from the RKE trans-

mitter, or having no optical verification. ² Programming Additional Transmitters -

Allows up to a total of four transmitter vehicle access

codes to be stored. ² Remote Unlock Sequence - Allows the option

of having only the driver side front door unlock when

the RKE transmitter Unlock button is depressed the

first time. The remaining doors unlock when the but-

ton is depressed a second time within 5 seconds of

the first unlock press. Another option is having all

doors unlock upon the first depression of the RKE

transmitter Unlock button. ² Sound Horn on Lock - Allows the option of

having the horn sound a short chirp as an audible

verification that the RKE system received a valid

Lock request from the RKE transmitter, or having no

audible verification.

OPERATION

POWER LOCKS

The Body Control Module (BCM) locks or unlocks

the doors when an actuation input signal from a door

lock switch, Central Lock key cylinder or Remote

Keyless Entry (RKE) is received. The BCM turns on

the output drivers and provides a voltage level to the

door lock motor for a specified time.

REMOTE KEYLESS ENTRY

The RKE transmitter uses radio frequency signals

to communicate with the SKREEM module. The

SKREEM is on the PCI bus. When the operator

presses a button on the transmitter, it sends a spe-

cific request to the SKREEM. In turn, the SKREEM

sends the appropriate request over the PCI bus to

the following: ² Integrated Power Module (IPM) - to activate

the park lamps, the headlamps and the horn for the

horn chirp. ² Power Liftgate Module (PLGM) - to control

the liftgate lock and unlock functions. After pressing the lock button on the RKE trans-

mitter, all of the door locks will lock, the illuminated

entry will turn off (if all doors are closed) and the

vehicle theft security system (if equipped) will arm. Pressing the unlock button one time will unlock

the driver door, or all doors based on the customer

programmable feature enabled, the illuminated entry

will turn on the courtesy lamps and the vehicle theft

security system (if equipped) will disarm. Pressing

8Ns - 2 POWER LOCKSRS

POWER LOCKS (Continued)

Page 640 of 2585

the unlock button a second time, the remaining door

locks will unlock.If the vehicle is equipped with the memory system,

the memory message will identify which transmitter

(1 or 2) sent the signal.

ROLLING CODE

The rolling code feature changes part of the trans-

mitter message each time that it is used. The trans-

mitter message and the receiver message increment

together. Under certain conditions with a rolling code

system, such as pressing a button on the RKE trans-

mitter over 255 times outside of receiver range or

replacing the battery, the receiver and transmitter

can fall out of synchronization. To re-synchronize,

press and release the UNLOCK button on the RKE

transmitter repeatedly (it may take up to eight

cycles) while listening carefully for the power door

locks in the vehicle to cycle, indicating that resyn-

chronization has occurred. The lock function works from the RKE transmitter

even in an out of synchronization condition, therefore

it could be verified by pressing the LOCK button on

the RKE key fob.

DOOR CYLINDER LOCK

SWITCH - EXPORT

DESCRIPTION

The Door Cylinder Lock Switch (If equipped) is

used to: ² Unlock/Lock all the doors via the Central Lock-

ing feature. ² Arm/Disarm the Vehicle Theft Security System.

² Trigger the Illuminated Entry feature.

The door cylinder lock switch is mounted to the

rear of the driver door lock cylinder. When installed

on the rear of the cylinder, there is a tab on the lock

cylinder that aligns with the switch to prevent it

from turning. An anti-rotating device. The door cylin-

der lock switch is a one time use switch. Once it is

removed from the rear of the door lock cylinder, it

may not be reinstalled and a new switch must be

used.

OPERATION

When the Door Cylinder Lock Switch is turned

either way using the door key cylinder, the BCM

reads a direct message signal from the switch. If turning the key cylinder once, toward the front

of the vehicle, this will: (1) Mechanically unlock the door lock.

(2) Disarm the Vehicle Theft Security System (if

equipped). (3) Turn on the Illuminated Entry (if equipped) for

approximately 30 seconds. If the key cylinder is turned to the unlock position

(toward the front of vehicle) twice within two sec-

onds, all the doors and liftgate will unlock (if

equipped with the central locking feature). To lock the vehicle using the door cylinder lock

switch, turn the key cylinder toward the rear of the

vehicle once. This will lock the door that you are

using the key on. If equipped with the central locking

feature, this will lock all the other doors and liftgate.

Furthermore, this will arm the vehicle theft security

system and turn off the illuminated entry.

DIAGNOSIS AND TESTING - DOOR CYLINDER

LOCK SWITCH - EXPORT

Any diagnosis of the power lock system

should begin with the use of the DRB III tdiag-

nostic tool. For information on the use of the

DRB III t, refer to the appropriate Diagnostic

Service Manual. For complete circuit diagrams, refer to the appro-

priate wiring information. (1) Visually inspect the switch for proper installa-

tion. Make sure it is seated on the rear of the key

cylinder, with the tab of the door key cylinder prop-

erly aligned with the slot on the door cylinder lock

switch. (2) Disconnect the switch at the harness connector

and check the resistance in each switch position.

CAUTION: Do not disconnect the switch from the

rear of the door key cylinder. This switch is a one

time use switch. Once it is removed from the rear of

the switch, it is not reusable and must be replaced.

Test the switch at the harness connector.

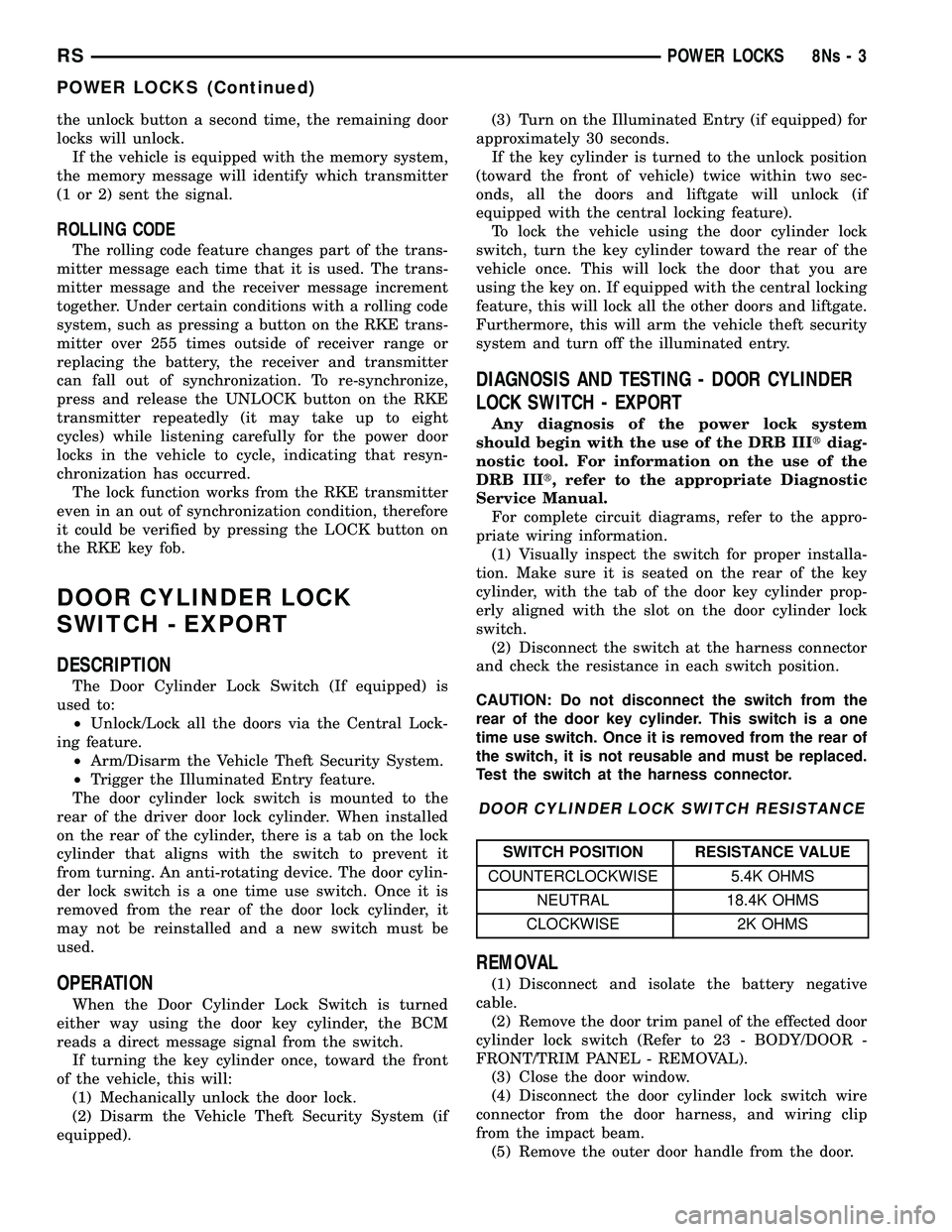

DOOR CYLINDER LOCK SWITCH RESISTANCE

SWITCH POSITION RESISTANCE VALUE

COUNTERCLOCKWISE 5.4K OHMS NEUTRAL 18.4K OHMS

CLOCKWISE 2K OHMS

REMOVAL

(1) Disconnect and isolate the battery negative

cable. (2) Remove the door trim panel of the effected door

cylinder lock switch (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - REMOVAL). (3) Close the door window.

(4) Disconnect the door cylinder lock switch wire

connector from the door harness, and wiring clip

from the impact beam. (5) Remove the outer door handle from the door.

RS POWER LOCKS8Ns-3

POWER LOCKS (Continued)