diagram CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1885 of 2585

40TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

40TE AUTOMATIC TRANSAXLE DESCRIPTION .........................25

OPERATION ...........................27

DIAGNOSIS AND TESTING DIAGNOSIS AND TESTING - 4XTETRANSAXLE GENERAL DIAGNOSIS .......27

DIAGNOSIS AND TESTING - ROAD TEST . . . 27

DIAGNOSIS AND TESTING - HYDRAULIC PRESSURE TESTS ....................28

DIAGNOSIS AND TESTING - CLUTCH AIR PRESSURE TESTS ....................30

DIAGNOSIS AND TESTING - TORQUE CONVERTER HOUSING FLUID LEAKAGE . . . 31

REMOVAL .............................31

DISASSEMBLY .........................34

ASSEMBLY ............................51

INSTALLATION .........................73

SCHEMATICS AND DIAGRAMS 4XTE TRANSAXLE HYDRAULICSCHEMATICS ........................75

SPECIFICATIONS - 41TE TRANSAXLE .......87

SPECIAL TOOLS .......................89

ACCUMULATOR DESCRIPTION .........................94

OPERATION ...........................94

DRIVING CLUTCHES DESCRIPTION .........................95

OPERATION ...........................95

FINAL DRIVE DESCRIPTION .........................95

OPERATION ...........................96

DISASSEMBLY .........................96

ASSEMBLY ............................99

ADJUSTMENTS DIFFERENTIAL BEARING PRELOADMEASUREMENT AND ADJUSTMENT ......100

FLUID STANDARD PROCEDURE FLUID LEVEL AND CONDITION CHECK . . . 102

STANDARD PROCEDURE - FLUID ANDFILTER SERVICE .....................104

GEAR SHIFT CABLE REMOVAL ............................105

HOLDING CLUTCHES DESCRIPTION ........................106

OPERATION ..........................106

INPUT CLUTCH ASSEMBLY DISASSEMBLY ........................107

ASSEMBLY ...........................116 OIL PUMP

DESCRIPTION ........................131

OPERATION ..........................131

DISASSEMBLY ........................131

ASSEMBLY ...........................132

PLANETARY GEARTRAIN DESCRIPTION ........................132

OPERATION ..........................132

SEAL - OIL PUMP REMOVAL ............................133

INSTALLATION ........................133

SHIFT INTERLOCK SOLENOID DESCRIPTION ........................133

OPERATION ..........................134

DIAGNOSIS AND TESTING - BRAKE/ TRANSMISSION SHIFT INTERLOCK

SOLENOID ..........................135

REMOVAL ............................135

INSTALLATION ........................136

SOLENOID/PRESSURE SWITCH ASSY DESCRIPTION ........................137

OPERATION ..........................137

REMOVAL ............................138

INSTALLATION ........................139

SPEED SENSOR - INPUT DESCRIPTION ........................140

OPERATION ..........................140

REMOVAL ............................141

INSTALLATION ........................141

SPEED SENSOR - OUTPUT DESCRIPTION ........................142

OPERATION ..........................142

REMOVAL ............................143

INSTALLATION ........................143

TORQUE CONVERTER DESCRIPTION ........................144

OPERATION ..........................148

REMOVAL ............................149

INSTALLATION ........................149

TRANSMISSION CONTROL RELAY DESCRIPTION ........................150

OPERATION ..........................150

TRANSMISSION RANGE SENSOR DESCRIPTION ........................150

OPERATION ..........................151

REMOVAL ............................151

INSTALLATION ........................152

VALVE BODY DESCRIPTION ........................152

21s - 24 40TE AUTOMATIC TRANSAXLERS

Page 1936 of 2585

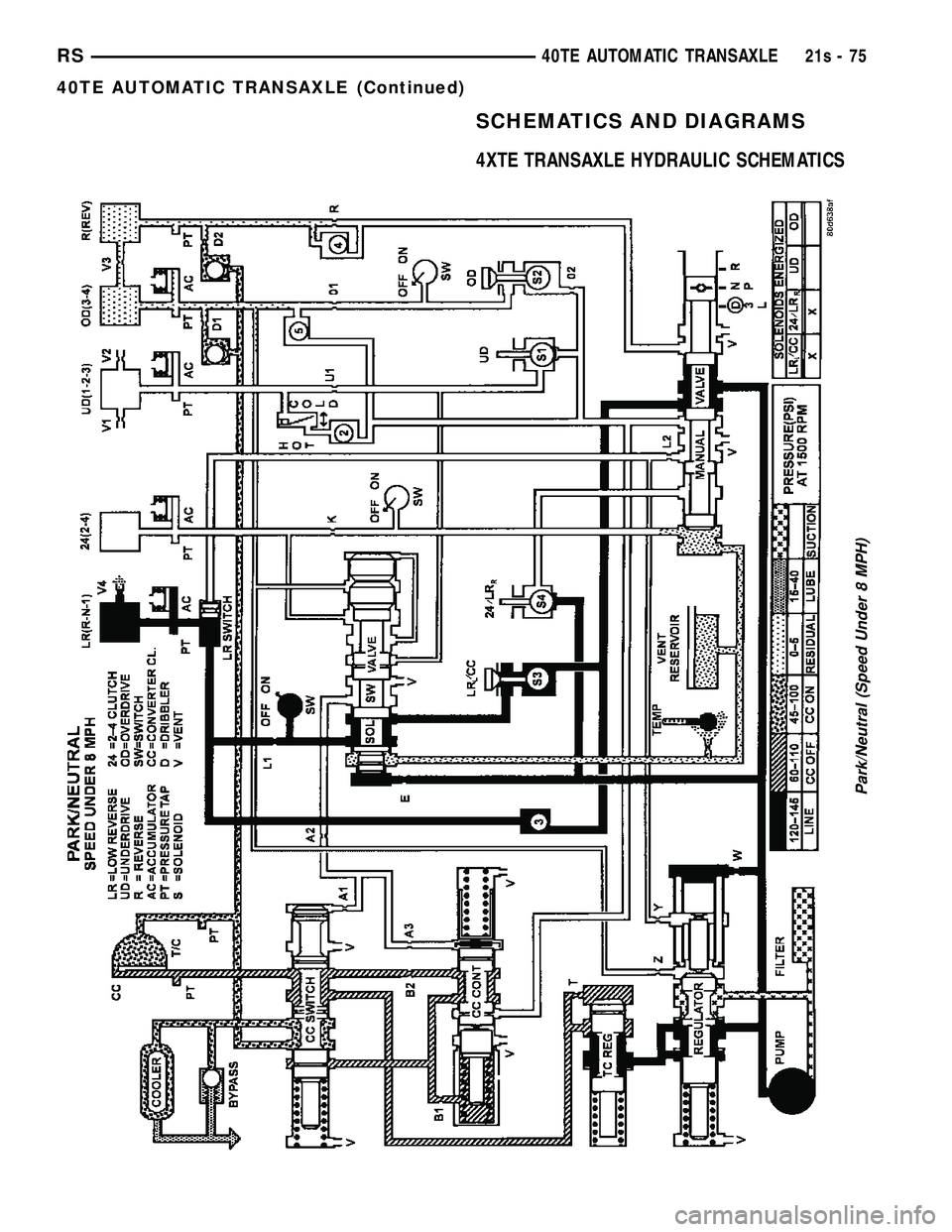

SCHEMATICS AND DIAGRAMS

4XTE TRANSAXLE HYDRAULIC SCHEMATICS

Park/Neutral (Speed Under 8 MPH)

RS40TE AUTOMATIC TRANSAXLE21s-75

40TE AUTOMATIC TRANSAXLE (Continued)

Page 2227 of 2585

SUNROOF

TABLE OF CONTENTS

page page

SUNROOF

DESCRIPTION........................116

DIAGNOSIS AND TESTING - SUNROOF.....116

DRAIN TUBE

REMOVAL............................119

INSTALLATION........................120

GLASS PANEL

REMOVAL............................120

INSTALLATION........................120

ADJUSTMENTS

SUNROOF GLASS PANEL ADJUSTMENT . . 120

SUNROOF ASSEMBLY

REMOVAL............................120

INSTALLATION........................120

SUNSHADE

REMOVAL............................120INSTALLATION........................121

WIND DEFLECTOR

REMOVAL............................121

INSTALLATION........................121

WATER CHANNEL

REMOVAL............................121

INSTALLATION........................121

SUNROOF MOTOR

REMOVAL............................121

INSTALLATION........................121

ADJUSTMENTS

ADJUSTMENT.......................122

SUNROOF SWITCH

REMOVAL............................123

INSTALLATION........................123

SUNROOF

DESCRIPTION

WARNING: Keep fingers and other body parts out

of sunroof opening at all times.

The sun roof features consists of: (Fig. 1)

²Sun roof glass

²Sun roof sun shade

The sunroof power sliding glass panel and sun-

shade can be positioned anywhere along its travel,

rearward of glass panel front edge.

The sunroof is electrically operated from a switch

located in the overhead console. To operate the sun-

roof the ignition switch must be in the Accessory or

On/Run position. Both switchs are a rocker style

design that open or close the sunroof. When pressing

and releasing the open button once, the sunroof will

express open to the comfort stop and the wind deflec-

tor will raise. If the button is pressed a second time,

the sunroof will continue to open to full travel unless

the button is released, at which time it will stop in

that position. Pressing and holding the close button

will close the sunroof. If the close button is released

before the glass fully closes, the sunroof will stop in

that position. The vent switch operates in a similar

manor. The sunroof will also operate for up to fifteenminutes after the ignition key is turned off for cus-

tomer comfort and convenance while parking.

DIAGNOSIS AND TESTING - SUNROOF

Refer to Sunroof Diagnostic Chart for possible

causes. Before beginning sunroof diagnostics verify

that all other power accessories are in proper operat-

ing condition. If not, a common electrical problem

may exist. Refer to Wiring Diagrams, in this publica-

tion for circuit, splice and component descriptions.

Check the condition of the circuit protection (20 amp

circuit breaker in the Junction Block). Inspect all

wiring connector pins for proper engagement and

continuity. Check for battery voltage at the power

sunroof controller, refer to Wiring Diagrams, for cir-

cuit information. If battery voltage of more than 10

volts is detected at the controller, proceed with the

following tests (the controller will not operate at less

than 10 volts).

Before beginning diagnosis for wind noise or water

leaks, verify that the problem was not caused by

releasing the control switch before the sunroof was

fully closed. The sunroof module has a water-man-

agement system. If however, the sunroof glass is in a

partial closed position, high pressure water may be

forced beyond the water management system bound-

aries and onto the headlining.

23 - 116 SUNROOFRS

Page 2415 of 2585

²The normally open terminal (87) provides a bat-

tery current output to the compressor clutch coil

through the compressor clutch relay output circuit

only when the compressor clutch relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the compressor

clutch relay coil is de-energized.

The A/C compressor clutch relay cannot be

repaired and, if faulty or damaged, it must be

replaced. Refer to the appropriate wiring information

for diagnosis and testing of the micro-relay and for

complete HVAC wiring diagrams.

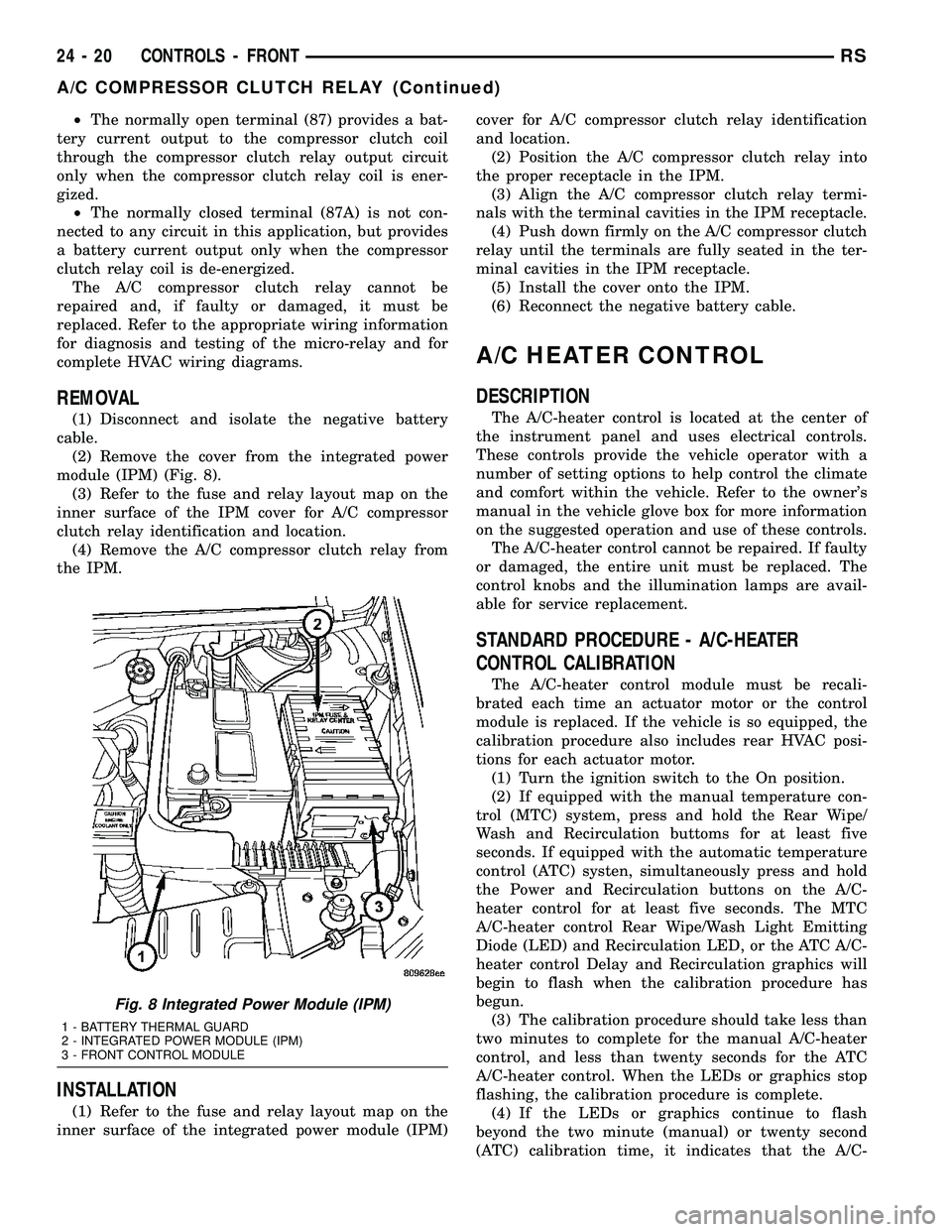

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the integrated power

module (IPM) (Fig. 8).

(3) Refer to the fuse and relay layout map on the

inner surface of the IPM cover for A/C compressor

clutch relay identification and location.

(4) Remove the A/C compressor clutch relay from

the IPM.

INSTALLATION

(1) Refer to the fuse and relay layout map on the

inner surface of the integrated power module (IPM)cover for A/C compressor clutch relay identification

and location.

(2) Position the A/C compressor clutch relay into

the proper receptacle in the IPM.

(3) Align the A/C compressor clutch relay termi-

nals with the terminal cavities in the IPM receptacle.

(4) Push down firmly on the A/C compressor clutch

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.

(6) Reconnect the negative battery cable.

A/C HEATER CONTROL

DESCRIPTION

The A/C-heater control is located at the center of

the instrument panel and uses electrical controls.

These controls provide the vehicle operator with a

number of setting options to help control the climate

and comfort within the vehicle. Refer to the owner's

manual in the vehicle glove box for more information

on the suggested operation and use of these controls.

The A/C-heater control cannot be repaired. If faulty

or damaged, the entire unit must be replaced. The

control knobs and the illumination lamps are avail-

able for service replacement.

STANDARD PROCEDURE - A/C-HEATER

CONTROL CALIBRATION

The A/C-heater control module must be recali-

brated each time an actuator motor or the control

module is replaced. If the vehicle is so equipped, the

calibration procedure also includes rear HVAC posi-

tions for each actuator motor.

(1) Turn the ignition switch to the On position.

(2) If equipped with the manual temperature con-

trol (MTC) system, press and hold the Rear Wipe/

Wash and Recirculation buttoms for at least five

seconds. If equipped with the automatic temperature

control (ATC) systen, simultaneously press and hold

the Power and Recirculation buttons on the A/C-

heater control for at least five seconds. The MTC

A/C-heater control Rear Wipe/Wash Light Emitting

Diode (LED) and Recirculation LED, or the ATC A/C-

heater control Delay and Recirculation graphics will

begin to flash when the calibration procedure has

begun.

(3) The calibration procedure should take less than

two minutes to complete for the manual A/C-heater

control, and less than twenty seconds for the ATC

A/C-heater control. When the LEDs or graphics stop

flashing, the calibration procedure is complete.

(4) If the LEDs or graphics continue to flash

beyond the two minute (manual) or twenty second

(ATC) calibration time, it indicates that the A/C-

Fig. 8 Integrated Power Module (IPM)

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE (IPM)

3 - FRONT CONTROL MODULE

24 - 20 CONTROLS - FRONTRS

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2420 of 2585

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. The resistor or diode is connected in

parallel with the relay coil in the relay, and helps to

dissipate voltage spikes and electromagnetic interfer-

ence that can be generated as the electromagnetic

field of the relay coil collapses.

The blower motor relay terminals are connected to

the vehicle electrical system through a receptacle in

the Integrated Power Module (IPM). The inputs and

outputs of the blower motor relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(automatic heater-A/C control) through a fuse in the

IPM on the fused front blower motor relay output cir-

cuit only when the blower motor relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the blower motor

relay coil is de-energized.

Refer to the appropriate wiring information for

diagnosis and testing of the micro-relay and for com-

plete HVAC wiring diagrams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Inte-

grated Power Module (IPM) (Fig. 13).

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for front blower

motor relay identification and location.(4) Remove the front blower motor relay from the

IPM by pulling the relay straight up.

INSTALLATION

(1) Refer to the fuse and relay layout map on the

inner surface of the integrated power module (IPM)

cover for front blower motor relay identification and

location.

(2) Position the front blower motor relay to the

proper receptacle in the IPM.

(3) Align the front blower motor relay terminals

with the terminal cavities in the IPM receptacle.

(4) Push down firmly on the front blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.

(6) Reconnect the negative battery cable.

Fig. 13 Integrated Power Module - Typical

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

RSCONTROLS - FRONT24-25

BLOWER MOTOR RELAY (Continued)

Page 2421 of 2585

BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

A blower motor resistor is used on this model when

it is equipped with the manual heater-A/C system.

Models equipped with the optional Automatic Tem-

perature Control (ATC) system use a blower power

module, instead of the blower motor resistor block

(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS/POWER MODULE - DESCRIPTION).

The blower motor resistor block is mounted to the

rear of the HVAC housing, directly behind the glove

box opening in the instrument panel. The resistor

block consists of a molded plastic mounting plate

with two integral connector receptacles. Concealed

behind the mounting plate are four coiled resistor

wires contained within a protective stamped steel

cage. The blower motor resistor block is accessed for

service by removing the glove box from the instru-

ment panel.

OPERATION

The blower motor resistor block is connected to the

vehicle electrical system through a dedicated take

out and connector of the instrument panel wire har-

ness. A second connector receptacle receives the pig-

tail wire connector from the blower motor. The

blower motor resistor has multiple resistor wires,

each of which will reduce the current flow through

the blower motor to change the blower motor speed.

The blower motor switch in the manual heater-A/C

system directs the ground path for the blower motor

through the correct resistor wire to obtain the

selected speed.

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through all of the resistor wires. Each higher speed

selected with the blower motor switch applies the

blower motor ground path through fewer of the resis-

tor wires, increasing the blower motor speed.

The blower motor resistor cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR BLOCK

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

(3) Disconnect the two wire harness connectors

from the blower motor resistor block.

(4) Check for continuity between each of the

blower motor switch input terminals of the resistor

and the resistor output terminal. In each case there

should be continuity. If OK, repair the wire harness

circuits between the blower motor switch and the

blower motor resistor, blower motor or blower motor

relay as required. If not OK, replace the faulty

blower motor resistor block.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE BLOWER MOTOR RESISTOR

BLOCK MAY GET VERY HOT DURING NORMAL

OPERATION. IF THE BLOWER MOTOR WAS

TURNED ON PRIOR TO SERVICING THE BLOWER

MOTOR RESISTOR BLOCK, WAIT FIVE MINUTES

TO ALLOW THE BLOWER MOTOR RESISTORS TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.

24 - 26 CONTROLS - FRONTRS

Page 2433 of 2585

Refer to the appropriate wiring information for

diagnosis and testing of the micro-relay and for com-

plete HVAC wiring diagrams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Inte-

grated Power Module (IPM) (Fig. 5).

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for rear blower

motor relay identification and location.

(4) Remove the rear blower motor relay from the

IPM.

INSTALLATION

(1) See the fuse and relay layout map molded into

the inner surface of the Integrated Power Module

(IPM) cover for rear blower motor relay identification

and location.

(2) Position the rear blower motor relay to the

proper receptacle in the IPM.

(3) Align the rear blower motor relay terminals

with the terminal cavities in the IPM relay recepta-

cle.

(4) Push down firmly on the rear blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.

(6) Reconnect the battery negative cable.

BLOWER MOTOR RESISTOR

DESCRIPTION

A rear blower motor resistor is used on this model

when it is equipped with the manual heater-A/C sys-

tem. Models equipped with the optional Automatic

Temperature Control (ATC) system use a rear blower

motor power module, instead of the blower motor

resistor block (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/POWER MODULE -

DESCRIPTION). The rear blower motor resistor

block is mounted to the rear HVAC housing, directly

above the expansion valve. The resistor block con-

sists of a molded plastic mounting plate with an inte-

gral connector receptacle. Concealed behind the

mounting plate is an electrical circuit board with two

resistors and a thermal fuse. The rear blower motor

resistor block is accessed for service by removing the

right quarter and D-pillar trim panels.

OPERATION

The rear blower motor resistor block is connected

to the vehicle electrical system through a dedicated

take out and connector of the rear HVAC wire har-

ness. The blower motor resistor has an electrical cir-

cuit board with two resistors, each of which will

reduce the current flow through the blower motor to

change the blower motor speed. The blower motor

switch in the manual heater-A/C system directs the

ground path for the rear blower motor through the

correct resistor to obtain the selected speed.

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through both resistors. Each higher speed selected

with the blower motor switch applies the blower

motor ground path through fewer of the resistors,

increasing the blower motor speed. When the blower

motor switch is in the highest speed position, the

blower motor resistors are bypassed and the blower

motor receives a direct path to ground through the

blower motor switch.

The rear blower motor resistor block cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

DIAGNOSIS AND TESTING - REAR BLOWER

MOTOR RESISTOR BLOCK

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

Fig. 5 Integrated Power Module - Typical

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

24 - 38 CONTROLS - REARRS

BLOWER MOTOR RELAY (Continued)

Page 2442 of 2585

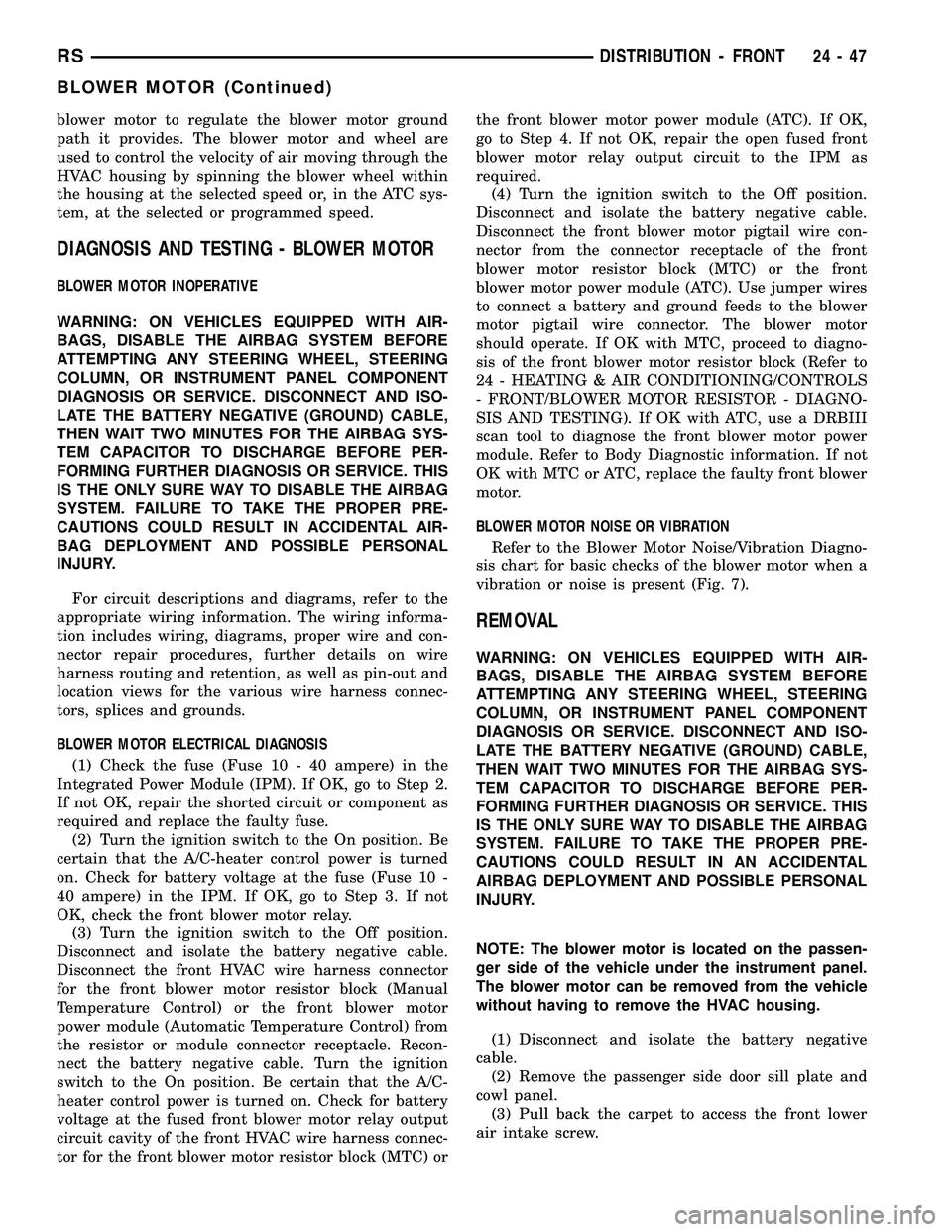

blower motor to regulate the blower motor ground

path it provides. The blower motor and wheel are

used to control the velocity of air moving through the

HVAC housing by spinning the blower wheel within

the housing at the selected speed or, in the ATC sys-

tem, at the selected or programmed speed.

DIAGNOSIS AND TESTING - BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 10 - 40 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the A/C-heater control power is turned

on. Check for battery voltage at the fuse (Fuse 10 -

40 ampere) in the IPM. If OK, go to Step 3. If not

OK, check the front blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front HVAC wire harness connector

for the front blower motor resistor block (Manual

Temperature Control) or the front blower motor

power module (Automatic Temperature Control) from

the resistor or module connector receptacle. Recon-

nect the battery negative cable. Turn the ignition

switch to the On position. Be certain that the A/C-

heater control power is turned on. Check for battery

voltage at the fused front blower motor relay output

circuit cavity of the front HVAC wire harness connec-

tor for the front blower motor resistor block (MTC) orthe front blower motor power module (ATC). If OK,

go to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front blower motor pigtail wire con-

nector from the connector receptacle of the front

blower motor resistor block (MTC) or the front

blower motor power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the front blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/BLOWER MOTOR RESISTOR - DIAGNO-

SIS AND TESTING). If OK with ATC, use a DRBIII

scan tool to diagnose the front blower motor power

module. Refer to Body Diagnostic information. If not

OK with MTC or ATC, replace the faulty front blower

motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 7).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The blower motor is located on the passen-

ger side of the vehicle under the instrument panel.

The blower motor can be removed from the vehicle

without having to remove the HVAC housing.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the passenger side door sill plate and

cowl panel.

(3) Pull back the carpet to access the front lower

air intake screw.

RSDISTRIBUTION - FRONT24-47

BLOWER MOTOR (Continued)

Page 2453 of 2585

DIAGNOSIS AND TESTING - REAR BLOWER

MOTOR

BLOWER MOTOR INOPERATIVE

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 12 - 25 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the rear A/C-heater control power is

turned on. Check for battery voltage at the fuse

(Fuse 12 - 25 ampere) in the IPM. If OK, go to Step

3. If not OK, check the rear blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear HVAC wire harness connector

from the rear blower motor resistor block (Manual

Temperature Control) or the rear blower motor power

module (Automatic Temperature Control). Reconnect

the battery negative cable. Turn the ignition switch

to the On position. Be certain that the rear A/C-

heater control power is turned on. Check for battery

voltage at the fused rear blower motor relay output

circuit cavity of the rear HVAC wire harness connec-

tor for the rear blower motor resistor block (MTC) or

the rear blower motor power module (ATC). If OK, go

to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear blower motor pigtail wire connec-

tor from the rear HVAC wire harness (MTC) or the

rear blower power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The rear blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the rear blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- REAR/BLOWER MOTOR RESISTOR - DIAGNOSIS

AND TESTING). If OK with ATC, use a DRBIII scan

tool to diagnose the rear blower motor power module.

Refer to the appropriate diagnostic information. If

not OK with MTC or ATC, replace the faulty rear

blower motor.BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 3).

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Remove the rear HVAC housing from the vehi-

cle (Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Disconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control sys-

tem, the blower motor pigtail wire is connected to a

take out and connector of the rear HVAC wire har-

ness. With the Automatic Temperature Control sys-

tem , the blower pigtail wire is connected to a

receptacle on the blower motor power module.

(3) Remove the three screws that secure the rear

blower motor to the outboard side of the rear HVAC

housing (Fig. 4).

(4) Remove the rear blower motor from the rear

HVAC housing.

INSTALLATION

(1) Position the rear blower motor into the rear

HVAC housing.

(2) Install the three screws that secure the blower

motor to the rear HVAC housing. Tighten the screws

to 2 N´m (17 in. lbs.).

(3) Reconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control system

, the blower pigtail wire is connected to a take out

and connector of the rear HVAC wire harness. With

the Automatic Temperature Control system, the

blower pigtail wire is connected to a receptacle on

the blower motor power module.

24 - 58 DISTRIBUTION - REARRS

BLOWER MOTOR (Continued)

Page 2553 of 2585

CV BOOT - INNER/OUTER -

INSTALLATION........................3-17

CV BOOT - INNER/OUTER - REMOVAL.....3-15

CV BOOT - OUTER - INSTALLATION.......3-10

CV BOOT - OUTER - REMOVAL...........3-10

CYCLE - STANDARD PROCEDURE,

POWER DOOR LEARN................8N-28

CYCLE - STANDARD PROCEDURE,

POWER LIFTGATE LEARN...............8N-9

CYLINDER - DESCRIPTION, KEY/LOCK....19-20

CYLINDER - DESCRIPTION, STANDARD 4 . . . 8I-9

CYLINDER - INSTALLATION, KEY/LOCK . . . 19-20

CYLINDER - INSTALLATION, LOCK . . 23-19,23-42

CYLINDER - INSTALLATION, SLAVE.......6-11

CYLINDER - INSTALLATION, SUPPORT....23-43

CYLINDER - LHD - INSTALLATION,

MASTER............................6-10

CYLINDER - LHD - REMOVAL, MASTER.....6-9

CYLINDER - OPERATION, KEY/LOCK......19-20

CYLINDER - REMOVAL, KEY/LOCK.......19-20

CYLINDER - REMOVAL, LOCK......23-19,23-42

CYLINDER - REMOVAL, SLAVE...........6-11

CYLINDER - REMOVAL, SUPPORT.......23-43

CYLINDER - RHD - INSTALLATION,

MASTER.............................6-9

CYLINDER - RHD - REMOVAL, MASTER.....6-8

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER............5-35,5s-34

CYLINDER BORE FITTING - STANDARD

PROCEDURE, PISTON TO...............9-42

CYLINDER BORE HONING - STANDARD

PROCEDURE....................9-112,9-35

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST - DIAGNOSIS AND

TESTING.........................9-83,9-9

CYLINDER COMPRESSION PRESSURE

TEST - DIAGNOSIS AND TESTING.....9-83,9-9

CYLINDER (FLUID RESERVOIR) -

ASSEMBLY, MASTER..............5-38,5s-37

CYLINDER (FLUID RESERVOIR) -

DISASSEMBLY, MASTER...........5-37,5s-36

CYLINDER HEAD - CLEANING . . 9-100,9-26,9s-17

CYLINDER HEAD - DESCRIPTION....9-24,9-99,

9s-16

CYLINDER HEAD - INSPECTION.....9-101,9-26,

9s-17

CYLINDER HEAD - INSTALLATION . . . 9-101,9-26,

9s-18

CYLINDER HEAD - REMOVAL . . 9-100,9-25,9s-17

CYLINDER HEAD COVER - CLEANING......9-31

CYLINDER HEAD COVER - INSPECTION....9-31

CYLINDER HEAD COVER -

INSTALLATION........................9-31

CYLINDER HEAD COVER - LEFT -

INSTALLATION.......................9-103

CYLINDER HEAD COVER - LEFT -

REMOVAL..........................9-103

CYLINDER HEAD COVER - REMOVAL......9-31

CYLINDER HEAD COVER - RIGHT -

INSTALLATION.......................9-103

CYLINDER HEAD COVER - RIGHT -

REMOVAL..........................9-102

CYLINDER HEAD COVER-LEFT -

INSTALLATION

.......................9s-20

CYLINDER HEAD COVER-LEFT -

REMOVAL

..........................9s-20

CYLINDER HEAD COVER-RIGHT -

INSTALLATION

.......................9s-19

CYLINDER HEAD COVER-RIGHT -

REMOVAL

..........................9s-19

CYLINDER HEAD COVER(S) -

DESCRIPTION

..................9-102,9s-19

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING

...............9-24,9-99,9s-16

CYLINDER HEAD OFF - INSTALLATION

. . . 9-108,

9-33,9s-26

CYLINDER HEAD OFF - REMOVAL

. . . 9-106,9-32,

9s-24

CYLINDER HEAD ON - INSTALLATION

....9-108,

9-33,9s-26

CYLINDER HEAD ON - REMOVAL

. . . 9-106,9-32,

9s-24

CYLINDER HOUSING - INSTALLATION,

LOCK

..............................19-19

CYLINDER HOUSING - REMOVAL, LOCK

. . 19-17

CYLINDER LOCK SWITCH -

DESCRIPTION, DOOR

.................8N-40CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR.................8N-40

CYLINDER LOCK SWITCH - EXPORT -

DESCRIPTION, DOOR..................8N-3

CYLINDER LOCK SWITCH - EXPORT -

DIAGNOSIS AND TESTING, DOOR........8N-3

CYLINDER LOCK SWITCH - EXPORT -

INSTALLATION, DOOR.................8N-4

CYLINDER LOCK SWITCH - EXPORT -

OPERATION, DOOR....................8N-3

CYLINDER LOCK SWITCH - EXPORT -

REMOVAL, DOOR.....................8N-3

CYLINDER LOCK SWITCH -

INSTALLATION, DOOR.................8N-41

CYLINDER LOCK SWITCH - OPERATION,

DOOR.............................8N-40

CYLINDER LOCK SWITCH - REMOVAL,

DOOR.............................8N-41

CYLINDERS - INSPECTION, WHEEL . . 5-57,5s-59

CYLINDERS - INSTALLATION, WHEEL . 5-57,5s-60

CYLINDERS - REMOVAL, WHEEL....5-57,5s-59

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR OF . . 9-10,9-86

DAMPER - INSTALLATION, VIBRATION . . . 9-130,

9-47

DAMPER - REMOVAL, VIBRATION . . . 9-130,9-47

DATA BUS COMMUNICATION RECEIVE -

PCM INPUT - OPERATION..............8E-15

DATA LINK CONNECTOR - DESCRIPTION . . . 8E-6

DATA LINK CONNECTOR - OPERATION.....8E-7

DAY / NIGHT MIRROR - DESCRIPTION,

AUTOMATIC..........................8N-47

DAY / NIGHT MIRROR - DIAGNOSIS AND

TESTING, AUTOMATIC................8N-47

DAY / NIGHT MIRROR - OPERATION,

AUTOMATIC........................8N-47

DEAERATION - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-4

DECOUPLER PULLEY - DESCRIPTION,

GENERATOR....................8F-25,8F-27

DECOUPLER PULLEY - DIAGNOSIS AND

TESTING, GENERATOR...........8F-25,8F-27

DECOUPLER PULLEY - INSTALLATION,

GENERATOR....................8F-26,8F-28

DECOUPLER PULLEY - OPERATION,

GENERATOR....................8F-25,8F-27

DECOUPLER PULLEY - REMOVAL,

GENERATOR....................8F-26,8F-28

DEFINITION - DESCRIPTION, TRIP........25-1

DEFLECTOR - INSTALLATION, WIND.....23-121

DEFLECTOR - REMOVAL, WIND........23-121

DEFOGGER RELAY - DESCRIPTION,

REAR WINDOW.......................8G-3

DEFOGGER RELAY - INSTALLATION,

REAR WINDOW.......................8G-3

DEFOGGER RELAY - OPERATION, REAR

WINDOW............................8G-3

DEFOGGER RELAY - REMOVAL, REAR

WINDOW............................8G-3

DEFOGGER SWITCH - DESCRIPTION,

REAR WINDOW.......................8G-4

DEFOGGER SWITCH - OPERATION, REAR

WINDOW............................8G-4

DEFOGGER SYSTEM - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-2

DEFROSTER DUCT - INSTALLATION......24-50

DEFROSTER DUCT - REMOVAL..........24-50

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS...............8M-4

DEMISTER DUCTS - INSTALLATION,

INSTRUMENT PANEL..................24-55

DEMISTER DUCTS - REMOVAL,

INSTRUMENT PANEL..................24-55

DEMISTER OUTLET - INSTALLATION.....24-46

DEMISTER OUTLET - REMOVAL.........24-45

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER AN

AIRBAG.............................8O-3

DETECTION ASSY - INSTALLATION,

NATURAL VAC LEAK

..................25-13

DETECTION ASSY - REMOVAL, NATURAL

VAC LEAK

..........................25-13

DETECTION PUMP - INSTALLATION,

LEAK

..............................25-13

DETECTION PUMP - REMOVAL, LEAK

....25-13

DEVICES - STANDARD PROCEDURE,

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE

........................8W-01-8DIAGNOSTIC SYSTEM - DIAGNOSIS AND

TESTING, ON-BOARD.................8F-21

DIAGNOSTIC TROUBLE CODES -

STANDARD PROCEDURE, OBTAINING.....8E-15

DIAGRAMS - 41TE TRANSAXLE

HYDRAULIC SCHEMATICS,

SCHEMATICS.......................21-169

DIAGRAMS - 4XTE TRANSAXLE

HYDRAULIC SCHEMATICS,

SCHEMATICS.......................21s-75

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS - SPECIAL TOOLS,

SCHEMATICS.......................21s-89

DIESEL - DESCRIPTION, 2.5L...........19-51

DIESEL - DIAGNOSIS AND TESTING,

SYSTEM CHARGE LEVEL TEST - 2.5L....24-68

DIESEL - INSTALLATION, 2.5L..........19-52

DIESEL - REMOVAL, 2.5L..............19-51

DIESEL ENGINE - DESCRIPTION, FUEL

REQUIREMENTS.......................0-6

DIESEL ENGINES - DESCRIPTION,

ENGINE OIL...........................0-6

DIESEL ENGINES - EXPORT -

DESCRIPTION........................0-24

DIESEL HEATER WIRING -

INSTALLATION, SUPPLEMENTAL........24-119

DIESEL HEATER WIRING - REMOVAL,

SUPPLEMENTAL....................24-119

DIESEL SUPPLEMENTAL CABIN HEATER

- DIAGNOSIS AND TESTING...........24-113

DIFFERENTIAL - ASSEMBLY............21-66

DIFFERENTIAL - DESCRIPTION...........21-62

DIFFERENTIAL - DISASSEMBLY.........21-62

DIFFERENTIAL - OPERATION............21-62

DIFFERENTIAL ASSEMBLY -

DESCRIPTION........................3-39

DIFFERENTIAL ASSEMBLY - OPERATION . . . 3-39

DIFFERENTIAL ASSEMBLY FLUID

CHANGE - STANDARD PROCEDURE.......3-40

DIFFERENTIAL BEARING PRELOAD -

ADJUSTMENT......................21-199

DIFFERENTIAL BEARING PRELOAD

MEASUREMENT AND ADJUSTMENT,

ADJUSTMENTS....................21s-100

DIFFERENTIAL CARRIER SEAL -

INSTALLATION........................21-9

DIFFERENTIAL CARRIER SEAL -

REMOVAL...........................21-9

DIFFERENTIAL SIDE GEAR END PLAY -

ADJUSTMENT.......................21-70

DIFFERENTIAL TURNING TORQUE -

ADJUSTMENT.......................21-69

DIMENSIONS - SPECIFICATIONS, BODY

OPENING..........................23-127

DIMENSIONS, SPECIFICATIONS - FRAME . . . 13-4

DIODE - INSTALLATION............8W-01-14

DIODE - REMOVAL................8W-01-14

DISC AND PRESSURE PLATE - 2.5L TD -

INSTALLATION, CLUTCH................6-12

DISC AND PRESSURE PLATE - 2.5L TD -

REMOVAL, CLUTCH....................6-11

DISC BRAKE CALIPER - INSTALLATION,

REAR..........................5-30,5s-29

DISC BRAKE CALIPER - REMOVAL,

REAR..........................5-27,5s-26

DISC BRAKE CALIPER ADAPTER -

INSTALLATION, FRONT............5-31,5s-30

DISC BRAKE CALIPER ADAPTER -

REMOVAL, FRONT................5-31,5s-30

DISC BRAKE CALIPER (CONTINENTAL

TEVES BRAKES) - INSTALLATION,

FRONT.............................5s-26

DISC BRAKE CALIPER (CONTINENTAL

TEVES BRAKES) - REMOVAL, FRONT.....5s-23

DISC BRAKE CALIPER (DISC/DISC

BRAKES) - INSTALLATION, FRONT........5-27

DISC BRAKE CALIPER (DISC/DISC

BRAKES) - REMOVAL, FRONT

............5-24

DISC BRAKE CALIPER (DISC/DRUM

BRAKES) - INSTALLATION, FRONT

........5-27

DISC BRAKE CALIPER (DISC/DRUM

BRAKES) - REMOVAL, FRONT

............5-24

DISC BRAKE CALIPER GUIDE PINS

(DISC/DRUM BRAKES) -

INSTALLATION

........................5-31

DISC BRAKE CALIPER GUIDE PINS

(DISC/DRUM BRAKES) - REMOVAL

.......5-31

10 INDEXRS

Description Group-Page Description Group-Page Description Group-Page