air condition CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1533 of 2585

INSTALLATION - 2.4L

(1) Install the crankshaft sensor.

(2) Install crankshaft sensor bolt and tighten.

(3) Connect the electrical connector (Fig. 8).

(4) Lower vehicle.

(5) Connect the negative battery cable.

ENGINE SPEED SENSOR

DESCRIPTION

The PCM receives a signal from the TCM to indi-

cate vehicle speed on automatic transmission cars.

On 4 cylinder Manual transmission cars (if equipped)

vehicle, a dedicated vehicle speed sensor is connectedto the PCM.On V-6 Manual transmission cars (if

equipped) vehicle, the ABS module provides the sig-

nal to the PCM for vehicle speed.

OPERATION

The Transmission Control Module (TCM) supplies

the road speed and distance traveled inputs to the

PCM. From these inputs and the throttle position

sensor input, the PCM determines when a decelera-

tion condition occurs.

FUEL INJECTOR

DESCRIPTION

The injectors are positioned in the intake manifold

or cylinder head with the nozzle ends directly above

the intake valve port (Fig. 10).

OPERATION

The fuel injectors are 12 volt electrical solenoids

(Fig. 11). The injector contains a pintle that closes off

an orifice at the nozzle end. When electric current is

supplied to the injector, the armature and needle

move a short distance against a spring, allowing fuel

to flow out the orifice. Because the fuel is under high

pressure, a fine spray is developed in the shape of a

hollow cone or two streams. The spraying action

atomizes the fuel, adding it to the air entering the

combustion chamber. Fuel injectors are not inter-

changeable between engines.

The PCM provides battery voltage to each injector

through the ASD relay. Injector operation is con-

trolled by a ground path provided for each injector by

the PCM. Injector on-time (pulse-width) is variable,

Fig. 7 Timing Slots

1 - TORQUE CONVERTER DRIVE PLATE

2 - SLOTS

Fig. 8 CRANKSHAFT SENSOR 2.4L

Fig. 9 CRANKSHAFT POSITION SENSOR LOCATION

2.4L

14 - 26 FUEL INJECTIONRS

CRANKSHAFT POSITION SENSOR (Continued)

Page 1536 of 2585

The PCM controls engine idle speed by adjusting

the position of the idle air control valve. The adjust-

ments are based on inputs the PCM receives. The

inputs are from the throttle position sensor, crank-

shaft position sensor, coolant temperature sensor,

MAP sensor, vehicle speed sensor and various switch

operations (brake, park/neutral, air conditioning).

When engine rpm is above idle speed, the IAC is

used for the following functions:

²Off-idle dashpot

²Deceleration air flow control²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

Target Idle

Target idle is determined by the following inputs:

²Gear position

²ECT Sensor

²Battery voltage

²Ambient/Battery Temperature Sensor

²VSS

²TPS

²MAP Sensor

REMOVAL

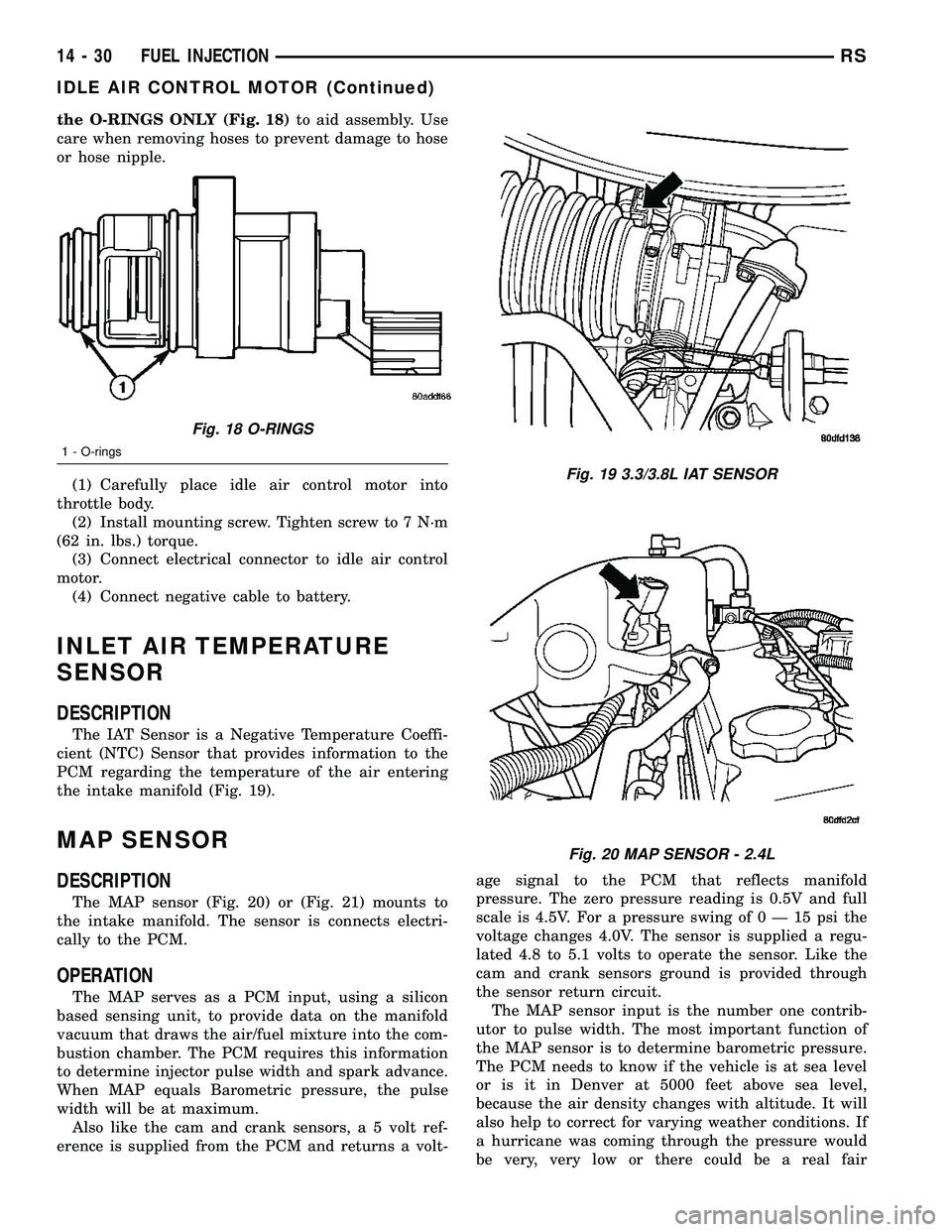

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. If assembly of component is diffi-

cult, a light coat of engine oil may be applied to the

O-RINGS ONLY to aid assembly. Use care when

removing hoses to prevent damage to hose or hose

nipple.

(1) Disconnect negative cable from battery.

(2) Remove electrical connector from idle air con-

trol valve (Fig. 17).

(3) Remove idle air control valve mounting screw.

(4) Remove valve from throttle body. Ensure the

O-rings is removed with the valve.

INSTALLATION

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. If assembly of component is diffi-

cult,a light coat of engine oil may be applied to

Fig. 15 TPS/IAC 2.4L

1 - Idle Air Control Valve

2 - Throttle Position Sensor

Fig. 16 TPS/IAC 3.3/3.8L

1 - Idle Air Control Valve

2 - Throttle Position Sensor

Fig. 17 IDLE AIR CONTROL VALVE LOCATION

RSFUEL INJECTION14-29

IDLE AIR CONTROL MOTOR (Continued)

Page 1537 of 2585

the O-RINGS ONLY (Fig. 18)to aid assembly. Use

care when removing hoses to prevent damage to hose

or hose nipple.

(1) Carefully place idle air control motor into

throttle body.

(2) Install mounting screw. Tighten screw to 7 N´m

(62 in. lbs.) torque.

(3) Connect electrical connector to idle air control

motor.

(4) Connect negative cable to battery.

INLET AIR TEMPERATURE

SENSOR

DESCRIPTION

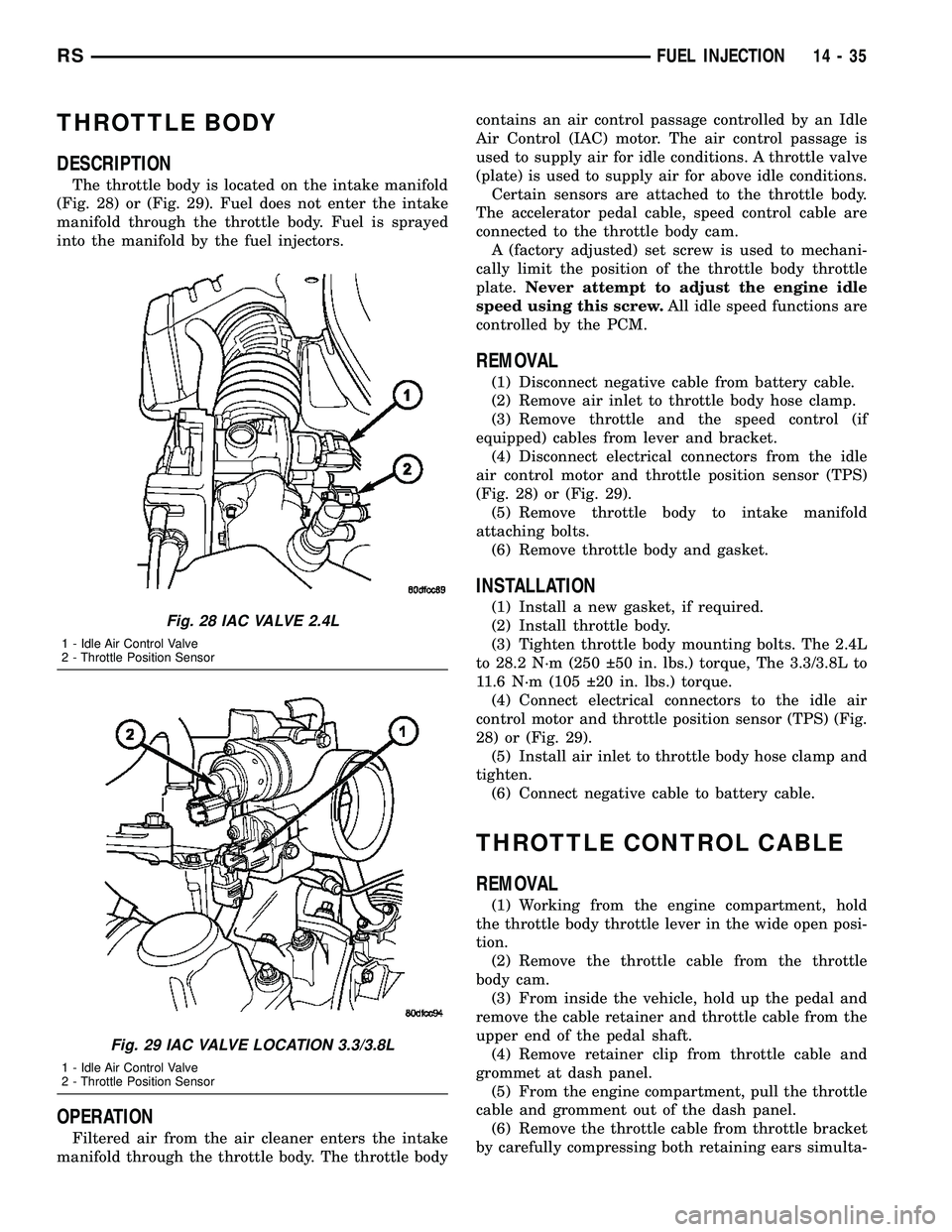

The IAT Sensor is a Negative Temperature Coeffi-

cient (NTC) Sensor that provides information to the

PCM regarding the temperature of the air entering

the intake manifold (Fig. 19).

MAP SENSOR

DESCRIPTION

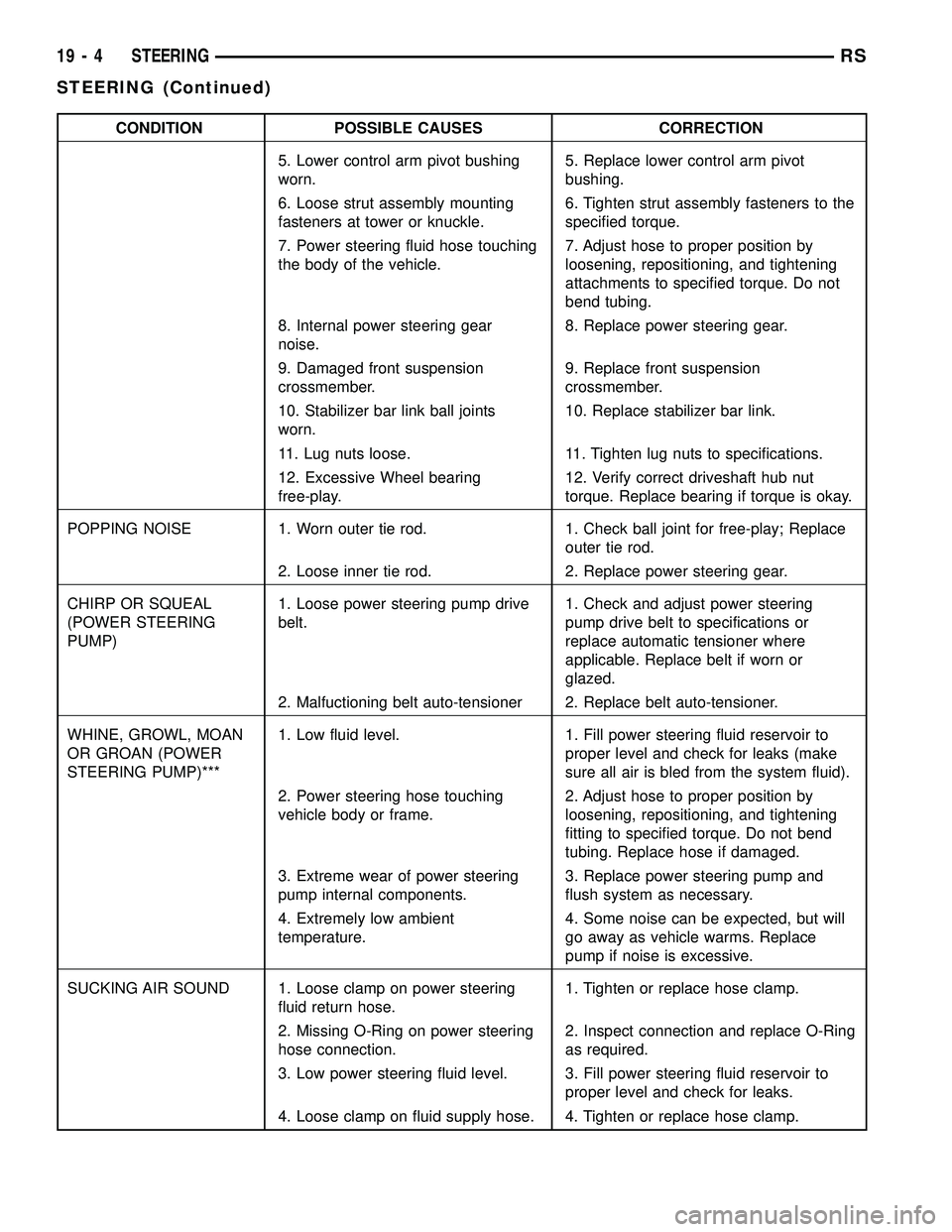

The MAP sensor (Fig. 20) or (Fig. 21) mounts to

the intake manifold. The sensor is connects electri-

cally to the PCM.

OPERATION

The MAP serves as a PCM input, using a silicon

based sensing unit, to provide data on the manifold

vacuum that draws the air/fuel mixture into the com-

bustion chamber. The PCM requires this information

to determine injector pulse width and spark advance.

When MAP equals Barometric pressure, the pulse

width will be at maximum.

Also like the cam and crank sensors, a 5 volt ref-

erence is supplied from the PCM and returns a volt-age signal to the PCM that reflects manifold

pressure. The zero pressure reading is 0.5V and full

scale is 4.5V. For a pressure swing of0Ð15psithe

voltage changes 4.0V. The sensor is supplied a regu-

lated 4.8 to 5.1 volts to operate the sensor. Like the

cam and crank sensors ground is provided through

the sensor return circuit.

The MAP sensor input is the number one contrib-

utor to pulse width. The most important function of

the MAP sensor is to determine barometric pressure.

The PCM needs to know if the vehicle is at sea level

or is it in Denver at 5000 feet above sea level,

because the air density changes with altitude. It will

also help to correct for varying weather conditions. If

a hurricane was coming through the pressure would

be very, very low or there could be a real fair

Fig. 18 O-RINGS

1 - O-rings

Fig. 19 3.3/3.8L IAT SENSOR

Fig. 20 MAP SENSOR - 2.4L

14 - 30 FUEL INJECTIONRS

IDLE AIR CONTROL MOTOR (Continued)

Page 1542 of 2585

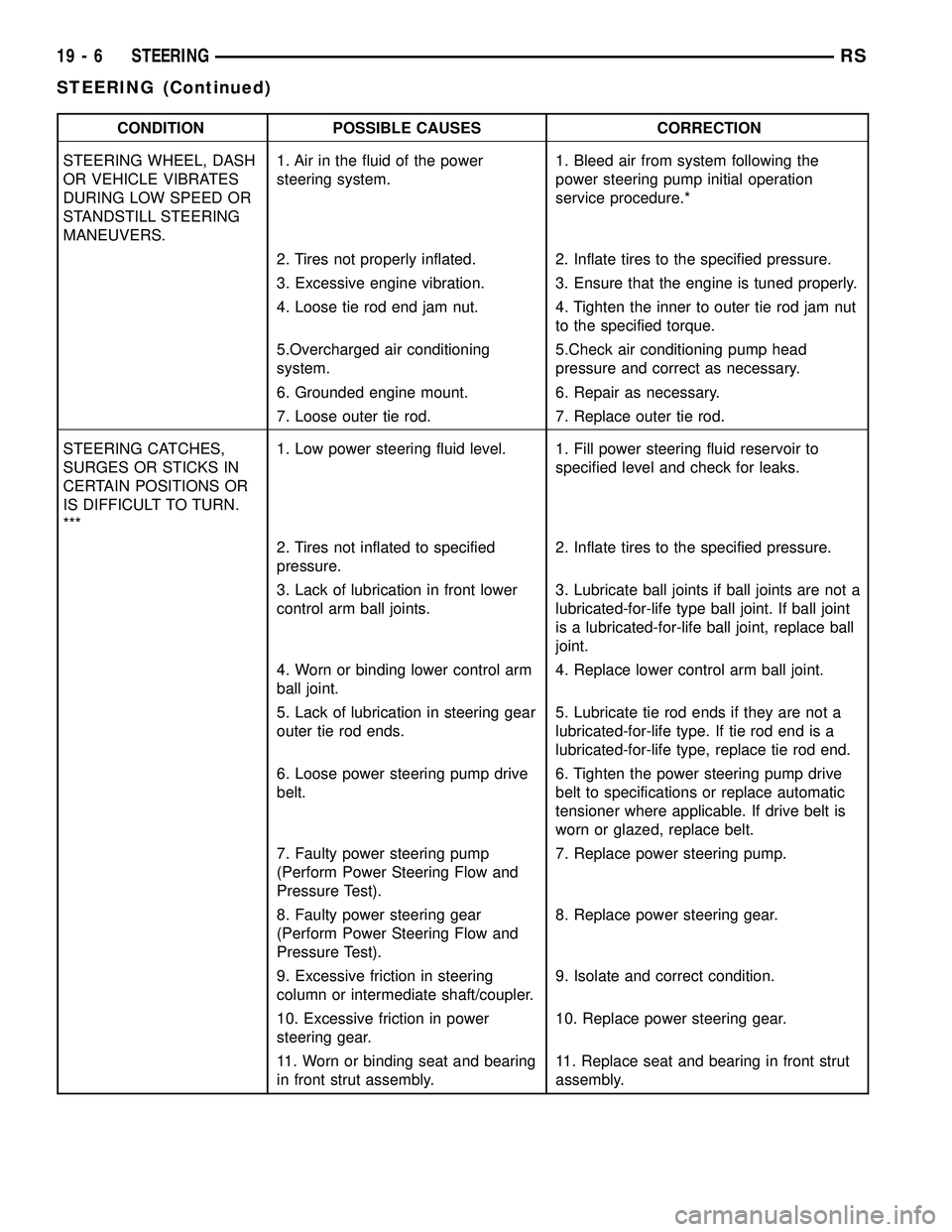

THROTTLE BODY

DESCRIPTION

The throttle body is located on the intake manifold

(Fig. 28) or (Fig. 29). Fuel does not enter the intake

manifold through the throttle body. Fuel is sprayed

into the manifold by the fuel injectors.

OPERATION

Filtered air from the air cleaner enters the intake

manifold through the throttle body. The throttle bodycontains an air control passage controlled by an Idle

Air Control (IAC) motor. The air control passage is

used to supply air for idle conditions. A throttle valve

(plate) is used to supply air for above idle conditions.

Certain sensors are attached to the throttle body.

The accelerator pedal cable, speed control cable are

connected to the throttle body cam.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

REMOVAL

(1) Disconnect negative cable from battery cable.

(2) Remove air inlet to throttle body hose clamp.

(3) Remove throttle and the speed control (if

equipped) cables from lever and bracket.

(4) Disconnect electrical connectors from the idle

air control motor and throttle position sensor (TPS)

(Fig. 28) or (Fig. 29).

(5) Remove throttle body to intake manifold

attaching bolts.

(6) Remove throttle body and gasket.

INSTALLATION

(1) Install a new gasket, if required.

(2) Install throttle body.

(3) Tighten throttle body mounting bolts. The 2.4L

to 28.2 N´m (250 50 in. lbs.) torque, The 3.3/3.8L to

11.6 N´m (105 20 in. lbs.) torque.

(4) Connect electrical connectors to the idle air

control motor and throttle position sensor (TPS) (Fig.

28) or (Fig. 29).

(5) Install air inlet to throttle body hose clamp and

tighten.

(6) Connect negative cable to battery cable.

THROTTLE CONTROL CABLE

REMOVAL

(1) Working from the engine compartment, hold

the throttle body throttle lever in the wide open posi-

tion.

(2) Remove the throttle cable from the throttle

body cam.

(3) From inside the vehicle, hold up the pedal and

remove the cable retainer and throttle cable from the

upper end of the pedal shaft.

(4) Remove retainer clip from throttle cable and

grommet at dash panel.

(5) From the engine compartment, pull the throttle

cable and gromment out of the dash panel.

(6) Remove the throttle cable from throttle bracket

by carefully compressing both retaining ears simulta-

Fig. 28 IAC VALVE 2.4L

1 - Idle Air Control Valve

2 - Throttle Position Sensor

Fig. 29 IAC VALVE LOCATION 3.3/3.8L

1 - Idle Air Control Valve

2 - Throttle Position Sensor

RSFUEL INJECTION14-35

Page 1543 of 2585

neously then gently pull the throttle cable from

throttle bracket or if it is the slide snap design you

have to slide the locking tab out of the hole and then

slide the cable assembly out of the bracket.

INSTALLATION

(1) From the engine compartment, push the hous-

ing end fitting and grommet into the dash panel.In-

stall gromment into the dash panel.

(2) Install the cable housing (throttle body end)

into the cable mounting bracket on the engine.

(3) From inside the vehicle, hold up the pedal and

install throttle cable and cable retainer in the upper

end of the pedal shaft.

(4) At the dash panel, install the cable retainer

clip between the end of the throttle cable fitting and

grommet

(5) From the engine compartment, rotate the

throttle lever wide open and install the throttle

cable.

THROTTLE POSITION SENSOR

DESCRIPTION

The throttle position sensor mounts to the side of

the throttle body (Fig. 30) or (Fig. 31).The sensor

connects to the throttle blade shaft. The TPS is a

variable resistor that provides the Powertrain Con-

trol Module (PCM) with an input signal (voltage).

OPERATION

The signal represents throttle blade position. As

the position of the throttle blade changes, the resis-

tance of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

powertrain control module) represents throttle blade

position. The TPS output voltage to the PCM varies

from approximately 0.6 volt at minimum throttle

opening (idle) to a maximum of 4.5 volts at wide open

throttle.

Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine oper-

ating conditions. The PCM also adjusts fuel injector

pulse width and ignition timing based on these

inputs.

REMOVAL - 3.3/3.8L

(1) Disconnect the negative battery cable.

(2) Remove the electrical connector from the Inlet

Air Temperature sensor.

(3) Remove the air cleaner box lid. Remove hose

from throttle body.

(4) Disconnect the electrical connector at TPS.

(5) Disconnect the electrical connector at IAC.

(6) Remove the throttle and speed control cables

from throttle body.

(7) Remove 3 mounting bolts from throttle body.

(8) Remove throttle body.

(9) Disconnect the purge vacuum line from the

throttle body.

(10) Remove TPS from throttle body.

Fig. 30 Throttle Position SensorÐ2.4L Engine

1 - Idle Air Control Valve

2 - Throttle Position Sensor

Fig. 31 Throttle Position SensorÐ3.3/3.8L Engine

1 - Idle Air Control Valve

2 - Throttle Position Sensor

14 - 36 FUEL INJECTIONRS

THROTTLE CONTROL CABLE (Continued)

Page 1548 of 2585

(6) Start engine and let idle just long enough to

circulate power steering fluid through the analyzer

and hoses. Shut off engine.

(7) Check power steering fluid level and add fluid

as necessary. Start engine again and let idle until the

air is out of the fluid.

(8) Gauge should read below 300 psi (2068 kPa). If

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the range

of 100-275 psi (689-1896 kPa) depending on fluid

temperature. The flow meter should read above 1.5

GPM.

CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than four seconds as the pump could be

damaged.

NOTE:

Power steering pump maximum pressure for

2.4L engines is 1,200 ± 1,350 psi (8,274 ± 9,308 kPa).

Power steering pump maximum pressure for all other

engines is 1,400 ± 1,500 psi (9,653 ± 10,342 kPa).

(9) Close analyzer valve fully three times and

record highest pressure indicated each time. All three

readings must be within specifications. If any of the

three power steering pump pressures are above orbelow specifications, replace pump. (Refer to 19 -

STEERING/PUMP - REMOVAL)

CAUTION: Do not force the steering to operate

against the stops for more than 4 seconds at a time

because pump damage can result.

(10) Once the pump has been verified as working

correctly, completely open the valve on the Power

Steering Analyzer. Turn the steering wheel to the

extreme left until the stop in the steering gear is

met. Hold it there for 2±4 seconds, then release it.

Now turn the steering wheel to the right until the

right stop is met. Hold it there for 2±4 seconds, then

release it. Record the stabilized pressure at each

position. Compare the recorded readings to the spec-

ifications. If the output pressures are not within 100

psi (689 kPa) of one another against either stop or

are below specifications, the steering gear is leaking

internally and must be replaced. (Refer to 19 -

STEERING/GEAR - REMOVAL)

DIAGNOSIS AND TESTING - STEERING

SYSTEM DIAGNOSIS CHARTS

NOTE: There are three diagnosis charts following

that cover POWER STEERING NOISE, STEERING

WHEEL FEEL, and POWER STEERING FLUID.

POWER STEERING NOISE

CONDITION POSSIBLE CAUSES CORRECTION

OBJECTIONABLE HISS

OR WHISTLE*1. Damaged or mispositioned

steering column shaft/coupling dash

panel seal.1. Reposition or replace steering column

shaft/coupling dash panel seal.

2. Noisy valve in power steering

gear.2. Replace power steering gear.

3. Mis-routed power steering hose. 3. Check routing of power steering

hoses. Ensure hoses do not come in

unwanted contact with other components

and objects.

RATTLE OR EXCESSIVE

CLUNK**1. Power steering gear loose on front

suspension crossmember.1. Inspect power steering gear mounting

bolts. Replace as necessary. Tighten to

the specified torque.

2. Front suspension crossmember

mounting fasteners loose at frame.2. Tighten the front suspension

crossmember mounting fasteners to the

specified torque.

3. Loose tie rod (outer or inner). 3. Check tie rod pivot points for wear.

Replace worn/loose parts as required.

4. Loose lower control arm mounting

bolts at front suspension

crossmember.4. Tighten control arm mounting bolts to

the specified torques.

RSSTEERING19-3

STEERING (Continued)

Page 1549 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

5. Lower control arm pivot bushing

worn.5. Replace lower control arm pivot

bushing.

6. Loose strut assembly mounting

fasteners at tower or knuckle.6. Tighten strut assembly fasteners to the

specified torque.

7. Power steering fluid hose touching

the body of the vehicle.7. Adjust hose to proper position by

loosening, repositioning, and tightening

attachments to specified torque. Do not

bend tubing.

8. Internal power steering gear

noise.8. Replace power steering gear.

9. Damaged front suspension

crossmember.9. Replace front suspension

crossmember.

10. Stabilizer bar link ball joints

worn.10. Replace stabilizer bar link.

11. Lug nuts loose. 11. Tighten lug nuts to specifications.

12. Excessive Wheel bearing

free-play.12. Verify correct driveshaft hub nut

torque. Replace bearing if torque is okay.

POPPING NOISE 1. Worn outer tie rod. 1. Check ball joint for free-play; Replace

outer tie rod.

2. Loose inner tie rod. 2. Replace power steering gear.

CHIRP OR SQUEAL

(POWER STEERING

PUMP)1. Loose power steering pump drive

belt.1. Check and adjust power steering

pump drive belt to specifications or

replace automatic tensioner where

applicable. Replace belt if worn or

glazed.

2. Malfuctioning belt auto-tensioner 2. Replace belt auto-tensioner.

WHINE, GROWL, MOAN

OR GROAN (POWER

STEERING PUMP)***1. Low fluid level. 1. Fill power steering fluid reservoir to

proper level and check for leaks (make

sure all air is bled from the system fluid).

2. Power steering hose touching

vehicle body or frame.2. Adjust hose to proper position by

loosening, repositioning, and tightening

fitting to specified torque. Do not bend

tubing. Replace hose if damaged.

3. Extreme wear of power steering

pump internal components.3. Replace power steering pump and

flush system as necessary.

4. Extremely low ambient

temperature.4. Some noise can be expected, but will

go away as vehicle warms. Replace

pump if noise is excessive.

SUCKING AIR SOUND 1. Loose clamp on power steering

fluid return hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power steering

hose connection.2. Inspect connection and replace O-Ring

as required.

3. Low power steering fluid level. 3. Fill power steering fluid reservoir to

proper level and check for leaks.

4. Loose clamp on fluid supply hose. 4. Tighten or replace hose clamp.

19 - 4 STEERINGRS

STEERING (Continued)

Page 1551 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL, DASH

OR VEHICLE VIBRATES

DURING LOW SPEED OR

STANDSTILL STEERING

MANEUVERS.1. Air in the fluid of the power

steering system.1. Bleed air from system following the

power steering pump initial operation

service procedure.*

2. Tires not properly inflated. 2. Inflate tires to the specified pressure.

3. Excessive engine vibration. 3. Ensure that the engine is tuned properly.

4. Loose tie rod end jam nut. 4. Tighten the inner to outer tie rod jam nut

to the specified torque.

5.Overcharged air conditioning

system.5.Check air conditioning pump head

pressure and correct as necessary.

6. Grounded engine mount. 6. Repair as necessary.

7. Loose outer tie rod. 7. Replace outer tie rod.

STEERING CATCHES,

SURGES OR STICKS IN

CERTAIN POSITIONS OR

IS DIFFICULT TO TURN.

***1. Low power steering fluid level. 1. Fill power steering fluid reservoir to

specified level and check for leaks.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified pressure.

3. Lack of lubrication in front lower

control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated-for-life type ball joint. If ball joint

is a lubricated-for-life ball joint, replace ball

joint.

4. Worn or binding lower control arm

ball joint.4. Replace lower control arm ball joint.

5. Lack of lubrication in steering gear

outer tie rod ends.5. Lubricate tie rod ends if they are not a

lubricated-for-life type. If tie rod end is a

lubricated-for-life type, replace tie rod end.

6. Loose power steering pump drive

belt.6. Tighten the power steering pump drive

belt to specifications or replace automatic

tensioner where applicable. If drive belt is

worn or glazed, replace belt.

7. Faulty power steering pump

(Perform Power Steering Flow and

Pressure Test).7. Replace power steering pump.

8. Faulty power steering gear

(Perform Power Steering Flow and

Pressure Test).8. Replace power steering gear.

9. Excessive friction in steering

column or intermediate shaft/coupler.9. Isolate and correct condition.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

11. Worn or binding seat and bearing

in front strut assembly.11. Replace seat and bearing in front strut

assembly.

19 - 6 STEERINGRS

STEERING (Continued)

Page 1552 of 2585

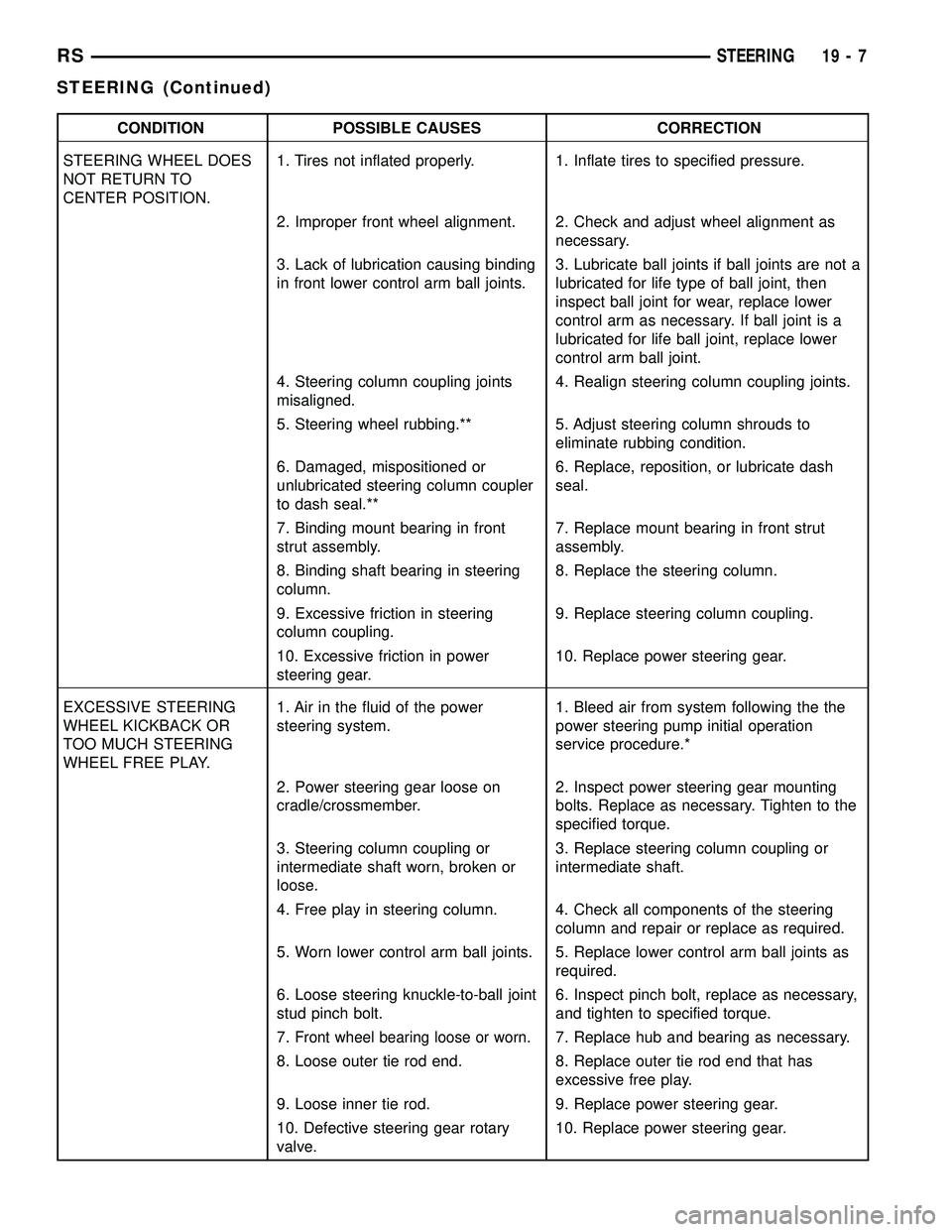

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL DOES

NOT RETURN TO

CENTER POSITION.1. Tires not inflated properly. 1. Inflate tires to specified pressure.

2. Improper front wheel alignment. 2. Check and adjust wheel alignment as

necessary.

3. Lack of lubrication causing binding

in front lower control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated for life type of ball joint, then

inspect ball joint for wear, replace lower

control arm as necessary. If ball joint is a

lubricated for life ball joint, replace lower

control arm ball joint.

4. Steering column coupling joints

misaligned.4. Realign steering column coupling joints.

5. Steering wheel rubbing.** 5. Adjust steering column shrouds to

eliminate rubbing condition.

6. Damaged, mispositioned or

unlubricated steering column coupler

to dash seal.**6. Replace, reposition, or lubricate dash

seal.

7. Binding mount bearing in front

strut assembly.7. Replace mount bearing in front strut

assembly.

8. Binding shaft bearing in steering

column.8. Replace the steering column.

9. Excessive friction in steering

column coupling.9. Replace steering column coupling.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

EXCESSIVE STEERING

WHEEL KICKBACK OR

TOO MUCH STEERING

WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Bleed air from system following the the

power steering pump initial operation

service procedure.*

2. Power steering gear loose on

cradle/crossmember.2. Inspect power steering gear mounting

bolts. Replace as necessary. Tighten to the

specified torque.

3. Steering column coupling or

intermediate shaft worn, broken or

loose.3. Replace steering column coupling or

intermediate shaft.

4. Free play in steering column. 4. Check all components of the steering

column and repair or replace as required.

5. Worn lower control arm ball joints. 5. Replace lower control arm ball joints as

required.

6. Loose steering knuckle-to-ball joint

stud pinch bolt.6. Inspect pinch bolt, replace as necessary,

and tighten to specified torque.

7.

Front wheel bearing loose or worn.7. Replace hub and bearing as necessary.

8. Loose outer tie rod end. 8. Replace outer tie rod end that has

excessive free play.

9. Loose inner tie rod. 9. Replace power steering gear.

10. Defective steering gear rotary

valve.10. Replace power steering gear.

RSSTEERING19-7

STEERING (Continued)

Page 1553 of 2585

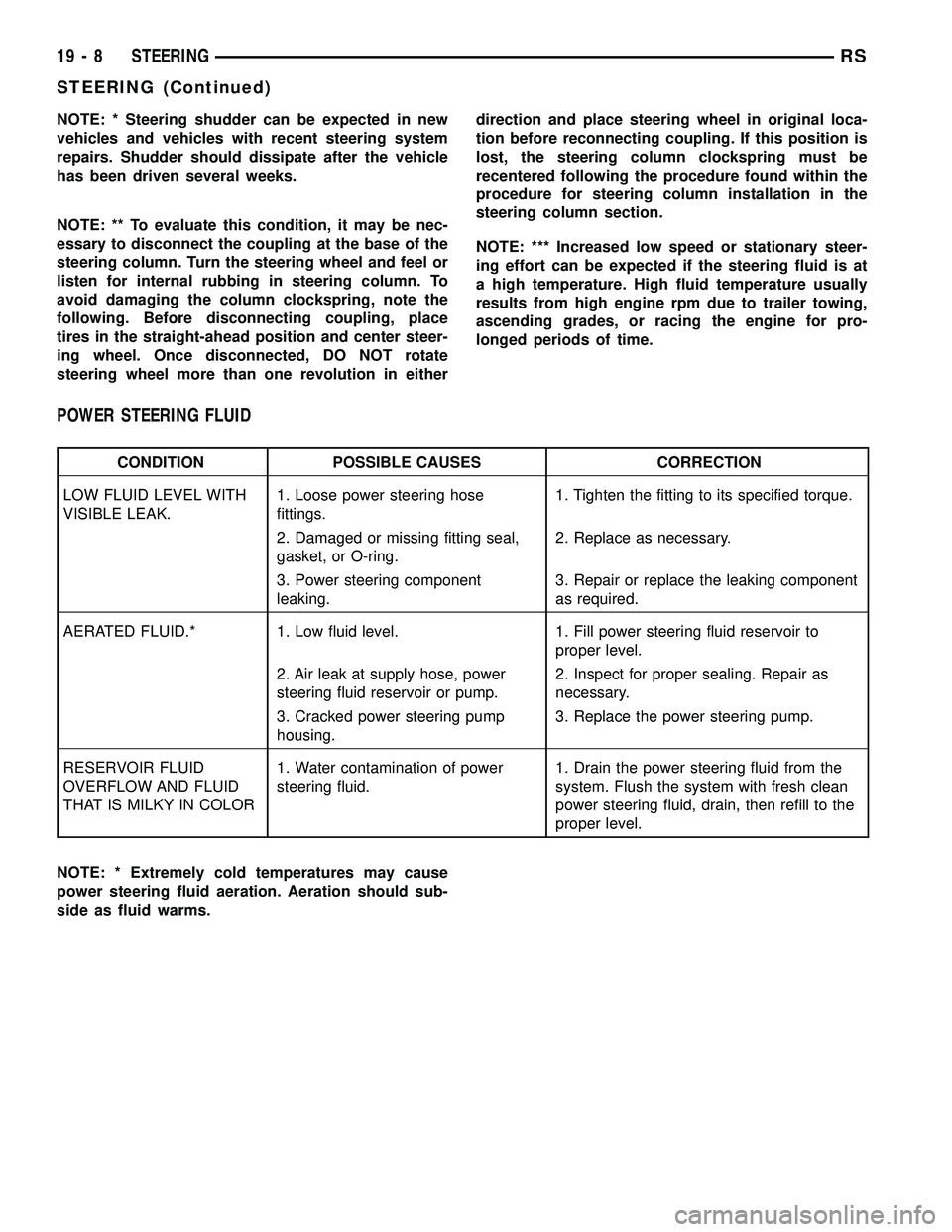

NOTE: * Steering shudder can be expected in new

vehicles and vehicles with recent steering system

repairs. Shudder should dissipate after the vehicle

has been driven several weeks.

NOTE: ** To evaluate this condition, it may be nec-

essary to disconnect the coupling at the base of the

steering column. Turn the steering wheel and feel or

listen for internal rubbing in steering column. To

avoid damaging the column clockspring, note the

following. Before disconnecting coupling, place

tires in the straight-ahead position and center steer-

ing wheel. Once disconnected, DO NOT rotate

steering wheel more than one revolution in eitherdirection and place steering wheel in original loca-

tion before reconnecting coupling. If this position is

lost, the steering column clockspring must be

recentered following the procedure found within the

procedure for steering column installation in the

steering column section.

NOTE: *** Increased low speed or stationary steer-

ing effort can be expected if the steering fluid is at

a high temperature. High fluid temperature usually

results from high engine rpm due to trailer towing,

ascending grades, or racing the engine for pro-

longed periods of time.

POWER STEERING FLUID

CONDITION POSSIBLE CAUSES CORRECTION

LOW FLUID LEVEL WITH

VISIBLE LEAK.1. Loose power steering hose

fittings.1. Tighten the fitting to its specified torque.

2. Damaged or missing fitting seal,

gasket, or O-ring.2. Replace as necessary.

3. Power steering component

leaking.3. Repair or replace the leaking component

as required.

AERATED FLUID.* 1. Low fluid level. 1. Fill power steering fluid reservoir to

proper level.

2. Air leak at supply hose, power

steering fluid reservoir or pump.2. Inspect for proper sealing. Repair as

necessary.

3. Cracked power steering pump

housing.3. Replace the power steering pump.

RESERVOIR FLUID

OVERFLOW AND FLUID

THAT IS MILKY IN COLOR1. Water contamination of power

steering fluid.1. Drain the power steering fluid from the

system. Flush the system with fresh clean

power steering fluid, drain, then refill to the

proper level.

NOTE: * Extremely cold temperatures may cause

power steering fluid aeration. Aeration should sub-

side as fluid warms.

19 - 8 STEERINGRS

STEERING (Continued)