air condition CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1557 of 2585

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIR BAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIR BAG COMPONENTS, HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY DESIGNED

FOR THE AIR BAG SYSTEM. THEY MUST NEVER

BE REPLACED WITH ANY SUBSTITUTES. ANYTIME

A NEW FASTENER IS NEEDED, REPLACE WITH

THE CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR FASTENERS LISTED IN

THE PARTS BOOKS.

WARNING: SAFETY GOGGLES SHOULD BE WORN

AT ALL TIMES WHEN WORKING ON STEERING

COLUMNS.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any column compo-

nent.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

DIAGNOSIS AND TESTING - STEERING

COLUMN

For diagnosis of conditions relating to the steering

column (Refer to 19 - STEERING - DIAGNOSIS AND

TESTING) and (Refer to 19 - STEERING - DIAGNO-

SIS AND TESTING).

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING).

(1) Make sure the front wheels of the vehicle are

in the STRAIGHT AHEAD position before beginning

the column removal procedure.

(2) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

(3) Remove the lower shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - REMOV-

AL).

(4) Remove the traction off switch.

(5) Remove the upper shroud.

(6) Remove the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

REMOVAL).

(7) Remove the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(8) Remove the parking brake handle link.

(9) Remove the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(10) Remove the airbag (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/DRIVER AIRBAG - REMOVAL).

(11) Remove the steering wheel retaining nut.

(12) Remove the vibration damper weight.

(13) Remove the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

REMOVAL). (Fig. 3)

(14) Disconnect the wiring harness connectors

from the clockspring, multi-function switch, halo

lamp, SKIM module, ignition switch and BTSI sole-

noid.

(15) Disconnect the shift cable at the lever. (Fig. 4)

(16) Remove the pinch side clip, then remove the

cable from the bracket on the column.

(17) Remove the pinch bolt coupling. (Fig. 5)

(18) Loosen the two lower mounting nuts.

(19) Remove the two upper mounting nuts

(20) Remove the steering column.

1 - CLOCKSPRING WIRING

2 - STEERING WHEEL

3 - UPPER SHROUD

4 - FIXED SHROUD

5 - SCREW

6 - STEERING COLUMN MOUNTING PLATE

7 - NUT

8 - DASH PANEL STEERING COLUMN MOUNTING BRACKET

9 - STUDS (4)

10 - STEERING COLUMN LOCKING PIN

11 - NUT/WASHER ASSEMBLY

12 - STEERING COLUMN ASSEMBLY

13 - LOWER SHROUD

14 - SCREWS

15 - STEERING WHEEL RETAINING NUT16 - STEERING WHEEL DAMPER

17 - CLOCKSPRING

18 - SCREW

19 - MULTI-FUNCTION SWITCH

20 - PINCH BOLT

21 - STEERING COLUMN COUPLER

22 - PINCH BOLT RETAINING PIN

23 - DASH PANEL

24 - SILENCER SHELL

25 - INTERMEDIATE SHAFT SHIELD AND SEAL

26 - INTERMEDIATE SHAFT

27 - ROLL PIN

28 - POWER STEERING GEAR

29 - FRONT SUSPENSION CRADLE/CROSSMEMBER

19 - 12 COLUMNRS

COLUMN (Continued)

Page 1570 of 2585

steering wheel onto the steering column shaft by

hand. Use care not to pinch any wiring.

NOTE: Before installing the damper on the steering

wheel, inspect the damper to ensure the rubber iso-

lator on the damper is not deteriorated or damaged.

If the damper is installed with a damaged isolator, a

buzz, squeak or rattle condition may develop.

(4) Install the steering wheel damper on the steer-

ing wheel (Fig. 36).

(5) Install the steering wheel retaining nut.

Tighten the steering wheel retaining nut to 61 N´m

(45 ft. lbs.) torque.(6) If the steering wheel is equipped with remote

radio controls, connect the wiring connector to the

clockspring (Fig. 36).

(7) Connect the airbag squib wiring connectors to

the airbag and the horn/speed control switch pigtail

connector to the clockspring (Fig. 35).

(8) Install the driver airbag in the steering wheel.

Install and tighten the airbag attaching bolts to 10

N´m (90 in. lbs.) torque.

(9) To properly connect the battery and test the

airbag system, (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

RSCOLUMN19-25

STEERING WHEEL (Continued)

Page 1628 of 2585

Misassembled synchronizer components also cause

shifting problems. Incorrectly installed synchronizer

sleeves, keys, balls, or springs can cause shift prob-

lems.

NOISY OPERATION

Transaxle noise is most often a result of worn or

damaged components. Chipped, broken gear or syn-

chronizer teeth, and brinnelled, spalled bearings all

cause noise.

Abnormal wear and damage to the internal compo-

nents is frequently the end result of insufficient

lubricant.

SLIPS OUT OF GEAR

Transaxle disengagement may be caused by mis-

aligned or damaged shift components, or worn teeth

on the drive gears or synchronizer components. Incor-

rect assembly also causes gear disengagement. Check

for missing snap rings.

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

REMOVAL

REMOVAL - 2.4L GAS

(1) Raise hood.

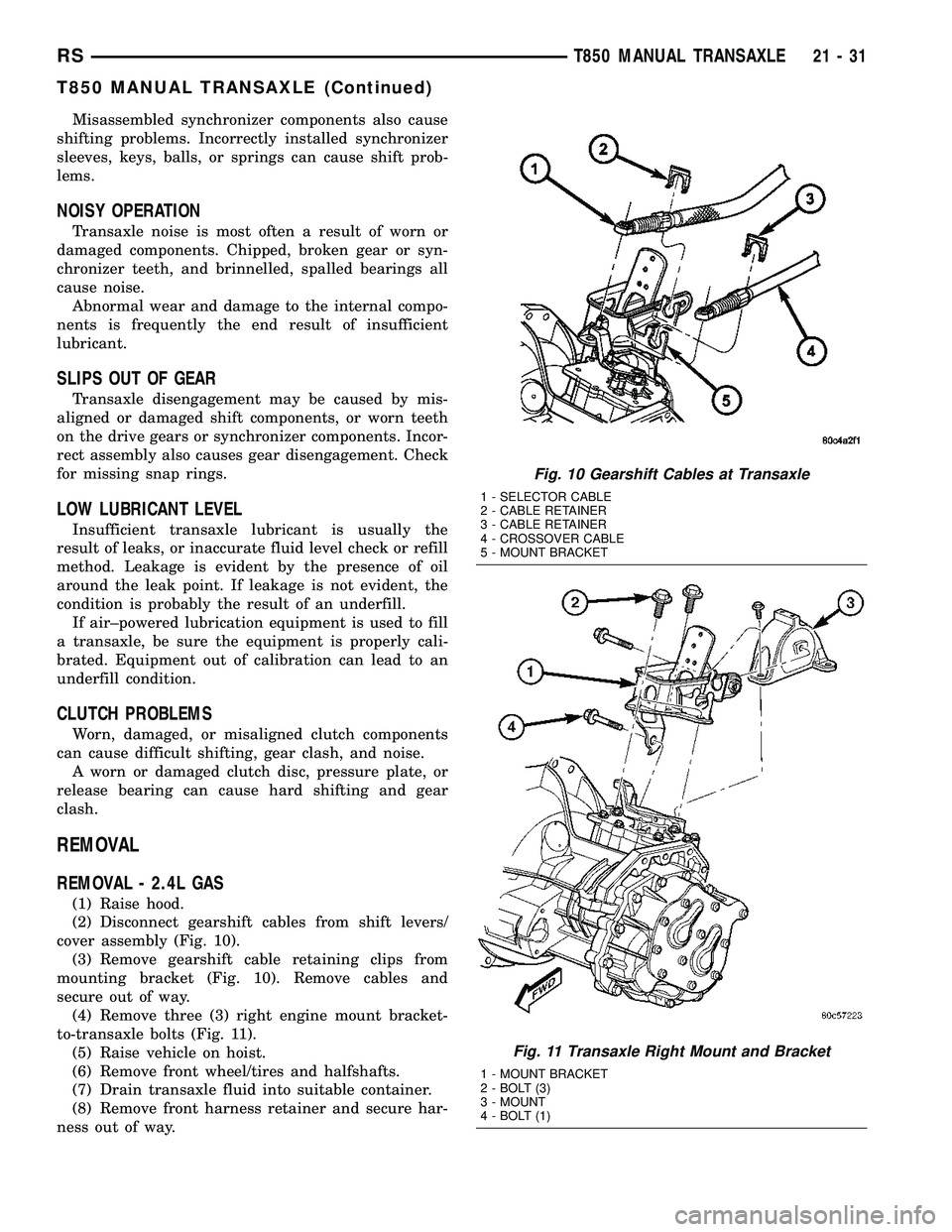

(2) Disconnect gearshift cables from shift levers/

cover assembly (Fig. 10).

(3) Remove gearshift cable retaining clips from

mounting bracket (Fig. 10). Remove cables and

secure out of way.

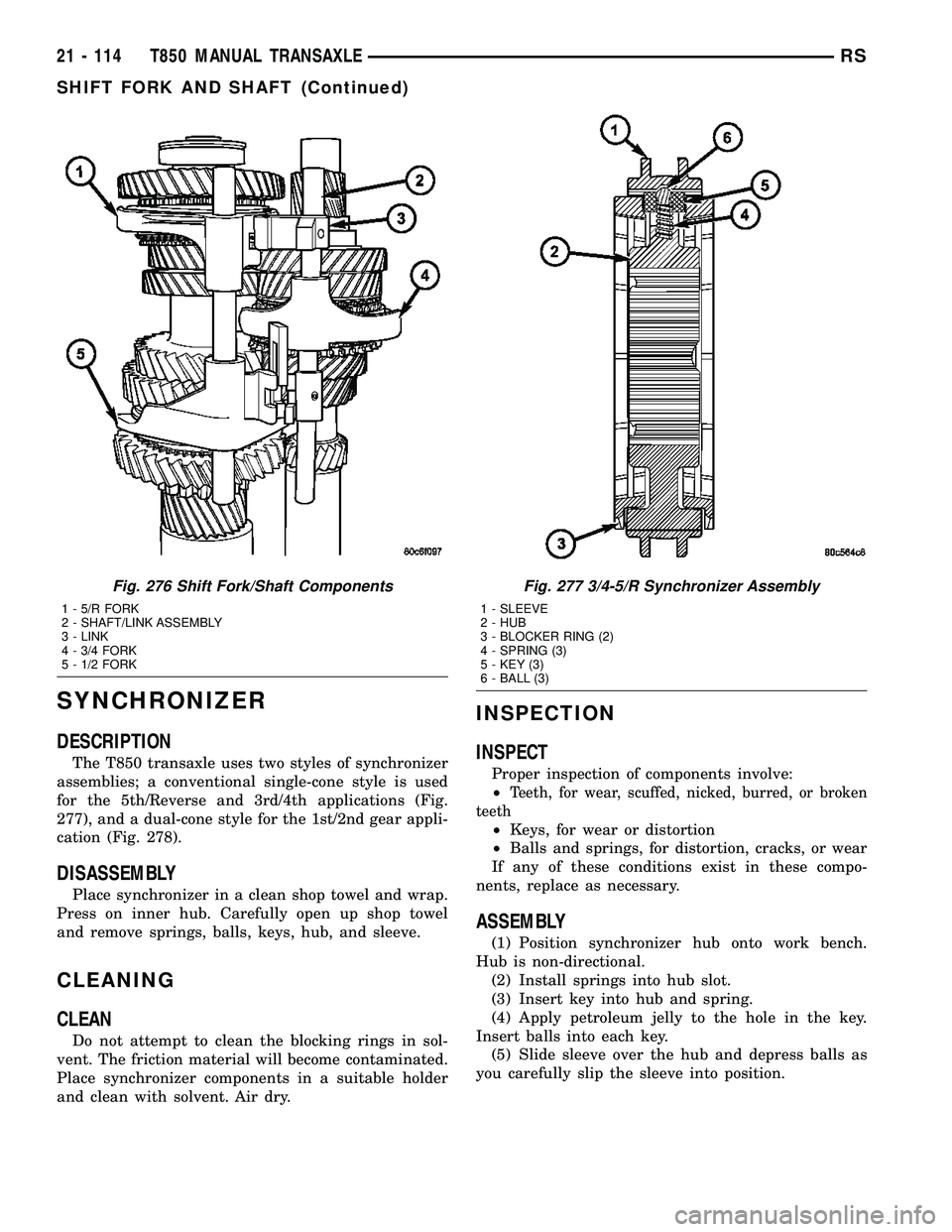

(4) Remove three (3) right engine mount bracket-

to-transaxle bolts (Fig. 11).

(5) Raise vehicle on hoist.

(6) Remove front wheel/tires and halfshafts.

(7) Drain transaxle fluid into suitable container.

(8) Remove front harness retainer and secure har-

ness out of way.

Fig. 10 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 11 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

RST850 MANUAL TRANSAXLE21-31

T850 MANUAL TRANSAXLE (Continued)

Page 1711 of 2585

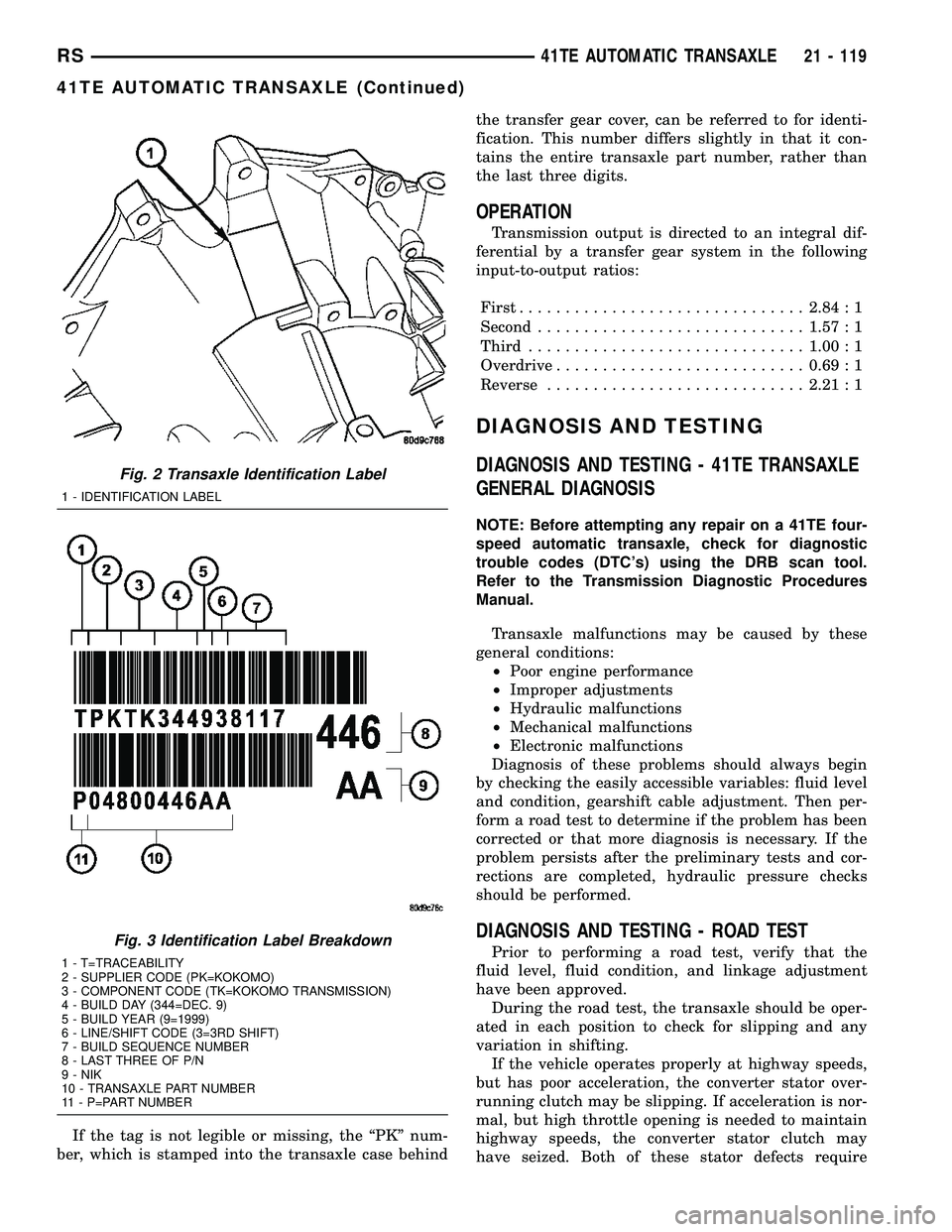

SYNCHRONIZER

DESCRIPTION

The T850 transaxle uses two styles of synchronizer

assemblies; a conventional single-cone style is used

for the 5th/Reverse and 3rd/4th applications (Fig.

277), and a dual-cone style for the 1st/2nd gear appli-

cation (Fig. 278).

DISASSEMBLY

Place synchronizer in a clean shop towel and wrap.

Press on inner hub. Carefully open up shop towel

and remove springs, balls, keys, hub, and sleeve.

CLEANING

CLEAN

Do not attempt to clean the blocking rings in sol-

vent. The friction material will become contaminated.

Place synchronizer components in a suitable holder

and clean with solvent. Air dry.

INSPECTION

INSPECT

Proper inspection of components involve:

²

Teeth, for wear, scuffed, nicked, burred, or broken

teeth

²Keys, for wear or distortion

²Balls and springs, for distortion, cracks, or wear

If any of these conditions exist in these compo-

nents, replace as necessary.

ASSEMBLY

(1) Position synchronizer hub onto work bench.

Hub is non-directional.

(2) Install springs into hub slot.

(3) Insert key into hub and spring.

(4) Apply petroleum jelly to the hole in the key.

Insert balls into each key.

(5) Slide sleeve over the hub and depress balls as

you carefully slip the sleeve into position.

Fig. 276 Shift Fork/Shaft Components

1 - 5/R FORK

2 - SHAFT/LINK ASSEMBLY

3 - LINK

4 - 3/4 FORK

5 - 1/2 FORK

Fig. 277 3/4-5/R Synchronizer Assembly

1 - SLEEVE

2 - HUB

3 - BLOCKER RING (2)

4 - SPRING (3)

5 - KEY (3)

6 - BALL (3)

21 - 114 T850 MANUAL TRANSAXLERS

SHIFT FORK AND SHAFT (Continued)

Page 1713 of 2585

41TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

41TE AUTOMATIC TRANSAXLE

DESCRIPTION........................117

OPERATION..........................119

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 41TE

TRANSAXLE GENERAL DIAGNOSIS......119

DIAGNOSIS AND TESTING - ROAD TEST . . 119

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TESTS...................120

DIAGNOSIS AND TESTING - CLUTCH AIR

PRESSURE TESTS...................122

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE . . 123

REMOVAL............................124

DISASSEMBLY........................125

ASSEMBLY...........................144

INSTALLATION........................166

SCHEMATICS AND DIAGRAMS

41TE TRANSAXLE HYDRAULIC

SCHEMATICS.......................169

SPECIFICATIONS - 41TE TRANSAXLE......181

SPECIAL TOOLS

41TE AUTOMATIC TRANSAXLE.........183

ACCUMULATOR

DESCRIPTION........................188

OPERATION..........................189

AUTOSTICK SWITCH

DESCRIPTION........................189

OPERATION..........................189

DRIVING CLUTCHES

DESCRIPTION........................190

OPERATION..........................190

FINAL DRIVE

DISASSEMBLY........................190

ASSEMBLY...........................195

ADJUSTMENTS

ADJUSTMENT - DIFFERENTIAL BEARING

PRELOAD..........................199

FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK . . . 201

STANDARD PROCEDURE - FLUID AND

FILTER SERVICE.....................203

GEAR SHIFT CABLE

REMOVAL............................204

INSTALLATION........................205

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT.......206HOLDING CLUTCHES

DESCRIPTION........................207

OPERATION..........................207

INPUT CLUTCH ASSEMBLY

DISASSEMBLY........................208

ASSEMBLY...........................216

OIL PUMP

DESCRIPTION........................230

OPERATION..........................230

DISASSEMBLY........................230

ASSEMBLY...........................232

PLANETARY GEARTRAIN

DESCRIPTION........................232

OPERATION..........................232

SEAL - OIL PUMP

REMOVAL............................232

INSTALLATION........................233

SHIFT INTERLOCK SOLENOID

DESCRIPTION........................233

OPERATION..........................233

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK

SOLENOID..........................235

REMOVAL............................235

INSTALLATION........................236

SOLENOID/PRESSURE SWITCH ASSY

DESCRIPTION........................237

OPERATION..........................237

REMOVAL............................238

INSTALLATION........................239

SPEED SENSOR - INPUT

DESCRIPTION........................239

OPERATION..........................240

REMOVAL............................240

INSTALLATION........................240

SPEED SENSOR - OUTPUT

DESCRIPTION........................241

OPERATION..........................241

REMOVAL............................241

INSTALLATION........................242

TORQUE CONVERTER

DESCRIPTION........................242

OPERATION..........................245

REMOVAL............................247

INSTALLATION........................247

TRANSMISSION CONTROL RELAY

DESCRIPTION........................247

OPERATION..........................248

21 - 116 41TE AUTOMATIC TRANSAXLERS

Page 1716 of 2585

If the tag is not legible or missing, the ªPKº num-

ber, which is stamped into the transaxle case behindthe transfer gear cover, can be referred to for identi-

fication. This number differs slightly in that it con-

tains the entire transaxle part number, rather than

the last three digits.

OPERATION

Transmission output is directed to an integral dif-

ferential by a transfer gear system in the following

input-to-output ratios:

First...............................2.84 : 1

Second.............................1.57 : 1

Third..............................1.00 : 1

Overdrive...........................0.69 : 1

Reverse............................2.21 : 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 41TE TRANSAXLE

GENERAL DIAGNOSIS

NOTE: Before attempting any repair on a 41TE four-

speed automatic transaxle, check for diagnostic

trouble codes (DTC's) using the DRB scan tool.

Refer to the Transmission Diagnostic Procedures

Manual.

Transaxle malfunctions may be caused by these

general conditions:

²Poor engine performance

²Improper adjustments

²Hydraulic malfunctions

²Mechanical malfunctions

²Electronic malfunctions

Diagnosis of these problems should always begin

by checking the easily accessible variables: fluid level

and condition, gearshift cable adjustment. Then per-

form a road test to determine if the problem has been

corrected or that more diagnosis is necessary. If the

problem persists after the preliminary tests and cor-

rections are completed, hydraulic pressure checks

should be performed.

DIAGNOSIS AND TESTING - ROAD TEST

Prior to performing a road test, verify that the

fluid level, fluid condition, and linkage adjustment

have been approved.

During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

If the vehicle operates properly at highway speeds,

but has poor acceleration, the converter stator over-

running clutch may be slipping. If acceleration is nor-

mal, but high throttle opening is needed to maintain

highway speeds, the converter stator clutch may

have seized. Both of these stator defects require

Fig. 2 Transaxle Identification Label

1 - IDENTIFICATION LABEL

Fig. 3 Identification Label Breakdown

1 - T=TRACEABILITY

2 - SUPPLIER CODE (PK=KOKOMO)

3 - COMPONENT CODE (TK=KOKOMO TRANSMISSION)

4 - BUILD DAY (344=DEC. 9)

5 - BUILD YEAR (9=1999)

6 - LINE/SHIFT CODE (3=3RD SHIFT)

7 - BUILD SEQUENCE NUMBER

8 - LAST THREE OF P/N

9 - NIK

10 - TRANSAXLE PART NUMBER

11 - P=PART NUMBER

RS41TE AUTOMATIC TRANSAXLE21 - 119

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1799 of 2585

(3) Select sensors.

(4) Read the transmission temperature value.

(5) Compare the fluid temperature value with the

fluid temperature chart (Fig. 210).

(6) Adjust transmission fluid level shown on the

indicator according to the chart.

(7) Check transmission for leaks.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is proba-

bly required. Be sure to examine the fluid on the dip-

stick closely. If there is any doubt about its condition,

drain out a sample for a double check.

MopartATF+4 (Automatic Transmission Fluid)

when new is red in color. The ATF is dyed red so it

can be identified from other fluids used in the vehicle

such as engine oil or antifreeze. The red color is not

permanent and is not an indicator of fluid condition.

As the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal.ATF+4 also has a unique odor that

may change with age. Consequently,odor and color

cannot be used to indicate the fluid condition

or the need for a fluid change.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

Fig. 210 Transmission Fluid Temperature Chart

1 - MAX. LEVEL

2 - MIN. LEVEL

21 - 202 41TE AUTOMATIC TRANSAXLERS

FLUID (Continued)

Page 1885 of 2585

40TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

40TE AUTOMATIC TRANSAXLE DESCRIPTION .........................25

OPERATION ...........................27

DIAGNOSIS AND TESTING DIAGNOSIS AND TESTING - 4XTETRANSAXLE GENERAL DIAGNOSIS .......27

DIAGNOSIS AND TESTING - ROAD TEST . . . 27

DIAGNOSIS AND TESTING - HYDRAULIC PRESSURE TESTS ....................28

DIAGNOSIS AND TESTING - CLUTCH AIR PRESSURE TESTS ....................30

DIAGNOSIS AND TESTING - TORQUE CONVERTER HOUSING FLUID LEAKAGE . . . 31

REMOVAL .............................31

DISASSEMBLY .........................34

ASSEMBLY ............................51

INSTALLATION .........................73

SCHEMATICS AND DIAGRAMS 4XTE TRANSAXLE HYDRAULICSCHEMATICS ........................75

SPECIFICATIONS - 41TE TRANSAXLE .......87

SPECIAL TOOLS .......................89

ACCUMULATOR DESCRIPTION .........................94

OPERATION ...........................94

DRIVING CLUTCHES DESCRIPTION .........................95

OPERATION ...........................95

FINAL DRIVE DESCRIPTION .........................95

OPERATION ...........................96

DISASSEMBLY .........................96

ASSEMBLY ............................99

ADJUSTMENTS DIFFERENTIAL BEARING PRELOADMEASUREMENT AND ADJUSTMENT ......100

FLUID STANDARD PROCEDURE FLUID LEVEL AND CONDITION CHECK . . . 102

STANDARD PROCEDURE - FLUID ANDFILTER SERVICE .....................104

GEAR SHIFT CABLE REMOVAL ............................105

HOLDING CLUTCHES DESCRIPTION ........................106

OPERATION ..........................106

INPUT CLUTCH ASSEMBLY DISASSEMBLY ........................107

ASSEMBLY ...........................116 OIL PUMP

DESCRIPTION ........................131

OPERATION ..........................131

DISASSEMBLY ........................131

ASSEMBLY ...........................132

PLANETARY GEARTRAIN DESCRIPTION ........................132

OPERATION ..........................132

SEAL - OIL PUMP REMOVAL ............................133

INSTALLATION ........................133

SHIFT INTERLOCK SOLENOID DESCRIPTION ........................133

OPERATION ..........................134

DIAGNOSIS AND TESTING - BRAKE/ TRANSMISSION SHIFT INTERLOCK

SOLENOID ..........................135

REMOVAL ............................135

INSTALLATION ........................136

SOLENOID/PRESSURE SWITCH ASSY DESCRIPTION ........................137

OPERATION ..........................137

REMOVAL ............................138

INSTALLATION ........................139

SPEED SENSOR - INPUT DESCRIPTION ........................140

OPERATION ..........................140

REMOVAL ............................141

INSTALLATION ........................141

SPEED SENSOR - OUTPUT DESCRIPTION ........................142

OPERATION ..........................142

REMOVAL ............................143

INSTALLATION ........................143

TORQUE CONVERTER DESCRIPTION ........................144

OPERATION ..........................148

REMOVAL ............................149

INSTALLATION ........................149

TRANSMISSION CONTROL RELAY DESCRIPTION ........................150

OPERATION ..........................150

TRANSMISSION RANGE SENSOR DESCRIPTION ........................150

OPERATION ..........................151

REMOVAL ............................151

INSTALLATION ........................152

VALVE BODY DESCRIPTION ........................152

21s - 24 40TE AUTOMATIC TRANSAXLERS

Page 1888 of 2585

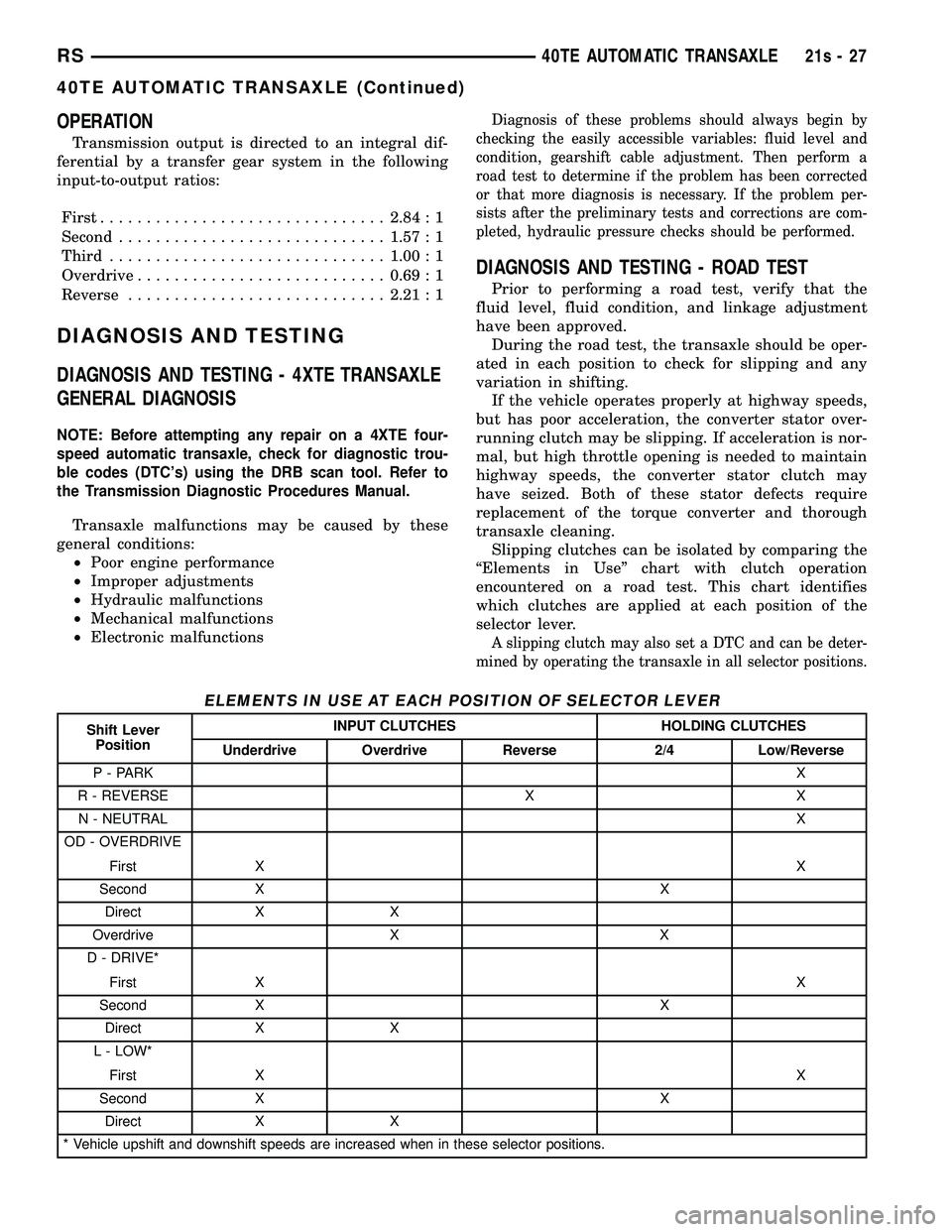

OPERATION

Transmission output is directed to an integral dif-

ferential by a transfer gear system in the following

input-to-output ratios:

First ............................... 2.84 : 1

Second ............................. 1.57 : 1

Third .............................. 1.00 : 1

Overdrive ........................... 0.69 : 1

Reverse ............................ 2.21 : 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 4XTE TRANSAXLE

GENERAL DIAGNOSIS

NOTE: Before attempting any repair on a 4XTE four-

speed automatic transaxle, check for diagnostic trou-

ble codes (DTC's) using the DRB scan tool. Refer to

the Transmission Diagnostic Procedures Manual.

Transaxle malfunctions may be caused by these

general conditions: ² Poor engine performance

² Improper adjustments

² Hydraulic malfunctions

² Mechanical malfunctions

² Electronic malfunctions

Diagnosis of these problems should always begin by

checking the easily accessible variables: fluid level and

condition, gearshift cable adjustment. Then perform a

road test to determine if the problem has been corrected

or that more diagnosis is necessary. If the problem per-

sists after the preliminary tests and corrections are com-

pleted, hydraulic pressure checks should be performed.

DIAGNOSIS AND TESTING - ROAD TEST

Prior to performing a road test, verify that the

fluid level, fluid condition, and linkage adjustment

have been approved. During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting. If the vehicle operates properly at highway speeds,

but has poor acceleration, the converter stator over-

running clutch may be slipping. If acceleration is nor-

mal, but high throttle opening is needed to maintain

highway speeds, the converter stator clutch may

have seized. Both of these stator defects require

replacement of the torque converter and thorough

transaxle cleaning. Slipping clutches can be isolated by comparing the

ªElements in Useº chart with clutch operation

encountered on a road test. This chart identifies

which clutches are applied at each position of the

selector lever.

A slipping clutch may also set a DTC and can be deter-

mined by operating the transaxle in all selector positions.

ELEMENTS IN USE AT EACH POSITION OF SELECTOR LEVER

Shift Lever Position INPUT CLUTCHES HOLDING CLUTCHES

Underdrive Overdrive Reverse 2/4 Low/Reverse

P - PARK X

R - REVERSE X X N - NEUTRAL X

OD - OVERDRIVE

First X X

Second X X Direct X X

Overdrive X X

D - DRIVE*

First X X

Second X X Direct X X

L - LOW*

First X X

Second X X

Direct X X

* Vehicle upshift and downshift speeds are increased when in these selector positions.

RS 40TE AUTOMATIC TRANSAXLE21s-27

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1964 of 2585

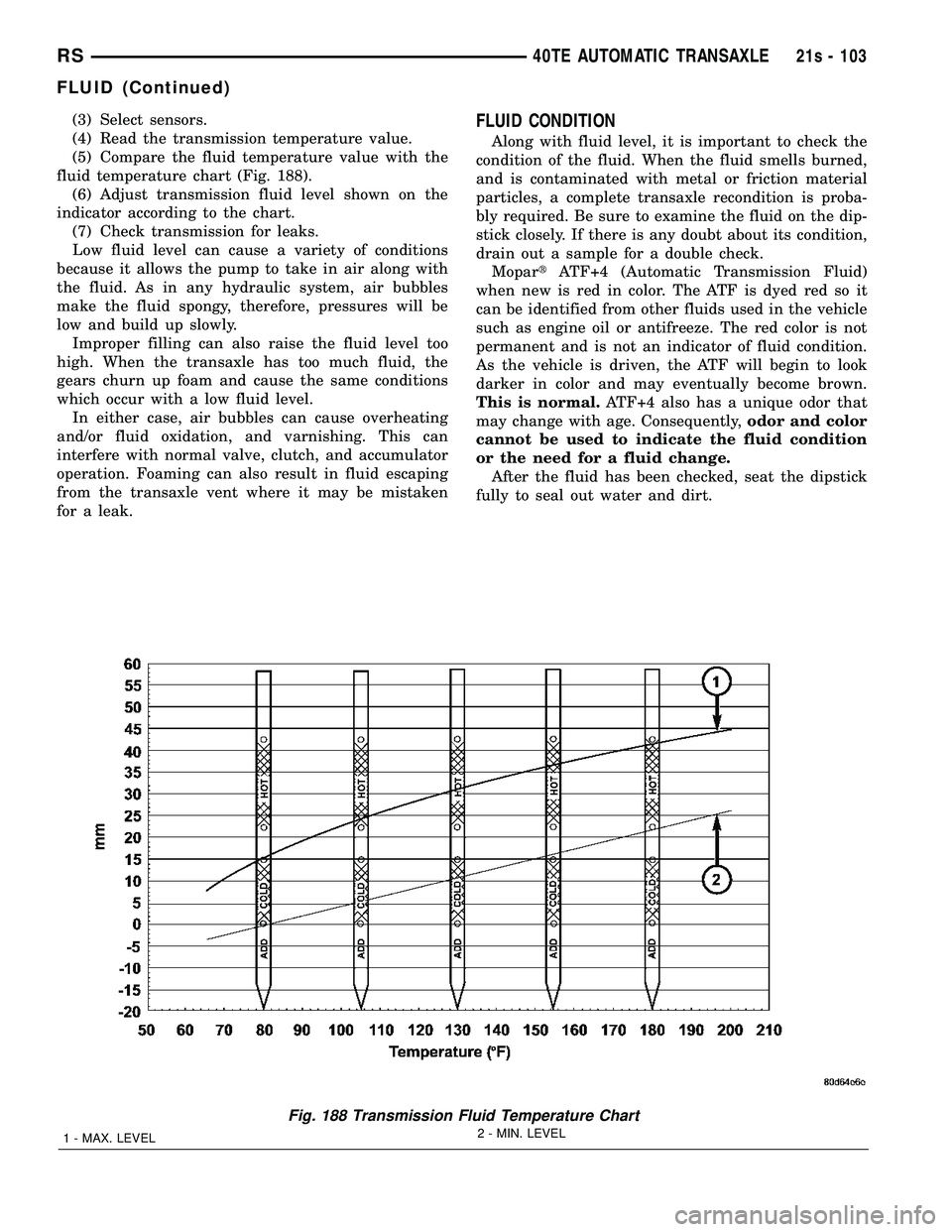

(3) Select sensors.

(4) Read the transmission temperature value.

(5) Compare the fluid temperature value with the

fluid temperature chart (Fig. 188). (6) Adjust transmission fluid level shown on the

indicator according to the chart. (7) Check transmission for leaks.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly. Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level. In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is proba-

bly required. Be sure to examine the fluid on the dip-

stick closely. If there is any doubt about its condition,

drain out a sample for a double check. Mopar tATF+4 (Automatic Transmission Fluid)

when new is red in color. The ATF is dyed red so it

can be identified from other fluids used in the vehicle

such as engine oil or antifreeze. The red color is not

permanent and is not an indicator of fluid condition.

As the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal. ATF+4 also has a unique odor that

may change with age. Consequently, odor and color

cannot be used to indicate the fluid condition

or the need for a fluid change. After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

Fig. 188 Transmission Fluid Temperature Chart

1 - MAX. LEVEL 2 - MIN. LEVEL

RS

40TE AUTOMATIC TRANSAXLE21s - 103

FLUID (Continued)