tow CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2278 of 2585

DESCRIPTION FIGURE

REAR SEAT REINFORCEMENTS - SHORT WHEEL BASE ONLY 100

CENTER CONSOLE REINFORCEMENT - SHORT WHEEL BASE ONLY 101

WHEELHOUSES - SHORT WHEEL BASE ONLY 102

FRONT SEAT CROSS MEMBER - SHORT WHEELBASE, ALL WHEEL DRIVE ONLY 103

FLOOR PAN SIDE RAIL - LONG WHEEL BASE ONLY 104

INNER BODY SIDE SILL REINFORCEMENTS 105

TOE BOARD CROSS MEMBER 106

FRONT SIDE RAIL - SHORT WHEEL BASE ONLY 107

DASH PANEL REINFORCEMENT 108

LOWER COWL PLENUM 109

UPPER COWL PLENUM SUPPORT 110

UPPER DASH PANEL 111

COWL SIDE PANELS 112

INSTRUMENT PANEL ATTACHMENT TAPPING PLATES 113

INSTRUMENT PANEL, DASH PANEL, ACM MODULE AND ACCELERATOR PEDAL 114

STRUT TOWER BRACKET AND COWL PLENUM 115

FRONT SIDE RAILS TO LOWER DASH PANEL 116

INNER BODY SIDE SILL TO LOWER DASH PANEL 117

FRONT HINGE TAPPING PLATE 118

FRONT HINGE PILLAR 119

INNER WINDSHIELD FRAME 120

WINDSHIELD FRAME 121

FENDER BRACKET 122

INNER B-PILLAR 123

STRIKER LATCH AND TAPPING PLATES 124

RIGHT REAR INNER QUARTER PANEL - LONG WHEEL BASE ONLY 125

RIGHT REAR INNER QUARTER PANEL/OUTER WHEELHOUSE - LONG WHEEL BASE

ONLY126

RIGHT REAR BODY SIDE APERTURE - LONG WHEEL BASE ONLY 127

STRIKER LATCH REINFORCEMENT - LONG WHEEL BASE ONLY 128

BELT TAPPING PLATE - LONG WHEEL BASE ONLY 129

C-PILLAR REINFORCEMENT - LONG WHEEL BASE ONLY 130

OUTER WHEELHOUSE - LONG WHEEL BASE ONLY 131

C AND D-PILLAR INNER REINFORCEMENTS - LONG WHEEL BASE ONLY 132

LEFT REAR INNER QUARTER PANEL - LONG WHEEL BASE ONLY 133

OUTER WHEELHOUSE EXTENSION - LONG WHEEL BASE ONLY 134

TAIL LAMP - LONG WHEEL BASE ONLY 135

SLIDING DOOR LATCH - LONG WHEEL BASE ONLY 136

ROOF BOW EXTENSION - LONG WHEEL BASE ONLY 137

RIGHT REAR INNER QUARTER PANEL - SHORT WHEEL BASE ONLY 138

LATCH REINFORCEMENT AND OUTER WHEELHOUSE - SHORT WHEEL BASE ONLY 139

D-PILLAR REINFORCEMENT - SHORT WHEEL BASE ONLY 140

RSBODY STRUCTURE23 - 167

WELD LOCATIONS (Continued)

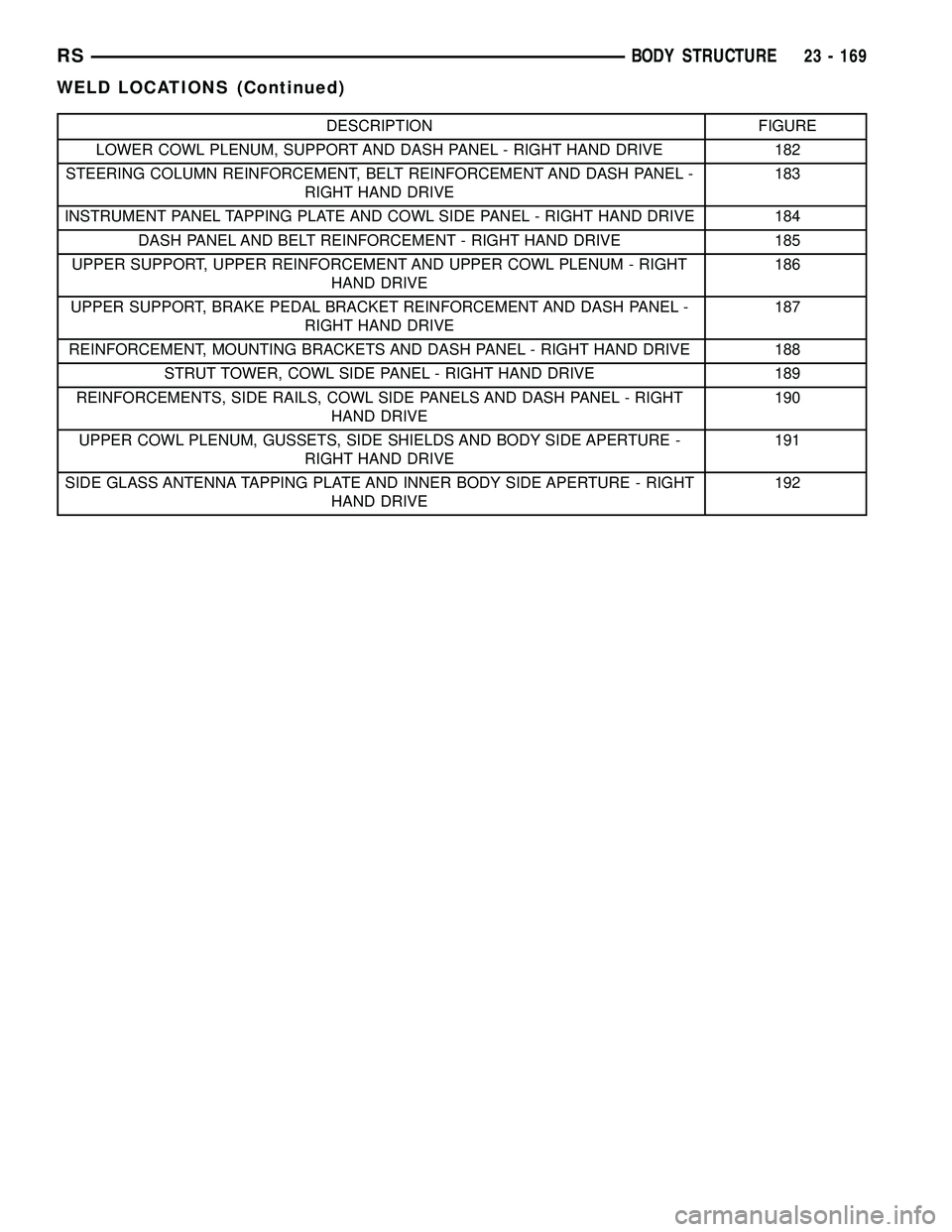

Page 2280 of 2585

DESCRIPTION FIGURE

LOWER COWL PLENUM, SUPPORT AND DASH PANEL - RIGHT HAND DRIVE 182

STEERING COLUMN REINFORCEMENT, BELT REINFORCEMENT AND DASH PANEL -

RIGHT HAND DRIVE183

INSTRUMENT PANEL TAPPING PLATE AND COWL SIDE PANEL - RIGHT HAND DRIVE 184

DASH PANEL AND BELT REINFORCEMENT - RIGHT HAND DRIVE 185

UPPER SUPPORT, UPPER REINFORCEMENT AND UPPER COWL PLENUM - RIGHT

HAND DRIVE186

UPPER SUPPORT, BRAKE PEDAL BRACKET REINFORCEMENT AND DASH PANEL -

RIGHT HAND DRIVE187

REINFORCEMENT, MOUNTING BRACKETS AND DASH PANEL - RIGHT HAND DRIVE 188

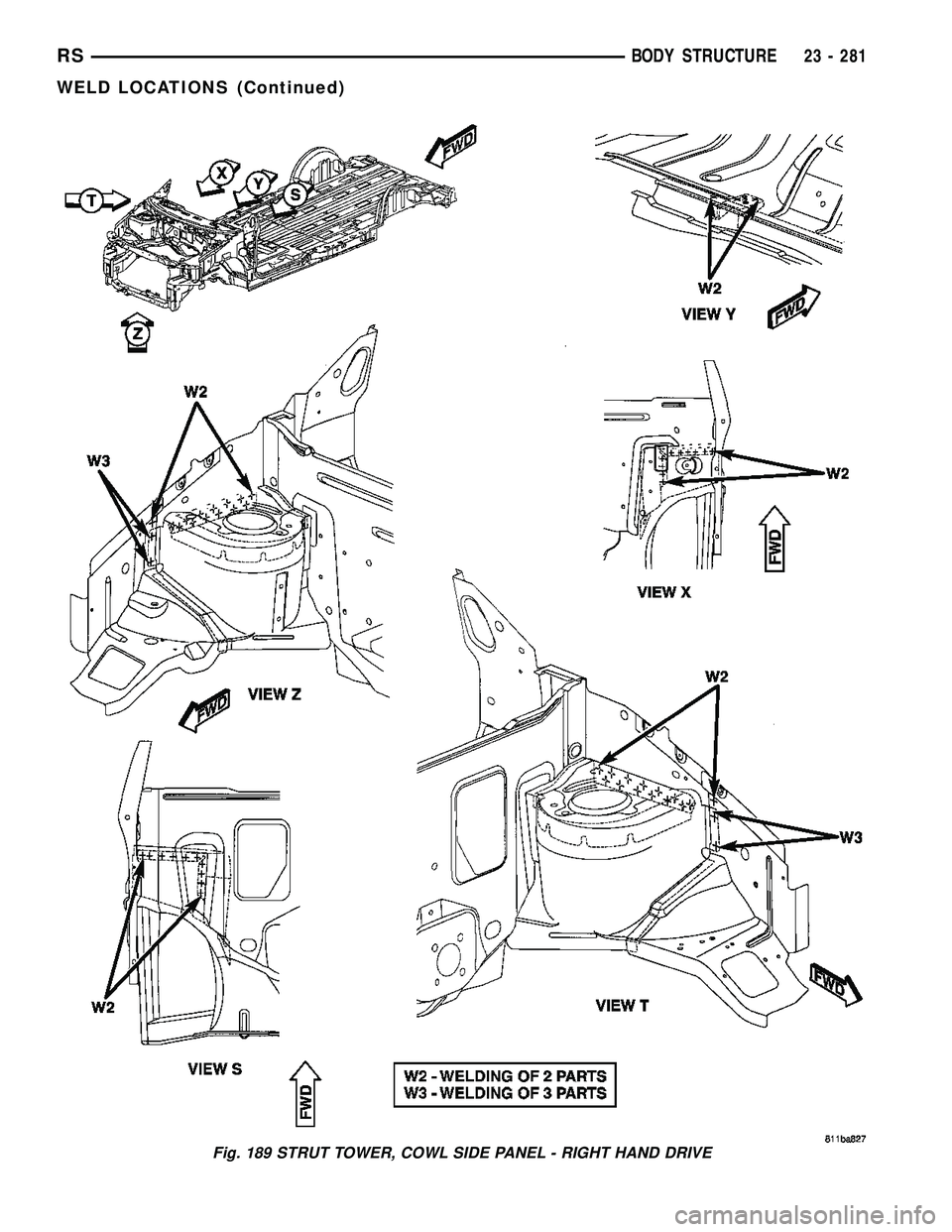

STRUT TOWER, COWL SIDE PANEL - RIGHT HAND DRIVE 189

REINFORCEMENTS, SIDE RAILS, COWL SIDE PANELS AND DASH PANEL - RIGHT

HAND DRIVE190

UPPER COWL PLENUM, GUSSETS, SIDE SHIELDS AND BODY SIDE APERTURE -

RIGHT HAND DRIVE191

SIDE GLASS ANTENNA TAPPING PLATE AND INNER BODY SIDE APERTURE - RIGHT

HAND DRIVE192

RSBODY STRUCTURE23 - 169

WELD LOCATIONS (Continued)

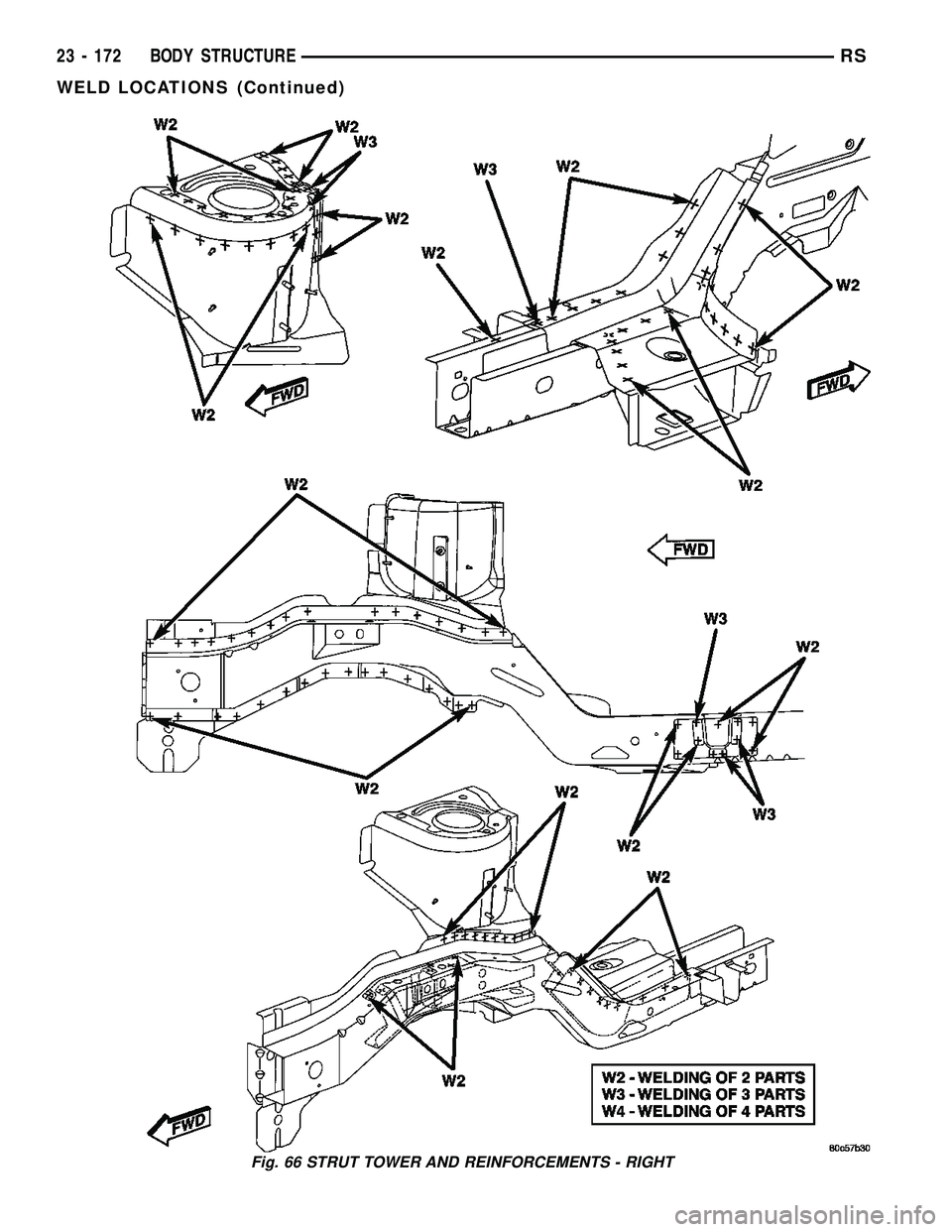

Page 2283 of 2585

Fig. 66 STRUT TOWER AND REINFORCEMENTS - RIGHT

23 - 172 BODY STRUCTURERS

WELD LOCATIONS (Continued)

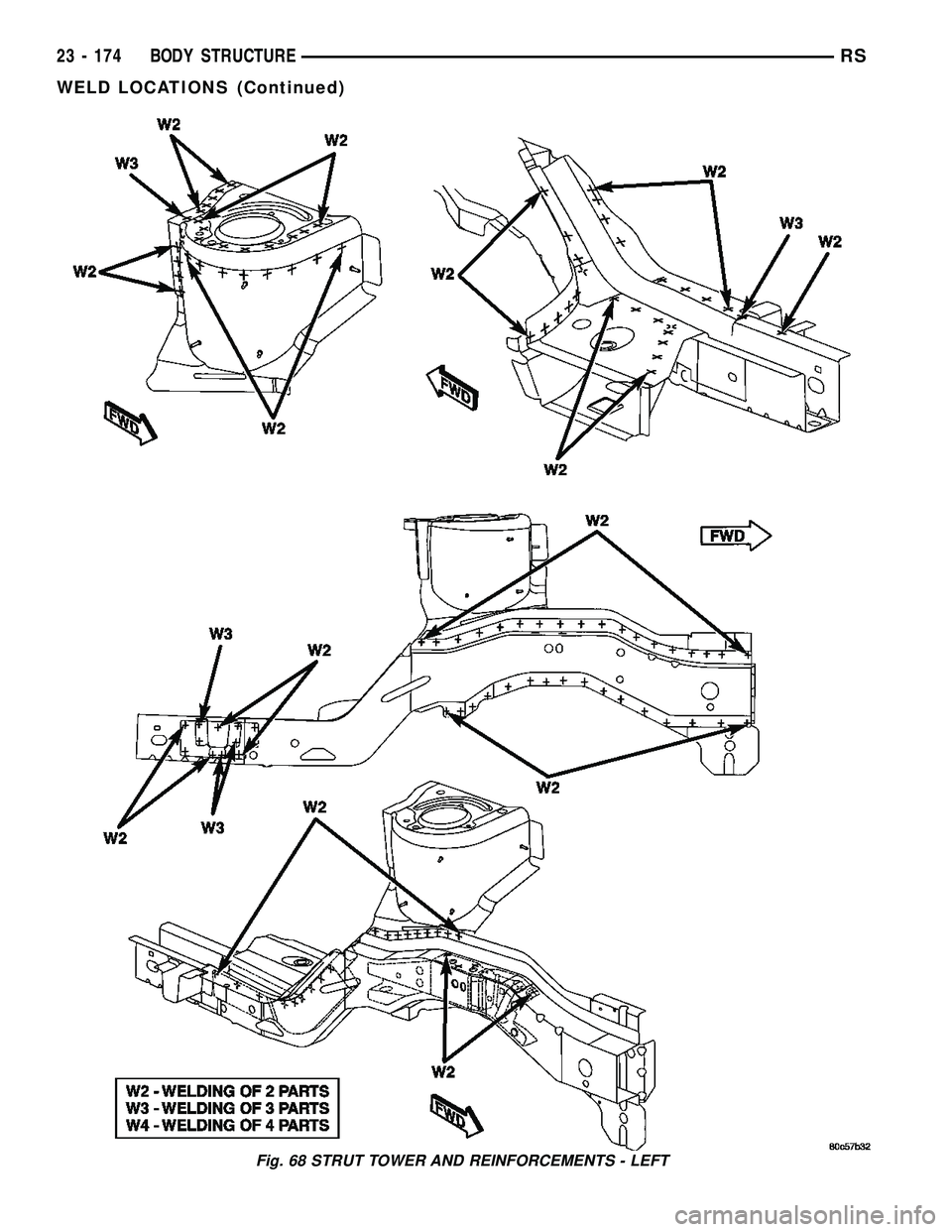

Page 2285 of 2585

Fig. 68 STRUT TOWER AND REINFORCEMENTS - LEFT

23 - 174 BODY STRUCTURERS

WELD LOCATIONS (Continued)

Page 2303 of 2585

Fig. 86 ENGINE MOUNTING PLATE & TOW BRACKET

23 - 192 BODY STRUCTURERS

WELD LOCATIONS (Continued)

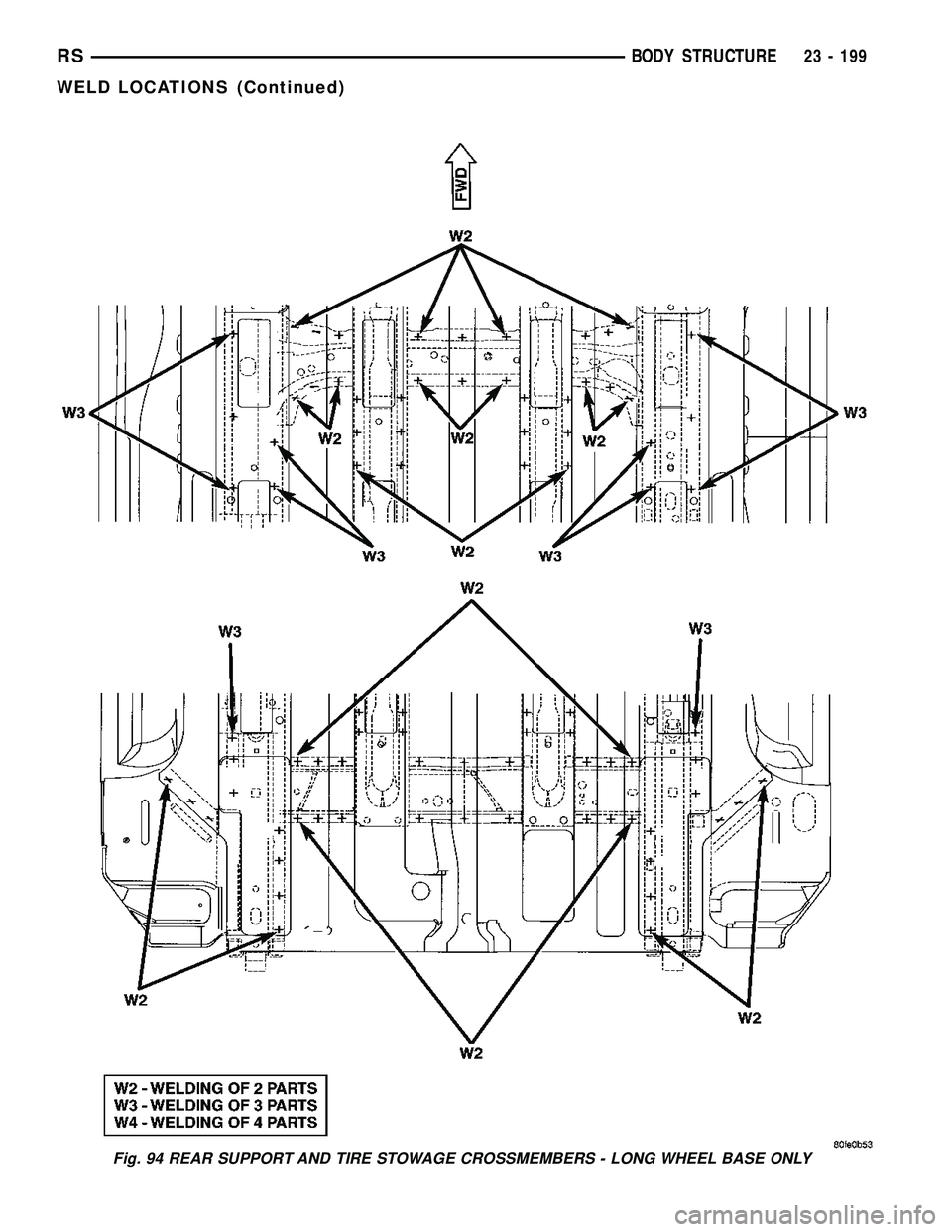

Page 2310 of 2585

Fig. 94 REAR SUPPORT AND TIRE STOWAGE CROSSMEMBERS - LONG WHEEL BASE ONLY

RSBODY STRUCTURE23 - 199

WELD LOCATIONS (Continued)

Page 2313 of 2585

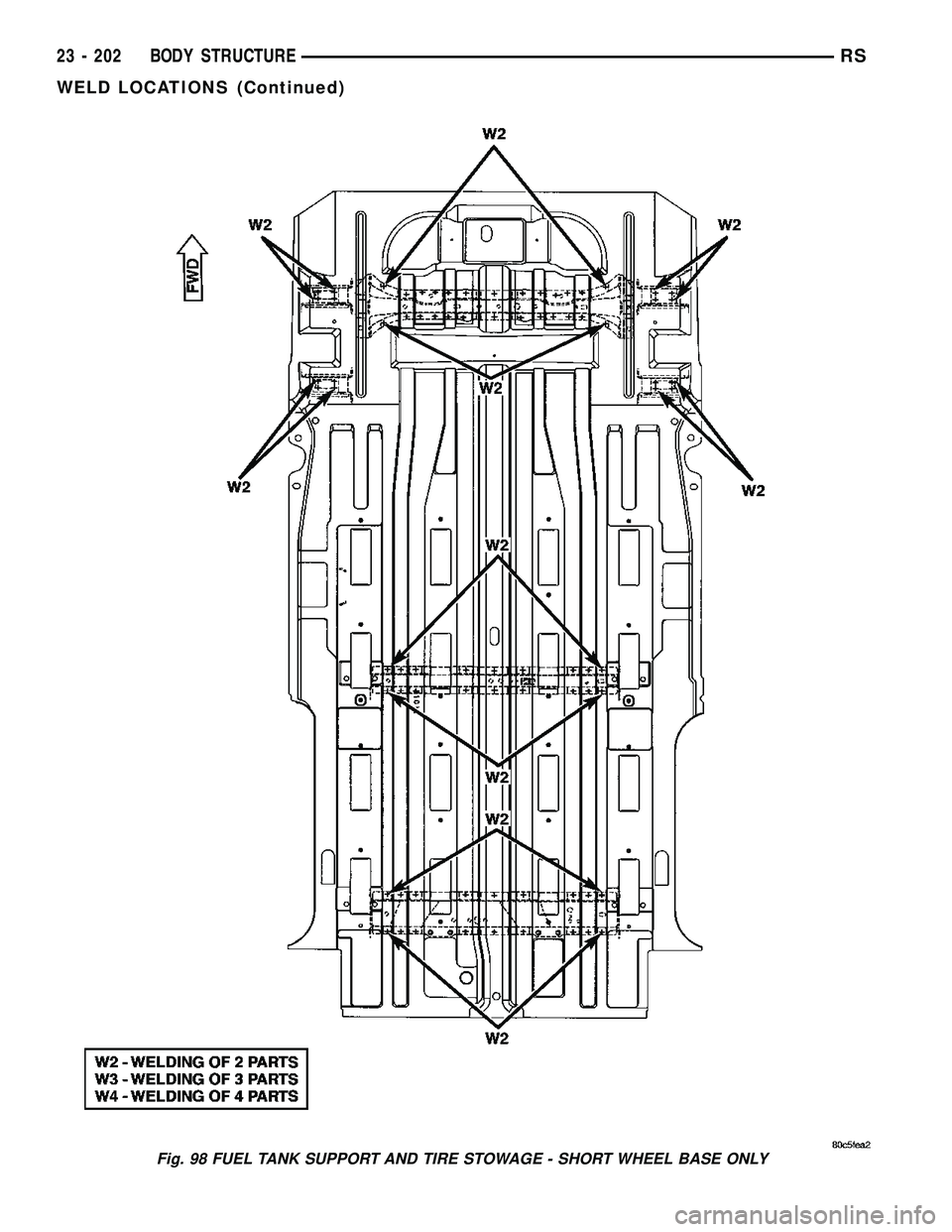

Fig. 98 FUEL TANK SUPPORT AND TIRE STOWAGE - SHORT WHEEL BASE ONLY

23 - 202 BODY STRUCTURERS

WELD LOCATIONS (Continued)

Page 2326 of 2585

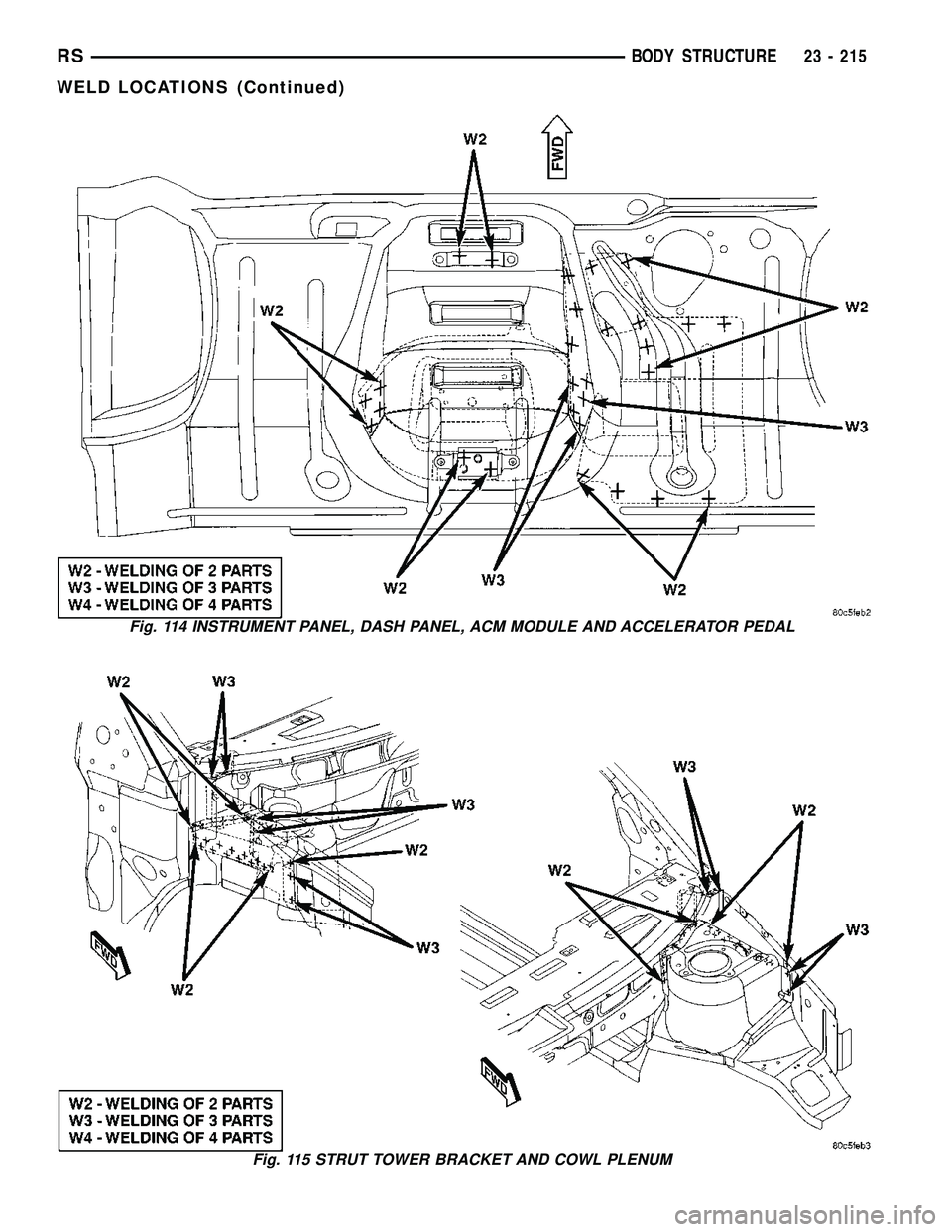

Fig. 114 INSTRUMENT PANEL, DASH PANEL, ACM MODULE AND ACCELERATOR PEDAL

Fig. 115 STRUT TOWER BRACKET AND COWL PLENUM

RSBODY STRUCTURE23 - 215

WELD LOCATIONS (Continued)

Page 2392 of 2585

Fig. 189 STRUT TOWER, COWL SIDE PANEL - RIGHT HAND DRIVE

RSBODY STRUCTURE23 - 281

WELD LOCATIONS (Continued)

Page 2417 of 2585

erence signal and a sensor ground to the transducer,

then monitors the output voltage of the transducer

on a sensor return circuit to determine refrigerant

pressure. The PCM is programmed to respond to this

and other sensor inputs by controlling the operation

of the A/C compressor clutch and the radiator cooling

fan to help optimize air conditioning system perfor-

mance and to protect the system components from

damage. The A/C pressure transducer input to the

PCM will also prevent the A/C compressor clutch

from engaging when ambient temperatures are below

about 4.5É C (40É F) due to the pressure/temperature

relationship of the refrigerant. The Schrader-type

valve in the liquid line fitting permits the A/C pres-

sure transducer to be removed or installed without

disturbing the refrigerant in the system. The A/C

pressure transducer is diagnosed using a DRBIIIt

scan tool. Refer to Body Diagnostic Procedures.

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER

The A/C pressure transducer is tested using a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information. Before testing the A/C pressure

transducer, be certain that the transducer wire har-

ness connection is clean of corrosion and properly

connected. For the A/C to operate, an A/C pressure

transducer voltage reading between 0.451 and 4.519

volts is required. Voltages outside this range indicate

a low or high refrigerant system pressure condition

to the powertrain control module (PCM). The PCM is

programmed to respond to a low or high refrigerant

system pressure by suppressing operation of the A/C

compressor. Refer to the A/C Pressure Transducer

Voltage chart for the possible conditions indicated by

the transducer voltage reading.

A/C PRESSURE TRANSDUCER VOLTAGE

Voltage Possible Indication

0.0 1. No sensor supply voltage from

PCM.

2. Shorted sensor circuit.

3. Faulty transducer.

0.150 TO 0.450 1. Ambient temperature below 10É

C (50É F).

2. Low refrigerant system pressure.

0.451 TO 4.519 1. Normal refrigerant system

pressure.

4.520 TO 4.850 1. High refrigerant system pressure.

5.0 1. Open sensor circuit.

2. Faulty transducer.

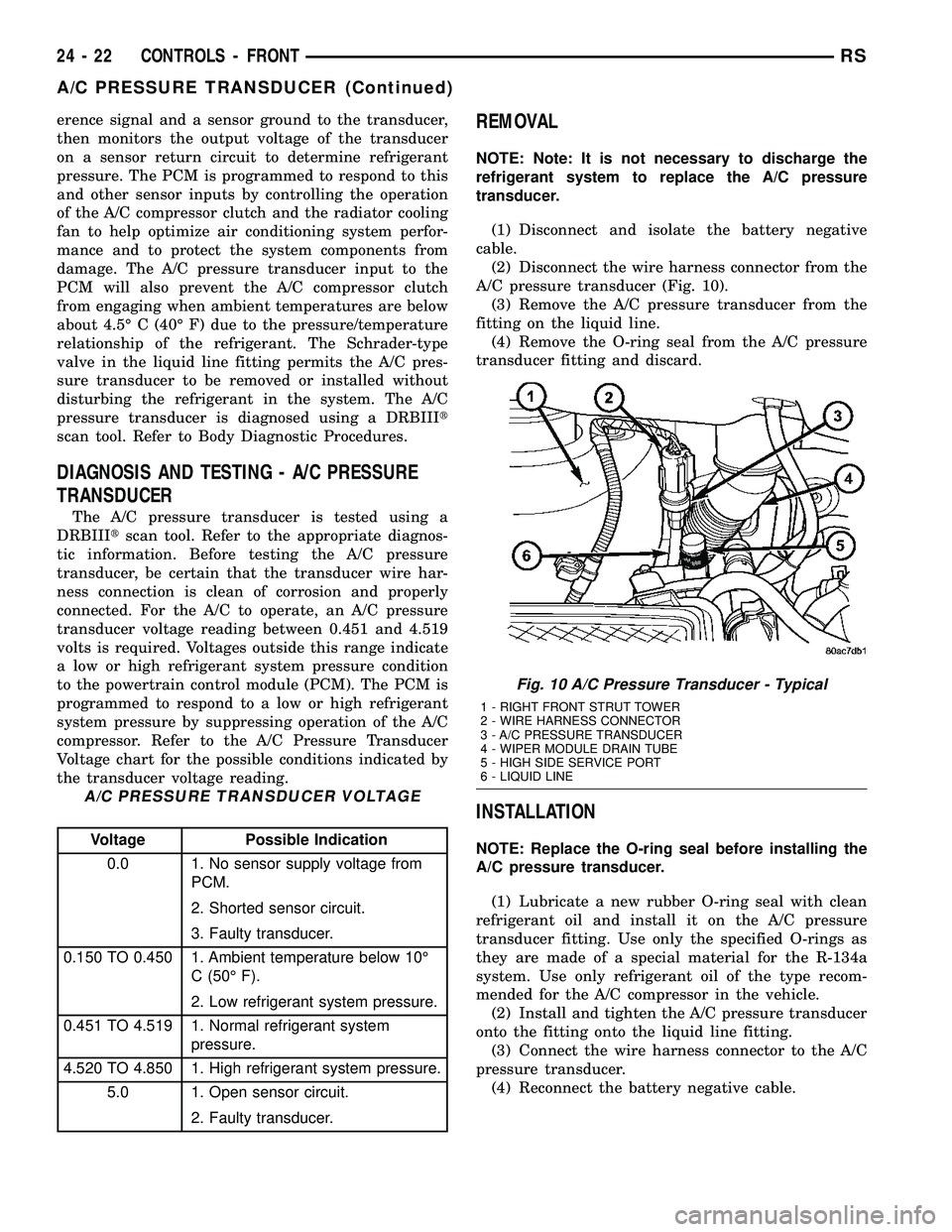

REMOVAL

NOTE: Note: It is not necessary to discharge the

refrigerant system to replace the A/C pressure

transducer.

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the wire harness connector from the

A/C pressure transducer (Fig. 10).

(3) Remove the A/C pressure transducer from the

fitting on the liquid line.

(4) Remove the O-ring seal from the A/C pressure

transducer fitting and discard.

INSTALLATION

NOTE: Replace the O-ring seal before installing the

A/C pressure transducer.

(1) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the A/C pressure

transducer fitting. Use only the specified O-rings as

they are made of a special material for the R-134a

system. Use only refrigerant oil of the type recom-

mended for the A/C compressor in the vehicle.

(2) Install and tighten the A/C pressure transducer

onto the fitting onto the liquid line fitting.

(3) Connect the wire harness connector to the A/C

pressure transducer.

(4) Reconnect the battery negative cable.

Fig. 10 A/C Pressure Transducer - Typical

1 - RIGHT FRONT STRUT TOWER

2 - WIRE HARNESS CONNECTOR

3 - A/C PRESSURE TRANSDUCER

4 - WIPER MODULE DRAIN TUBE

5 - HIGH SIDE SERVICE PORT

6 - LIQUID LINE

24 - 22 CONTROLS - FRONTRS

A/C PRESSURE TRANSDUCER (Continued)