tow CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2083 of 2585

If runout is still excessive, perform the following:

²If the new high spot is within 102 mm (4.0 inch)

of the first high spot on the tire, replace the tire.

²If the new high spot is within 102 mm (4.0 inch)

of the first high spot on the wheel, the wheel may be

out of specification. Refer to Wheel Runout above.²If the new high spot is NOT within 102 mm (4.0

inch) of either high spot, draw an arrow on the tread

from new high spot toward the original (Fig. 7).

Break down the tire and remount it 90 degrees on

rim in that direction, then re-measure runout. This

will normally reduce the runout to an acceptable

amount.

(6) Once back together, road test the vehicle for at

least 5 miles, following the format described in Road

Test. If vibration persists, and all components tested

are within specification, the tires may have an exces-

sive radial force condition. Radial force variation can

only be checked as indicated below. If this equipment

is not available, consult with the tire manufacturer.

RADIAL FORCE VARIATION

Radial Force Variation can be checked using the

Hunter GSP 9700 Vibration Control System (Wheel

Balancer) or equivalent, if available. This type of

equipment helps to correct ride disturbances by

reducing the radial force variation of an assembly

through re-indexing of the tire to wheel.

The equipment manufacturer or DaimlerChrysler

Corporation may supply reference values as guide-

lines. Radial force measurements above the reference

value may not always result in a ride disturbance,

nor do they automatically mean the assembly compo-

nents are out of specification. Do not replace compo-

nents based on radial force values alone. Balancing,

runout diagnosis, re-indexing, and subjective road

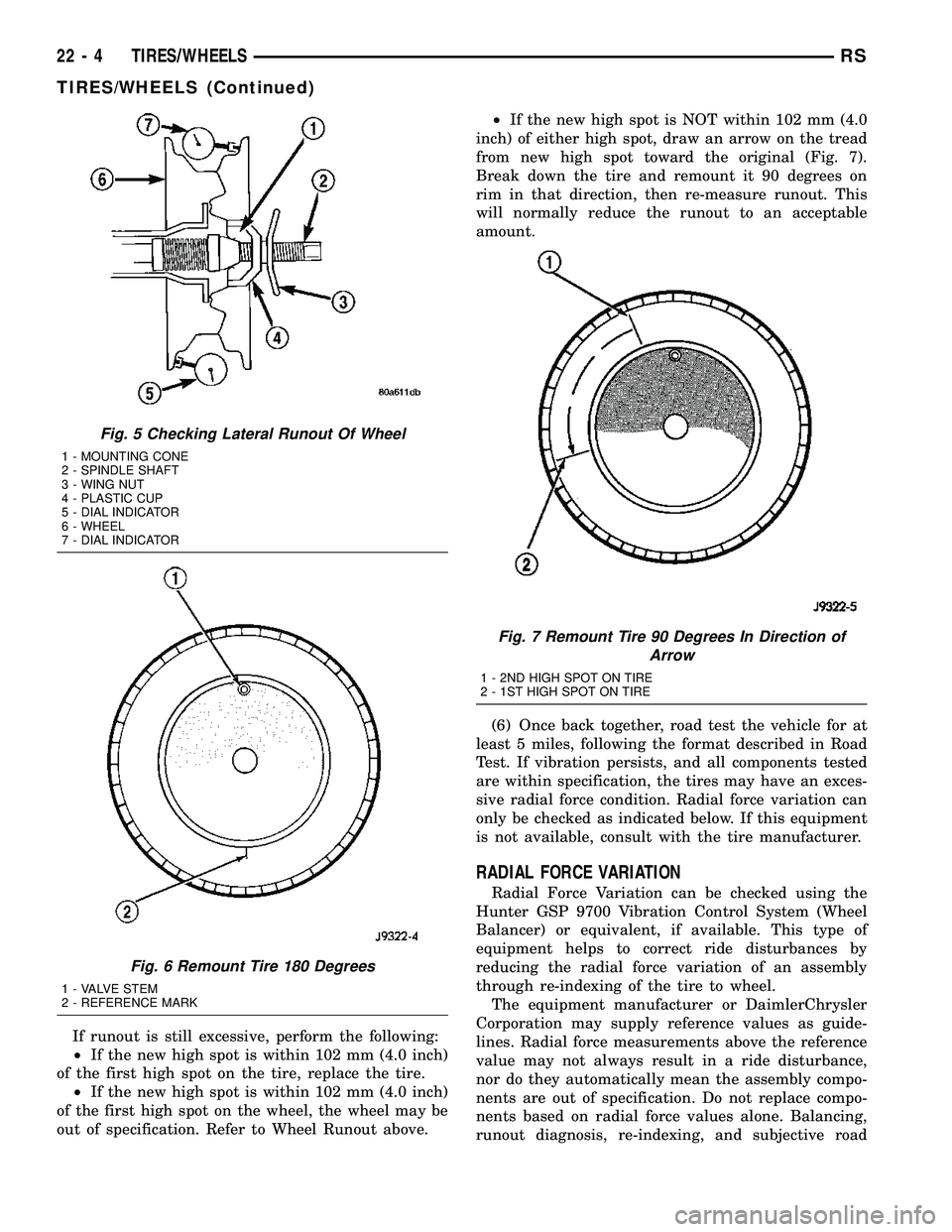

Fig. 5 Checking Lateral Runout Of Wheel

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

Fig. 6 Remount Tire 180 Degrees

1 - VALVE STEM

2 - REFERENCE MARK

Fig. 7 Remount Tire 90 Degrees In Direction of

Arrow

1 - 2ND HIGH SPOT ON TIRE

2 - 1ST HIGH SPOT ON TIRE

22 - 4 TIRES/WHEELSRS

TIRES/WHEELS (Continued)

Page 2130 of 2585

(10) Verify door latch and power door lock opera-

tion.

(11) Install watershield and front door trim panel.

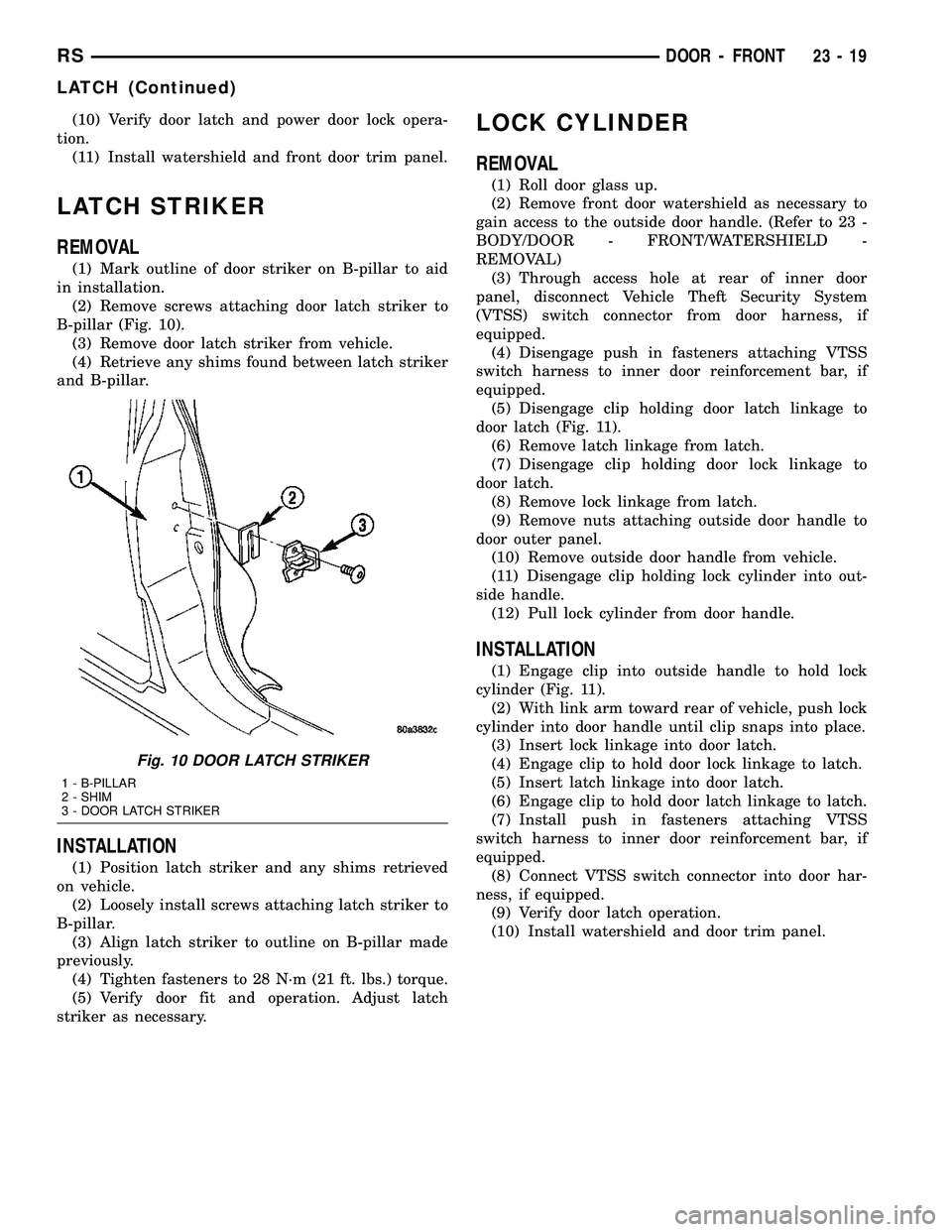

LATCH STRIKER

REMOVAL

(1) Mark outline of door striker on B-pillar to aid

in installation.

(2) Remove screws attaching door latch striker to

B-pillar (Fig. 10).

(3) Remove door latch striker from vehicle.

(4) Retrieve any shims found between latch striker

and B-pillar.

INSTALLATION

(1) Position latch striker and any shims retrieved

on vehicle.

(2) Loosely install screws attaching latch striker to

B-pillar.

(3) Align latch striker to outline on B-pillar made

previously.

(4) Tighten fasteners to 28 N´m (21 ft. lbs.) torque.

(5) Verify door fit and operation. Adjust latch

striker as necessary.

LOCK CYLINDER

REMOVAL

(1) Roll door glass up.

(2) Remove front door watershield as necessary to

gain access to the outside door handle. (Refer to 23 -

BODY/DOOR - FRONT/WATERSHIELD -

REMOVAL)

(3) Through access hole at rear of inner door

panel, disconnect Vehicle Theft Security System

(VTSS) switch connector from door harness, if

equipped.

(4) Disengage push in fasteners attaching VTSS

switch harness to inner door reinforcement bar, if

equipped.

(5) Disengage clip holding door latch linkage to

door latch (Fig. 11).

(6) Remove latch linkage from latch.

(7) Disengage clip holding door lock linkage to

door latch.

(8) Remove lock linkage from latch.

(9) Remove nuts attaching outside door handle to

door outer panel.

(10) Remove outside door handle from vehicle.

(11) Disengage clip holding lock cylinder into out-

side handle.

(12) Pull lock cylinder from door handle.

INSTALLATION

(1) Engage clip into outside handle to hold lock

cylinder (Fig. 11).

(2) With link arm toward rear of vehicle, push lock

cylinder into door handle until clip snaps into place.

(3) Insert lock linkage into door latch.

(4) Engage clip to hold door lock linkage to latch.

(5) Insert latch linkage into door latch.

(6) Engage clip to hold door latch linkage to latch.

(7) Install push in fasteners attaching VTSS

switch harness to inner door reinforcement bar, if

equipped.

(8) Connect VTSS switch connector into door har-

ness, if equipped.

(9) Verify door latch operation.

(10) Install watershield and door trim panel.

Fig. 10 DOOR LATCH STRIKER

1 - B-PILLAR

2 - SHIM

3 - DOOR LATCH STRIKER

RSDOOR - FRONT23-19

LATCH (Continued)

Page 2132 of 2585

(4) Place front door trim panel in position on door.

(5) Install trim panel into inner belt molding at

top of door.

(6) Install clips to attach door trim to door frame

around perimeter of panel.

(7) If equipped, install screw to attach door trim to

door panel behind inside latch release handle.

(8) If equipped, connect power switch into wire

connector.

(9) Place power accessary switch in position on

door trim.

(10) Connect wire connector into memory seat/mir-

ror switch and install switch into trim panel.

(11) Install screws to attach accessary switch

panel to door trim.

(12) Install screw cover into switch panel.

(13) If equipped, install window crank.

(14) If equipped, install screws to attach trim

panel to door inside map pocket.

(15) If equipped, install screw to attach door pull

cup to inner door panel.

(16) If equipped, install screws to attach door

assist handle to inner door panel.

(17) Connect wire connector into courtesy lamp.

(18) Install lamp in door trim.

(19) Install switch bezel.

WATERSHIELD

REMOVAL

(1) Remove door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL)

(2) Remove the front door speaker. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

INSTALLATION

(1) Insure that enough adhesive remains to

securely retain the water dam. Replace as necessary.

(2) Place the shield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(3) Install the front door speaker. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - INSTALLATION)

(4) Install door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

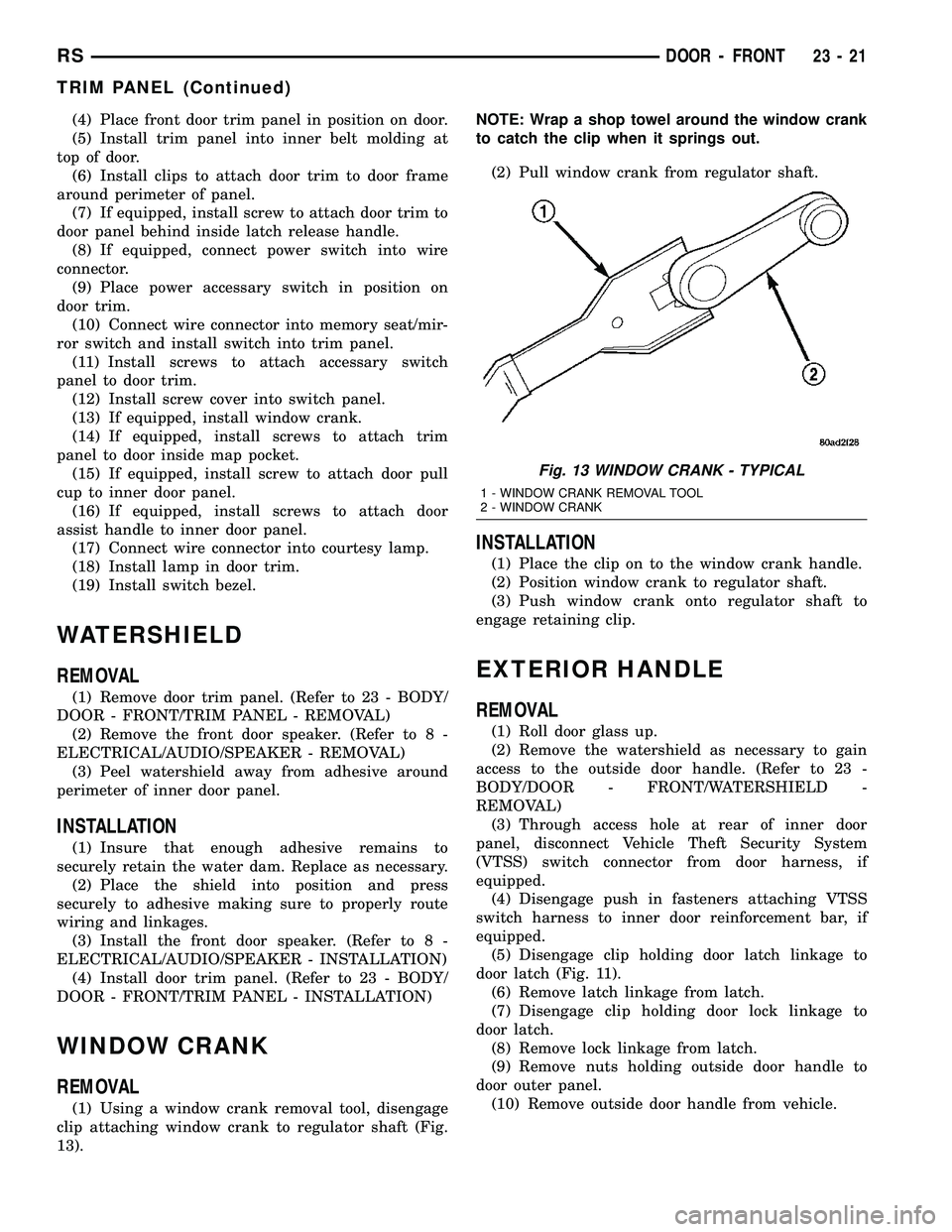

WINDOW CRANK

REMOVAL

(1) Using a window crank removal tool, disengage

clip attaching window crank to regulator shaft (Fig.

13).NOTE: Wrap a shop towel around the window crank

to catch the clip when it springs out.

(2) Pull window crank from regulator shaft.

INSTALLATION

(1) Place the clip on to the window crank handle.

(2) Position window crank to regulator shaft.

(3) Push window crank onto regulator shaft to

engage retaining clip.

EXTERIOR HANDLE

REMOVAL

(1) Roll door glass up.

(2) Remove the watershield as necessary to gain

access to the outside door handle. (Refer to 23 -

BODY/DOOR - FRONT/WATERSHIELD -

REMOVAL)

(3) Through access hole at rear of inner door

panel, disconnect Vehicle Theft Security System

(VTSS) switch connector from door harness, if

equipped.

(4) Disengage push in fasteners attaching VTSS

switch harness to inner door reinforcement bar, if

equipped.

(5) Disengage clip holding door latch linkage to

door latch (Fig. 11).

(6) Remove latch linkage from latch.

(7) Disengage clip holding door lock linkage to

door latch.

(8) Remove lock linkage from latch.

(9) Remove nuts holding outside door handle to

door outer panel.

(10) Remove outside door handle from vehicle.

Fig. 13 WINDOW CRANK - TYPICAL

1 - WINDOW CRANK REMOVAL TOOL

2 - WINDOW CRANK

RSDOOR - FRONT23-21

TRIM PANEL (Continued)

Page 2143 of 2585

(4) If the sliding door is low at the C-post;

(a) Open the door to mid-point of travel.

(b) Mark outline of center hinge on sliding door

to assist in making adjustments.

(c) Adjust the adjustment bolt up or down to

move the door position. (Fig. 14).

(d) Move hinge downward to raise the door.

(e) Tighten center hinge bolts.

(f) Verify alignment adjust as necessary.

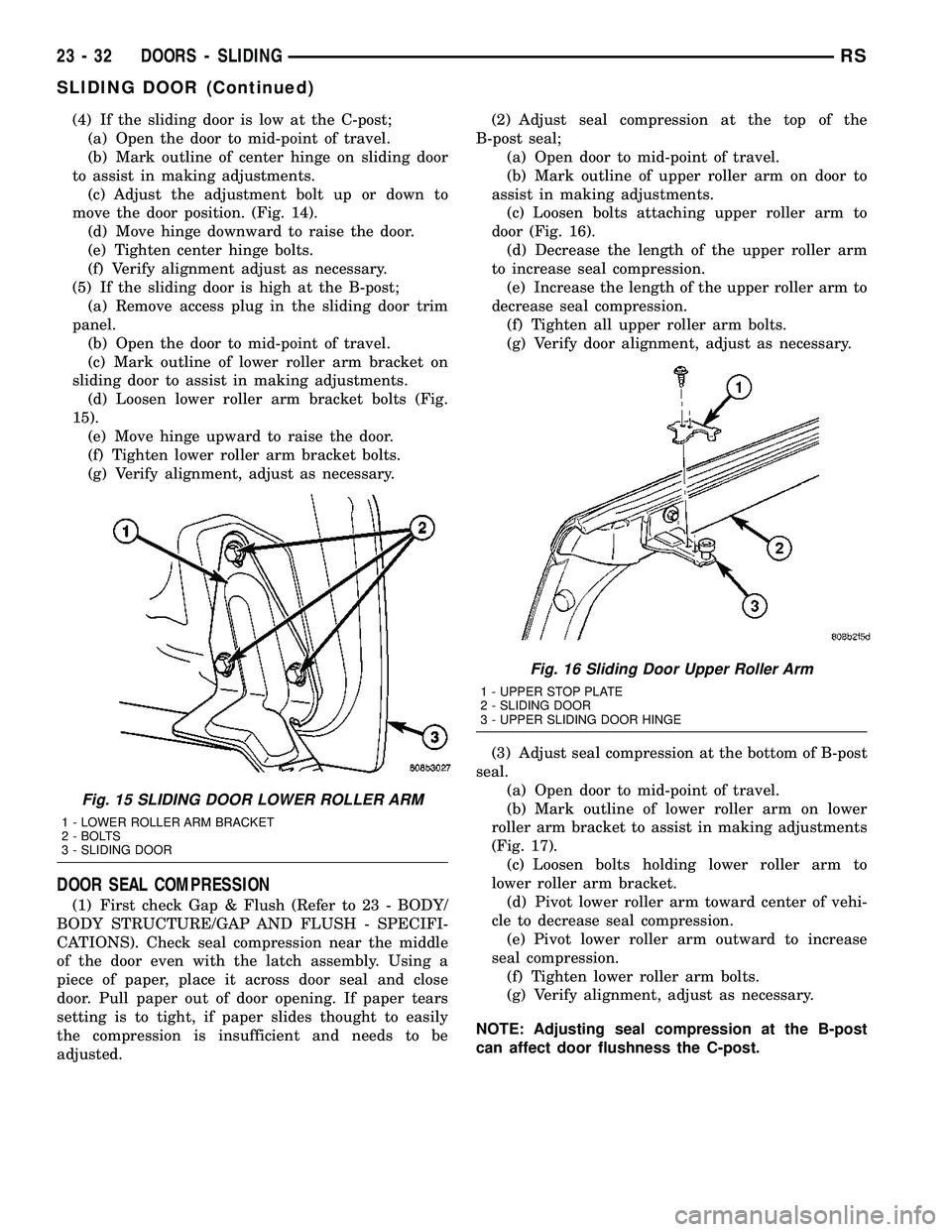

(5) If the sliding door is high at the B-post;

(a) Remove access plug in the sliding door trim

panel.

(b) Open the door to mid-point of travel.

(c) Mark outline of lower roller arm bracket on

sliding door to assist in making adjustments.

(d) Loosen lower roller arm bracket bolts (Fig.

15).

(e) Move hinge upward to raise the door.

(f) Tighten lower roller arm bracket bolts.

(g) Verify alignment, adjust as necessary.

DOOR SEAL COMPRESSION

(1) First check Gap & Flush (Refer to 23 - BODY/

BODY STRUCTURE/GAP AND FLUSH - SPECIFI-

CATIONS). Check seal compression near the middle

of the door even with the latch assembly. Using a

piece of paper, place it across door seal and close

door. Pull paper out of door opening. If paper tears

setting is to tight, if paper slides thought to easily

the compression is insufficient and needs to be

adjusted.(2) Adjust seal compression at the top of the

B-post seal;

(a) Open door to mid-point of travel.

(b) Mark outline of upper roller arm on door to

assist in making adjustments.

(c) Loosen bolts attaching upper roller arm to

door (Fig. 16).

(d) Decrease the length of the upper roller arm

to increase seal compression.

(e) Increase the length of the upper roller arm to

decrease seal compression.

(f) Tighten all upper roller arm bolts.

(g) Verify door alignment, adjust as necessary.

(3) Adjust seal compression at the bottom of B-post

seal.

(a) Open door to mid-point of travel.

(b) Mark outline of lower roller arm on lower

roller arm bracket to assist in making adjustments

(Fig. 17).

(c) Loosen bolts holding lower roller arm to

lower roller arm bracket.

(d) Pivot lower roller arm toward center of vehi-

cle to decrease seal compression.

(e) Pivot lower roller arm outward to increase

seal compression.

(f) Tighten lower roller arm bolts.

(g) Verify alignment, adjust as necessary.

NOTE: Adjusting seal compression at the B-post

can affect door flushness the C-post.

Fig. 15 SLIDING DOOR LOWER ROLLER ARM

1 - LOWER ROLLER ARM BRACKET

2 - BOLTS

3 - SLIDING DOOR

Fig. 16 Sliding Door Upper Roller Arm

1 - UPPER STOP PLATE

2 - SLIDING DOOR

3 - UPPER SLIDING DOOR HINGE

23 - 32 DOORS - SLIDINGRS

SLIDING DOOR (Continued)

Page 2161 of 2585

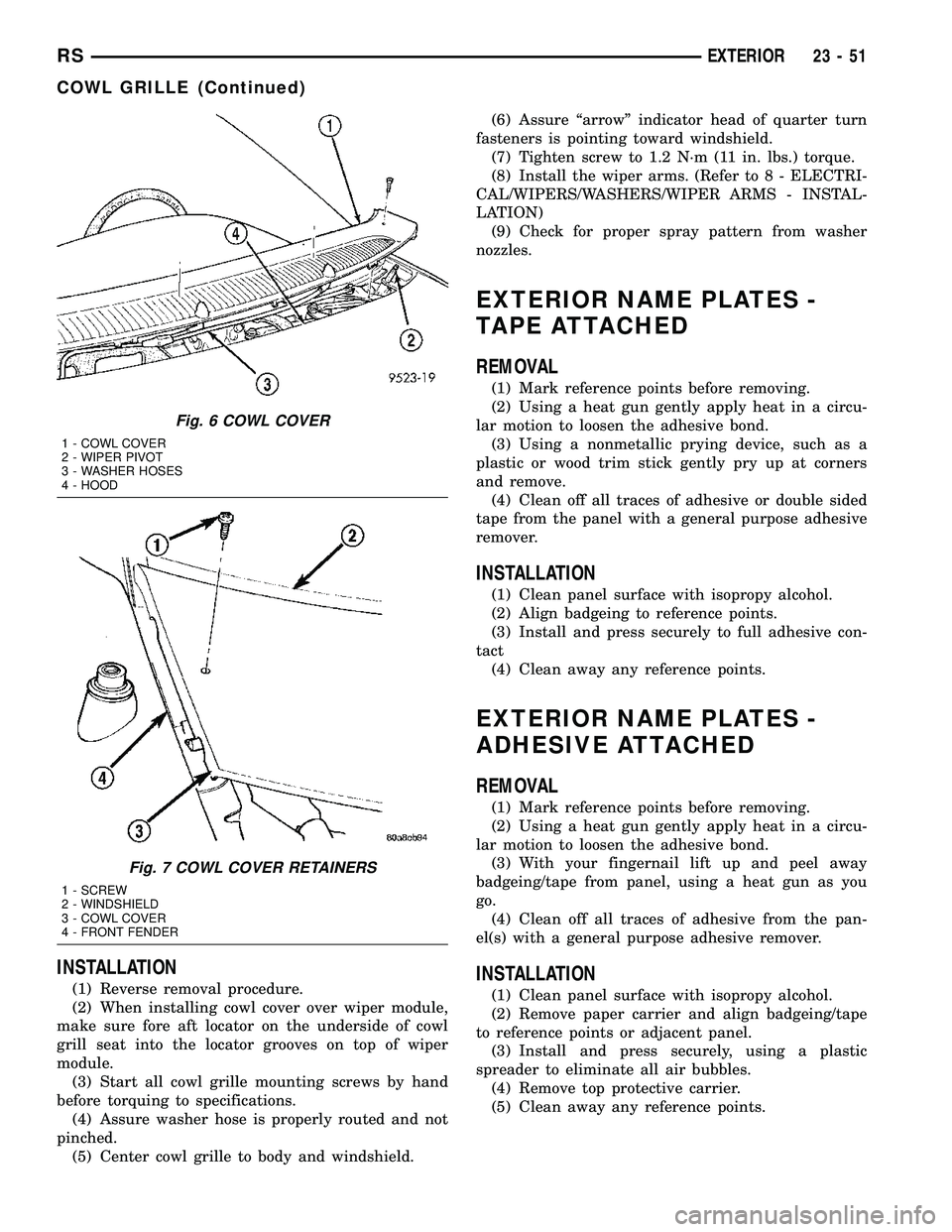

COWL GRILLE

REMOVAL

(1) Remove wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL)

(2) Remove four (4) screws securing cowl cover to

wiper module (Fig. 6).

(3) Disengage quarter turn fasteners at outboard

ends of cowl grill from body.

(4) Release hood latch and open hood.

CAUTION: To prevent hood scratching of cowl grille

before removal, cover outboard exterior ends of

cowl grille with masking tape or equivalent method.

NOTE: Do not over bend cowl grille during removal.

Bend cowl grille just enough to clear top of wiper

pivot shaft and bottom rear corner of hood.

(5) Remove cowl grill by raising above driver side

wiper pivot shaft and swinging away towards engine

compartment. The cowl grille will need to be bent onoutboard end to clear simultaneously top of wiper

pivot shaft and bottom corner of hood.

(6) Close hood. Do not latch. Remove outboard

screws. (Fig. 7).

(7) Disconnect washer hose in line connector.

(8) Disconnect washer hose and grommet from

hole in wiper module and pull out.

(9) Remove cowl grille by raising over opposite

wiper pivot shaft and removing away from vehicle.

(10) Remove cowl cover from vehicle.

Fig. 5 BODY SIDE MOLDINGS WITH APPLIQUE - TYPICAL

1 - FRONT ROCKER PANEL APPLIQUE

2 - FRONT DOOR MOLDING

3 - SLIDING DOOR MOLDING4 - REAR ROCKER PANEL APPLIQUE

5 - LIFTGATE MOLDING

6 - POP-RIVET

23 - 50 EXTERIORRS

BODY SIDE MOLDINGS (Continued)

Page 2162 of 2585

INSTALLATION

(1) Reverse removal procedure.

(2) When installing cowl cover over wiper module,

make sure fore aft locator on the underside of cowl

grill seat into the locator grooves on top of wiper

module.

(3) Start all cowl grille mounting screws by hand

before torquing to specifications.

(4) Assure washer hose is properly routed and not

pinched.

(5) Center cowl grille to body and windshield.(6) Assure ªarrowº indicator head of quarter turn

fasteners is pointing toward windshield.

(7) Tighten screw to 1.2 N´m (11 in. lbs.) torque.

(8) Install the wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - INSTAL-

LATION)

(9) Check for proper spray pattern from washer

nozzles.

EXTERIOR NAME PLATES -

TAPE ATTACHED

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) Using a nonmetallic prying device, such as a

plastic or wood trim stick gently pry up at corners

and remove.

(4) Clean off all traces of adhesive or double sided

tape from the panel with a general purpose adhesive

remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Align badgeing to reference points.

(3) Install and press securely to full adhesive con-

tact

(4) Clean away any reference points.

EXTERIOR NAME PLATES -

ADHESIVE ATTACHED

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) With your fingernail lift up and peel away

badgeing/tape from panel, using a heat gun as you

go.

(4) Clean off all traces of adhesive from the pan-

el(s) with a general purpose adhesive remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Remove paper carrier and align badgeing/tape

to reference points or adjacent panel.

(3) Install and press securely, using a plastic

spreader to eliminate all air bubbles.

(4) Remove top protective carrier.

(5) Clean away any reference points.

Fig. 6 COWL COVER

1 - COWL COVER

2 - WIPER PIVOT

3 - WASHER HOSES

4 - HOOD

Fig. 7 COWL COVER RETAINERS

1 - SCREW

2 - WINDSHIELD

3 - COWL COVER

4 - FRONT FENDER

RSEXTERIOR23-51

COWL GRILLE (Continued)

Page 2168 of 2585

INSTALLATION

NOTE: The crossbar assemblies are designed to be

installed in only one way. Check top and bottom

surfaces of the crossbar for the word FRONT and

directional arrows. The directional arrows must

point toward the front of the vehicle.

(1) Place crossbar in position on vehicle.

(2) Work from side to side sliding the crossbar

assembly back a little at a time to ensure it remains

perpendicular to the side rails.

(3) Position first crossbar assembly crossbar at the

second most rearward locator holes. Press the top of

the stanchion lever to lock it into position.

(4) Position the second crossbar assembly in the

second hole from the front. Lock into place.

(5) Place luggage rack riser into position.

(6) Install two fasteners into riser. Tighten fasten-

ers to 4 mm (35 in. lbs.) torque.

REAR QUARTER PANEL/

FENDER AIR EXHAUSTER

DESCRIPTION

Air exhausters, designed to conform to the body

structure, allow air entering at the front of the vehi-

cle to flow out the back. By reducing air pressure

within the vehicle, the exhausters also reduce blower

noise at any given air flow level compared to operat-

ing without them and help reduce door closing effort.

They are located in the lower rear comers of the

body.

REMOVAL

SHORT WHEELBASE

(1) Remove the rear fascia from the body. (Refer to

13 - FRAMES & BUMPERS/BUMPERS/REAR FAS-

CIA - REMOVAL).

(2) Using a trim stick or another suitable wide flat

bladed tool, carefully pry the air exhauster away

from the opening in the lower aperture panel until

the snap features release (Fig. 19).

(3) Remove the air exhauster from the hole in the

lower aperture panel.

LONG WHEELBASE

NOTE: Models with the optional rear heater and air

conditioner do not have an air exhauster on the

right side of the vehicle, but have a plastic plug

installed in the right lower aperture panel. This plug

is removed using the same procedure used toremove the air exhauster from the short wheelbase

model. Refer to SHORT WHEELBASE.

(1) Remove the quarter trim panel from the inside

of the left or right quarter inner panel (Refer to 23 -

BODY/INTERIOR/RIGHT QUARTER TRIM PANEL

- REMOVAL) or (Refer to 23 - BODY/INTERIOR/

LEFT QUARTER TRIM PANEL - REMOVAL).

(2) Using a trim stick or another suitable wide flat

bladed tool, carefully pry the air exhauster away

from the opening in the lower aperture panel until

the snap features release (Fig. 20).

(1) Remove the air exhauster from the hole in the

lower aperture panel.

Fig. 19 AIR EXHAUSTER - SWB

1 - LOWER APERTURE PANEL

2 - AIR EXHAUSTER

Fig. 20 AIR EXHAUSTER - LWB

1 - AIR EXHAUSTER

2 - PLUG

3 - LOWER APERTURE PANEL

RSEXTERIOR23-57

LUGGAGE RACK CROSSBAR (Continued)

Page 2173 of 2585

(8) Route cable back from latch through engine

compartment toward dash panel near power brake

booster (Fig. 5).

(9) Remove attaching clips from cable case.

(10) From inside vehicle, pull cable through dash

panel until mechanic's wire is exposed.

(11) Disconnect cable from mechanic's wire.

(12) Remove hood release cable from vehicle.

INSTALLATION

(1) Place hood release cable in position under

instrument panel.

(2) Attach latch end of hood release cable to

mechanic's wire protruding through dash panel.

(3) Route cable forward through engine compart-

ment toward latch by pulling on mechanic's wire

(Fig. 5).(4) Disconnect mechanic's wire from cable.

(5) Engage rubber grommet cable insulator into

hole in dash panel.

(6) Install hood release handle into instrument

panel.

(7) Place cable in position on latch.

(8) Slide cable case end sideways into keyhole slot

of hood latch.

(9) Engage cable end into hood latch locking mech-

anism.

(10) Install hood latch.

(11) Install attaching clips to cable case and install

clips into original holes in strut tower, fender, head-

lamp area, and radiator closure panel crossmember.

LATCH STRIKER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching striker to inside of

hood.

(3) Remove hood latch striker from vehicle.

INSTALLATION

(1) Position hood latch striker on vehicle.

(2) Install bolts attaching hood latch striker to

hood.

(3) Align hood latch striker to engage smoothly

into hood latch.

(4) Verify hood operation and alignment. Adjust as

necessary.

(5) Tighten attaching bolts to 13.5 N´m (10 ft. lbs.)

torque.Fig. 5 HOOD RELEASE CABLE ROUTING

1 - GROMMET

2 - HOOD RELEASE CABLE

3 - RADIATOR CLOSURE PANEL CROSSMEMBER

23 - 62 HOODRS

LATCH RELEASE CABLE (Continued)

Page 2177 of 2585

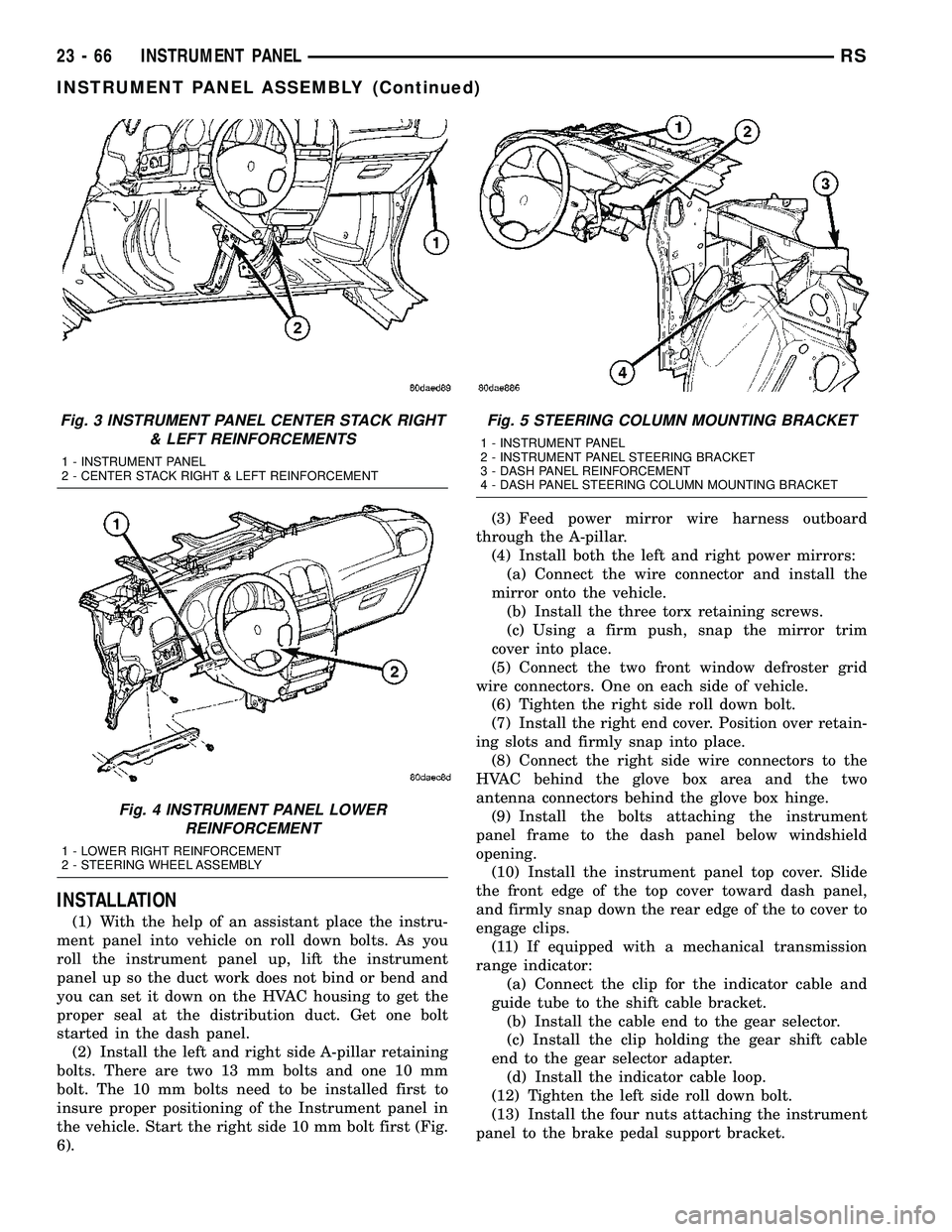

INSTALLATION

(1) With the help of an assistant place the instru-

ment panel into vehicle on roll down bolts. As you

roll the instrument panel up, lift the instrument

panel up so the duct work does not bind or bend and

you can set it down on the HVAC housing to get the

proper seal at the distribution duct. Get one bolt

started in the dash panel.

(2) Install the left and right side A-pillar retaining

bolts. There are two 13 mm bolts and one 10 mm

bolt. The 10 mm bolts need to be installed first to

insure proper positioning of the Instrument panel in

the vehicle. Start the right side 10 mm bolt first (Fig.

6).(3) Feed power mirror wire harness outboard

through the A-pillar.

(4) Install both the left and right power mirrors:

(a) Connect the wire connector and install the

mirror onto the vehicle.

(b) Install the three torx retaining screws.

(c) Using a firm push, snap the mirror trim

cover into place.

(5) Connect the two front window defroster grid

wire connectors. One on each side of vehicle.

(6) Tighten the right side roll down bolt.

(7) Install the right end cover. Position over retain-

ing slots and firmly snap into place.

(8) Connect the right side wire connectors to the

HVAC behind the glove box area and the two

antenna connectors behind the glove box hinge.

(9) Install the bolts attaching the instrument

panel frame to the dash panel below windshield

opening.

(10) Install the instrument panel top cover. Slide

the front edge of the top cover toward dash panel,

and firmly snap down the rear edge of the to cover to

engage clips.

(11) If equipped with a mechanical transmission

range indicator:

(a) Connect the clip for the indicator cable and

guide tube to the shift cable bracket.

(b) Install the cable end to the gear selector.

(c) Install the clip holding the gear shift cable

end to the gear selector adapter.

(d) Install the indicator cable loop.

(12) Tighten the left side roll down bolt.

(13) Install the four nuts attaching the instrument

panel to the brake pedal support bracket.

Fig. 3 INSTRUMENT PANEL CENTER STACK RIGHT

& LEFT REINFORCEMENTS

1 - INSTRUMENT PANEL

2 - CENTER STACK RIGHT & LEFT REINFORCEMENT

Fig. 4 INSTRUMENT PANEL LOWER

REINFORCEMENT

1 - LOWER RIGHT REINFORCEMENT

2 - STEERING WHEEL ASSEMBLY

Fig. 5 STEERING COLUMN MOUNTING BRACKET

1 - INSTRUMENT PANEL

2 - INSTRUMENT PANEL STEERING BRACKET

3 - DASH PANEL REINFORCEMENT

4 - DASH PANEL STEERING COLUMN MOUNTING BRACKET

23 - 66 INSTRUMENT PANELRS

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2187 of 2585

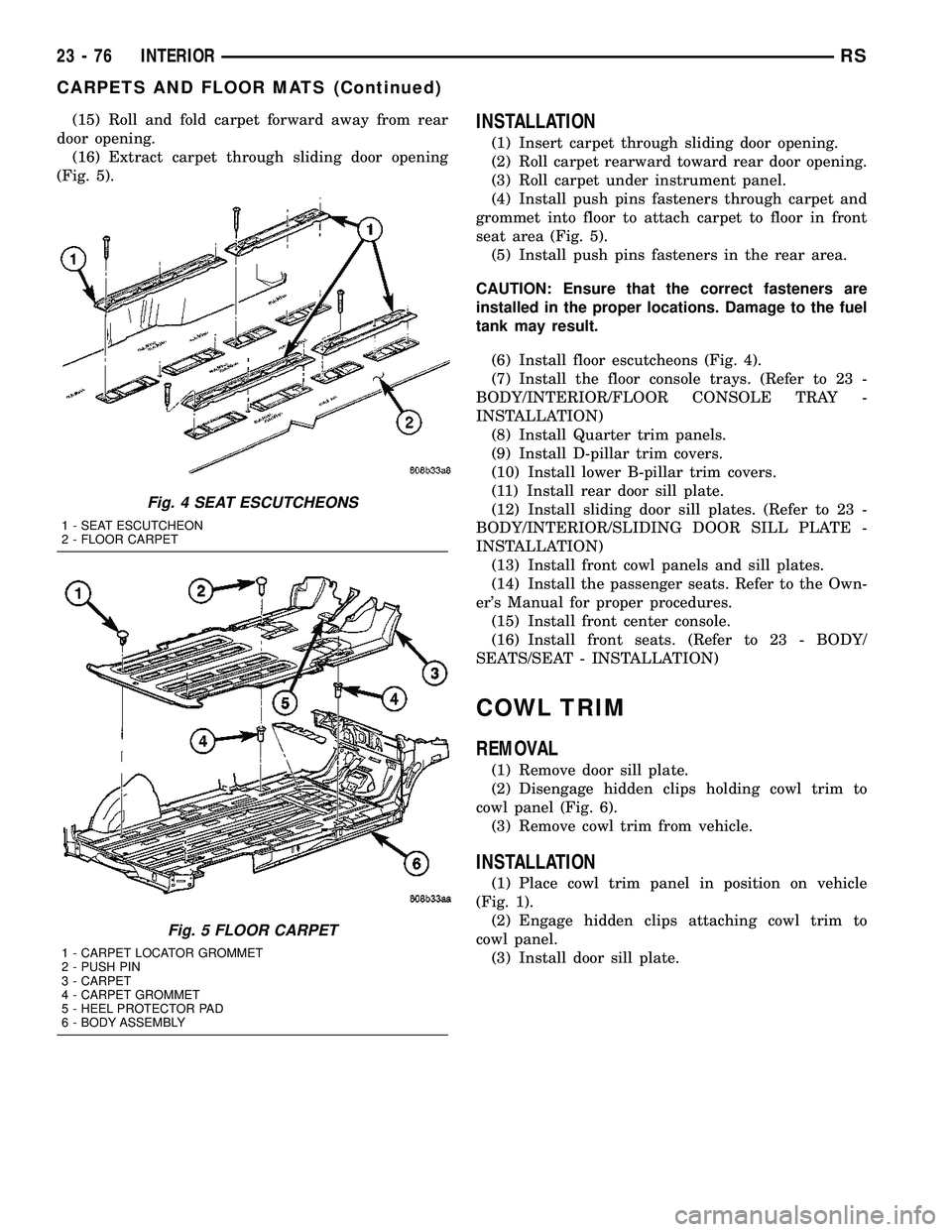

(15) Roll and fold carpet forward away from rear

door opening.

(16) Extract carpet through sliding door opening

(Fig. 5).INSTALLATION

(1) Insert carpet through sliding door opening.

(2) Roll carpet rearward toward rear door opening.

(3) Roll carpet under instrument panel.

(4) Install push pins fasteners through carpet and

grommet into floor to attach carpet to floor in front

seat area (Fig. 5).

(5) Install push pins fasteners in the rear area.

CAUTION: Ensure that the correct fasteners are

installed in the proper locations. Damage to the fuel

tank may result.

(6) Install floor escutcheons (Fig. 4).

(7) Install the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

INSTALLATION)

(8) Install Quarter trim panels.

(9) Install D-pillar trim covers.

(10) Install lower B-pillar trim covers.

(11) Install rear door sill plate.

(12) Install sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION)

(13) Install front cowl panels and sill plates.

(14) Install the passenger seats. Refer to the Own-

er's Manual for proper procedures.

(15) Install front center console.

(16) Install front seats. (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION)

COWL TRIM

REMOVAL

(1) Remove door sill plate.

(2) Disengage hidden clips holding cowl trim to

cowl panel (Fig. 6).

(3) Remove cowl trim from vehicle.

INSTALLATION

(1) Place cowl trim panel in position on vehicle

(Fig. 1).

(2) Engage hidden clips attaching cowl trim to

cowl panel.

(3) Install door sill plate.

Fig. 4 SEAT ESCUTCHEONS

1 - SEAT ESCUTCHEON

2 - FLOOR CARPET

Fig. 5 FLOOR CARPET

1 - CARPET LOCATOR GROMMET

2 - PUSH PIN

3 - CARPET

4 - CARPET GROMMET

5 - HEEL PROTECTOR PAD

6 - BODY ASSEMBLY

23 - 76 INTERIORRS

CARPETS AND FLOOR MATS (Continued)