volt CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1206 of 2585

POWERTRAIN CONTROL MODULE C2 - BLACK 38 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3- -

4 K58 16BR/VT (3.3L/3.8L) INJECTOR CONTROL NO. 6

5 K38 16BR/OR (3.3L/3.8L) INJECTOR CONTROL NO. 5

6- -

7 K18 16BR/OR (3.3L/3.8L) COIL CONTROL NO. 3

8 K35 18DB/VT (3.3L) EGR SOLENOID CONTROL

9 K17 18DB/TN IGNITION COIL NO. 2 DRIVER

10 K19 18DB/DG COIL CONTROL NO. 1

11 K14 16 BR/TN INJECTOR CONTROL NO. 4

12 K13 16BR/LB INJECTOR CONTROL NO. 3

13 K12 16BR/DB INJECTOR CONTROL NO. 2

14 K11 16BR/YL INJECTOR CONTROL NO. 1

15 - -

16 - -

17 - -

18 K99 18BR/LG O2 1/1 HEATER CONTROL

19 K20 18BR/GY GEN FIELD CONTROL

20 K2 18VT/OR ECT SIGNAL

21 K22 18BR/OR TP NO. 1 SIGNAL

22 K34 18DB/LG (3.3L) EGR SOLENOID SIGNAL

23 K1 18VT/BR MAP SIGNAL

24 K942 18BR/LG KS RETURN

25 K42 18DB/YL KNOCK SENSOR NO. 1 SIGNAL

26 - -

27 K900 18DB/DG SENSOR GROUND

28 K961 18BR/VT IAC RETURN

29 F855 20PK/YL 5 VOLT SUPPLY

30 K21 18DB/LG INTAKE AIR TEMPERATURE SENSOR SIGNAL

31 K41 18DB/LB O2 1/1 SIGNAL

32 K902 18BR/DG O2 RETURN (UP)

33 - -

34 K44 18DB/GY CMP SIGNAL

35 K24 18BR/LB CKP SIGNAL

36 - -

37 - -

38 K61 18VT/GY IAC MOTOR CONTROL

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 111

Page 1211 of 2585

RADIO C1 - 22 WAY

CAV CIRCUIT FUNCTION

1 A114 16GY/RD FUSED B(+) (I.O.D.)

2 F306 18DB/PK FUSED ACCESSORY RELAY OUTPUT

3 E14 20OR/TN PANEL LAMPS DRIVER

4- -

5- -

6- -

7 X54 20GY (EXCEPT LOWLINE 1) RIGHT FRONT SPEAKER (+)

7 X154 20GY/YL (LOWLINE 1) RIGHT INSTRUMENT PANEL SPEAKER (+)

8 X56 20GY/BR (EXCEPT LOWLINE 1) RIGHT FRONT SPEAKER (-)

8 X156 20GY/LB (LOWLINE 1) RIGHT INSTRUMENT PANEL SPEAKER (-)

9 X55 20DG/BR (EXCEPT LOWLINE 1) LEFT FRONT SPEAKER (-)

9 X155 20DG/LB (LOWLINE 1) LEFT INSTRUMENT PANEL SPEAKER (-)

10 X53 20DG (EXCEPT LOWLINE 1) LEFT FRONT SPEAKER (+)

10 X153 20DG/YL (LOWLINE 1) LEFT INSTRUMENT PANEL SPEAKER (+)

11 Z514 16BK/LG GROUND

12 A114 16GY/RD FUSED B(+) (I.O.D.)

13 X60 20GY/YL RADIO 12 VOLT OUTPUT

14 D25 20WT/VT PCI BUS

15 - -

16 - -

17 - -

18 X51 22DG/DB LEFT REAR SPEAKER (+)

19 X57 22DG/OR LEFT REAR SPEAKER (-)

20 X58 22GY/OR RIGHT REAR SPEAKER (-)

21 X52 22GY/DB RIGHT REAR SPEAKER (+)

22 Z515 16BK GROUND

RADIO C2 (CD CHANGER)-8WAY

CAV CIRCUIT FUNCTION

1 X40 22GY/WT (EXCEPT EXPORT) AUDIO OUT RIGHT

1 X40 20GY/WT (EXPORT) AUDIO OUT RIGHT

2 X140 22GY/OR (EXCEPT EXPORT) COMMON AUDIO

2 Z140 18BK/OR (EXPORT) GROUND

3 X235 20GY/LB (EXCEPT EXPORT) SHIELD

4 D25 20WT/VT (EXCEPT EXPORT) PCI BUS

4 D25 20VT/YL (EXPORT) PCI BUS

5 X112 20DG/GY (EXCEPT EXPORT) IGNITION SWITCH SIGNAL

5 X112 20RD (EXPORT) IGNITION SWITCH SIGNAL

6 X41 22DG/WT (EXCEPT EXPORT) AUDIO OUT LEFT

6 X41 20DG/WT (EXPORT) AUDIO OUT LEFT

7 Z141 20BK/TN (EXCEPT EXPORT) GROUND

7 Z141 18BK/TN (EXPORT) GROUND

8- -

9 E14 22OR/TN (EXCEPT EXPORT) PANEL LAMPS DRIVER

9 E14 18OR/TN (EXPORT) PANEL LAMPS DRIVER

10 X160 20GY/YL FUSED B(+)

8W - 80 - 116 8W-80 CONNECTOR PIN-OUTSRS

Page 1214 of 2585

REAR BLOWER REAR CONTROL SWITCH C2 (3 ZONE MTC) - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1- -

2 C22 20LB/DB REAR TEMPERATURE FEEDBACK SIGNAL

3 E10 20OR/DG PANEL LAMPS DRIVER

4 F850 20LB/PK 5 VOLT SUPPLY

5 C121 20DB/DG REAR TEMPERATURE RETURN

6 Z409 20BK/OR GROUND

REAR DOME LAMP (EXCEPT LUXURY) - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 M22 20YL/OR COURTESY LAMPS DRIVER

2 Z327 20BK/OR GROUND

3- -

REAR INTRUSION SENSOR (UNITED KINGDOM)-3WAY

CAV CIRCUIT FUNCTION

1 A645 20RD/VT REAR INTRUSION SENSOR SIGNAL

2- -

3 G945 20VT/DG SENSOR GROUND

REAR MODE MOTOR (3 ZONE ATC) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 C154 18LB/GY REAR MODE DOOR DRIVER (B)

2 C53 18LB REAR MODE DOOR DRIVER (A)

REAR POWER OUTLET - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 F307 18LB/PK (ACCESSORY RELAY

POSITION)FUSED ACCESSORY RELAY OUTPUT

1 F307 18LB/PK (BATTERY POSITION) FUSED B(+)

2- -

3 Z737 18BK/LB GROUND

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 119

Page 1218 of 2585

RIGHT FRONT PARK/TURN SIGNAL LAMP (EXCEPT EXPORT) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 L60 18WT/TN RIGHT FRONT TURN SIGNAL DRIVER

2 L78 18WT/OR FUSED PARK LAMP RELAY OUTPUT (RIGHT)

3 Z378 18BK/TN GROUND

RIGHT FRONT WHEEL SPEED SENSOR - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 B7 18DG/VT RIGHT FRONT WHEEL SPEED SENSOR 12 VOLT

SUPPLY

2 B6 18DG/WT RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

RIGHT FULL OPEN SWITCH (POWER SLIDING DOOR) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q52 20OR RIGHT FULL OPEN SWITCH SENSE

2 Z76 20BK/YL GROUND

RIGHT HEADLAMP (EXCEPT EXPORT) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 L44 16WT/TN RIGHT LOW BEAM DRIVER

2 Z344 16BK/TN GROUND

3 L34 16WT/GY RIGHT HIGH BEAM DRIVER

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 123

Page 1222 of 2585

RIGHT REAR SPEAKER (LOWLINE)-3WAY

CAV CIRCUIT FUNCTION

1 X58 20GY/OR RIGHT REAR SPEAKER (-)

2- -

3 X52 20GY/DB RIGHT REAR SPEAKER (+)

RIGHT REAR VENT MOTOR - NATURAL 3 WAY

CAV CIRCUIT FUNCTION

1- -

2 Q14 16OR/BR (LHD EXCEPT EXPORT) PASSENGER SIDE REAR WINDOW CLOSE

2 Q14 16OR/BR (LHD EXPORT) PASSENGER SIDE REAR WINDOW CLOSE

2 Q13 16OR/DB (RHD) DRIVER SIDE REAR WINDOW CLOSE

3 Q24 16OR/DG (LHD) PASSENGER SIDE REAR WINDOW OPEN

3 Q23 16OR/LB (RHD) DRIVER SIDE REAR WINDOW OPEN

RIGHT REAR WHEEL SPEED SENSOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 B2 18DG/LB RIGHT REAR WHEEL SPEED SENSOR 12 VOLT SUP-

PLY

2 B1 18DG/OR RIGHT REAR WHEEL SPEED SENSOR SIGNAL

RIGHT REMOTE RADIO SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X10 22RD/DB RADIO CONTROL MUX

2 X20 22RD/BK RADIO CONTROL MUX RETURN

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 127

Page 1228 of 2585

THROTTLE POSITION SENSOR (GAS) - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 K900 18DB/DG SENSOR GROUND

2 K22 18BR/OR TP NO. 1 SIGNAL

3 F855 20PK/YL (2.4L) 5 VOLT SUPPLY

3 F855 18PK/YL (3.3L/3.8L) 5 VOLT SUPPLY

TRACTION CONTROL SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 B27 20DG/WT TRACTION CONTROL SWITCH SENSE

2 Z427 20BK/WT GROUND

TRAILER TOW CONNECTOR (EXCEPT EXPORT)-4WAY

CAV CIRCUIT FUNCTION

1 L62 18LG RIGHT REAR TURN SIGNAL DRIVER

2 Z362 18WT GROUND

3 L77 18BR FUSED PARK LAMP RELAY OUTPUT (LEFT)

4 L63 18YL LEFT REAR TURN SIGNAL DRIVER

TRANSMISSION RANGE SENSOR - DK. GRAY 10 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3 T13 18DG/VT SPEED SENSOR GROUND

4 T54 18DG/OR TRANSMISSION TEMPERATURE SENSOR SIGNAL

5- -

6- -

7 T1 18DG/LB TRS T1 SENSE

8 T3 18DG/DB TRS T3 SENSE

9 T42 18DG/YL TRS T42 SENSE

10 T41 18DG/GY TRS T41 SENSE

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 133

Page 1229 of 2585

TRANSMISSION SOLENOID/PRESSURE SWITCH ASSEMBLY - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1 T47 18YL/DG 2-4 PRESSURE SWITCH SENSE

2 T50 18YL/TN LOW/REVERSE PRESSURE SWITCH SENSE

3 T9 18DG/TN OVERDRIVE PRESSURE SWITCH SENSE

4 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

5 T59 18YL/LB UNDERDRIVE SOLENOID CONTROL

6 T60 18YL/GY OVERDRIVE SOLENOID CONTROL

7 T20 18DG/WT LOW/REVERSE SOLENOID CONTROL

8 T19 18YL/DB 2-4 SOLENOID CONTROL

VEHICLE SPEED SENSOR (MTX) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 F855 20PK/YL (2.4L) 5 VOLT SUPPLY

1 F202 18PK/GY (DIESEL) FUSED IGNITION SWITCH OUTPUT (RUN-START)

2 K900 18DB/DG (2.4L) SENSOR GROUND

2 K900 20DB/DG (DIESEL) SENSOR GROUND

3 N7 18DB/OR (2.4L) VEHICLE SPEED SIGNAL

3 N7 20DB/OR (DIESEL) VEHICLE SPEED SENSOR SIGNAL

WASHER FLUID LEVEL SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z401 18BK/LB (EXCEPT EXPORT) GROUND

1 Z401 20BK/LB (EXPORT) GROUND

2 W1 18BR/TN WASHER FLUID LEVEL SWITCH SENSE

WASHER PUMP MOTOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 W20 18BR/YL REAR WASHER PUMP MOTOR CONTROL

2 W10 18BR FRONT WASHER PUMP MOTOR CONTROL

8W - 80 - 134 8W-80 CONNECTOR PIN-OUTSRS

Page 1293 of 2585

INTEGRATED POWER MODULE

DESCRIPTION

The Integrated Power Module (IPM) is a combina-

tion of the Power Distribution Center (PDC) and the

Front Control Module (FCM). The IPM is located in

the engine compartment, next to the battery on this

model (Fig. 1). The power distribution center mates

directly with the Front Control Module (FCM) to

form the IPM Fuse and Relay Center. The power dis-

tribution center (PDC) is a printed circuit board

based module that contains fuses and relays, while

the front control module contains the electronics con-

trolling the IPM and other functions. This IPM con-

nects directly to the battery positive via a four pin

connector. The ground connection is via two other

connectors. The IPM provides the primary means of

voltage distribution and protection for the entire

vehicle.

The molded plastic IPM housing includes a base

and cover. The IPM cover is easily opened or removed

for service access by squeezing the two marked cover

latches and has a fuse and relay layout map integral

to the inside surface of the cover. This IPM housing

base and cover are secured in place by an IPM

mounting bracket. This mounting bracket is designed

to allow the IPM to rotate counter-clockwise once the

locking tab is disengaged. The IPM mounting bracketis secured in place by bolts threaded into the left

front wheel house.

OPERATION

All of the current from the battery and the gener-

ator output enters the Integrated Power Module

(IPM) via a four- pin connector on the bottom of the

module. The IPM cover is unlatched and opened or

removed to access the fuses or relays. Internal con-

nections of all of the power distribution center cir-

cuits is accomplished by a combination of bus bars

and a printed circuit board. Refer to the Wiring sec-

tion of the service manual for complete IPM circuit

schematics.

REMOVAL

(1) Disconnect the negative and positive battery

cables.

(2) Remove the battery thermal guard from the

vehicle. Refer to the Battery section for the proce-

dure.

(3) Remove the battery from the vehicle. Refer to

the Battery section for the procedure.

(4) Using a flat-bladed screwdriver, twist the Inte-

grated Power Module (IPM) bracket retaining latch

outward to free the intelligent power module from its

mounting bracket (Fig. 2).

(5) Rotate the IPM counter-clockwise to access and

disconnect the various electrical connectors (Fig. 3).

(6) Free the IPM from its mounting bracket by

removing the IPM bracket clips from the hinge. A

screwdriver slipped up from under the hinge will free

the clips.

Fig. 1 BATTERY THERMAL GUARD

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

Fig. 2 RELEASING INTEGRATED POWER MODULE

FROM ITS MOUNTING BRACKET

8W - 97 - 2 8W-97 POWER DISTRIBUTION SYSTEMRS

Page 1295 of 2585

POWER OUTLET

DESCRIPTION

Accessory power outlets are standard equipment on

this model. Two power outlets are installed in the

instrument panel center lower bezel, which is located

near the bottom of the instrument panel center stack

area. Two additional power outlets are also incorpo-

rated into the vehicle, one on the left rear C-pillar

trim and the other in the center console, if equipped.

The power outlets bases are secured by a snap fit in

the appropriate bezels. A hinged plug flips closed to

conceal and protect the power outlet base when the

power outlet is not being used.

The power outlet receptacle unit and the power

outlet plugs are each available for service replace-

ment.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the on position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

For complete circuit diagrams, refer toCigar

Lighter/Power Outletin Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the IPM. If OK, go to Step 3. If not OK, repair the

open fused B(+) circuit to the IPM fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

outlet receptacle and a good ground. There should be

continuity. If OK, go to Step 4. If not OK, go to Step

5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the appropriate bezel. Check for conti-

nuity between the ground circuit cavity of the power

outlet wire harness connector and a good ground.

There should be continuity. If OK, go to Step 6. If not

OK, repair the open ground circuit to ground as

required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the IPM fuse as

required.

8W - 97 - 4 8W-97 POWER DISTRIBUTION SYSTEMRS

Page 1296 of 2585

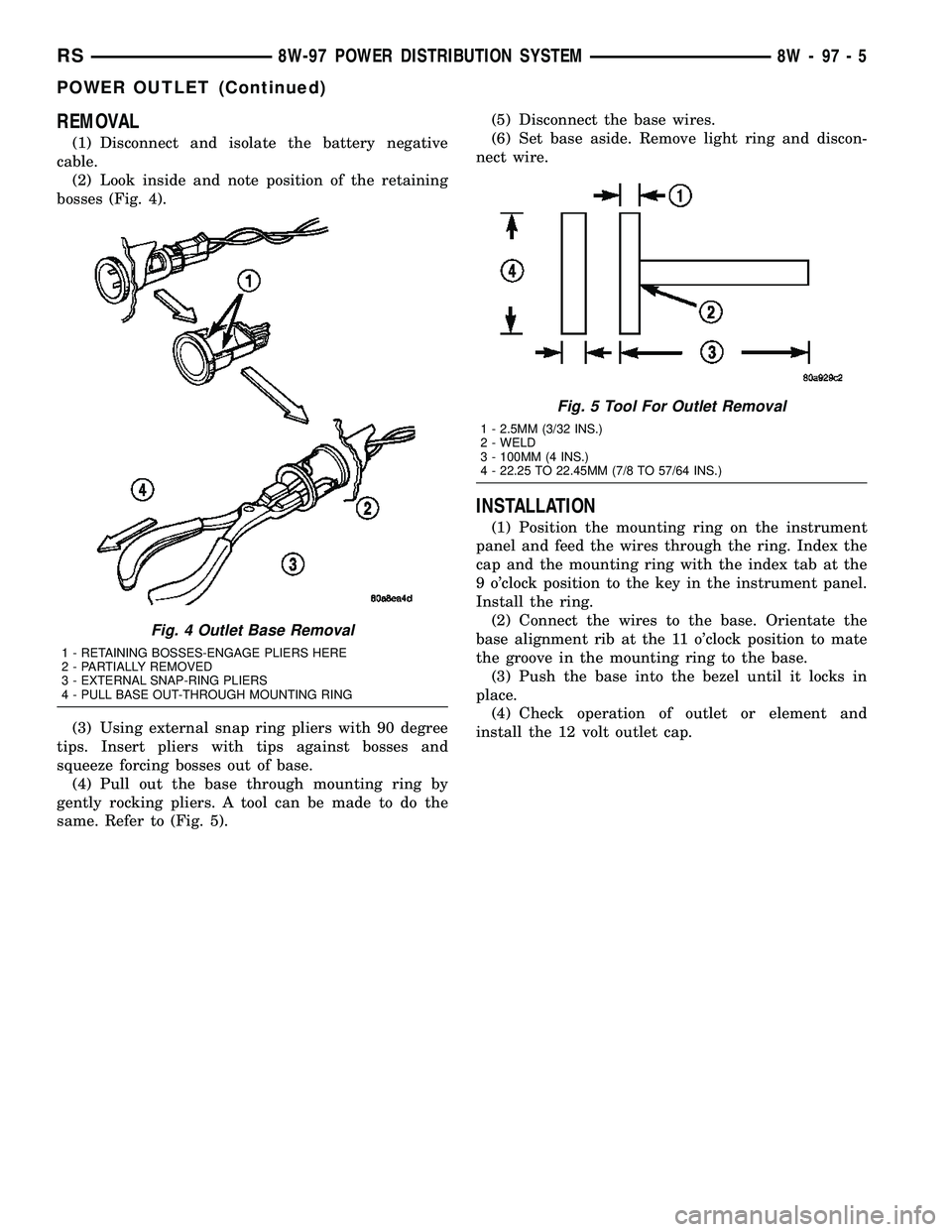

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Look inside and note position of the retaining

bosses (Fig. 4).

(3) Using external snap ring pliers with 90 degree

tips. Insert pliers with tips against bosses and

squeeze forcing bosses out of base.

(4) Pull out the base through mounting ring by

gently rocking pliers. A tool can be made to do the

same. Refer to (Fig. 5).(5) Disconnect the base wires.

(6) Set base aside. Remove light ring and discon-

nect wire.

INSTALLATION

(1) Position the mounting ring on the instrument

panel and feed the wires through the ring. Index the

cap and the mounting ring with the index tab at the

9 o'clock position to the key in the instrument panel.

Install the ring.

(2) Connect the wires to the base. Orientate the

base alignment rib at the 11 o'clock position to mate

the groove in the mounting ring to the base.

(3) Push the base into the bezel until it locks in

place.

(4) Check operation of outlet or element and

install the 12 volt outlet cap.

Fig. 4 Outlet Base Removal

1 - RETAINING BOSSES-ENGAGE PLIERS HERE

2 - PARTIALLY REMOVED

3 - EXTERNAL SNAP-RING PLIERS

4 - PULL BASE OUT-THROUGH MOUNTING RING

Fig. 5 Tool For Outlet Removal

1 - 2.5MM (3/32 INS.)

2 - WELD

3 - 100MM (4 INS.)

4 - 22.25 TO 22.45MM (7/8 TO 57/64 INS.)

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-5

POWER OUTLET (Continued)