instrument panel CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2186 of 2585

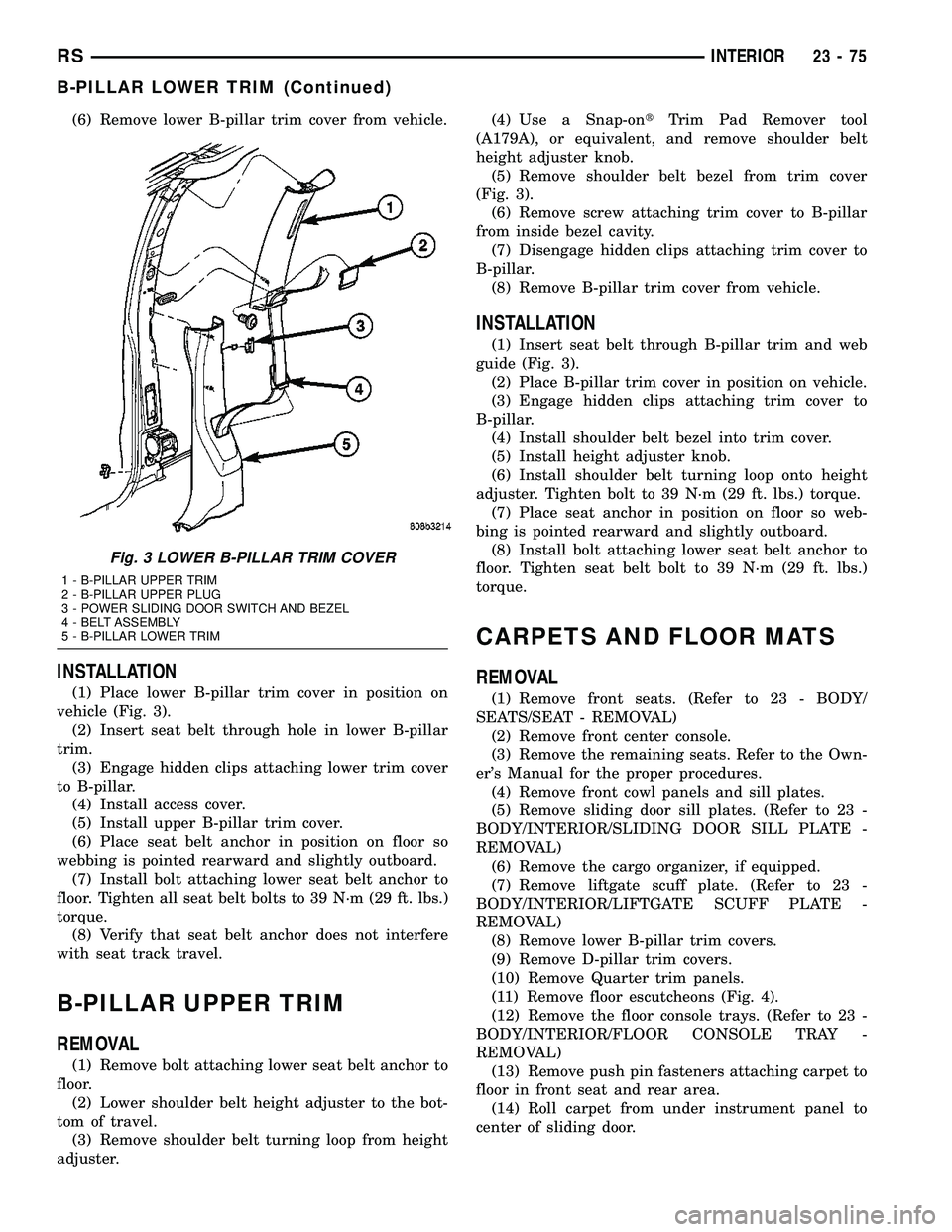

(6) Remove lower B-pillar trim cover from vehicle.

INSTALLATION

(1) Place lower B-pillar trim cover in position on

vehicle (Fig. 3).

(2) Insert seat belt through hole in lower B-pillar

trim.

(3) Engage hidden clips attaching lower trim cover

to B-pillar.

(4) Install access cover.

(5) Install upper B-pillar trim cover.

(6) Place seat belt anchor in position on floor so

webbing is pointed rearward and slightly outboard.

(7) Install bolt attaching lower seat belt anchor to

floor. Tighten all seat belt bolts to 39 N´m (29 ft. lbs.)

torque.

(8) Verify that seat belt anchor does not interfere

with seat track travel.

B-PILLAR UPPER TRIM

REMOVAL

(1) Remove bolt attaching lower seat belt anchor to

floor.

(2) Lower shoulder belt height adjuster to the bot-

tom of travel.

(3) Remove shoulder belt turning loop from height

adjuster.(4) Use a Snap-ontTrim Pad Remover tool

(A179A), or equivalent, and remove shoulder belt

height adjuster knob.

(5) Remove shoulder belt bezel from trim cover

(Fig. 3).

(6) Remove screw attaching trim cover to B-pillar

from inside bezel cavity.

(7) Disengage hidden clips attaching trim cover to

B-pillar.

(8) Remove B-pillar trim cover from vehicle.

INSTALLATION

(1) Insert seat belt through B-pillar trim and web

guide (Fig. 3).

(2) Place B-pillar trim cover in position on vehicle.

(3) Engage hidden clips attaching trim cover to

B-pillar.

(4) Install shoulder belt bezel into trim cover.

(5) Install height adjuster knob.

(6) Install shoulder belt turning loop onto height

adjuster. Tighten bolt to 39 N´m (29 ft. lbs.) torque.

(7) Place seat anchor in position on floor so web-

bing is pointed rearward and slightly outboard.

(8) Install bolt attaching lower seat belt anchor to

floor. Tighten seat belt bolt to 39 N´m (29 ft. lbs.)

torque.

CARPETS AND FLOOR MATS

REMOVAL

(1) Remove front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL)

(2) Remove front center console.

(3) Remove the remaining seats. Refer to the Own-

er's Manual for the proper procedures.

(4) Remove front cowl panels and sill plates.

(5) Remove sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(6) Remove the cargo organizer, if equipped.

(7) Remove liftgate scuff plate. (Refer to 23 -

BODY/INTERIOR/LIFTGATE SCUFF PLATE -

REMOVAL)

(8) Remove lower B-pillar trim covers.

(9) Remove D-pillar trim covers.

(10) Remove Quarter trim panels.

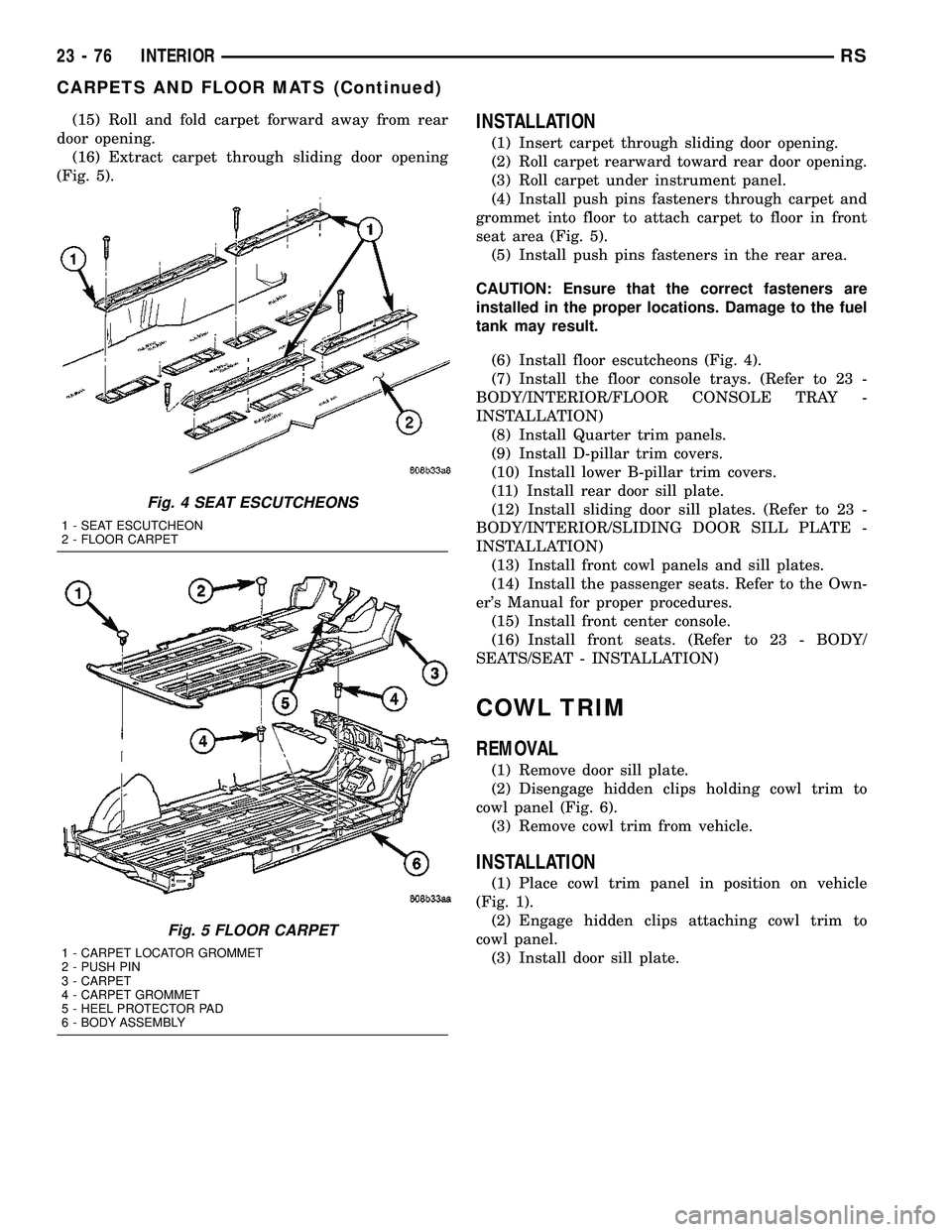

(11) Remove floor escutcheons (Fig. 4).

(12) Remove the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

REMOVAL)

(13) Remove push pin fasteners attaching carpet to

floor in front seat and rear area.

(14) Roll carpet from under instrument panel to

center of sliding door.

Fig. 3 LOWER B-PILLAR TRIM COVER

1 - B-PILLAR UPPER TRIM

2 - B-PILLAR UPPER PLUG

3 - POWER SLIDING DOOR SWITCH AND BEZEL

4 - BELT ASSEMBLY

5 - B-PILLAR LOWER TRIM

RSINTERIOR23-75

B-PILLAR LOWER TRIM (Continued)

Page 2187 of 2585

(15) Roll and fold carpet forward away from rear

door opening.

(16) Extract carpet through sliding door opening

(Fig. 5).INSTALLATION

(1) Insert carpet through sliding door opening.

(2) Roll carpet rearward toward rear door opening.

(3) Roll carpet under instrument panel.

(4) Install push pins fasteners through carpet and

grommet into floor to attach carpet to floor in front

seat area (Fig. 5).

(5) Install push pins fasteners in the rear area.

CAUTION: Ensure that the correct fasteners are

installed in the proper locations. Damage to the fuel

tank may result.

(6) Install floor escutcheons (Fig. 4).

(7) Install the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

INSTALLATION)

(8) Install Quarter trim panels.

(9) Install D-pillar trim covers.

(10) Install lower B-pillar trim covers.

(11) Install rear door sill plate.

(12) Install sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION)

(13) Install front cowl panels and sill plates.

(14) Install the passenger seats. Refer to the Own-

er's Manual for proper procedures.

(15) Install front center console.

(16) Install front seats. (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION)

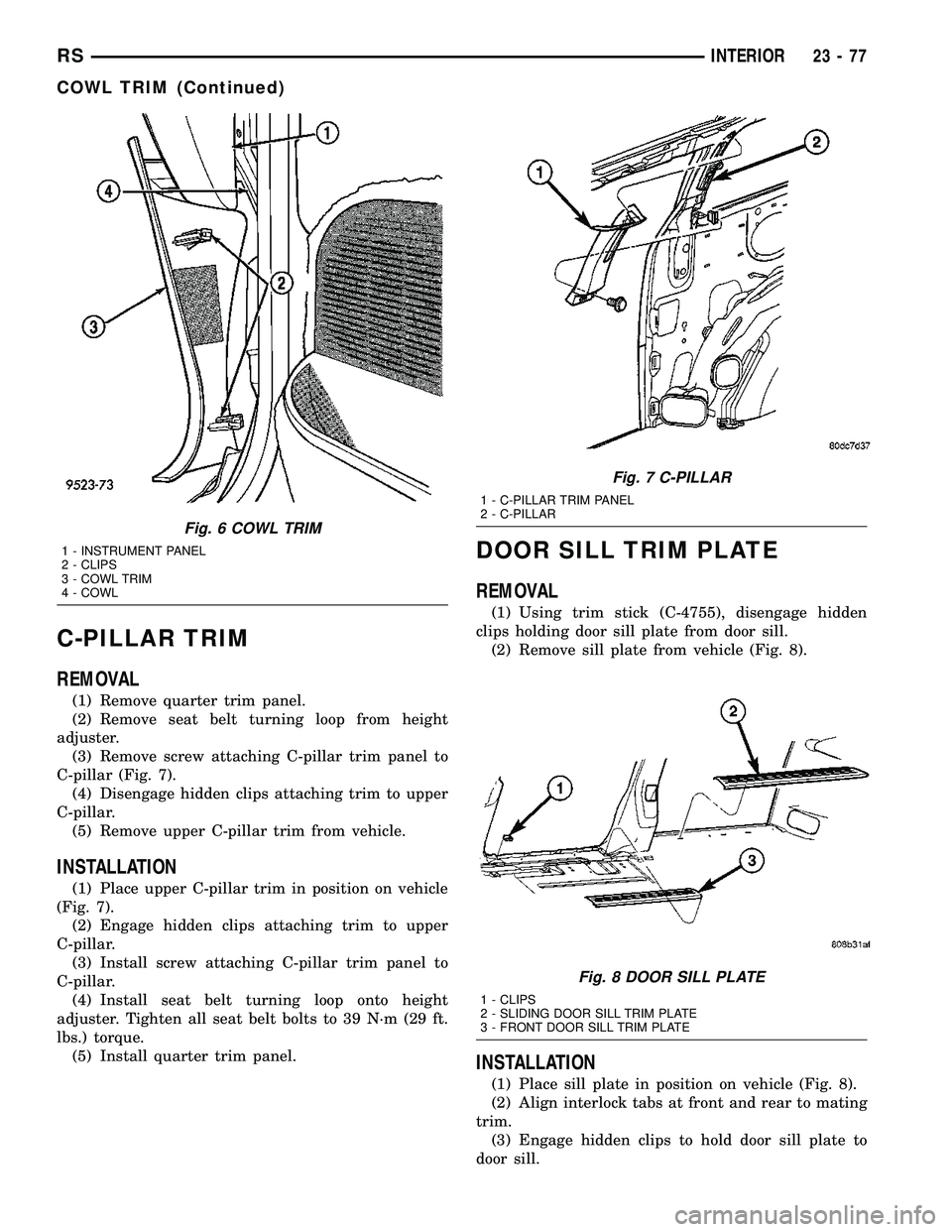

COWL TRIM

REMOVAL

(1) Remove door sill plate.

(2) Disengage hidden clips holding cowl trim to

cowl panel (Fig. 6).

(3) Remove cowl trim from vehicle.

INSTALLATION

(1) Place cowl trim panel in position on vehicle

(Fig. 1).

(2) Engage hidden clips attaching cowl trim to

cowl panel.

(3) Install door sill plate.

Fig. 4 SEAT ESCUTCHEONS

1 - SEAT ESCUTCHEON

2 - FLOOR CARPET

Fig. 5 FLOOR CARPET

1 - CARPET LOCATOR GROMMET

2 - PUSH PIN

3 - CARPET

4 - CARPET GROMMET

5 - HEEL PROTECTOR PAD

6 - BODY ASSEMBLY

23 - 76 INTERIORRS

CARPETS AND FLOOR MATS (Continued)

Page 2188 of 2585

C-PILLAR TRIM

REMOVAL

(1) Remove quarter trim panel.

(2) Remove seat belt turning loop from height

adjuster.

(3) Remove screw attaching C-pillar trim panel to

C-pillar (Fig. 7).

(4) Disengage hidden clips attaching trim to upper

C-pillar.

(5) Remove upper C-pillar trim from vehicle.

INSTALLATION

(1) Place upper C-pillar trim in position on vehicle

(Fig. 7).

(2) Engage hidden clips attaching trim to upper

C-pillar.

(3) Install screw attaching C-pillar trim panel to

C-pillar.

(4) Install seat belt turning loop onto height

adjuster. Tighten all seat belt bolts to 39 N´m (29 ft.

lbs.) torque.

(5) Install quarter trim panel.

DOOR SILL TRIM PLATE

REMOVAL

(1) Using trim stick (C-4755), disengage hidden

clips holding door sill plate from door sill.

(2) Remove sill plate from vehicle (Fig. 8).

INSTALLATION

(1) Place sill plate in position on vehicle (Fig. 8).

(2) Align interlock tabs at front and rear to mating

trim.

(3) Engage hidden clips to hold door sill plate to

door sill.

Fig. 6 COWL TRIM

1 - INSTRUMENT PANEL

2 - CLIPS

3 - COWL TRIM

4 - COWL

Fig. 7 C-PILLAR

1 - C-PILLAR TRIM PANEL

2 - C-PILLAR

Fig. 8 DOOR SILL PLATE

1 - CLIPS

2 - SLIDING DOOR SILL TRIM PLATE

3 - FRONT DOOR SILL TRIM PLATE

RSINTERIOR23-77

COWL TRIM (Continued)

Page 2220 of 2585

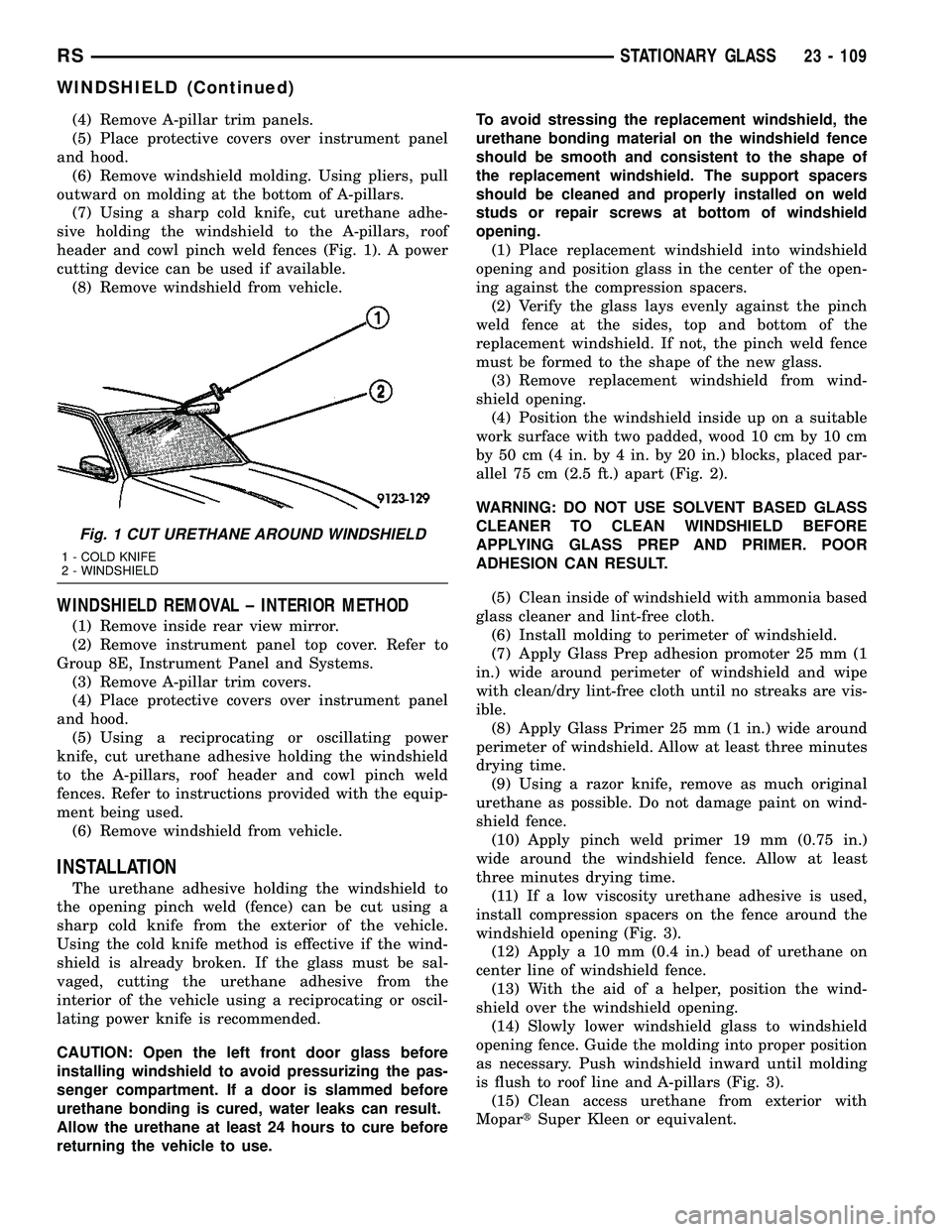

(4) Remove A-pillar trim panels.

(5) Place protective covers over instrument panel

and hood.

(6) Remove windshield molding. Using pliers, pull

outward on molding at the bottom of A-pillars.

(7) Using a sharp cold knife, cut urethane adhe-

sive holding the windshield to the A-pillars, roof

header and cowl pinch weld fences (Fig. 1). A power

cutting device can be used if available.

(8) Remove windshield from vehicle.

WINDSHIELD REMOVAL ± INTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove instrument panel top cover. Refer to

Group 8E, Instrument Panel and Systems.

(3) Remove A-pillar trim covers.

(4) Place protective covers over instrument panel

and hood.

(5) Using a reciprocating or oscillating power

knife, cut urethane adhesive holding the windshield

to the A-pillars, roof header and cowl pinch weld

fences. Refer to instructions provided with the equip-

ment being used.

(6) Remove windshield from vehicle.

INSTALLATION

The urethane adhesive holding the windshield to

the opening pinch weld (fence) can be cut using a

sharp cold knife from the exterior of the vehicle.

Using the cold knife method is effective if the wind-

shield is already broken. If the glass must be sal-

vaged, cutting the urethane adhesive from the

interior of the vehicle using a reciprocating or oscil-

lating power knife is recommended.

CAUTION: Open the left front door glass before

installing windshield to avoid pressurizing the pas-

senger compartment. If a door is slammed before

urethane bonding is cured, water leaks can result.

Allow the urethane at least 24 hours to cure before

returning the vehicle to use.To avoid stressing the replacement windshield, the

urethane bonding material on the windshield fence

should be smooth and consistent to the shape of

the replacement windshield. The support spacers

should be cleaned and properly installed on weld

studs or repair screws at bottom of windshield

opening.

(1) Place replacement windshield into windshield

opening and position glass in the center of the open-

ing against the compression spacers.

(2) Verify the glass lays evenly against the pinch

weld fence at the sides, top and bottom of the

replacement windshield. If not, the pinch weld fence

must be formed to the shape of the new glass.

(3) Remove replacement windshield from wind-

shield opening.

(4) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart (Fig. 2).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN WINDSHIELD BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

(5) Clean inside of windshield with ammonia based

glass cleaner and lint-free cloth.

(6) Install molding to perimeter of windshield.

(7) Apply Glass Prep adhesion promoter 25 mm (1

in.) wide around perimeter of windshield and wipe

with clean/dry lint-free cloth until no streaks are vis-

ible.

(8) Apply Glass Primer 25 mm (1 in.) wide around

perimeter of windshield. Allow at least three minutes

drying time.

(9) Using a razor knife, remove as much original

urethane as possible. Do not damage paint on wind-

shield fence.

(10) Apply pinch weld primer 19 mm (0.75 in.)

wide around the windshield fence. Allow at least

three minutes drying time.

(11) If a low viscosity urethane adhesive is used,

install compression spacers on the fence around the

windshield opening (Fig. 3).

(12) Apply a 10 mm (0.4 in.) bead of urethane on

center line of windshield fence.

(13) With the aid of a helper, position the wind-

shield over the windshield opening.

(14) Slowly lower windshield glass to windshield

opening fence. Guide the molding into proper position

as necessary. Push windshield inward until molding

is flush to roof line and A-pillars (Fig. 3).

(15) Clean access urethane from exterior with

MopartSuper Kleen or equivalent.

Fig. 1 CUT URETHANE AROUND WINDSHIELD

1 - COLD KNIFE

2 - WINDSHIELD

RSSTATIONARY GLASS23 - 109

WINDSHIELD (Continued)

Page 2278 of 2585

DESCRIPTION FIGURE

REAR SEAT REINFORCEMENTS - SHORT WHEEL BASE ONLY 100

CENTER CONSOLE REINFORCEMENT - SHORT WHEEL BASE ONLY 101

WHEELHOUSES - SHORT WHEEL BASE ONLY 102

FRONT SEAT CROSS MEMBER - SHORT WHEELBASE, ALL WHEEL DRIVE ONLY 103

FLOOR PAN SIDE RAIL - LONG WHEEL BASE ONLY 104

INNER BODY SIDE SILL REINFORCEMENTS 105

TOE BOARD CROSS MEMBER 106

FRONT SIDE RAIL - SHORT WHEEL BASE ONLY 107

DASH PANEL REINFORCEMENT 108

LOWER COWL PLENUM 109

UPPER COWL PLENUM SUPPORT 110

UPPER DASH PANEL 111

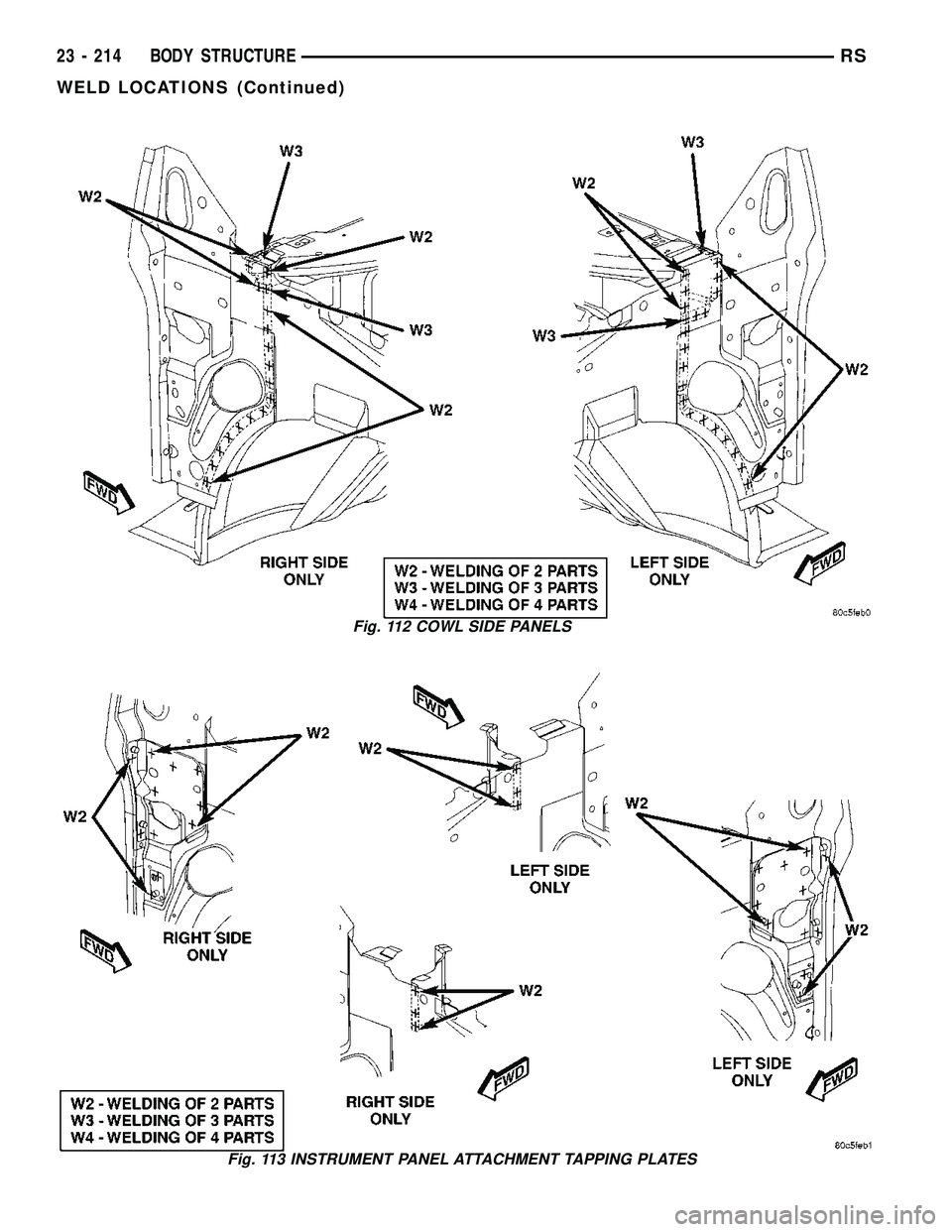

COWL SIDE PANELS 112

INSTRUMENT PANEL ATTACHMENT TAPPING PLATES 113

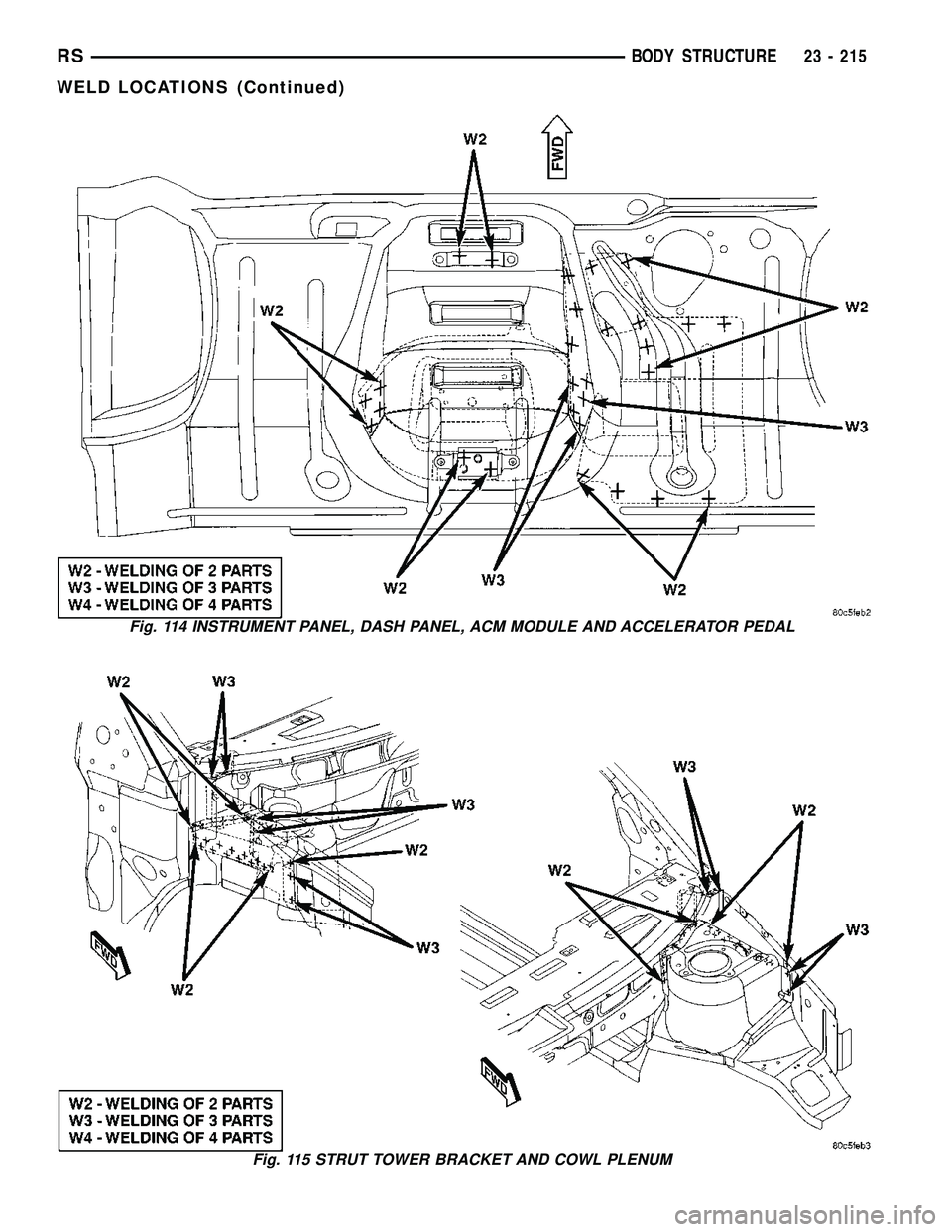

INSTRUMENT PANEL, DASH PANEL, ACM MODULE AND ACCELERATOR PEDAL 114

STRUT TOWER BRACKET AND COWL PLENUM 115

FRONT SIDE RAILS TO LOWER DASH PANEL 116

INNER BODY SIDE SILL TO LOWER DASH PANEL 117

FRONT HINGE TAPPING PLATE 118

FRONT HINGE PILLAR 119

INNER WINDSHIELD FRAME 120

WINDSHIELD FRAME 121

FENDER BRACKET 122

INNER B-PILLAR 123

STRIKER LATCH AND TAPPING PLATES 124

RIGHT REAR INNER QUARTER PANEL - LONG WHEEL BASE ONLY 125

RIGHT REAR INNER QUARTER PANEL/OUTER WHEELHOUSE - LONG WHEEL BASE

ONLY126

RIGHT REAR BODY SIDE APERTURE - LONG WHEEL BASE ONLY 127

STRIKER LATCH REINFORCEMENT - LONG WHEEL BASE ONLY 128

BELT TAPPING PLATE - LONG WHEEL BASE ONLY 129

C-PILLAR REINFORCEMENT - LONG WHEEL BASE ONLY 130

OUTER WHEELHOUSE - LONG WHEEL BASE ONLY 131

C AND D-PILLAR INNER REINFORCEMENTS - LONG WHEEL BASE ONLY 132

LEFT REAR INNER QUARTER PANEL - LONG WHEEL BASE ONLY 133

OUTER WHEELHOUSE EXTENSION - LONG WHEEL BASE ONLY 134

TAIL LAMP - LONG WHEEL BASE ONLY 135

SLIDING DOOR LATCH - LONG WHEEL BASE ONLY 136

ROOF BOW EXTENSION - LONG WHEEL BASE ONLY 137

RIGHT REAR INNER QUARTER PANEL - SHORT WHEEL BASE ONLY 138

LATCH REINFORCEMENT AND OUTER WHEELHOUSE - SHORT WHEEL BASE ONLY 139

D-PILLAR REINFORCEMENT - SHORT WHEEL BASE ONLY 140

RSBODY STRUCTURE23 - 167

WELD LOCATIONS (Continued)

Page 2280 of 2585

DESCRIPTION FIGURE

LOWER COWL PLENUM, SUPPORT AND DASH PANEL - RIGHT HAND DRIVE 182

STEERING COLUMN REINFORCEMENT, BELT REINFORCEMENT AND DASH PANEL -

RIGHT HAND DRIVE183

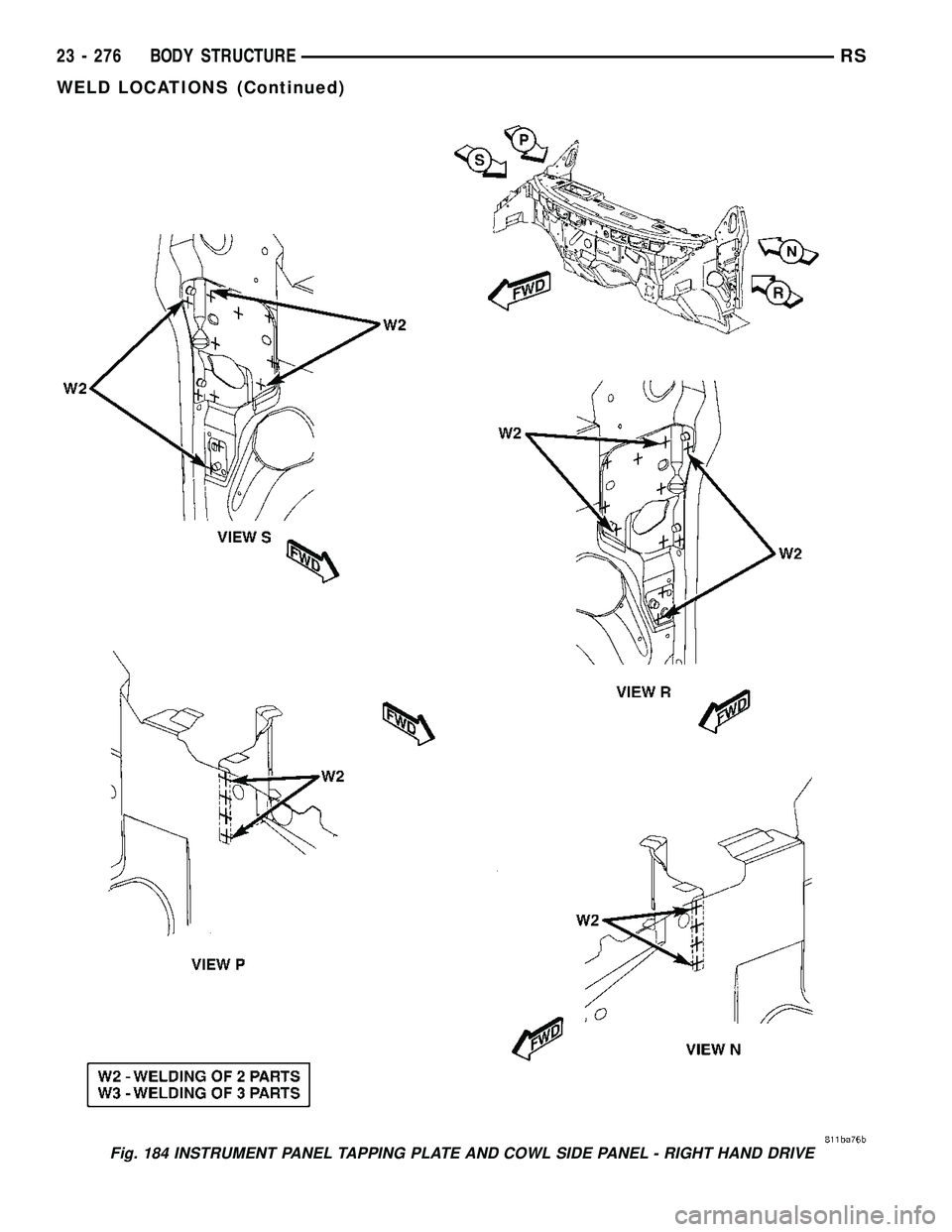

INSTRUMENT PANEL TAPPING PLATE AND COWL SIDE PANEL - RIGHT HAND DRIVE 184

DASH PANEL AND BELT REINFORCEMENT - RIGHT HAND DRIVE 185

UPPER SUPPORT, UPPER REINFORCEMENT AND UPPER COWL PLENUM - RIGHT

HAND DRIVE186

UPPER SUPPORT, BRAKE PEDAL BRACKET REINFORCEMENT AND DASH PANEL -

RIGHT HAND DRIVE187

REINFORCEMENT, MOUNTING BRACKETS AND DASH PANEL - RIGHT HAND DRIVE 188

STRUT TOWER, COWL SIDE PANEL - RIGHT HAND DRIVE 189

REINFORCEMENTS, SIDE RAILS, COWL SIDE PANELS AND DASH PANEL - RIGHT

HAND DRIVE190

UPPER COWL PLENUM, GUSSETS, SIDE SHIELDS AND BODY SIDE APERTURE -

RIGHT HAND DRIVE191

SIDE GLASS ANTENNA TAPPING PLATE AND INNER BODY SIDE APERTURE - RIGHT

HAND DRIVE192

RSBODY STRUCTURE23 - 169

WELD LOCATIONS (Continued)

Page 2325 of 2585

Fig. 112 COWL SIDE PANELS

Fig. 113 INSTRUMENT PANEL ATTACHMENT TAPPING PLATES

23 - 214 BODY STRUCTURERS

WELD LOCATIONS (Continued)

Page 2326 of 2585

Fig. 114 INSTRUMENT PANEL, DASH PANEL, ACM MODULE AND ACCELERATOR PEDAL

Fig. 115 STRUT TOWER BRACKET AND COWL PLENUM

RSBODY STRUCTURE23 - 215

WELD LOCATIONS (Continued)

Page 2387 of 2585

Fig. 184 INSTRUMENT PANEL TAPPING PLATE AND COWL SIDE PANEL - RIGHT HAND DRIVE

23 - 276 BODY STRUCTURERS

WELD LOCATIONS (Continued)

Page 2396 of 2585

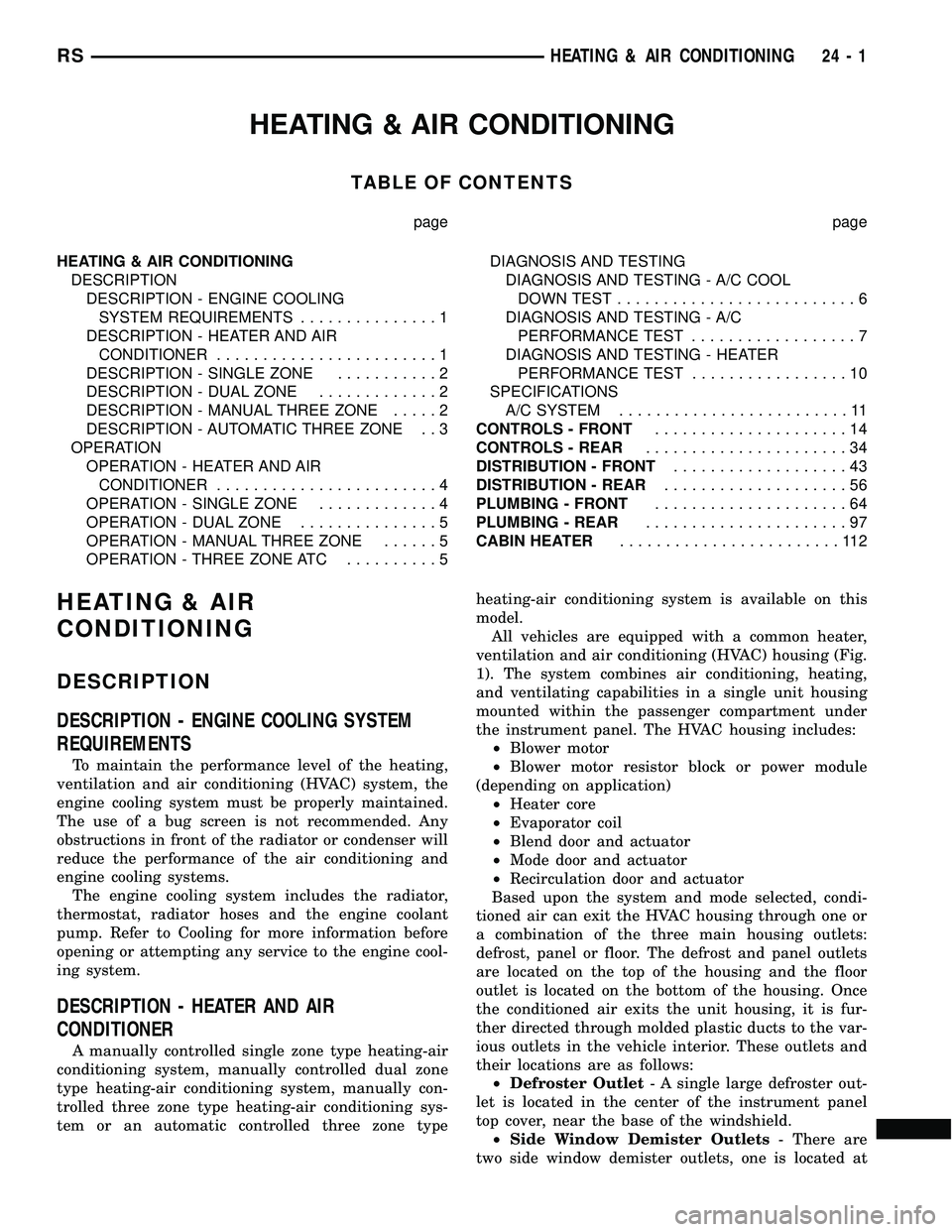

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - ENGINE COOLING

SYSTEM REQUIREMENTS...............1

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

DESCRIPTION - SINGLE ZONE...........2

DESCRIPTION - DUAL ZONE.............2

DESCRIPTION - MANUAL THREE ZONE.....2

DESCRIPTION - AUTOMATIC THREE ZONE . . 3

OPERATION

OPERATION - HEATER AND AIR

CONDITIONER........................4

OPERATION - SINGLE ZONE.............4

OPERATION - DUAL ZONE...............5

OPERATION - MANUAL THREE ZONE......5

OPERATION - THREE ZONE ATC..........5DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C COOL

DOWN TEST..........................6

DIAGNOSIS AND TESTING - A/C

PERFORMANCE TEST..................7

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE TEST.................10

SPECIFICATIONS

A/C SYSTEM.........................11

CONTROLS - FRONT.....................14

CONTROLS - REAR......................34

DISTRIBUTION - FRONT...................43

DISTRIBUTION - REAR....................56

PLUMBING - FRONT.....................64

PLUMBING - REAR......................97

CABIN HEATER........................112

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - ENGINE COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the heating,

ventilation and air conditioning (HVAC) system, the

engine cooling system must be properly maintained.

The use of a bug screen is not recommended. Any

obstructions in front of the radiator or condenser will

reduce the performance of the air conditioning and

engine cooling systems.

The engine cooling system includes the radiator,

thermostat, radiator hoses and the engine coolant

pump. Refer to Cooling for more information before

opening or attempting any service to the engine cool-

ing system.

DESCRIPTION - HEATER AND AIR

CONDITIONER

A manually controlled single zone type heating-air

conditioning system, manually controlled dual zone

type heating-air conditioning system, manually con-

trolled three zone type heating-air conditioning sys-

tem or an automatic controlled three zone typeheating-air conditioning system is available on this

model.

All vehicles are equipped with a common heater,

ventilation and air conditioning (HVAC) housing (Fig.

1). The system combines air conditioning, heating,

and ventilating capabilities in a single unit housing

mounted within the passenger compartment under

the instrument panel. The HVAC housing includes:

²Blower motor

²Blower motor resistor block or power module

(depending on application)

²Heater core

²Evaporator coil

²Blend door and actuator

²Mode door and actuator

²Recirculation door and actuator

Based upon the system and mode selected, condi-

tioned air can exit the HVAC housing through one or

a combination of the three main housing outlets:

defrost, panel or floor. The defrost and panel outlets

are located on the top of the housing and the floor

outlet is located on the bottom of the housing. Once

the conditioned air exits the unit housing, it is fur-

ther directed through molded plastic ducts to the var-

ious outlets in the vehicle interior. These outlets and

their locations are as follows:

²Defroster Outlet- A single large defroster out-

let is located in the center of the instrument panel

top cover, near the base of the windshield.

²Side Window Demister Outlets- There are

two side window demister outlets, one is located at

RSHEATING & AIR CONDITIONING24-1