wheel CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1295 of 2585

POWER OUTLET

DESCRIPTION

Accessory power outlets are standard equipment on

this model. Two power outlets are installed in the

instrument panel center lower bezel, which is located

near the bottom of the instrument panel center stack

area. Two additional power outlets are also incorpo-

rated into the vehicle, one on the left rear C-pillar

trim and the other in the center console, if equipped.

The power outlets bases are secured by a snap fit in

the appropriate bezels. A hinged plug flips closed to

conceal and protect the power outlet base when the

power outlet is not being used.

The power outlet receptacle unit and the power

outlet plugs are each available for service replace-

ment.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the on position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

For complete circuit diagrams, refer toCigar

Lighter/Power Outletin Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the IPM. If OK, go to Step 3. If not OK, repair the

open fused B(+) circuit to the IPM fuse as required.

(3) Open the power outlet door. Check for continu-

ity between the inside circumference of the power

outlet receptacle and a good ground. There should be

continuity. If OK, go to Step 4. If not OK, go to Step

5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the appropriate bezel. Check for conti-

nuity between the ground circuit cavity of the power

outlet wire harness connector and a good ground.

There should be continuity. If OK, go to Step 6. If not

OK, repair the open ground circuit to ground as

required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the IPM fuse as

required.

8W - 97 - 4 8W-97 POWER DISTRIBUTION SYSTEMRS

Page 1300 of 2585

TIMING BELT AND SPROCKET(S)

REMOVAL

REMOVAL - TIMING BELT...............63

REMOVAL - CAMSHAFT SPROCKETS.....64

REMOVAL - CRANKSHAFT SPROCKET....64

CLEANING............................64

INSTALLATION

INSTALLATION - CRANKSHAFT SPROCKET . 65

INSTALLATION - CAMSHAFT SPROCKETS . . 65INSTALLATION - TIMING BELT...........65

TIMING BELT TENSIONER & PULLEY

REMOVAL.............................68

INSTALLATION.........................69

BALANCE SHAFTS AND CARRIER ASSEMBLY

DESCRIPTION.........................69

OPERATION...........................69

REMOVAL.............................69

INSTALLATION.........................72

ENGINE 2.4L

DESCRIPTION

The 2.4 Liter (148 cu. in.) in-line four cylinder

engine is a double over head camshaft with hydraulic

lash adjusters and four valve per cylinder design.

The engine is free-wheeling; meaning it has provi-

sions for piston-to-valve clearance. However valve-to-

valve interference can occur, if camshafts are rotated

independently.

The cylinders are numbered from front of the

engine to the rear. The firing order is 1±3±4±2.

The engine identification number is located on the

rear of the cylinder block (Fig. 1).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Engine Mechanical and the Engine

Performance diagnostic charts, for possible causes

and corrections of malfunctions (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING - MECHANICAL)

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING

- PERFORMANCE).

For fuel system diagnosis, (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Hydraulic Lash Adjuster Noise Diagnosis

²Engine Oil Leak Inspection

Fig. 1 Engine Identification

1 - ENGINE IDENTIFICATION LOCATION

RSENGINE 2.4L9-3

Page 1304 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Excessive end play. 6. Check thrust bearing for wear on

flanges.

7. Crankshaft journal out-of-round

or worn.7. Replace crankshaft or grind

journals.

8. Loose flywheel or torque

converter.8. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sensor/switch. 2. Replace oil pressure sensor/

switch.

3. Low oil pressure. 3. Check oil pressure sensor/switch

and main bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

RSENGINE 2.4L9-7

ENGINE 2.4L (Continued)

Page 1310 of 2585

REMOVAL - ENGINE ASSEMBLY

(1) Perform fuel pressure release procedure (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE)

(2) Disconnect battery negative cable.

(3) Remove air cleaner housing and inlet tube.

(4) Disconnect the fuel line from fuel rail. (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- STANDARD PROCEDURE)

(5) Disconnect all vacuum hoses.

(6) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(7) Remove radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL)

(8) Remove radiator upper and lower hoses.

NOTE: When the transaxle cooler lines are removed

from the rolled-groove type fittings at the transaxle,

damage to the inner wall of the hose will occur. To

prevent prevent potential leakage, the cooler hoses

must be cut off flush at the transaxle fitting, and a

service cooler hose splice kit must be installed

upon reassembly.(9) Using a blade or suitable hose cutter, cut trans-

axle oil cooler lines off flush with fittings. Plug cooler

lines and fittings to prevent debris from entering

transaxle or cooler circuit. A service splice kit will be

installed upon reassembly.

(10) Disconnect transmission shift linkage and

electrical connectors.

(11) Disconnect throttle body linkage.

(12) Disconnect engine wiring harness.

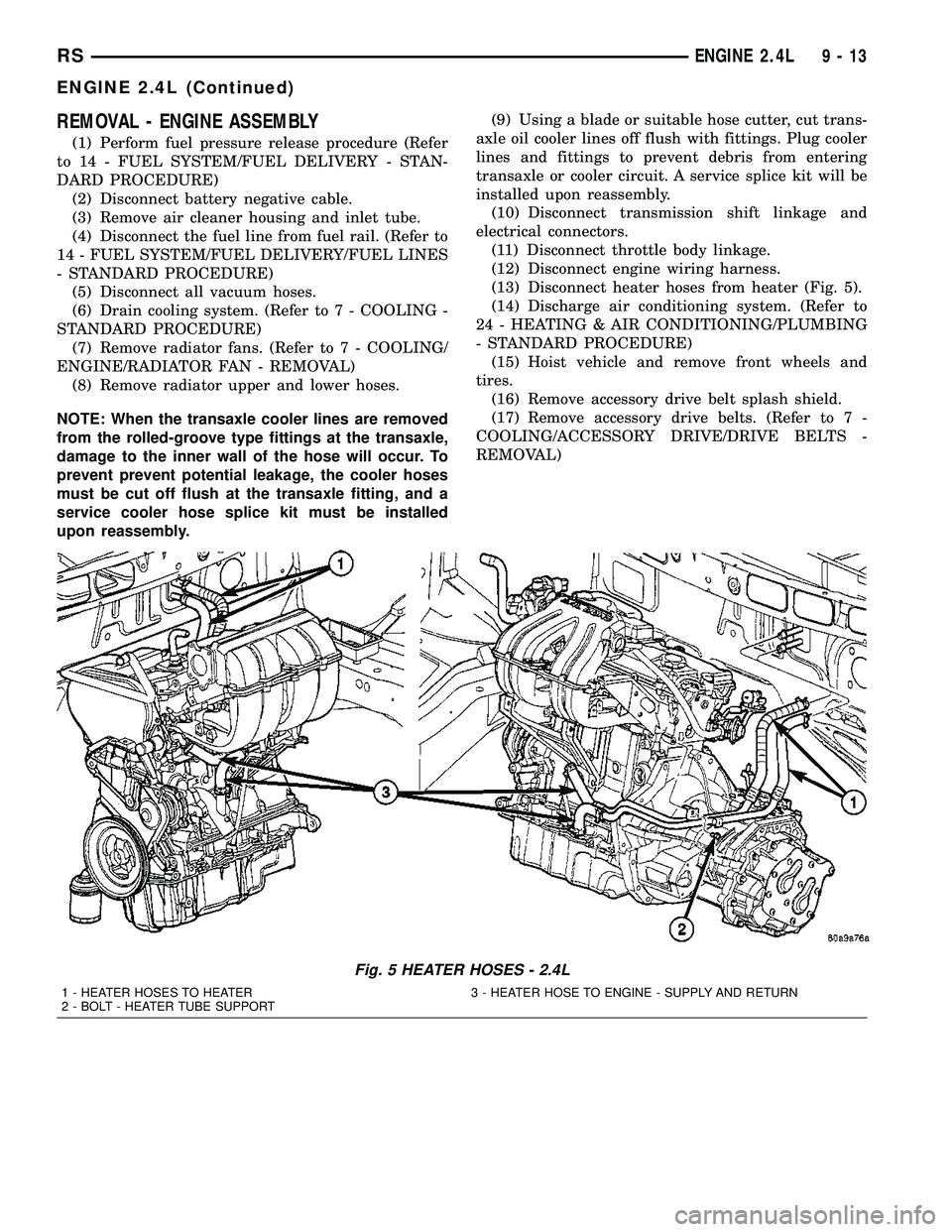

(13) Disconnect heater hoses from heater (Fig. 5).

(14) Discharge air conditioning system. (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE)

(15) Hoist vehicle and remove front wheels and

tires.

(16) Remove accessory drive belt splash shield.

(17) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

Fig. 5 HEATER HOSES - 2.4L

1 - HEATER HOSES TO HEATER 3 - HEATER HOSE TO ENGINE - SUPPLY AND RETURN

2 - BOLT - HEATER TUBE SUPPORT

RSENGINE 2.4L9-13

ENGINE 2.4L (Continued)

Page 1313 of 2585

INSTALLATION - ENGINE ASSEMBLY

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

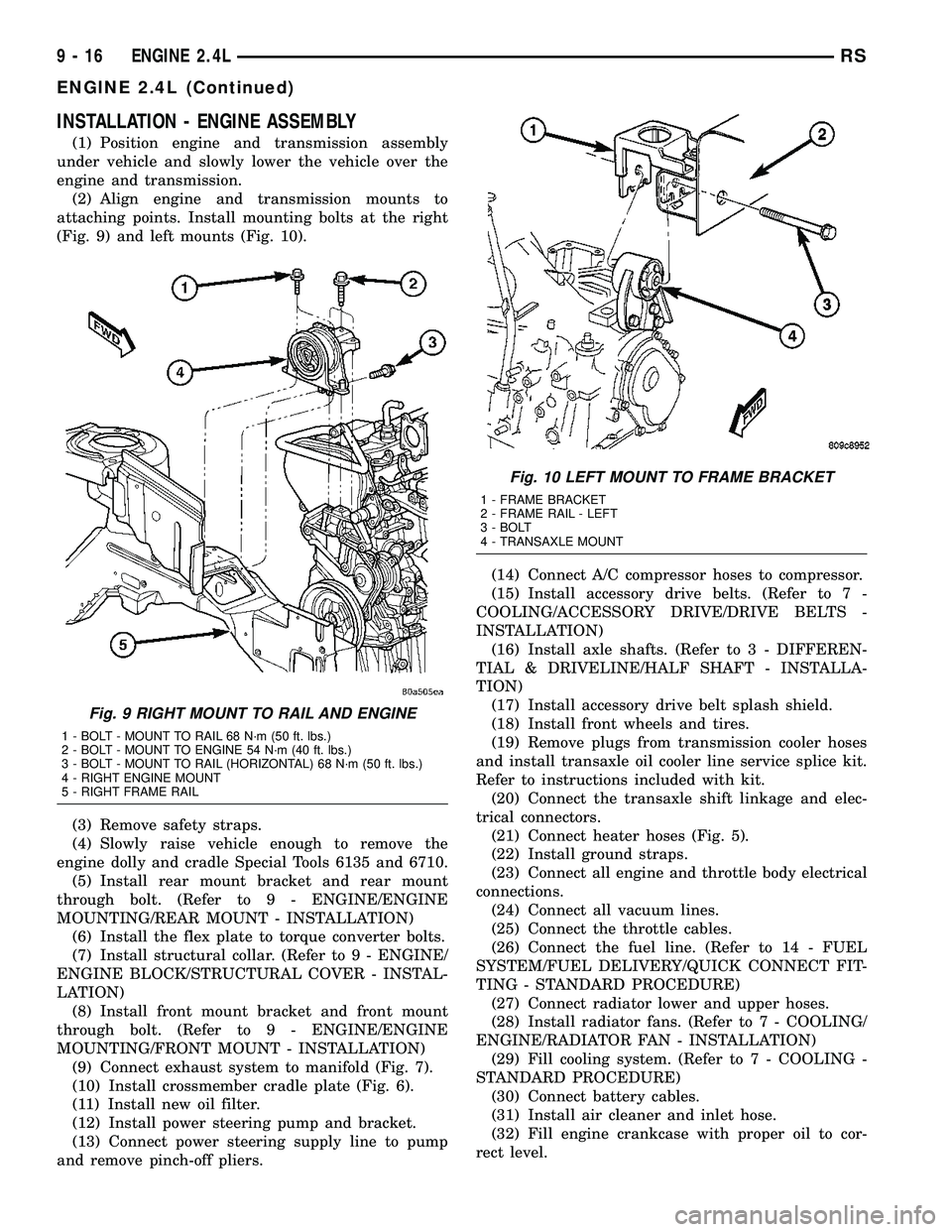

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

(Fig. 9) and left mounts (Fig. 10).

(3) Remove safety straps.

(4) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(5) Install rear mount bracket and rear mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/REAR MOUNT - INSTALLATION)

(6) Install the flex plate to torque converter bolts.

(7) Install structural collar. (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION)

(8) Install front mount bracket and front mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/FRONT MOUNT - INSTALLATION)

(9) Connect exhaust system to manifold (Fig. 7).

(10) Install crossmember cradle plate (Fig. 6).

(11) Install new oil filter.

(12) Install power steering pump and bracket.

(13) Connect power steering supply line to pump

and remove pinch-off pliers.(14) Connect A/C compressor hoses to compressor.

(15) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(16) Install axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(17) Install accessory drive belt splash shield.

(18) Install front wheels and tires.

(19) Remove plugs from transmission cooler hoses

and install transaxle oil cooler line service splice kit.

Refer to instructions included with kit.

(20) Connect the transaxle shift linkage and elec-

trical connectors.

(21) Connect heater hoses (Fig. 5).

(22) Install ground straps.

(23) Connect all engine and throttle body electrical

connections.

(24) Connect all vacuum lines.

(25) Connect the throttle cables.

(26) Connect the fuel line. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(27) Connect radiator lower and upper hoses.

(28) Install radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION)

(29) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(30) Connect battery cables.

(31) Install air cleaner and inlet hose.

(32) Fill engine crankcase with proper oil to cor-

rect level.

Fig. 9 RIGHT MOUNT TO RAIL AND ENGINE

1 - BOLT - MOUNT TO RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO ENGINE 54 N´m (40 ft. lbs.)

3 - BOLT - MOUNT TO RAIL (HORIZONTAL) 68 N´m (50 ft. lbs.)

4 - RIGHT ENGINE MOUNT

5 - RIGHT FRAME RAIL

Fig. 10 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

9 - 16 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1334 of 2585

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Engine Specifica-

tions.

REMOVAL - CRANKSHAFT

NOTE: Crankshaft can not be removed when engine

is in vehicle.

(1) Remove engine assembly from vehicle (Refer to

9 - ENGINE - REMOVAL).

(2) Separate transaxle from engine.

(3) Remove drive plate/flex plate.

(4) Remove crankshaft rear oil seal (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

(5) Mount engine on a suitable repair stand.

(6) Drain engine oil and remove oil filter.

(7) Remove crankshaft vibration damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(8) Remove engine mount support bracket.

(9) Remove front timing belt covers (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- REMOVAL).

(10) Remove the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

REMOVAL).

(11) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(12) Remove oil pump pick-up tube.

(13) Remove the crankshaft sprocket and oil pump

(Refer to 9 - ENGINE/LUBRICATION/OIL PUMP -

REMOVAL).

(14) Remove balance shafts and housing assembly

(Refer to 9 - ENGINE/VALVE TIMING/BALANCE

SHAFT - REMOVAL).

(15) Remove crankshaft position sensor.NOTE: If piston/connecting rod replacement is nec-

essary, remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(16) Using a permanent ink or paint marker, iden-

tify cylinder number on each connecting rod cap (Fig.

44).

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods. Damage to connecting

rod could occur.

(17) Remove all connecting rod bolts and caps.

Care should be taken not to damage the fracture rod

and cap surfaces.

NOTE: Do not reuse connecting rod bolts.

(18) Remove all bedplate bolts from the engine

block (Fig. 45).

(19) Using a mallet gently tap the bedplate loose

from the engine block dowel pins.

CAUTION: Do not pry up on one side of the bed-

plate. Damage may occur to cylinder block to bed-

plate alignment and thrust bearing.

(20) Bedplate should be removed evenly from the

cylinder block dowel pins to prevent damage to the

dowel pins and thrust bearing.

CAUTION: Use extreme care when handling crank-

shaft. Tone wheel damage can occur if crankshaft is

mis-handled.

(21) Lift out crankshaft from cylinder block. Do

not damage the main bearings or journals when

removing the crankshaft.

INSPECTION

For crankshaft specifications (Refer to 9 - ENGINE

- SPECIFICATIONS).

Fig. 43 CHECKING CRANKSHAFT END PLAY

Fig. 44 Identify Connecting Rod to Cylinder

RSENGINE 2.4L9-37

CRANKSHAFT (Continued)

Page 1346 of 2585

FRONT MOUNT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the front engine mount through bolt

from the insulator (Fig. 78).

(3) Remove the engine front mount bolts and

remove the insulator assembly (Fig. 78).

(4) Remove the front mounting bracket from

engine, if necessary (Fig. 78).

INSTALLATION

(1) Install the front mount bracket to engine, if

removed (Fig. 78).

(2) Install the insulator mount assembly (Fig. 78).

(3) Install the front engine mount through bolt to

the insulator (Fig. 78).

(4) Lower the vehicle.

LEFT MOUNT

REMOVAL

(1) Raise the vehicle on hoist.

(2) Remove the left front wheel.

(3) Remove the left mount through bolt access

cover.

(4) Support the transaxle with a suitable jack.

(5) Remove the engine front mount through bolt to

allow left mount removal clearance (Fig. 78).

(6) Remove the left mount through frame rail bolt

(Fig. 79).

(7) Lower transaxle for access to horizontal bolts.

(8) Remove the horizontal bolts from the mount to

the transaxle (Fig. 80).

NOTE: To remove mount, additional lowering of

transaxle may be required.

(9) Remove left mount.

Fig. 78 Front Mount and Bracket

1 - BRACKET - FRONT MOUNT

2 - NUT - 68 N´m (50 ft. lbs.)

3 - BOLT - 54 N´m (40 ft. lbs.)

4 - MOUNT - FRONT INSULATOR

5 - BOLT - 68 N´m (50 ft. lbs.)

6 - BOLT - 68 N´m (50 ft. lbs.)

7 - FRONT CROSSMEMBER

Fig. 79 LEFT MOUNT TO BRACKET

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

RSENGINE 2.4L9-49

Page 1347 of 2585

INSTALLATION

(1) Install left mount on transaxle (Fig. 80).

(2) Raise transaxle with jack until left mount is in

position.

(3) Install left mount through bolt (Fig. 79).

(4) Install left mount through bolt access cover.

(5) Install front mount through bolt (Fig. 78).

(6) Install left front wheel.

(7) Lower vehicle.

REAR MOUNT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the rear mount heat shield (Fig. 81).

(3) Remove the through bolt from the mount and

rear mount bracket (Fig. 82).

(4) Remove the mount bolts (Fig. 82).

(5) Remove the rear mount (Fig. 82).

(6) For rear mount bracket removal, remove the

bolts attaching bracket to transaxle (Fig. 83).

(7) Remove rear mount bracket.

INSTALLATION

(1) Install rear mount bracket, if removed (Fig.

83).

(2) Install the rear mount and bolts (Fig. 82).

Tighten bolts to 54 N´m (40 ft. lbs.).(3) Install the mount through bolt to the mount

and bracket (Fig. 82). Tighten through bolt to 54 N´m

(40 ft. lbs.).

(4) Install the rear mount heat shield (Fig. 81).

(5) Lower vehicle on hoist.

Fig. 80 LEFT MOUNT - 41TE TRANSAXLE

1 - LEFT MOUNT ASSEMBLY

2 - BOLT - 54 N´m (40 ft. lbs.)

3 - TRANSAXLE - 41TE

Fig. 81 REAR MOUNT HEAT SHIELD

1 - BOLT - HEAT SHIELD 11 N´m (100 in. lbs.)

2 - HEAT SHIELD

3 - CLIP

4 - REAR MOUNT

Fig. 82 REAR MOUNT

1 - BOLT 54 N´m (40 ft. lbs.)

2 - REAR MOUNT BRACKET

3 - THRU-BOLT 54 N´m (40 ft. lbs.)

4 - REAR MOUNT

9 - 50 ENGINE 2.4LRS

LEFT MOUNT (Continued)

Page 1360 of 2585

(2) Install camshaft sprockets. Hold sprockets with

Special Tool 6848 and tighten center bolt to 101 N´m

(75 ft. lbs.) (Fig. 112).

(3) Install timing belt idler pulley and tighten

mounting bolt to 61 N´m (45 ft. lbs.) (Fig. 113).

(4) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

INSTALLATION).

(5) Install engine mount bracket and tighten bolts

to 61 N´m (45 ft. lbs.) (Fig. 111).

(6) Install front covers.

TIMING BELT AND

SPROCKET(S)

REMOVAL

REMOVAL - TIMING BELT

(1) Remove air cleaner upper cover, housing, and

clean air tube.

(2) Remove make-up air hose from cylinder head

cover.

(3) Raise vehicle on hoist.

(4) Remove right front wheel.

(5) Remove right inner splash shield.(6) Remove accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove crankshaft vibration damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(8) Remove air conditioner/generator belt tensioner

and pulley assembly (Refer to 7 - COOLING/ACCES-

SORY DRIVE/BELT TENSIONERS - REMOVAL).

(9) Remove timing belt lower front cover bolts and

remove cover (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT COVER(S) - REMOVAL).

(10) Lower vehicle.

(11) Remove bolts attaching timing belt upper

front cover and remove cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT COVER(S) -

REMOVAL).

(12) Remove right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

REMOVAL).

(13) Remove engine mount bracket (Fig. 115).

Fig. 114 Rear Timing Belt Cover Fasteners

1 - M6 BOLTS - 12 N´m (105 in. lbs.)

2 - M8 BOLTS - 28 N´m (250 in. lbs.)

3 - TIMING BELT TENSIONER

Fig. 115 Engine Mount Bracket

1 - ENGINE MOUNT BRACKET

2 - BOLTS - 61 N´m (45 ft. lbs.)

RSENGINE 2.4L9-63

TIMING BELT COVER(S) (Continued)

Page 1364 of 2585

(8) Check if the spring tang is within the tolerance

window (Fig. 125). If the spring tang is within the

tolerance window, the installation process is complete

and nothing further is required. If the spring tang is

not within the tolerance window, repeat Steps 5

through 7.

(9) Install engine mount bracket to engine (Fig.

115).

(10) Install timing belt front covers and bolts

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT COVER(S) - INSTALLATION).

(11) Install air conditioning/generator belt ten-

sioner and pulley (Refer to 7 - COOLING/ACCES-

SORY DRIVE/BELT TENSIONERS -

INSTALLATION).(12) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(13) Install crankshaft vibration damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

(14) Install accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(15) Install drive belt splash shield.

(16) Install right front wheel.

(17) Connect make-up air hose to cylinder head

cover.

(18) Install air cleaner housing, upper cover, and

clean air tube.

Fig. 124 Crankshaft and Camshaft Timing

1 - CAMSHAFT TIMING MARKS

2 - CRANKSHAFT TDC MARKS

3 - TRAILING EDGE OF SPROCKET TOOTH

Fig. 125 Timing Belt Tension Verification

1 - SPRING TANG

2 - TOLERANCE WINDOW

RSENGINE 2.4L9-67

TIMING BELT AND SPROCKET(S) (Continued)