clutch CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2014 of 2585

SOLENOID SWITCH VALVE

The solenoid switch valve controls line pressure

from the LR/CC solenoid. In one position, it allows

the low/reverse clutch to be pressurized. In the other,

it directs line pressure to the converter control and

converter clutch valves.

MANUAL VALVE

The manual valve is operated by the mechanical

shift linkage. Its primary responsibility is to send

line pressure to the appropriate hydraulic circuits

and solenoids. The valve has three operating ranges

or positions.

CONVERTER CLUTCH SWITCH VALVE

The main responsibility of the converter clutch

switch valve is to control hydraulic pressure applied

to the front (off) side of the converter clutch piston.

Line pressure from the regulator valve is fed to the

torque converter regulator valve, where it passes

through the valve, and is slightly regulated. The

pressure is then directed to the converter clutch

switch valve and to the front side of the converter

clutch piston. This pressure pushes the piston back

and disengages the converter clutch.

CONVERTER CLUTCH CONTROL VALVE

The converter clutch control valve controls the

back (on) side of the torque converter clutch. When

the PCM/TCM energizes or modulates the LR/CC

solenoid to apply the converter clutch piston, both

the converter clutch control valve and the converter

control valve move, allowing pressure to be applied to

the back side of the clutch.

T/C REGULATOR VALVE

The torque converter regulator valve slightly regu-

lates the flow of fluid to the torque converter.

LOW/REVERSE SWITCH VALVE

The low/reverse clutch is applied from different

sources, depending on whether low (1st) gear or

reverse is selected. The low/reverse switch valve

alternates positions depending on from which direc-

tion fluid pressure is applied. By design, when the

valve is shifted by fluid pressure from one channel,

the opposing channel is blocked. The switch valve

alienates the possibility of a sticking ball check, thus

providing consistent application of the low/reverse

clutch under all operating conditions.

REMOVAL

NOTE: If valve body is replaced or reconditioned,

the TCM Quick Learn Procedure must be per-

formed. (Refer t o 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

(1) Disconnect battery negative cable.

(2) Disconnect gearshift cable from manual valve

lever. (3) Remove manual valve lever from manual shaft.

(4) Raise vehicle on hoist.

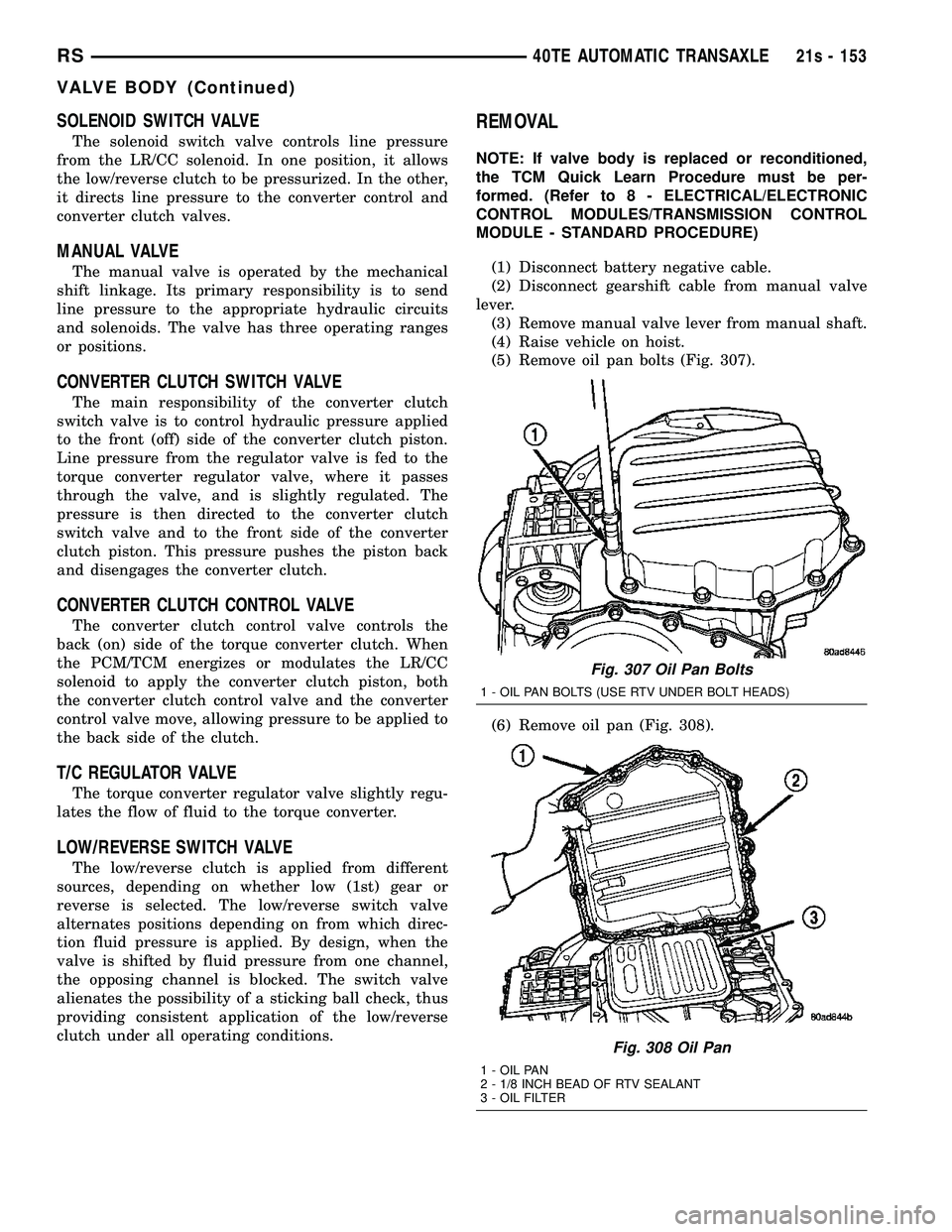

(5) Remove oil pan bolts (Fig. 307).

(6) Remove oil pan (Fig. 308).

Fig. 307 Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

Fig. 308 Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

RS 40TE AUTOMATIC TRANSAXLE21s - 153

VALVE BODY (Continued)

Page 2018 of 2585

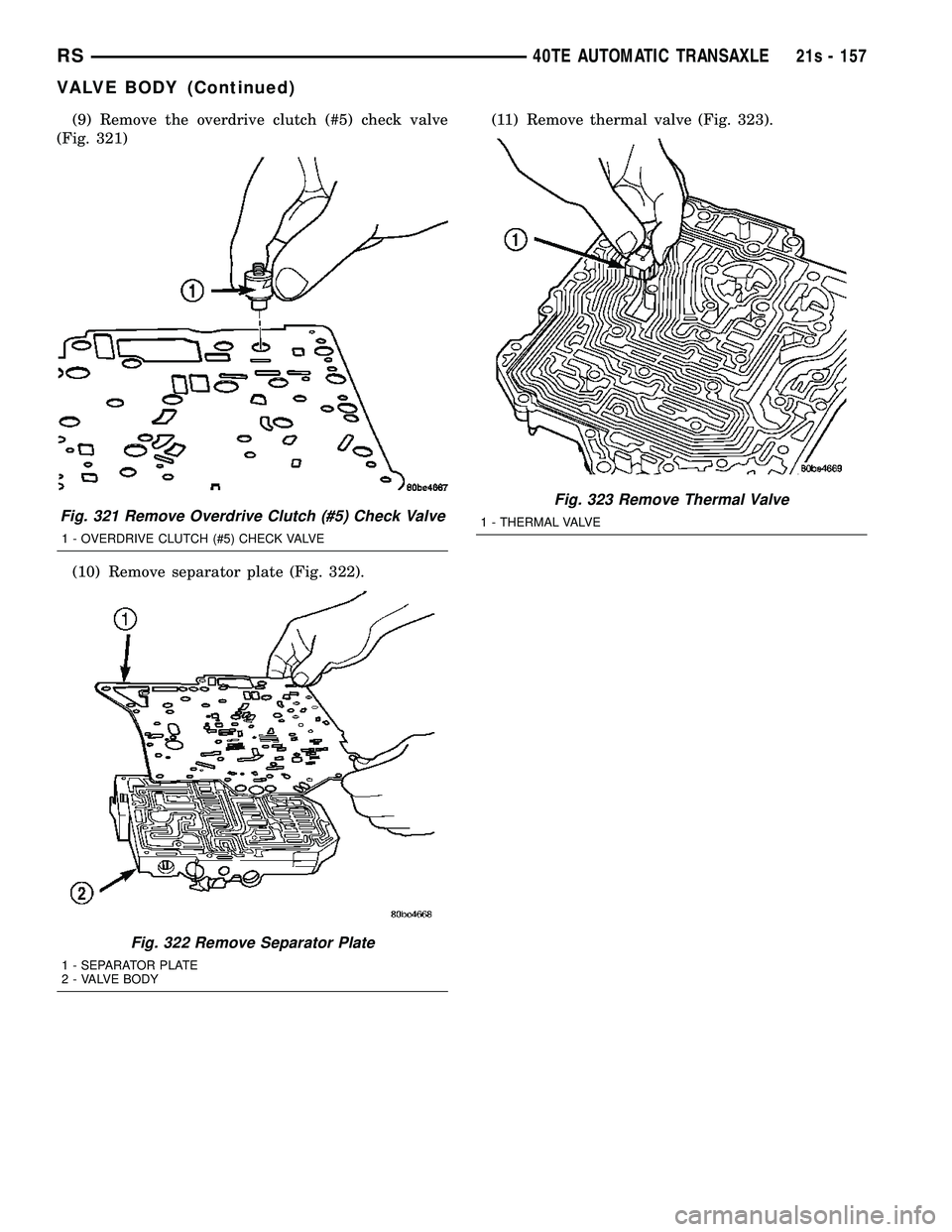

(9) Remove the overdrive clutch (#5) check valve

(Fig. 321)

(10) Remove separator plate (Fig. 322). (11) Remove thermal valve (Fig. 323).

Fig. 321 Remove Overdrive Clutch (#5) Check Valve

1 - OVERDRIVE CLUTCH (#5) CHECK VALVE

Fig. 322 Remove Separator Plate

1 - SEPARATOR PLATE

2 - VALVE BODY

Fig. 323 Remove Thermal Valve

1 - THERMAL VALVE

RS

40TE AUTOMATIC TRANSAXLE21s - 157

VALVE BODY (Continued)

Page 2020 of 2585

(15) Remove remaining retainers as shown in (Fig.

327). (16) Remove valves and springs as shown in (Fig.

328).

NOTE: Refer to Valve Body Cleaning and Inspection

for cleaning procedures.

ASSEMBLY

NOTE: If valve body assembly is reconditioned, the

PCM/TCM Quick Learn Procedure must be per-

formed. (Refer t o 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

(1) Install valves and springs as shown in (Fig.

328).

Fig. 328 Springs and Valves Location

1 - VALVE BODY 5 - MANUAL VALVE

2 - T/C REGULATOR VALVE 6 - CONVERTER CLUTCH SWITCH VALVE

3 - L/R SWITCH VALVE 7 - SOLENOID SWITCH VALVE

4 - CONVERTER CLUTCH CONTROL VALVE 8 - REGULATOR VALVE

Fig. 327 Valve Retainer Location

1 - RETAINER

2 - RETAINER

RS 40TE AUTOMATIC TRANSAXLE21s - 159

VALVE BODY (Continued)

Page 2023 of 2585

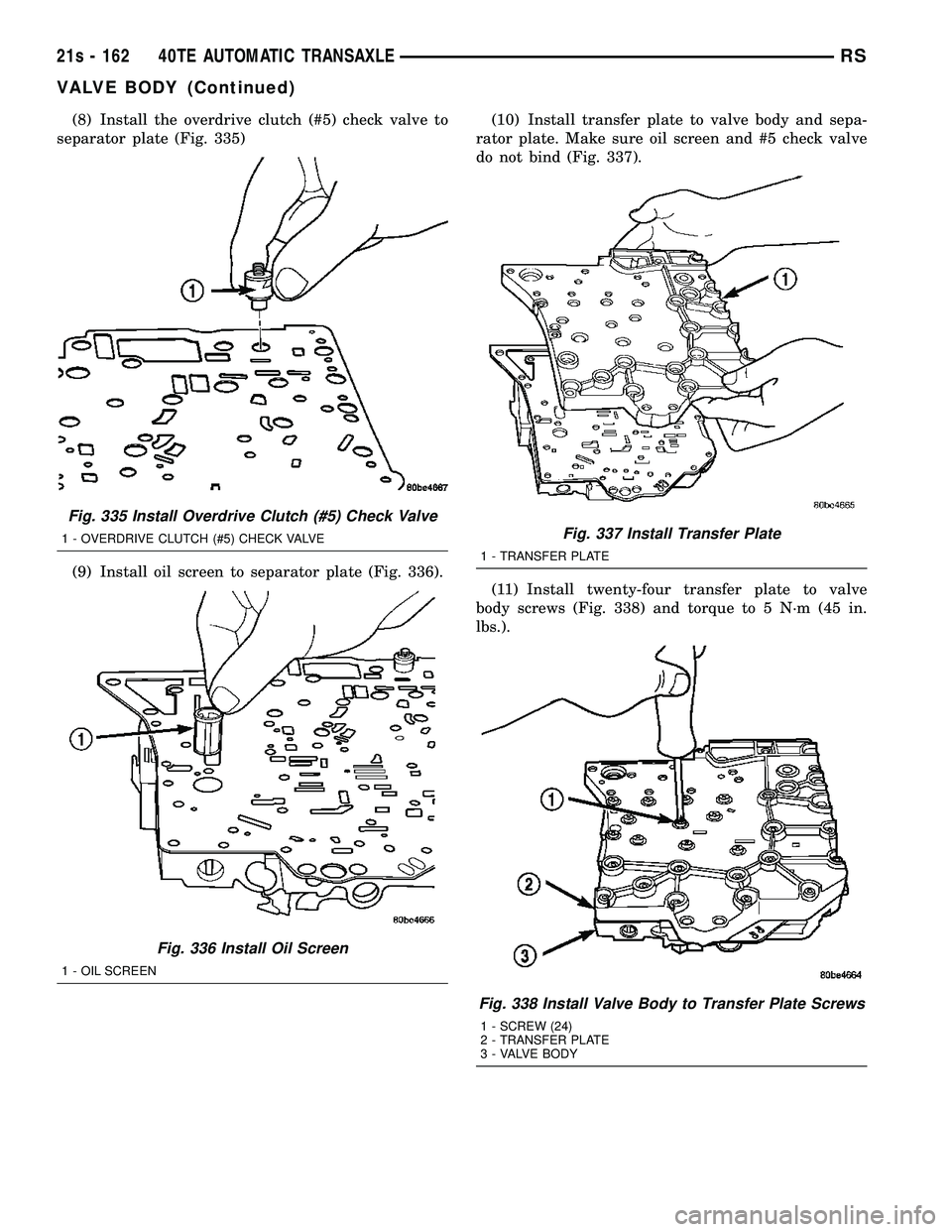

(8) Install the overdrive clutch (#5) check valve to

separator plate (Fig. 335)

(9) Install oil screen to separator plate (Fig. 336). (10) Install transfer plate to valve body and sepa-

rator plate. Make sure oil screen and #5 check valve

do not bind (Fig. 337).

(11) Install twenty-four transfer plate to valve

body screws (Fig. 338) and torque to 5 N´m (45 in.

lbs.).

Fig. 335 Install Overdrive Clutch (#5) Check Valve

1 - OVERDRIVE CLUTCH (#5) CHECK VALVE

Fig. 336 Install Oil Screen

1 - OIL SCREEN

Fig. 337 Install Transfer Plate

1 - TRANSFER PLATE

Fig. 338 Install Valve Body to Transfer Plate Screws

1 - SCREW (24)

2 - TRANSFER PLATE

3 - VALVE BODY

21s - 162 40TE AUTOMATIC TRANSAXLERS

VALVE BODY (Continued)

Page 2027 of 2585

41TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

41TE AUTOMATIC TRANSAXLE DISASSEMBLY ........................166

ASSEMBLY ...........................184

ACCUMULATOR DESCRIPTION ........................206 VALVE BODY

REMOVAL ............................206

DISASSEMBLY ........................208

ASSEMBLY ...........................212

INSTALLATION ........................217

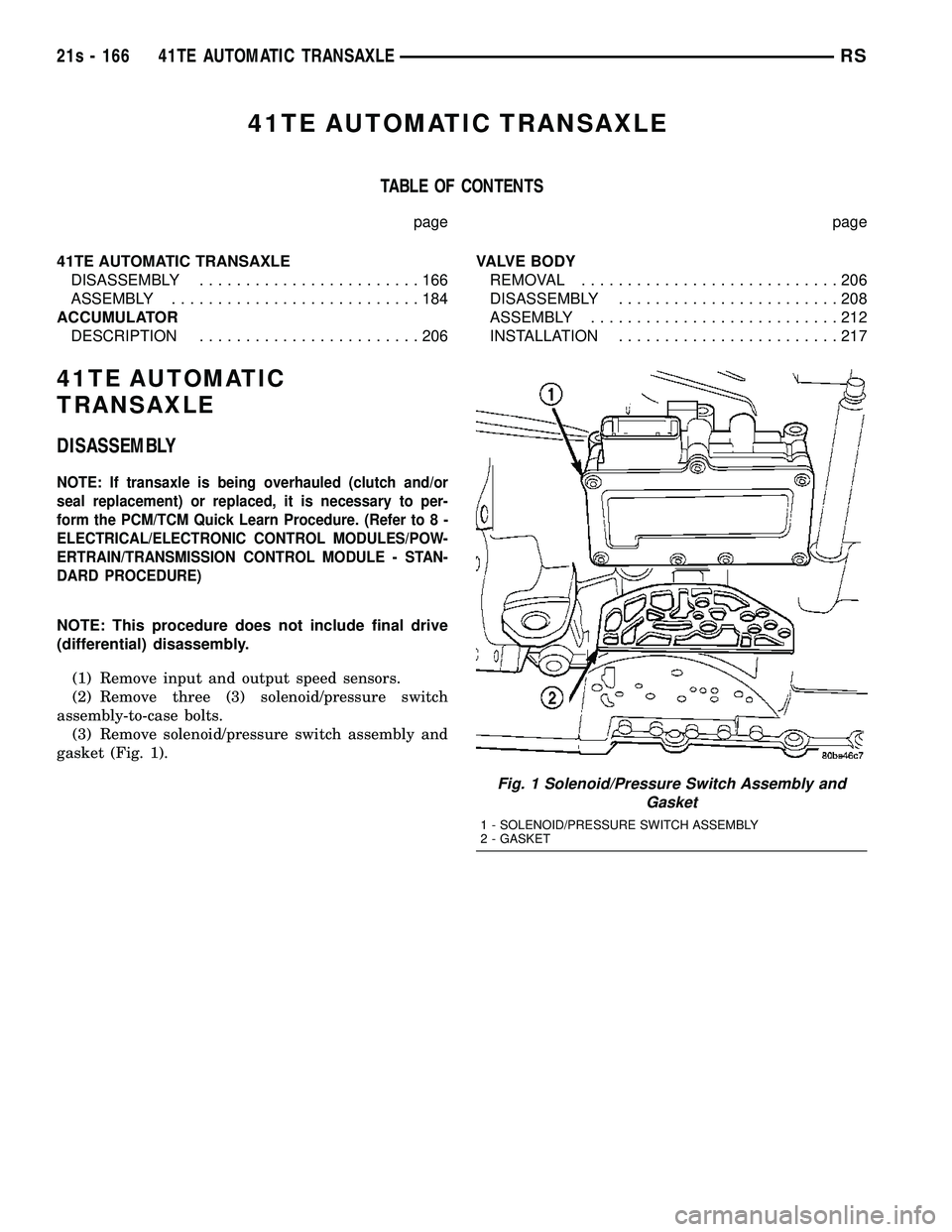

41TE AUTOMATIC

TRANSAXLE

DISASSEMBLY

NOTE: If transaxle is being overhauled (clutch and/or

seal replacement) or replaced, it is necessary to per-

form the PCM/TCM Quick Learn Procedure. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/POW-

ERTRAIN/TRANSMISSION CONTROL MODULE - STAN-

DARD PROCEDURE)

NOTE: This procedure does not include final drive

(differential) disassembly.

(1) Remove input and output speed sensors.

(2) Remove three (3) solenoid/pressure switch

assembly-to-case bolts. (3) Remove solenoid/pressure switch assembly and

gasket (Fig. 1).

Fig. 1 Solenoid/Pressure Switch Assembly and Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

21s - 166 41TE AUTOMATIC TRANSAXLERS

Page 2032 of 2585

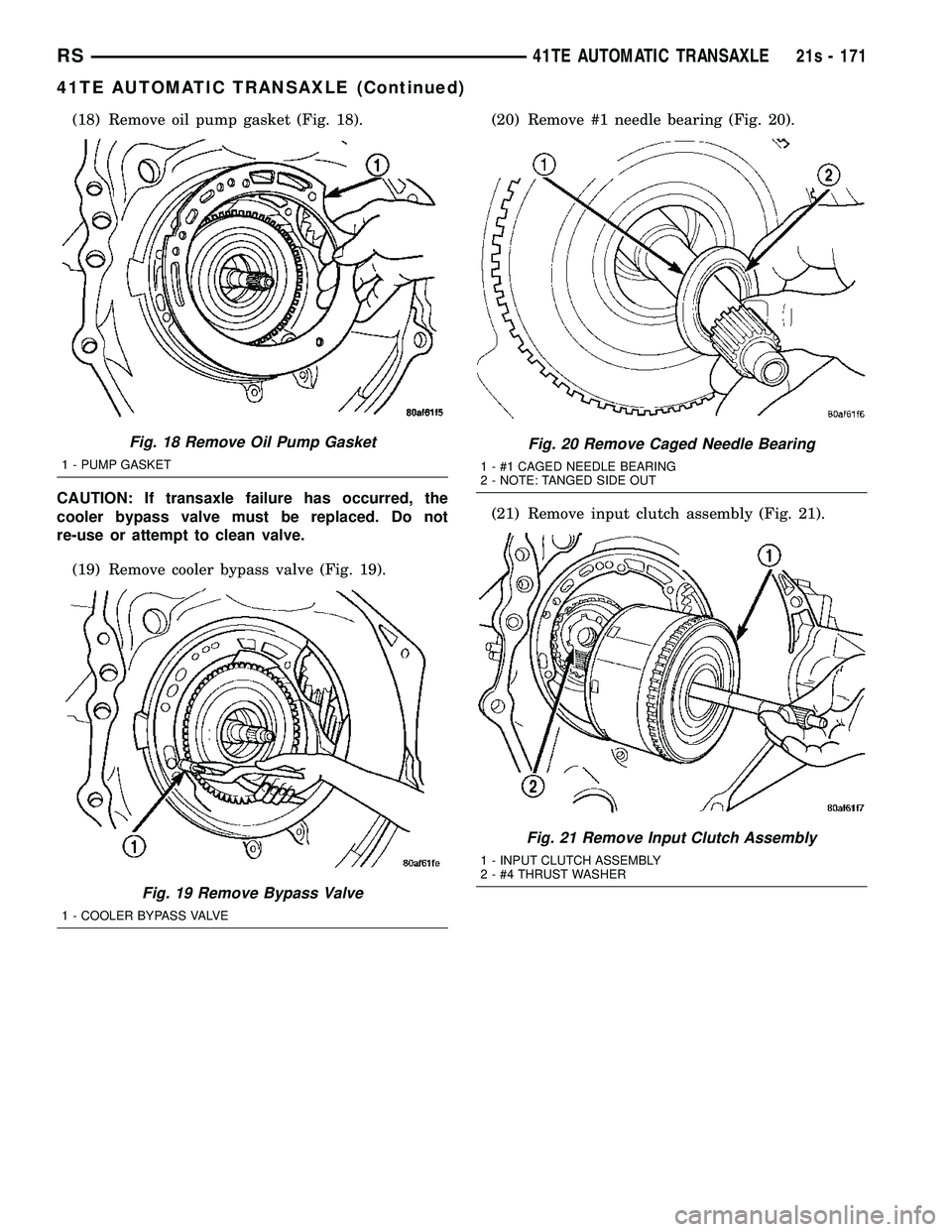

(18) Remove oil pump gasket (Fig. 18).

CAUTION: If transaxle failure has occurred, the

cooler bypass valve must be replaced. Do not

re-use or attempt to clean valve. (19) Remove cooler bypass valve (Fig. 19). (20) Remove #1 needle bearing (Fig. 20).

(21) Remove input clutch assembly (Fig. 21).

Fig. 18 Remove Oil Pump Gasket

1 - PUMP GASKET

Fig. 19 Remove Bypass Valve

1 - COOLER BYPASS VALVE

Fig. 20 Remove Caged Needle Bearing

1 - #1 CAGED NEEDLE BEARING

2 - NOTE: TANGED SIDE OUT

Fig. 21 Remove Input Clutch Assembly

1 - INPUT CLUTCH ASSEMBLY

2 - #4 THRUST WASHER

RS

41TE AUTOMATIC TRANSAXLE21s - 171

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2034 of 2585

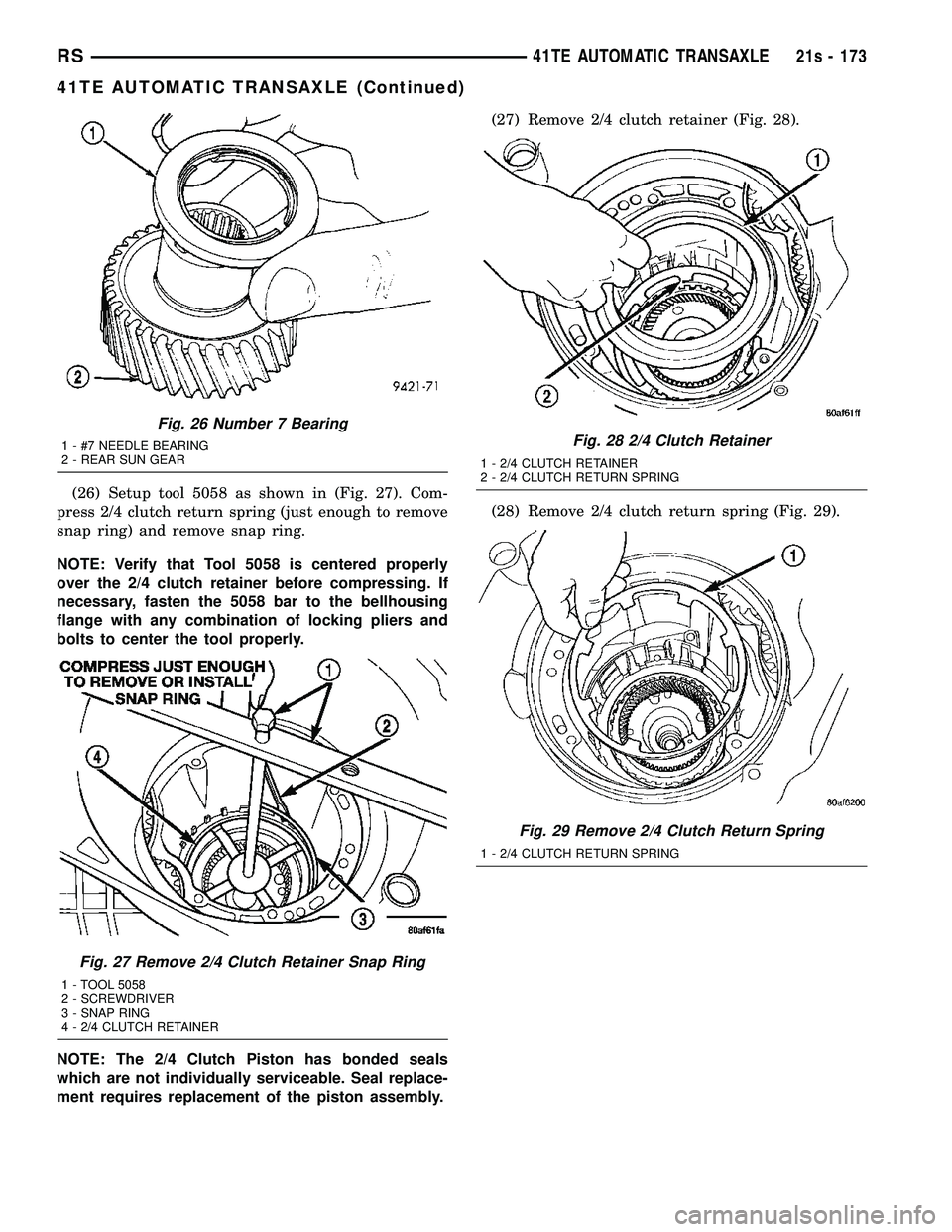

(26) Setup tool 5058 as shown in (Fig. 27). Com-

press 2/4 clutch return spring (just enough to remove

snap ring) and remove snap ring.

NOTE: Verify that Tool 5058 is centered properly

over the 2/4 clutch retainer before compressing. If

necessary, fasten the 5058 bar to the bellhousing

flange with any combination of locking pliers and

bolts to center the tool properly.

NOTE: The 2/4 Clutch Piston has bonded seals

which are not individually serviceable. Seal replace-

ment requires replacement of the piston assembly. (27) Remove 2/4 clutch retainer (Fig. 28).

(28) Remove 2/4 clutch return spring (Fig. 29).

Fig. 26 Number 7 Bearing

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 27 Remove 2/4 Clutch Retainer Snap Ring

1 - TOOL 5058

2 - SCREWDRIVER

3 - SNAP RING

4 - 2/4 CLUTCH RETAINER

Fig. 28 2/4 Clutch Retainer

1 - 2/4 CLUTCH RETAINER

2 - 2/4 CLUTCH RETURN SPRING

Fig. 29 Remove 2/4 Clutch Return Spring

1 - 2/4 CLUTCH RETURN SPRING

RS

41TE AUTOMATIC TRANSAXLE21s - 173

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2035 of 2585

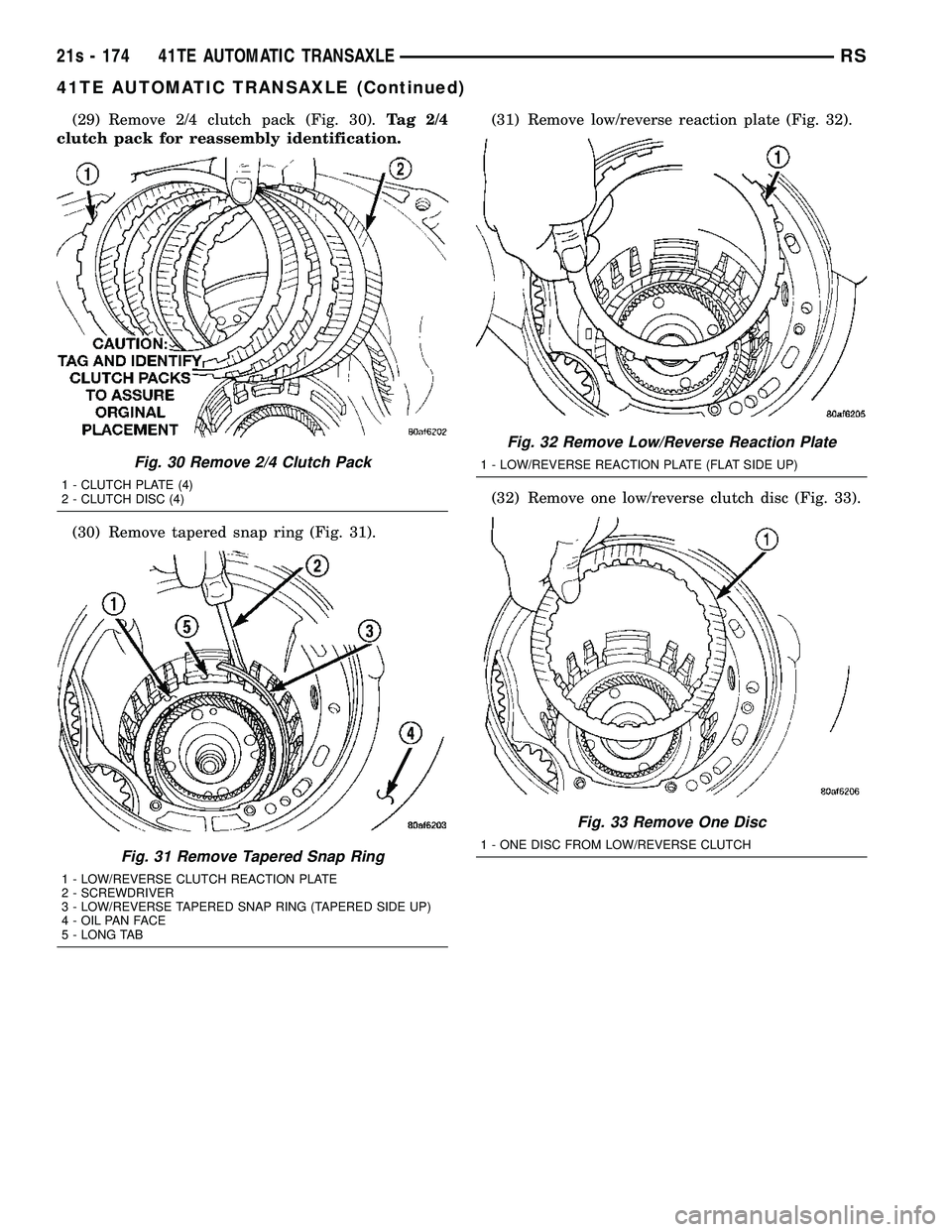

(29) Remove 2/4 clutch pack (Fig. 30).Tag 2/4

clutch pack for reassembly identification.

(30) Remove tapered snap ring (Fig. 31). (31) Remove low/reverse reaction plate (Fig. 32).

(32) Remove one low/reverse clutch disc (Fig. 33).

Fig. 30 Remove 2/4 Clutch Pack

1 - CLUTCH PLATE (4)

2 - CLUTCH DISC (4)

Fig. 31 Remove Tapered Snap Ring

1 - LOW/REVERSE CLUTCH REACTION PLATE

2 - SCREWDRIVER

3 - LOW/REVERSE TAPERED SNAP RING (TAPERED SIDE UP)

4 - OIL PAN FACE

5 - LONG TAB

Fig. 32 Remove Low/Reverse Reaction Plate

1 - LOW/REVERSE REACTION PLATE (FLAT SIDE UP)

Fig. 33 Remove One Disc

1 - ONE DISC FROM LOW/REVERSE CLUTCH

21s - 174 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2036 of 2585

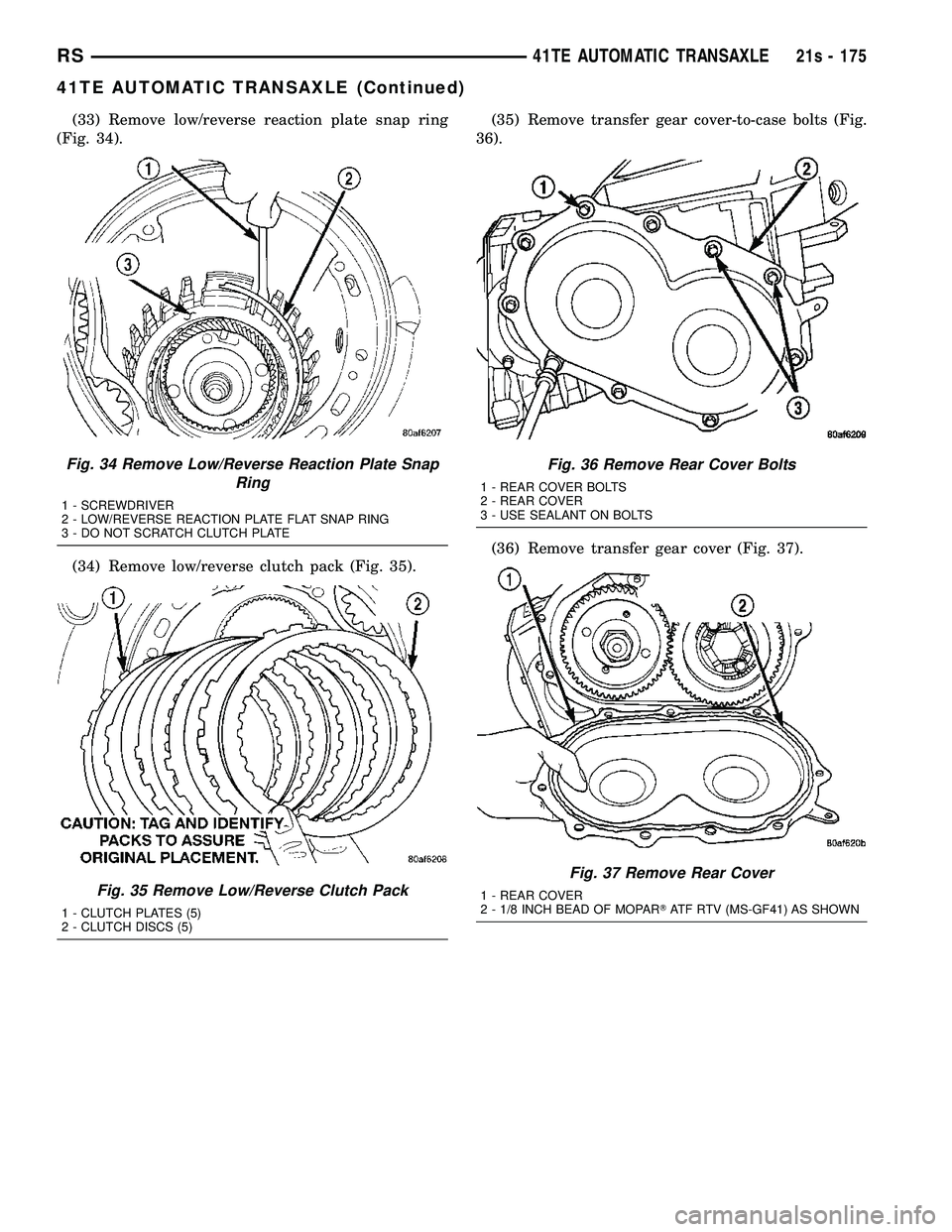

(33) Remove low/reverse reaction plate snap ring

(Fig. 34).

(34) Remove low/reverse clutch pack (Fig. 35). (35) Remove transfer gear cover-to-case bolts (Fig.

36).

(36) Remove transfer gear cover (Fig. 37).

Fig. 34 Remove Low/Reverse Reaction Plate Snap Ring

1 - SCREWDRIVER

2 - LOW/REVERSE REACTION PLATE FLAT SNAP RING

3 - DO NOT SCRATCH CLUTCH PLATE

Fig. 35 Remove Low/Reverse Clutch Pack

1 - CLUTCH PLATES (5)

2 - CLUTCH DISCS (5)

Fig. 36 Remove Rear Cover Bolts

1 - REAR COVER BOLTS

2 - REAR COVER

3 - USE SEALANT ON BOLTS

Fig. 37 Remove Rear Cover

1 - REAR COVER

2 - 1/8 INCH BEAD OF MOPAR TATF RTV (MS-GF41) AS SHOWN

RS 41TE AUTOMATIC TRANSAXLE21s - 175

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2042 of 2585

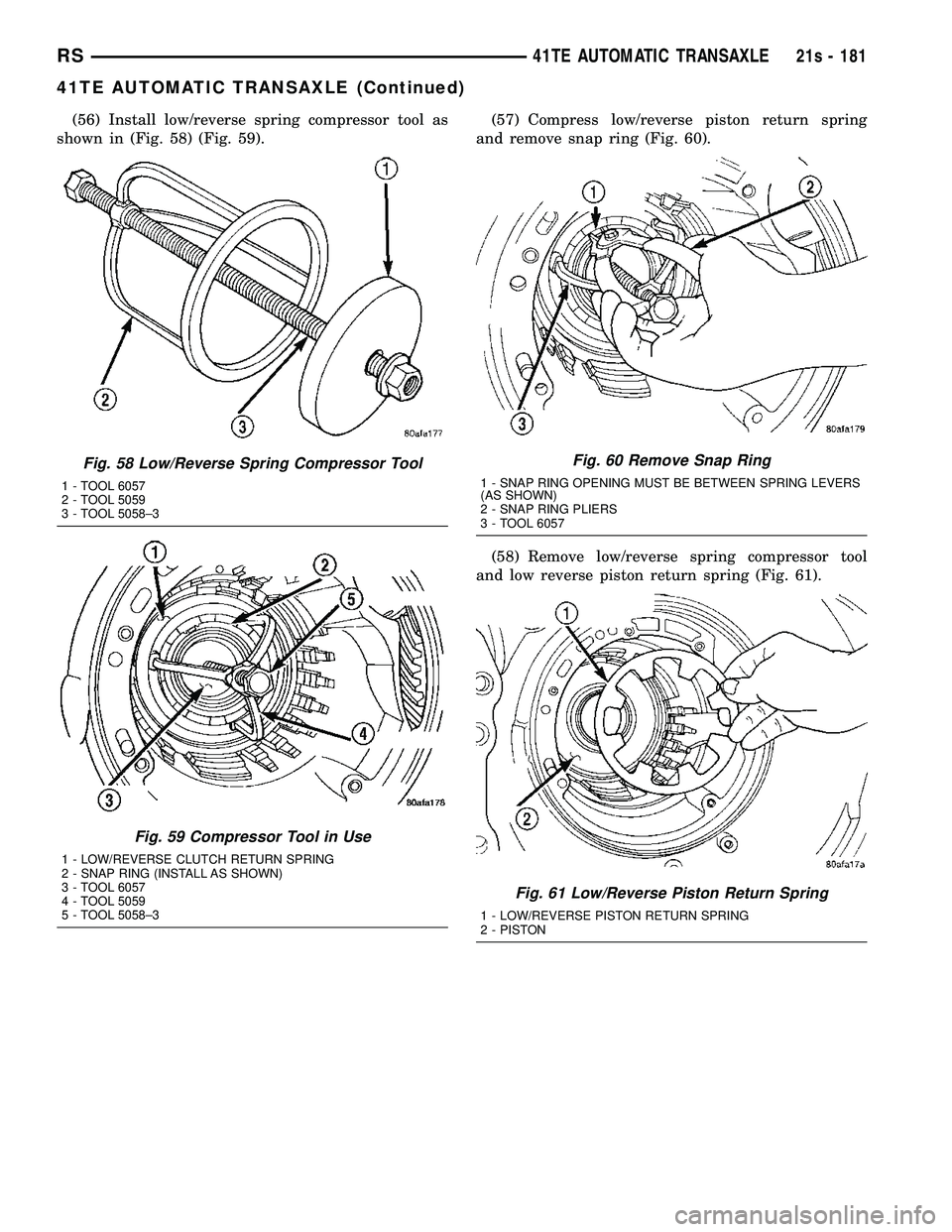

(56) Install low/reverse spring compressor tool as

shown in (Fig. 58) (Fig. 59). (57) Compress low/reverse piston return spring

and remove snap ring (Fig. 60).

(58) Remove low/reverse spring compressor tool

and low reverse piston return spring (Fig. 61).

Fig. 58 Low/Reverse Spring Compressor Tool

1 - TOOL 6057

2 - TOOL 5059

3 - TOOL 5058±3

Fig. 59 Compressor Tool in Use

1 - LOW/REVERSE CLUTCH RETURN SPRING

2 - SNAP RING (INSTALL AS SHOWN)

3 - TOOL 6057

4 - TOOL 5059

5 - TOOL 5058±3

Fig. 60 Remove Snap Ring

1 - SNAP RING OPENING MUST BE BETWEEN SPRING LEVERS

(AS SHOWN)

2 - SNAP RING PLIERS

3 - TOOL 6057

Fig. 61 Low/Reverse Piston Return Spring

1 - LOW/REVERSE PISTON RETURN SPRING

2 - PISTON

RS 41TE AUTOMATIC TRANSAXLE21s - 181

41TE AUTOMATIC TRANSAXLE (Continued)