8e electrical CHRYSLER VOYAGER 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 285 of 2585

(24) Install knee blocker reinforcement plate (Fig.

53). (25) Connect parking brake release link to release

handle. (26) Install data link diagnostic connector to

mounting hole in reinforcement plate. (27) Install lower steering column cover/knee

blocker (Fig. 53). (28) Install throttle cable onto throttle body lever.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - INSTALLATION)

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(29) Reconnect ground cable to negative post of

battery following special Diagnosis And Testing pro-

cedure. (Refer t o 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING) (30) Test operation of adjustable pedals and all

functions that are steering column operated. If appli-

cable, reset radio and clock. (31) Road test the vehicle to ensure proper opera-

tion of steering and brake systems.

PEDAL TORQUE SHAFT - RHD

REMOVAL

(1) Remove the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL) (2) Remove the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL) (3) Remove the retaining clip at the torque shaft

end of the brake pedal-to-torque shaft link. Remove

the link from the torque shaft. Discard the retaining

clip. It is not to be reused. Replace with a new clip

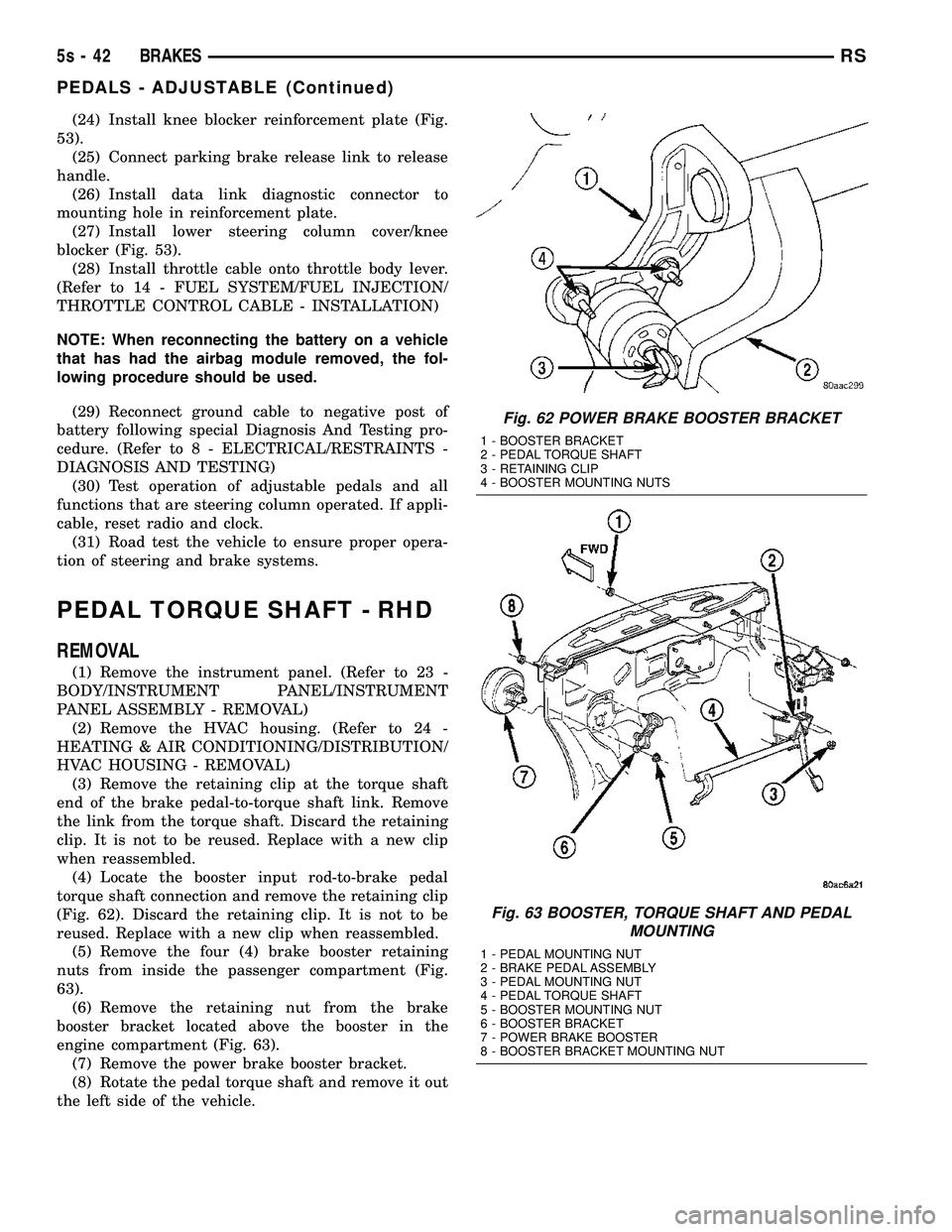

when reassembled. (4) Locate the booster input rod-to-brake pedal

torque shaft connection and remove the retaining clip

(Fig. 62). Discard the retaining clip. It is not to be

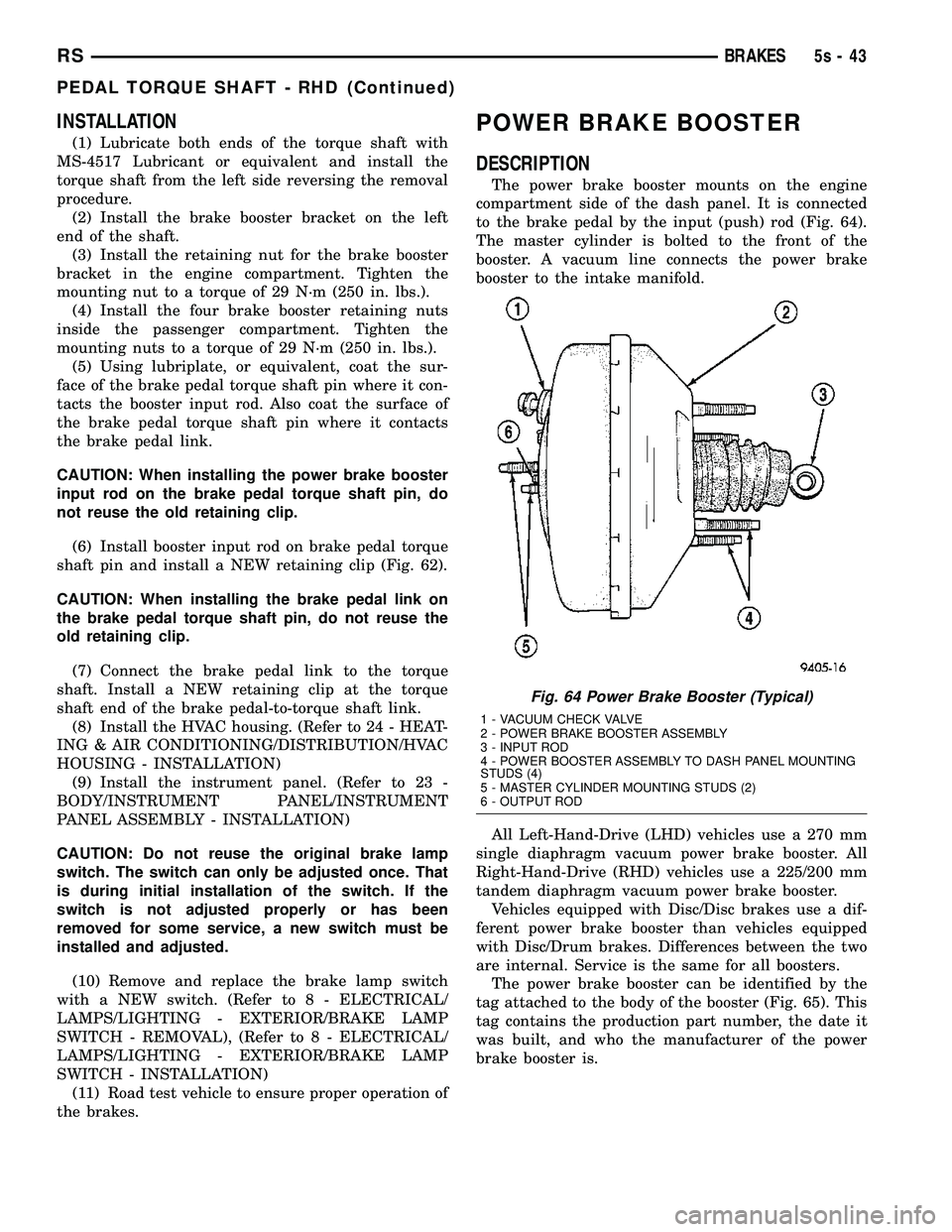

reused. Replace with a new clip when reassembled. (5) Remove the four (4) brake booster retaining

nuts from inside the passenger compartment (Fig.

63). (6) Remove the retaining nut from the brake

booster bracket located above the booster in the

engine compartment (Fig. 63). (7) Remove the power brake booster bracket.

(8) Rotate the pedal torque shaft and remove it out

the left side of the vehicle.

Fig. 62 POWER BRAKE BOOSTER BRACKET

1 - BOOSTER BRACKET

2 - PEDAL TORQUE SHAFT

3 - RETAINING CLIP

4 - BOOSTER MOUNTING NUTS

Fig. 63 BOOSTER, TORQUE SHAFT AND PEDAL MOUNTING

1 - PEDAL MOUNTING NUT

2 - BRAKE PEDAL ASSEMBLY

3 - PEDAL MOUNTING NUT

4 - PEDAL TORQUE SHAFT

5 - BOOSTER MOUNTING NUT

6 - BOOSTER BRACKET

7 - POWER BRAKE BOOSTER

8 - BOOSTER BRACKET MOUNTING NUT

5s - 42 BRAKESRS

PEDALS - ADJUSTABLE (Continued)

Page 286 of 2585

INSTALLATION

(1) Lubricate both ends of the torque shaft with

MS-4517 Lubricant or equivalent and install the

torque shaft from the left side reversing the removal

procedure. (2) Install the brake booster bracket on the left

end of the shaft. (3) Install the retaining nut for the brake booster

bracket in the engine compartment. Tighten the

mounting nut to a torque of 29 N´m (250 in. lbs.). (4) Install the four brake booster retaining nuts

inside the passenger compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.). (5) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod. Also coat the surface of

the brake pedal torque shaft pin where it contacts

the brake pedal link.

CAUTION: When installing the power brake booster

input rod on the brake pedal torque shaft pin, do

not reuse the old retaining clip.

(6) Install booster input rod on brake pedal torque

shaft pin and install a NEW retaining clip (Fig. 62).

CAUTION: When installing the brake pedal link on

the brake pedal torque shaft pin, do not reuse the

old retaining clip.

(7) Connect the brake pedal link to the torque

shaft. Install a NEW retaining clip at the torque

shaft end of the brake pedal-to-torque shaft link. (8) Install the HVAC housing. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION) (9) Install the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION)

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(10) Remove and replace the brake lamp switch

with a NEW switch. (Refer t o 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer t o 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION) (11) Road test vehicle to ensure proper operation of

the brakes.

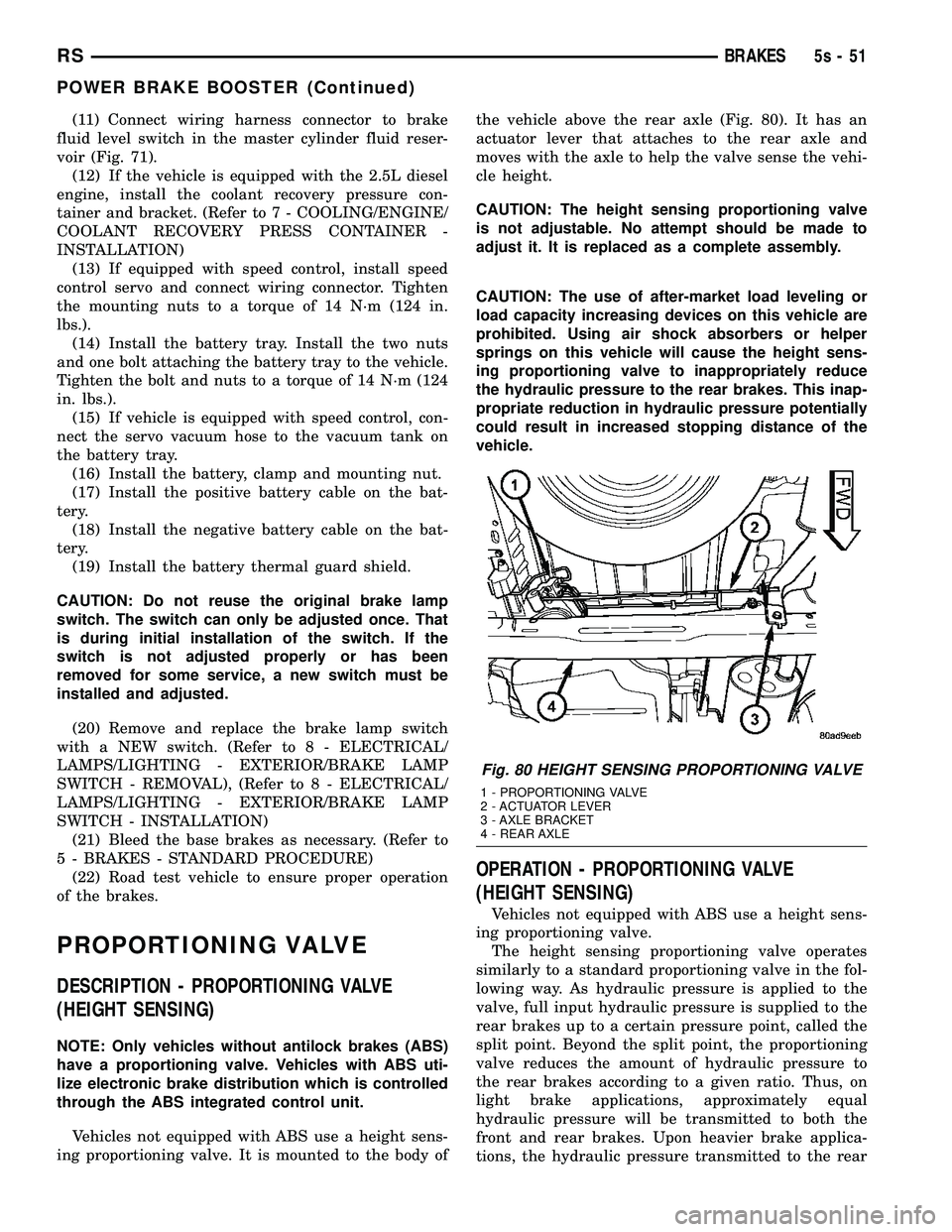

POWER BRAKE BOOSTER

DESCRIPTION

The power brake booster mounts on the engine

compartment side of the dash panel. It is connected

to the brake pedal by the input (push) rod (Fig. 64).

The master cylinder is bolted to the front of the

booster. A vacuum line connects the power brake

booster to the intake manifold.

All Left-Hand-Drive (LHD) vehicles use a 270 mm

single diaphragm vacuum power brake booster. All

Right-Hand-Drive (RHD) vehicles use a 225/200 mm

tandem diaphragm vacuum power brake booster. Vehicles equipped with Disc/Disc brakes use a dif-

ferent power brake booster than vehicles equipped

with Disc/Drum brakes. Differences between the two

are internal. Service is the same for all boosters. The power brake booster can be identified by the

tag attached to the body of the booster (Fig. 65). This

tag contains the production part number, the date it

was built, and who the manufacturer of the power

brake booster is.

Fig. 64 Power Brake Booster (Typical)

1 - VACUUM CHECK VALVE

2 - POWER BRAKE BOOSTER ASSEMBLY

3 - INPUT ROD

4 - POWER BOOSTER ASSEMBLY TO DASH PANEL MOUNTING

STUDS (4)

5 - MASTER CYLINDER MOUNTING STUDS (2)

6 - OUTPUT ROD

RS BRAKES5s-43

PEDAL TORQUE SHAFT - RHD (Continued)

Page 288 of 2585

(6) Apply light effort (approximately 15 lbs. of

force) to the brake pedal and hold the pedal steady.

Do not move the pedal once the pressure is applied

or the test results may vary. (7) Have an assistant reattach the vacuum line

pliers to the vacuum supply hose. (8) Allow 5 seconds for stabilization, then observe

the vacuum gauge. If the vacuum drop exceeds 3.0 inches Hg (10 kPa)

in 15 seconds, repeat the above steps to confirm the

reading. The vacuum loss should be less than 3.0

inches Hg in 15 seconds time span. If the loss is

more than 3.0 inches Hg, replace the power brake

booster. If it is not, the booster is not defective. (9) Remove the pliers and vacuum gauge.

REMOVAL

REMOVAL - LHD

CAUTION: Reserve vacuum in power brake booster

must be pumped down (removed) before removing

master cylinder from booster. This is necessary to

prevent booster from sucking in any contamination

as master cylinder is removed. This can be done

simply by pumping the brake pedal, with the vehi-

cle's engine not running, until a firm feeling brake

pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes). (2) Remove negative battery cable terminal from

battery. (3) Remove positive battery cable terminal from

battery. (4) Remove battery thermal guard shield.

(5) Remove battery clamp, nut and battery from

the battery tray. (6) Remove screw securing engine coolant filler

tube to battery tray. (7) If the vehicle is equipped with speed control,

disconnect the vacuum hose at the vacuum tank built

into the battery tray. (8) Remove the two nuts and one bolt securing bat-

tery tray in place. Remove battery tray. (9) If vehicle is equipped with speed control:(a) Disconnect wiring harness connector from

the speed control servo. (b) Remove the two servo mounting nuts.

(c) Lay speed control servo off to the side, out of

the way.

(10) Remove the wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL) (11) Disconnect wiring harness connector from

brake fluid level switch in master cylinder fluid res-

ervoir (Fig. 66).

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(12) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as Mopar tBrake Parts Cleaner or equivalent.

(13) Disconnect primary and secondary brake

tubes from ABS integrated control unit or non-ABS

junction block (Fig. 67). Install sealing plugs in the

now open brake tube ports and install caps on ends

of tubes.

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the vacuum booster.

(14) Remove two nuts attaching master cylinder to

power brake booster (Fig. 67). (15) Slide master cylinder straight out of power

brake booster. Remove master cylinder with primary

and secondary tubes from vehicle.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

Fig. 66 Master Cylinder And Booster

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

RS BRAKES5s-45

POWER BRAKE BOOSTER (Continued)

Page 292 of 2585

INSTALLATION

INSTALLATION - LHD

(1) Position power brake booster on dash panel

using the reverse procedure of its removal (Fig. 70).

It may be necessary to push in on booster input rod

as it is guided through the dash panel. (2) Install the four nuts mounting the booster to

the dash panel (Fig. 69). Tighten the mounting nuts

to a torque of 29 N´m (250 in. lbs.). (3) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal pin where it contacts the

booster input rod.

CAUTION: When installing the brake pedal pin on

the power brake booster input rod, do not re-use

the old retaining clip.

(4) Install booster input rod on brake pedal pin

and install a NEW retaining clip (Fig. 76).

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(5) Remove and replace the brake lamp switch

with a NEW switch. (Refer t o 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer t o 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION) (6) Install the silencer panel below the steering

column. (7) Connect vacuum hose to check valve on power

brake booster.

CAUTION: The master cylinder (and its rear seal) is

used to create the seal for holding vacuum in the

vacuum booster. The vacuum seal on the master

cylinder MUST be replaced with a NEW seal when-

ever the master cylinder is removed from the vac-

uum booster.

CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(8) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange. (9) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 77).

(10) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston. (11) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 67). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.). (12) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 66). (13) Connect primary and secondary brake tubes

to ABS ICU or non-ABS junction block (Fig. 67).

Tighten the tube nuts to 17 N´m (145 in lbs.). (14) Install wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION) (15) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

Fig. 76 Retaining Pin Installed On Brake Pedal Pin

1 - BRAKE PEDAL

2 - RETAINING CLIP

3 - BOOSTER INPUT ROD

Fig. 77 Vacuum Seal (Typical)

1 - MASTER CYLINDER ASSEMBLY

2 - VACUUM SEAL

RS BRAKES5s-49

POWER BRAKE BOOSTER (Continued)

Page 294 of 2585

(11) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 71). (12) If the vehicle is equipped with the 2.5L diesel

engine, install the coolant recovery pressure con-

tainer and bracket. (Refer t o 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESS CONTAINER -

INSTALLATION) (13) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

the mounting nuts to a torque of 14 N´m (124 in.

lbs.). (14) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.). (15) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray. (16) Install the battery, clamp and mounting nut.

(17) Install the positive battery cable on the bat-

tery. (18) Install the negative battery cable on the bat-

tery. (19) Install the battery thermal guard shield.

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted. (20) Remove and replace the brake lamp switch

with a NEW switch. (Refer t o 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer t o 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION) (21) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE) (22) Road test vehicle to ensure proper operation

of the brakes.

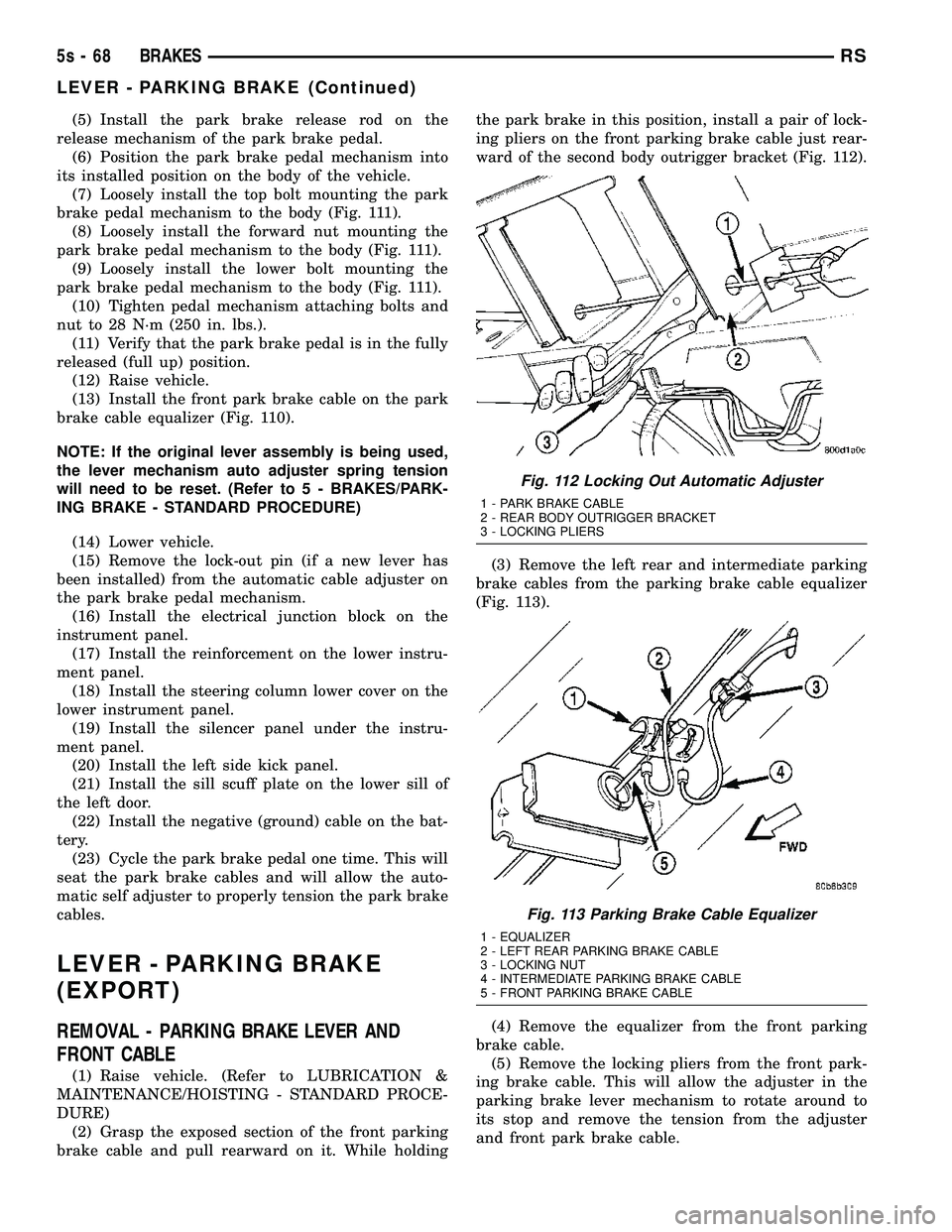

PROPORTIONING VALVE

DESCRIPTION - PROPORTIONING VALVE

(HEIGHT SENSING)

NOTE: Only vehicles without antilock brakes (ABS)

have a proportioning valve. Vehicles with ABS uti-

lize electronic brake distribution which is controlled

through the ABS integrated control unit.

Vehicles not equipped with ABS use a height sens-

ing proportioning valve. It is mounted to the body of the vehicle above the rear axle (Fig. 80). It has an

actuator lever that attaches to the rear axle and

moves with the axle to help the valve sense the vehi-

cle height.

CAUTION: The height sensing proportioning valve

is not adjustable. No attempt should be made to

adjust it. It is replaced as a complete assembly.

CAUTION: The use of after-market load leveling or

load capacity increasing devices on this vehicle are

prohibited. Using air shock absorbers or helper

springs on this vehicle will cause the height sens-

ing proportioning valve to inappropriately reduce

the hydraulic pressure to the rear brakes. This inap-

propriate reduction in hydraulic pressure potentially

could result in increased stopping distance of the

vehicle.

OPERATION - PROPORTIONING VALVE

(HEIGHT SENSING)

Vehicles not equipped with ABS use a height sens-

ing proportioning valve. The height sensing proportioning valve operates

similarly to a standard proportioning valve in the fol-

lowing way. As hydraulic pressure is applied to the

valve, full input hydraulic pressure is supplied to the

rear brakes up to a certain pressure point, called the

split point. Beyond the split point, the proportioning

valve reduces the amount of hydraulic pressure to

the rear brakes according to a given ratio. Thus, on

light brake applications, approximately equal

hydraulic pressure will be transmitted to both the

front and rear brakes. Upon heavier brake applica-

tions, the hydraulic pressure transmitted to the rear

Fig. 80 HEIGHT SENSING PROPORTIONING VALVE

1 - PROPORTIONING VALVE

2 - ACTUATOR LEVER

3 - AXLE BRACKET

4 - REAR AXLE

RS BRAKES5s-51

POWER BRAKE BOOSTER (Continued)

Page 311 of 2585

(5) Install the park brake release rod on the

release mechanism of the park brake pedal. (6) Position the park brake pedal mechanism into

its installed position on the body of the vehicle. (7) Loosely install the top bolt mounting the park

brake pedal mechanism to the body (Fig. 111). (8) Loosely install the forward nut mounting the

park brake pedal mechanism to the body (Fig. 111). (9) Loosely install the lower bolt mounting the

park brake pedal mechanism to the body (Fig. 111). (10) Tighten pedal mechanism attaching bolts and

nut to 28 N´m (250 in. lbs.). (11) Verify that the park brake pedal is in the fully

released (full up) position. (12) Raise vehicle.

(13) Install the front park brake cable on the park

brake cable equalizer (Fig. 110).

NOTE: If the original lever assembly is being used,

the lever mechanism auto adjuster spring tension

will need to be reset. (Refer t o 5 - BRAKES/PARK-

ING BRAKE - STANDARD PROCEDURE)

(14) Lower vehicle.

(15) Remove the lock-out pin (if a new lever has

been installed) from the automatic cable adjuster on

the park brake pedal mechanism. (16) Install the electrical junction block on the

instrument panel. (17) Install the reinforcement on the lower instru-

ment panel. (18) Install the steering column lower cover on the

lower instrument panel. (19) Install the silencer panel under the instru-

ment panel. (20) Install the left side kick panel.

(21) Install the sill scuff plate on the lower sill of

the left door. (22) Install the negative (ground) cable on the bat-

tery. (23) Cycle the park brake pedal one time. This will

seat the park brake cables and will allow the auto-

matic self adjuster to properly tension the park brake

cables.

LEVER - PARKING BRAKE

(EXPORT)

REMOVAL - PARKING BRAKE LEVER AND

FRONT CABLE

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE) (2) Grasp the exposed section of the front parking

brake cable and pull rearward on it. While holding the park brake in this position, install a pair of lock-

ing pliers on the front parking brake cable just rear-

ward of the second body outrigger bracket (Fig. 112).

(3) Remove the left rear and intermediate parking

brake cables from the parking brake cable equalizer

(Fig. 113).

(4) Remove the equalizer from the front parking

brake cable. (5) Remove the locking pliers from the front park-

ing brake cable. This will allow the adjuster in the

parking brake lever mechanism to rotate around to

its stop and remove the tension from the adjuster

and front park brake cable.

Fig. 112 Locking Out Automatic Adjuster

1 - PARK BRAKE CABLE

2 - REAR BODY OUTRIGGER BRACKET

3 - LOCKING PLIERS

Fig. 113 Parking Brake Cable Equalizer

1 - EQUALIZER

2 - LEFT REAR PARKING BRAKE CABLE

3 - LOCKING NUT

4 - INTERMEDIATE PARKING BRAKE CABLE

5 - FRONT PARKING BRAKE CABLE

5s - 68 BRAKESRS

LEVER - PARKING BRAKE (Continued)

Page 329 of 2585

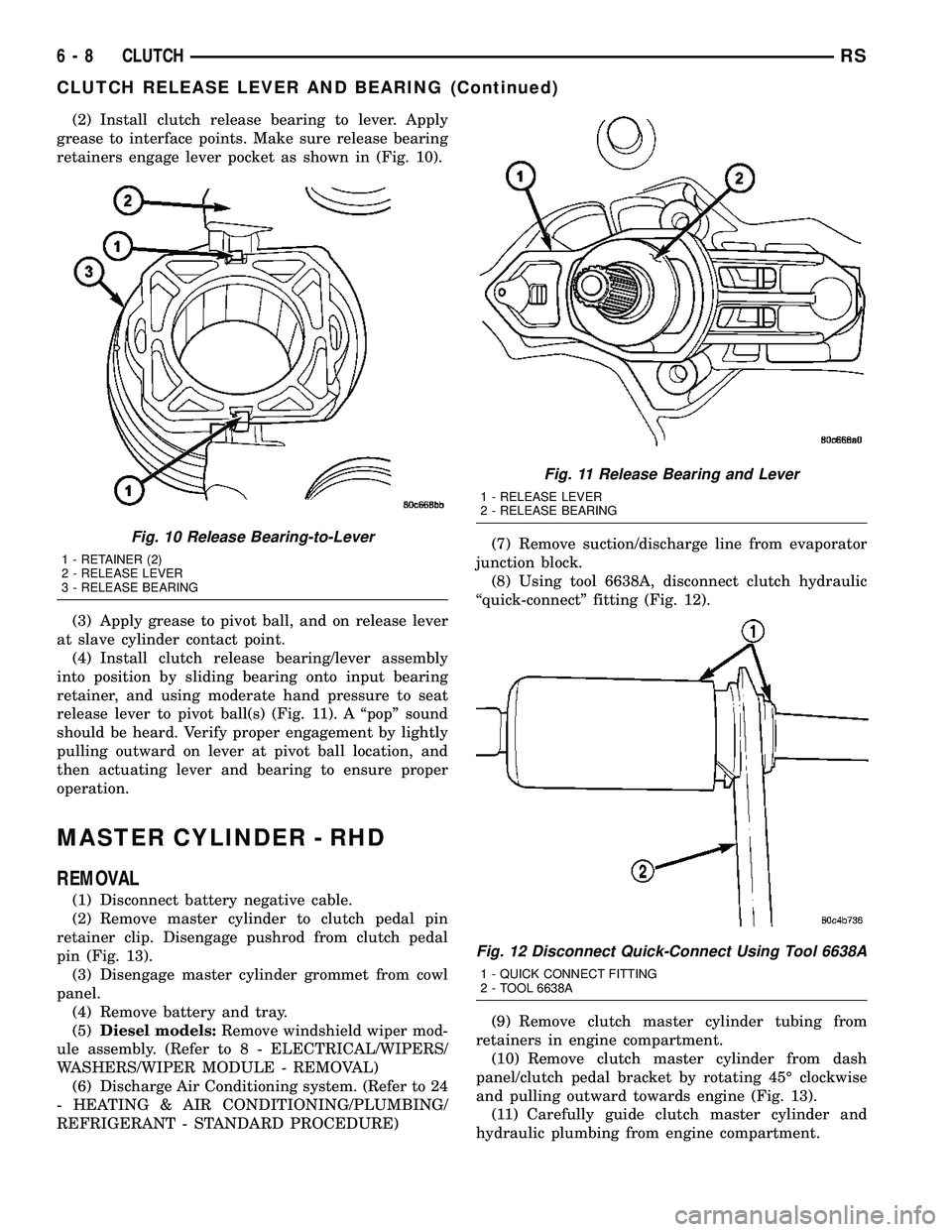

(2) Install clutch release bearing to lever. Apply

grease to interface points. Make sure release bearing

retainers engage lever pocket as shown in (Fig. 10).

(3) Apply grease to pivot ball, and on release lever

at slave cylinder contact point.

(4) Install clutch release bearing/lever assembly

into position by sliding bearing onto input bearing

retainer, and using moderate hand pressure to seat

release lever to pivot ball(s) (Fig. 11). A ªpopº sound

should be heard. Verify proper engagement by lightly

pulling outward on lever at pivot ball location, and

then actuating lever and bearing to ensure proper

operation.

MASTER CYLINDER - RHD

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove master cylinder to clutch pedal pin

retainer clip. Disengage pushrod from clutch pedal

pin (Fig. 13).

(3) Disengage master cylinder grommet from cowl

panel.

(4) Remove battery and tray.

(5)Diesel models:Remove windshield wiper mod-

ule assembly. (Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MODULE - REMOVAL)

(6) Discharge Air Conditioning system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

REFRIGERANT - STANDARD PROCEDURE)(7) Remove suction/discharge line from evaporator

junction block.

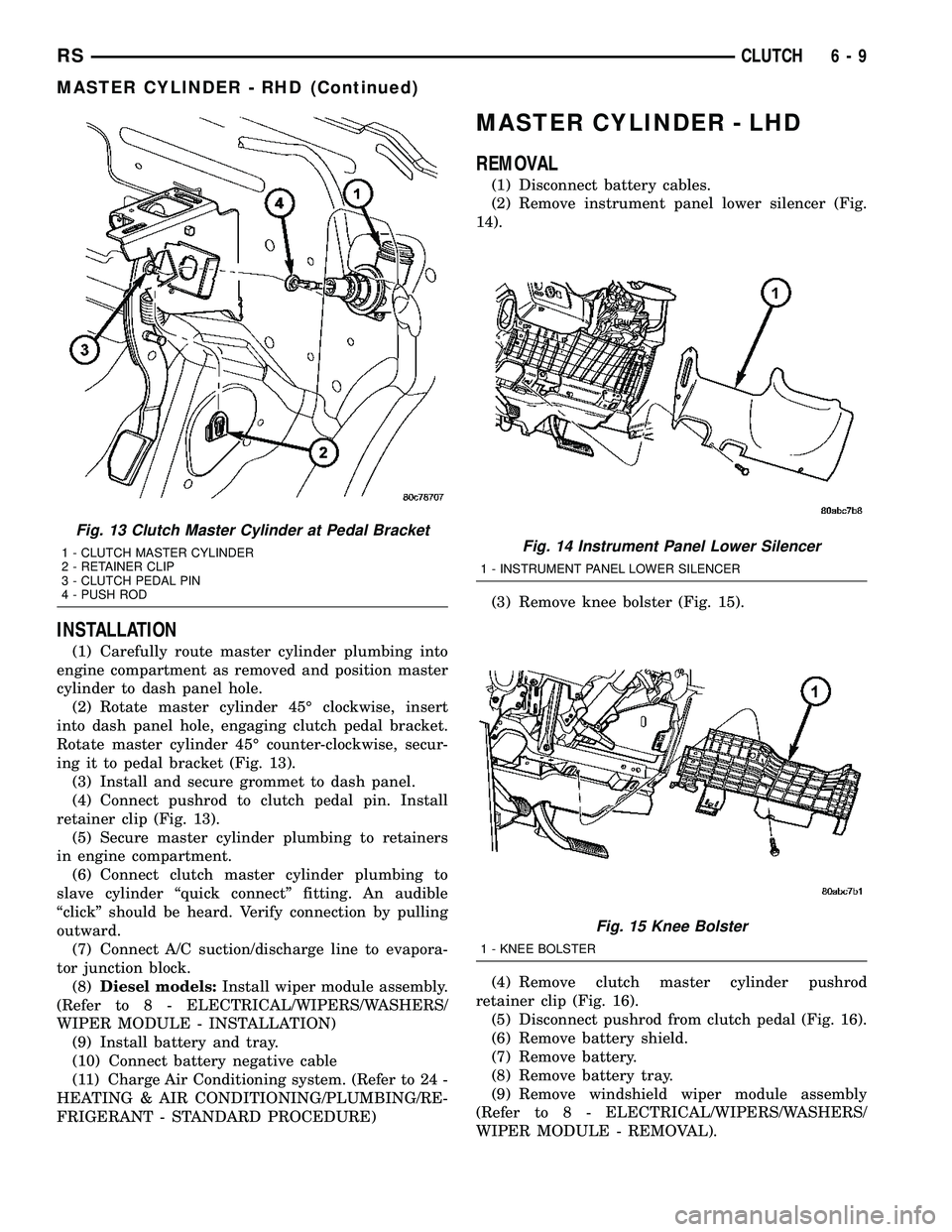

(8) Using tool 6638A, disconnect clutch hydraulic

ªquick-connectº fitting (Fig. 12).

(9) Remove clutch master cylinder tubing from

retainers in engine compartment.

(10) Remove clutch master cylinder from dash

panel/clutch pedal bracket by rotating 45É clockwise

and pulling outward towards engine (Fig. 13).

(11) Carefully guide clutch master cylinder and

hydraulic plumbing from engine compartment.

Fig. 10 Release Bearing-to-Lever

1 - RETAINER (2)

2 - RELEASE LEVER

3 - RELEASE BEARING

Fig. 11 Release Bearing and Lever

1 - RELEASE LEVER

2 - RELEASE BEARING

Fig. 12 Disconnect Quick-Connect Using Tool 6638A

1 - QUICK CONNECT FITTING

2 - TOOL 6638A

6 - 8 CLUTCHRS

CLUTCH RELEASE LEVER AND BEARING (Continued)

Page 330 of 2585

INSTALLATION

(1) Carefully route master cylinder plumbing into

engine compartment as removed and position master

cylinder to dash panel hole.

(2) Rotate master cylinder 45É clockwise, insert

into dash panel hole, engaging clutch pedal bracket.

Rotate master cylinder 45É counter-clockwise, secur-

ing it to pedal bracket (Fig. 13).

(3) Install and secure grommet to dash panel.

(4) Connect pushrod to clutch pedal pin. Install

retainer clip (Fig. 13).

(5) Secure master cylinder plumbing to retainers

in engine compartment.

(6) Connect clutch master cylinder plumbing to

slave cylinder ªquick connectº fitting. An audible

ªclickº should be heard. Verify connection by pulling

outward.

(7) Connect A/C suction/discharge line to evapora-

tor junction block.

(8)Diesel models:Install wiper module assembly.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - INSTALLATION)

(9) Install battery and tray.

(10) Connect battery negative cable

(11) Charge Air Conditioning system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/RE-

FRIGERANT - STANDARD PROCEDURE)

MASTER CYLINDER - LHD

REMOVAL

(1) Disconnect battery cables.

(2) Remove instrument panel lower silencer (Fig.

14).

(3) Remove knee bolster (Fig. 15).

(4) Remove clutch master cylinder pushrod

retainer clip (Fig. 16).

(5) Disconnect pushrod from clutch pedal (Fig. 16).

(6) Remove battery shield.

(7) Remove battery.

(8) Remove battery tray.

(9) Remove windshield wiper module assembly

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - REMOVAL).

Fig. 13 Clutch Master Cylinder at Pedal Bracket

1 - CLUTCH MASTER CYLINDER

2 - RETAINER CLIP

3 - CLUTCH PEDAL PIN

4 - PUSH RODFig. 14 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 15 Knee Bolster

1 - KNEE BOLSTER

RSCLUTCH6-9

MASTER CYLINDER - RHD (Continued)

Page 331 of 2585

(10) Using Tool 6638A, disconnect clutch master

cylinder ªquick connectº fitting (Fig. 17). Disengage

plumbing retainer from body stud.

(11) Remove master cylinder reservoir-to-strut

tower nuts (Fig. 18). Reposition reservoir off to side.

(12) Remove clutch master cylinder from dash

panel by rotating clockwise 45É and removing from

dash panel (Fig. 18).(13) Remove master cylinder and plumbing from

engine compartment. Use care not to bend or kink

plumbing. Note plumbing routing to aid in installa-

tion.

INSTALLATION

(1) Install master cylinder into position, while

routing plumbing as originally installed.

(2) Insert master cylinder pushrod through dash

panel (Fig. 18) and rotate 45É counter-clockwise to

secure.

(3) Connect master cylinder plumbing quick-con-

nect fitting. An audible ªclickº should be heard. Ver-

ify connection by pulling outward.

(4) Install master cylinder reservoir onto strut

tower. Install and tighten two (2) master cylinder

reservoir-to-strut tower nuts to 11 N´m (100 in. lbs.)

(Fig. 18).

(5) Install windshield wiper module assembly

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - INSTALLATION).

(6) Install battery tray.

(7) Install battery.

(8) Install battery shield.

(9) Connect master cylinder pushrod to clutch

pedal lever (Fig. 16). Install retainer clip.

(10) Install knee bolster and instrument panel

lower silencer (Fig. 15) (Fig. 14).

(11) Connect battery cables.

Fig. 16 Master Cylinder Pushrod at Pedal

1 - MASTER CYLINDER PUSHROD

2 - CLUTCH/BRAKE PEDAL ASSEMBLY

3 - PUSHROD RETAINER

Fig. 17 Disconnect Quick-Connect Using Tool 6638A

1 - QUICK CONNECT FITTING

2 - TOOL 6638A

Fig. 18 Clutch Master Cylinder Removal/Installation

1 - CLUTCH MASTER CYLINDER

2 - RESERVOIR

3 - NUT (2)

6 - 10 CLUTCHRS

MASTER CYLINDER - LHD (Continued)

Page 351 of 2585

ENGINE

DIAGNOSIS AND TESTING - ENGINE COOLING

SYSTEM

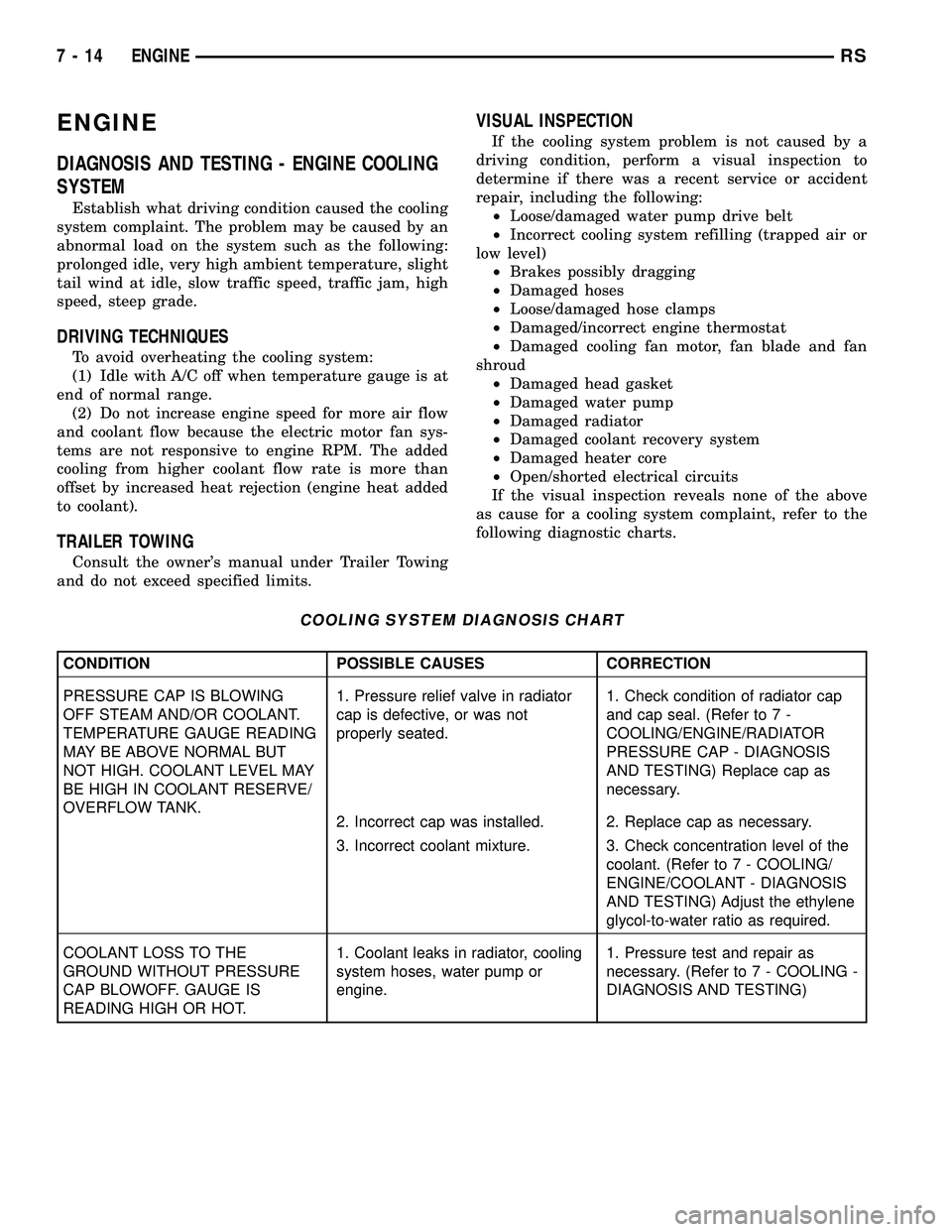

Establish what driving condition caused the cooling

system complaint. The problem may be caused by an

abnormal load on the system such as the following:

prolonged idle, very high ambient temperature, slight

tail wind at idle, slow traffic speed, traffic jam, high

speed, steep grade.

DRIVING TECHNIQUES

To avoid overheating the cooling system:

(1) Idle with A/C off when temperature gauge is at

end of normal range.

(2) Do not increase engine speed for more air flow

and coolant flow because the electric motor fan sys-

tems are not responsive to engine RPM. The added

cooling from higher coolant flow rate is more than

offset by increased heat rejection (engine heat added

to coolant).

TRAILER TOWING

Consult the owner's manual under Trailer Towing

and do not exceed specified limits.

VISUAL INSPECTION

If the cooling system problem is not caused by a

driving condition, perform a visual inspection to

determine if there was a recent service or accident

repair, including the following:

²Loose/damaged water pump drive belt

²Incorrect cooling system refilling (trapped air or

low level)

²Brakes possibly dragging

²Damaged hoses

²Loose/damaged hose clamps

²Damaged/incorrect engine thermostat

²Damaged cooling fan motor, fan blade and fan

shroud

²Damaged head gasket

²Damaged water pump

²Damaged radiator

²Damaged coolant recovery system

²Damaged heater core

²Open/shorted electrical circuits

If the visual inspection reveals none of the above

as cause for a cooling system complaint, refer to the

following diagnostic charts.

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT.

TEMPERATURE GAUGE READING

MAY BE ABOVE NORMAL BUT

NOT HIGH. COOLANT LEVEL MAY

BE HIGH IN COOLANT RESERVE/

OVERFLOW TANK.1. Pressure relief valve in radiator

cap is defective, or was not

properly seated.1. Check condition of radiator cap

and cap seal. (Refer to 7 -

COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS

AND TESTING) Replace cap as

necessary.

2. Incorrect cap was installed. 2. Replace cap as necessary.

3. Incorrect coolant mixture. 3. Check concentration level of the

coolant. (Refer to 7 - COOLING/

ENGINE/COOLANT - DIAGNOSIS

AND TESTING) Adjust the ethylene

glycol-to-water ratio as required.

COOLANT LOSS TO THE

GROUND WITHOUT PRESSURE

CAP BLOWOFF. GAUGE IS

READING HIGH OR HOT.1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.1. Pressure test and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING)

7 - 14 ENGINERS