ad blue CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 710 of 2585

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD.................Left Hand Drive Vehicles

RHD ...............Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX . . . Manual Transmissions-Front Wheel Drive

AT....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export....... Vehicles Built For Sale In

Markets Other Than North America

Except Built-Up-Export . Vehicles Built For Sale In

North America

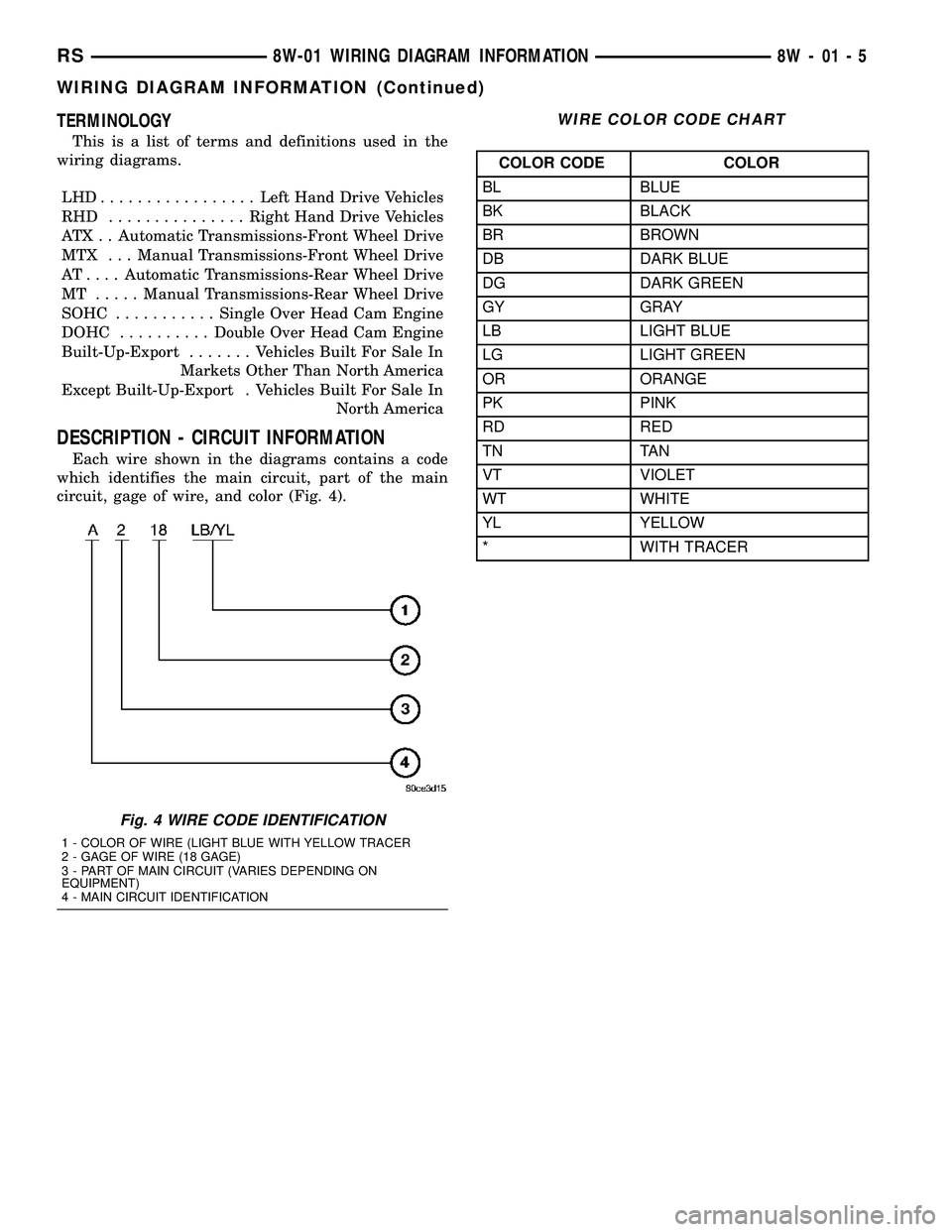

DESCRIPTION - CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 4).

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

Fig. 4 WIRE CODE IDENTIFICATION

1 - COLOR OF WIRE (LIGHT BLUE WITH YELLOW TRACER

2 - GAGE OF WIRE (18 GAGE)

3 - PART OF MAIN CIRCUIT (VARIES DEPENDING ON

EQUIPMENT)

4 - MAIN CIRCUIT IDENTIFICATION

RS8W-01 WIRING DIAGRAM INFORMATION8W-01-5

WIRING DIAGRAM INFORMATION (Continued)

Page 1102 of 2585

A/C-HEATER CONTROL C2 (MTC) - BLACK/BLUE 10 WAY

CAV CIRCUIT FUNCTION

1- -

2 C75 12DB/GY BLOWER MOTOR HIGH DRIVER

3 C73 14DB/VT (EXCEPT EXPORT) BLOWER MOTOR M2 DRIVER

3 C74 12DB/WT (EXPORT) BLOWER MOTOR M3 DRIVER

4 Z134 12BK/LG GROUND

5 C71 16DB/BR (EXPORT) BLOWER MOTOR LOW DRIVER

6- -

7- -

8- -

9 C72 16DB/OR (EXCEPT EXPORT) BLOWER MOTOR M1 DRIVER

9 C73 14DB/VT (EXPORT) BLOWER MOTOR M2 DRIVER

10 C71 16DB/BR (EXCEPT EXPORT) BLOWER MOTOR LOW DRIVER

10 C72 16DB/OR (EXPORT) BLOWER MOTOR M1 DRIVER

ACCELERATOR PEDAL POSITION SENSOR (DIESEL) - 10 WAY

CAV CIRCUIT FUNCTION

A- -

B- -

C- -

D K4 20BK/LB LOW IDLE POSITION SWITCH GROUND

E K151 20WT LOW IDLE POSITION SWITCH SENSE

F- -

G K22 20OR/DB ACCELERATOR PEDAL POSITION SENSOR SIGNAL

H- -

J- -

K F852 20VT/PK ACCELERATOR PEDAL POSITION SENSOR 5 VOLT

SUPPLY

ADJUSTABLE PEDALS MODULE (EXCEPT EXPORT) - 14 WAY

CAV CIRCUIT FUNCTION

1 Q102 18OR/LG ADJUSTABLE PEDALS SWITCH FORWARD

2 Q103 18OR/LB ADJUSTABLE PEDALS SWITCH REARWARD

3 P205 18LG/DB ADJUSTABLE PEDALS MOTOR FORWARD

4 A108 18LG/RD (MEMORY) FUSED B(+)

5-

6 P206 18LG/TN ADJUSTABLE PEDALS MOTOR REARWARD

7 G11 18VT/TN ADJUSTABLE PEDALS SENSOR FEED

8 G12 18VT/BR ADJUSTABLE PEDALS SENSOR SIGNAL

9 G912 18VT/WT ADJUSTABLE PEDALS SENSOR RETURN

10 Z246 18BK/YL (MEMORY) GROUND

11 -

12 -

13 D25 18WT/VT (MEMORY) PCI BUS

14 -

RS8W-80 CONNECTOR PIN-OUTS8W-80-7

Page 1166 of 2585

ENGINE COOLANT TEMP SENSOR (DIESEL) - BLUE 2 WAY

CAV CIRCUIT FUNCTION

1 K2 20TN/BK ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

2 K900 20DB/DG SENSOR GROUND

ENGINE COOLANT TEMP SENSOR (GAS) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 K900 18DB/DG SENSOR GROUND

2 K2 18VT/OR ECT SIGNAL

ENGINE OIL PRESSURE SENSOR (DIESEL) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 F855 20PK/YL SENSOR REFERENCE VOLTAGE A

2 G6 20VT/GY ENGINE OIL PRESSURE SENSOR SIGNAL

3 K936 20BR/YL ENGINE OIL PRESSURE SENSOR GROUND

ENGINE OIL PRESSURE SWITCH (GAS) - LT. GREEN 2 WAY

CAV CIRCUIT FUNCTION

1 G6 16VT/GY OIL PRESSURE SIGNAL

2- -

RS8W-80 CONNECTOR PIN-OUTS8W-80-71

Page 1178 of 2585

INTEGRATED POWER MODULE C2 - GREEN/BLUE 10 WAY

CAV CIRCUIT FUNCTION

1 N173 18DB/VT (GAS) RAD FAN RELAY CONTROL

2 V53 12BR/OR (EXPORT) HEADLAMP WASHER RELAY OUTPUT

3 L60 18WT/TN RIGHT FRONT TURN SIGNAL DRIVER

4 L13 18WT/YL (EXPORT) HEADLAMP ADJUST SIGNAL

5 X2 18DG/OR HORN RELAY OUTPUT

6 L90 18WT/OR (FOG LAMPS) FRONT FOG LAMP RELAY OUTPUT

7 L61 18WT/LB LEFT FRONT TURN SIGNAL DRIVER

8- -

9 A112 12OR/RD FUSED B(+)

10 L89 18WT/YL (FOG LAMPS) FRONT FOG LAMP RELAY OUTPUT

INTEGRATED POWER MODULE C3 - 20 WAY

CAV CIRCUIT FUNCTION

1 Z115 18BK/OR (2.4L EATX) GROUND

1 Z115 20BK/OR (3.3L/3.8L) GROUND

1 N21 20DB/TN (DIESEL) LIFT PUMP RELAY CONTROL

2 F1 18PK/WT (GAS EATX) FCM OUTPUT (UNLOCK-RUN-START)

3 T751 20YL (DIESEL) FUSED IGNITION SWITCH OUTPUT (START)

3 T751 18YL (GAS) FUSED IGNITION SWITCH OUTPUT (START)

4 T2 18DG/WT (MTX) TRS REVERSE SENSE

5 N2 18DB/YL (DIESEL) LIFT PUMP RELAY OUTPUT

5 T16 18YL/OR (GAS EATX) TRANSMISSION CONTROL RELAY OUTPUT

6 F202 20PK/GY (DIESEL) FUSED IGNITION SWITCH OUTPUT (RUN-START)

6 T15 18YL/BR (GAS EATX) TRANSMISSION CONTROL RELAY CONTROL

7 C3 20DB/YL A/C CLUTCH RELAY OUTPUT

8 Z114 18BK/LG (DIESEL) GROUND

8 K31 18BR (GAS) FUEL PUMP RELAY CONTROL

9 C13 20LB/OR (DIESEL) A/C COMPRESSOR CLUTCH RELAY CONTROL

9 C13 18LB/OR (GAS) A/C COMPRESSOR CLUTCH RELAY CONTROL

10 A119 16RD/OR (DIESEL) FUSED B(+)

11 C41 20LB/DG (DIESEL) CABIN HEATER ASSIST CONTROL

12 - -

13 D25 20WT/VT (DIESEL) PCI BUS

13 D25 18WT/VT (GAS) PCI BUS

14 T752 20DG/OR (DIESEL) STARTER MOTOR RELAY CONTROL

14 T752 18DG/OR (GAS) STARTER RELAY CONTROL

15 Z116 18BK/VT GROUND

16 K51 20BR/WT (DIESEL) ECM/PCM RELAY CONTROL

16 K51 18BR/WT (GAS) ASD RELAY CONTROL

17 F202 20PK/GY FUSED IGNITION SWITCH OUTPUT (RUN-START)

18 K173 18BR/VT (GAS) RAD FAN RELAY CONTROL

19 K342 16BR/WT (DIESEL) ECM/PCM RELAY OUTPUT

19 F202 20PK/GY (GAS) FUSED IGNITION SWITCH OUTPUT (RUN-START)

20 A109 18OR/RD (GAS) FUSED B(+)

RS8W-80 CONNECTOR PIN-OUTS8W-80-83

Page 1179 of 2585

INTEGRATED POWER MODULE C4 - BLUE 10 WAY

CAV CIRCUIT FUNCTION

1 Z127 12BK (ASSY. PLANT EVAC &

FILL)GROUND

2 T750 12YL/GY STARTER MOTOR RELAY OUTPUT

3 K342 16BR/WT (DIESEL) ECM/PCM RELAY OUTPUT

3 K342 16BR/WT (GAS) ASD RELAY OUTPUT

4 F500 16DG/PK (ASSY. PLANT EVAC &

FILL)FUSED IGNITION SWITCH OUTPUT (RUN)

5- -

6 D25 18WT/VT (ABS) PCI BUS

7 A107 12TN/RD (ABS) FUSED B(+)

8 A111 12DG/RD (ABS) FUSED B(+)

9- -

10 - -

INTEGRATED POWER MODULE C5 - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 A1 4RD B(+)

2- -

3- -

4- -

INTEGRATED POWER MODULE C6 - NATURAL 10 WAY

CAV CIRCUIT FUNCTION

1 A101 12VT/RD FUSED B(+)

2 Z117 16BK/WT GROUND

3 Z118 16BK/WT (LWB/EXPORT) GROUND

3 Z118 16BK/YL (SWB/EXCEPT EXPORT) GROUND

4 A110 12OR/RD (POWER SEAT) FUSED B(+)

5- -

6- -

7 C7 12DB FUSED FRONT BLOWER MOTOR RELAY OUTPUT

8 F307 18LB/PK (ACCESSORY RELAY

POSITION)FUSED ACCESSORY RELAY OUTPUT

8 F307 18LB/PK (BATTERY POSITION) FUSED B(+)

9 A113 12WT/RD (POWER SLIDING

DOOR)FUSED B(+)

10 - -

8W - 80 - 84 8W-80 CONNECTOR PIN-OUTSRS

Page 1193 of 2585

LIFTGATE CINCH/RELEASE MOTOR (POWER LIFTGATE) - BLUE 7 WAY

CAV CIRCUIT FUNCTION

1 Z78 20BK/OR GROUND

2 G78 20VT/OR LIFTGATE AJAR SWITCH SENSE

3 Q60 20OR/YL LIFTGATE PAWL SWITCH SENSE

4 Z245 18BK/GY GROUND

5 Q85 18TN/WT LIFTGATE LATCH RELEASE DRIVER

6 Q84 18TN/GY LIFTGATE LATCH CINCH DRIVER

7 Q83 18OR/GY LIFTGATE LATCH CLUTCH DRIVER

LIFTGATE LEFT PINCH SENSOR (POWER LIFTGATE) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q77 20OR/DB RIGHT PINCH SENSOR SIGNAL

2 Q76 20OR/LB PINCH SENSOR SIGNAL

LIFTGATE RIGHT PINCH SENSOR (POWER LIFTGATE) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q77 20OR/DB RIGHT PINCH SENSOR SIGNAL

2 Z78 20BK/OR GROUND

LOW NOTE HORN - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z298 20BK/DB GROUND

2 X2 18DG/OR HORN RELAY OUTPUT

MANIFOLD ABSOLUTE PRESSURE SENSOR (GAS) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 K1 18VT/BR MAP SIGNAL

2 K900 18DB/DG SENSOR GROUND

3 F855 18PK/YL 5 VOLT SUPPLY

8W - 80 - 98 8W-80 CONNECTOR PIN-OUTSRS

Page 1199 of 2585

PASSENGER FOLDING MIRROR RELAY (EXPORT) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3- -

4 A108 20LG/RD FUSED B(+)

5 P164 18LG/DB PASSENGER FOLDING MIRROR RELAY INPUT

6 P162 18LG/DG PASSENGER FOLDING MIRROR RELAY CONTROL

7- -

8 P160 18TN/LG PASSENGER FOLDING MIRROR RELAY OUTPUT

9- -

PASSENGER HEATED SEAT BACK - GREEN 2 WAY

CAV CIRCUIT FUNCTION

A S1 18WT (LHD) SEAT BACK HEATER B(+) DRIVER

A S2 18GY (RHD) SEAT BACK HEATER GROUND

B S2 18GY (LHD) SEAT BACK HEATER GROUND

B S1 18WT (RHD) SEAT BACK HEATER B(+) DRIVER

PASSENGER HEATED SEAT CUSHION - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 P87 16LG/OR SEAT TEMP SENSOR INPUT

2 P89 20LG/BR SEAT SENSOR 5 VOLT SUPPLY

3 Z848 18BK/OR GROUND

4 P88 16LG/LB SEAT CUSHION HEATER B(+) DRIVER

PASSENGER HEATED SEAT MODULE C1 - GRAY 4 WAY

CAV CIRCUIT FUNCTION

1 Z848 18BK/OR GROUND

2 P8 20LG/WT PASSENGER HEATED SEAT SWITCH MUX

3 F503 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

4 A210 14OR/RD FUSED B(+)

8W - 80 - 104 8W-80 CONNECTOR PIN-OUTSRS

Page 1210 of 2585

RADIATOR FAN RELAY (GAS)-4WAY

CAV CIRCUIT FUNCTION

1 A112 12OR/RD FUSED B(+)

2 N23 12DB/DG RADIATOR FAN RELAY OUTPUT

3 Z723 18BK/DG GROUND

4 N173 18DB/VT CONDENSER FAN RELAY CONTROL

RADIATOR FAN RELAY NO. 1 (DIESEL) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2 N201 12DB/LG RADIATOR FAN RELAY NO. 1 OUTPUT

3- -

4 K342 16BR/WT ECM/PCM RELAY OUTPUT

5- -

6 N210 18DB/DG LOW SPEED RADIATOR FAN RELAY CONTROL

7- -

8 A201 12RD/LG FUSED B(+)

9- -

RADIATOR FAN RELAY NO. 2 (DIESEL) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2 N112 12DB/OR RADIATOR FAN RELAY NO. 2 AND NO. 3 COMMON

OUTPUT

3- -

4 K342 16BR/WT ECM/PCM RELAY OUTPUT

5- -

6 N122 18DB/YL HIGH SPEED RADIATOR FAN DUAL RELAY CONTROL

7- -

8 A112 12OR/RD FUSED B(+)

9- -

RADIATOR FAN RELAY NO. 3 (DIESEL) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2 Z823 12BK/DG GROUND

3- -

4 K342 16BR/WT ECM/PCM RELAY OUTPUT

5 N112 12DB/OR RADIATOR FAN RELAY NO. 2 AND NO. 3 COMMON

OUTPUT

6 N122 18DB/YL HIGH SPEED RADIATOR FAN DUAL RELAY CONTROL

7- -

8 N202 12DB/OR RADIATOR FAN NO. 1 CONTROL

9- -

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 115

Page 1306 of 2585

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 2.4L9-9

ENGINE 2.4L (Continued)

Page 1380 of 2585

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 3.3/3.8L9-83

ENGINE 3.3/3.8L (Continued)