Gasoline CHRYSLER VOYAGER 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1509 of 2585

FUEL DELIVERY

DESCRIPTION

The front wheel drive car uses a plastic fuel tank

located rear center of the vehicle.

The Fuel Delivery System consists of: the following

items:

²Electric fuel pump module

²Fuel filter

²Tubes/lines/hoses

²Fuel injectors

The in-tank fuel pump module contains the fuel

pump. The pump is serviced as part of the fuel pump

module. Refer to Fuel Pump Module.

The fuel filter is replaceable only as part of the

fuel pump module.

OPERATION

The fuel system provides fuel pressure by an

in-tank pump module. The Powertrain Control Mod-

ule (PCM) controls the operation of the fuel system

by providing battery voltage to the fuel pump

through the fuel pump relay. The PCM requires only

three inputs and a good ground to operate the fuel

pump relay. The three inputs are:

²Ignition voltage

²Crankshaft Position (CKP) sensor

²Camshaft Position (CMP) sensor

DIAGNOSIS AND TESTING - FUEL DELIVERY

SYSTEM

(Refer to Appropriate Diagnostic Information)

STANDARD PROCEDURE

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE PROCEDURE

(1) Remove Fuel Pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(2) Start and run engine until it stalls.

(3) Attempt restarting engine until it will no

longer run.

(4) Turn ignition key to OFF position.

(5) Return fuel pump relay to PDC.

(6) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRB IIItscan tool must be

used to erase a DTC.

STANDARD PROCEDURE - DRAINING FUEL

TANK

Two different procedures may be used to drain fuel

tank (lowering tank or using DRBIIItscan tool).The quickest draining procedure involves lowering

the fuel tank.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE. THIS MAY

RESULT IN PERSONAL INJURY OR DEATH.

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRBIIItscan tool for fuel

pump activation procedures. Before disconnecting

fuel line at fuel rail, release fuel pressure. Refer to

the Fuel System Pressure Release Procedure in this

group for procedures. Disconnect the fuel line at the

fuel rail and remove the plastic retainer from the

fuel rail. Take plastic retainer and install it back into

the fuel line from body. Check the O-ring and make

sure that it is in place and not damaged. Attach end

of special test hose tool number 6539 at fuel line con-

nection from the body line. Position opposite end of

this hose tool to an approved gasoline draining sta-

tion. Activate fuel pump and drain tank until empty.

When done remove the special test hose tool number

6539 from the body line. Remove the plastic retainer

from the special test hose tool number 6539 and rein-

stall it into the fuel line from the body. Check the

O-ring and make sure that it is in place and not

damaged. Install the fuel line to the fuel rail.

If electric fuel pump is not operating, tank must be

lowered for fuel draining. Refer to following proce-

dures.

(1) Remove fuel filler cap.

(2) Perform the Fuel System Pressure Release pro-

cedure.

(3) Disconnect negative cable from battery.

(4) Raise vehicle and support.

(5) Certain models are equipped with a separate

grounding wire (strap) connecting the fuel fill tube

assembly to the body. Disconnect wire by removing

screw.

(6) Open fuel fill door and remove screws mount-

ing fuel filler tube assembly to body. Do not discon-

nect rubber fuel fill or vent hoses from tank at this

time.

(7) Place a transmission jack under center of fuel

tank. Apply a slight amount of pressure to fuel tank

with transmission jack.

(8) Remove fuel tank mounting straps.

(9)Lower the tank just enough so that the

filler tube fitting is the highest point of the fuel

tank.

(10) Remove filler tube from fuel tank. Tank will

be drained through this fitting.

14 - 2 FUEL DELIVERYRS

Page 1510 of 2585

NOTE: WRAP SHOP TOWELS AROUND HOSES TO

CATCH ANY GASOLINE SPILLAGE.

(11) Drain fuel tank into holding tank or a prop-

erly labeledGasolinesafety container.

WARNING: GASOLINE OR GASOLINE VAPORS ARE

HIGHLY FLAMMABLE. A FIRE COULD OCCUR IF AN

IGNITION SOURCE IS PRESENT. NEVER DRAIN ORSTORE GASOLINE OR DIESEL FUEL IN AN OPEN

CONTAINER, DUE TO THE POSSIBILITY OF FIRE

OR EXPLOSION. THIS MAY RESULT IN PERSONAL

INJURY OR DEATH.

(12) If fuel pump module removal is necessary,

refer to Fuel Pump Module Removal/Installation in

this section.

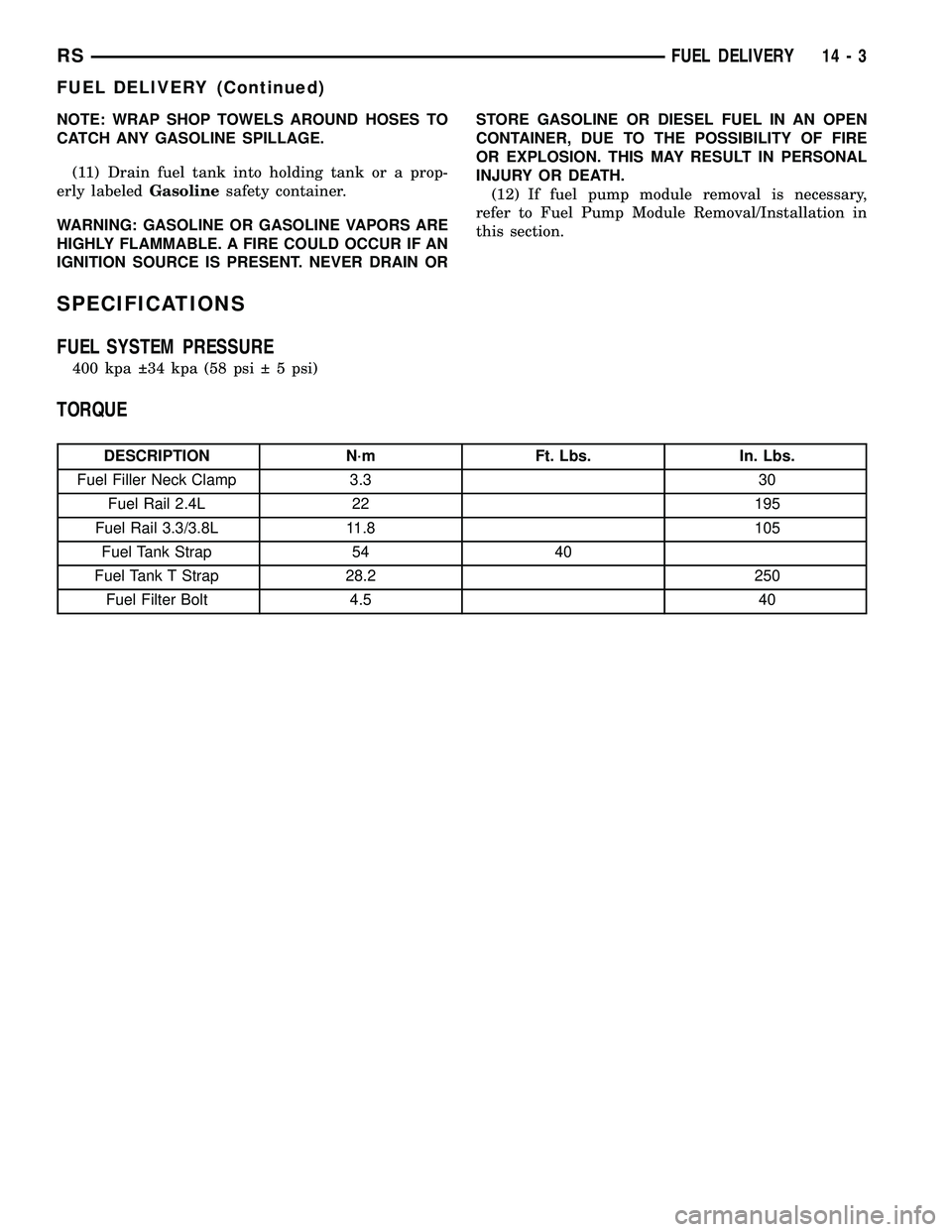

SPECIFICATIONS

FUEL SYSTEM PRESSURE

400 kpa 34 kpa (58 psi 5 psi)

TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fuel Filler Neck Clamp 3.3 30

Fuel Rail 2.4L 22 195

Fuel Rail 3.3/3.8L 11.8 105

Fuel Tank Strap 54 40

Fuel Tank T Strap 28.2 250

Fuel Filter Bolt 4.5 40

RSFUEL DELIVERY14-3

FUEL DELIVERY (Continued)

Page 1517 of 2585

(6) Remove harness from vehicle.

(7) Remove fuel hose quick connect fitting from the

chassis tube.Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in this Section.Place a

shop towel under the connections to absorb any fuel

spilled from the fitting.

WARNING: WRAP A SHOP TOWEL AROUND HOSES

TO CATCH ANY GASOLINE SPILLAGE.

(8) Remove fuel rail attaching bolts.

(9) Remove fuel rail. Be careful not to damage the

injector O-rings upon removal from their ports.

REMOVAL - 3.3/3.8L

(1) Perform fuel system pressure release procedure

before servicing or starting repairs.Refer to

Fuel System Pressure Release Procedure in this sec-

tion.

(2) Disconnect negative cable from battery.

(3) Remove upper intake manifold, refer to the

Engine/Manifolds/Upper Intake for more informa-

tion..

(4) Cover intake manifold with suitable cover

when servicing.

(5) Remove the fuel hose quick connect fitting from

the chassis tube.Refer to Fuel Hoses, Clamps

and Quick Connect Fittings in this Section.

WARNING: WRAP A SHOP TOWEL AROUND HOSES

TO CATCH ANY GASOLINE SPILLAGE.

(6) Remove the fuel rail attaching bolts (Fig. 13).

(7) Remove fuel rail. Be careful not to damage the

injector O-rings upon removal from their ports.

INSTALLATION

INSTALLATION - 2.4L

(1) Ensure injector holes are clean. Replace

O-rings if damaged.

(2) Lubricate injector O-rings with a drop of clean

engine oil to ease installation.

(3) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports.

(4) Install the fuel rail mounting bolts. Tighten

bolts to 22 N´m (200 in. lbs.) torque.

(5) Connect the connectors to the fuel injectors.

(6) Install wiring harness to brackets.

(7) Connect the wiring connectors to fuel injectors

harness (Fig. 12).

(8) Connect negative battery cable.

(9) Use the DRBIIItscan tool to pressurize the

fuel system. Check for leaks.

INSTALLATION - 3.3/3.8L

(1) Ensure injector holes are clean. Replace

O-rings if damaged.

(2) Lubricate injector O-rings with a drop of clean

engine oil to ease installation.

(3) Put the tip of each injector into their ports.

Push the assembly into place until the injectors are

seated in the ports.

(4) Install the fuel rail mounting bolts. Tighten

bolts to 22 N´m (200 in. lbs.) torque.

(5) Remove covering on lower intake manifold and

clean surface.

(6) Install the Upper Intake Manifold, refer to

Engine/Manifolds/Upper Intake for more information.

(7) Install fuel hose quick connector fitting to chas-

sis tubes.Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in this Section.Push the

fitting onto the chassis tube until it clicks into place.

Pull on the fitting to ensure complete insertion.

(8) Connect negative cable to battery.

(9) Use the DRBIIItscan tool to pressurize the

fuel system. Check for leaks.

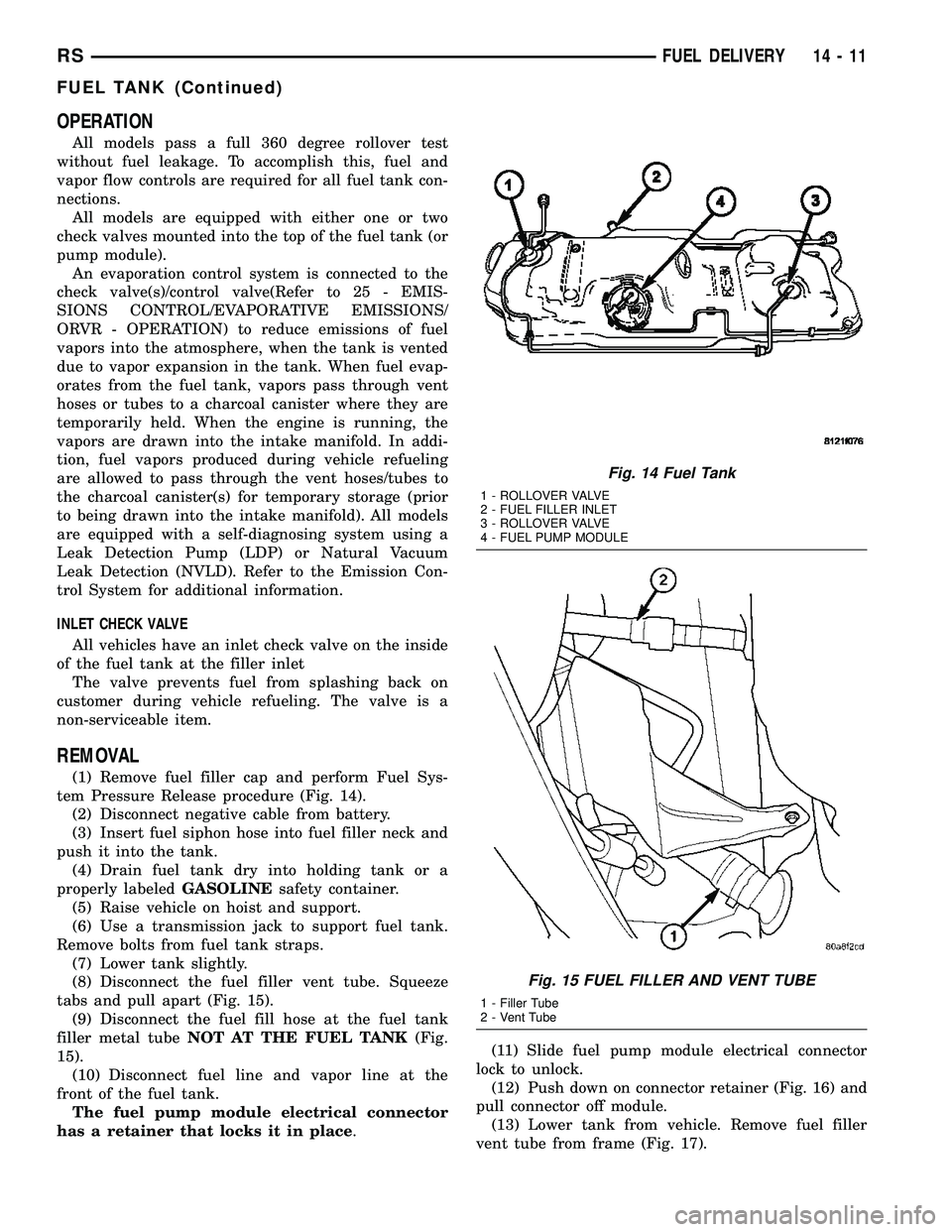

FUEL TANK

DESCRIPTION

The fuel tank is constructed of a plastic material.

Its main functions are for fuel storage and for place-

ment of the fuel pump module. The tank is made

from High density Polyethylene (HDPE) material.If

equipped with ORVR (Onboard Refueling Vapor

Recovery) it has been added to the fuel tank to con-

trol refueling vapor emissions.

Fig. 13 FUEL INJECTORS 3.3/3.8L

14 - 10 FUEL DELIVERYRS

FUEL RAIL (Continued)

Page 1518 of 2585

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank con-

nections.

All models are equipped with either one or two

check valves mounted into the top of the fuel tank (or

pump module).

An evaporation control system is connected to the

check valve(s)/control valve(Refer to 25 - EMIS-

SIONS CONTROL/EVAPORATIVE EMISSIONS/

ORVR - OPERATION) to reduce emissions of fuel

vapors into the atmosphere, when the tank is vented

due to vapor expansion in the tank. When fuel evap-

orates from the fuel tank, vapors pass through vent

hoses or tubes to a charcoal canister where they are

temporarily held. When the engine is running, the

vapors are drawn into the intake manifold. In addi-

tion, fuel vapors produced during vehicle refueling

are allowed to pass through the vent hoses/tubes to

the charcoal canister(s) for temporary storage (prior

to being drawn into the intake manifold). All models

are equipped with a self-diagnosing system using a

Leak Detection Pump (LDP) or Natural Vacuum

Leak Detection (NVLD). Refer to the Emission Con-

trol System for additional information.

INLET CHECK VALVE

All vehicles have an inlet check valve on the inside

of the fuel tank at the filler inlet

The valve prevents fuel from splashing back on

customer during vehicle refueling. The valve is a

non-serviceable item.

REMOVAL

(1) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure (Fig. 14).

(2) Disconnect negative cable from battery.

(3) Insert fuel siphon hose into fuel filler neck and

push it into the tank.

(4) Drain fuel tank dry into holding tank or a

properly labeledGASOLINEsafety container.

(5) Raise vehicle on hoist and support.

(6) Use a transmission jack to support fuel tank.

Remove bolts from fuel tank straps.

(7) Lower tank slightly.

(8) Disconnect the fuel filler vent tube. Squeeze

tabs and pull apart (Fig. 15).

(9) Disconnect the fuel fill hose at the fuel tank

filler metal tubeNOT AT THE FUEL TANK(Fig.

15).

(10) Disconnect fuel line and vapor line at the

front of the fuel tank.

The fuel pump module electrical connector

has a retainer that locks it in place.(11) Slide fuel pump module electrical connector

lock to unlock.

(12) Push down on connector retainer (Fig. 16) and

pull connector off module.

(13) Lower tank from vehicle. Remove fuel filler

vent tube from frame (Fig. 17).

Fig. 14 Fuel Tank

1 - ROLLOVER VALVE

2 - FUEL FILLER INLET

3 - ROLLOVER VALVE

4 - FUEL PUMP MODULE

Fig. 15 FUEL FILLER AND VENT TUBE

1 - Filler Tube

2 - Vent Tube

RSFUEL DELIVERY14-11

FUEL TANK (Continued)

Page 2097 of 2585

white letters. To remove the protective coating, apply

warm water and let it soak for a few minutes. After-

wards, scrub the coating away with a soft bristle

brush. Steam cleaning may also be used to remove

the coating.

CAUTION: DO NOT use gasoline, mineral oil, oil-

based solvent or a wire brush for cleaning.

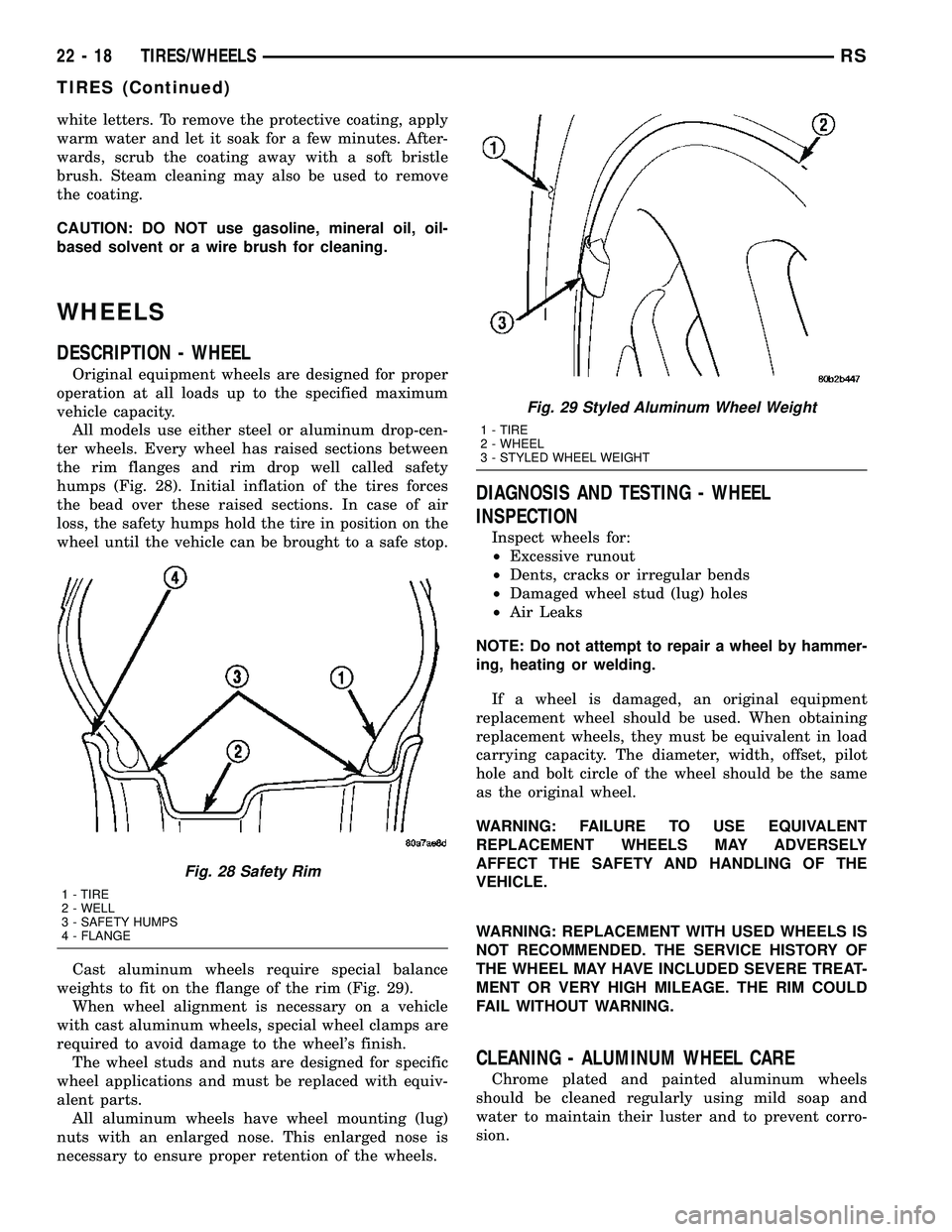

WHEELS

DESCRIPTION - WHEEL

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

vehicle capacity.

All models use either steel or aluminum drop-cen-

ter wheels. Every wheel has raised sections between

the rim flanges and rim drop well called safety

humps (Fig. 28). Initial inflation of the tires forces

the bead over these raised sections. In case of air

loss, the safety humps hold the tire in position on the

wheel until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights to fit on the flange of the rim (Fig. 29).

When wheel alignment is necessary on a vehicle

with cast aluminum wheels, special wheel clamps are

required to avoid damage to the wheel's finish.

The wheel studs and nuts are designed for specific

wheel applications and must be replaced with equiv-

alent parts.

All aluminum wheels have wheel mounting (lug)

nuts with an enlarged nose. This enlarged nose is

necessary to ensure proper retention of the wheels.

DIAGNOSIS AND TESTING - WHEEL

INSPECTION

Inspect wheels for:

²Excessive runout

²Dents, cracks or irregular bends

²Damaged wheel stud (lug) holes

²Air Leaks

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged, an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they must be equivalent in load

carrying capacity. The diameter, width, offset, pilot

hole and bolt circle of the wheel should be the same

as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE.

WARNING: REPLACEMENT WITH USED WHEELS IS

NOT RECOMMENDED. THE SERVICE HISTORY OF

THE WHEEL MAY HAVE INCLUDED SEVERE TREAT-

MENT OR VERY HIGH MILEAGE. THE RIM COULD

FAIL WITHOUT WARNING.

CLEANING - ALUMINUM WHEEL CARE

Chrome plated and painted aluminum wheels

should be cleaned regularly using mild soap and

water to maintain their luster and to prevent corro-

sion.

Fig. 28 Safety Rim

1 - TIRE

2 - WELL

3 - SAFETY HUMPS

4 - FLANGE

Fig. 29 Styled Aluminum Wheel Weight

1 - TIRE

2 - WHEEL

3 - STYLED WHEEL WEIGHT

22 - 18 TIRES/WHEELSRS

TIRES (Continued)

Page 2111 of 2585

CLEANING - TIRES

Before delivery of a vehicle, remove the protective

coating on the tires with white sidewalls or raised

white letters. To remove the protective coating, apply

warm water and let it soak for a few minutes. After-

wards, scrub the coating away with a soft bristle

brush. Steam cleaning may also be used to remove

the coating. CAUTION: DO NOT use gasoline, mineral oil, oil-

based solvent or a wire brush for cleaning.

22s - 10 TIRESRS

TIRES (Continued)

Page 2459 of 2585

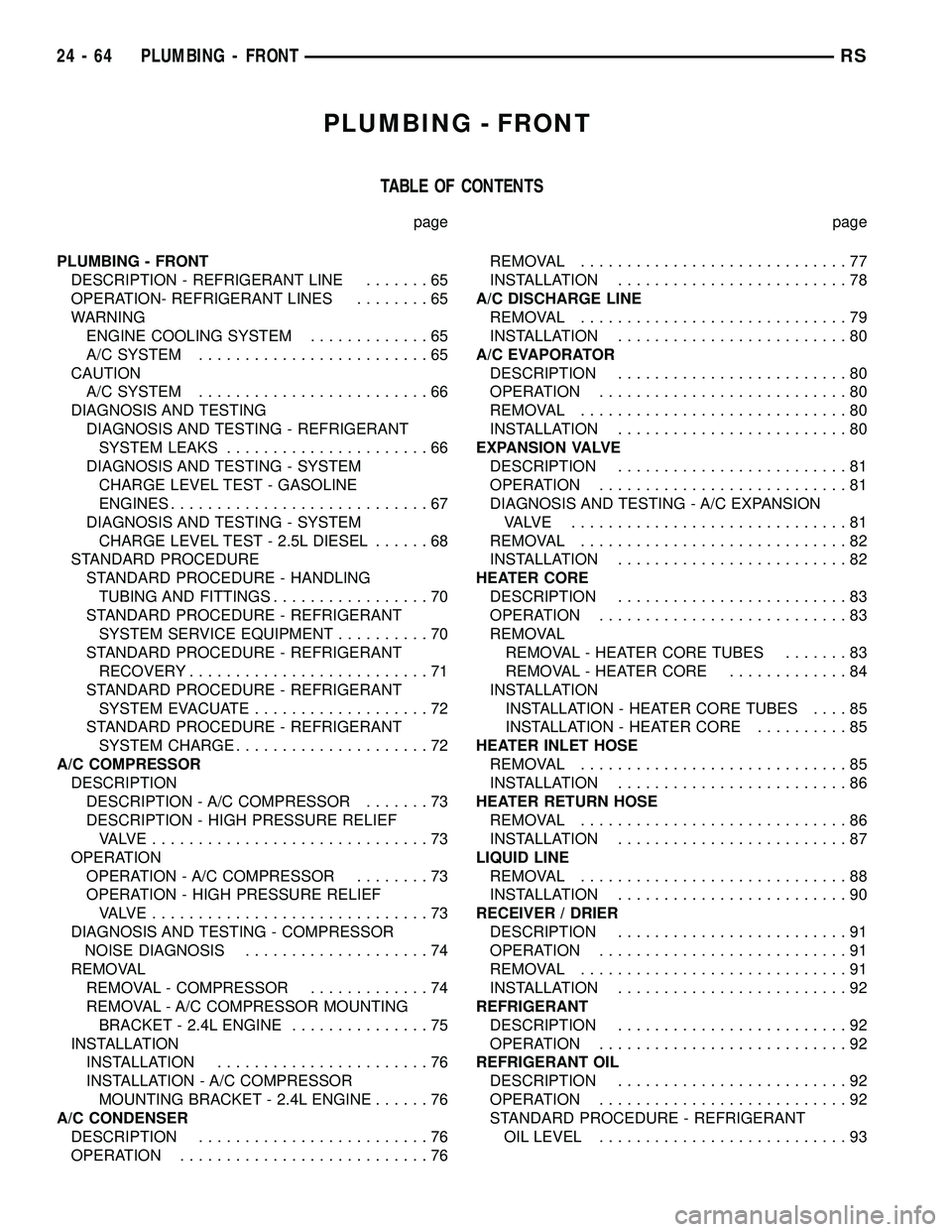

PLUMBING - FRONT

TABLE OF CONTENTS

page page

PLUMBING - FRONT

DESCRIPTION - REFRIGERANT LINE.......65

OPERATION- REFRIGERANT LINES........65

WARNING

ENGINE COOLING SYSTEM.............65

A/C SYSTEM.........................65

CAUTION

A/C SYSTEM.........................66

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM LEAKS......................66

DIAGNOSIS AND TESTING - SYSTEM

CHARGE LEVEL TEST - GASOLINE

ENGINES............................67

DIAGNOSIS AND TESTING - SYSTEM

CHARGE LEVEL TEST - 2.5L DIESEL......68

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

TUBING AND FITTINGS.................70

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT..........70

STANDARD PROCEDURE - REFRIGERANT

RECOVERY..........................71

STANDARD PROCEDURE - REFRIGERANT

SYSTEM EVACUATE...................72

STANDARD PROCEDURE - REFRIGERANT

SYSTEM CHARGE.....................72

A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR.......73

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE..............................73

OPERATION

OPERATION - A/C COMPRESSOR........73

OPERATION - HIGH PRESSURE RELIEF

VALVE..............................73

DIAGNOSIS AND TESTING - COMPRESSOR

NOISE DIAGNOSIS....................74

REMOVAL

REMOVAL - COMPRESSOR.............74

REMOVAL - A/C COMPRESSOR MOUNTING

BRACKET - 2.4L ENGINE...............75

INSTALLATION

INSTALLATION.......................76

INSTALLATION - A/C COMPRESSOR

MOUNTING BRACKET - 2.4L ENGINE......76

A/C CONDENSER

DESCRIPTION.........................76

OPERATION...........................76REMOVAL.............................77

INSTALLATION.........................78

A/C DISCHARGE LINE

REMOVAL.............................79

INSTALLATION.........................80

A/C EVAPORATOR

DESCRIPTION.........................80

OPERATION...........................80

REMOVAL.............................80

INSTALLATION.........................80

EXPANSION VALVE

DESCRIPTION.........................81

OPERATION...........................81

DIAGNOSIS AND TESTING - A/C EXPANSION

VALVE ..............................81

REMOVAL.............................82

INSTALLATION.........................82

HEATER CORE

DESCRIPTION.........................83

OPERATION...........................83

REMOVAL

REMOVAL - HEATER CORE TUBES.......83

REMOVAL - HEATER CORE.............84

INSTALLATION

INSTALLATION - HEATER CORE TUBES....85

INSTALLATION - HEATER CORE..........85

HEATER INLET HOSE

REMOVAL.............................85

INSTALLATION.........................86

HEATER RETURN HOSE

REMOVAL.............................86

INSTALLATION.........................87

LIQUID LINE

REMOVAL.............................88

INSTALLATION.........................90

RECEIVER / DRIER

DESCRIPTION.........................91

OPERATION...........................91

REMOVAL.............................91

INSTALLATION.........................92

REFRIGERANT

DESCRIPTION.........................92

OPERATION...........................92

REFRIGERANT OIL

DESCRIPTION.........................92

OPERATION...........................92

STANDARD PROCEDURE - REFRIGERANT

OIL LEVEL...........................93

24 - 64 PLUMBING - FRONTRS

Page 2462 of 2585

present. If system will not maintain vacuum level,

proceed with this procedure.

(2) Prepare a 0.284 Kg. (10 oz.) refrigerant charge

to be injected into the system.

(3) Connect and dispense 0.284 Kg. (10 oz.) of

refrigerant into the evacuated refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT/REFRIGERANT - STANDARD

PROCEDURE - REFRIGERANT SYSTEM

CHARGE).

(4) Proceed to the SYSTEM LOW procedures.

SYSTEM LOW

(1) Position the vehicle in a wind-free work area.

This will aid in detecting small leaks.

(2) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run for five minutes with the system

set to the following:

²Transaxle in Park

²Engine idling

²Rear A/C Off (if equipped)

²A/C controls set to 100 percent outside air

²Blower switch in the highest speed position

²A/C in the ON position

²Front windows open

CAUTION: A leak detector designed for R-12 refrig-

erant (only) will not detect leaks in a R-134a refrig-

erant system.

(3) Shut off the vehicle and wait 2 to 7 minutes.

Then use an Electronic Leak Detector that is

designed to detect R-134a type refrigerant and search

for leaks. Fittings, lines, or components that appear

to be oily usually indicates a refrigerant leak. To

inspect the evaporator core for leaks, insert the leak

detector probe into the drain tube opening or a heat

duct. A R-134a dye is available to aid in leak detec-

tion, use only DaimlerChrysler approved refrigerant

dye.

DIAGNOSIS AND TESTING - SYSTEM CHARGE

LEVEL TEST - GASOLINE ENGINES

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

NOTE: The proper amount of R-134a refrigerant for

the refrigerant system in this model is:²Single or Dual Zone (Front Unit Only) - 0.96

kilograms (2.13 pounds or 34 ounces)

²Three Zone (Front and Rear Units) - 1.31 kilo-

grams (2.88 pounds or 46 ounces)

The procedure that follows should be used to deter-

mine whether the refrigerant system contains the

proper refrigerant charge. Symptoms of an improper

refrigerant charge (low) include: poor air conditioner

performance, fog emitted from the air conditioner

outlets, a hissing sound from the expansion valve/

evaporator area. There are two different methods

with which the refrigerant charge level may be

tested:

1. Using a DRBIIItscan tool, a thermocouple and

the Charge Determination Chart (Fig. 1). Refer to

the appropriate diagnostic information.

2. Using a manifold gauge set, a thermocouple and

the Charge Determination Chart (Fig. 1).

A temperature probe is required to measure liquid

line temperature. The clamp-on, Type K thermocou-

ple temperature probe used in this procedure is

available through the DaimlerChrysler Professional

Service Equipment (PSE) program. This probe (PSE

#66-324-0014 or #80PK-1A) is compatible with tem-

perature-measuring instruments that accept Type K

thermocouples, and have a miniature connector

input. Other temperature probes are available

through aftermarket sources; however, all references

in this procedure will reflect the use of the probe

made available through the PSE program.

In order to use the temperature probe, a digital

thermometer will also be required. If a digital ther-

mometer is not available, an adapter is available

through the PSE program that will convert any stan-

dard digital multimeter into a digital thermometer.

This adapter is designed to accept any standard Type

K thermocouple. If a digital multimeter is not avail-

able, this tool is also available through the PSE pro-

gram.

NOTE: When connecting the service equipment

couplings to the refrigerant system service ports,

be certain that the valve of each coupling is fully

closed. This will reduce the amount of effort

required to make the connection.

(1) Remove the caps from the refrigerant system

service ports and attach a manifold gauge set or a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 to the refriger-

ant system.

(2) Attach a clamp-on thermocouple to the liquid

line. The thermocouple must be placed as close to the

A/C pressure transducer as possible to accurately

observe liquid line temperature.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

RSPLUMBING - FRONT24-67

PLUMBING - FRONT (Continued)

Page 2468 of 2585

CHARGING PROCEDURE

CAUTION: A small amount of refrigerant oil is

removed from the A/C system each time the refrig-

erant system is recovered and evacuated. Before

charging the A/C system, you MUST replenish any

oil lost during the recovery process. Refer the

equipment manufacturer instructions for more infor-

mation.

(1) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(2) A manifold gauge set and a R-134a refrigerant

recovery/recycling/charging station that meets SAE

Standard J2210 should still be connected to the

refrigerant system.

(3) Measure the proper amount of refrigerant and

heat it to 52É C (125É F) with the charging station.

See the operating instructions supplied by the equip-

ment manufacturer for proper use of this equipment.

(4) Open both the suction and discharge valves,

then open the charge valve to allow the heated

refrigerant to flow into the system.

(5) When the transfer of refrigerant has stopped,

close both the suction and discharge valves.

(6) If all of the refrigerant charge did not transfer

from the dispensing device, open all of the windows

in the vehicle and set the heater-air conditioner con-

trols so that the compressor is engaged and the

blower motor is operating at its lowest speed setting.

Run the engine at a steady high idle (about 1400

rpm). If the compressor will not engage, test the com-

pressor clutch control circuit and repair as required.

(7) Open the suction valve to allow the remaining

refrigerant to transfer to the refrigerant system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH PRESSURE) VALVE AT THIS TIME.

(8) Close the suction valve and test the system

performance. (Refer to 24 - HEATING & AIR CON-

DITIONING - STANDARD PROCEDURE - A/C PER-

FORMANCE TEST).

(9) Disconnect the charging station and manifold

gauge set from the refrigerant system service ports.

(10) Reinstall the caps onto the refrigerant system

service ports.

(11) Run the HVAC Control Cooldown test to ver-

ify proper operation(Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND TESTING).A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR

Vehicles equipped with the 2.5L diesel, 3.3L and

3.8L gasoline engines use the Denso 10S20 A/C com-

pressor. Vehicles equipped with the 2.4L gasoline

engine use the Denso 10S17 A/C compressor. Both

A/C compressors include an integral high pressure

relief valve. The A/C compressor is secured to a

mounting bracket on the 2.4L gasoline engine and

directly to the cylinder block on the 2.5L diesel, 3.3L

and 3.8L gasoline engines.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the rear

of the A/C compressor. This mechanical valve is

designed to vent refrigerant from the A/C system to

protect against damage to the compressor and other

system components, caused by condenser air flow

restriction or an overcharge of refrigerant.

OPERATION

OPERATION - A/C COMPRESSOR

The A/C compressor is driven by the engine

through an electric clutch, drive pulley and belt

arrangement. The compressor is lubricated by refrig-

erant oil that is circulated throughout the refrigerant

system with the refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor. The compressor

pumps the high-pressure refrigerant vapor to the

condenser through the compressor discharge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

when a minimum discharge pressure of 2756 kPa

(400 psi) is reached.

The high pressure relief valve vents only enough

refrigerant to reduce the system pressure, and then

re-seats itself. The majority of the refrigerant is con-

served in the system. If the valve vents refrigerant, it

does not mean that the valve is faulty.

RSPLUMBING - FRONT24-73

PLUMBING - FRONT (Continued)

Page 2550 of 2585

CHAIN WEAR - STANDARD PROCEDURE,

MEASURING TIMING..................9-153

CHANGE - STANDARD PROCEDURE,

DIFFERENTIAL ASSEMBLY FLUID.........3-40

CHANGE - STANDARD PROCEDURE,

ENGINE OIL AND FILTER...........9-137,9-53

CHANGE - STANDARD PROCEDURE,

OVERRUNNING CLUTCH HOUSING

FLUID..............................3-41

CHANGE - STANDARD PROCEDURE, PTU

FLUID..............................21-5

CHANGER - DESCRIPTION, CD...........8A-7

CHANGER - INSTALLATION, CD..........8A-8

CHANGER - OPERATION, CD.............8A-7

CHANGER - REMOVAL, CD..............8A-8

CHANNEL - INSTALLATION, WATER.....23-121

CHANNEL - REMOVAL, WATER.........23-121

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-72

CHARGE LEVEL TEST - 2.5L DIESEL -

DIAGNOSIS AND TESTING, SYSTEM......24-68

CHARGE LEVEL TEST - GASOLINE

ENGINES - DIAGNOSIS AND TESTING,

SYSTEM............................24-67

CHARGING - STANDARD PROCEDURE,

CONVENTIONAL BATTERY..............8F-11

CHARGING - STANDARD PROCEDURE,

SPIRAL PLATE BATTERY...............8F-10

CHARGING SYSTEM - DESCRIPTION.....8F-20

CHARGING SYSTEM - OPERATION.......8F-20

CHARTS - DIAGNOSIS AND TESTING,

STEERING SYSTEM DIAGNOSIS...........19-3

CHARTS - SPECIFICATIONS, COLOR

CODE..............................23-84

CHATTER COMPLAINTS - DIAGNOSIS

AND TESTING, CLUTCH.................6-6

CHECK - DIAGNOSIS AND TESTING,

COOLING SYSTEM FLOW................7-3

CHECK - DIAGNOSIS AND TESTING,

EXHAUST SYSTEM RESTRICTION.........11-2

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL.......................7-5

CHECK - STANDARD PROCEDURE,

ENGINE OIL LEVEL...................9-137

CHECK - STANDARD PROCEDURE, FLUID

LEVEL.............................21-71

CHECK, STANDARD PROCEDURE -

ENGINE OIL LEVEL....................9-53

CHECK, STANDARD PROCEDURE - FLUID

LEVEL AND CONDITION........21-201,21s-102

CHECK STRAP - INSTALLATION.........23-15

CHECK STRAP - REMOVAL.............23-15

CHECKING - STANDARD PROCEDURE,

BRAKE FLUID LEVEL..............5-32,5s-31

CHECKING - STANDARD PROCEDURE,

POWER STEERING FLUID LEVEL........19-44

CHECKING BATTERY ELECTROLYTE

LEVEL - STANDARD PROCEDURE........8F-14

CHECKING ENGINE OIL PRESSURE -

DIAGNOSIS AND TESTING..............9-52

CHECKING POWER STEERING BELT

TENSION - STANDARD PROCEDURE.......7-8

CHILD RESTRAINT ANCHOR -

DESCRIPTION........................8O-4

CHILD RESTRAINT ANCHOR -

OPERATION..........................8O-4

CHILD SEAT - INSTALLATION, QUAD.....23-89

CHILD SEAT - REMOVAL, QUAD.........23-89

CHILD SEAT MODULE, BENCH SEAT -

REMOVAL..........................23-87

CHIME SYSTEM - DIAGNOSIS AND

TESTING

............................8B-1

CHIME/BUZZER - DESCRIPTION

..........8B-1

CHIME/BUZZER - OPERATION

............8B-1

CHIME/BUZZER - WARNING

.............8B-1

CHIME/THERMISTOR - DESCRIPTION

....8N-10

CHIME/THERMISTOR - INSTALLATION

....8N-10

CHIME/THERMISTOR - OPERATION

......8N-10

CHIME/THERMISTOR - REMOVAL

.......8N-10

CHIRP PREFERENCE - STANDARD

PROCEDURE, HORN

..............8N-42,8N-5

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR

......8M-12

CIRCUIT FUNCTIONS - DESCRIPTION

. . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION

. 8W-01-5

CIRCUIT RESISTANCE TEST -

DIAGNOSIS AND TESTING, FEED

. . . 8F-32,8F-34CIRCUIT TEST - DIAGNOSIS AND

TESTING, CONTROL..............8F-30,8F-32

CIRCUIT TEST - DIAGNOSIS AND

TESTING, FEED.................8F-33,8F-35

CIRCUITS - OPERATION, NON-

MONITORED.........................25-5

CIRCUITS AND VALVES - OPERATION,

HYDRAULIC..........................5-83

CLAMP - STANDARD PROCEDURE,

HOSES..............................14-7

CLAMPS - DESCRIPTION, FUEL

LINES/HOSES........................14-6

CLAMPS - DESCRIPTION, HOSE...........7-1

CLAMPS - OPERATION, HOSE.............7-2

CLEAN, CLEANING...................21-114

CLEARANCE - STANDARD PROCEDURE,

MEASURING CONNECTING ROD

BEARING...........................9-120

CLEARANCE USING PLASTIGAGE -

STANDARD PROCEDURE, MEASURING

BEARING........................9-12,9-84

CLOCK SPRING - DESCRIPTION..........8O-4

CLOCK SPRING - INSTALLATION.........8O-5

CLOCK SPRING - OPERATION...........8O-4

CLOCK SPRING - REMOVAL.............8O-5

CLOCK SPRING CENTERING -

STANDARD PROCEDURE...............8O-5

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-1

CLUSTER - OPERATION, INSTRUMENT.....8J-1

CLUSTER BEZEL - INSTALLATION........23-63

CLUSTER BEZEL - REMOVAL.............23-63

CLUSTER DIAGNOSIS - DIAGNOSIS AND

TESTING............................8J-2

CLUSTER ILLUMINATION LAMPS -

INSTALLATION.......................8L-21

CLUSTER ILLUMINATION LAMPS -

REMOVAL..........................8L-21

CLUSTER LENS - INSTALLATION........8J-10

CLUSTER LENS - REMOVAL............8J-10

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, BI-

DIRECTIONAL OVERRUNNING...........3-34

CLUTCH - OPERATION, BI-DIRECTIONAL

OVERRUNNING.......................3-36

CLUTCH AIR PRESSURE TESTS -

DIAGNOSIS AND TESTING.......21-122,21s-30

CLUTCH ASSEMBLY - ASSEMBLY,

INPUT.....................21-216,21s-116

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT.....................21-208,21s-107

CLUTCH ASSY - 2.4L GAS -

INSTALLATION, MODULAR..............6-11

CLUTCH ASSY - 2.4L GAS - REMOVAL,

MODULAR...........................6-11

CLUTCH CHATTER COMPLAINTS -

DIAGNOSIS AND TESTING...............6-6

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-15

CLUTCH COVER AND DISC RUNOUT -

DIAGNOSIS AND TESTING...............6-6

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - INSTALLATION

...............6-12

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - REMOVAL

...................6-11

CLUTCH HOUSING FLUID CHANGE -

STANDARD PROCEDURE,

OVERRUNNING

.......................3-41

CLUTCH PEDAL INTERLOCK SWITCH -

INSTALLATION

........................6-14

CLUTCH PEDAL INTERLOCK SWITCH -

REMOVAL

...........................6-13

CLUTCH PEDAL UPSTOP SWITCH -

INSTALLATION

........................6-16

CLUTCH PEDAL UPSTOP SWITCH -

REMOVAL

...........................6-15

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR

.......................24-19

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR

.......................24-20

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR

.......................24-19

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR

.......................24-20

CLUTCH RELEASE LEVER AND BEARING

- INSTALLATION

.......................6-7

CLUTCH RELEASE LEVER AND BEARING

- REMOVAL

...........................6-6CLUTCH SYSTEM - DIAGNOSIS AND

TESTING.............................6-3

CLUTCH/COIL - DESCRIPTION, A/C

COMPRESSOR.......................24-15

CLUTCH/COIL - INSPECTION, A/C

COMPRESSOR.......................24-17

CLUTCH/COIL - INSTALLATION, A/C

COMPRESSOR.......................24-17

CLUTCH/COIL - OPERATION, A/C

COMPRESSOR.......................24-15

CLUTCH/COIL - REMOVAL, A/C

COMPRESSOR.......................24-16

CLUTCHES - DESCRIPTION, DRIVING . . . 21-190,

21s-95

CLUTCHES - DESCRIPTION, HOLDING . . . 21-207,

21s-106

CLUTCHES - OPERATION, DRIVING.....21-190,

21s-95

CLUTCHES - OPERATION, HOLDING....21-207,

21s-106

COAT/CLEARCOAT FINISH -

DESCRIPTION, BASE..................23-85

CODE - DESCRIPTION, PAINT...........23-85

CODE CHARTS - SPECIFICATIONS,

COLOR.............................23-84

CODE PLATE - DESCRIPTION, BODY....Intro.-1

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER..............8M-11

CODES - STANDARD PROCEDURE,

OBTAINING DIAGNOSTIC TROUBLE......8E-15

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER..............8M-11

COIL - DESCRIPTION, IGNITION............8I-6

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-15

COIL - OPERATION, IGNITION............8I-7

COLLAR - INSTALLATION, STRUCTURAL . . . 9-48

COLLAR - REMOVAL, STRUCTURAL.......9-47

COLOR CODE CHARTS -

SPECIFICATIONS.....................23-84

COLUMN - DESCRIPTION, STEERING.....19-10

COLUMN - DIAGNOSIS AND TESTING,

STEERING..........................19-12

COLUMN COVER - INSTALLATION,

LOWER STEERING...................23-70

COLUMN COVER - INSTALLATION, OVER

STEERING..........................23-70

COLUMN COVER - REMOVAL, LOWER

STEERING..........................23-70

COLUMN COVER - REMOVAL, OVER

STEERING..........................23-70

COLUMN COVER BACKING PLATE -

INSTALLATION, STEERING.............23-70

COLUMN COVER BACKING PLATE -

REMOVAL, STEERING.................23-70

COLUMN TORQUE, SPECIFICATIONS.....19-14

COMBUSTION PRESSURE LEAKAGE

TEST - DIAGNOSIS AND TESTING,

CYLINDER........................9-83,9-9

COMMON PROBLEM CAUSES -

DIAGNOSIS AND TESTING.............21-30

COMMUNICATION RECEIVE - PCM INPUT

- OPERATION, DATA BUS..............8E-15

COMMUNICATIONS INTERFACE (PCI)

BUS, OPERATION - PROGRAMMABLE....14-21

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-3

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-4

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING.............8M-10

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-5

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-9

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION......................8M-10

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-9

COMPASS/MINI-TRIP COMPUTER -

REMOVAL..........................8M-10

COMPLAINTS - DIAGNOSIS AND

TESTING, CLUTCH CHATTER

..............6-6

COMPRESSION PRESSURE TEST -

DIAGNOSIS AND TESTING, CYLINDER

. . 9-83,9-9

COMPRESSOR - DESCRIPTION, A/C

......24-73

COMPRESSOR - OPERATION, A/C

........24-73

COMPRESSOR - REMOVAL

.............24-74

RSINDEX7

Description Group-Page Description Group-Page Description Group-Page