Power steering CHRYSLER VOYAGER 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 60 of 2585

The stabilizer bar to front crossmember cushion

bushings are split for easy removal and installation.

The split in the bushings should be positioned toward

the rear of the vehicle, with the square corner facing

down, when the stabilizer bar is installed.

OPERATION

Jounce and rebound movements affecting one

wheel are partially transmitted to the opposite wheel

of the vehicle through the stabilizer bar. This helps

to minimize the body roll of the vehicle during sus-

pension movement.

Connecting the stabilizer bar links to the strut

assemblies helps reduce the fore-and-aft rate of the

stabilizer bar from the rest of the front suspension.

REMOVAL

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove the bolts fastening the power steering

cooler to the front suspension cradle crossmember

reinforcement (Fig. 31).

(3) Remove the lower control arm rear bushing

retainer bolts located on each side of each lower con-

trol arm rear bushing.

NOTE: The bolts fastening the cradle crossmember

reinforcement are of two different thread sizes. Note

the location of the various sizes.(4) Remove the bolts attaching the cradle cross-

member reinforcement to the front suspension cradle

crossmember (Fig. 32). Remove the 2 bolts fastening

the reinforcement and rear of cradle crossmember to

the body of the vehicle. Remove the reinforcement.

Fig. 31 Power Steering Cooler

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

Fig. 32 Cradle Crossmember Reinforcement

Attachment

1 - STEERING GEAR

2 - RIGHT LOWER CONTROL ARM

3 - LEFT LOWER CONTROL ARM

4 - CRADLE CROSSMEMBER REINFORCEMENT

5 - REAR CRADLE CROSSMEMBER ISOLATOR BUSHING

6 - STABILIZER BAR

7 - CRADLE CROSSMEMBER

RSFRONT SUSPENSION2-17

STABILIZER BAR (Continued)

Page 62 of 2585

(2) Position stabilizer bar into front suspension

cradle so stabilizer bar bushings are aligned with

depressions in cradle. Install stabilizer bar bushing

retainers onto crossmember aligning raised bead on

retainer with cutouts in bushings (Fig. 36).Do not

tighten Stabilizer bar bushing retainers bolts at

this time.

(3) Check position of the stabilizer bar in the front

suspension cradle. The center of the curved section of

the stabilizer bar must be aligned with the raised

line in the center of the front suspension cradle (Fig.

37).

(4) Install the stabilizer bar link mounting stud

through the hole in each end of the stabilizer bar

(Fig. 33).

CAUTION: When installing the nut on the mounting

stud of the stabilizer bar link, do not allow the stud

to rotate in it's socket. Hold the stud from rotating

by placing an open-end wrench on the flat

machined into the stud (Fig. 33).

(5) Hand-thread the nut on the end of each stabi-

lizer bar link stud. Hold the studs from turning by

placing an open-end wrench on the flat machined

into the link's mounting stud, then tighten each nut

while holding the wrench in place (Fig. 33). Tighten

each nut to a torque of 88 N´m (65 ft. lbs.).

(6) Tighten the stabilizer bar bushing retainer to

cradle attaching bolts (Fig. 34) to 68 N´m (50 ft. lbs.)

torque.

(7) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-ing the reinforcement to the cradle crossmember

(Fig. 32). Tighten the M-14 size bolts to a torque of

153 N´m (113 ft. lbs.). Tighten the M-12 size bolts to

a torque of 106 N´m (78 ft. lbs.).

(8) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten these

M-10 size bolts to a torque of 61 N´m (45 ft. lbs.).

(9) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 32). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(10) Install the power steering cooler (Fig. 31).

Tighten bolts to a torque of 11 N´m (100 in. lbs.).

(11) Lower the vehicle.

STRUT

DESCRIPTION - STRUT ASSEMBLY

A Macpherson type strut assembly is used in place

of a conventional front suspension's upper control

arm and upper ball joint. The bottom of the strut

mounts directly to the steering knuckle using two

bolts and nuts going through the strut clevis bracket

and steering knuckle. The top of the strut mounts

directly to the strut tower of the vehicle using the

threaded studs on the strut assemblies upper mount.

The strut assembly includes the components listed

in the figure (Fig. 38).

Each component is serviced by removing the strut

assembly from the vehicle and disassembling it.

The coil springs are side-oriented. Springs on the

left side of the vehicle have a left-hand wind top-to-

Fig. 36 Stabilizer Bar Bushing Retainer Installation

1-SWAYBAR

2 - SWAY BAR BUSHING

3 - BUSHING SPLIT

4 - FRONT SUSPENSION CRADLE

5 - BUSHING CUT-OUT

6 - BUSHING RETAINER

7 - RAISED BEAD

Fig. 37 Stabilizer Bar Correctly Positioned In Cradle

1 - RAISED BEAD

2-SWAYBAR

3 - WHEN INSTALLING SWAY BAR THE RAISED BEAD ON THE

SUSPENSION CRADLE MUST BE IN THE CENTER OF RADIUS

IN SWAY BAR

4 - FRONT SUSPENSION CRADLE

RSFRONT SUSPENSION2-19

STABILIZER BAR (Continued)

Page 94 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

Front End Whine With

Vehicle Going Straight At A

Constant Speed1. Defective wheel bearing 1. Replace wheel bearing

2. Incorrect wheel alignment 2. Check and reset wheel alignment

3. Worn tires 3. Replace tires

4. Worn or defective transaxle gears or

bearings4. Replace transaxle gears or bearings

Front End Growl Or

Grinding With Vehicle

Going Straight At A

Constant Speed1. Engine mount grounding 1. Reposition engine as required

2. Worn or broken C/V joint 2. Replace C/V joint

Front End Whine When

Accelerating Or

Decelerating1. Worn or defective transaxle gears or

bearings1. Replace transaxle gears or bearings

Front End Clunk When

Accelerating Or

Decelerating1. Worn or broken engine mount 1. Replace engine mount

2. Worn or defective transaxle gears or

bearings2. Replace transaxle gears or bearings

3. Loose lug nuts 3. Verify wheel lug nut torque

4. Worn or broken C/V joint 4. Replace C/V joint

5. Worn or loose ball joint 5. Tighten or replace ball joint

6. Worn or loose control arm bushing 6. Replace control arm bushing

7. Loose crossmember bolts 7. Tighten crossmember bolts to

specified torque

8. Worn tie rod end 8. Replace tie rod end

Road Wander 1. Incorrect tire pressure 1. Inflate tires to recommended pressure

2. Incorrect front or rear wheel toe 2. Check and reset wheel toe

3. Worn wheel bearings 3. Replace wheel bearing

4. Worn control arm bushings 4. Replace control arm bushing

5. Excessive friction in steering gear 5. Replace steering gear

6. Excessive friction in steering shaft

coupling6. Replace steering coupler

7. Excessive friction in strut upper

bearing7. Replace strut bearing

Lateral Pull 1. Unequal tire pressure 1. Inflate all tires to recommended

pressure

2. Radial tire lead 2. Perform lead correction procedure

3. Incorrect front wheel camber 3. Check and reset front wheel camber

4. Power steering gear imbalance 4. Replace power steering gear

5. Wheel braking 5. Correct braking condition causing

lateral pull

RSWHEEL ALIGNMENT2-51

WHEEL ALIGNMENT (Continued)

Page 95 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

Excessive Steering Free

Play1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to specified

torque

4. Loose or worn steering shaft coupler 4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering pump

drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering coupler 7. Replace steering coupler

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL ALIGNMENT

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment, the following inspection and

necessary corrections must be made to ensure proper

alignment.

(1) Verify that the fuel tank is full of fuel. If the

tank is not full, the reduction in weight will affect

the curb height of the vehicle and the alignment

angles.

(2) The passenger and luggage compartments of

the vehicle should be free of any load that is not fac-

tory equipment.

(3) Check the tires on the vehicle. All tires must be

the same size and in good condition with approxi-

mately the same amount of tread wear. Inflate all

the tires to the recommended air pressure.

(4) Check the front wheel and tire assemblies for

excessive radial runout.

(5) Inspect lower ball joints and all steering link-

age for looseness, binding, wear or damage. Repair as

necessary.

(6) Check suspension fasteners for proper torque

and retighten as necessary.

(7) Inspect all suspension component rubber bush-

ings for signs of wear or deterioration. Replace any

faulty bushings or components before aligning the

vehicle.

(8) Check the vehicle's curb height to verify it is

within specifications. Refer to Curb Height Measure-

ment.

WHEEL ALIGNMENT SETUP

(1) Position the vehicle on an alignment rack.

(2) Install all required alignment equipment on

the vehicle per the alignment equipment manufactur-

er's instructions. On this vehicle, a four-wheel align-

ment is recommended.

NOTE: Prior to reading the vehicle's alignment

readouts, the front and rear of vehicle should be

jounced. Induce jounce (rear first, then front) by

grasping the center of the bumper and jouncing

each end of vehicle an equal number of times. The

bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Read the vehicle's current front and rear align-

ment settings. Compare the vehicle's current align-

ment settings to the vehicle specifications for camber,

caster and toe-in. (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - SPECIFICATIONS)

(4) If front camber and caster are not within spec-

ifications, proceed to CAMBER AND CASTER below.

If caster and camber are within specifications, pro-

ceed to TOE which can be found following CAMBER

AND CASTER. Rear camber, caster and toe are not

adjustable. If found not to be within specifications,

reinspect for damaged suspension or body compo-

nents and replace as necessary.

CAMBER AND CASTER

Camber and caster settings on this vehicle are

determined at the time the vehicle is designed, by

the location of the vehicle's suspension components.

This is referred to as NET BUILD. The result is no

2 - 52 WHEEL ALIGNMENTRS

WHEEL ALIGNMENT (Continued)

Page 180 of 2585

Use only brake fluid that was stored in a tightly-

sealed container.

DO NOTuse petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid etc.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications (DOT 4 and DOT 4+ are

acceptable) and SAE J1703 standards. No other type

of brake fluid is recommended or approved for usage

in the vehicle brake system. Use only MopartBrake

Fluid or equivalent from a tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

JUNCTION BLOCK

DESCRIPTION - NON-ABS JUNCTION BLOCK

A junction block is used on vehicles that are not

equipped with antilock brakes (ABS). The junction

block mounts in the same location as the integrated

control unit (ICU) does on vehicles equipped with

ABS. This allows for use of the same brake tube con-

figuration on all vehicles. The junction block is

located on the driver's side of the front suspension

cradle/crossmember below the master cylinder (Fig.

45).

It has six threaded ports to which the brake tubes

connect. Two are for the primary and secondary

brake tubes coming from the master cylinder. The

remaining four are for the chassis brake tubes going

to each brake assembly.

OPERATION - NON-ABS JUNCTION BLOCK

The junction block distributes the brake fluid com-

ing from the master cylinder primary and secondary

ports to the four chassis brake tubes leading to the

brakes at each wheel. Since the junction blockmounts in the same location as the ABS integrated

control unit (ICU), it allows for the common use of

brake tubes going to the brakes whether the vehicle

is equipped with or without ABS.

NOTE: Although the brake tubes coming from the

master cylinder to the junction block or ABS ICU

may appear to be the same, they are not. They are

unique to each brake system application.

REMOVAL - NON-ABS JUNCTION BLOCK

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block.

(2) Disconnect the battery negative cable.

(3) If the vehicle is equipped with speed control,

perform the following:

(a) Disconnect the battery positive cable.

(b) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(c) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(d) Remove the screw securing the coolant filler

neck to the battery tray.

(e) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(f) Remove the fasteners and move the speed

control servo off to the side, out of the way.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hydraulic system.

(4) Remove the four chassis brake tubes from the

top of the junction block (Fig. 45).

(5) Remove the primary and secondary brake

tubes from the top of the junction block.

(6) Remove the bolts attaching the junction block

mounting bracket to the front suspension crossmem-

ber (Fig. 45), then remove the junction block.

INSTALLATION - NON-ABS JUNCTION BLOCK

(1) Install the junction block and mounting bracket

on the front suspension crossmember (Fig. 45).

Install the mounting bolts and tighten to a torque of

28 N´m (250 in. lbs.).

(2) Install the primary and secondary brake tubes

from the master cylinder in their ports. Tighten tube

nuts to a torque of 17 N´m (145 in. lbs.).Take care

not to twist tubes when tightening tube nuts.

They must be properly positioned to allow free

RSBRAKES - BASE5-33

FLUID (Continued)

Page 190 of 2585

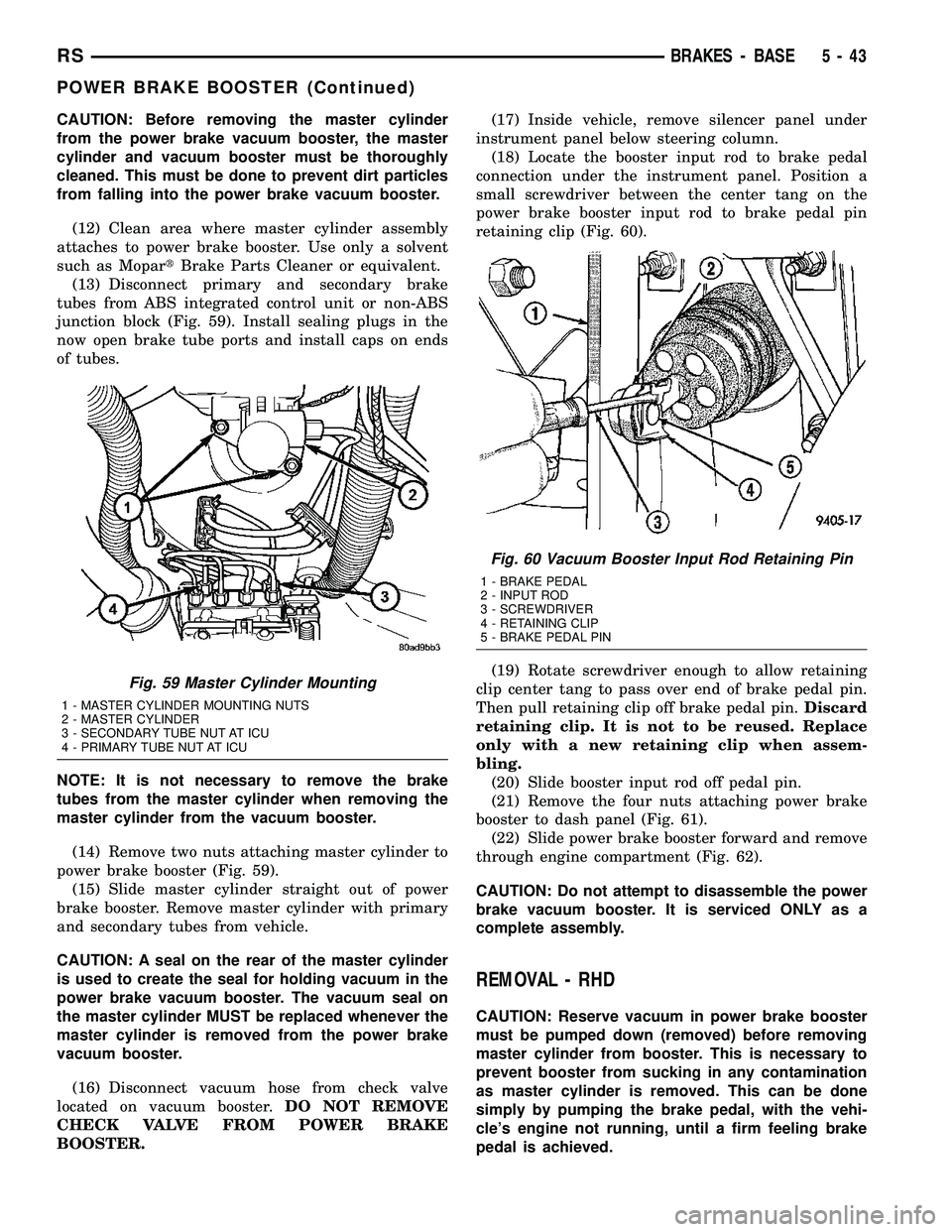

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(12) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as MopartBrake Parts Cleaner or equivalent.

(13) Disconnect primary and secondary brake

tubes from ABS integrated control unit or non-ABS

junction block (Fig. 59). Install sealing plugs in the

now open brake tube ports and install caps on ends

of tubes.

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the vacuum booster.

(14) Remove two nuts attaching master cylinder to

power brake booster (Fig. 59).

(15) Slide master cylinder straight out of power

brake booster. Remove master cylinder with primary

and secondary tubes from vehicle.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

(16) Disconnect vacuum hose from check valve

located on vacuum booster.DO NOT REMOVE

CHECK VALVE FROM POWER BRAKE

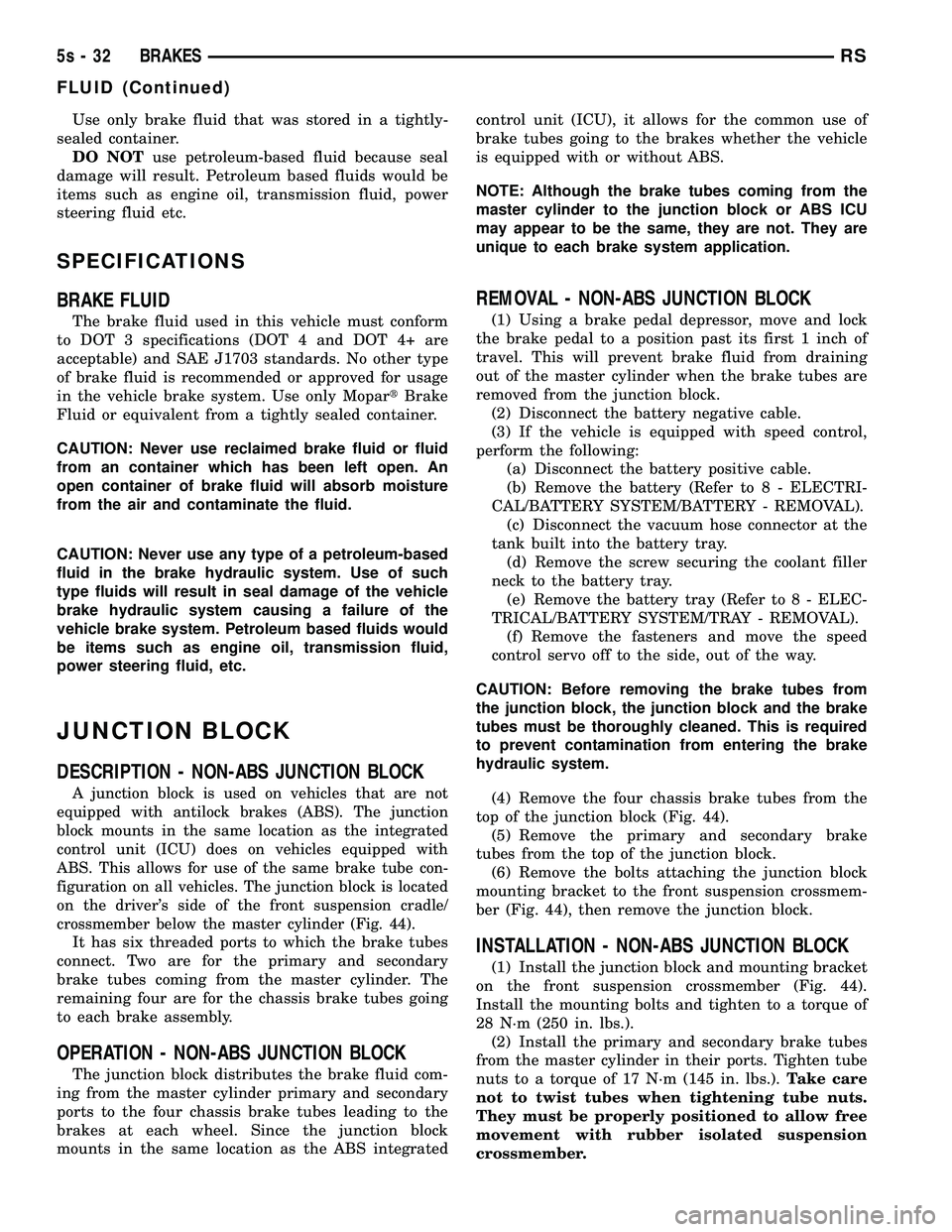

BOOSTER.(17) Inside vehicle, remove silencer panel under

instrument panel below steering column.

(18) Locate the booster input rod to brake pedal

connection under the instrument panel. Position a

small screwdriver between the center tang on the

power brake booster input rod to brake pedal pin

retaining clip (Fig. 60).

(19) Rotate screwdriver enough to allow retaining

clip center tang to pass over end of brake pedal pin.

Then pull retaining clip off brake pedal pin.Discard

retaining clip. It is not to be reused. Replace

only with a new retaining clip when assem-

bling.

(20) Slide booster input rod off pedal pin.

(21) Remove the four nuts attaching power brake

booster to dash panel (Fig. 61).

(22) Slide power brake booster forward and remove

through engine compartment (Fig. 62).

CAUTION: Do not attempt to disassemble the power

brake vacuum booster. It is serviced ONLY as a

complete assembly.

REMOVAL - RHD

CAUTION: Reserve vacuum in power brake booster

must be pumped down (removed) before removing

master cylinder from booster. This is necessary to

prevent booster from sucking in any contamination

as master cylinder is removed. This can be done

simply by pumping the brake pedal, with the vehi-

cle's engine not running, until a firm feeling brake

pedal is achieved.

Fig. 59 Master Cylinder Mounting

1 - MASTER CYLINDER MOUNTING NUTS

2 - MASTER CYLINDER

3 - SECONDARY TUBE NUT AT ICU

4 - PRIMARY TUBE NUT AT ICU

Fig. 60 Vacuum Booster Input Rod Retaining Pin

1 - BRAKE PEDAL

2 - INPUT ROD

3 - SCREWDRIVER

4 - RETAINING CLIP

5 - BRAKE PEDAL PIN

RSBRAKES - BASE5-43

POWER BRAKE BOOSTER (Continued)

Page 193 of 2585

INSTALLATION

INSTALLATION - LHD

(1) Position power brake booster on dash panel

using the reverse procedure of its removal (Fig. 62).

It may be necessary to push in on booster input rod

as it is guided through the dash panel.

(2) Install the four nuts mounting the booster to

the dash panel (Fig. 61). Tighten the mounting nuts

to a torque of 29 N´m (250 in. lbs.).

(3) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal pin where it contacts the

booster input rod.

CAUTION: When installing the brake pedal pin on

the power brake booster input rod, do not re-use

the old retaining clip.

(4) Install booster input rod on brake pedal pin

and install a NEW retaining clip (Fig. 68).

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(5) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)

(6) Install the silencer panel below the steering

column.(7) Connect vacuum hose to check valve on power

brake booster.

CAUTION: The master cylinder (and its rear seal) is

used to create the seal for holding vacuum in the

vacuum booster. The vacuum seal on the master

cylinder MUST be replaced with a NEW seal when-

ever the master cylinder is removed from the vac-

uum booster.

CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(8) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(9) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 69).

(10) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston.

(11) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 59). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

(12) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 58).

(13) Connect primary and secondary brake tubes

to ABS ICU or non-ABS junction block (Fig. 59).

Tighten the tube nuts to 17 N´m (145 in lbs.).

(14) Install wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION)

(15) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

Fig. 67 RHD Booster Removal/Installation

1 - POWER BRAKE BOOSTER

2 - MASTER CYLINDER

Fig. 68 Retaining Pin Installed On Brake Pedal Pin

1 - BRAKE PEDAL

2 - RETAINING CLIP

3 - BOOSTER INPUT ROD

5 - 46 BRAKES - BASERS

POWER BRAKE BOOSTER (Continued)

Page 253 of 2585

line in the master cylinder fluid reservoir, the

entire brake hydraulic system should be

checked for evidence of a leak.

REMOVAL

(1) Remove wiring harness connector from brake

fluid reservoir level switch (Fig. 3).

(2) Using fingers, compress the retaining tabs on

the opposite end of brake fluid level switch. (3) With retaining tabs compressed, grasp the con-

nector end of brake fluid level switch and pull it out

of master cylinder brake fluid reservoir.

INSTALLATION

(1) Insert brake fluid level switch into left side of

brake fluid reservoir. Be sure switch is pushed in

until retaining tabs lock it to brake fluid reservoir. (2) Connect vehicle wiring harness connector to

brake fluid level switch (Fig. 3).

ADJUSTABLE PEDALS

SWITCH

REMOVAL

(1) Remove steering column lower shroud. (Refer

to 19 - STEERING/COLUMN/LOWER SHROUD -

REMOVAL) (2) Depress retaining tabs on top and bottom of

switch and remove switch from lower shroud.

INSTALLATION

(1) Install the switch into the lower shroud, snap-

ping it into place. (2) Connect wiring harness connector to switch,

then install lower shroud on steering column. (Refer

to 19 - STEERING/COLUMN/LOWER SHROUD -

INSTALLATION) (3) Ensure proper operation of adjustable pedals.

HYDRAULIC/MECHANICAL

DESCRIPTION

DESCRIPTION - DISC BRAKES (FRONT)

Each front disc brake consists of the following com-

ponents: ² Brake Rotor

² Brake Caliper

² Brake Caliper Adapter

² Shoes (Pads)

There are two non-interchangeable front disc brake

systems. One is manufactured by TRW and the other

by Continental Teves.

CAUTION: Components used on the TRW brakes

are not interchangeable with the Continental Teves

brakes. The two different systems must not be

mixed. Improper performance, noise and increased

stopping distance can occur.

The TRW front brake caliper is a one piece casting

containing a single 64 mm diameter piston bore (Fig.

4) with a phenolic piston. The caliper mounts to a

caliper adapter using two guide pin bolts that thread

into guide pins slid into the caliper adapter (Fig. 5).

The pins are lubricated and have boots that seal

them in place in the adapter. The Continental Teves front brake caliper is a one

piece casting containing a single piston 66 mm diam-

eter bore (Fig. 4) with a phenolic piston. The caliper

mounts to a caliper adapter using two guide pin bolts

that thread into the caliper adapter and slide on

bushings mounted in the caliper.

CAUTION: TRW and Continental Teves calipers are

not interchangeable. Each caliper is specifically

designed for the unique brake system. If calipers

are interchanged, improper performance, noise and

increased stopping distance can occur.

Fig. 3 MASTER CYLINDER AND BOOSTER

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

5s - 10 BRAKESRS

BRAKE FLUID LEVEL SWITCH (Continued)

Page 275 of 2585

Use only brake fluid that was stored in a tightly-

sealed container. DO NOT use petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid etc.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications (DOT 4 and DOT 4+ are

acceptable) and SAE J1703 standards. No other type

of brake fluid is recommended or approved for usage

in the vehicle brake system. Use only Mopar tBrake

Fluid or equivalent from a tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

JUNCTION BLOCK

DESCRIPTION - NON-ABS JUNCTION BLOCK

A junction block is used on vehicles that are not

equipped with antilock brakes (ABS). The junction

block mounts in the same location as the integrated

control unit (ICU) does on vehicles equipped with

ABS. This allows for use of the same brake tube con-

figuration on all vehicles. The junction block is located

on the driver's side of the front suspension cradle/

crossmember below the master cylinder (Fig. 44).

It has six threaded ports to which the brake tubes

connect. Two are for the primary and secondary

brake tubes coming from the master cylinder. The

remaining four are for the chassis brake tubes going

to each brake assembly.

OPERATION - NON-ABS JUNCTION BLOCK

The junction block distributes the brake fluid com-

ing from the master cylinder primary and secondary

ports to the four chassis brake tubes leading to the

brakes at each wheel. Since the junction block

mounts in the same location as the ABS integrated control unit (ICU), it allows for the common use of

brake tubes going to the brakes whether the vehicle

is equipped with or without ABS.

NOTE: Although the brake tubes coming from the

master cylinder to the junction block or ABS ICU

may appear to be the same, they are not. They are

unique to each brake system application.

REMOVAL - NON-ABS JUNCTION BLOCK

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block. (2) Disconnect the battery negative cable.

(3) If the vehicle is equipped with speed control,

perform the following: (a) Disconnect the battery positive cable.

(b) Remove the battery (Refer t o 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL). (c) Disconnect the vacuum hose connector at the

tank built into the battery tray. (d) Remove the screw securing the coolant filler

neck to the battery tray. (e) Remove the battery tray (Refer t o 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL). (f) Remove the fasteners and move the speed

control servo off to the side, out of the way.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hydraulic system. (4) Remove the four chassis brake tubes from the

top of the junction block (Fig. 44). (5) Remove the primary and secondary brake

tubes from the top of the junction block. (6) Remove the bolts attaching the junction block

mounting bracket to the front suspension crossmem-

ber (Fig. 44), then remove the junction block.

INSTALLATION - NON-ABS JUNCTION BLOCK

(1) Install the junction block and mounting bracket

on the front suspension crossmember (Fig. 44).

Install the mounting bolts and tighten to a torque of

28 N´m (250 in. lbs.). (2) Install the primary and secondary brake tubes

from the master cylinder in their ports. Tighten tube

nuts to a torque of 17 N´m (145 in. lbs.). Take care

not to twist tubes when tightening tube nuts.

They must be properly positioned to allow free

movement with rubber isolated suspension

crossmember.

5s - 32 BRAKESRS

FLUID (Continued)

Page 281 of 2585

CAUTION: When tightening the primary and sec-

ondary brake tube nuts at master cylinder, be sure

brake tubes do not contact any other components

within the vehicle and that there is slack in the flex-

ible sections of the tubes. This is required due to

the movement between the ABS ICU and the master

cylinder while the vehicle is in motion.(4) Connect primary and secondary brake tubes to

master cylinder primary and secondary ports (Fig.

48). Brake tubes must be held securely when tight-

ened to control orientation of flex section. Tighten

tube nuts to a torque of 17 N´m (145 in. lbs.). (5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

48). (6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopar t

Brake Fluid or equivalent. (11) Road test vehicle to ensure proper operation of

brakes.

INSTALLATION - RHD

CAUTION: Different types of master cylinders are

used on this vehicle depending on brake options. If

a new master cylinder is being installed, be sure it

is the correct master cylinder for the type of brake

system the vehicle is equipped with.

CAUTION: When replacing the master cylinder on a

vehicle, a NEW vacuum seal MUST be installed on

the master cylinder.

(1) Install a NEW vacuum seal on master cylinder

making sure seal fits squarely in groove of master

cylinder casting. (2) Position master cylinder on studs of power

brake booster, aligning booster push rod with master

cylinder piston. (3) Install the two master cylinder mounting nuts

(Fig. 50). Tighten both mounting nuts to a torque of

25 N´m (225 in. lbs.).

CAUTION: When tightening the primary and sec-

ondary brake tube nuts at master cylinder, be sure

brake tubes do not contact any other components

within the vehicle and that there is slack in the flex-

ible sections of the tubes. This is required due to

the movement between the ABS ICU and the master

cylinder while the vehicle is in motion. (4) Connect primary and secondary brake tubes to

master cylinder primary and secondary ports (Fig.

50). Brake tubes must be held securely when tight-

ened to control orientation of flex section. Tighten

tube nuts to a torque of 17 N´m (145 in. lbs.). (5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

46). (6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopar t

Brake Fluid or equivalent. (11) Road test vehicle to ensure proper operation of

brakes.

PEDALS - ADJUSTABLE

REMOVAL

NOTE: Before proceeding, review all Steering Col-

umn and Airbag Warnings and Cautions. (Refer to

19 - STEERING/COLUMN - WARNING)(Refer to 8 -

ELECTRICAL/RESTRAINTS - WARNING)

(1) Move driver's seat to full rearward position.

(2) Disconnect negative battery cable from battery

post and isolate. (3) Remove throttle cable from throttle body lever.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - REMOVAL) (4) Remove screws securing lower steering column

cover/knee blocker, then remove it (Fig. 53). (5) Disconnect parking brake release link at

release handle. (6) Compress tabs on sides of data link diagnostic

connector and remove it from knee blocker reinforce-

ment plate. (7) Remove screws securing knee blocker reinforce-

ment plate in place, then remove reinforcement plate

(Fig. 53). (8) Remove hood release from lower left reinforce-

ment. (9) Remove screws securing instrument panel

lower left reinforcement in place, then remove rein-

forcement (Fig. 54). (10) Remove brake lamp switch. Discard original

switch; it must not be reused. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE

LAMP SWITCH - REMOVAL) (11) Remove upper and lower steering column

shrouds. (Refer to 19 - STEERING/COLUMN/

LOWER SHROUD - REMOVAL)

5s - 38 BRAKESRS

MASTER CYLINDER (Continued)