Power steering CHRYSLER VOYAGER 2004 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 349 of 2585

INSTALLATION

(1) Route and position the drive belt onto all pul-

leys, except for the crankshaft (Fig. 10).

(2) Rotate belt tensioner counterclockwise until

belt can be installed onto the crankshaft pulley (Fig.

8). Slowly release belt tensioner.

(3) Verify belt is properly routed and engaged on

all pulleys.

(4) Install drive belt shield (Fig. 7) and lower vehi-

cle.

BELT TENSIONER - 3.3/3.8L

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the drive belt shield.

(3) Remove the drive belt. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - REMOVAL)

(4) Remove the belt tensioner (Fig. 11).

INSTALLATION

(1) Install the belt tensioner and bolt (Fig. 11).

Tighten bolt to 28 N´m (250 in. lbs.).

(2) Install the drive belt. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION)

(3) Install the drive belt shield.

(4) Lower the vehicle.

Fig. 10 ACCESSORY DRIVE BELT

1 - DRIVE BELT

2 - POWER STEERING PUMP PULLEY

3 - BELT TENIONER PULLEY

4 - IDLER PULLEY

5 - GENERATOR PULLEY

6 - AIR CONDITIONING COMPRESSOR PULLEY

7 - CRANKSHAFT PULLEY

8 - WATER PUMP PULLEY

Fig. 11 BELT TENSIONER - 3.3/3.8L

1 - BELT TENSIONER

2 - BOLT

7 - 12 ACCESSORY DRIVERS

DRIVE BELTS - 3.3/3.8L (Continued)

Page 358 of 2585

(3) With heater seated, tighten center screw

securely to assure a positive seal.

(4) Install power cord plug to heater.

(5) Fill cooling system with coolant to the proper

level. (Refer to 7 - COOLING - STANDARD PROCE-

DURE)

ENGINE COOLANT

TEMPERATURE SENSOR - 2.4L

DESCRIPTION

The engine coolant temperature sensor threads

into the top of the thermostat housing (Fig. 3). New

sensors have sealant applied to the threads.

REMOVAL

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

(1) Drain the cooling system below thermostat

level. (Refer to 7 - COOLING - STANDARD PROCE-

DURE)

(2) Disconnect coolant temperature sensor electri-

cal connector.

(3) Remove coolant temperature sensor (Fig. 3).

INSTALLATION

(1) Install coolant temperature sensor (Fig. 3).

Tighten sensor to 7 N´m (60 in. lbs.).

(2) Connect electrical connector to sensor.

(3) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

ENGINE COOLANT

TEMPERATURE SENSOR -

3.3/3.8L

DESCRIPTION

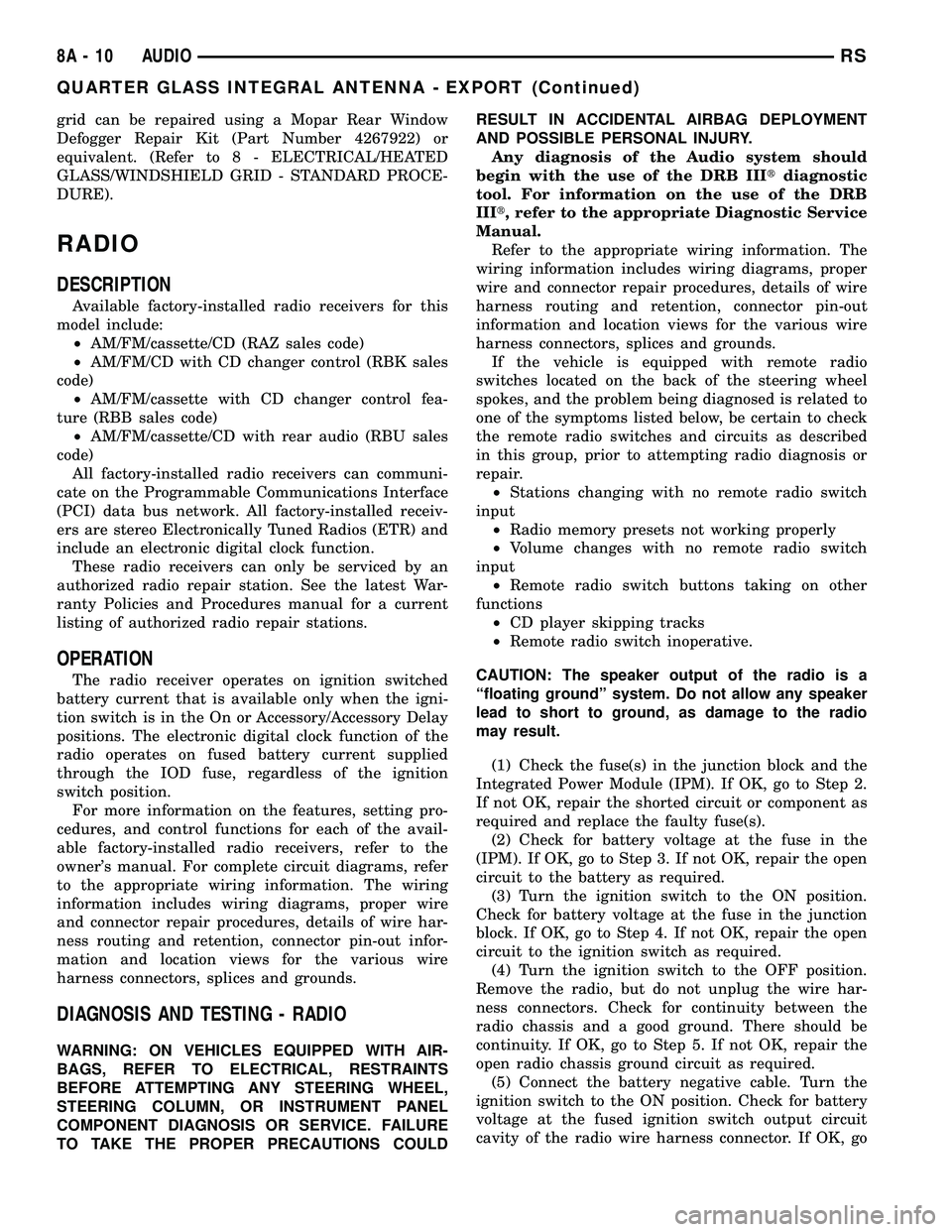

The engine coolant temperature sensor threads

into a coolant passage on lower intake manifold near

the thermostat (Fig. 6). New sensors have sealant

applied to the threads.

REMOVAL

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

(1) Drain cooling system below engine coolant tem-

perature sensor level. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(2) Remove power steering reservoir and relocate

(Fig. 4). Do not disconnect hoses.

Fig. 3 Engine Coolant Temperature Sensor - 2.4L

1 - MAP SENSOR

2 - COOLANT TEMPERATURE SENSORFig. 4 Power Steering Fluid Reservoir

1 - POWER STEERING RESERVOIR

2 - BOLT - RESERVOIR TO MANIFOLD

3 - NUT - RESERVOIR TO COIL BRACKET

RSENGINE7-21

ENGINE BLOCK HEATER (Continued)

Page 359 of 2585

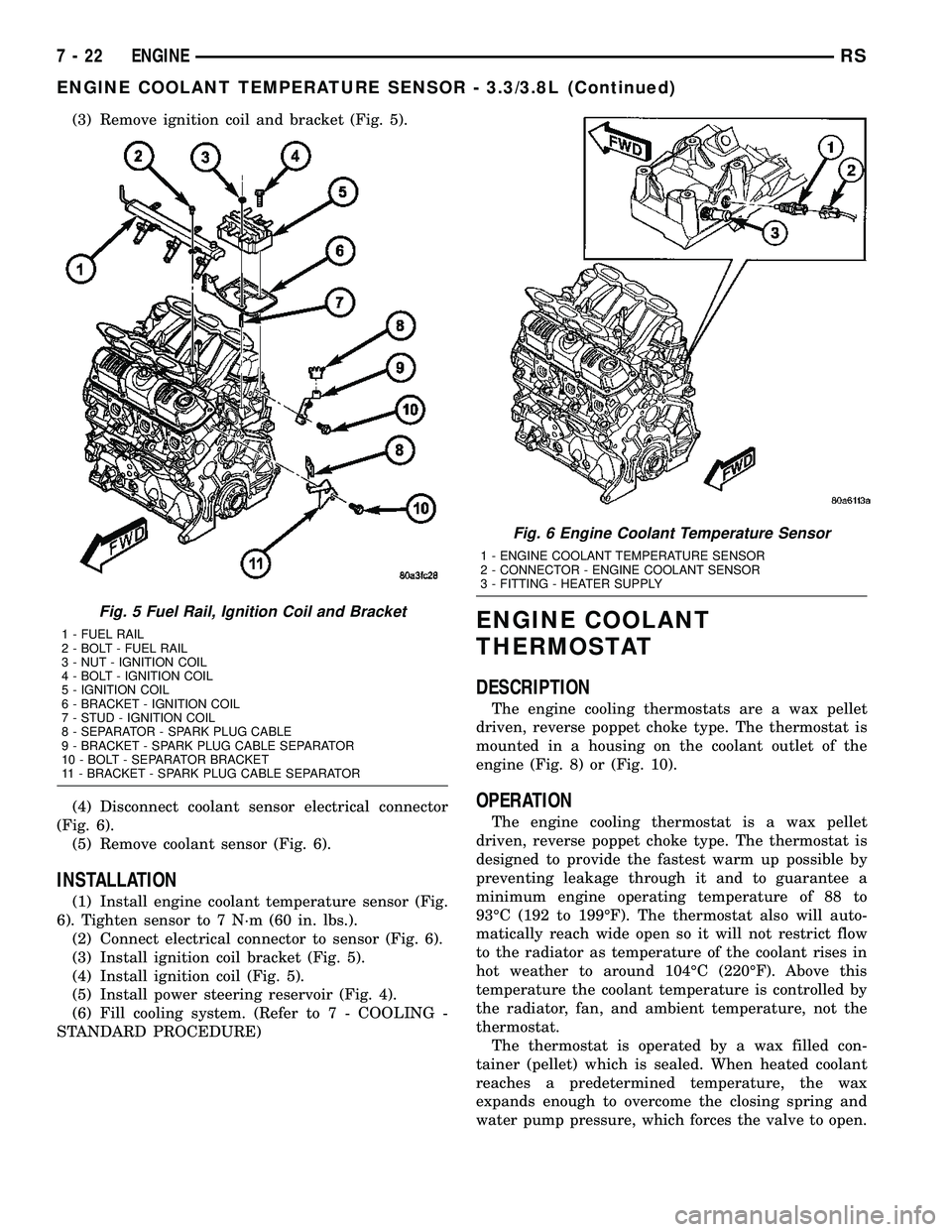

(3) Remove ignition coil and bracket (Fig. 5).

(4) Disconnect coolant sensor electrical connector

(Fig. 6).

(5) Remove coolant sensor (Fig. 6).

INSTALLATION

(1) Install engine coolant temperature sensor (Fig.

6). Tighten sensor to 7 N´m (60 in. lbs.).

(2) Connect electrical connector to sensor (Fig. 6).

(3) Install ignition coil bracket (Fig. 5).

(4) Install ignition coil (Fig. 5).

(5) Install power steering reservoir (Fig. 4).

(6) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

ENGINE COOLANT

THERMOSTAT

DESCRIPTION

The engine cooling thermostats are a wax pellet

driven, reverse poppet choke type. The thermostat is

mounted in a housing on the coolant outlet of the

engine (Fig. 8) or (Fig. 10).

OPERATION

The engine cooling thermostat is a wax pellet

driven, reverse poppet choke type. The thermostat is

designed to provide the fastest warm up possible by

preventing leakage through it and to guarantee a

minimum engine operating temperature of 88 to

93ÉC (192 to 199ÉF). The thermostat also will auto-

matically reach wide open so it will not restrict flow

to the radiator as temperature of the coolant rises in

hot weather to around 104ÉC (220ÉF). Above this

temperature the coolant temperature is controlled by

the radiator, fan, and ambient temperature, not the

thermostat.

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed. When heated coolant

reaches a predetermined temperature, the wax

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

Fig. 5 Fuel Rail, Ignition Coil and Bracket

1 - FUEL RAIL

2 - BOLT - FUEL RAIL

3 - NUT - IGNITION COIL

4 - BOLT - IGNITION COIL

5 - IGNITION COIL

6 - BRACKET - IGNITION COIL

7 - STUD - IGNITION COIL

8 - SEPARATOR - SPARK PLUG CABLE

9 - BRACKET - SPARK PLUG CABLE SEPARATOR

10 - BOLT - SEPARATOR BRACKET

11 - BRACKET - SPARK PLUG CABLE SEPARATOR

Fig. 6 Engine Coolant Temperature Sensor

1 - ENGINE COOLANT TEMPERATURE SENSOR

2 - CONNECTOR - ENGINE COOLANT SENSOR

3 - FITTING - HEATER SUPPLY

7 - 22 ENGINERS

ENGINE COOLANT TEMPERATURE SENSOR - 3.3/3.8L (Continued)

Page 383 of 2585

that chamber to receive and load a new disc in that

chamber.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove screws holding CD changer.

(3) Disconnect the wire connector from the back of

the CD changer.

(4) Remove the CD changer from the vehicle (Fig.

6).

INSTALLATION

(1) Reconnect the wire connector to the CD

changer.

(2) Insert the CD changer into the instrument

panel.

NOTE: Use care when inserting CD changer so that

cable is not pinched or trapped against instrument

panel.

(3) Install screws holding CD changer.

(4) Reconnect the battery negative cable.

DVD PLAYER

DESCRIPTION

The DVD player (if equipped) is located in the

instrument panel below the radio. The DVD player

can hold one DVD at a time. Three RCA jacks on the

front of the unit allow the use of MP3 players, video

game systems or camcorders.

OPERATION

Operating instructions for the factory installed

DVD player can be found in the owner's manual pro-

vided with this vehicle.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove screws holding DVD player (Fig. 7).

(3) Disconnect the wire connector from the back of

the DVD player.

(4) Remove the DVD player from the vehicle.

INSTALLATION

(1) Connect the wire harness connector to the DVD

player.

(2) Insert the DVD player into the instrument

panel.

(3) Install mounting screws.

(4) Connect the battery negative cable.

INSTRUMENT PANEL

ANTENNA CABLE

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Fig. 6 CD - CHANGER

1 - CD-CHANGER

2 - POWER OUTLET

Fig. 7 DVD PLAYER

1 - DVD PLAYER

2 - POWER OUTLET

8A - 8 AUDIORS

CD CHANGER (Continued)

Page 385 of 2585

grid can be repaired using a Mopar Rear Window

Defogger Repair Kit (Part Number 4267922) or

equivalent. (Refer to 8 - ELECTRICAL/HEATED

GLASS/WINDSHIELD GRID - STANDARD PROCE-

DURE).

RADIO

DESCRIPTION

Available factory-installed radio receivers for this

model include:

²AM/FM/cassette/CD (RAZ sales code)

²AM/FM/CD with CD changer control (RBK sales

code)

²AM/FM/cassette with CD changer control fea-

ture (RBB sales code)

²AM/FM/cassette/CD with rear audio (RBU sales

code)

All factory-installed radio receivers can communi-

cate on the Programmable Communications Interface

(PCI) data bus network. All factory-installed receiv-

ers are stereo Electronically Tuned Radios (ETR) and

include an electronic digital clock function.

These radio receivers can only be serviced by an

authorized radio repair station. See the latest War-

ranty Policies and Procedures manual for a current

listing of authorized radio repair stations.

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory/Accessory Delay

positions. The electronic digital clock function of the

radio operates on fused battery current supplied

through the IOD fuse, regardless of the ignition

switch position.

For more information on the features, setting pro-

cedures, and control functions for each of the avail-

able factory-installed radio receivers, refer to the

owner's manual. For complete circuit diagrams, refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire har-

ness routing and retention, connector pin-out infor-

mation and location views for the various wire

harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - RADIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

If the vehicle is equipped with remote radio

switches located on the back of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) Check the fuse(s) in the junction block and the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(2) Check for battery voltage at the fuse in the

(IPM). If OK, go to Step 3. If not OK, repair the open

circuit to the battery as required.

(3) Turn the ignition switch to the ON position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 4. If not OK, repair the open

circuit to the ignition switch as required.

(4) Turn the ignition switch to the OFF position.

Remove the radio, but do not unplug the wire har-

ness connectors. Check for continuity between the

radio chassis and a good ground. There should be

continuity. If OK, go to Step 5. If not OK, repair the

open radio chassis ground circuit as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the ON position. Check for battery

voltage at the fused ignition switch output circuit

cavity of the radio wire harness connector. If OK, go

8A - 10 AUDIORS

QUARTER GLASS INTEGRAL ANTENNA - EXPORT (Continued)

Page 405 of 2585

NOTE: PCM Inputs:

²Air Conditioning Pressure Transducer

²Ambient temperature Sensor

²ASD Relay

²Battery Temperature Sensor (NGC)

²Battery Voltage

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Distance Sensor (from transmission control mod-

ule)

²EGR Position Feedback

²Engine Coolant Temperature Sensor

²Heated Oxygen Sensors

²Ignition sense

²Intake Air Temperature Sensor

²Knock Sensor

²Leak Detection Pump Feedback

²Manifold Absolute Pressure (MAP) Sensor

²Park/Neutral

²PCI Bus

²Power Steering Pressure Switch

²Proportional Purge Sense

²SCI Receive

²Speed Control

²Throttle Position Sensor

²Torque Management Input

²Transaxle Control Module (3.3/3.8L Only)

²Transmission Control Relay (Switched B+) (2.4L

Only)

²Transmission Pressure Switches (2.4L Only)

²Transmission Temperature Sensor (2.4L Only)

²Transmission Input Shaft Speed Sensor (2.4L

Only)

²Transmission Output Shaft Speed Sensor (2.4L

Only)

²Transaxle Gear Engagement

²Vehicle Speed

NOTE: PCM Outputs:

²Air Conditioning Clutch Relay

²Automatic Shut Down (ASD) and Fuel Pump

Relays

²Data Link Connector (PCI and SCI Transmit)

²Double Start Override

²EGR Solenoid

²Fuel Injectors

²Generator Field

²High Speed Fan Relay

²Idle Air Control Motor

²Ignition Coils

²Leak Detection Pump

²Low Speed Fan Relay

²MTV Actuator

²Proportional Purge Solenoid²SRV Valve

²Speed Control Relay

²Speed Control Vent Relay

²Speed Control Vacuum Relay

²8 Volt Output

²5 Volt Output

²Torque Reduction Request

²Transmission Control Relay (2.4L Only)

²Transmission Solenoids (2.4L Only)

²Vehicle Speed

Based on inputs it receives, the powertrain control

module (PCM) adjusts fuel injector pulse width, idle

speed, ignition timing, and canister purge operation.

The PCM regulates the cooling fans, air conditioning

and speed control systems. The PCM changes gener-

ator charge rate by adjusting the generator field.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery Voltage

²Intake Air Temperature Sensor

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Exhaust Gas Oxygen Content (heated oxygen

sensors)

²Manifold Absolute Pressure

²Throttle Position

The PCM adjusts engine idle speed through the

idle air control motor based on the following inputs.

²Brake Switch

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Park/Neutral

²Transaxle Gear Engagement

²Throttle Position

²Vehicle Speed

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Intake Air Temperature

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Knock Sensor

²Manifold Absolute Pressure

²Park/Neutral

²Transaxle Gear Engagement

²Throttle Position

The automatic shut down (ASD) and fuel pump

relays are mounted externally, but turned on and off

by the powertrain control module through the same

circuit.

The camshaft and crankshaft signals are sent to

the powertrain control module. If the PCM does not

receive both signals within approximately one second

of engine cranking, it deactivates the ASD and fuel

pump relays. When these relays are deactivated,

power is shut off to the fuel injectors, ignition coils,

8E - 12 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 408 of 2585

OPERATION - SENSOR RETURN - PCM INPUT

The sensor return circuit provides a low electrical

noise ground reference for all of the systems sensors.

The sensor return circuit connects to internal ground

circuits within the Powertrain Control Module

(PCM).

OPERATION - DATA BUS COMMUNICATION

RECEIVE - PCM INPUT

The PCM uses the SCI communication bus to pre-

form engine diagnostics and flash operations. The

transmission side of the PCM uses the SCI commu-

nication bus to flash new software. However, diagnos-

tics is performed via the vehicles J1850 bus for the

transmission side of the PCM.

OPERATION - IGNITION SENSE - PCM INPUT

The ignition sense input informs the Powertrain

Control Module (PCM) that the ignition switch is in

the crank or run position.

OPERATION - PCM GROUND

Ground is provided through multiple pins of the

PCM connector. Depending on the vehicle there may

be as many as two different ground pins. There are

power grounds and sensor grounds.

The power grounds are used to control the ground

side relays, solenoids, ignition coil or injectors. The

signal ground is used for any input that uses sensor

return for ground, and the ground side of any inter-

nal processing component.

The PCM case is shielded to prevent RFI and EMI.

The PCM case is grounded and must be firmly

attached to a good, clean body ground.

Internally all grounds are connected together, how-

ever there is noise suppression on the sensor ground.

For EMI and RFI protection the housing and cover

are also grounded separately from the ground pins.

OPERATION

OPERATION - 8-VOLT SUPPLY - PCM OUTPUT

- SBEC CONTROLLER

The PCM supplies 8 volts to the crankshaft posi-

tion sensor, camshaft position sensor.

OPERATION - 5 VOLT SUPPLY - PCM OUTPUT

The PCM supplies 5 volts to the following sensors:

²A/C pressure transducer

²Ambient Temperature sensor

²Battery temperature

²Camshaft Position Sensor (NGC)

²Crankshaft Position Sensor (NGC)

²Electronic Throttle Control (1.6L)²Engine coolant temperature sensor

²Inlet Air Temperature Sensor

²Knock sensor

²Linear EGR solenoid (if equipped)

²Manifold absolute pressure sensor

²Oil Pressure Switch

²Pedal Position Sensor (1.6L)

²Throttle position sensor

²Vehicle Speed Sensor

STANDARD PROCEDURE

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES

BULB CHECK

Key on: Bulb illuminated until vehicle starts, as

long as all once per trip (readiness) monitors com-

pleted. If monitors havenotbeen completed, then:

Key on: bulb check for about 5 to 8 seconds, lamp

then flashes if once per trip (readiness) monitors

havenotbeen completed until vehicle is started,

then MIL is extinguished.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

STANDARD PROCEDURE - PINION FACTOR

SETTING

NOTE: This procedure must be performed if the

PCM/TCM has been replaced with a NEW or

replacement unit. Failure to perform this procedure

will result in an inoperative or improperly calibrated

speedometer.

The vehicle speed readings for the speedometer are

taken from the output speed sensor. The PCM/TCM

must be calibrated to the different combinations of

equipment (final drive and tires) available. Pinion

Factor allows the technician to set the Powertrain/

Transmission Control Module initial setting so that

the speedometer readings will be correct. To properly

RSELECTRONIC CONTROL MODULES8E-15

POWERTRAIN CONTROL MODULE (Continued)

Page 411 of 2585

Refer to the appropriate Powertrain Diagnostic Man-

ual and the DRBIIItscan tool.

(1) Install PCM module to the mounting bracket.

(2) Install electrical connectors and lock.

(3) Install the splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.

(6) Using DRBIIItscan tool, program mileage and

vehicle identification number (VIN) into PCM. Refer

to the DRBIIItscan tool and the appropriate Power-

train Diagnostic Manual.

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a

microprocessor. The SKIM retains in memory the ID

numbers of any Sentry Key that is programmed to it.

The maximum number of keys that may be pro-

grammed to each module is eight (8). The SKIM also

communicates over the Programmable Communica-

tion Interface (PCI) data bus with the Powertrain

Control Module (PCM), the Body Control Module

(BCM), the Mechanical Instrument Cluster (MIC),

and the DRB IIItscan tool. The SKIM transmits and

receives RF signals through a tuned antenna

enclosed within a molded plastic ring formation that

is integral to the SKIM housing. When the SKIM is

properly installed on the steering column, the

antenna ring fits snugly around the circumference of

the ignition lock cylinder housing. If this ring is not

mounted properly, communication problems may

arise in the form of transponder-related faults.

For added system security, each SKIM is pro-

grammed with a unique9Secret Key9code. This code

is stored in memory and is sent over the PCI bus to

the PCM and to each key that is programmed to

work with the vehicle. The9Secret Key9code is there-

fore a common element found in all components of

the Sentry Key Immobilizer System (SKIS). In the

event that a SKIM replacement is required, the

9Secret Key9code can be restored from the PCM by

following the SKIM replacement procedure found in

the DRB IIItscan tool. Proper completion of this

task will allow the existing ignition keys to be repro-

grammed. Therefore, new keys will NOT be needed.

In the event that the original9Secret Key9code can

not be recovered, new ignition keys will be required.

The DRB IIItscan tool will alert the technician if

key replacement is necessary. Another security code,

called a PIN, is used to gain secured access to the

SKIM for service. The SKIM also stores in its mem-

ory the Vehicle Identification Number (VIN), which itlearns through a bus message from the assembly

plant tester. The SKIS scrambles the information

that is communicated between its components in

order to reduce the possibility of unauthorized SKIM

access and/or disabling.

OPERATION

When the ignition switch is moved to the RUN

position, the Sentry Key Immobilizer Module (SKIM)

transmits an Radio Frequency (RF) signal to the

transponder in the ignition key. The SKIM then

waits for a response RF signal from the transponder

in the key. If the response received identifies the key

as valid, the SKIM sends a9valid key9message to

the Powertrain Control Module (PCM) over the Pro-

grammable Communication Interface (PCI) data bus.

If the response received identifies the key as invalid

or no response is received from the transponder in

the ignition key, the SKIM sends an9invalid key9

message to the PCM. The PCM will enable or disable

engine operation based upon the status of the SKIM

messages. It is important to note that the default

condition in the PCM is9invalid key.9Therefore, if no

response is received by the PCM, the engine will be

immobilized after two (2) seconds of running.

The SKIM also sends indicator light status mes-

sages to the Mechanical Instrument Cluster (MIC) to

operate the light. This is the method used to turn the

light ON solid or to flash it after the indicator light

test is complete to signify a fault in the SKIS. If the

light comes ON and stays ON solid after the indica-

tor light test, this signifies that the SKIM has

detected a system malfunction and/or that the SKIS

has become inoperative. If the SKIM detects an

invalid keyORa key-related fault exists, the indica-

tor light will flash following the indicator light test.

The SKIM may also request an audible chime if the

customer key programming feature is available and

the procedure is being utilized (Refer to 8 - ELEC-

TRICAL/VEHICLE THEFT SECURITY/TRANSPON-

DER KEY - STANDARD PROCEDURE).

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove Lower Instrument Panel Cover. Refer

to Body, Instrument Panel, Lower Instrument Panel

Cover, Removal.

(3) Remove the steering column upper and lower

shrouds. Refer to Steering, Column, Column Shroud,

Removal.

(4) Disengage the steering column wire harness

from the Sentry Key Immobilizer Module (SKIM).

(5) Remove the one screws securing the SKIM to

the steering column.

8E - 18 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 412 of 2585

(6) Rotate the SKIM upwards and then to the side

away from the steering column to slide the SKIM

antenna ring from around the ignition switch lock

cylinder housing.

(7) Remove the SKIM from the vehicle.

INSTALLATION

(1) Slip the SKIM antenna ring around the igni-

tion switch lock cylinder housing. Rotate the SKIM

downwards and then towards the steering column.

(2) Install the one screws securing the SKIM to

the steering column.

(3) Engage the steering column wire harness from

the Sentry Key Immobilizer Module (SKIM).

(4) Install the steering column upper and lower

shrouds. Refer to Steering, Column, Column Shroud,

Installation.

(5) Install the Lower Instrument Panel Cover.

Refer to Body, Instrument Panel, Lower Instrument

Panel Cover, Installation.

(6) Connect the battery negative cable.

SLIDING DOOR CONTROL

MODULE

DESCRIPTION

Vehicles equipped with a power sliding door utilize

a sliding door control module. The sliding door con-

trol module is located behind the sliding door trim

panel in the center of the door, just above the sliding

door motor (Fig. 15). This module controls the opera-

tion of the door through the Programmable Commu-

nication Interface (PCI) J1850 data bus circuit and

the Body Control Module. The sliding door control

module contains software technology which enables it

to detect resistance to door travel and to reverse door

travel in order to avoid damage to the door or to

avoid possible personal injury if the obstruction is a

person. This feature functions in both the opening

and closing cycles. If the power sliding door system

develops any problems the control module will store

and recall Diagnostic Trouble Codes (DTC). The use

of a diagnostic scan tool, such as the DRB IIItis

required to read and troubleshoot these trouble

codes. The sliding door control module can be

reflashed if necessary. Refer to the latest Technical

Service Bulletin (TSB) Information for any updates.

The power door control module is a replaceable

component and cannot be repaired, if found to be

faulty it must be replaced. Consult your MoparŸ

parts catalog for a specific part number.

OPERATION

The power sliding door control module serves as

the main computer for the power sliding side doorsystem. All power door functions are processed

through the power door control module and/or the

vehicles body control module (BCM). At the start of a

power open command, a signal is sent to the BCM

and then to the power door control module via the

J1850 data bus circuit. This signal, generated by any

of the power door command switches, tells the power

door control module to activate a power latch release,

engage the clutch assembly and drive the door into

the full open position. If an obstacle is felt during

this power open cycle, the module will reverse direc-

tion and close the door. This process is also enabled

during a power close cycle. This process will repeat

three times, and if a fourth obstacle is detected, the

door will go into full manual mode. Once the full

open position is obtained, a hold open latch assembly

mounted full open switch tells the control module

that the door has reached the full open position. If

the power sliding door system develops any problems

the control module will store and recall Diagnostic

Trouble Codes (DTC). The use of a diagnostic scan

tool, such as the DRB IIItis required to read and

troubleshoot these trouble codes.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

Fig. 15 Power Side Door Components

1 - SLIDING DOOR CONTROL MODULE

2 - MODULE RETAINING SCREW

3 - MODULE ELECTRICAL CONNECTORS

4 - DOOR MOTOR ASSEMBLY

5 - FLEX DRIVE ASSEMBLY

6 - DOOR MOTOR RETAINING FASTENERS

7 - DOOR MOTOR ELECTRICAL CONNECTOR

RSELECTRONIC CONTROL MODULES8E-19

SENTRY KEY IMMOBILIZER MODULE (Continued)

Page 449 of 2585

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................28

OPERATION...........................28

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST.......................28

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST........................30

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST....................32

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST...............................33SPECIFICATIONS

Torques.............................33

STARTER ...........................34

STARTER MOTOR

REMOVAL

REMOVAL - 2.4L......................34

REMOVAL - 3.3/3.8L...................35

INSTALLATION

INSTALLATION - 2.4L..................35

INSTALLATION - 3.3/3.8L................36

STARTING

DESCRIPTION

The starting system consists of:

²Starter relay

²Starter motor (including an integral starter sole-

noid)

Other components to be considered as part of start-

ing system are:

²Battery

²Battery cables

²Ignition switch and key lock cylinder

²Clutch pedal position switch (manual transmis-

sion)

²Park/neutral position switch (automatic trans-

mission)

²Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.

OPERATION

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

The PCM controls a double start over-ride safety

that does not allow the starter to be engaged if the

engine is already running.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST

For circuit descriptions and diagrams, refer to the

Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE PASSIVE RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

INSPECTION

Before removing any unit from the starting system

for repair or diagnosis, perform the following inspec-

tions:

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

8F - 28 STARTINGRS