battery CHRYSLER VOYAGER 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 242 of 2585

(22) Road test vehicle to ensure proper operation

of the base and antilock brake systems.

INSTALLATION - RHD

(1) Install the ICU on the mounting bracket (Fig.

21). Install the 3 bolts (Fig. 21) attaching the ICU to

the mounting bracket. Tighten the 3 mounting bolts

to a torque of 11 N´m (97 in. lbs.).

CAUTION: The ICU mounting bracket to front sus-

pension cradle mounting bolts have a unique corro-

sion protection coating and a special aluminum

washer. For this reason, only the original, or origi-

nal equipment Mopar replacement bolts can be

used to mount the ICU bracket to the front suspen-

sion crossmember.

(2) Install the ICU and its mounting bracket as an

assembly on the front suspension crossmember.

Install the 3 bolts attaching the ICU bracket to the

crossmember (Fig. 20). Tighten the 3 mounting bolts

to a torque of 28 N´m (250 in. lbs.).

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, and the brake

tubes between the HCU and the proportioning

valve, the brake tubes must be held in proper ori-

entation when tightened and torqued. These tubes

must not contact each other or other vehicle com-

ponents when installed. Also, after the brake tubes

are installed on the HCU, ensure all spacer clips are

reinstalled on the brake tubes.

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation. Refer to (Fig. 19) for the correct chassis

brake tube locations.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the ICU

mounting bracket.

(3) Install the 6 chassis brake tubes into their cor-

rect port locations on the HCU valve block as shown

in (Fig. 19). Tighten the tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: Before installing the 24-way connector in the

CAB be sure the seal is properly installed in the

connector.(4) Install the 24-way connector (Fig. 17) on the

CAB using the following procedure. Position the

24-way connector in the socket of the CAB and care-

fully push it down as far as possible. When connector

is fully seated by hand into the CAB socket, push in

the connector lock (Fig. 18). This will pull the connec-

tor into the socket of the CAB and lock it in the

installed position.

NOTE: The CAB wiring harness must be clipped to

the ICU mounting bracket. This will ensure the wir-

ing harness is properly routed and does not contact

the brake tubes or the body of the vehicle.

(5) Clip the cab wiring harness (Fig. 17) to the

ICU mounting bracket.

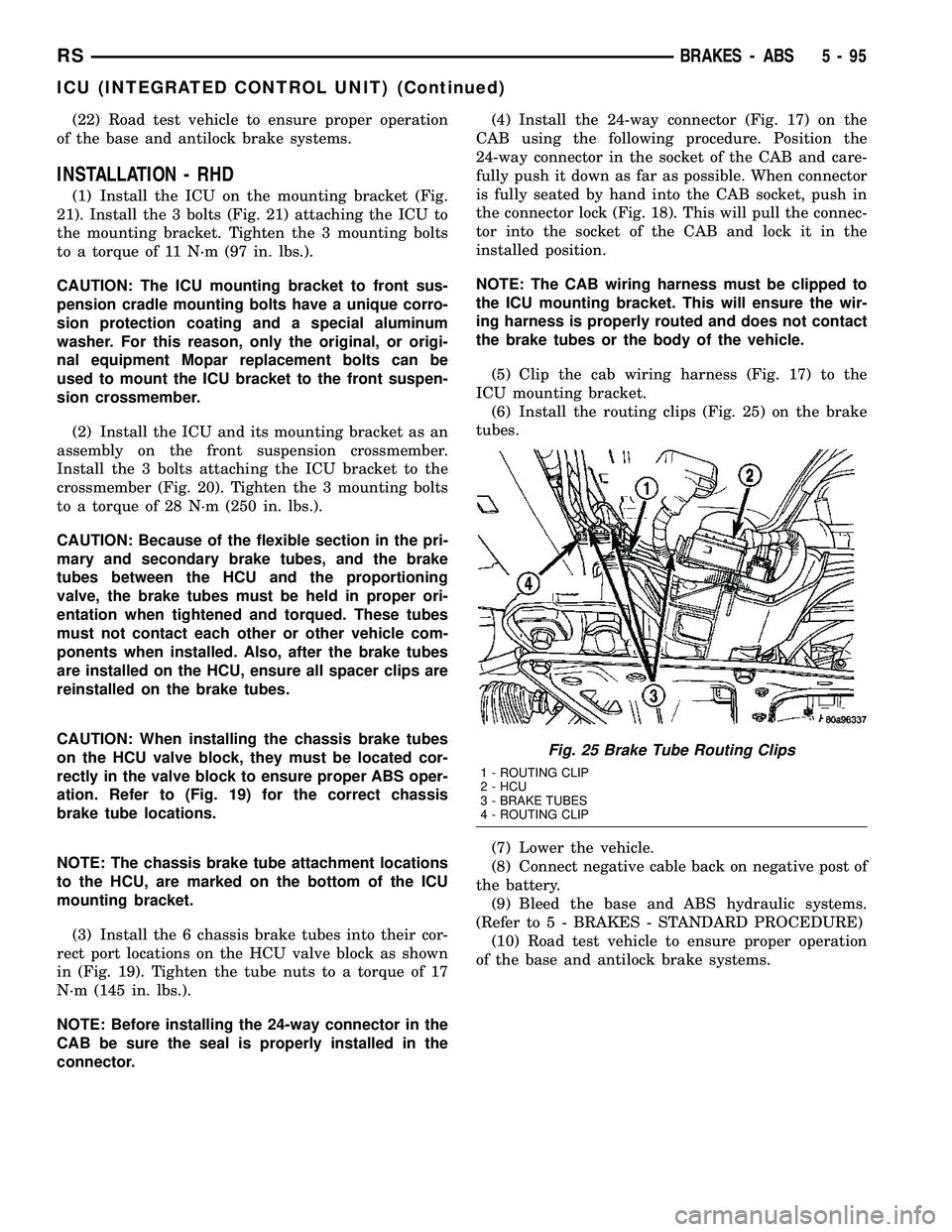

(6) Install the routing clips (Fig. 25) on the brake

tubes.

(7) Lower the vehicle.

(8) Connect negative cable back on negative post of

the battery.

(9) Bleed the base and ABS hydraulic systems.

(Refer to 5 - BRAKES - STANDARD PROCEDURE)

(10) Road test vehicle to ensure proper operation

of the base and antilock brake systems.

Fig. 25 Brake Tube Routing Clips

1 - ROUTING CLIP

2 - HCU

3 - BRAKE TUBES

4 - ROUTING CLIP

RSBRAKES - ABS5-95

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 275 of 2585

Use only brake fluid that was stored in a tightly-

sealed container. DO NOT use petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid etc.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications (DOT 4 and DOT 4+ are

acceptable) and SAE J1703 standards. No other type

of brake fluid is recommended or approved for usage

in the vehicle brake system. Use only Mopar tBrake

Fluid or equivalent from a tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

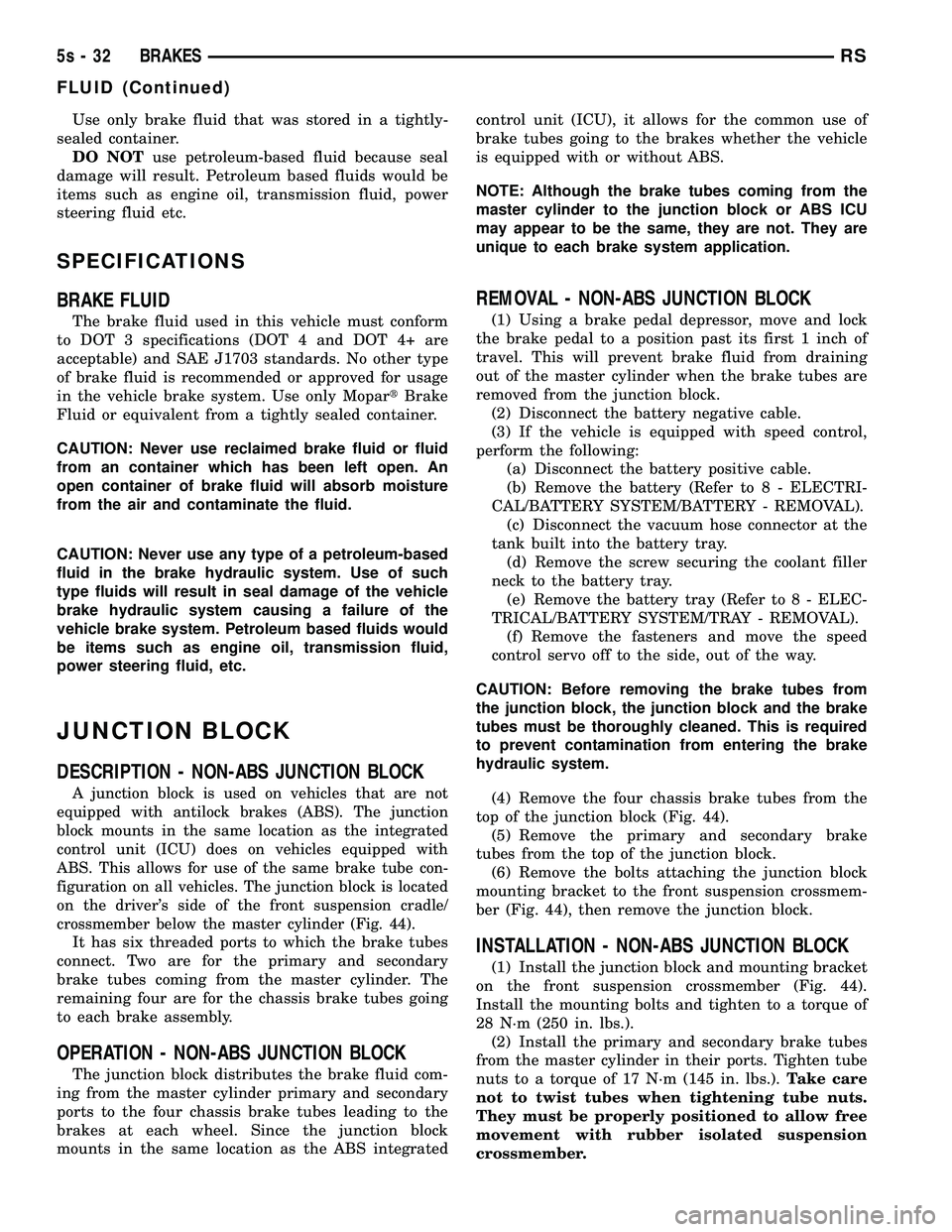

JUNCTION BLOCK

DESCRIPTION - NON-ABS JUNCTION BLOCK

A junction block is used on vehicles that are not

equipped with antilock brakes (ABS). The junction

block mounts in the same location as the integrated

control unit (ICU) does on vehicles equipped with

ABS. This allows for use of the same brake tube con-

figuration on all vehicles. The junction block is located

on the driver's side of the front suspension cradle/

crossmember below the master cylinder (Fig. 44).

It has six threaded ports to which the brake tubes

connect. Two are for the primary and secondary

brake tubes coming from the master cylinder. The

remaining four are for the chassis brake tubes going

to each brake assembly.

OPERATION - NON-ABS JUNCTION BLOCK

The junction block distributes the brake fluid com-

ing from the master cylinder primary and secondary

ports to the four chassis brake tubes leading to the

brakes at each wheel. Since the junction block

mounts in the same location as the ABS integrated control unit (ICU), it allows for the common use of

brake tubes going to the brakes whether the vehicle

is equipped with or without ABS.

NOTE: Although the brake tubes coming from the

master cylinder to the junction block or ABS ICU

may appear to be the same, they are not. They are

unique to each brake system application.

REMOVAL - NON-ABS JUNCTION BLOCK

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block. (2) Disconnect the battery negative cable.

(3) If the vehicle is equipped with speed control,

perform the following: (a) Disconnect the battery positive cable.

(b) Remove the battery (Refer t o 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL). (c) Disconnect the vacuum hose connector at the

tank built into the battery tray. (d) Remove the screw securing the coolant filler

neck to the battery tray. (e) Remove the battery tray (Refer t o 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL). (f) Remove the fasteners and move the speed

control servo off to the side, out of the way.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hydraulic system. (4) Remove the four chassis brake tubes from the

top of the junction block (Fig. 44). (5) Remove the primary and secondary brake

tubes from the top of the junction block. (6) Remove the bolts attaching the junction block

mounting bracket to the front suspension crossmem-

ber (Fig. 44), then remove the junction block.

INSTALLATION - NON-ABS JUNCTION BLOCK

(1) Install the junction block and mounting bracket

on the front suspension crossmember (Fig. 44).

Install the mounting bolts and tighten to a torque of

28 N´m (250 in. lbs.). (2) Install the primary and secondary brake tubes

from the master cylinder in their ports. Tighten tube

nuts to a torque of 17 N´m (145 in. lbs.). Take care

not to twist tubes when tightening tube nuts.

They must be properly positioned to allow free

movement with rubber isolated suspension

crossmember.

5s - 32 BRAKESRS

FLUID (Continued)

Page 276 of 2585

(3) Install the four chassis brake tubes into the

outlet ports of the junction block. Tighten all 6 tube

nuts to a torque of 17 N´m (145 in. lbs.). (4) If the vehicle is equipped with speed control,

perform the following: (a) Install the speed control servo with its

mounting nuts. (b) Connect the wiring harness to the speed con-

trol servo. (c) Install the battery tray (Refer t o 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - INSTALLA-

TION). (d) Install the screw securing the coolant filler

neck to the battery tray. (e) Reconnect the vacuum hose connector at the

tank built into the battery tray. (f) Install the battery (Refer t o 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - INSTALLA-

TION). (g) Install the battery shield.

(5) Remove the brake pedal holder.

(6) Connect negative cable back on negative post of

the battery. (7) Bleed the brake system thoroughly to ensure

that all air has been expelled from the hydraulic sys-

tem. (Refer t o 5 - BRAKES - STANDARD PROCE-

DURE). (8) Road test the vehicle to verify proper operation

of the brake system.

MASTER CYLINDER

DESCRIPTION

DESCRIPTION

The master cylinder is located on the power brake

booster in the engine compartment on the driver's

side (Fig. 45). This vehicle uses 3 different master

cylinders. Master cylinder usage depends on what

type of brake system the vehicle is equipped with.

CAUTION: Master cylinders are not interchangeable

between systems. Performance and stopping dis-

tance issues will result if the incorrect master cyl-

inder is installed on the vehicle.

For information on master cylinder application,

bore and type, view the following table:

BRAKE SYSTEM MASTER CYLINDER

BORE/TYPE

Disc/Drum - ABS 23.8 mm (15/16 in.)

Conventional

Compensating Port

Disc/Drum - Non-ABS 23.8 mm (15/16 in.)

Conventional

Compensating Port

Disc/Disc - ABS 25.4 mm (1.0 in.)

Conventional

Compensating Port

Disc/Disc ABS With

Traction Control 25.4 mm (1.0 in.) Dual

Center Port

Fig. 44 NON-ABS JUNCTION BLOCK

1 - MASTER CYLINDER

2 - JUNCTION BLOCK

3 - SUSPENSION CROSSMEMBER

4 - MOUNTING BOLTS

Fig. 45 Master Cylinder And Booster Location

1 - MASTER CYLINDER

2 - POWER BRAKE BOOSTER

RS BRAKES5s-33

JUNCTION BLOCK (Continued)

Page 278 of 2585

(4) Using a wooden dowel as a pushrod (Fig. 47),

slowly depress master cylinder pistons, then release

pressure, allowing pistons to return to released posi-

tion. Repeat several times until all air bubbles are

expelled. Make sure fluid level stays above tips of

bleeder tubes in reservoir while bleeding. (5) Remove bleeder tubes from master cylinder

outlet ports, then plug outlet ports and install fill cap

on reservoir. (6) Remove master cylinder from vise.

(7) Install master cylinder on vehicle. (Refer to 5 -

BRAKES - BASE/HYDRAULIC/MECHANICAL/MAS-

TER CYLINDER - INSTALLATION)

REMOVAL

REMOVAL - LHD

CAUTION: Vacuum in the power brake booster must

be pumped down (removed) before removing mas-

ter cylinder from power brake booster. This is nec-

essary to prevent the power brake booster from

sucking in any contamination as the master cylin-

der is removed. This can be done simply by pump-

ing the brake pedal, with the vehicle's engine not

running, until a firm feeling brake pedal is achieved.

(1) With engine not running, pump brake pedal

until a firm pedal is achieved (4-5 strokes). (2) Disconnect negative battery terminal. (3) Disconnect positive battery terminal.

(4) Remove battery shield.

(5) Remove nut and clamp securing battery to tray,

remove battery. (6) Thoroughly clean all surfaces of the brake fluid

reservoir and master cylinder. Use only solvent such

as Mopar tBrake Parts Cleaner or equivalent.

(7) Remove wiring harness connector from brake

fluid level switch in master cylinder brake fluid res-

ervoir (Fig. 48).

(8) Disconnect primary and secondary brake tubes

from master cylinder housing (Fig. 48). Install seal-

ing plugs in the now open brake tube outlet ports.

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(9) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as Mopar tBrake Parts Cleaner or equivalent.

(10) Remove two nuts attaching master cylinder to

power brake booster (Fig. 49). (11) Slide master cylinder straight out of power

brake booster.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

Fig. 47 Master Cylinder Set Up For Bleeding

1 - BLEEDER TUBES 8358

2 - WOODEN DOWEL

3 - ADAPTER 8822-2 (USE ONLY ON TRACTION CONTROL

EQUIPPED MASTER CYLINDERS)

4 - ADAPTER 8822-2 (USE ONLY ON TRACTION CONTROL

EQUIPPED MASTER CYLINDERS)

Fig. 48 MASTER CYLINDER AND BOOSTER

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

RS BRAKES5s-35

MASTER CYLINDER (Continued)

Page 279 of 2585

(12) Remove vacuum seal located on the mounting

flange of the master cylinder. The vacuum seal is

removed from master cylinder by carefullypulling it

off the rear of master cylinder. Do not attempt to

pry the seal off the master cylinder by inserting

a sharp tool between seal and master cylinder

casting.

REMOVAL - RHD

CAUTION: Vacuum in the power brake booster must

be pumped down (removed) before removing mas-

ter cylinder from power brake booster. This is nec-

essary to prevent the power brake booster from

sucking in any contamination as the master cylin-

der is removed. This can be done simply by pump-

ing the brake pedal, with the vehicle's engine not

running, until a firm feeling brake pedal is achieved.

(1) With engine not running, pump brake pedal

until a firm pedal is achieved (4 or 5 strokes). (2) Disconnect negative battery terminal.

(3) Disconnect positive battery terminal.

(4) Remove battery shield.

(5) Remove nut and clamp securing battery to tray,

remove battery. (6) Thoroughly clean all surfaces of the brake fluid

reservoir and master cylinder. Use only solvent such

as Mopar tBrake Parts Cleaner or equivalent.

(7) Remove wiring harness connector from brake

fluid level switch in master cylinder brake fluid res-

ervoir (Fig. 46). (8) Disconnect primary and secondary brake tubes

from master cylinder housing (Fig. 50). Install seal-

ing plugs in the now open brake tube outlet ports. CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(9) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as Mopar tBrake Parts Cleaner or equivalent.

(10) Remove two nuts attaching master cylinder to

power brake booster (Fig. 50). (11) Slide master cylinder straight out of power

brake booster.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

(12) Remove vacuum seal located on the mounting

flange of the master cylinder. The vacuum seal is

removed from master cylinder by carefullypulling it

off the rear of master cylinder. Do not attempt to

pry the seal off the master cylinder by inserting

a sharp tool between seal and master cylinder

casting.

DISASSEMBLY - MASTER CYLINDER (FLUID

RESERVOIR)

(1) Clean master cylinder housing and brake fluid

reservoir. Use only a solvent such as Mopar Brake

Parts Cleaner or an equivalent.

Fig. 49 MASTER CYLINDER MOUNTING

1 - MASTER CYLINDER MOUNTING NUTS

2 - MASTER CYLINDER

3 - SECONDARY TUBE NUT AT ICU

4 - PRIMARY TUBE NUT AT ICU

Fig. 50 RHD MASTER CYLINDER MOUNTING

1 - PRIMARY BRAKE TUBE NUT

2 - SECONDARY BRAKE TUBE NUT

3 - MASTER CYLINDER MOUNTING NUTS

5s - 36 BRAKESRS

MASTER CYLINDER (Continued)

Page 281 of 2585

CAUTION: When tightening the primary and sec-

ondary brake tube nuts at master cylinder, be sure

brake tubes do not contact any other components

within the vehicle and that there is slack in the flex-

ible sections of the tubes. This is required due to

the movement between the ABS ICU and the master

cylinder while the vehicle is in motion.(4) Connect primary and secondary brake tubes to

master cylinder primary and secondary ports (Fig.

48). Brake tubes must be held securely when tight-

ened to control orientation of flex section. Tighten

tube nuts to a torque of 17 N´m (145 in. lbs.). (5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

48). (6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopar t

Brake Fluid or equivalent. (11) Road test vehicle to ensure proper operation of

brakes.

INSTALLATION - RHD

CAUTION: Different types of master cylinders are

used on this vehicle depending on brake options. If

a new master cylinder is being installed, be sure it

is the correct master cylinder for the type of brake

system the vehicle is equipped with.

CAUTION: When replacing the master cylinder on a

vehicle, a NEW vacuum seal MUST be installed on

the master cylinder.

(1) Install a NEW vacuum seal on master cylinder

making sure seal fits squarely in groove of master

cylinder casting. (2) Position master cylinder on studs of power

brake booster, aligning booster push rod with master

cylinder piston. (3) Install the two master cylinder mounting nuts

(Fig. 50). Tighten both mounting nuts to a torque of

25 N´m (225 in. lbs.).

CAUTION: When tightening the primary and sec-

ondary brake tube nuts at master cylinder, be sure

brake tubes do not contact any other components

within the vehicle and that there is slack in the flex-

ible sections of the tubes. This is required due to

the movement between the ABS ICU and the master

cylinder while the vehicle is in motion. (4) Connect primary and secondary brake tubes to

master cylinder primary and secondary ports (Fig.

50). Brake tubes must be held securely when tight-

ened to control orientation of flex section. Tighten

tube nuts to a torque of 17 N´m (145 in. lbs.). (5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

46). (6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopar t

Brake Fluid or equivalent. (11) Road test vehicle to ensure proper operation of

brakes.

PEDALS - ADJUSTABLE

REMOVAL

NOTE: Before proceeding, review all Steering Col-

umn and Airbag Warnings and Cautions. (Refer to

19 - STEERING/COLUMN - WARNING)(Refer to 8 -

ELECTRICAL/RESTRAINTS - WARNING)

(1) Move driver's seat to full rearward position.

(2) Disconnect negative battery cable from battery

post and isolate. (3) Remove throttle cable from throttle body lever.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - REMOVAL) (4) Remove screws securing lower steering column

cover/knee blocker, then remove it (Fig. 53). (5) Disconnect parking brake release link at

release handle. (6) Compress tabs on sides of data link diagnostic

connector and remove it from knee blocker reinforce-

ment plate. (7) Remove screws securing knee blocker reinforce-

ment plate in place, then remove reinforcement plate

(Fig. 53). (8) Remove hood release from lower left reinforce-

ment. (9) Remove screws securing instrument panel

lower left reinforcement in place, then remove rein-

forcement (Fig. 54). (10) Remove brake lamp switch. Discard original

switch; it must not be reused. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE

LAMP SWITCH - REMOVAL) (11) Remove upper and lower steering column

shrouds. (Refer to 19 - STEERING/COLUMN/

LOWER SHROUD - REMOVAL)

5s - 38 BRAKESRS

MASTER CYLINDER (Continued)

Page 285 of 2585

(24) Install knee blocker reinforcement plate (Fig.

53). (25) Connect parking brake release link to release

handle. (26) Install data link diagnostic connector to

mounting hole in reinforcement plate. (27) Install lower steering column cover/knee

blocker (Fig. 53). (28) Install throttle cable onto throttle body lever.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - INSTALLATION)

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(29) Reconnect ground cable to negative post of

battery following special Diagnosis And Testing pro-

cedure. (Refer t o 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING) (30) Test operation of adjustable pedals and all

functions that are steering column operated. If appli-

cable, reset radio and clock. (31) Road test the vehicle to ensure proper opera-

tion of steering and brake systems.

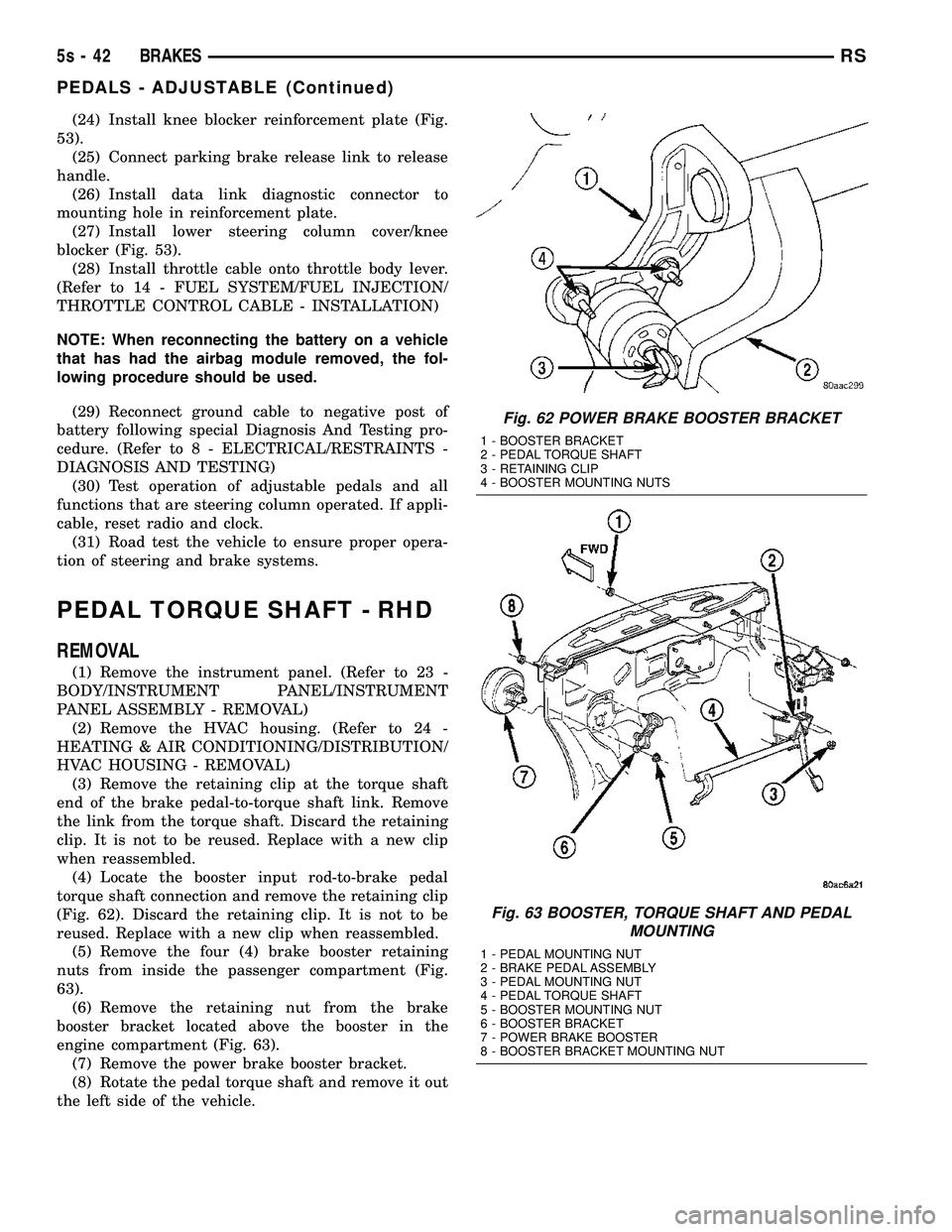

PEDAL TORQUE SHAFT - RHD

REMOVAL

(1) Remove the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL) (2) Remove the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL) (3) Remove the retaining clip at the torque shaft

end of the brake pedal-to-torque shaft link. Remove

the link from the torque shaft. Discard the retaining

clip. It is not to be reused. Replace with a new clip

when reassembled. (4) Locate the booster input rod-to-brake pedal

torque shaft connection and remove the retaining clip

(Fig. 62). Discard the retaining clip. It is not to be

reused. Replace with a new clip when reassembled. (5) Remove the four (4) brake booster retaining

nuts from inside the passenger compartment (Fig.

63). (6) Remove the retaining nut from the brake

booster bracket located above the booster in the

engine compartment (Fig. 63). (7) Remove the power brake booster bracket.

(8) Rotate the pedal torque shaft and remove it out

the left side of the vehicle.

Fig. 62 POWER BRAKE BOOSTER BRACKET

1 - BOOSTER BRACKET

2 - PEDAL TORQUE SHAFT

3 - RETAINING CLIP

4 - BOOSTER MOUNTING NUTS

Fig. 63 BOOSTER, TORQUE SHAFT AND PEDAL MOUNTING

1 - PEDAL MOUNTING NUT

2 - BRAKE PEDAL ASSEMBLY

3 - PEDAL MOUNTING NUT

4 - PEDAL TORQUE SHAFT

5 - BOOSTER MOUNTING NUT

6 - BOOSTER BRACKET

7 - POWER BRAKE BOOSTER

8 - BOOSTER BRACKET MOUNTING NUT

5s - 42 BRAKESRS

PEDALS - ADJUSTABLE (Continued)

Page 288 of 2585

(6) Apply light effort (approximately 15 lbs. of

force) to the brake pedal and hold the pedal steady.

Do not move the pedal once the pressure is applied

or the test results may vary. (7) Have an assistant reattach the vacuum line

pliers to the vacuum supply hose. (8) Allow 5 seconds for stabilization, then observe

the vacuum gauge. If the vacuum drop exceeds 3.0 inches Hg (10 kPa)

in 15 seconds, repeat the above steps to confirm the

reading. The vacuum loss should be less than 3.0

inches Hg in 15 seconds time span. If the loss is

more than 3.0 inches Hg, replace the power brake

booster. If it is not, the booster is not defective. (9) Remove the pliers and vacuum gauge.

REMOVAL

REMOVAL - LHD

CAUTION: Reserve vacuum in power brake booster

must be pumped down (removed) before removing

master cylinder from booster. This is necessary to

prevent booster from sucking in any contamination

as master cylinder is removed. This can be done

simply by pumping the brake pedal, with the vehi-

cle's engine not running, until a firm feeling brake

pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes). (2) Remove negative battery cable terminal from

battery. (3) Remove positive battery cable terminal from

battery. (4) Remove battery thermal guard shield.

(5) Remove battery clamp, nut and battery from

the battery tray. (6) Remove screw securing engine coolant filler

tube to battery tray. (7) If the vehicle is equipped with speed control,

disconnect the vacuum hose at the vacuum tank built

into the battery tray. (8) Remove the two nuts and one bolt securing bat-

tery tray in place. Remove battery tray. (9) If vehicle is equipped with speed control:(a) Disconnect wiring harness connector from

the speed control servo. (b) Remove the two servo mounting nuts.

(c) Lay speed control servo off to the side, out of

the way.

(10) Remove the wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL) (11) Disconnect wiring harness connector from

brake fluid level switch in master cylinder fluid res-

ervoir (Fig. 66).

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(12) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as Mopar tBrake Parts Cleaner or equivalent.

(13) Disconnect primary and secondary brake

tubes from ABS integrated control unit or non-ABS

junction block (Fig. 67). Install sealing plugs in the

now open brake tube ports and install caps on ends

of tubes.

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the vacuum booster.

(14) Remove two nuts attaching master cylinder to

power brake booster (Fig. 67). (15) Slide master cylinder straight out of power

brake booster. Remove master cylinder with primary

and secondary tubes from vehicle.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

Fig. 66 Master Cylinder And Booster

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

RS BRAKES5s-45

POWER BRAKE BOOSTER (Continued)

Page 290 of 2585

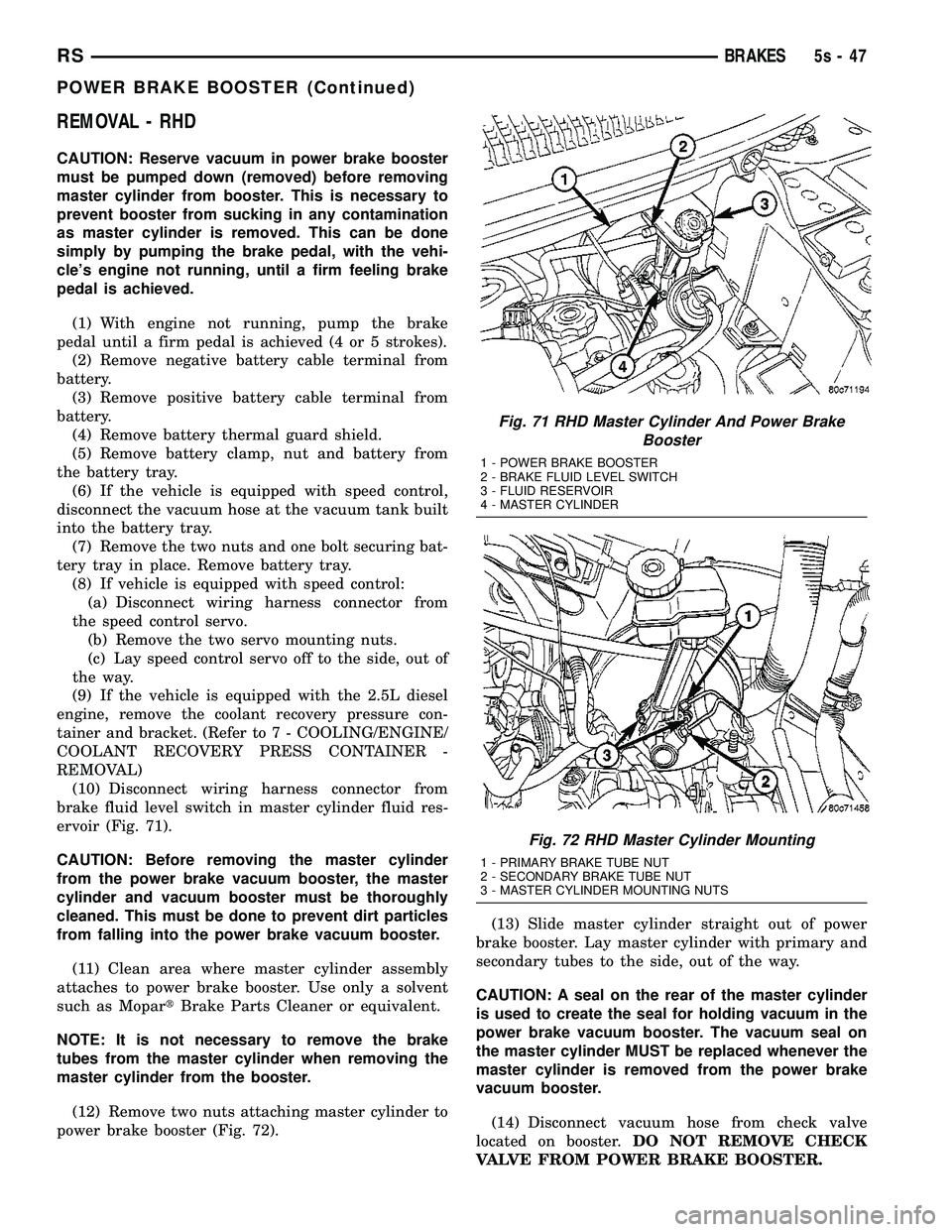

REMOVAL - RHD

CAUTION: Reserve vacuum in power brake booster

must be pumped down (removed) before removing

master cylinder from booster. This is necessary to

prevent booster from sucking in any contamination

as master cylinder is removed. This can be done

simply by pumping the brake pedal, with the vehi-

cle's engine not running, until a firm feeling brake

pedal is achieved.(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4 or 5 strokes). (2) Remove negative battery cable terminal from

battery. (3) Remove positive battery cable terminal from

battery. (4) Remove battery thermal guard shield.

(5) Remove battery clamp, nut and battery from

the battery tray. (6) If the vehicle is equipped with speed control,

disconnect the vacuum hose at the vacuum tank built

into the battery tray. (7) Remove the two nuts and one bolt securing bat-

tery tray in place. Remove battery tray. (8) If vehicle is equipped with speed control:(a) Disconnect wiring harness connector from

the speed control servo. (b) Remove the two servo mounting nuts.

(c) Lay speed control servo off to the side, out of

the way.

(9) If the vehicle is equipped with the 2.5L diesel

engine, remove the coolant recovery pressure con-

tainer and bracket. (Refer t o 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESS CONTAINER -

REMOVAL) (10) Disconnect wiring harness connector from

brake fluid level switch in master cylinder fluid res-

ervoir (Fig. 71).

CAUTION: Before removing the master cylinder

from the power brake vacuum booster, the master

cylinder and vacuum booster must be thoroughly

cleaned. This must be done to prevent dirt particles

from falling into the power brake vacuum booster.

(11) Clean area where master cylinder assembly

attaches to power brake booster. Use only a solvent

such as Mopar tBrake Parts Cleaner or equivalent.

NOTE: It is not necessary to remove the brake

tubes from the master cylinder when removing the

master cylinder from the booster. (12) Remove two nuts attaching master cylinder to

power brake booster (Fig. 72). (13) Slide master cylinder straight out of power

brake booster. Lay master cylinder with primary and

secondary tubes to the side, out of the way.

CAUTION: A seal on the rear of the master cylinder

is used to create the seal for holding vacuum in the

power brake vacuum booster. The vacuum seal on

the master cylinder MUST be replaced whenever the

master cylinder is removed from the power brake

vacuum booster.

(14) Disconnect vacuum hose from check valve

located on booster. DO NOT REMOVE CHECK

VALVE FROM POWER BRAKE BOOSTER.

Fig. 71 RHD Master Cylinder And Power Brake Booster

1 - POWER BRAKE BOOSTER

2 - BRAKE FLUID LEVEL SWITCH

3 - FLUID RESERVOIR

4 - MASTER CYLINDER

Fig. 72 RHD Master Cylinder Mounting

1 - PRIMARY BRAKE TUBE NUT

2 - SECONDARY BRAKE TUBE NUT

3 - MASTER CYLINDER MOUNTING NUTS

RS BRAKES5s-47

POWER BRAKE BOOSTER (Continued)

Page 293 of 2585

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).(16) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.). (17) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray. (18) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing. Securely tighten hose clamp at air cleaner hous-

ing and throttle body. (19) Secure the engine coolant filler neck to the

battery tray with its mounting screw. (20) Install the battery, clamp and mounting nut.

(21) Install the positive battery cable on the bat-

tery. (22) Install the negative battery cable on the bat-

tery. (23) Install the battery thermal guard shield.

(24) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE) (25) Road test vehicle to ensure operation of the

brakes.

INSTALLATION - RHD

(1) Position power brake booster on dash panel

using the reverse procedure of its removal (Fig. 75). (2) Below instrument panel, first install the two

upper nuts mounting the booster to the dash panel,

drawing it into place, then install the two lower

mounting nuts. Tighten the mounting nuts to a

torque of 29 N´m (250 in. lbs.). (3) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod.

CAUTION: When installing the brake pedal torque

shaft pin on the power brake booster input rod, do

not re-use the old retaining clip.

(4) Install booster input rod on brake pedal torque

shaft pin and install a NEW retaining clip (Fig. 78). (5) Install booster input rod trim cover.

(6) Connect vacuum hose to check valve on power

brake booster.

CAUTION: The master cylinder (and its rear seal) is

used to create the seal for holding vacuum in the

vacuum booster. The vacuum seal on the master

cylinder MUST be replaced with a NEW seal when-

ever the master cylinder is removed from the vac-

uum booster. CAUTION: When removing the vacuum seal from

the master cylinder, do not use a sharp tool.

(7) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange. (8) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 79).

(9) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston. (10) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 72). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

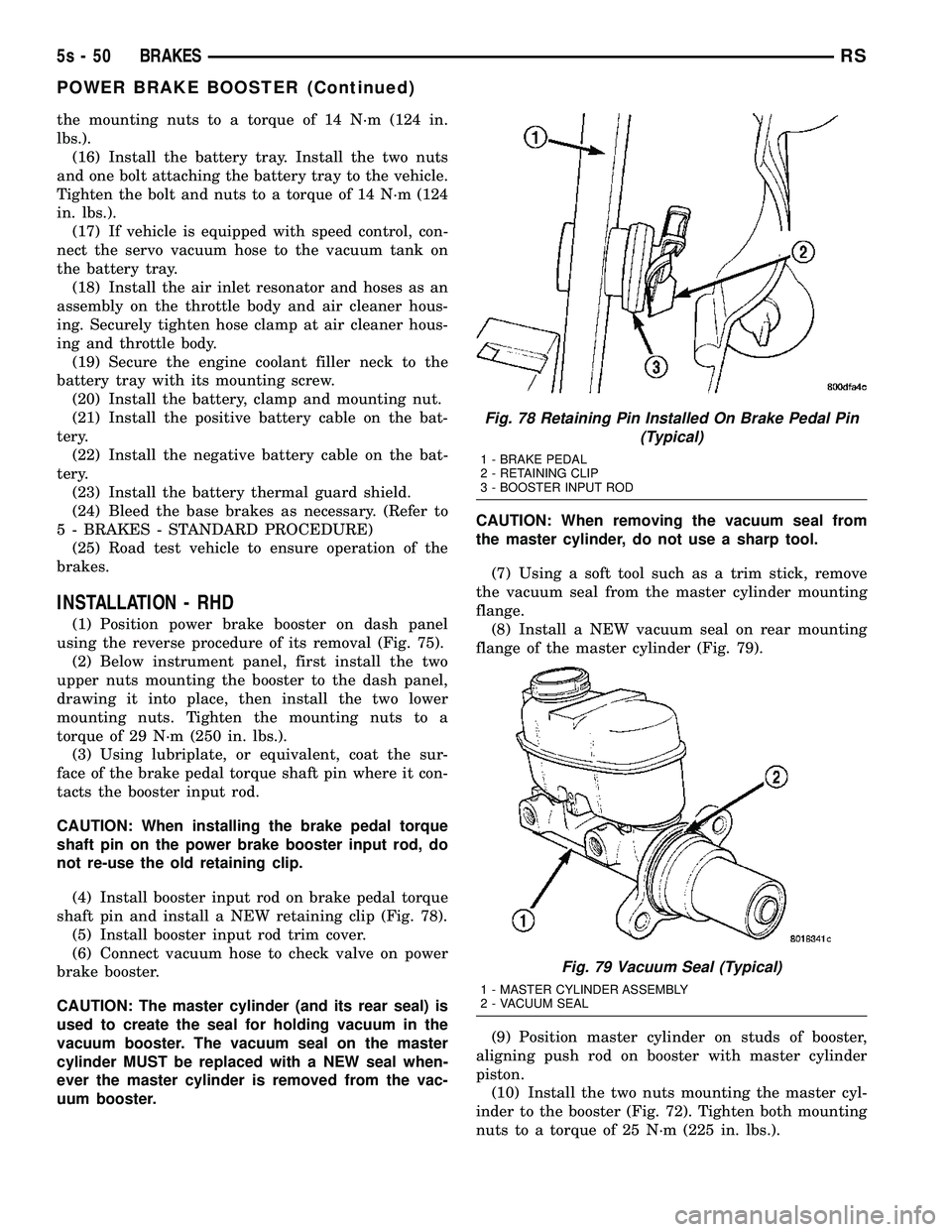

Fig. 78 Retaining Pin Installed On Brake Pedal Pin (Typical)

1 - BRAKE PEDAL

2 - RETAINING CLIP

3 - BOOSTER INPUT ROD

Fig. 79 Vacuum Seal (Typical)

1 - MASTER CYLINDER ASSEMBLY

2 - VACUUM SEAL

5s - 50 BRAKESRS

POWER BRAKE BOOSTER (Continued)