battery replacement CHRYSLER VOYAGER 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 486 of 2585

VOLTAGE REGULATOR

DESCRIPTION

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the Powertrain Control

Module (PCM). The EVR is not serviced separately. If

replacement is necessary, the PCM must be replaced.

OPERATION

The amount of DC current produced by the gener-

ator is controlled by EVR circuitry contained within

the PCM. This circuitry is connected in series with

the generators second rotor field terminal and its

ground. Voltage is regulated within the PCM on the NGC

vehicles, to control the strength of the rotor magnetic

field. The EVR circuitry monitors system line voltage

at the PDC and calculated battery temperature or

inlet air temperature sensor (refer to Inlet Air Tem-

perature Sensor, if equipped, for more information ).

It then determines a target charging voltage. If

sensed battery voltage is lower than the target volt-

age, the PCM feeds the field winding until sensed

battery voltage is at the target voltage. A circuit in

the PCM cycles the feed side of the generator field at

250 times per second (250Hz), but has the capability

to feed the field control wire 100% of the time (full

field) to achieve the target voltage. If the charging

rate cannot be monitored (limp-in), a duty cycle of

20% is used by the PCM in order to have some gen-

erator output. Also refer to Charging System Opera-

tion for additional information.

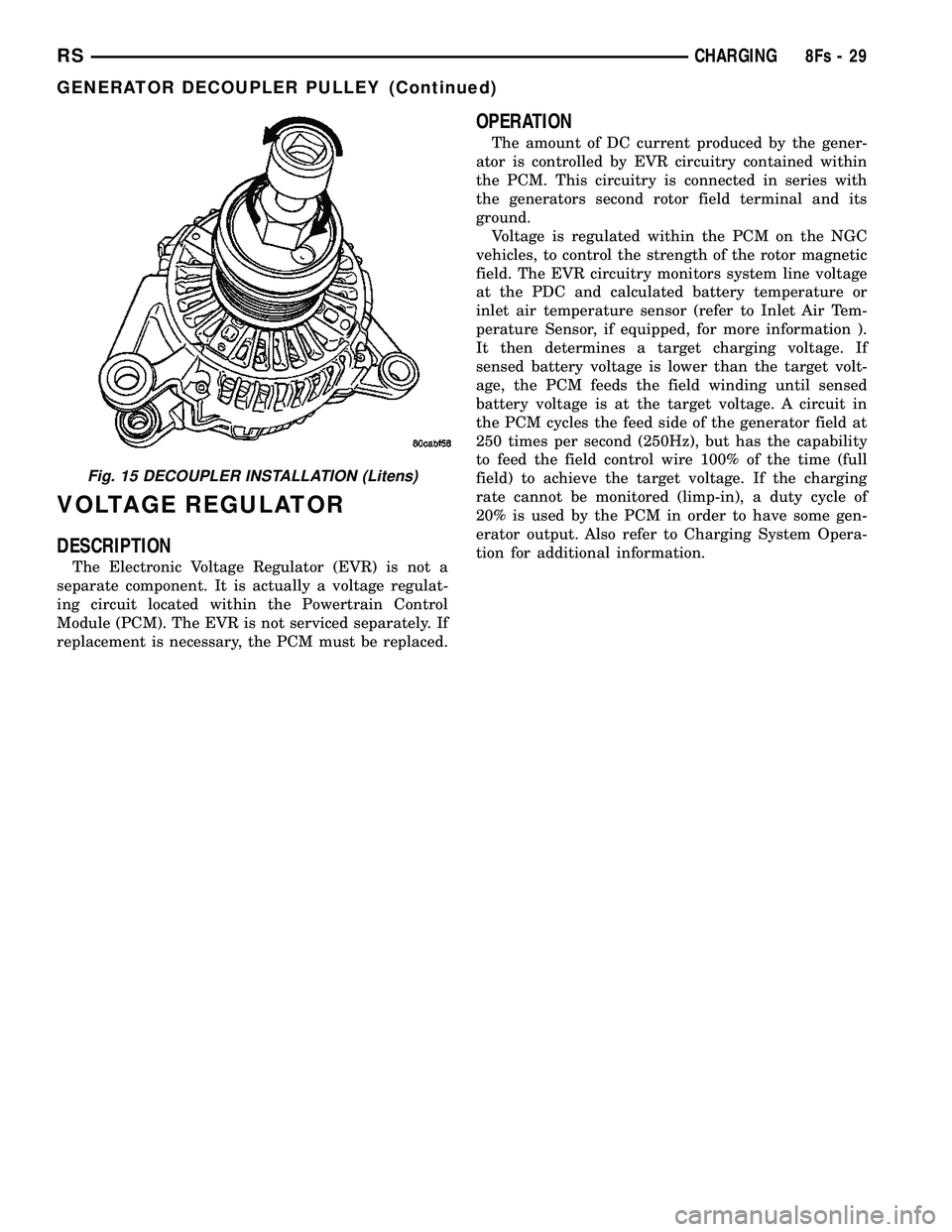

Fig. 15 DECOUPLER INSTALLATION (Litens)

RS CHARGING8Fs-29

GENERATOR DECOUPLER PULLEY (Continued)

Page 506 of 2585

front seat retaining bolts and lay the seat rearward,

up against one of the rear seats. It is not necessary

to disconnect the seat electrical connectors, just use

care not to damage the attached wire harnesses

while testing.

NOTE: When checking heated seat elements for

continuity, be certain to move the heating element

being checked. Moving the element, such as sitting

in the seat will eliminate the possibility of an inter-

mittent open in the element which would only be

evident if the element was in a certain position.

Failure to check the element in various positions

could result in an incomplete test.

SEAT CUSHION ELEMENT

(1) From under the vehicle, remove the appropri-

ate seats four retaining nuts.

(2) From inside the vehicle, pull the seat up, off

the mounting studs and lay it back, up against one of

the rear seats.

(3) Locate the heated seat module, attached to the

bottom of the seat cushion pan. Remove the heated

seat module from the seat cushion pan. Do not dis-

connect the electrical connectors at this time.

(4) Locate and disconnect the green 4-way electri-

cal connector, connected to the heated seat module.

(5) Check for continuity between the two outboard

circuit cavities of the wire harness connector (Pins

1&4). There should be continuity. If OK, refer to

Heated Seat Module Diagnosis and Testing in the

Electronic Control Modules section of the service

manual for complete system testing procedures. If

not OK, install a replacement heated seat cushion

element. Refer to the procedure in this section.

SEAT BACK ELEMENT

(1) From under the vehicle, remove the appropri-

ate seats four retaining nuts.

(2) From inside the vehicle, pull the seat up and

off the mounting studs and lay it back, up against

one of the rear seats.

(3) Locate the heated seat module, attached to the

bottom of the seat cushion pan. Remove the heated

seat module from the seat cushion pan. Do not dis-

connect the electrical connectors at this time.

(4) Locate and disconnect the gray 2-way electrical

connector, connected to the heated seat module.

(5) Check for continuity between the two circuit

cavities of the 2-way wire harness connector. There

should be continuity. If OK, refer to Heated Seat

Module Diagnosis and Testing in the Electronic Con-

trol Modules section of the service manual for com-

plete system testing procedures. If not OK, install a

replacement heated seat back element. Refer to the

procedure in this section.

REMOVAL

Do not remove the OEM heating element from the

seat or seat back cushion/trim covers. The original

element is permanently attached and cannot be

removed without permanent damage. The service

replacement heating element is designed to be

applied directly on the seat cushion.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate seat cushion or seat

back trim cover. Refer to the Body section of the ser-

vice manual for the procedures.

(3) Disconnect the inoperative heated seat cushion

or seat back element electrical connectors.

(4) Locate the wires leading from the inoperative

heating element and cut them off flush with the edge

of the original heating element.

INSTALLATION

(1) Peel off the adhesive backing on the back of the

replacement heating element and stick directly on

the foam cushion.

CAUTION: During the installation of the replace-

ment heating element, be careful not to fold or

crease the element assembly. Folds or creases will

cause premature failure.

(2) Connect the new heating element electrical

connectors (Fig. 5).

Fig. 5 HEATING ELEMENT INSTALLED - TYPICAL

1 - SEAT BACK WIRE HARNESS

2 - HEATED SEAT WIRE HARNESS CONNECTOR

3 - HEATED SEAT CUSHION ELEMENT

RSHEATED SEAT SYSTEM8G-11

HEATED SEAT ELEMENTS (Continued)

Page 526 of 2585

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS.........................2

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS...........................2REMOVAL.............................10

INSTALLATION.........................10

CLUSTER LENS

REMOVAL.............................10

INSTALLATION.........................10

INSTRUMENT CLUSTER

DESCRIPTION

The instrumentation gauges are contained in a

subdial assembly within the instrument cluster. The

individual gauges are not serviceable. If one of the

cluster gauges becomes faulty, the entire cluster

would require replacement.

The Mechanical Instrument Cluster (MIC) with a

tachometer is equipped with a electronic vacuum flu-

orescent transmission range indicator (PRND3L),

odometer, and trip odometer display.

The MIC without a tachometer is equipped with a

Light Emitting Diode (LED) transmission range indi-

cator (PRND3L) and a vacuum fluorescent odometer

display.

The MIC is equipped with the following warning

lamps.

²Lift Gate Ajar

²Low Fuel Level

²Low Windshield Washer Fluid Level

²Cruise

²Battery Voltage

²Fasten Seat Belt

²Door Ajar

²Coolant Temperature

²Anti-Lock Brake

²Brake

²Oil Pressure

²MIL (Malfunction Indicator Lamp)

²VTSS/SKIS Indicator

²Airbag

²Traction Control

²Autostick

The MIC without a tachometer also has the follow-

ing warning lamps:

²Turns Signals

²High Beam

WATER IN FUEL LAMP - EXPORT

The Water In Fuel Lamp is located in the message

center. When moisture is found within the fuel sys-

tem, the sensor sends a message via the PCI data

bus to the instrument cluster. The MIC illuminates

the bulb in the message center, The sensor is located

underneath the vehicle, directly above the rear axle.

The sensor is housed within the fuel filter/water sep-

arator assembly cover. The sensor is not serviced sep-

arately. If found defective, the entire assembly cover

must be replaced.

OPERATION

Refer to the vehicle Owner's Manual for operation

instructions and conditions for the Instrument Clus-

ter Gauges.

WATER IN FUEL LAMP - EXPORT

The Water In Fuel Sensor is a resistive type

switch. It is calibrated to sense the different resis-

tance between diesel fuel and water. When water

enters the fuel system, it is caught in the bottom of

the fuel filter/water separator assembly, where the

sensor is located. Water has less resistance than die-

sel fuel. The sensor then sends a PCI data bus mes-

sage to the instrument cluster to illuminate the

lamp.

If the lamp is inoperative, perform the self diag-

nostic test on the instrument cluster to check the

lamp operation before continuing diagnosis.

RSINSTRUMENT CLUSTER8J-1

Page 558 of 2585

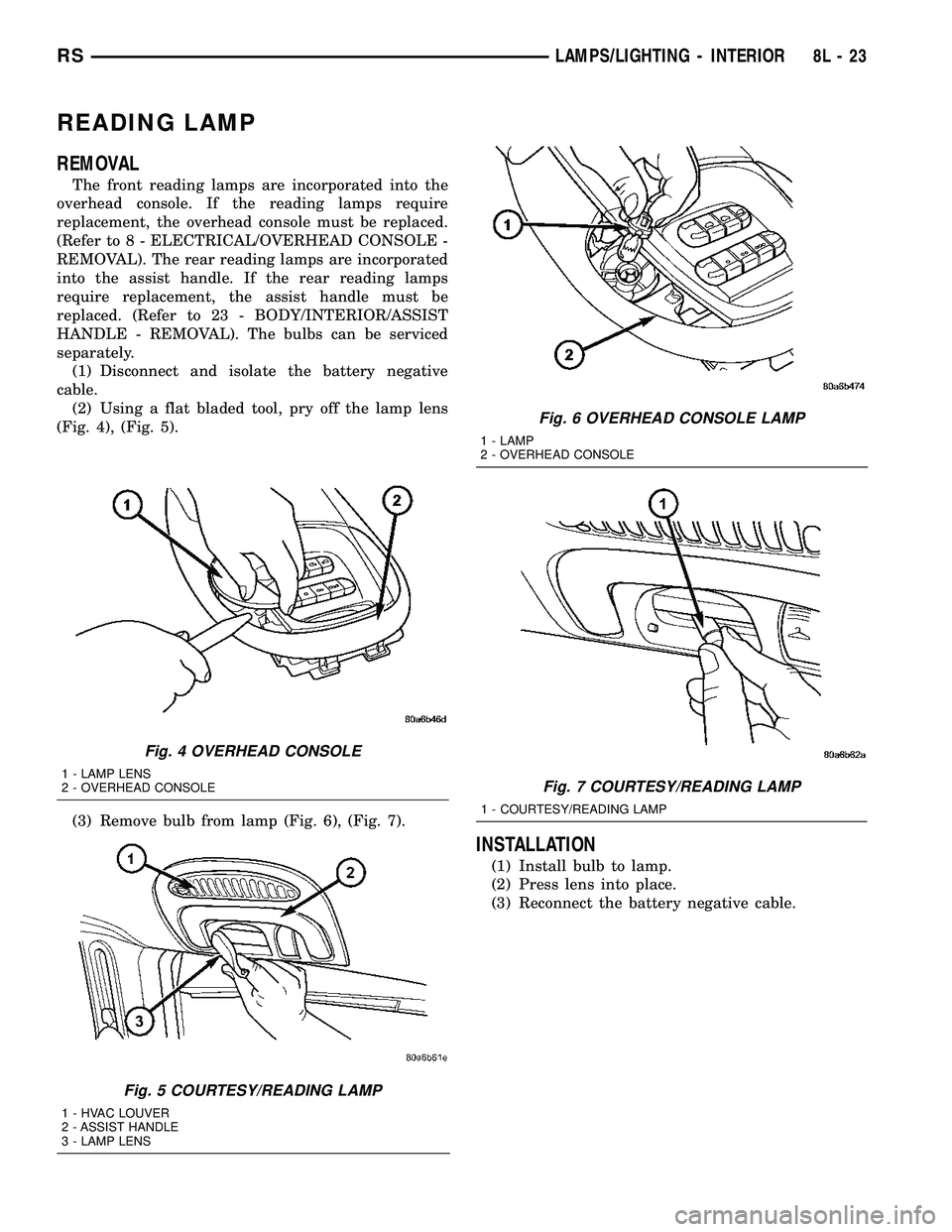

READING LAMP

REMOVAL

The front reading lamps are incorporated into the

overhead console. If the reading lamps require

replacement, the overhead console must be replaced.

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

REMOVAL). The rear reading lamps are incorporated

into the assist handle. If the rear reading lamps

require replacement, the assist handle must be

replaced. (Refer to 23 - BODY/INTERIOR/ASSIST

HANDLE - REMOVAL). The bulbs can be serviced

separately.

(1) Disconnect and isolate the battery negative

cable.

(2) Using a flat bladed tool, pry off the lamp lens

(Fig. 4), (Fig. 5).

(3) Remove bulb from lamp (Fig. 6), (Fig. 7).

INSTALLATION

(1) Install bulb to lamp.

(2) Press lens into place.

(3) Reconnect the battery negative cable.

Fig. 4 OVERHEAD CONSOLE

1 - LAMP LENS

2 - OVERHEAD CONSOLE

Fig. 5 COURTESY/READING LAMP

1 - HVAC LOUVER

2 - ASSIST HANDLE

3 - LAMP LENS

Fig. 6 OVERHEAD CONSOLE LAMP

1 - LAMP

2 - OVERHEAD CONSOLE

Fig. 7 COURTESY/READING LAMP

1 - COURTESY/READING LAMP

RSLAMPS/LIGHTING - INTERIOR8L-23

Page 562 of 2585

(2) Turn the ignition switch to the On position.

(3)

Following completion of these tests, the electron-

ics module will display one of the following messages:

a.Pass Self Test (EVIC only), PASS (CT,

CMTC)- The electronics module is working properly.

b.Failed Self Test (EVIC only), FAIL (CT,

CMTC)- The electronics module has an internal fail-

ure. The electronics module is faulty and must be

replaced.

c.Failed J1850 Communication (EVIC only),

BUS (CT, CMTC)- The electronics module is not

receiving proper message input through the J1850

PCI data bus circuit. This can result from one or

more faulty electronic modules in the vehicle, or from

a faulty PCI data bus. The use of a DRB IIItscan

tool and the proper Diagnostic Procedures manual

are required for further diagnosis.

NOTE: If the compass functions, but accuracy is

suspect, it may be necessary to perform a variation

adjustment. This procedure allows the compass

unit to accommodate variations in the earth's mag-

netic field strength, based on geographic location.

Refer to Compass Variation Adjustment in the Stan-

dard Procedures section of this group.

NOTE: If the compass reading displays dashes, and

only ªCALº appears in the display, demagnetizing

may be necessary to remove excessive residual

magnetic fields from the vehicle. Refer to Compass

Demagnetizing in the Standard Procedures section

of this group.

STANDARD PROCEDURE

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT

(1) Open hood, disconnect and isolate the negative

battery cable remote terminal from the remote bat-

tery post.

(2) Remove the reading/courtesy lamp lens. Using

a trim stick, gently pry the forward edge of the read-

ing/courtesy lamp lens outward.

(3) Remove the reading/courtesy lamp socket from

the overhead console. Rotate the reading/courtesy

lamp socket one quarter turn counter clockwise.

(4) Remove the lamp and socket assembly.

(5) Reverse the above procedure to install.

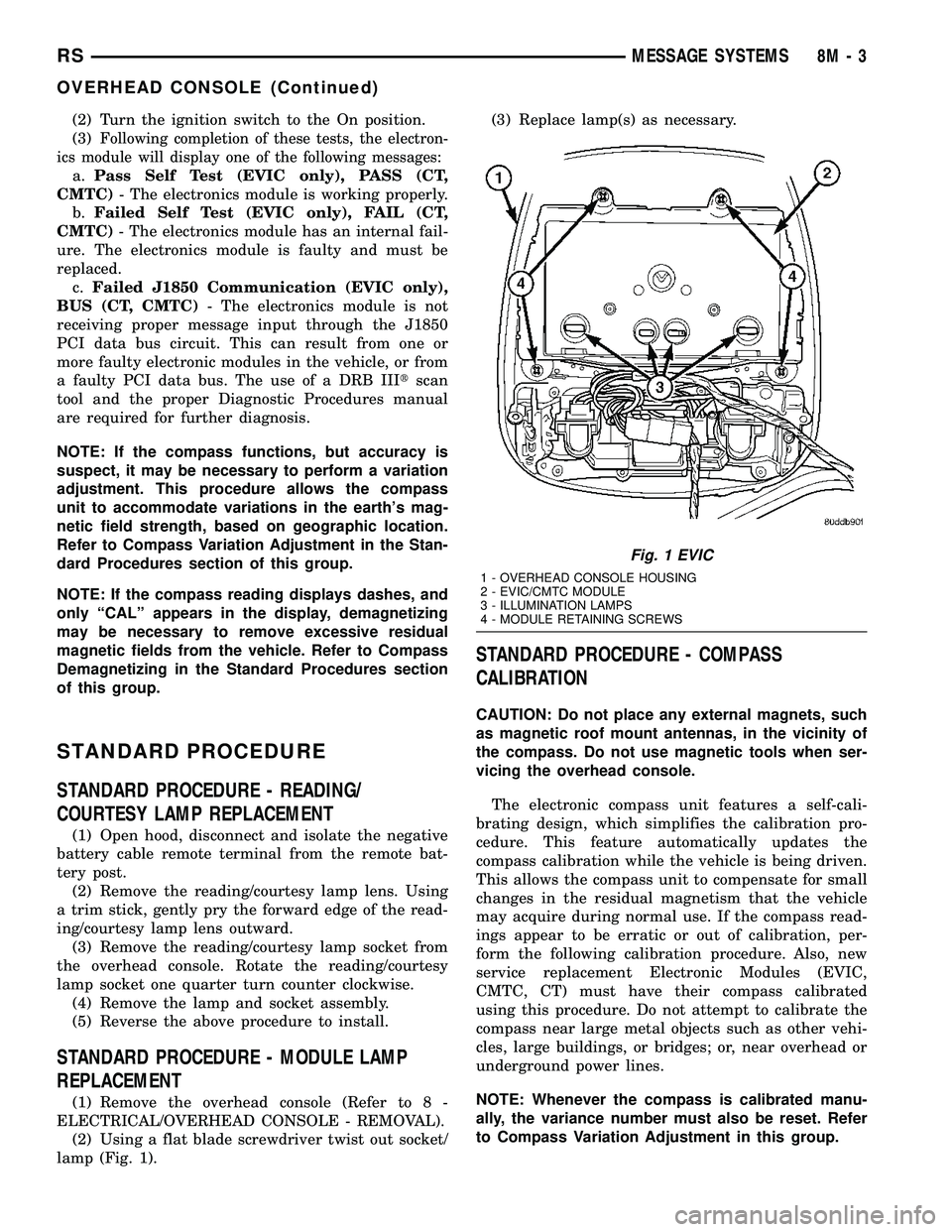

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOVAL).

(2) Using a flat blade screwdriver twist out socket/

lamp (Fig. 1).(3) Replace lamp(s) as necessary.

STANDARD PROCEDURE - COMPASS

CALIBRATION

CAUTION: Do not place any external magnets, such

as magnetic roof mount antennas, in the vicinity of

the compass. Do not use magnetic tools when ser-

vicing the overhead console.

The electronic compass unit features a self-cali-

brating design, which simplifies the calibration pro-

cedure. This feature automatically updates the

compass calibration while the vehicle is being driven.

This allows the compass unit to compensate for small

changes in the residual magnetism that the vehicle

may acquire during normal use. If the compass read-

ings appear to be erratic or out of calibration, per-

form the following calibration procedure. Also, new

service replacement Electronic Modules (EVIC,

CMTC, CT) must have their compass calibrated

using this procedure. Do not attempt to calibrate the

compass near large metal objects such as other vehi-

cles, large buildings, or bridges; or, near overhead or

underground power lines.

NOTE: Whenever the compass is calibrated manu-

ally, the variance number must also be reset. Refer

to Compass Variation Adjustment in this group.

Fig. 1 EVIC

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC/CMTC MODULE

3 - ILLUMINATION LAMPS

4 - MODULE RETAINING SCREWS

RSMESSAGE SYSTEMS8M-3

OVERHEAD CONSOLE (Continued)

Page 586 of 2585

NOTE: Be certain wires are reinstalled in the correct

wire cavities. Failure to do so could result in dam-

age to the latch actuator. Refer to Wiring Diagrams

if previous notes were not made.

(4) Secure the main connector retaining push pins

on the latch actuator housing.

(5) Grab the latch assembly and hook the key cyl-

inder link rod on the key cylinder.

(6) Position the latch and install three new latch

retaining bolts. Torque to 10 N´m (90 in. lbs.).

(7) Connect the power latch electrical connector.

(8) Install the lower liftgate trim panel. Refer to

Body for the procedure.

(9) Connect the negative battery cable.

LIFTGATE MOTOR

DESCRIPTION

Vehicles equipped with a power liftgate, utilize a

liftgate gear/motor assembly (Fig. 11). The gear

motor assembly consists of a DC motor, hall effect

sensor, engage actuator, full open switch, lift gear,

aluminum housing, drive gears and wire harness.

The gears and motor portion of the assembly pro-

vides the power and torque required to open or close

the liftgate under the worst case conditions. The hall

effect sensor is used to provide the liftgate control

module with a speed reading, which is used to mon-itor the resistance of liftgate travel. This speed read-

ing also allows the power liftgate control module to

detect obstructions and move the liftgate accordingly.

The engage actuator is used to toggle between power

open/close mode and full manual mode when desired.

The full open switch is used to let the power liftgate

control module know when the liftgate is approach-

ing the full open position.

Serviceable components of the power liftgate gear/

motor assembly are the complete gear/motor assem-

bly, motor and wire harness, lift gear and control rod,

engage actuator, full open switch and the transverse

bracket. Refer to additional information in this group

for more component details.

OPERATION

With the push of a power liftgate command switch

(liftgate closed), the power liftgate control module

will signal the latch assembly to release the door

from its primary closed and latched position to the

released and movable position. The liftgate motor-

mounted engage actuator then engages the liftgate

motor assembly, which moves the liftgate into the

open position. The liftgate motor provides the torque

and power to move the door to its full open or closed

position(Refer to 8 - ELECTRICAL/POWER DOORS -

OPERATION) for additional information.

REMOVAL

The power liftgate gear/motor assembly is serviced

in two ways: the complete gear/motor assembly, or

the motor, aluminum housing, drive gears and wire

harness assembly. To perform this service, use the

following procedure to remove the gear/motor assem-

bly from the vehicle. Then refer to the other proce-

dures called out this section to transfer the

remaining components (engage actuator, full open

switch, transverse bracket and lift gear and rod) to

the replacement gear/motor assembly.

(1) Disconnect and isolate the negative battery

cable.

(2)

Remove the left rear D-pillar trim panel from the

vehicle. Refer to the Body section for the procedure.

(3) Disconnect the wire harness connector from the

motor assembly (Fig. 11).

(4) Remove the two bolts from the motor housing

and the one bolt from the transverse mount bracket.

(5) Grab the liftgate motor assembly and lift

upward and out to unhook the motor assembly from

the D-pillar.

(6) Remove the liftgate motor assembly from the

vehicle.

INSTALLATION

(1) Using the motor housing tab, hook the liftgate

motor assembly on the D-pillar.

Fig. 11 POWER LIFTGATE COMPONENTS

1 - POWER LIFTGATE GEAR MOTOR/ASSEMBLY

2 - POWER LIFTGATE CONTROL MODULE

3 - ELECTRICAL GROUND LOCATION

RSPOWER LIFTGATE SYSTEM8N-15

LATCH ACTUATOR (Continued)

Page 600 of 2585

SPECIFICATIONS

SPECIFICATIONS TABLE

TORQUE SPECIFICATIONS

DESCRIPTION N´m In. Lbs.

Door Latch 12 100

Lower Drive Unit

Allen Head980

Lower Drive Unit

Screw328

Lower Track Nuts 8 70

LATCH

DESCRIPTION

Vehicles equipped with a power side door or doors

utilize a power latch. One power latch is used for

each power door. The latch is located on the trailing

edge of the side door assembly (Fig. 5). This power

latch assembly is comprised of many different compo-

nents which have the ability to perform the power

cinch, release, lock, unlock and safety related opera-

tions. These components are the door latch, lock/un-

lock actuator, cinch/release actuator and child

lockout, pawl, ratchet and handle switches. The pawl

and ratchet switches are used to indicate the primaryand secondary latched positions. The cinch latch also

provides a connection point for the interior handle,

exterior handle and hold open latch cables.

The power latch is a replaceable component. Con-

sult your Mopar parts catalog for specific part num-

bers.

OPERATION

The power latch performs the same operation as a

full manual door latch as well as power cinch,

release, lock and unlock operations. The power latch

mounted actuator cinches the door closed and latches

it in its primary latched position. During a power

close cycle, the power cinch actuator will not operate

until the side door has reached its secondary latch

position (determined by pawl and ratchet switches).

During a power open cycle, the power release actua-

tor will stop once the side door has moved from pri-

mary latch position.

The power latch uses inputs from the lock/unlock

actuator, power side door control module and child

lockout, pawl, ratchet and handle switches to provide

safe power cinch and release operations. Refer to

Power Side Door Operation for additional informa-

tion.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate side door trim panel.

Refer to the Body section for the procedure.

(3) Remove the weather shield if necessary. Refer

to the Body section for the procedure.

(4) Open the side door all the way and remove the

door latch retaining bolts (Fig. 6).

(5) Partially close the door and pull the latch

assembly out of the side door inner panel.

(6) Disconnect all electrical connectors leading to

the latch assembly.

(7) Disconnect the inside and outside handle cables

from the latch assembly. Refer to the Body Section of

the service manual for the procedure.

(8) Disconnect the hold open latch cable from the

latch assembly. Refer to the Body Section of the ser-

vice manual for the procedure.

(9) Disconnect lock actuator link rod from the

latch assembly.

(10) Remove the latch assembly from the vehicle.

INSTALLATION

(1) Position the latch assembly in the vehicle. Be

certain all latch mounted components are installed

on the replacement latch assembly. If not, transfer

components from the old latch to the new latch

assembly.

Fig. 5 Removing/Installing Power Latch in Sliding

Door

1 - Power Latch Assembly

RSPOWER SLIDING DOOR SYSTEM8N-29

POWER SLIDING DOOR SYSTEM (Continued)

Page 609 of 2585

POWER LOCKS

TABLE OF CONTENTS

page page

POWER LOCKS

DESCRIPTION.........................38

OPERATION...........................39

DOOR CYLINDER LOCK SWITCH

DESCRIPTION.........................40

OPERATION...........................40

DIAGNOSIS AND TESTING - DOOR

CYLINDER LOCK SWITCH..............40

REMOVAL.............................41

INSTALLATION.........................41

DOOR LOCK MOTOR

DIAGNOSIS AND TESTING - DOOR LOCK

MOTOR .............................41

DOOR LOCK SWITCH

DIAGNOSIS AND TESTING - DOOR LOCK

SWITCH............................41

REMOVAL.............................42

INSTALLATION.........................42

KEYLESS ENTRY TRANSMITTER

DIAGNOSIS AND TESTING - KEYLESS ENTRY

TRANSMITTER.......................42STANDARD PROCEDURE

STANDARD PROCEDURE - HORN CHIRP

PREFERENCE........................42

STANDARD PROCEDURE - BATTERY

REPLACEMENT.......................42

STANDARD PROCEDURE - RKE

TRANSMITTER PROGRAMING...........43

SPECIFICATIONS

RANGE.............................43

BATTERY...........................43

REMOTE KEYLESS ENTRY MODULE

DESCRIPTION.........................43

OPERATION...........................43

DIAGNOSIS AND TESTING - REMOTE

KEYLESS ENTRY MODULE..............43

REMOVAL.............................44

INSTALLATION.........................44

SLIDING DOOR LOCK MOTOR

REMOVAL.............................44

INSTALLATION.........................44

POWER LOCKS

DESCRIPTION

POWER DOOR LOCK SYSTEM

The front doors, sliding door(s) and liftgate are

equipped with actuator motors to lock or unlock the

latch mechanisms. The door lock actuator motor is

not serviced separately from the door latch, except

for the sliding door(s).

AUTOMATIC DOOR LOCK

The vehicle comes with two options for power door

locks:

²Rolling automatic lock (ENABLE), doors auto-

matically lock at approximately at 25.7 Km/h (16

mph).

²No rolling automatic lock (DISABLE), doors do

not automatically lock when the vehicle is moving.

AUTOMATIC DOOR UNLOCK

The doors will unlock automatically on vehicles

equipped with power door locks if:

²Auto door locks feature is enabled and automatic

unlock is enabled.²The transmission was in gear and speed was

above zero.

²The transmission in park or neutral and speed

is zero.

²Any door (excluding liftgate) opens.

DOOR LOCK INHIBIT

The BCM cancels out the door lock switch actua-

tion, when the key is in the Ignition Switch and

either front door is open.

Pressing the key fob RKE lock/unlock under these

conditions results in normal lock/unlock activation.

CENTRAL LOCKING

If equipped with Vehicle Theft Security System

(VTSS), all the doors can be locked with the key by

using the driver door lock cylinder. Turning the key

to the lock position will lock all the doors.

DOOR LOCK CIRCUIT PROTECTION

The door lock system is protected by a 40 amp fuse

located in the IPM. The BCM receives lock/unlock

input and will turn on the appropriate drivers and

provide a voltage level to the door lock motor for a

specific time. The IPM is located along the side of the

vehicle battery in the engine compartment.

8N - 38 POWER LOCKSRS

Page 613 of 2585

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove door trim panel. Refer to Body, Door -

Front, Trim Panel, Removal.

(3) Disconnect wire connector from back of door

lock switch.

(4) Remove two screws to door lock switch.

(5) Remove switch from vehicle.

INSTALLATION

(1) Install the switch into the vehicle.

(2) Install the two screws to door lock switch.

(3) Connect wire connector to back of door lock

switch.

(4) Install door trim panel. Refer to Body, Door -

Front, Trim Panel, Installation.

(5) Connect the battery negative cable.

KEYLESS ENTRY

TRANSMITTER

DIAGNOSIS AND TESTING - KEYLESS ENTRY

TRANSMITTER

Using special tool 9001, first test to ensure that

the transmitter is functioning. Typical testing dis-

tance is 2.5 centimeters (1 inch) for Asian transmit-

ters and 30.5 centimeters (12 inches) for all others.

To test, position the transmitter as shown (Fig. 3).

Press any transmitter button, then test each button

individually. The tool will beep if a radio signal

strength that lights five or more LED's is detected.

Repeat this test three times. If transmitter fails any

of the test, test the batteries. If batteries test OK,

refer to the Diagnostic Procedures manual.

STANDARD PROCEDURE

STANDARD PROCEDURE - HORN CHIRP

PREFERENCE

DISABLING

The horn chirp can be toggled using a DRB IIItor

by using a programmed Remote Keyless Entry (RKE)

transmitter.

To DISABLE (cancelling) the horn chirp feature,

press and hold the transmitter LOCK button for a

minimum of five seconds. While pressing the LOCK

button in, press the UNLOCK button. The horn chirp

feature will not function until the above procedure is

repeated.

ENABLING

The horn chirp can be toggled using a DRB IIItor

by using the Remote Keyless Entry (RKE) transmit-

ter.

To ENABLE (reinstate) the horn chirp feature, use

any one of the four programmed key fob transmitters

and reverse the above procedures. It will ENABLE

the horn chirp feature for all transmitters.

STANDARD PROCEDURE - BATTERY

REPLACEMENT

(1) With the transmitter buttons facing down, use

a coin (a penny is suggested) to pry the two halves of

the transmitter apart (Fig. 4). Make sure not to dam-

age the rubber gasket during separation of the hous-

ing halves.

(2) Remove the battery from the transmitter back

housing holder.

(3) Replace the batteries. Avoid touching the new

batteries with your fingers, Skin oils may cause bat-

tery deterioration. If you touch a battery, clean it off

with rubbing alcohol.

(4) To assemble the transmitter case, snap the two

halves together.

Fig. 3 TRANSMITTER DIAGNOSIS

Fig. 4 RKE TRANSMITTER BATTERY

REPLACEMENT - TYPICAL

1 - INSERT THIN COIN

8N - 42 POWER LOCKSRS

DOOR LOCK SWITCH (Continued)

Page 635 of 2585

INSTALLATION

(1) Obtain new vent window motor.

(2) Snap the actuator link socket onto the quarter

window ball socket. Using a soft rubber mallet, push

the circular link tab flush with link surface.

(3) Install bolts holding power vent motor to D-pil-

lar.

(4) Reconnect wire connector to power vent motor.

(5) Reconnect the battery negative cable.

(6) Cycle quarter window open/close to verify func-

tion.

(7) Install D-pillar trim panel.

WINDOW MOTOR

REMOVAL

The window motor is incorporated into the window

regulator assembly. If the window motor requires

replacement, the window regulator must be replaced.

(Refer to 23 - BODY/DOOR - FRONT/WINDOW

REGULATOR - REMOVAL).

WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW SWITCH

(1) Remove the desired switch to be tested from

the door trim panel. Driver's side (master) or passen-

ger side. (Refer to 8 - ELECTRICAL/POWER WIN-

DOWS/POWER WINDOW SWITCH - REMOVAL).

(2) Using an ohmmeter, Test driver door switch for

continuity as described in (Fig. 2).

POWER WINDOW MASTER SWITCH TEST

SWITCH POSITION CONTINUITY BETWEEN

OFF 13 and 1

13 and 2

13 and 3

13 and 4

13 and 5

13 and 6

13 and 7

13 and 8

SWITCH POSITION CONTINUITY BETWEEN

UP DRIVER 11 and 8

*DOWN DRIVER 11 and 6

*X DOWN DRIVER 11and 6

UP PASSENGER 9 and 4

DOWN PASSENGER 9 and 2

LEFT VENT OPEN 11 and 7

LEFT VENT CLOSE 9 and 3

RIGHT VENT OPEN 9 and 1

RIGHT VENT CLOSE 11 and 5

* MUST TEST WITH B+ ON PIN 9 AND

GROUND ON PIN 13 FOR CONTINUITY

BETWEEN PINS 11 AND 6

(3) If the result are not OK, replace the driver side

window lift switch.

(4) Test passenger door switch for continuity as

described in (Fig. 3).

PASSENGER WINDOW SWITCH TEST

SWITCH POSITION CONTINUITY BETWEEN

OFF 3 AND 8

OFF 2 AND 5

UP 1 AND 8

DOWN 1 AND 5

(5) If the results are not OK, replace the switch.

The power window master switch has a Auto-Down

feature. The switch is equipped with two detent posi-

tions when actuating the power window OPEN. The

first detent position allows the window to roll down

and stop when the switch is released. The second

detent position actuates an integral express roll

down relay that rolls the window down after the

switch is released. When the express down circuit

Fig. 2 Power Window Master Switch Connector

Fig. 3 Passenger Door Power Window Switch

8N - 64 POWER WINDOWSRS

VENT WINDOW MOTOR (Continued)