brake pads CHRYSLER VOYAGER 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 210 of 2585

INSTALLATION

INSTALLATION - PARKING BRAKE CABLE

(FRONT)

(1) Pass front parking brake cable assembly

through hole in floor pan from the inside of the vehi-

cle.

(2) Pass cable strand button through the hole in

the lever (pedal) assembly bracket.

(3) Install cable retainer onto the park brake cable

and then install cable retainer into pedal assembly

bracket.

(4) Install the end of the park brake cable into the

retainer previously installed into the park brake

pedal bracket.

(5) Install cable strand button into the clevis on

the park brake pedal mechanism.

(6) Install the front park brake cable floor pan seal

into hole in floor pan. Seal is to be installed so the

flange on the seal is flush with the floor pan (Fig.

91). Fold carpeting back down on floor.

(7) Raise vehicle.

(8) Insert brake cable and housing into body out-

rigger bracket making certain that housing retainer

fingers lock the housing firmly into place (Fig. 90).

(9) Manually reset the automatic self-adjusting

mechanism tension of the parking brake lever (pedal)

assembly. (Refer to 5 - BRAKES - STANDARD PRO-

CEDURE).

(10) Assemble the park brake cables onto the park

brake cable equalizer (Fig. 89).

(11) Lower vehicle and apply the park brake pedal

1 time. This will seat the parking brake cables.

INSTALLATION - PARKING BRAKE CABLE

(INTERMEDIATE)

(1) Install the ends of the park brake cables

through the frame rails and into the side brackets.

(2) Install the locking nuts at each end of the cable

and securely tighten (Fig. 92) (Fig. 93).

(3) If the vehicle is a short-wheel-base model, it

will be necessary to reinstall the fuel tank to its nor-

mal mounting position. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL TANK -

INSTALLATION).

(4) Install the intermediate parking brake cable on

the cable connector at the right rear parking brake

cable (Fig. 93).

(5) Install the intermediate park brake cable on

the cable equalizer (Fig. 92).

(6) Remove the locking pliers from the front park

brake cable. This will activate the automatic adjuster

and correctly adjust the parking brake cables.

(7) Install and position the foam collar on the

parking brake cable to prevent it from rattling

against the vehicle's floor.

(8) Lower the vehicle and apply the park brake

pedal 1 time, this will seat the park brake cables.

INSTALLATION - PARKING BRAKE CABLE

(RIGHT REAR)

(1) Install the rear parking brake cable in the

brake support plate. Insert cable housing retainer

into brake support plate making certain that cable

housing retainer fingers lock the housing and

retainer firmly into place.

(2) Attach the parking brake cable onto the park-

ing brake actuator lever.

(3) Install the brake shoes on the rear brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES -

INSTALLATION).

(4) Insert cable housing retainer into body outrig-

ger bracket making certain that cable housing

retainer fingers lock the housing firmly into place.

(5) Connect the right rear parking brake cable to

the connector on the intermediate parking brake

cable (Fig. 95).

(6) Install the brake drum, then the wheel and tire

assembly.

(7) Remove the locking pliers from the front park

brake cable. This will automatically adjust the park

brake cables.

(8) Lower the vehicle.

(9) Apply and release park brake pedal 1 time.

This will seat the park brake cables.

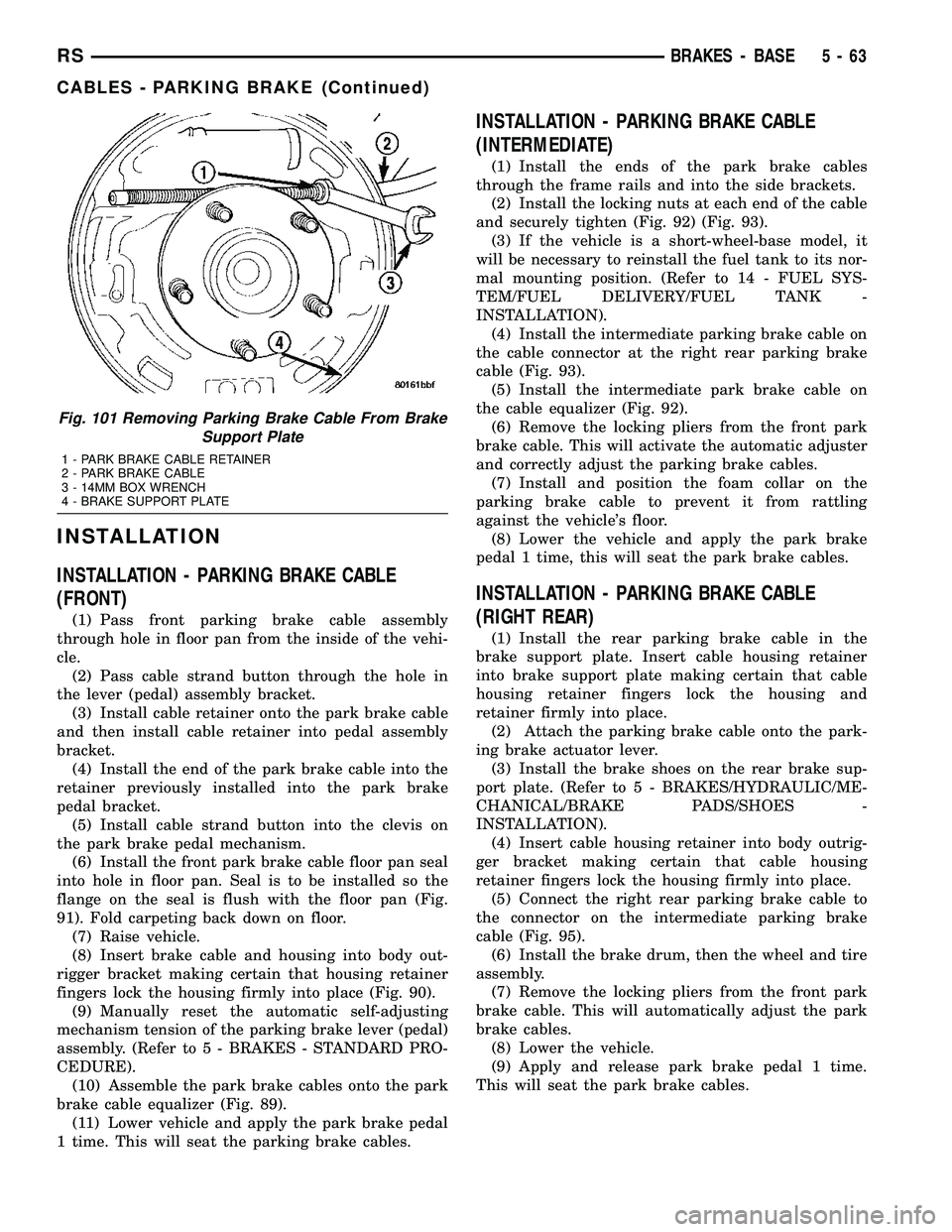

Fig. 101 Removing Parking Brake Cable From Brake

Support Plate

1 - PARK BRAKE CABLE RETAINER

2 - PARK BRAKE CABLE

3 - 14MM BOX WRENCH

4 - BRAKE SUPPORT PLATE

RSBRAKES - BASE5-63

CABLES - PARKING BRAKE (Continued)

Page 211 of 2585

INSTALLATION - PARKING BRAKE CABLE

(LEFT REAR)

(1) Install the rear parking brake cable in the

brake support plate. Insert cable housing retainer

into brake support plate making certain that cable

housing retainer fingers lock the housing and

retainer firmly into place.

(2) Attach the parking brake cable onto the park

brake actuator lever.

(3) Install the brake shoes on the rear brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES -

INSTALLATION).

(4) Insert cable housing retainer into body outrig-

ger bracket making certain that cable housing

retainer fingers lock the housing firmly into place.

(5) Connect rear parking brake cable to the equal-

izer bracket (Fig. 99).

(6) Install brake drum, and wheel and tire assem-

bly.

(7) Remove the locking pliers from the front park

brake cable. This will automatically adjust the park

brake cables.

(8) Apply and release park brake pedal 1 time.

This will seat the park brake cables.

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE CABLES

The park brake cables on this vehicle have an

automatic self adjuster built into the park brake

pedal mechanism. When the foot operated park brake

pedal is in its released (upward most) position, a

clock spring automatically adjusts the park brake

cables. The park brake cables are adjusted (ten-

sioned) just enough to remove all the slack from the

cables. The automatic adjuster system will not over

adjust the cables causing rear brake drag.

Due to the automatic adjust feature of the park

brake pedal, adjustment of the parking brake cables

on these vehicles relies on proper drum brake and

park brake shoe adjustment. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/DRUM - ADJUST-

MENTS) and (Refer to 5 - BRAKES/PARKING

BRAKE/SHOES - ADJUSTMENTS).

When the park brake pedal is applied the self

adjuster is by-passed and the pedal operates nor-

mally to engage the park brakes.

When a service procedure needs to be performed on

the park brake pedal or the park brake cables, the

automatic self adjuster can be manually locked out

by the service technician.

CABLES - PARKING BRAKE

(EXPORT)

REMOVAL - FRONT CABLE

(Refer to 5 - BRAKES - BASE/PARKING BRAKE/

LEVER - REMOVAL)

INSTALLATION - FRONT CABLE

(Refer to 5 - BRAKES - BASE/PARKING BRAKE/

LEVER - INSTALLATION)

LEVER - PARKING BRAKE

REMOVAL

(1) Manually release the automatic self-adjusting

mechanism tension of the parking brake lever (pedal)

assembly. (Refer to 5 - BRAKES/PARKING BRAKE -

STANDARD PROCEDURE).

(2) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

(3) Remove sill scuff plate from left door sill.

(4) Remove the left side kick panel.

(5) Remove the silencer panel under the instru-

ment panel.

(6) Remove the steering column cover from the

lower instrument panel.

(7) Remove the reinforcement from the lower

instrument panel.

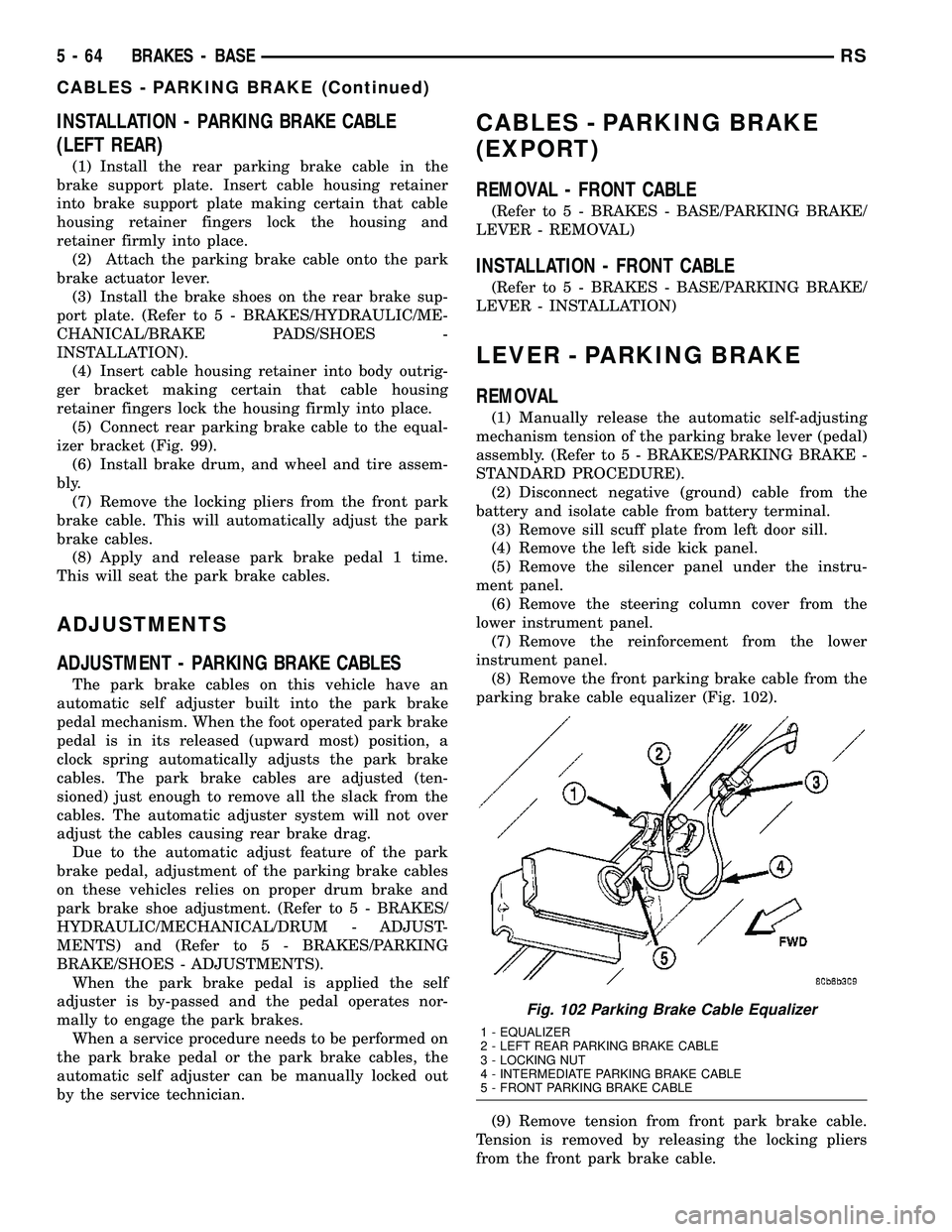

(8) Remove the front parking brake cable from the

parking brake cable equalizer (Fig. 102).

(9) Remove tension from front park brake cable.

Tension is removed by releasing the locking pliers

from the front park brake cable.

Fig. 102 Parking Brake Cable Equalizer

1 - EQUALIZER

2 - LEFT REAR PARKING BRAKE CABLE

3 - LOCKING NUT

4 - INTERMEDIATE PARKING BRAKE CABLE

5 - FRONT PARKING BRAKE CABLE

5 - 64 BRAKES - BASERS

CABLES - PARKING BRAKE (Continued)

Page 244 of 2585

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE DESCRIPTION DESCRIPTION - BASE BRAKES ...........3

DESCRIPTION - BASE BRAKES (EXPORT) . . . 3

OPERATION - BASE BRAKES ..............3

WARNING .............................3

CAUTION ..............................4

DIAGNOSIS AND TESTING - BASE BRAKE SYSTEM .............................4

STANDARD PROCEDURE - BASE BRAKE BLEEDING ............................7

SPECIFICATIONS BRAKE FASTENER TORQUE .............8

SPECIAL TOOLS BASE BRAKE SYSTEM ..................9

BRAKE FLUID LEVEL SWITCH DESCRIPTION ..........................9

OPERATION ............................9

REMOVAL .............................10

INSTALLATION .........................10

ADJUSTABLE PEDALS SWITCH REMOVAL .............................10

INSTALLATION .........................10

HYDRAULIC/MECHANICAL DESCRIPTION DESCRIPTION - DISC BRAKES (FRONT) . . . 10

DESCRIPTION - DISC BRAKES (REAR) ....12

DESCRIPTION - DISC BRAKES (EXPORT) . . 12

DESCRIPTION - DRUM BRAKES (REAR) . . . 12

OPERATION OPERATION - DISC BRAKES (FRONT) .....12

OPERATION - DISC BRAKES (REAR) ......13

DIAGNOSIS AND TESTING - DRUM BRAKE AUTOMATIC ADJUSTER ................13

BRAKE LINES DESCRIPTION - BRAKE TUBES AND HOSES . 13

OPERATION - BRAKE TUBES AND HOSES . . . 13

INSPECTION - BRAKE TUBES AND HOSES . . . 13

BRAKE PADS/SHOES - FRONT REMOVAL REMOVAL - FRONT DISC BRAKE SHOES(CONTINENTAL TEVES BRAKES) .........14

REMOVAL - FRONT DISC BRAKE SHOES (TRW BRAKES) .......................14

CLEANING - DISC BRAKE SHOES ..........15

INSPECTION - DISC BRAKE SHOES ........15

INSTALLATION INSTALLATION - FRONT DISC BRAKESHOES (CONTINENTAL TEVES BRAKES) . . . 15 INSTALLATION - FRONT DISC BRAKE

SHOES (TRW BRAKES) ................16

BRAKE PADS/SHOES - REAR DISC REMOVAL - REAR DISC BRAKE SHOES .....16

CLEANING - DISC BRAKE SHOES ..........17

INSPECTION - DISC BRAKE SHOES ........17

INSTALLATION - REAR DISC BRAKE SHOES . . 18

BRAKE PADS/SHOES - REAR DRUM REMOVAL - REAR DRUM BRAKE SHOES ....18

INSPECTION - REAR DRUM BRAKE SHOE LINING ..............................21

INSTALLATION - REAR DRUM BRAKE SHOES . 21

ADJUSTMENTS ADJUSTMENT - REAR DRUM BRAKESHOES .............................22

DISC BRAKE CALIPER - FRONT REMOVAL REMOVAL - FRONT DISC BRAKE CALIPER(CONTINENTAL TEVES BRAKES) .........23

REMOVAL - FRONT DISC BRAKE CALIPER (TRW BRAKES) .......................23

DISASSEMBLY DISASSEMBLY - CALIPER GUIDE PINBUSHINGS (CONTINENTAL TEVES

BRAKES) ............................23

DISASSEMBLY - CALIPER PISTON AND SEAL ...............................23

CLEANING - CALIPER ...................24

INSPECTION - CALIPER ..................24

ASSEMBLY ASSEMBLY - CALIPER GUIDE PINBUSHINGS (CONTINENTAL TEVES

BRAKES) ............................24

ASSEMBLY - CALIPER PISTON AND SEAL . . 25

INSTALLATION INSTALLATION - FRONT DISC BRAKECALIPER (CONTINENTAL TEVES

BRAKES) ............................26

INSTALLATION - FRONT DISC BRAKE CALIPER (TRW BRAKES) ...............26

DISC BRAKE CALIPER - REAR REMOVAL - REAR DISC BRAKE CALIPER ....26

DISASSEMBLY - CALIPER PISTON AND SEAL . 27

CLEANING - CALIPER ...................28

INSPECTION - CALIPER ..................28

ASSEMBLY - CALIPER PISTON AND SEAL . . . 28

INSTALLATION - REAR DISC BRAKE CALIPER ............................29

RS BRAKES5s-1

Page 253 of 2585

line in the master cylinder fluid reservoir, the

entire brake hydraulic system should be

checked for evidence of a leak.

REMOVAL

(1) Remove wiring harness connector from brake

fluid reservoir level switch (Fig. 3).

(2) Using fingers, compress the retaining tabs on

the opposite end of brake fluid level switch. (3) With retaining tabs compressed, grasp the con-

nector end of brake fluid level switch and pull it out

of master cylinder brake fluid reservoir.

INSTALLATION

(1) Insert brake fluid level switch into left side of

brake fluid reservoir. Be sure switch is pushed in

until retaining tabs lock it to brake fluid reservoir. (2) Connect vehicle wiring harness connector to

brake fluid level switch (Fig. 3).

ADJUSTABLE PEDALS

SWITCH

REMOVAL

(1) Remove steering column lower shroud. (Refer

to 19 - STEERING/COLUMN/LOWER SHROUD -

REMOVAL) (2) Depress retaining tabs on top and bottom of

switch and remove switch from lower shroud.

INSTALLATION

(1) Install the switch into the lower shroud, snap-

ping it into place. (2) Connect wiring harness connector to switch,

then install lower shroud on steering column. (Refer

to 19 - STEERING/COLUMN/LOWER SHROUD -

INSTALLATION) (3) Ensure proper operation of adjustable pedals.

HYDRAULIC/MECHANICAL

DESCRIPTION

DESCRIPTION - DISC BRAKES (FRONT)

Each front disc brake consists of the following com-

ponents: ² Brake Rotor

² Brake Caliper

² Brake Caliper Adapter

² Shoes (Pads)

There are two non-interchangeable front disc brake

systems. One is manufactured by TRW and the other

by Continental Teves.

CAUTION: Components used on the TRW brakes

are not interchangeable with the Continental Teves

brakes. The two different systems must not be

mixed. Improper performance, noise and increased

stopping distance can occur.

The TRW front brake caliper is a one piece casting

containing a single 64 mm diameter piston bore (Fig.

4) with a phenolic piston. The caliper mounts to a

caliper adapter using two guide pin bolts that thread

into guide pins slid into the caliper adapter (Fig. 5).

The pins are lubricated and have boots that seal

them in place in the adapter. The Continental Teves front brake caliper is a one

piece casting containing a single piston 66 mm diam-

eter bore (Fig. 4) with a phenolic piston. The caliper

mounts to a caliper adapter using two guide pin bolts

that thread into the caliper adapter and slide on

bushings mounted in the caliper.

CAUTION: TRW and Continental Teves calipers are

not interchangeable. Each caliper is specifically

designed for the unique brake system. If calipers

are interchanged, improper performance, noise and

increased stopping distance can occur.

Fig. 3 MASTER CYLINDER AND BOOSTER

1 - POWER BRAKE BOOSTER

2 - BOOSTER IDENTIFICATION LABEL

3 - FLUID LEVEL SWITCH CONNECTOR

4 - PRIMARY BRAKE TUBE NUT

5 - SECONDARY BRAKE TUBE NUT

6 - MASTER CYLINDER

5s - 10 BRAKESRS

BRAKE FLUID LEVEL SWITCH (Continued)

Page 255 of 2585

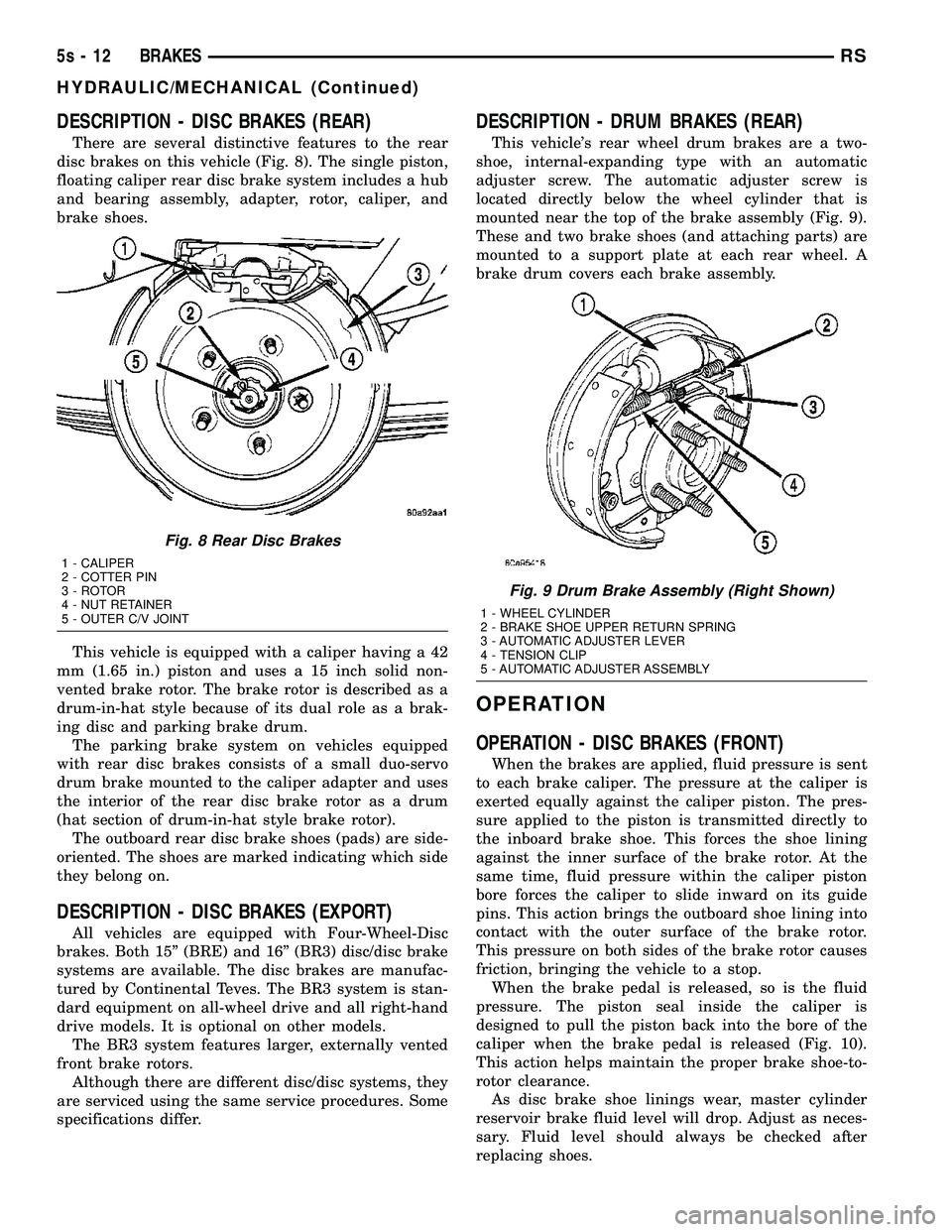

DESCRIPTION - DISC BRAKES (REAR)

There are several distinctive features to the rear

disc brakes on this vehicle (Fig. 8). The single piston,

floating caliper rear disc brake system includes a hub

and bearing assembly, adapter, rotor, caliper, and

brake shoes.

This vehicle is equipped with a caliper having a 42

mm (1.65 in.) piston and uses a 15 inch solid non-

vented brake rotor. The brake rotor is described as a

drum-in-hat style because of its dual role as a brak-

ing disc and parking brake drum. The parking brake system on vehicles equipped

with rear disc brakes consists of a small duo-servo

drum brake mounted to the caliper adapter and uses

the interior of the rear disc brake rotor as a drum

(hat section of drum-in-hat style brake rotor). The outboard rear disc brake shoes (pads) are side-

oriented. The shoes are marked indicating which side

they belong on.

DESCRIPTION - DISC BRAKES (EXPORT)

All vehicles are equipped with Four-Wheel-Disc

brakes. Both 15º (BRE) and 16º (BR3) disc/disc brake

systems are available. The disc brakes are manufac-

tured by Continental Teves. The BR3 system is stan-

dard equipment on all-wheel drive and all right-hand

drive models. It is optional on other models. The BR3 system features larger, externally vented

front brake rotors. Although there are different disc/disc systems, they

are serviced using the same service procedures. Some

specifications differ.

DESCRIPTION - DRUM BRAKES (REAR)

This vehicle's rear wheel drum brakes are a two-

shoe, internal-expanding type with an automatic

adjuster screw. The automatic adjuster screw is

located directly below the wheel cylinder that is

mounted near the top of the brake assembly (Fig. 9).

These and two brake shoes (and attaching parts) are

mounted to a support plate at each rear wheel. A

brake drum covers each brake assembly.

OPERATION

OPERATION - DISC BRAKES (FRONT)

When the brakes are applied, fluid pressure is sent

to each brake caliper. The pressure at the caliper is

exerted equally against the caliper piston. The pres-

sure applied to the piston is transmitted directly to

the inboard brake shoe. This forces the shoe lining

against the inner surface of the brake rotor. At the

same time, fluid pressure within the caliper piston

bore forces the caliper to slide inward on its guide

pins. This action brings the outboard shoe lining into

contact with the outer surface of the brake rotor.

This pressure on both sides of the brake rotor causes

friction, bringing the vehicle to a stop. When the brake pedal is released, so is the fluid

pressure. The piston seal inside the caliper is

designed to pull the piston back into the bore of the

caliper when the brake pedal is released (Fig. 10).

This action helps maintain the proper brake shoe-to-

rotor clearance. As disc brake shoe linings wear, master cylinder

reservoir brake fluid level will drop. Adjust as neces-

sary. Fluid level should always be checked after

replacing shoes.

Fig. 8 Rear Disc Brakes

1 - CALIPER

2 - COTTER PIN

3 - ROTOR

4 - NUT RETAINER

5 - OUTER C/V JOINT

Fig. 9 Drum Brake Assembly (Right Shown)

1 - WHEEL CYLINDER

2 - BRAKE SHOE UPPER RETURN SPRING

3 - AUTOMATIC ADJUSTER LEVER

4 - TENSION CLIP

5 - AUTOMATIC ADJUSTER ASSEMBLY

5s - 12 BRAKESRS

HYDRAULIC/MECHANICAL (Continued)

Page 257 of 2585

BRAKE PADS/SHOES - FRONT

REMOVAL

REMOVAL - FRONT DISC BRAKE SHOES

(CONTINENTAL TEVES BRAKES)

(1) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE). (2) Remove both front wheel and tire assemblies.

(3) Begin on one side of the vehicle.

(4) Remove the anti-rattle clip from the outboard

side of the caliper and adapter. (5) Remove the two caliper guide pin bolts.

(6) Remove caliper from caliper adapter and brake

rotor.

CAUTION: Supporting weight of caliper by the flex-

ible brake fluid hose can damage the hose.

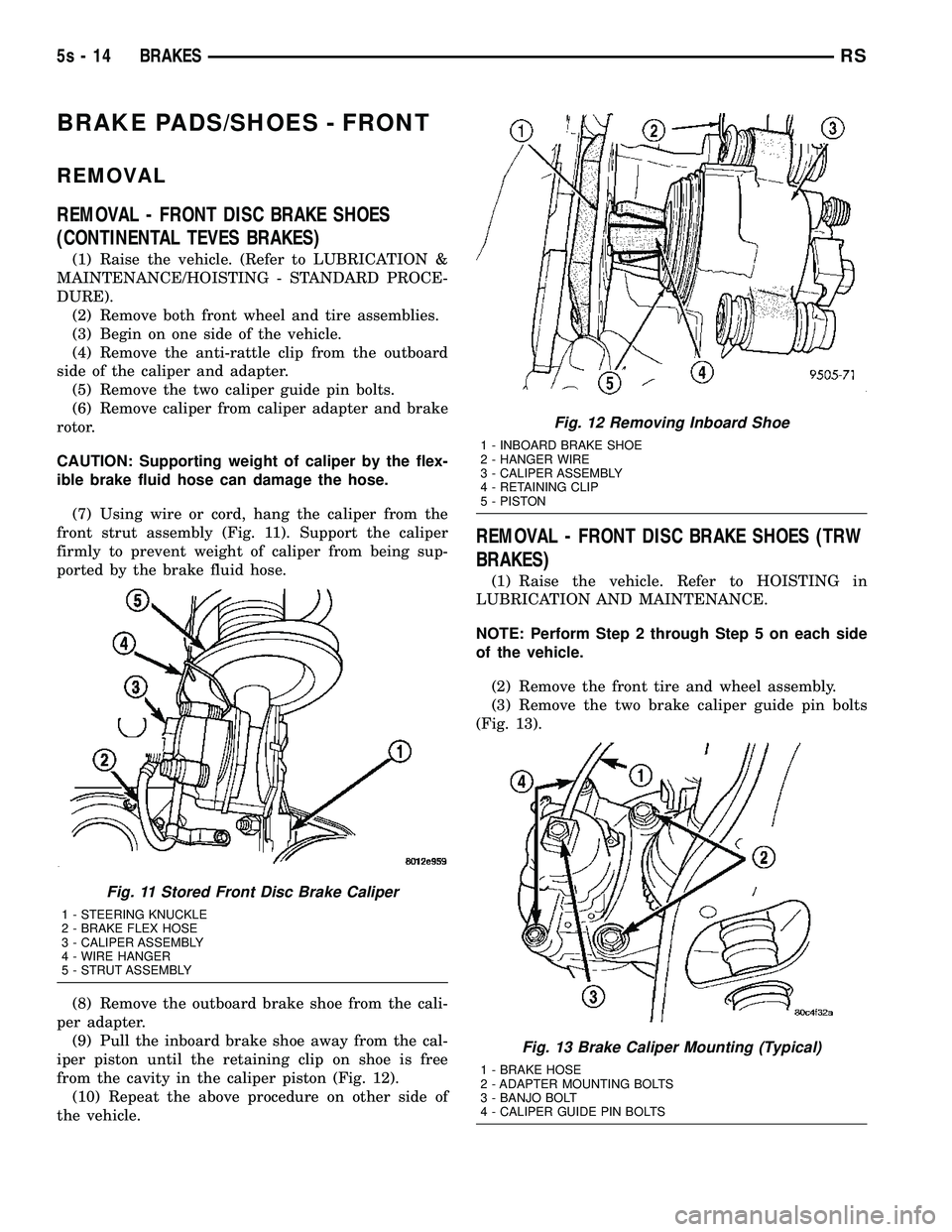

(7) Using wire or cord, hang the caliper from the

front strut assembly (Fig. 11). Support the caliper

firmly to prevent weight of caliper from being sup-

ported by the brake fluid hose.

(8) Remove the outboard brake shoe from the cali-

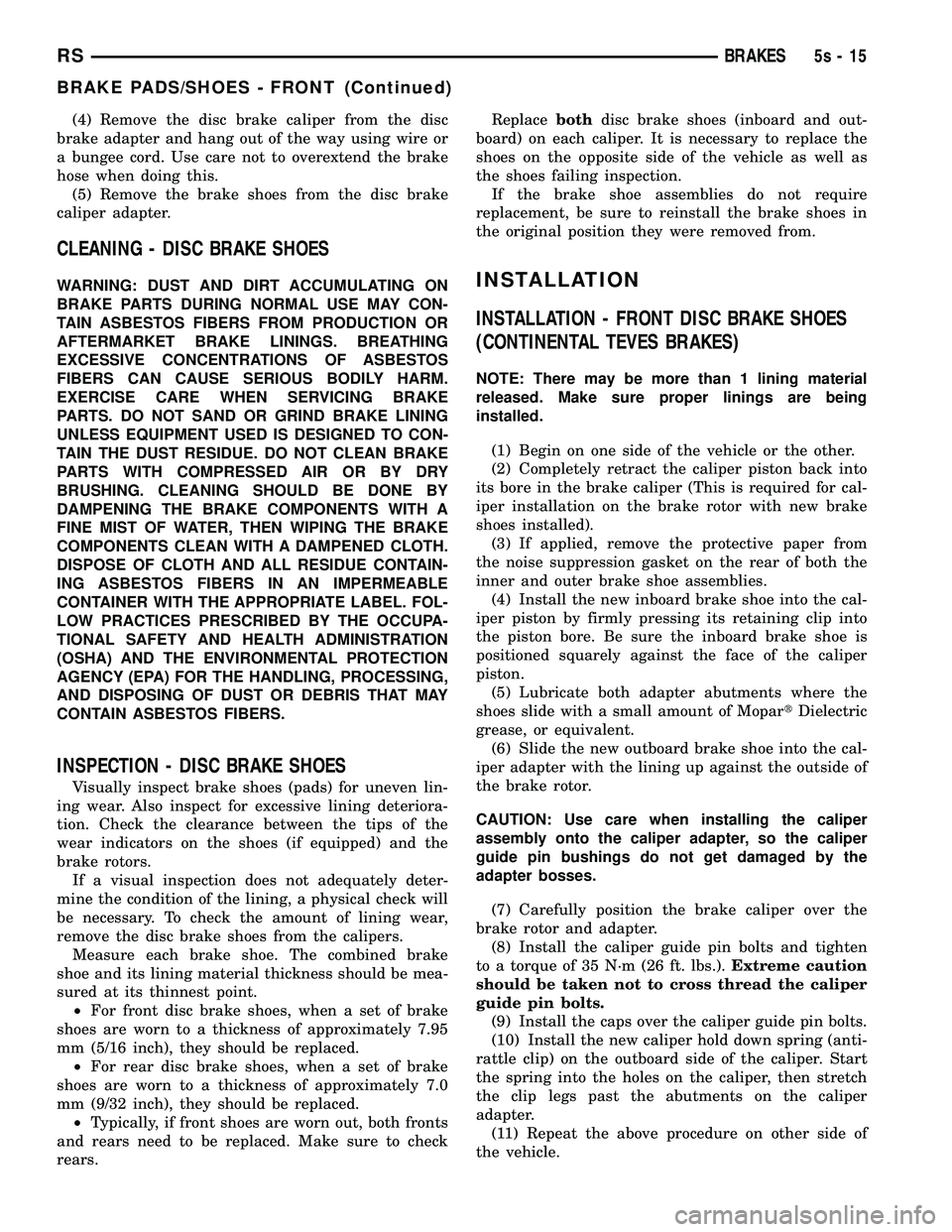

per adapter. (9) Pull the inboard brake shoe away from the cal-

iper piston until the retaining clip on shoe is free

from the cavity in the caliper piston (Fig. 12). (10) Repeat the above procedure on other side of

the vehicle.

REMOVAL - FRONT DISC BRAKE SHOES (TRW

BRAKES)

(1) Raise the vehicle. Refer to HOISTING in

LUBRICATION AND MAINTENANCE.

NOTE: Perform Step 2 through Step 5 on each side

of the vehicle.

(2) Remove the front tire and wheel assembly.

(3) Remove the two brake caliper guide pin bolts

(Fig. 13).

Fig. 11 Stored Front Disc Brake Caliper

1 - STEERING KNUCKLE

2 - BRAKE FLEX HOSE

3 - CALIPER ASSEMBLY

4 - WIRE HANGER

5 - STRUT ASSEMBLY

Fig. 12 Removing Inboard Shoe

1 - INBOARD BRAKE SHOE

2 - HANGER WIRE

3 - CALIPER ASSEMBLY

4 - RETAINING CLIP

5 - PISTON

Fig. 13 Brake Caliper Mounting (Typical)

1 - BRAKE HOSE

2 - ADAPTER MOUNTING BOLTS

3 - BANJO BOLT

4 - CALIPER GUIDE PIN BOLTS

5s - 14 BRAKESRS

Page 258 of 2585

(4) Remove the disc brake caliper from the disc

brake adapter and hang out of the way using wire or

a bungee cord. Use care not to overextend the brake

hose when doing this. (5) Remove the brake shoes from the disc brake

caliper adapter.

CLEANING - DISC BRAKE SHOES

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.

DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

INSPECTION - DISC BRAKE SHOES

Visually inspect brake shoes (pads) for uneven lin-

ing wear. Also inspect for excessive lining deteriora-

tion. Check the clearance between the tips of the

wear indicators on the shoes (if equipped) and the

brake rotors. If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary. To check the amount of lining wear,

remove the disc brake shoes from the calipers. Measure each brake shoe. The combined brake

shoe and its lining material thickness should be mea-

sured at its thinnest point. ² For front disc brake shoes, when a set of brake

shoes are worn to a thickness of approximately 7.95

mm (5/16 inch), they should be replaced. ² For rear disc brake shoes, when a set of brake

shoes are worn to a thickness of approximately 7.0

mm (9/32 inch), they should be replaced. ² Typically, if front shoes are worn out, both fronts

and rears need to be replaced. Make sure to check

rears. Replace

bothdisc brake shoes (inboard and out-

board) on each caliper. It is necessary to replace the

shoes on the opposite side of the vehicle as well as

the shoes failing inspection. If the brake shoe assemblies do not require

replacement, be sure to reinstall the brake shoes in

the original position they were removed from.

INSTALLATION

INSTALLATION - FRONT DISC BRAKE SHOES

(CONTINENTAL TEVES BRAKES)

NOTE: There may be more than 1 lining material

released. Make sure proper linings are being

installed.

(1) Begin on one side of the vehicle or the other.

(2) Completely retract the caliper piston back into

its bore in the brake caliper (This is required for cal-

iper installation on the brake rotor with new brake

shoes installed). (3) If applied, remove the protective paper from

the noise suppression gasket on the rear of both the

inner and outer brake shoe assemblies. (4) Install the new inboard brake shoe into the cal-

iper piston by firmly pressing its retaining clip into

the piston bore. Be sure the inboard brake shoe is

positioned squarely against the face of the caliper

piston. (5) Lubricate both adapter abutments where the

shoes slide with a small amount of Mopar tDielectric

grease, or equivalent. (6) Slide the new outboard brake shoe into the cal-

iper adapter with the lining up against the outside of

the brake rotor.

CAUTION: Use care when installing the caliper

assembly onto the caliper adapter, so the caliper

guide pin bushings do not get damaged by the

adapter bosses.

(7) Carefully position the brake caliper over the

brake rotor and adapter. (8) Install the caliper guide pin bolts and tighten

to a torque of 35 N´m (26 ft. lbs.). Extreme caution

should be taken not to cross thread the caliper

guide pin bolts. (9) Install the caps over the caliper guide pin bolts.

(10) Install the new caliper hold down spring (anti-

rattle clip) on the outboard side of the caliper. Start

the spring into the holes on the caliper, then stretch

the clip legs past the abutments on the caliper

adapter. (11) Repeat the above procedure on other side of

the vehicle.

RS BRAKES5s-15

BRAKE PADS/SHOES - FRONT (Continued)

Page 259 of 2585

(12) Install the wheel and tire assemblies. Tighten

the wheel mounting nuts in proper sequence until all

nuts are torqued to half specification, then repeat the

tightening sequence to the full specified torque of 135

N´m (100 ft. lbs.). (13) Lower vehicle.

(14) Pump the brake pedal several times. This will

set the shoes to the brake rotor. (15) Check and adjust brake fluid level as neces-

sary. (16) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoes.

INSTALLATION - FRONT DISC BRAKE SHOES

(TRW BRAKES)

NOTE: Perform steps Step 1 through Step 5on each

side of the vehicle.

(1) Place the brake shoes in the adapter anti-rattle

clips. (2) Completely retract the caliper piston back into

the bore of the caliper.

CAUTION: Use care when installing the caliper onto

the disc brake adapter to avoid damaging the boots

on the caliper guide pins.

(3) Install the disc brake caliper over the brake

shoes on the brake caliper adapter. (4) Align the caliper guide pin bolt holes with the

guide pins. Install the caliper guide pin bolts and

tighten them to a torque of 35 N´m (26 ft. lbs.) (Fig.

13). (5) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.). (6) Lower the vehicle.

(7) Pump the brake pedal several times. This will

set the shoes to the brake rotor. (8) Check and adjust the brake fluid level as nec-

essary. (9) Road test the vehicle and make several stops to

wear off any foreign material on the brakes and to

seat the brake shoes.

BRAKE PADS/SHOES - REAR

DISC

REMOVAL - REAR DISC BRAKE SHOES

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE). (2) Remove rear wheel and tire assemblies from

vehicle. (3) Remove the caliper to adapter guide pin bolts

(Fig. 14).

(4) Remove rear caliper from adapter using the fol-

lowing procedure. First rotate front of caliper up

from the adapter. Then pull the rear of the caliper

and the outboard brake shoe anti-rattle clip out from

under the rear abutment on the adapter (Fig. 15).

Fig. 14 Caliper Guide Pin Bolts

1 - DISC BRAKE CALIPER

2 - ADAPTER

3 - AXLE

4 - GUIDE PIN BOLTS

5 - DRIVESHAFT (AWD MODELS ONLY)

Fig. 15 Removing/Installing Caliper

1 - LIFT THIS END OF CALIPER AWAY FROM ADAPTER FIRST

2 - DISC BRAKE CALIPER

3 - ADAPTER ABUTMENT

4 - OUTBOARD BRAKE SHOE HOLD DOWN CLIP

5 - OUTBOARD BRAKE SHOE

6 - ROTOR

7 - ADAPTER

5s - 16 BRAKESRS

BRAKE PADS/SHOES - FRONT (Continued)

Page 260 of 2585

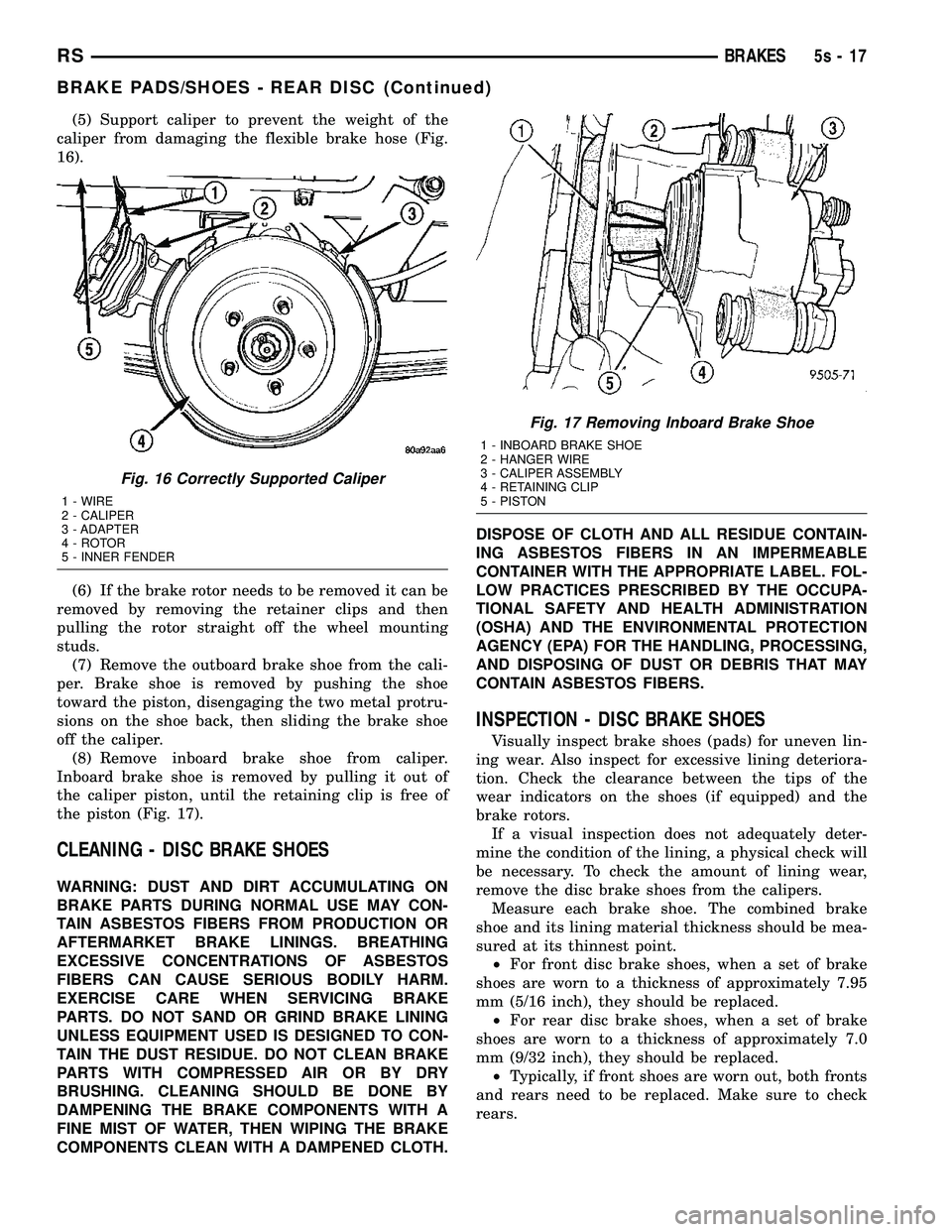

(5) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

16).

(6) If the brake rotor needs to be removed it can be

removed by removing the retainer clips and then

pulling the rotor straight off the wheel mounting

studs. (7) Remove the outboard brake shoe from the cali-

per. Brake shoe is removed by pushing the shoe

toward the piston, disengaging the two metal protru-

sions on the shoe back, then sliding the brake shoe

off the caliper. (8) Remove inboard brake shoe from caliper.

Inboard brake shoe is removed by pulling it out of

the caliper piston, until the retaining clip is free of

the piston (Fig. 17).

CLEANING - DISC BRAKE SHOES

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH. DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

INSPECTION - DISC BRAKE SHOES

Visually inspect brake shoes (pads) for uneven lin-

ing wear. Also inspect for excessive lining deteriora-

tion. Check the clearance between the tips of the

wear indicators on the shoes (if equipped) and the

brake rotors. If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary. To check the amount of lining wear,

remove the disc brake shoes from the calipers. Measure each brake shoe. The combined brake

shoe and its lining material thickness should be mea-

sured at its thinnest point. ² For front disc brake shoes, when a set of brake

shoes are worn to a thickness of approximately 7.95

mm (5/16 inch), they should be replaced. ² For rear disc brake shoes, when a set of brake

shoes are worn to a thickness of approximately 7.0

mm (9/32 inch), they should be replaced. ² Typically, if front shoes are worn out, both fronts

and rears need to be replaced. Make sure to check

rears.

Fig. 16 Correctly Supported Caliper

1 - WIRE

2 - CALIPER

3 - ADAPTER

4 - ROTOR

5 - INNER FENDER

Fig. 17 Removing Inboard Brake Shoe

1 - INBOARD BRAKE SHOE

2 - HANGER WIRE

3 - CALIPER ASSEMBLY

4 - RETAINING CLIP

5 - PISTON

RS BRAKES5s-17

BRAKE PADS/SHOES - REAR DISC (Continued)

Page 261 of 2585

Replacebothdisc brake shoes (inboard and out-

board) on each caliper. It is necessary to replace the

shoes on the opposite side of the vehicle as well as

the shoes failing inspection. If the brake shoe assemblies do not require

replacement, be sure to reinstall the brake shoes in

the original position they were removed from.

INSTALLATION - REAR DISC BRAKE SHOES

(1) Completely retract caliper piston back into pis-

ton bore of caliper assembly. (2) Lubricate both adapter abutments where the

shoes contact with a liberal amount of Mopar tMul-

tipurpose Lubricant, or equivalent. (3) If removed, install the brake rotor on the hub,

making sure it is squarely seated on the face of the

hub. (4) Install the inboard brake shoe into the caliper

piston by firmly pressing it into the piston bore using

your thumbs. Be sure inboard brake shoe is posi-

tioned squarely against the face of the caliper piston.

NOTE: The outboard shoes are different left to

right. They can be identified by a L or R stamped on

the clip.

(5) Install the outboard brake shoe on the disc

brake caliper. Be sure the outboard shoe is positioned

squarely against the outboard fingers of the caliper.

CAUTION: Use care when installing the caliper

assembly onto the adapter, so the caliper guide pin

bushings do not get damaged by the mounting

bosses.

(6) Carefully lower caliper and brake shoes over

rotor and onto adapter, reversing the removal proce-

dure (Fig. 15).

CAUTION: When installing the caliper guide pin

bolts extreme caution should be taken not to

crossthread the guide pin bolts.

(7) Install the caliper guide pin bolts. Tighten the

guide pin bolts to a torque of 35 N´m (26 ft. lbs.). (8) Install the wheel and tire assembly. Tighten

the wheel mounting nuts in proper sequence until all

nuts are torqued to half specification. Then repeat

the tightening sequence to the full specified torque of

135 N´m (100 ft. lbs.). (9) Lower vehicle.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop the vehicle. (10) Pump brake pedal several times to set brake

shoes to rotors. (11) Check fluid level in reservoir.

(12) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoe linings.

BRAKE PADS/SHOES - REAR

DRUM

REMOVAL - REAR DRUM BRAKE SHOES

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE). (2) Remove the rear wheel and tire assemblies

from the vehicle. (3) Remove rear brake drum to hub retaining clips

(if equipped), then remove rear brake drums. (Refer

to 5 - BRAKES/HYDRAULIC/MECHANICAL/DRUM

- REMOVAL)

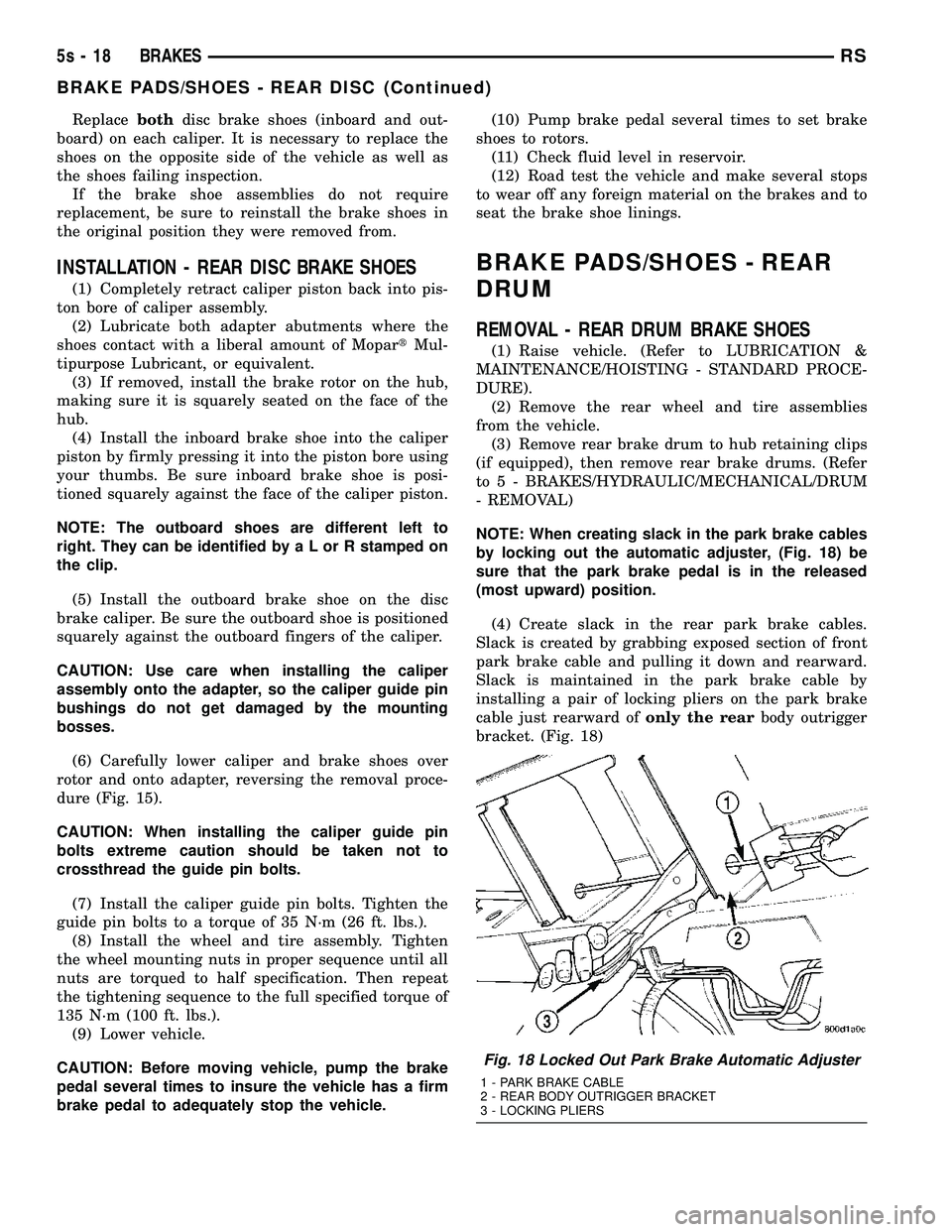

NOTE: When creating slack in the park brake cables

by locking out the automatic adjuster, (Fig. 18) be

sure that the park brake pedal is in the released

(most upward) position.

(4) Create slack in the rear park brake cables.

Slack is created by grabbing exposed section of front

park brake cable and pulling it down and rearward.

Slack is maintained in the park brake cable by

installing a pair of locking pliers on the park brake

cable just rearward of only the rearbody outrigger

bracket. (Fig. 18)

Fig. 18 Locked Out Park Brake Automatic Adjuster

1 - PARK BRAKE CABLE

2 - REAR BODY OUTRIGGER BRACKET

3 - LOCKING PLIERS

5s - 18 BRAKESRS

BRAKE PADS/SHOES - REAR DISC (Continued)