open hood CHRYSLER VOYAGER 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 681 of 2585

during the arming process, although the system will

still arm.

If the indicator LED does not illuminate at all

upon door closing it indicates that the system is not

arming.

Passive disarming occurs upon normal vehicle

entry by unlocking either door with the remote trans-

mitter (RG - ignition key or remote transmitter). This

disarming will also halt the alarm once it has been

activated.

A tamper alert exists to notify the driver that the

VTSS had been activated. This alert consists of 3

horn pulses when the vehicle is disarmed.

NOTE: The VTSS will not arm by pushing down the

door lock mechanism. This will manually override

the system.

RG Only- For Door Cylinder Lock Switch

Removal and Installation, refer to Electrical, Power

Locks, Door Cylinder Lock Switch.

If the VTSS is triggered, the horn will pulse, head-

lamps/marker lamps will flash, and the VTSS warn-

ing lamp will flash. If BCM determines the threat to

be false and the VTSS is not triggered again, the sys-

tem will shut down and rearm itself after three min-

utes. If a trigger is still active, the alarm will

continue for an additional 15 minutes without the

horn. The VTSS monitors the passenger compart-

ment (for RG - Export it also monitors the engine

compartment. If a malfunction occurs in the engine

compartment, the passenger compartment would still

arm and function normally).

NOTE: System will not arm if passenger compart-

ment is not secure.

NOTE: (RG - Export - If hood is not secure during

the arming sequence, the lamp will stay lit and not

flash. The system will arm with hood not secured

and the liftgate open).

ARMING THE VTSS - METHOD A

(1) With the key removed from the ignition lock

and any door open (excluding liftgate), actuate one of

the following:

²Power door lock button to LOCK,

²Key fob LOCK button

²Driver door lock key cylinder to locked position

(RG Only).

(2) Close all opened doors. Liftgate can remain

open.

(3) After the last door is closed, an arming time-

out period of sixteen seconds will start, then the

VTSS will become armed.

ARMING THE VTSS - METHOD B

Actuating the key fob transmitter LOCK button,

key locking the front doors with the doors closed and

the ignition locked will begin the arming time-out

period. If method A, 16 second time-out sequence was

in process when method B was actuated, the 16 sec-

ond time-out will restart from the time of the second

actuation.

If the security lamp does not illuminate at all upon

final door closure, it indicates that the system is not

arming.

The current VTSS status armed or disarmed shall

be maintained in memory to prevent battery discon-

nects from disarming the system.

TRIGGERING THE VTSS

After the VTSS is armed, the following actions will

trigger the alarm:

²Opening any door (liftgate - only if opening via

liftgate button on key fob).

²Opening the hood (RG - Export)

²Turning the ignition to the RUN position.

NOTE: When the VTSS is ARMED, the interior

power door lock switch ªUNLOCKº will be disabled

until the vehicle is disarmed.

CAUTION: The VTSS indicator LED will trigger and

engine will continue to run if the vehicle is

equipped with SKREES and the proper key is used

to start the vehicle. This condition will occur if the

VTSS has been triggered. If valid key is used, VTSS

will disarm

SENTRY KEY REMOTE ENTRY SYSTEM

The SKREES includes keys from the factory which

are pre-programmed. Each SKREEM will recognize a

maximum of eight Sentry Keys. If the customer

would like to own additional keys other than those

provided with the vehicle, they can be purchased

from any authorized dealer. These keys must be pro-

grammed to the SKREEM on the vehicle in order for

the system to recognize them as valid keys. This can

be done by the dealer with a DRBllltscan tool or by

a customer if this feature is available in their market

and they have two (2) valid keys already available to

them. Refer to the Service Procedures portion of this

system for additional details. The SKREES performs

a self-test each time the ignition switch is turned to

the ON position and will store Diagnostic Trouble

Codes (DTC's) if a system malfunction is detected.

The SKREES can be diagnosed and any stored DTC's

can be retrieved using a DRBllltscan tool as

described in the appropriate Body Diagnostic Proce-

dures information.

8Q - 2 VEHICLE THEFT SECURITYRS

VEHICLE THEFT SECURITY (Continued)

Page 682 of 2585

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SENTRY KEY

REMOTE ENTRY SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS,

WARNINGS, BEFORE ATTEMPTING COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY OR DEATH.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Sentry Key Remote Entry System (SKREES)

involves the use of a DRBIIITscan tool. Refer to the

proper Body Diagnostic Procedures information.

The Sentry Key Remote Entry System (SKREES)

and the Programmable Communication Interface

(PCI) bus network should be diagnosed using a

DRBIIItscan tool. The DRBIIItwill allow confirma-

tion that the PCI bus is functional, that the Sentry

Key Remote Entry Module (SKREEM) is placing the

proper messages on the PCI bus, and that the Pow-

ertrain Control Module (PCM) is receiving the PCI

bus messages. Refer to the proper Body Diagnostic

Procedures information, and Wiring Diagrams for

complete circuit descriptions and diagrams.

(1) Check the fuses in the Integrated Power Mod-

ule (IPM). If OK, go to Step 2. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(2) Disconnect and isolate the battery negative

remote cable from the remote terminal. Unplug the

wire harness connector at the SKREEM. Check for

continuity between the ground circuit cavity of the

SKREEM wire harness connector and a good ground.

There should be continuity. If OK, go to Step 3. If not

OK, repair the open circuit to ground as required.

(3) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

SKREEM wire harness connector. If OK, go to Step

4. If not OK, repair the open circuit to the fuse in the

IPM as required.

(4) Turn the ignition switch to the ON position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the SKREEM wire

harness connector. If OK, use a DRBIIItscan tool

and the proper Body Diagnostic Procedures informa-

tion to complete the diagnosis of the SKREES. If not

OK, repair the open circuit to the fuse in the IPM as

required.

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. Using a

DRBIIItscan tool. Refer to the proper Body Diagnos-

tic Procedures information for test procedures.

HOOD AJAR SWITCH -

EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a small flat blade screwdriver, pry trig-

ger switch from the bracket on the left fender well.

(3) Disconnect the hood ajar switch from the wire

connector and remove from vehicle.

INSTALLATION

(1) Connect the hood ajar switch to the wire conec-

tor.

(2) Press the hood ajar switch into position on the

bracket located on the left inner fender well.

(3) Reconnect the battery negative cable.

(4) Close the hood and check for proper operation.

SENTRY KEY REMOTE ENTRY

MODULE

DESCRIPTION

The Sentry Key Remote Entry Module (SKREEM)

performs the functions of the Sentry Key Immobilizer

Module (SKIM), Remote Keyless Entry (RKE) Mod-

ule, and the Tire Pressure Monitoring (TPM) System

(previously part of the Electronic Vehicle Information

Center (EVIC).

The SKREEM is located in the same location as

the SKIM was and is mounted the same way. It looks

identical, but has added capabilities.

SENTRY KEY IMMOBILIZER

The Sentry Key Immobilizer System (SKIS)

authenticates an electronically coded Transponder

Key placed into the ignition and sends a valid/invalid

key message to the Powertrain Control Module

(PCM) based upon the results. The ªVALID/INVALID

KEYº message communication is performed using a

rolling code algorithm via the Programmable Com-

munication Interface (PCI) data bus. A ªVALID KEYº

RSVEHICLE THEFT SECURITY8Q-3

VEHICLE THEFT SECURITY (Continued)

Page 702 of 2585

WIPER MODULE

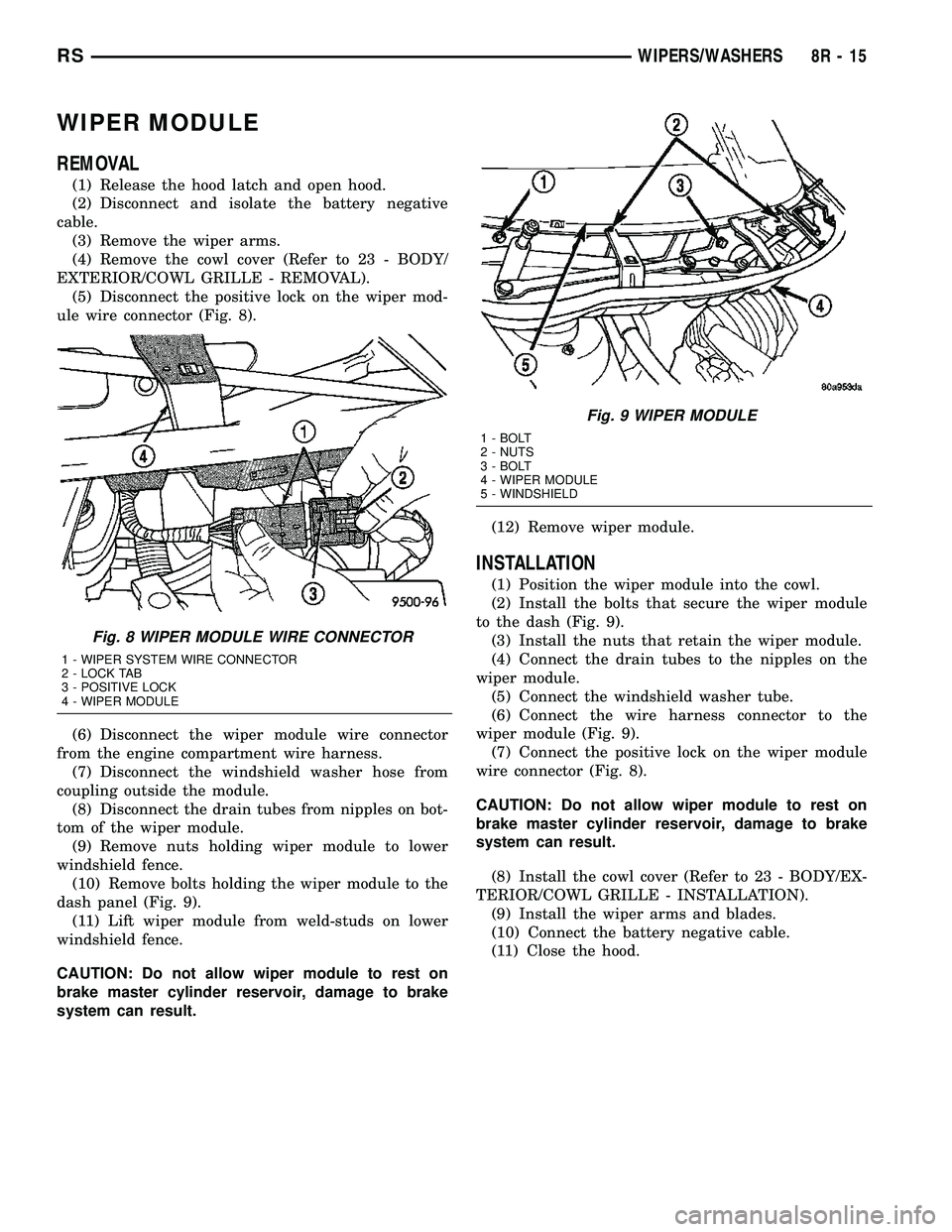

REMOVAL

(1) Release the hood latch and open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the wiper arms.

(4) Remove the cowl cover (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL).

(5) Disconnect the positive lock on the wiper mod-

ule wire connector (Fig. 8).

(6) Disconnect the wiper module wire connector

from the engine compartment wire harness.

(7) Disconnect the windshield washer hose from

coupling outside the module.

(8) Disconnect the drain tubes from nipples on bot-

tom of the wiper module.

(9) Remove nuts holding wiper module to lower

windshield fence.

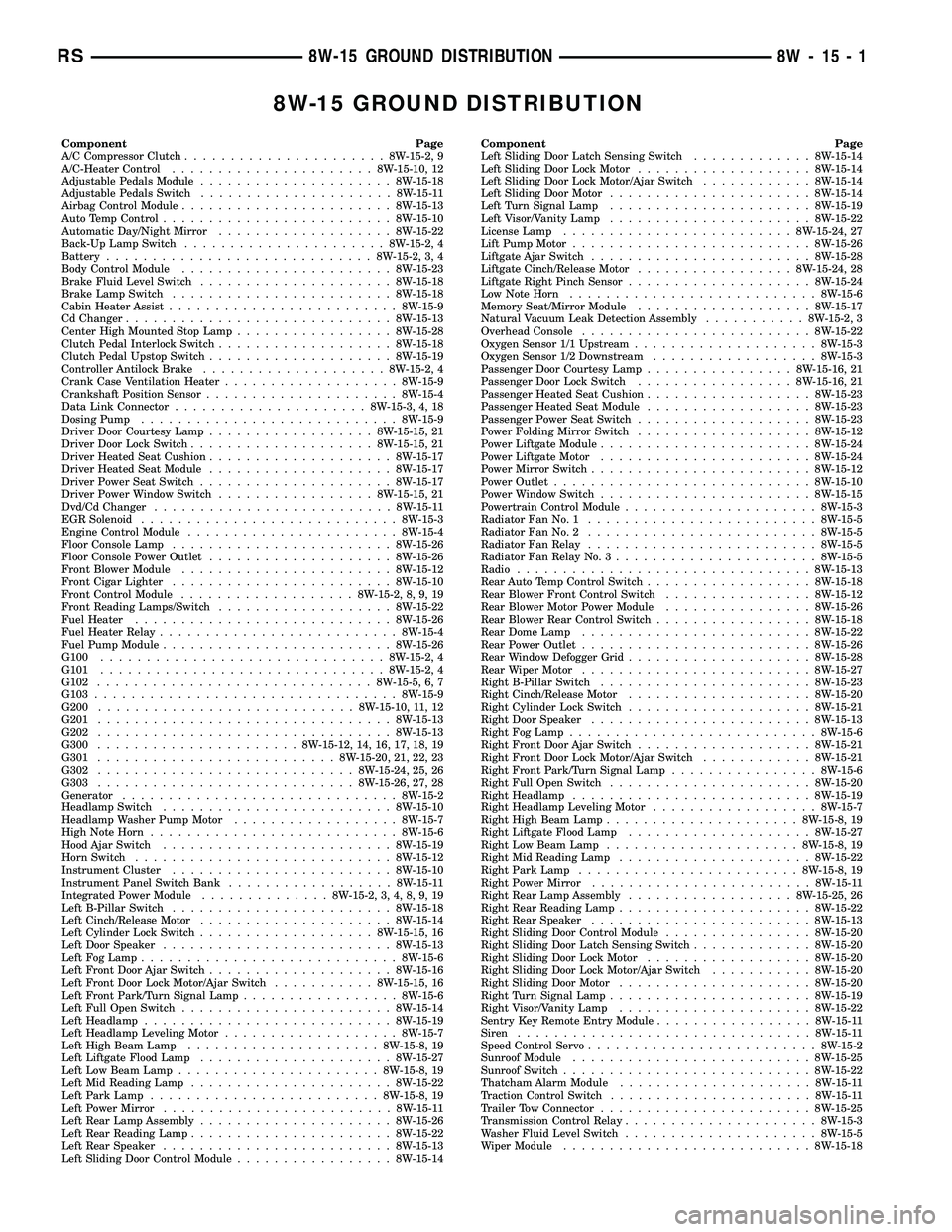

(10) Remove bolts holding the wiper module to the

dash panel (Fig. 9).

(11) Lift wiper module from weld-studs on lower

windshield fence.

CAUTION: Do not allow wiper module to rest on

brake master cylinder reservoir, damage to brake

system can result.(12) Remove wiper module.

INSTALLATION

(1) Position the wiper module into the cowl.

(2) Install the bolts that secure the wiper module

to the dash (Fig. 9).

(3) Install the nuts that retain the wiper module.

(4) Connect the drain tubes to the nipples on the

wiper module.

(5) Connect the windshield washer tube.

(6) Connect the wire harness connector to the

wiper module (Fig. 9).

(7) Connect the positive lock on the wiper module

wire connector (Fig. 8).

CAUTION: Do not allow wiper module to rest on

brake master cylinder reservoir, damage to brake

system can result.

(8) Install the cowl cover (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION).

(9) Install the wiper arms and blades.

(10) Connect the battery negative cable.

(11) Close the hood.

Fig. 8 WIPER MODULE WIRE CONNECTOR

1 - WIPER SYSTEM WIRE CONNECTOR

2 - LOCK TAB

3 - POSITIVE LOCK

4 - WIPER MODULE

Fig. 9 WIPER MODULE

1 - BOLT

2 - NUTS

3 - BOLT

4 - WIPER MODULE

5 - WINDSHIELD

RSWIPERS/WASHERS8R-15

Page 722 of 2585

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch................. 8W-42

A/C Compressor Clutch Relay............ 8W-42

A/C Pressure Sensor................... 8W-42

A/C-Heater Control.................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Accessory Relay....................... 8W-10

Adjustable Pedals Module............... 8W-30

Adjustable Pedals Motor................ 8W-30

Adjustable Pedals Relay................ 8W-30

Adjustable Pedals Sensor............... 8W-30

Adjustable Pedals Switch............... 8W-30

Airbags............................. 8W-43

Airbag Control Module................. 8W-43

Airbag Squibs........................ 8W-43

Ambient Temperature Sensor............ 8W-49

Antenna............................ 8W-47

ATC Remote Sensor.................... 8W-42

Auto Shut Down Relay................. 8W-30

Auto Temp Control.................... 8W-42

Automatic Day/Night Mirror............. 8W-49

B-Pillar Switches...................... 8W-61

Back-Up Lamp Switch.................. 8W-51

Battery............................. 8W-20

Battery Temperature Sensor............. 8W-20

Blend Door Actuators.................. 8W-42

Blower Motors........................ 8W-42

Blower Motor Relays................... 8W-42

Blower Motor Resistor.................. 8W-42

Body Control Module................... 8W-45

Boost Pressure Sensor.................. 8W-30

Brake Fluid Level Switch............... 8W-40

Brake Lamp Switch................. 8W-30, 51

Brake Transmission Shift Interlock

Solenoid........................... 8W-31

Cabin Heater Assist................... 8W-30

Camshaft Position Sensor............... 8W-30

CD Changer......................... 8W-47

Center High Mounted Stop Lamp......... 8W-51

Cinch/Release Motors.................. 8W-61

Clockspring................. 8W-33, 41, 43, 47

Clutch Pedal Interlock Switch......... 8W-10, 30

Clutch Pedal Upstop Switch............. 8W-30

Controller Antilock Brake............... 8W-35

Crank Case Ventilation Heater........... 8W-30

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switches................. 8W-39

Data Link Connector................... 8W-18

Defogger Relay....................... 8W-48

Door Ajar Switches.................... 8W-39

Door Courtesy Lamps.................. 8W-44

Door Lock Switches.................... 8W-61

Dosing Pump......................... 8W-30Component Page

DVD Screen.......................... 8W-47

DVD/CD Changer..................... 8W-47

ECM/PCM Relay...................... 8W-30

EGR Solenoid........................ 8W-30

Electronic Control Unit................. 8W-64

Engine Control Module................. 8W-30

Engine Coolant Temp Sensor............. 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Oil Pressure Switch.............. 8W-30

EVAP/Purge Solenoid.................. 8W-30

Evaporator Temperature Sensor.......... 8W-42

Floor Console Lamp................... 8W-44

Floor Console Power Outlet.............. 8W-41

Fog Lamps.......................... 8W-50

Folding Mirror Relay................... 8W-62

Front Blower Module.................. 8W-42

Front Cigar Lighter.................... 8W-41

Front Control Module.................. 8W-10

Front Fog Lamp Relay................. 8W-50

Front Reading Lamps/Switch............ 8W-44

Front Wiper High/Low Relay............. 8W-53

Front Wiper On/Off Relay............... 8W-53

Fuel Heater.......................... 8W-30

Fuel Heater Relay..................... 8W-30

Fuel Injectors........................ 8W-30

Fuel Pressure Sensor.................. 8W-30

Fuel Pressure Solenoid................. 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Relay...................... 8W-30

Full Open Switches.................... 8W-61

Fuselink............................ 8W-10

Fuses............................... 8W-10

Generator........................... 8W-20

Glow Plug Relay...................... 8W-30

Glow Plugs.......................... 8W-30

Grounds............................ 8W-15

Headlamp Leveling Motors.............. 8W-50

Headlamp Switch..................... 8W-50

Headlamp Washer Pump Motor.......... 8W-53

Headlamp Washer Relay................ 8W-53

Headlamps.......................... 8W-50

Heated Seat Backs.................... 8W-63

Heated Seat Cushions.................. 8W-63

Heated Seat Modules.................. 8W-63

High Beam Lamps..................... 8W-50

High Note Horn....................... 8W-41

Hood Ajar Switch..................... 8W-39

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Coil......................... 8W-30

Ignition Switch....................... 8W-10

RS8W-02 COMPONENT INDEX8W-02-1

Page 792 of 2585

8W-15 GROUND DISTRIBUTION

Component Page

A/C Compressor Clutch......................8W-15-2, 9

A/C-Heater Control......................8W-15-10, 12

Adjustable Pedals Module.....................8W-15-18

Adjustable Pedals Switch.....................8W-15-11

Airbag Control Module.......................8W-15-13

Auto Temp Control.........................8W-15-10

Automatic Day/Night Mirror...................8W-15-22

Back-Up Lamp Switch......................8W-15-2, 4

Battery.............................8W-15-2, 3, 4

Body Control Module.......................8W-15-23

Brake Fluid Level Switch.....................8W-15-18

Brake Lamp Switch........................8W-15-18

Cabin Heater Assist.........................8W-15-9

Cd Changer.............................8W-15-13

Center High Mounted Stop Lamp.................8W-15-28

Clutch Pedal Interlock Switch...................8W-15-18

Clutch Pedal Upstop Switch....................8W-15-19

Controller Antilock Brake....................8W-15-2, 4

Crank Case Ventilation Heater...................8W-15-9

Crankshaft Position Sensor.....................8W-15-4

Data Link Connector.....................8W-15-3, 4, 18

Dosing Pump............................8W-15-9

Driver Door Courtesy Lamp..................8W-15-15, 21

Driver Door Lock Switch....................8W-15-15, 21

Driver Heated Seat Cushion....................8W-15-17

Driver Heated Seat Module....................8W-15-17

Driver Power Seat Switch.....................8W-15-17

Driver Power Window Switch.................8W-15-15, 21

Dvd/Cd Changer..........................8W-15-11

EGR Solenoid............................8W-15-3

Engine Control Module.......................8W-15-4

Floor Console Lamp........................8W-15-26

Floor Console Power Outlet....................8W-15-26

Front Blower Module.......................8W-15-12

Front Cigar Lighter........................8W-15-10

Front Control Module...................8W-15-2, 8, 9, 19

Front Reading Lamps/Switch...................8W-15-22

Fuel Heater............................8W-15-26

Fuel Heater Relay..........................8W-15-4

Fuel Pump Module.........................8W-15-26

G100...............................8W-15-2, 4

G101...............................8W-15-2, 4

G102..............................8W-15-5, 6, 7

G103.................................8W-15-9

G200............................8W-15-10, 11, 12

G201................................8W-15-13

G202................................8W-15-13

G300......................8W-15-12, 14, 16, 17, 18, 19

G301..........................8W-15-20, 21, 22, 23

G302............................8W-15-24, 25, 26

G303............................8W-15-26, 27, 28

Generator..............................8W-15-2

Headlamp Switch.........................8W-15-10

Headlamp Washer Pump Motor..................8W-15-7

High Note Horn...........................8W-15-6

Hood Ajar Switch.........................8W-15-19

Horn Switch............................8W-15-12

Instrument Cluster........................8W-15-10

Instrument Panel Switch Bank..................8W-15-11

Integrated Power Module..............8W-15-2, 3, 4, 8, 9, 19

Left B-Pillar Switch........................8W-15-18

Left Cinch/Release Motor.....................8W-15-14

Left Cylinder Lock Switch...................8W-15-15, 16

Left Door Speaker.........................8W-15-13

Left Fog Lamp............................8W-15-6

Left Front Door Ajar Switch....................8W-15-16

Left Front Door Lock Motor/Ajar Switch...........8W-15-15, 16

Left Front Park/Turn Signal Lamp.................8W-15-6

Left Full Open Switch.......................8W-15-14

Left Headlamp...........................8W-15-19

Left Headlamp Leveling Motor...................8W-15-7

Left High Beam Lamp.....................8W-15-8, 19

Left Liftgate Flood Lamp.....................8W-15-27

Left Low Beam Lamp......................8W-15-8, 19

Left Mid Reading Lamp......................8W-15-22

Left Park Lamp.........................8W-15-8, 19

Left Power Mirror.........................8W-15-11

Left Rear Lamp Assembly.....................8W-15-26

Left Rear Reading Lamp......................8W-15-22

Left Rear Speaker.........................8W-15-13

Left Sliding Door Control Module.................8W-15-14Component Page

Left Sliding Door Latch Sensing Switch.............8W-15-14

Left Sliding Door Lock Motor...................8W-15-14

Left Sliding Door Lock Motor/Ajar Switch............8W-15-14

Left Sliding Door Motor......................8W-15-14

Left Turn Signal Lamp......................8W-15-19

Left Visor/Vanity Lamp......................8W-15-22

License Lamp.........................8W-15-24, 27

Lift Pump Motor..........................8W-15-26

Liftgate Ajar Switch........................8W-15-28

Liftgate Cinch/Release Motor.................8W-15-24, 28

Liftgate Right Pinch Sensor....................8W-15-24

Low Note Horn...........................8W-15-6

Memory Seat/Mirror Module...................8W-15-17

Natural Vacuum Leak Detection Assembly...........8W-15-2, 3

Overhead Console.........................8W-15-22

Oxygen Sensor 1/1 Upstream....................8W-15-3

Oxygen Sensor 1/2 Downstream..................8W-15-3

Passenger Door Courtesy Lamp................8W-15-16, 21

Passenger Door Lock Switch.................8W-15-16, 21

Passenger Heated Seat Cushion..................8W-15-23

Passenger Heated Seat Module..................8W-15-23

Passenger Power Seat Switch...................8W-15-23

Power Folding Mirror Switch...................8W-15-12

Power Liftgate Module.......................8W-15-24

Power Liftgate Motor.......................8W-15-24

Power Mirror Switch........................8W-15-12

Power Outlet............................8W-15-10

Power Window Switch.......................8W-15-15

Powertrain Control Module.....................8W-15-3

Radiator Fan No. 1.........................8W-15-5

Radiator Fan No. 2.........................8W-15-5

Radiator Fan Relay.........................8W-15-5

Radiator Fan Relay No. 3......................8W-15-5

Radio................................8W-15-13

Rear Auto Temp Control Switch..................8W-15-18

Rear Blower Front Control Switch................8W-15-12

Rear Blower Motor Power Module................8W-15-26

Rear Blower Rear Control Switch.................8W-15-18

Rear Dome Lamp.........................8W-15-22

Rear Power Outlet.........................8W-15-26

Rear Window Defogger Grid....................8W-15-28

Rear Wiper Motor.........................8W-15-27

Right B-Pillar Switch.......................8W-15-23

Right Cinch/Release Motor....................8W-15-20

Right Cylinder Lock Switch....................8W-15-21

Right Door Speaker........................8W-15-13

Right Fog Lamp...........................8W-15-6

Right Front Door Ajar Switch...................8W-15-21

Right Front Door Lock Motor/Ajar Switch............8W-15-21

Right Front Park/Turn Signal Lamp................8W-15-6

Right Full Open Switch......................8W-15-20

Right Headlamp..........................8W-15-19

Right Headlamp Leveling Motor..................8W-15-7

Right High Beam Lamp.....................8W-15-8, 19

Right Liftgate Flood Lamp....................8W-15-27

Right Low Beam Lamp.....................8W-15-8, 19

Right Mid Reading Lamp.....................8W-15-22

Right Park Lamp........................8W-15-8, 19

Right Power Mirror........................8W-15-11

Right Rear Lamp Assembly..................8W-15-25, 26

Right Rear Reading Lamp.....................8W-15-22

Right Rear Speaker........................8W-15-13

Right Sliding Door Control Module................8W-15-20

Right Sliding Door Latch Sensing Switch.............8W-15-20

Right Sliding Door Lock Motor..................8W-15-20

Right Sliding Door Lock Motor/Ajar Switch...........8W-15-20

Right Sliding Door Motor.....................8W-15-20

Right Turn Signal Lamp......................8W-15-19

Right Visor/Vanity Lamp.....................8W-15-22

Sentry Key Remote Entry Module.................8W-15-11

Siren................................8W-15-11

Speed Control Servo.........................8W-15-2

Sunroof Module..........................8W-15-25

Sunroof Switch...........................8W-15-22

Thatcham Alarm Module.....................8W-15-11

Traction Control Switch......................8W-15-11

Trailer Tow Connector.......................8W-15-25

Transmission Control Relay.....................8W-15-3

Washer Fluid Level Switch.....................8W-15-5

Wiper Module...........................8W-15-18

RS8W-15 GROUND DISTRIBUTION8W-15-1

Page 1098 of 2585

Component Page

Floor Console Lamp................. 8W-80-72

Floor Console Power Outlet........... 8W-80-72

Front Blower Module C1 (ATC)........ 8W-80-73

Front Blower Module C2 (ATC)........ 8W-80-73

Front Cigar Lighter................. 8W-80-73

Front Control Module................ 8W-80-74

Front Intrusion Sensor (United

Kingdom)....................... 8W-80-75

Front Reading Lamps/Switch.......... 8W-80-75

Fuel Heater (Diesel)................. 8W-80-75

Fuel Injector No. 1 (2.4L/3.3L/3.8L)..... 8W-80-75

Fuel Injector No. 1 (Diesel)............ 8W-80-75

Fuel Injector No. 2 (2.4L/3.3L/3.8L)..... 8W-80-76

Fuel Injector No. 2 (Diesel)............ 8W-80-76

Fuel Injector No. 3 (2.4L/3.3L/3.8L)..... 8W-80-76

Fuel Injector No. 3 (Diesel)............ 8W-80-76

Fuel Injector No. 4 (2.4L/3.3L/3.8L)..... 8W-80-77

Fuel Injector No. 4 (Diesel)............ 8W-80-77

Fuel Injector No. 5 (3.3L/3.8L)......... 8W-80-77

Fuel Injector No. 6 (3.3L/3.8L)......... 8W-80-77

Fuel Pressure Sensor (Diesel).......... 8W-80-78

Fuel Pressure Solenoid (Diesel)........ 8W-80-78

Fuel Pump Module.................. 8W-80-78

Generator......................... 8W-80-78

Glow Plug Relay (Diesel)............. 8W-80-79

Headlamp Switch................... 8W-80-79

Headlamp Washer Pump Motor (Export) . 8W-80-79

High Note Horn.................... 8W-80-79

Hood Ajar Switch (Export)............ 8W-80-80

Idle Air Control Motor (Gas)........... 8W-80-80

Ignition Coil (2.4L).................. 8W-80-80

Ignition Coil (3.3L/3.8L).............. 8W-80-80

Ignition Switch..................... 8W-80-80

Inlet Air Temperature Sensor.......... 8W-80-81

Input Speed Sensor................. 8W-80-81

Instrument Cluster.................. 8W-80-81

Instrument Panel Switch Bank (Heated

Seats).......................... 8W-80-81

Instrument Panel Switch Bank (Except Heated

Seats).......................... 8W-80-82

Integrated Power Module C1.......... 8W-80-82

Integrated Power Module C2.......... 8W-80-83

Integrated Power Module C3.......... 8W-80-83

Integrated Power Module C4.......... 8W-80-84

Integrated Power Module C5.......... 8W-80-84

Integrated Power Module C6.......... 8W-80-84

Integrated Power Module C7.......... 8W-80-85

Integrated Power Module C8.......... 8W-80-85

Integrated Power Module C9.......... 8W-80-86

Knock Sensor (2.4L)................. 8W-80-86

Knock Sensor (3.3L/3.8L ABS Except

Export)......................... 8W-80-86

Left B-Pillar Switch (Power Sliding

Door).......................... 8W-80-86Component Page

Left Cinch/Release Motor (Power Sliding

Door).......................... 8W-80-87

Left Cylinder Lock Switch............ 8W-80-87

Left Door Speaker (Highline).......... 8W-80-87

Left Door Speaker (Lowline)........... 8W-80-87

Left Fog Lamp (Except Export)........ 8W-80-87

Left Fog Lamp (Export).............. 8W-80-88

Left Front Door Ajar Switch (Base)..... 8W-80-88

Left Front Door Lock Motor/Ajar Switch (Except

Base).......................... 8W-80-88

Left Front Impact Sensor (Except

Export)......................... 8W-80-88

Left Front Park/Turn Signal Lamp (Except

Export)......................... 8W-80-89

Left Front Wheel Speed Sensor........ 8W-80-89

Left Full Open Switch (Power Sliding

Door).......................... 8W-80-89

Left Headlamp (Except Export)........ 8W-80-89

Left Headlamp Leveling Motor (Export) . . 8W-80-90

Left High Beam Lamp (Export)........ 8W-80-90

Left Instrument Panel Speaker........ 8W-80-90

Left Liftgate Flood Lamp (Power

Liftgate)........................ 8W-80-90

Left Low Beam Lamp (Export)......... 8W-80-90

Left Mid Reading Lamp (Premium/

Luxury)........................ 8W-80-91

Left Park Lamp (Export)............. 8W-80-91

Left Power Mirror................... 8W-80-91

Left Rear Lamp Assembly............ 8W-80-91

Left Rear Pillar Speaker.............. 8W-80-92

Left Rear Reading Lamp (Luxury)...... 8W-80-92

Left Rear Speaker (Lowline)........... 8W-80-92

Left Rear Speaker (Highline).......... 8W-80-92

Left Rear Vent Motor................ 8W-80-92

Left Rear Wheel Speed Sensor......... 8W-80-93

Left Remote Radio Switch............ 8W-80-93

Left Repeater Lamp (Export).......... 8W-80-93

Left Seat Airbag.................... 8W-80-93

Left Side Impact Sensor 1 (Premium

ORC).......................... 8W-80-94

Left Sliding Door Control Module C1 (Power Sliding

Door).......................... 8W-80-94

Left Sliding Door Control Module C2 (Power Sliding

Door).......................... 8W-80-94

Left Sliding Door Latch Sensing Switch (Power

Sliding Door).................... 8W-80-95

Left Sliding Door Lock Motor (Power Sliding

Door).......................... 8W-80-95

Left Sliding Door Lock Motor/Ajar Switch (Manual

Sliding Door).................... 8W-80-95

Left Sliding Door Motor (Power Sliding

Door).......................... 8W-80-95

Left Speed Control Switch............ 8W-80-96

Left Turn Signal Lamp (Export)........ 8W-80-96

RS8W-80 CONNECTOR PIN-OUTS8W-80-3

Page 1434 of 2585

OIL

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE OIL AND

FILTER CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. (Refer to

LUBRICATION & MAINTENANCE/MAINTE-

NANCE SCHEDULES - DESCRIPTION)

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

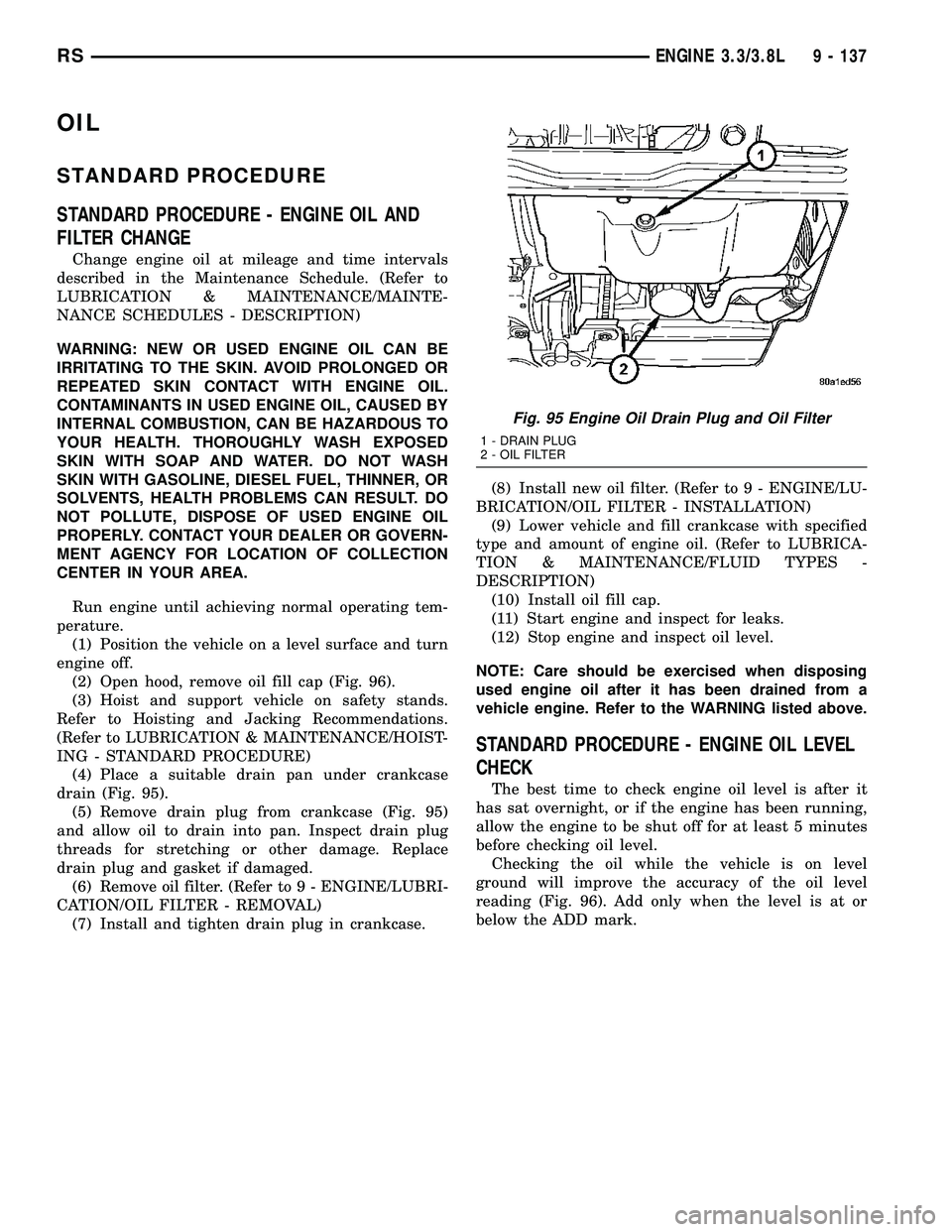

(2) Open hood, remove oil fill cap (Fig. 96).

(3) Hoist and support vehicle on safety stands.

Refer to Hoisting and Jacking Recommendations.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE)

(4) Place a suitable drain pan under crankcase

drain (Fig. 95).

(5) Remove drain plug from crankcase (Fig. 95)

and allow oil to drain into pan. Inspect drain plug

threads for stretching or other damage. Replace

drain plug and gasket if damaged.

(6) Remove oil filter. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL)

(7) Install and tighten drain plug in crankcase.(8) Install new oil filter. (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION)

(9) Lower vehicle and fill crankcase with specified

type and amount of engine oil. (Refer to LUBRICA-

TION & MAINTENANCE/FLUID TYPES -

DESCRIPTION)

(10) Install oil fill cap.

(11) Start engine and inspect for leaks.

(12) Stop engine and inspect oil level.

NOTE: Care should be exercised when disposing

used engine oil after it has been drained from a

vehicle engine. Refer to the WARNING listed above.

STANDARD PROCEDURE - ENGINE OIL LEVEL

CHECK

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,

allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading (Fig. 96). Add only when the level is at or

below the ADD mark.

Fig. 95 Engine Oil Drain Plug and Oil Filter

1 - DRAIN PLUG

2 - OIL FILTER

RSENGINE 3.3/3.8L9 - 137

Page 1496 of 2585

FRAME & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE...............1

FRONT FASCIA

REMOVAL.............................1

INSTALLATION..........................1

FRONT BUMPER REINFORCEMENT

REMOVAL.............................2

INSTALLATION..........................2

REAR FASCIA

REMOVAL.............................2

INSTALLATION..........................2

REAR BUMPER REINFORCEMENT

REMOVAL.............................3

INSTALLATION..........................3

REAR FASCIA - SCUFF PAD

REMOVAL.............................3INSTALLATION..........................4

FRAME

SPECIFICATIONS

FRAME DIMENSIONS...................4

SPECIFICATIONS - TORQUE.............9

FRONT CRADLE CROSSMEMBER

DESCRIPTION

DESCRIPTION - FRONT CRADLE

CROSSMEMBER.......................9

DESCRIPTION - FRONT CRADLE

CROSSMEMBER THREAD REPAIR.........9

REMOVAL.............................10

INSTALLATION.........................11

FRONT CROSSMEMBER MOUNT BUSHINGS

REMOVAL.............................12

INSTALLATION.........................12

BUMPERS

SPECIFICATIONS - TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front bumper reinforcement attaching nut 54 40 Ð

Rear bumper reinforcement attaching nut 27 20 Ð

FRONT FASCIA

REMOVAL

(1) Release hood latch and open hood.

(2) Remove the headlamp assemblies (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP - REMOVAL).

(3) Hoist vehicle and support with safety stands.

(4) Remove the five bolts attaching bottom of fas-

cia/air dam to radiator closure panel.

(5) Remove front wheels.

(6) Remove front wheelhouse splash shields fasten-

ers as necessary to gain access to bolts attaching

front fascia to fender. (Refer to 23 - BODY/EXTERI-

OR/ WHEELHOUSE SPLASH SHIELD -

REMOVAL).

(7) Remove the two bolts and two nuts attaching

fascia to the front fenders (Fig. 1).

(8) Disconnect fog lamp wire connectors, if neces-

sary.

(9) Lower vehicle.(10) Remove two bolts attaching the upper grille

support to the headlamp mounting panel at each side

of the grille.

(11) Remove bumper fascia from vehicle.

INSTALLATION

(1) Position front bumper fascia on vehicle.

(2) Install the two bolts attaching fascia to head-

lamp mounting panel at each side of grille.

(3) Hoist vehicle and support with safety stands.

(4) Install the two bolts and two nuts attaching

fascia to the front fenders (Fig. 1). The fascia should

be flush to fender.

(5) Install front wheelhouse splash shields fasten-

ers. (Refer to 23 - BODY/EXTERIOR/ WHEEL-

HOUSE SPLASH SHIELD - INSTALLATION).

(6) Install front wheels.

(7) Connect fog lamp wire connectors, if necessary.

(8) Install the five bolts attaching bottom of fascia

to radiator closure panel.

(9) Lower the vehicle.

RSFRAME & BUMPERS13-1

Page 1596 of 2585

(2) Align routing clip located toward center of sup-

ply hose with hole in bracket on cylinder head cover

and push into place (Fig. 21).

(3) Install supply hose onto reservoir (Fig. 21).

Slide the hose clamp into position on fluid reservoir

and attach it.Be sure hose clamp in installed

past bead on fluid reservoir fitting.

(4) Fill and bleed power steering system using

Power Steering Pump Initial Operation Procedure.

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE)

(5) Inspect system for leaks.

RESERVOIR - POWER

STEERING FLUID

DESCRIPTION

DESCRIPTION - 2.4L/3.3L/3.8L ENGINE

All vehicles use a remote mounted power steering

fluid reservoir. The power steering fluid reservoir is

mounted to the engine near the battery (Fig. 24).

DESCRIPTION - 2.5L DIESEL

All vehicles use a remote mounted power steering

fluid reservoir. The power steering fluid reservoir is

mounted to a bracket on the engine manifold (Fig.

25).

OPERATION

The power steering fluid reservoir stores and sup-

plies power steering fluid for the power steering sys-

tem.

REMOVAL

REMOVAL - 2.4L ENGINE

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Open retainer on side of reservoir and remove

cables from retainer.

(4) Remove clamp attaching supply hose to power

steering fluid reservoir. Disconnect hose from reser-

voir.

(5) Remove bolts and nut securing reservoir in

place.

(6) Remove reservoir.

REMOVAL - 3.3L/3.8L ENGINE

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Open retainer on side of reservoir and remove

cables from retainer.

(4) Remove clamp attaching supply hose to power

steering fluid reservoir. Disconnect hose from reser-

voir (Fig. 21).

(5) Remove clamp attaching return hose to power

steering fluid reservoir. Disconnect hose from reser-

voir (Fig. 21).

(6) Remove bolts and nut securing reservoir in

place (Fig. 21).

(7) Remove reservoir.

REMOVAL - 2.5L DIESEL

(1) Open hood.

(2) Remove engine cover.

(3) Remove the filler cap from remote power steer-

ing fluid reservoir.

(4) Siphon as much fluid as possible from the fluid

reservoir.

(5) Remove the clamp attaching the return hose to

the power steering fluid reservoir. Disconnect hose

from reservoir (Fig. 25).

(6) Remove the clamp attaching the supply hose to

the power steering fluid reservoir. Disconnect hose

from reservoir (Fig. 25).

(7) Press the tang on the reservoir mounting

bracket retaining the reservoir to the bracket, then

pull upward on reservoir and remove it from the

bracket.

Fig. 24 Power Steering Fluid Reservoir (Typical)

RSPUMP19-51

HOSE - POWER STEERING SUPPLY (Continued)

Page 2123 of 2585

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lifgate stabilizer wedge striker to D-pillar bolts 3 Ð 30

Luggage rack crossbar fasteners 4 Ð 35

Lumbar support handle screw 1 Ð 9

Pivot bolt to the body half of hood hinge 28 21 Ð

Prop assembly to lifgate bolts 28 21 Ð

Rear door glass to regulator bolt 11 8 Ð

Rear door hinge to B-pillar bolt 28 20 Ð

Rear door hinge to door bolt 28 20 Ð

Rear door latch striker 28 20 Ð

Rear latch to sliding door end frame 28 20 Ð

Rear seat back to seat cushion bolt 27 19 Ð

Recliner to seat back frame 12 9 Ð

Seatback frame upper rail 8 Ð 71

Seatback hinge bolt 48 35 Ð

Seatback hinge cover screws 2.3 Ð 20

Shoulder belt turning loop onto height adjuster 39 29 Ð

Side view mirror bolts 10 Ð 85

Sliding door center hinge adjusting bolt 15 Ð 130

Sliding door glass nuts 3.4 Ð 30

Sliding door latch striker 28 21 Ð

Sliding door to roller arm bracket 12 9 Ð

Storage bin track guide to seat riser 3.5 Ð 31

Sunroof opening panel to lifter arm screws 5 44

Sunroof opening panel motor screws 4 35

Sunroof trough bracket to roof bolts 6 53

Sunroof trough to trough bracket bolts 6 53

Sunroof trough bracket bolts 6 53

Support cylinders to liftgate 28 21 Ð

BODY LUBRICATION

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating acomponent, any excess oil or grease should be

removed.LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

23 - 12 BODYRS

BODY (Continued)