brake CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1559 of 2585

(10) Install the coupling onto the intermediate

shaft and install the pinch bolt. Tighten the pinch

bolt to 28 N´m (250 in. lbs.).

(11) Install the cable from the bracket on the col-

umn, then install the pinch side clips.

(12) Reconnect the shift cable at the lever.

(13) Reconnect the wiring harness connectors to

the clockspring, multi-function switch, halo lamp,

SKIM module, ignition switch and BTSI solenoid.

(14) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(15) Install the vibration damper weight.

(16) Install the steering wheel retaining nut.

Tighten the nut to 61 N´m (45 ft. lbs.)

(17) Install the airbag (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(18) Install the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - INSTALLATION).

(19) Install the parking brake handle link.

(20) Install the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

(21) Install the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(22) Install the upper shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - INSTAL-

LATION).

(23) Install the traction off switch.

(24) Install the lower shroud.

SPECIFICATIONS

COLUMN TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Driver Airbag Attaching Bolts 10 Ð 90

Steering Column Coupling

Pinch Bolt28 Ð 250

Steering Column Mounting

Nuts12 Ð 105

Steering Wheel Retaining

Nut61 45 Ð

IGNITION SWITCH

REMOVAL

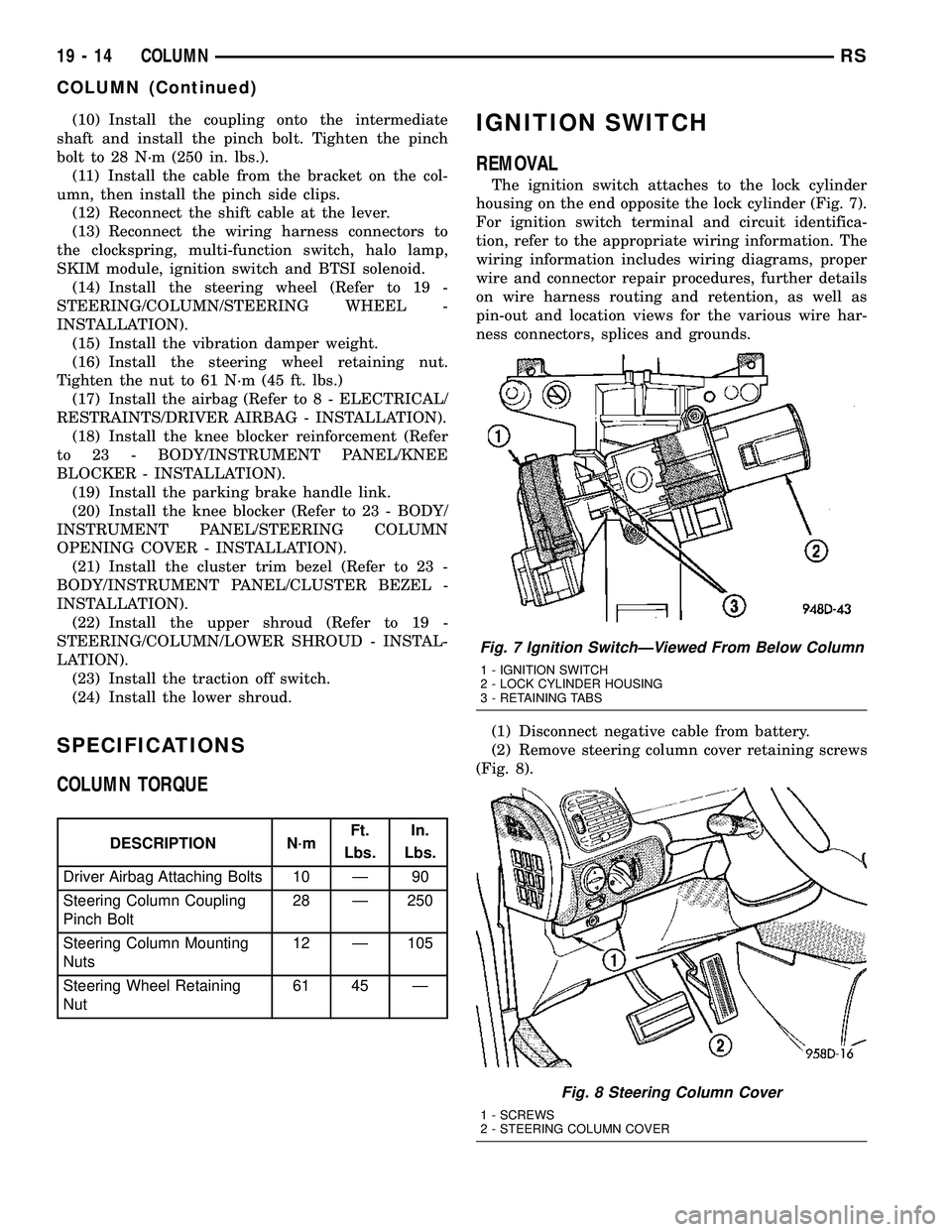

The ignition switch attaches to the lock cylinder

housing on the end opposite the lock cylinder (Fig. 7).

For ignition switch terminal and circuit identifica-

tion, refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

(1) Disconnect negative cable from battery.

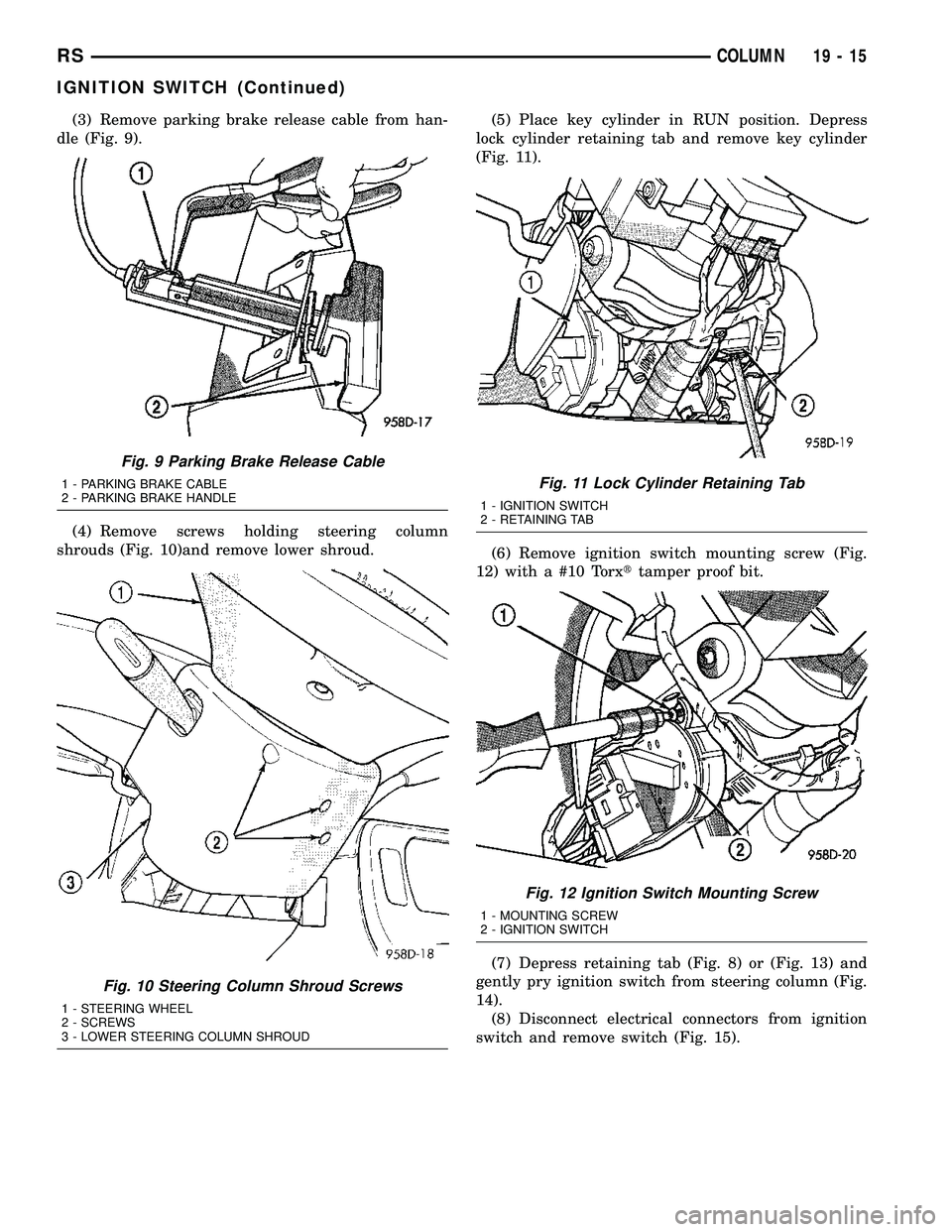

(2) Remove steering column cover retaining screws

(Fig. 8).

Fig. 7 Ignition SwitchÐViewed From Below Column

1 - IGNITION SWITCH

2 - LOCK CYLINDER HOUSING

3 - RETAINING TABS

Fig. 8 Steering Column Cover

1 - SCREWS

2 - STEERING COLUMN COVER

19 - 14 COLUMNRS

COLUMN (Continued)

Page 1560 of 2585

(3) Remove parking brake release cable from han-

dle (Fig. 9).

(4) Remove screws holding steering column

shrouds (Fig. 10)and remove lower shroud.(5) Place key cylinder in RUN position. Depress

lock cylinder retaining tab and remove key cylinder

(Fig. 11).

(6) Remove ignition switch mounting screw (Fig.

12) with a #10 Torxttamper proof bit.

(7) Depress retaining tab (Fig. 8) or (Fig. 13) and

gently pry ignition switch from steering column (Fig.

14).

(8) Disconnect electrical connectors from ignition

switch and remove switch (Fig. 15).

Fig. 9 Parking Brake Release Cable

1 - PARKING BRAKE CABLE

2 - PARKING BRAKE HANDLE

Fig. 10 Steering Column Shroud Screws

1 - STEERING WHEEL

2 - SCREWS

3 - LOWER STEERING COLUMN SHROUD

Fig. 11 Lock Cylinder Retaining Tab

1 - IGNITION SWITCH

2 - RETAINING TAB

Fig. 12 Ignition Switch Mounting Screw

1 - MOUNTING SCREW

2 - IGNITION SWITCH

RSCOLUMN19-15

IGNITION SWITCH (Continued)

Page 1562 of 2585

LOCK CYLINDER HOUSING

DESCRIPTION - IGNITION INTERLOCK

All vehicles equipped with automatic transaxles

have an interlock system. The system prevents shift-

ing the vehicle out of Park unless the ignition lock

cylinder is in the Unlock, Run or Start position. In

addition, the operator cannot rotate the key to the

lock position unless the shifter is in the park posi-

tion. On vehicles equipped with floor shift refer to

the - Transaxle for Automatic Transmission Shifter/

Ignition Interlock.

REMOVAL

NOTE: Before proceeding, review all Steering Col-

umn and Airbag Warnings and Cautions. (Refer to

19 - STEERING/COLUMN - WARNING)(Refer to 8 -

ELECTRICAL/RESTRAINTS - WARNING)

(1) Remove battery ground cable terminal from

battery negative post and isolate.

(2) Under instrument panel, remove silencer panel

below lower steering column cover.

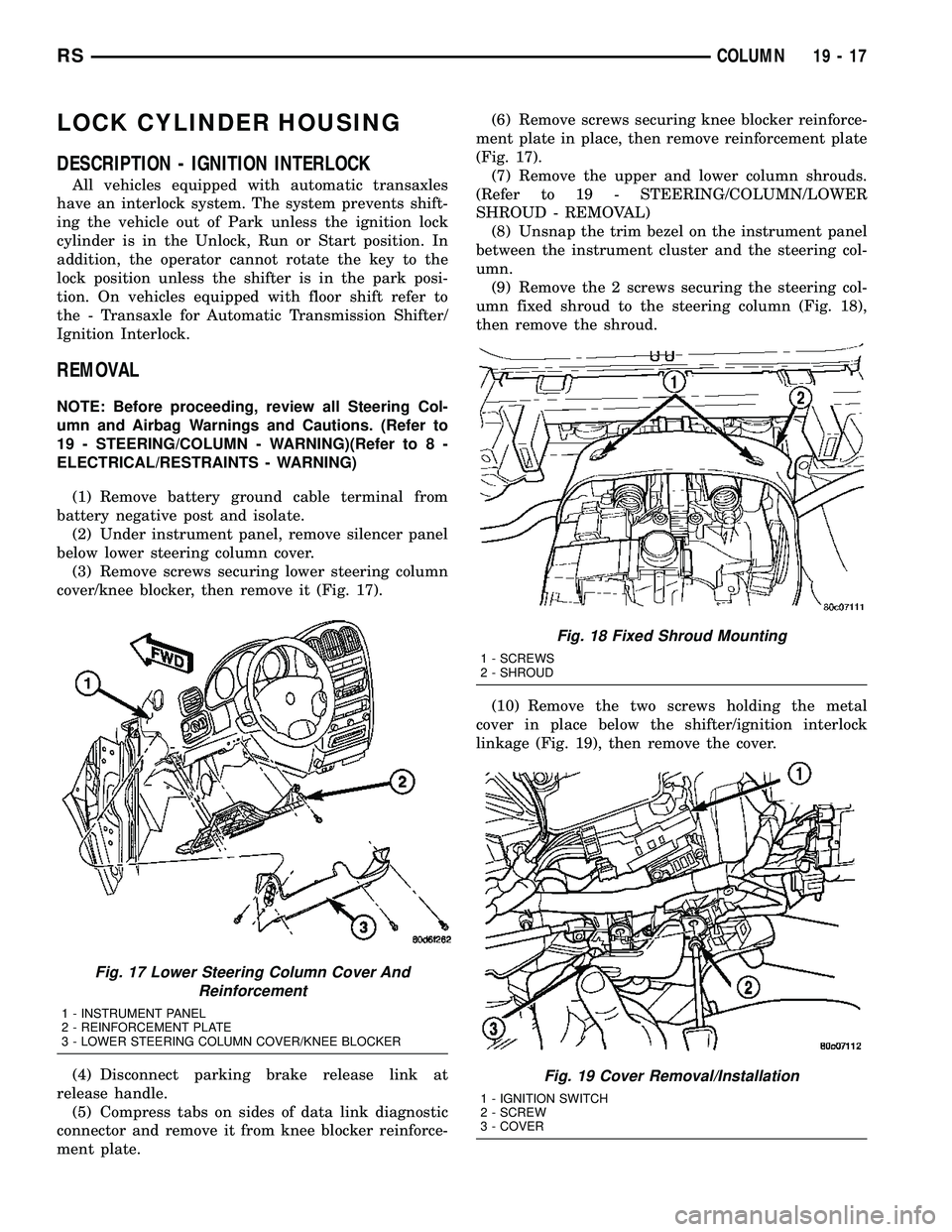

(3) Remove screws securing lower steering column

cover/knee blocker, then remove it (Fig. 17).

(4) Disconnect parking brake release link at

release handle.

(5) Compress tabs on sides of data link diagnostic

connector and remove it from knee blocker reinforce-

ment plate.(6) Remove screws securing knee blocker reinforce-

ment plate in place, then remove reinforcement plate

(Fig. 17).

(7) Remove the upper and lower column shrouds.

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL)

(8) Unsnap the trim bezel on the instrument panel

between the instrument cluster and the steering col-

umn.

(9) Remove the 2 screws securing the steering col-

umn fixed shroud to the steering column (Fig. 18),

then remove the shroud.

(10) Remove the two screws holding the metal

cover in place below the shifter/ignition interlock

linkage (Fig. 19), then remove the cover.

Fig. 17 Lower Steering Column Cover And

Reinforcement

1 - INSTRUMENT PANEL

2 - REINFORCEMENT PLATE

3 - LOWER STEERING COLUMN COVER/KNEE BLOCKER

Fig. 18 Fixed Shroud Mounting

1 - SCREWS

2 - SHROUD

Fig. 19 Cover Removal/Installation

1 - IGNITION SWITCH

2 - SCREW

3 - COVER

RSCOLUMN19-17

Page 1565 of 2585

retaining tab on the lever with the ramp on the link

(Fig. 20), then pushing the two together.

(12) Install the metal cover in place below the

shifter/ignition interlock linkage using the two

screws (Fig. 19).

(13) Install the steering column fixed shroud on

the steering column (Fig. 18) using its 2 mounting

screws.

(14) Install the trim bezel on the instrument panel

above the steering column. The trim bezel is

mounted to the instrument panel using 2 screws (one

on each side of the column) and retaining clips.

(15) Install the lower and upper steering column

shrouds. (Refer to 19 - STEERING/COLUMN/

LOWER SHROUD - INSTALLATION)

(16) Install the knee blocker reinforcement plate

(Fig. 17).

(17) Connect the parking brake release link to the

release handle.

(18) Install the data link diagnostic connector to

the mounting hole in the reinforcement plate.

(19) Install the lower steering column cover/knee

blocker (Fig. 17).

(20) Connect the negative (ground) cable to the

battery terminal.

KEY/LOCK CYLINDER

DESCRIPTION

The lock cylinder is inserted in the end of the

housing opposite the ignition switch.

OPERATION

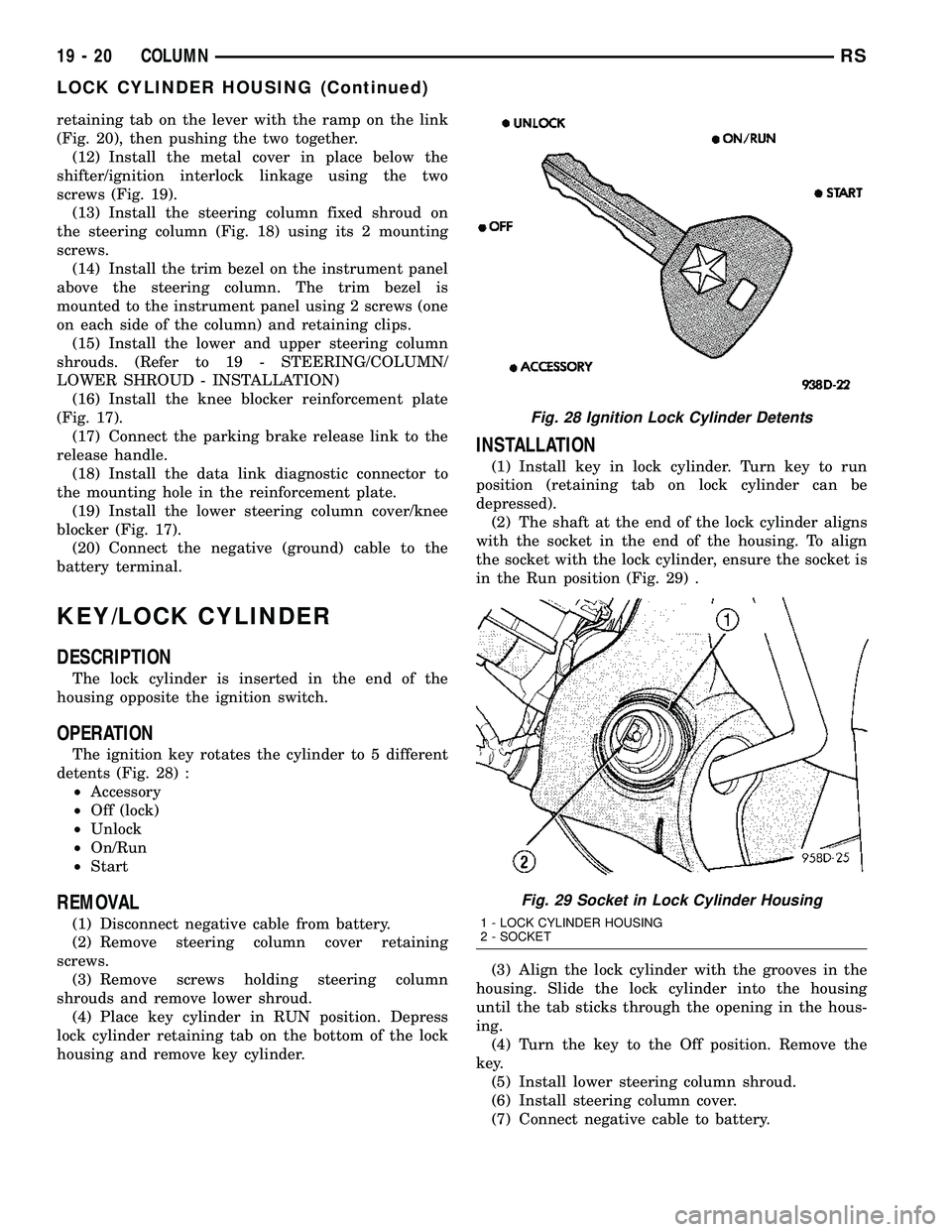

The ignition key rotates the cylinder to 5 different

detents (Fig. 28) :

²Accessory

²Off (lock)

²Unlock

²On/Run

²Start

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove steering column cover retaining

screws.

(3) Remove screws holding steering column

shrouds and remove lower shroud.

(4) Place key cylinder in RUN position. Depress

lock cylinder retaining tab on the bottom of the lock

housing and remove key cylinder.

INSTALLATION

(1) Install key in lock cylinder. Turn key to run

position (retaining tab on lock cylinder can be

depressed).

(2) The shaft at the end of the lock cylinder aligns

with the socket in the end of the housing. To align

the socket with the lock cylinder, ensure the socket is

in the Run position (Fig. 29) .

(3) Align the lock cylinder with the grooves in the

housing. Slide the lock cylinder into the housing

until the tab sticks through the opening in the hous-

ing.

(4) Turn the key to the Off position. Remove the

key.

(5) Install lower steering column shroud.

(6) Install steering column cover.

(7) Connect negative cable to battery.

Fig. 28 Ignition Lock Cylinder Detents

Fig. 29 Socket in Lock Cylinder Housing

1 - LOCK CYLINDER HOUSING

2 - SOCKET

19 - 20 COLUMNRS

LOCK CYLINDER HOUSING (Continued)

Page 1670 of 2585

INSTALLATION

(1) Install gearshift boot to console and secure

with three (3) retaining clips (Fig. 130).

(2) Install gearshift knob (Fig. 129). Orient shift

pattern

1¤4-turn clockwise, press down, and rotate1¤4-

turn counter-clockwise.

(3) Secure gearshift boot to base of knob.

GEARSHIFT CABLE -

CROSSOVER

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating

1¤4-turn clock-wise (Fig. 131).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 132).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

133).

Fig. 131 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 132 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 133 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

RST850 MANUAL TRANSAXLE21-73

GEARSHIFT BOOT (Continued)

Page 1677 of 2585

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

157).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

158).(7) Loosen crossover cable adjustment screw (Fig.

159).

(8) Rock gearshift lever back and forth between

1±2 and 5±R planes. Release lever, allowing shifter

spring to return lever to the neutral position in the

3±4 plane. Place gearshift lever in the 3rd gear posi-

tion.

(9) Torque crossover lever adjustment screw to 8

N´m (70 in. lbs.).No load should be applied to

the shifter lever in any direction (hands off)

while tightening screw.

(10) Verify gearshift lever travel through all gear

ranges with engine off (not running).

(11) Install center console assembly (Fig. 158).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(12) Install cupholder plugs (Fig. 157).

(13) Install gearshift boot to console (Fig. 156).

Secure boot to console with three (3) retainer clips.

(14) Install gearshift knob to gearshift lever (Fig.

155). Orient shift pattern on knob

1¤4-turn clockwise,

push down and rotate1¤4-turn counter-clockwise and

release. Secure boot to knob.

(15) Connect battery negative cable.

Fig. 157 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 158 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 159 Crossover Cable Adjustment Screw

1 - CROSSOVER CABLE

2 - ADJUSTMENT SCREW

21 - 80 T850 MANUAL TRANSAXLERS

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 1678 of 2585

GEARSHIFT CABLE -

SELECTOR

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove gearshift knob by pushing down and

rotating

1¤4-turn clock-wise (Fig. 160).

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 161).(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

162).

(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

163).

Fig. 160 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

Fig. 161 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 162 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 163 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

RST850 MANUAL TRANSAXLE21-81

Page 1685 of 2585

(3) Remove gearshift boot from center console by

disengaging at three (3) retaining clips (Fig. 186).

(4) Apply park brake to allow park brake handle to

clear center console upon removal.

(5) Remove two (2) cupholder bottom plugs (Fig.

187).(6) Remove four (4) center console-to-gearshift

mechanism screws. Remove console assembly (Fig.

188).

(7) Remove center console support bracket (Fig.

189).

Fig. 186 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 187 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 188 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 189 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

21 - 88 T850 MANUAL TRANSAXLERS

GEARSHIFT MECHANISM (Continued)

Page 1686 of 2585

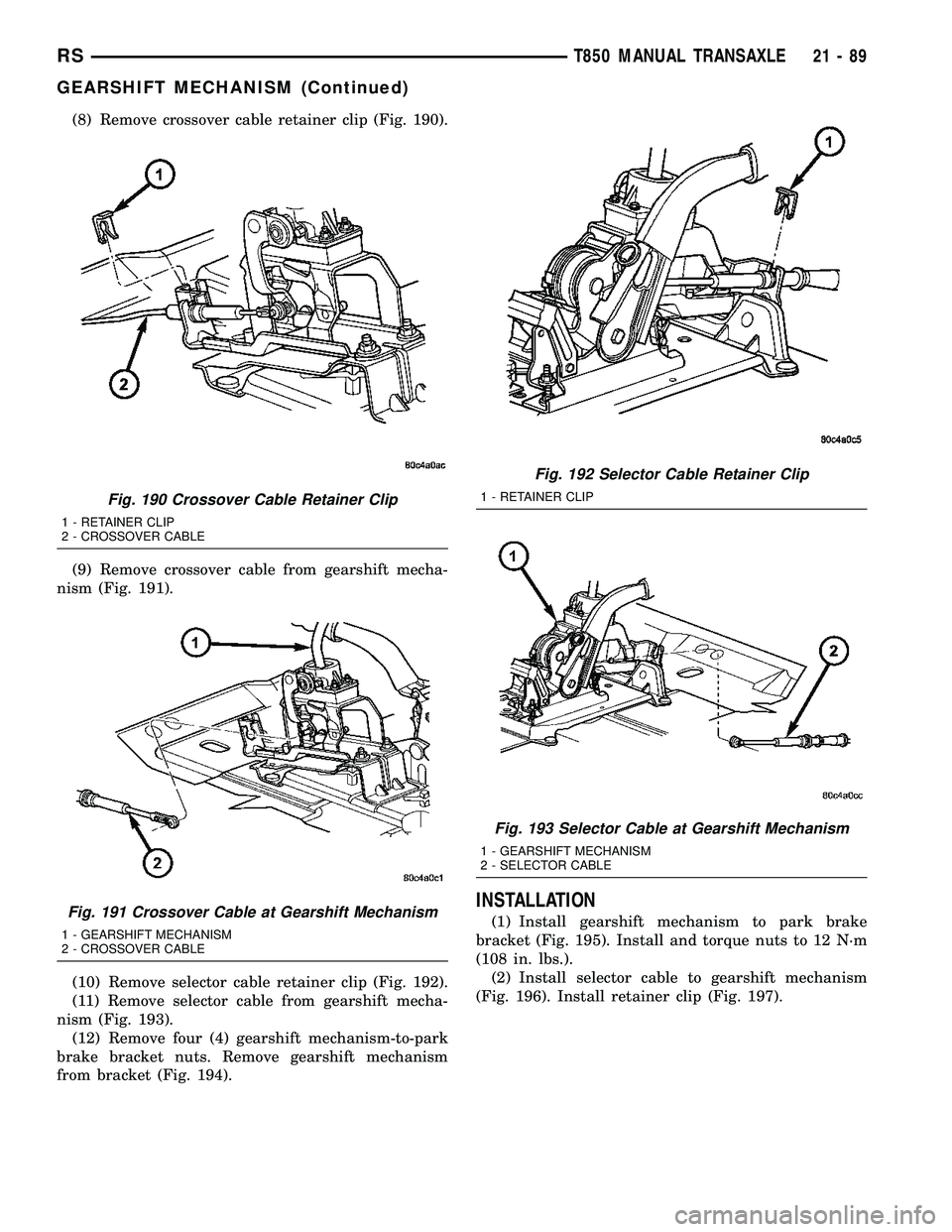

(8) Remove crossover cable retainer clip (Fig. 190).

(9) Remove crossover cable from gearshift mecha-

nism (Fig. 191).

(10) Remove selector cable retainer clip (Fig. 192).

(11) Remove selector cable from gearshift mecha-

nism (Fig. 193).

(12) Remove four (4) gearshift mechanism-to-park

brake bracket nuts. Remove gearshift mechanism

from bracket (Fig. 194).

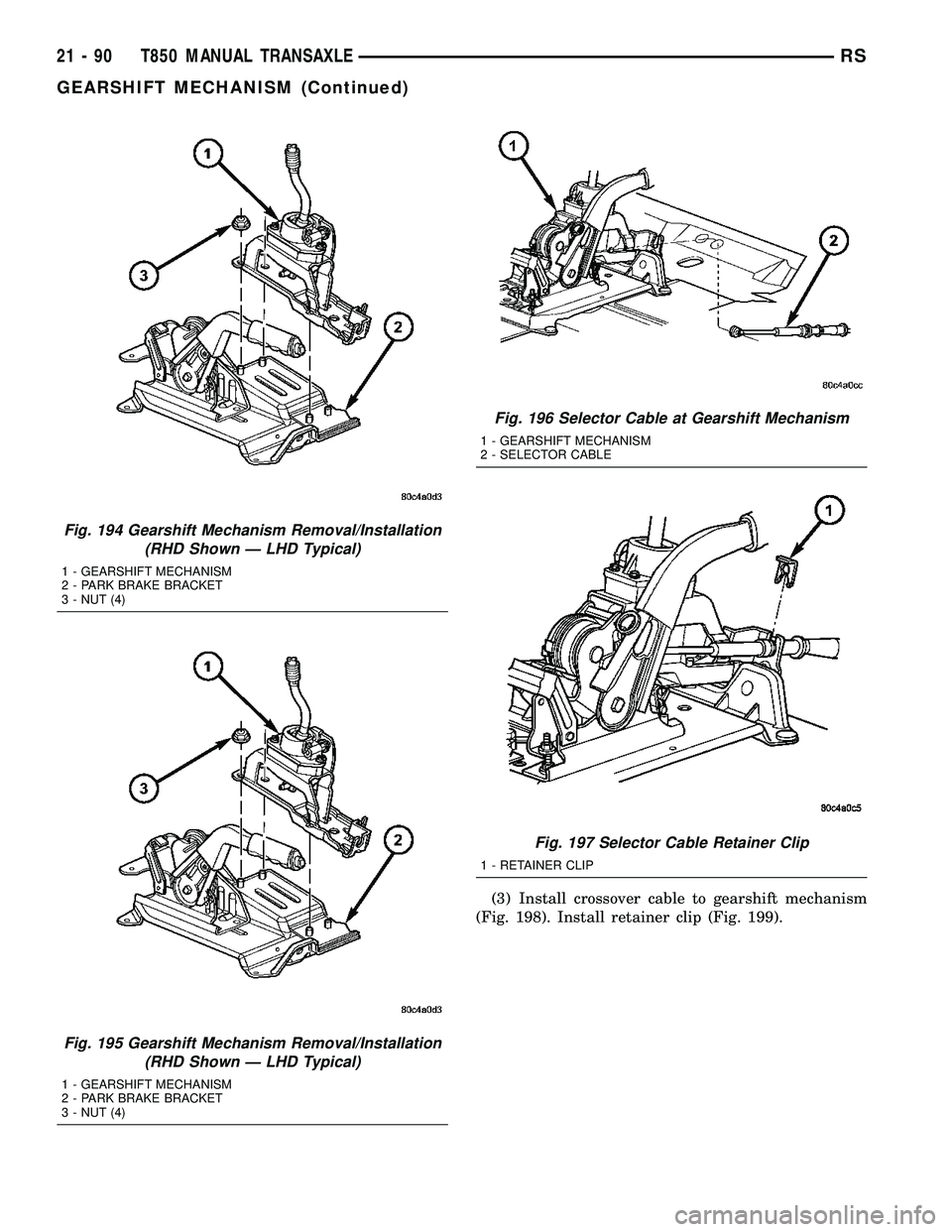

INSTALLATION

(1) Install gearshift mechanism to park brake

bracket (Fig. 195). Install and torque nuts to 12 N´m

(108 in. lbs.).

(2) Install selector cable to gearshift mechanism

(Fig. 196). Install retainer clip (Fig. 197).

Fig. 190 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 191 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

Fig. 192 Selector Cable Retainer Clip

1 - RETAINER CLIP

Fig. 193 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

RST850 MANUAL TRANSAXLE21-89

GEARSHIFT MECHANISM (Continued)

Page 1687 of 2585

(3) Install crossover cable to gearshift mechanism

(Fig. 198). Install retainer clip (Fig. 199).

Fig. 194 Gearshift Mechanism Removal/Installation

(RHD Shown Ð LHD Typical)

1 - GEARSHIFT MECHANISM

2 - PARK BRAKE BRACKET

3 - NUT (4)

Fig. 195 Gearshift Mechanism Removal/Installation

(RHD Shown Ð LHD Typical)

1 - GEARSHIFT MECHANISM

2 - PARK BRAKE BRACKET

3 - NUT (4)

Fig. 196 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

Fig. 197 Selector Cable Retainer Clip

1 - RETAINER CLIP

21 - 90 T850 MANUAL TRANSAXLERS

GEARSHIFT MECHANISM (Continued)